Method for plating gold on surface of circuit board

A surface gold-plated, circuit board technology, applied in printed circuits, removal of conductive materials by chemical/electrolytic methods, printed circuit manufacturing, etc. and other problems, to achieve the effect of less gold-plated wire residue, uniform gold-plated wire residue, and good bonding and welding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

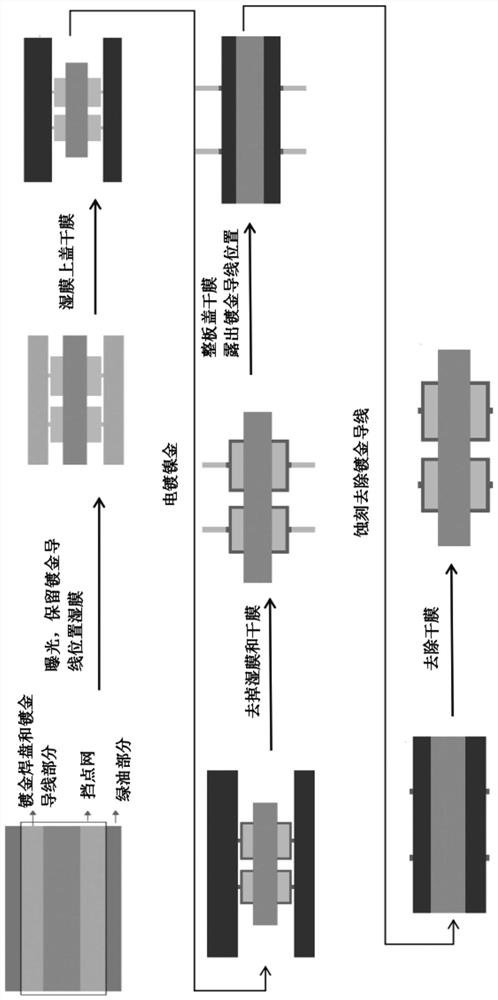

[0036] A method of gold plating on the surface of a circuit board, the schematic diagram of the process is shown in figure 1 , including the following steps:

[0037] (1) Select the circuit board that has been covered with solder resist, cover the circuit board with a blocking point net, and leak the position where gold-plated and gold-plated wires are needed; use a photosensitive wet film (Taiyang PPR-50EB01) to cover the gold-plated pads and gold-plated wire parts, The position of the solder resist is not covered with the photosensitive wet film; then it is dried, the drying temperature is 75 ℃, and the drying time is 25 minutes.

[0038] (2) Use an LDI machine to expose (350mj) the gold-plated wire part, develop and remove the unexposed photosensitive wet film, leave the photosensitive wet film of the gold-plated wire part, and remove the photosensitive wet film of the gold-plated part.

[0039] (3) Paste the anti-plating dry film on the circuit board, use the LDI machine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com