Self-aligning metal patterning based on photonic sintering of metal nanoparticles

A metal nanoparticle, nanoparticle technology, applied in nano-optics, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as limited thickness, limited resolution, and reduced conductivity of metal films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

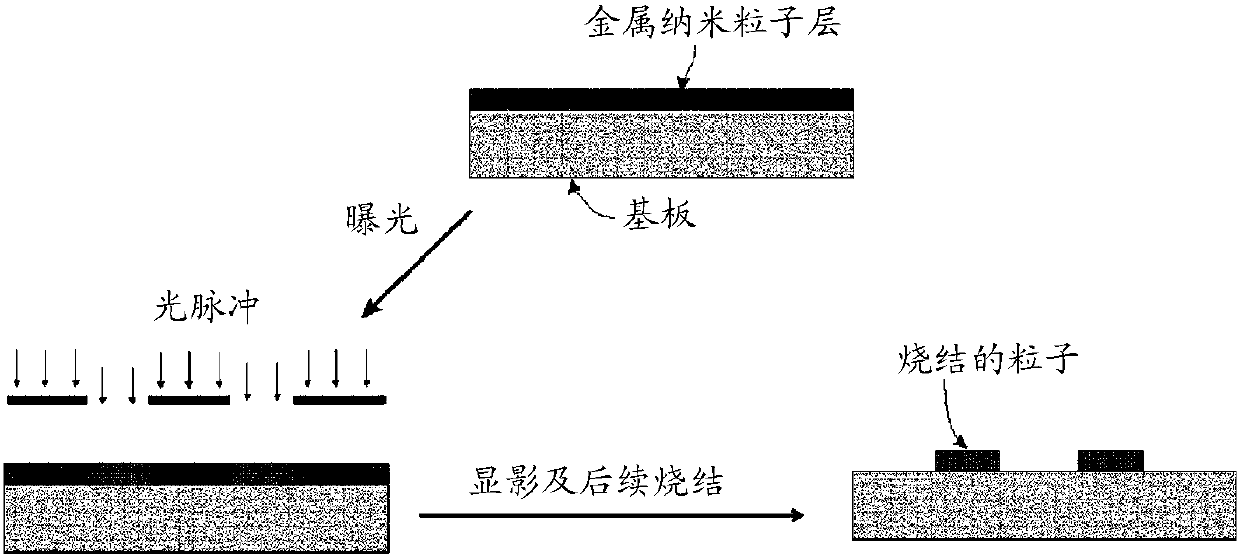

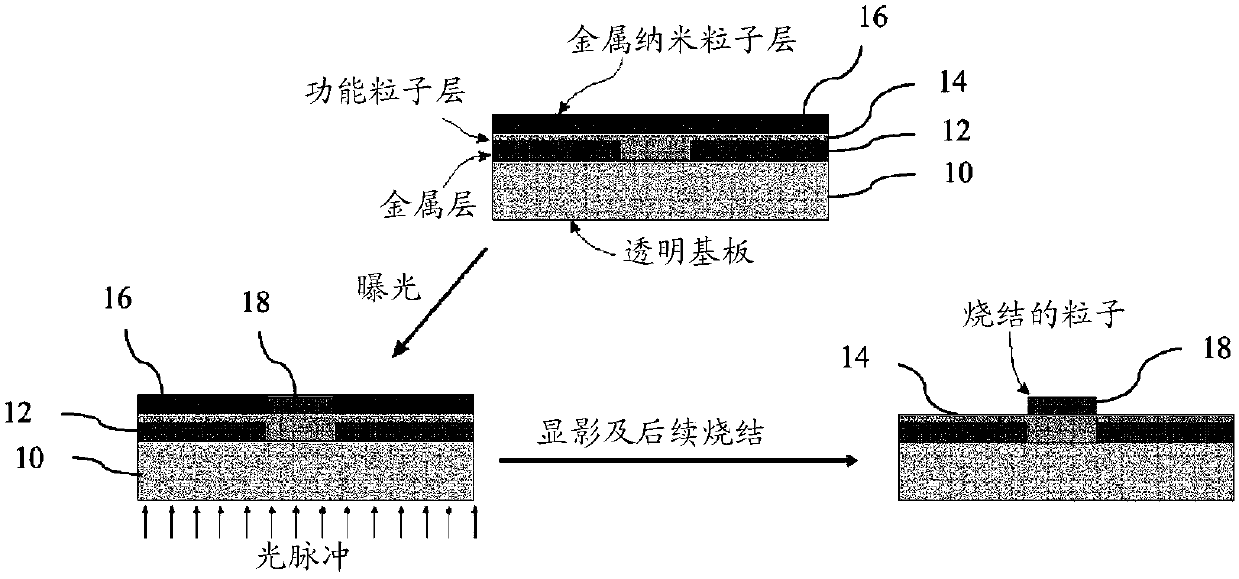

[0025] A method for self-aligned metal patterning using photonic sintering process and metal nanoparticle ink is disclosed herein. This approach avoids the need for multiple photolithography steps or vacuum deposition of metals. High-precision alignment of the upper layer to the underlying layer and the metal pattern between the lower layers is accomplished by using metal nanoparticle ink as a negative photoresist. The first metal layer printed on the transparent substrate acts as a mask to block light applied from the backside of the substrate. Intense pulses of light applied from the backside of the substrate partially sinter the exposed nanoparticles, ie those not covered by the mask. Masked metal nanoparticles are not affected by sintering and, therefore, can be washed away.

[0026] This method is primarily intended for use in the manufacture of electronic devices with multilayer structures by printing or equivalent low-cost deposition processes. Many electronic device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com