Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about "Resist details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

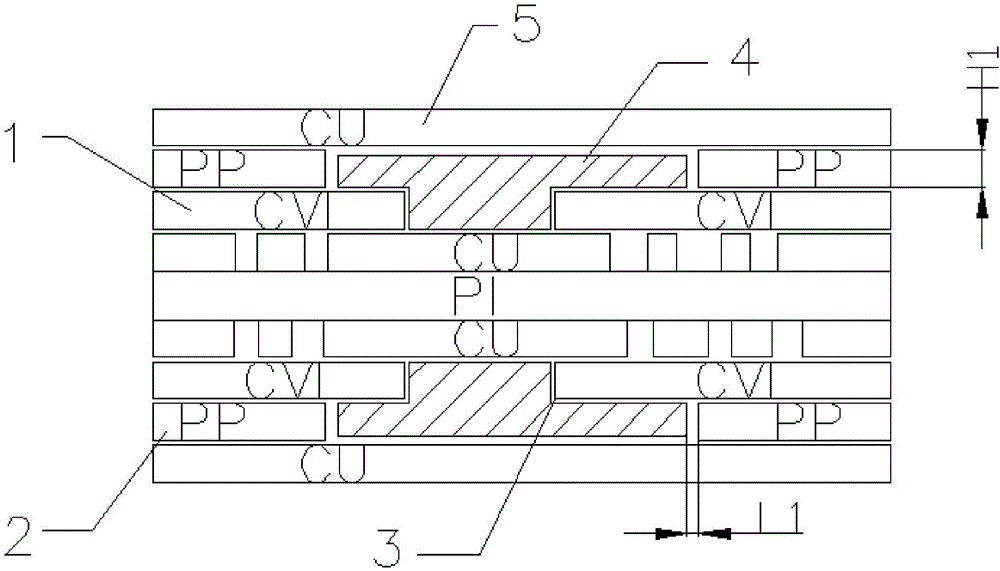

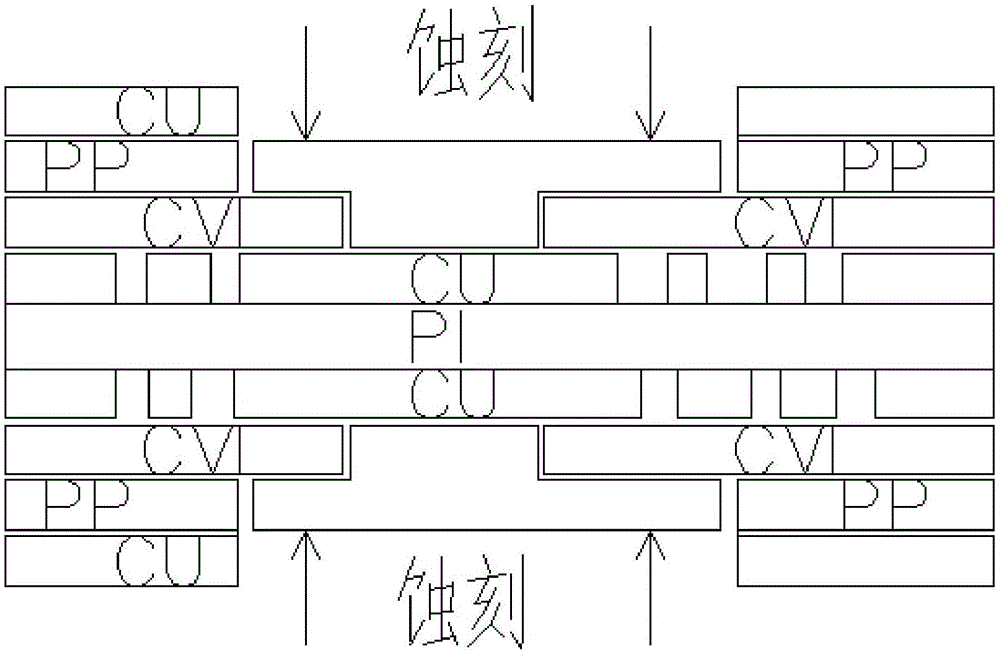

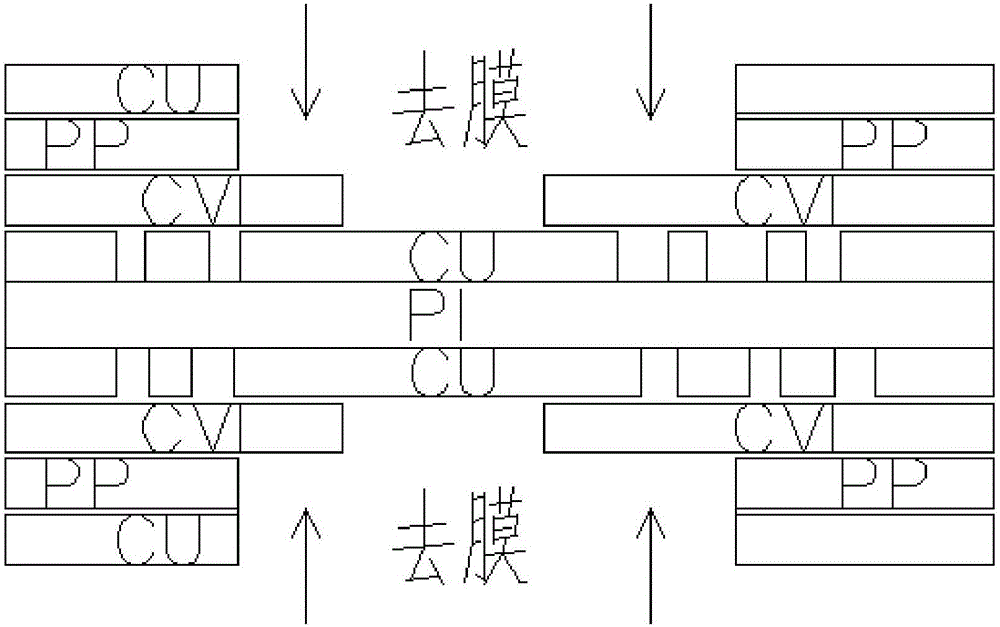

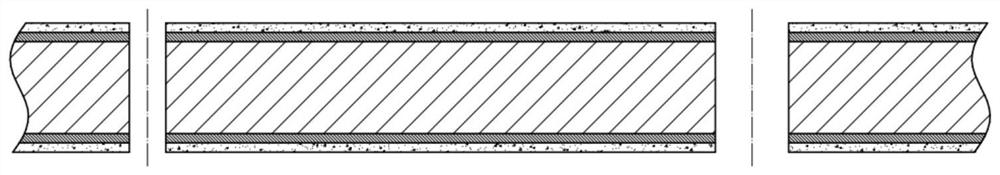

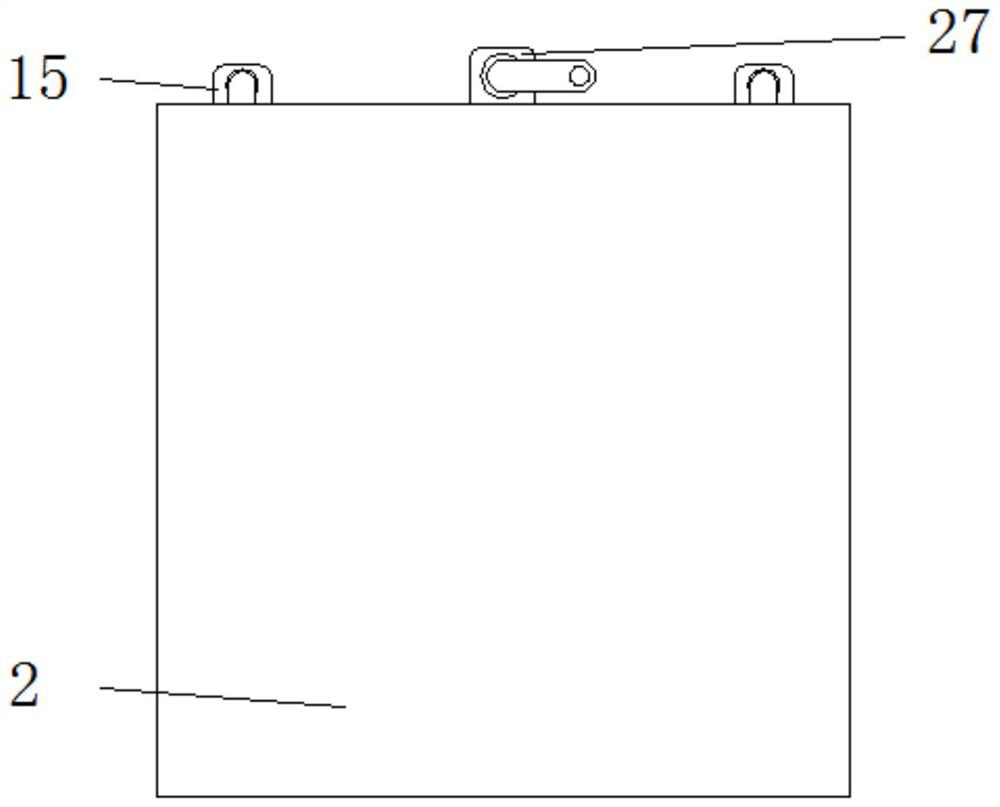

Novel de-cap method of rigid-flex board

InactiveCN106535507ASo as not to damageImprove qualityResist detailsConductive material chemical/electrolytical removalScreen printingTectorial membrane

The invention relates to a novel de-cap method of a rigid-flex board. The method includes the following steps that: (1) after the inner layer covering film of the rigid-flex board is bonded, and the inner layer covering film is covered with a layer of PP prepregs, a layer of cleanable printing ink is printed through screen printing at interdigital windows or grounding points , and a cleanable printing ink protection film is formed; (2) a copper-clad film is laminated and pressed, the copper-clad film is pressed for 3 hours under 180 DEC C; (3) drilling, electroplating, dry film attachment, exposure and development are carried out after pressing and molding; (4) etching processing is carried out by means of an acid etching solution after the development; and (5) an alkaline solution is adopted to carry out film removal after etching is completed, and the cleanable printing ink protection film is dissolved. The novel de-cap method of the invention has the advantages of simple process, convenient operation and cost-saving performance.

Owner:江苏弘信华印电路科技有限公司

Method for metallizing and electroplating only hole wall

ActiveCN113056117AEasy to handleGuaranteed YieldResist detailsInsulating layers/substrates workingChemical platingHigh volume manufacturing

The invention provides a method for metallizing and electroplating only a hole wall. The method comprises the following steps of coating a material of a sparse-hole metallization active substance on a copper-clad plate to mask the plate surface, drilling a hole, only activating the hole wall, and only directly electroplating or firstly carrying out chemical plating and then electroplating the hole wall to the required thickness. The material adopted by the invention has the performance of the sparse-hole metallization active substance, the plate surface is masked, metal is only deposited on the hole wall, the thickness of a plating layer is easy to control, the quality of the metallization hole is better, the circuit board can better meet the electrical requirements, finer conductive patterns can be manufactured, the cost is reduced, and the method is environment-friendly. The method is suitable for mass production of various circuit boards, and is further suitable for small-batch and multi-variety production of circuit board samples.

Owner:德中(天津)技术发展股份有限公司

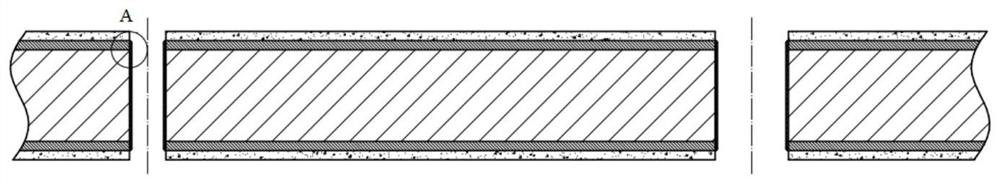

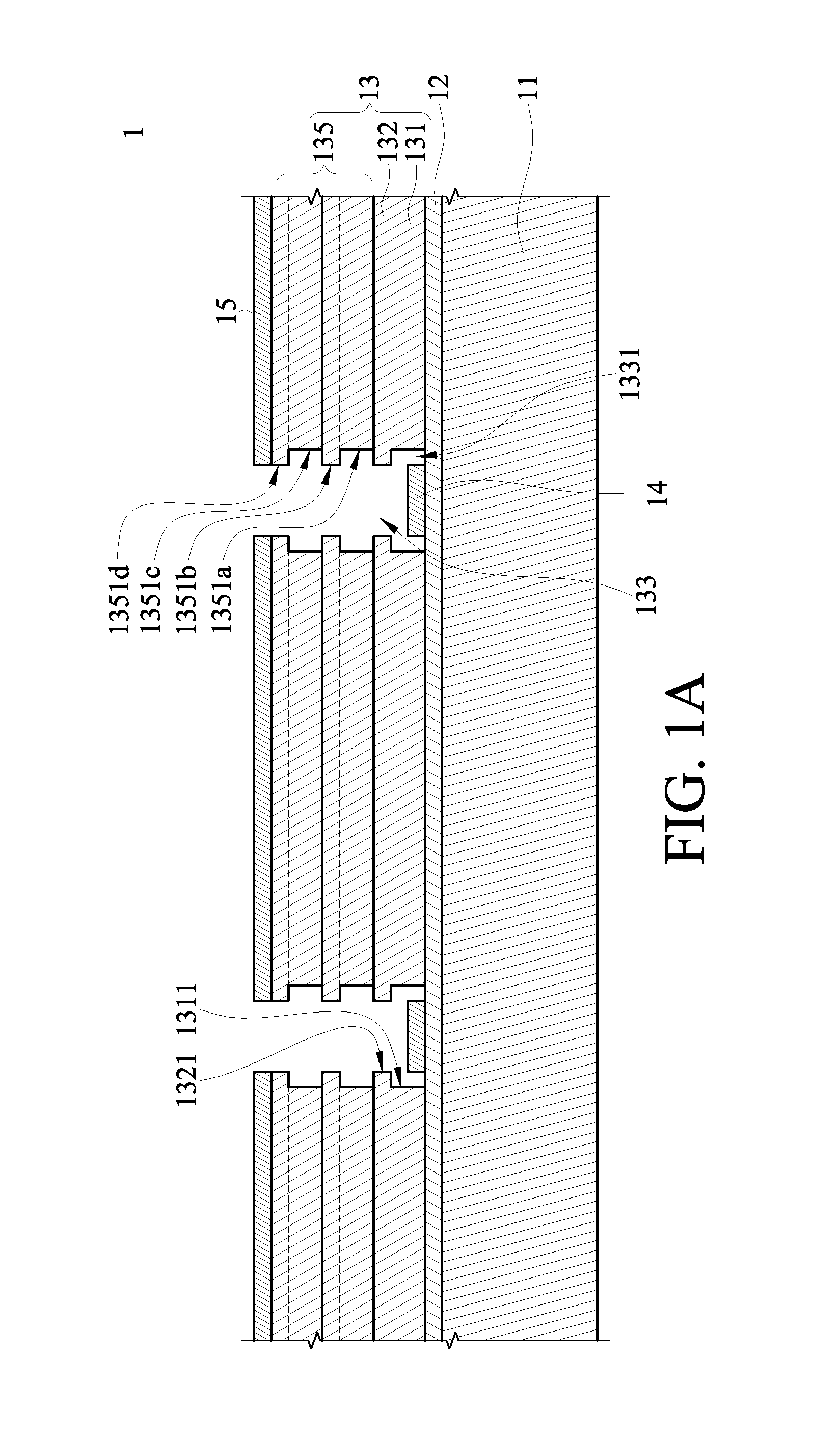

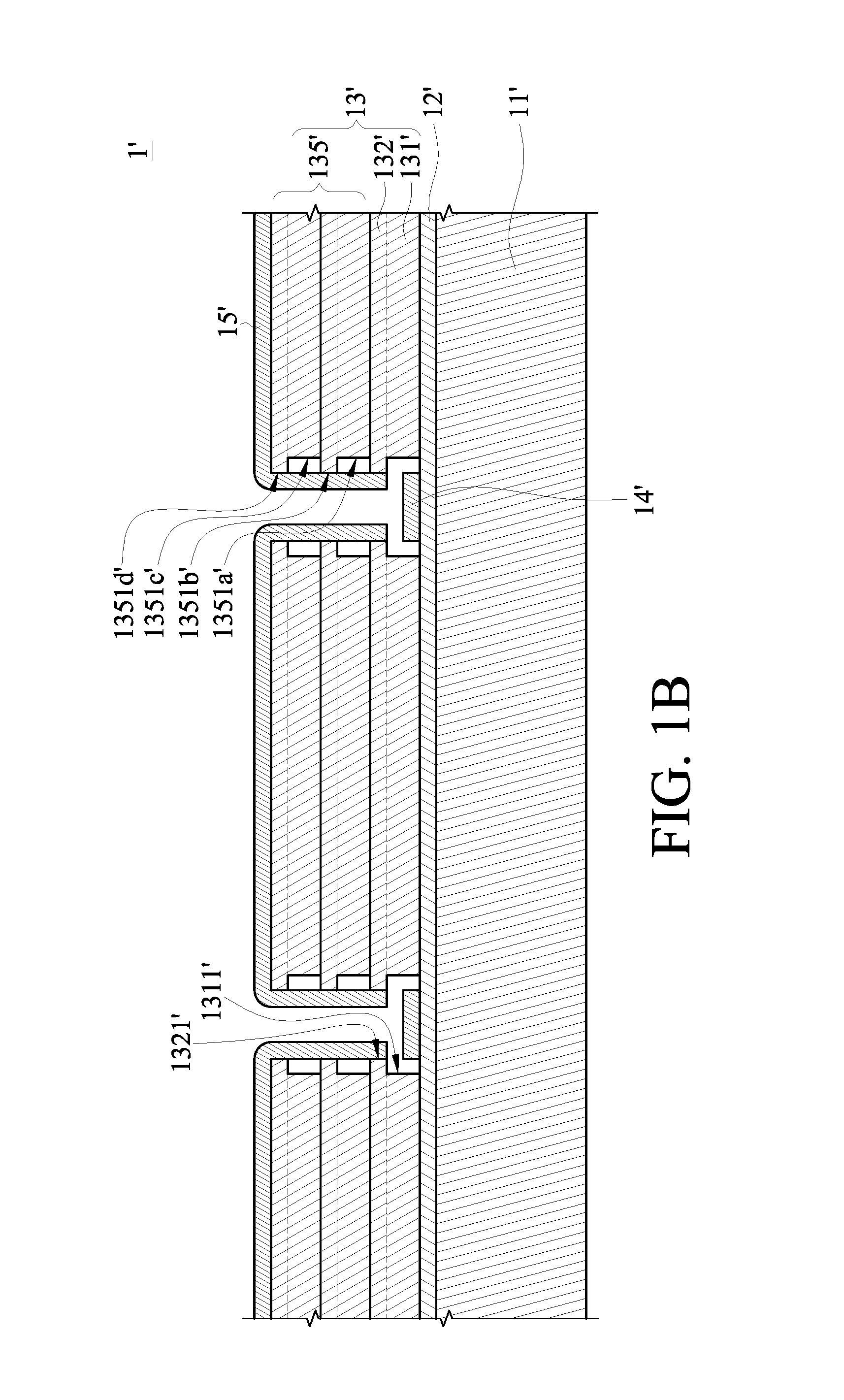

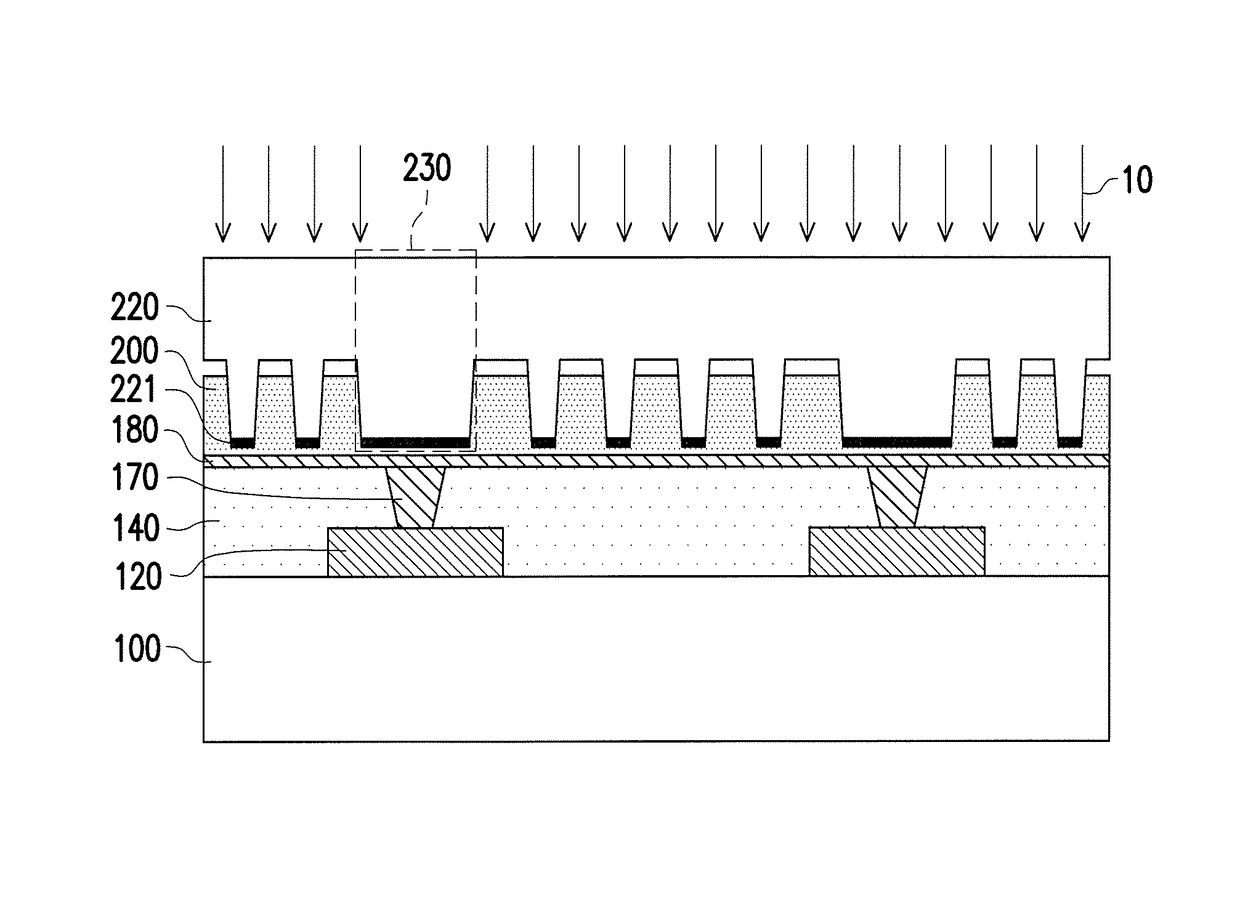

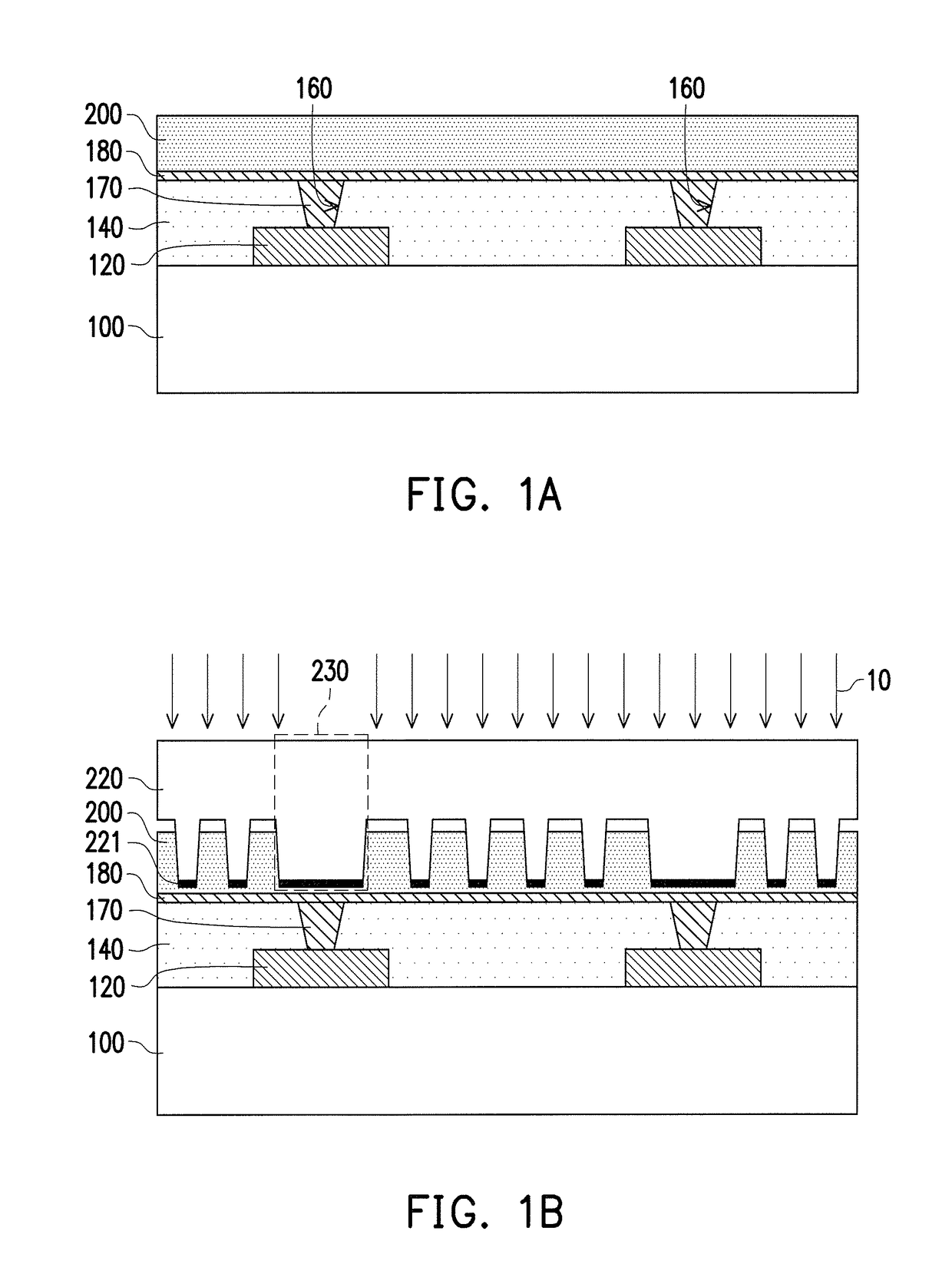

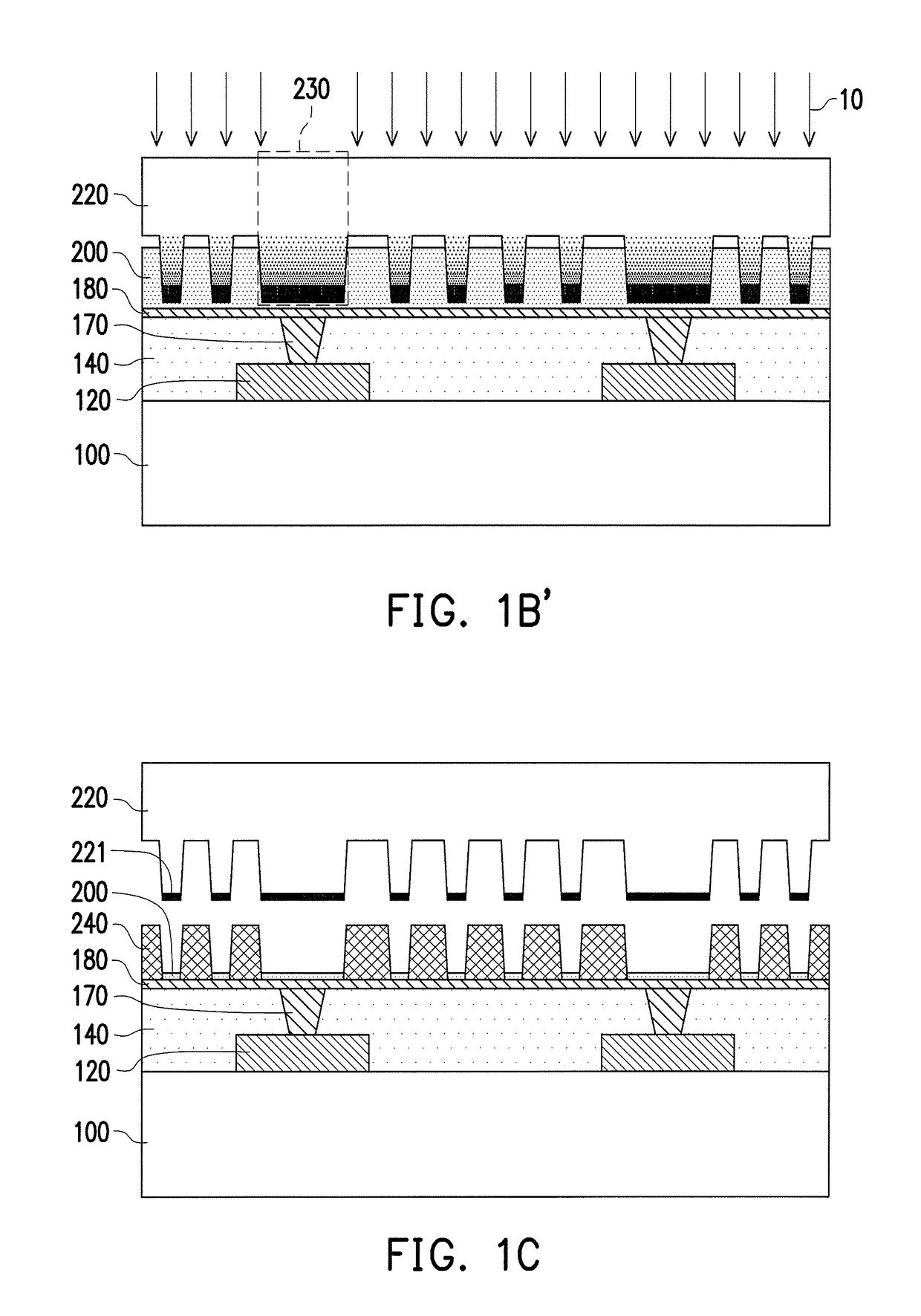

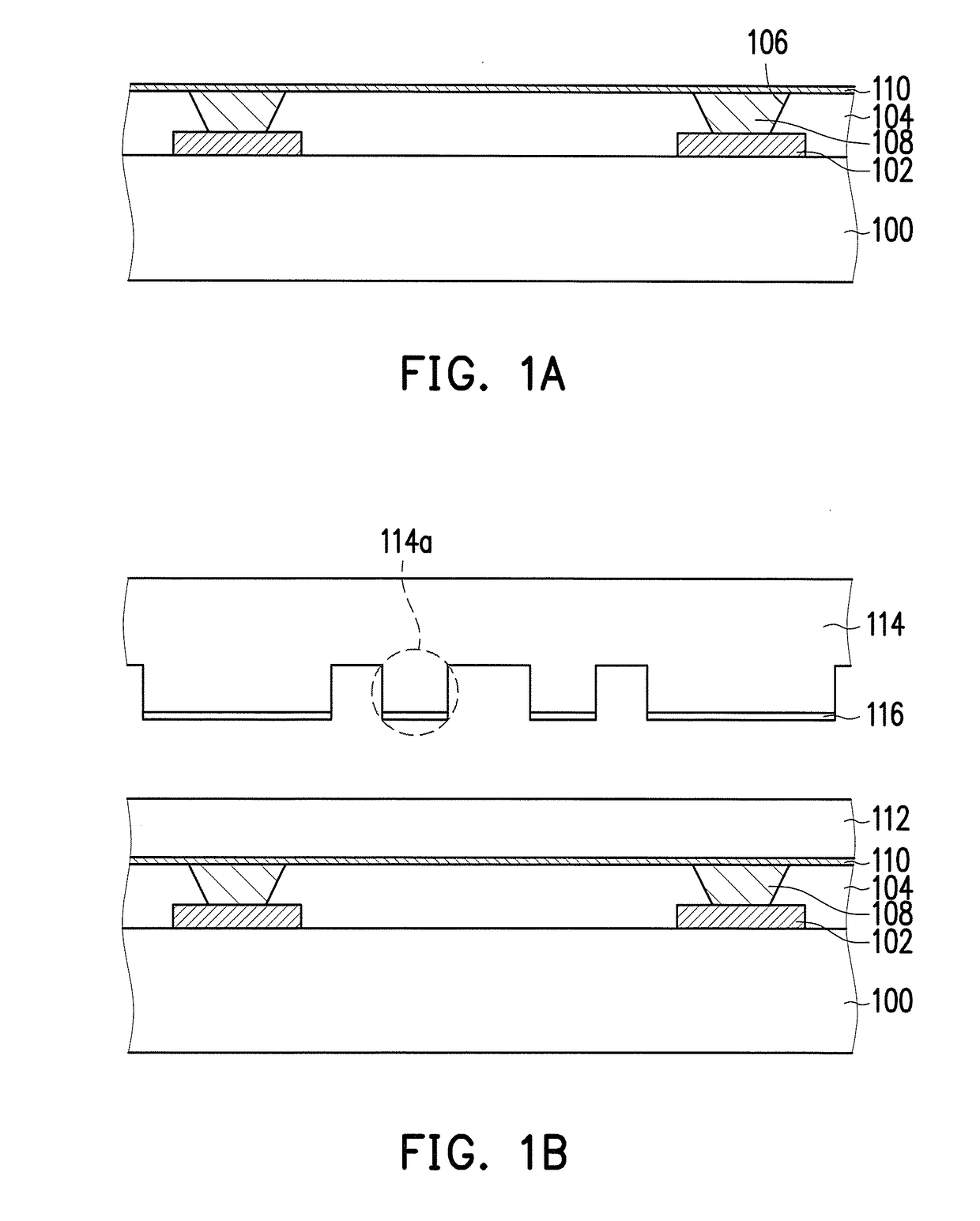

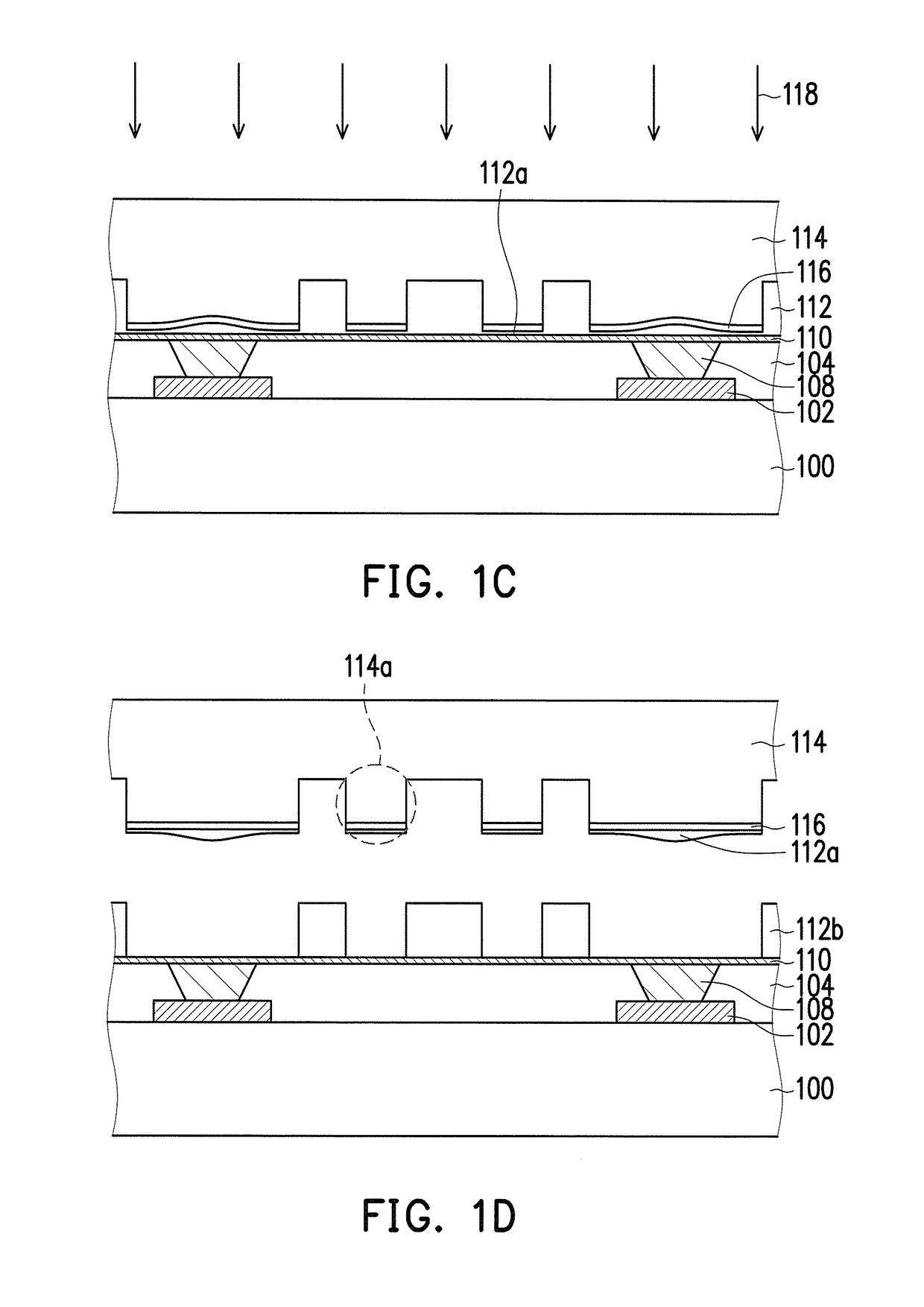

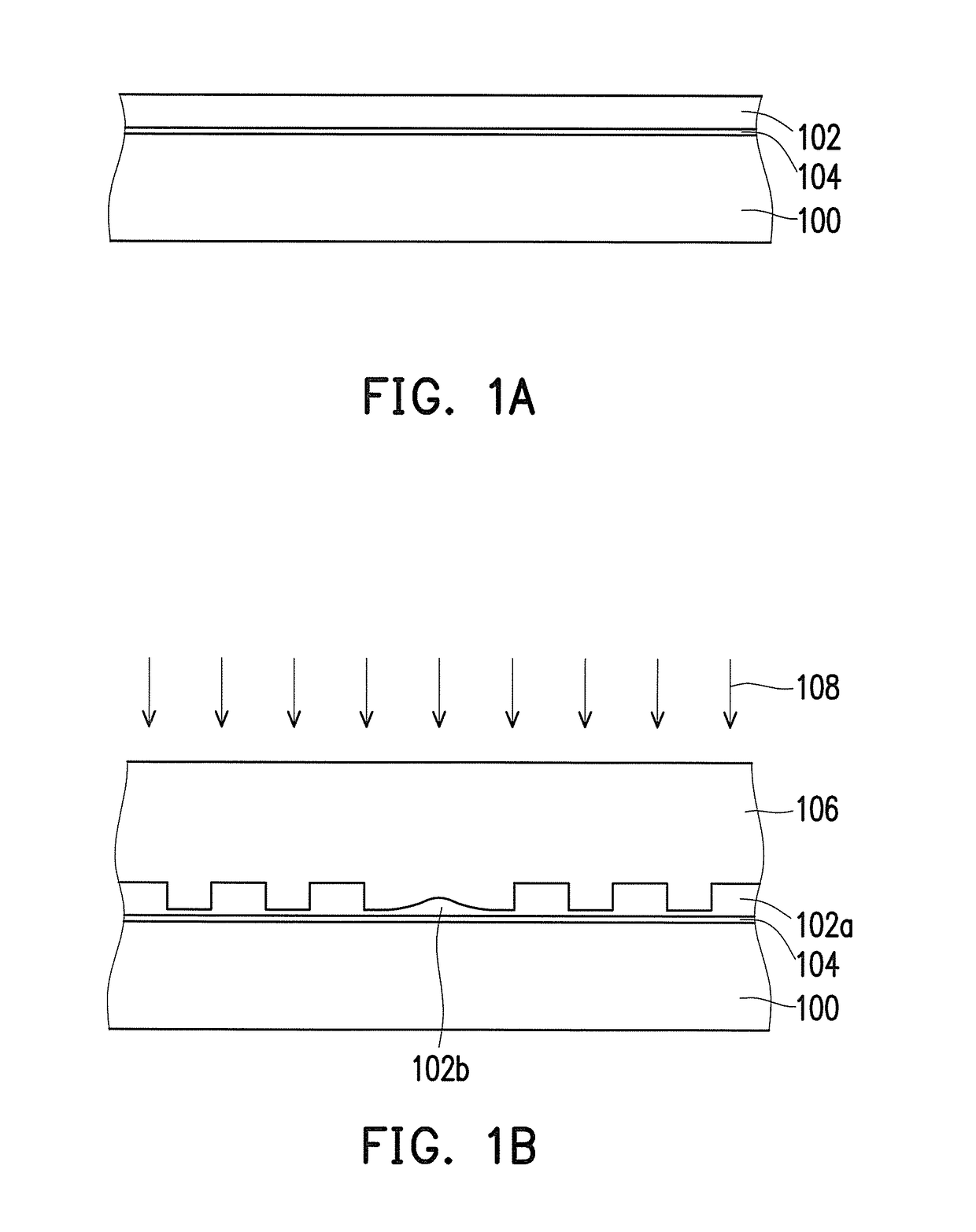

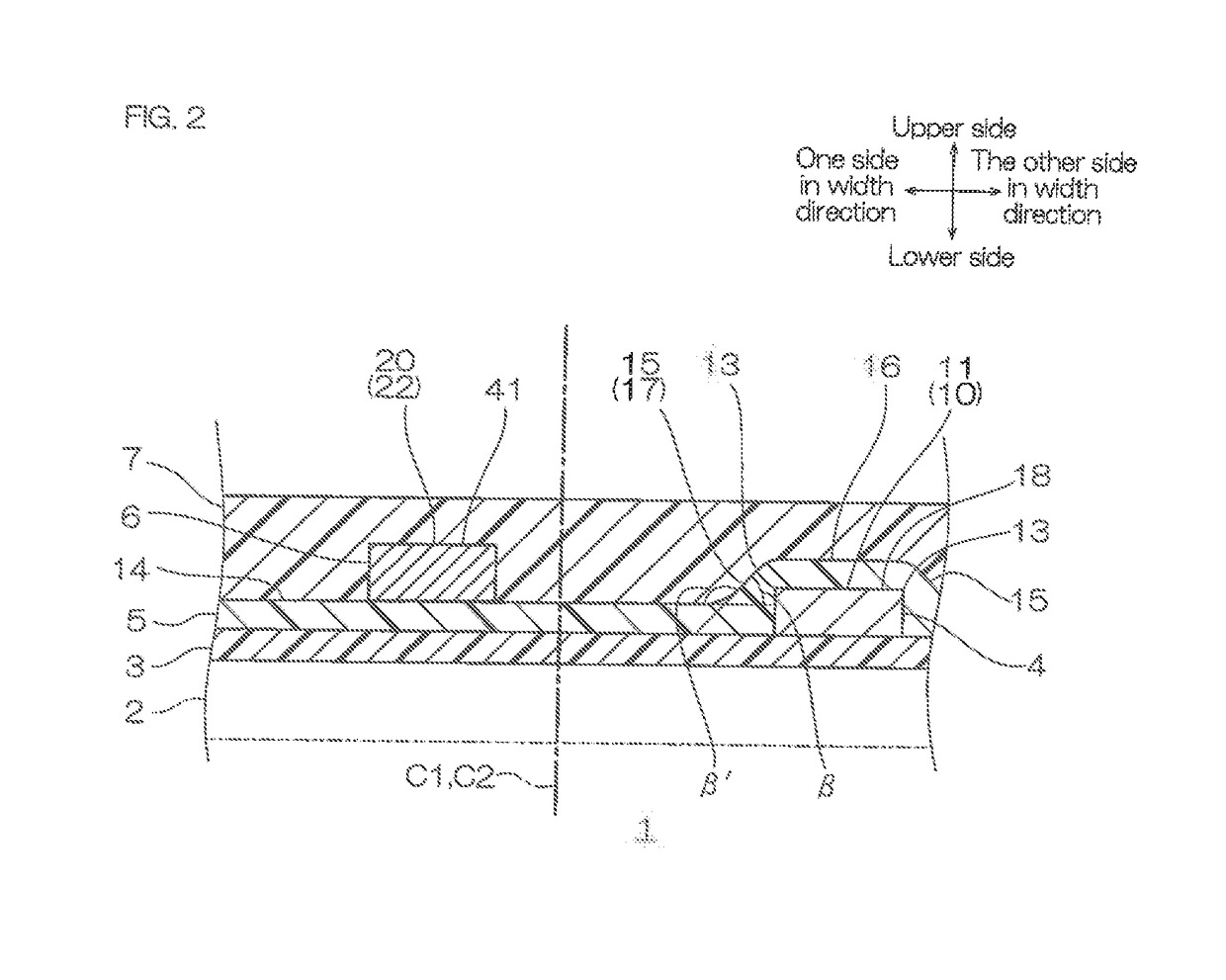

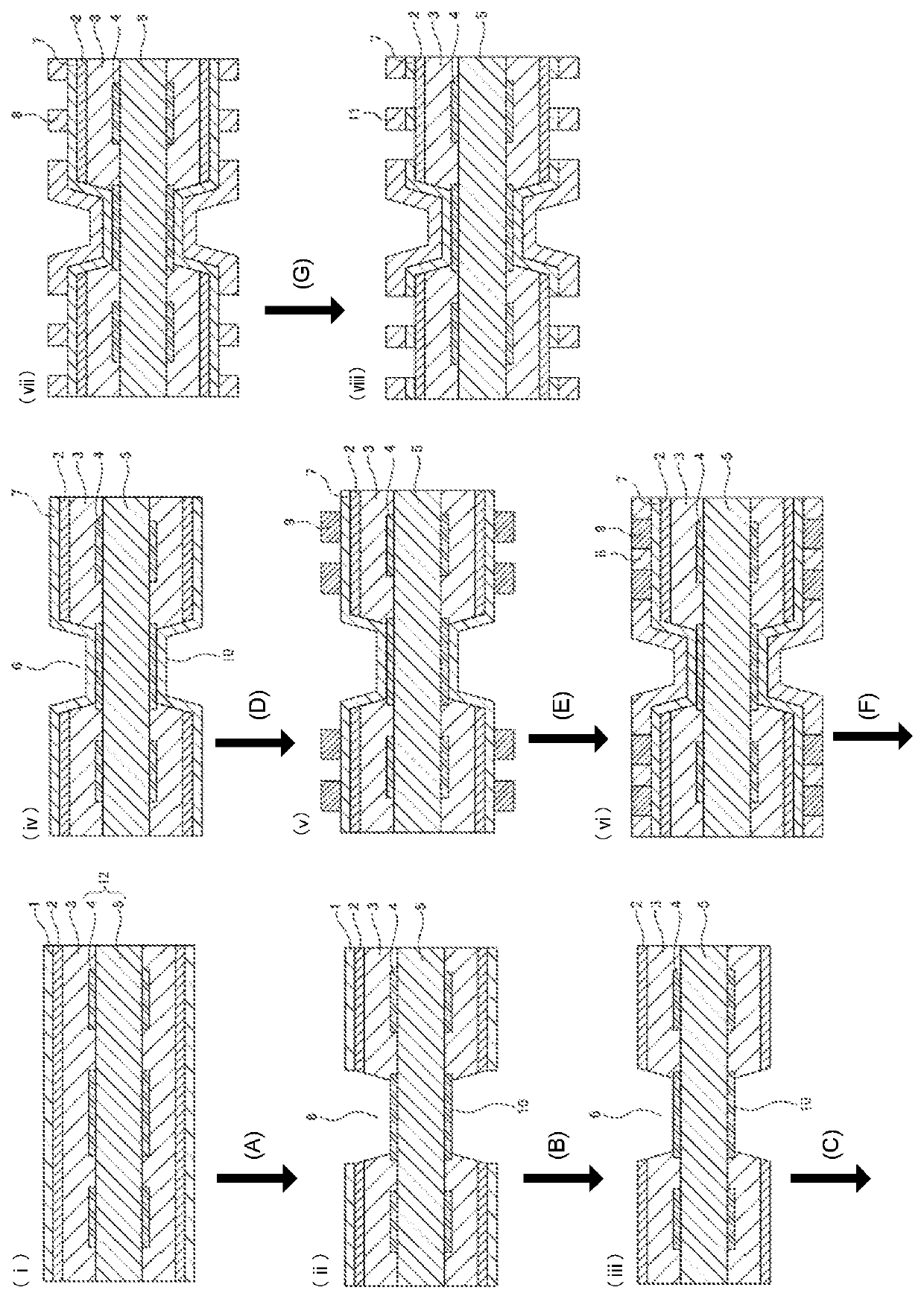

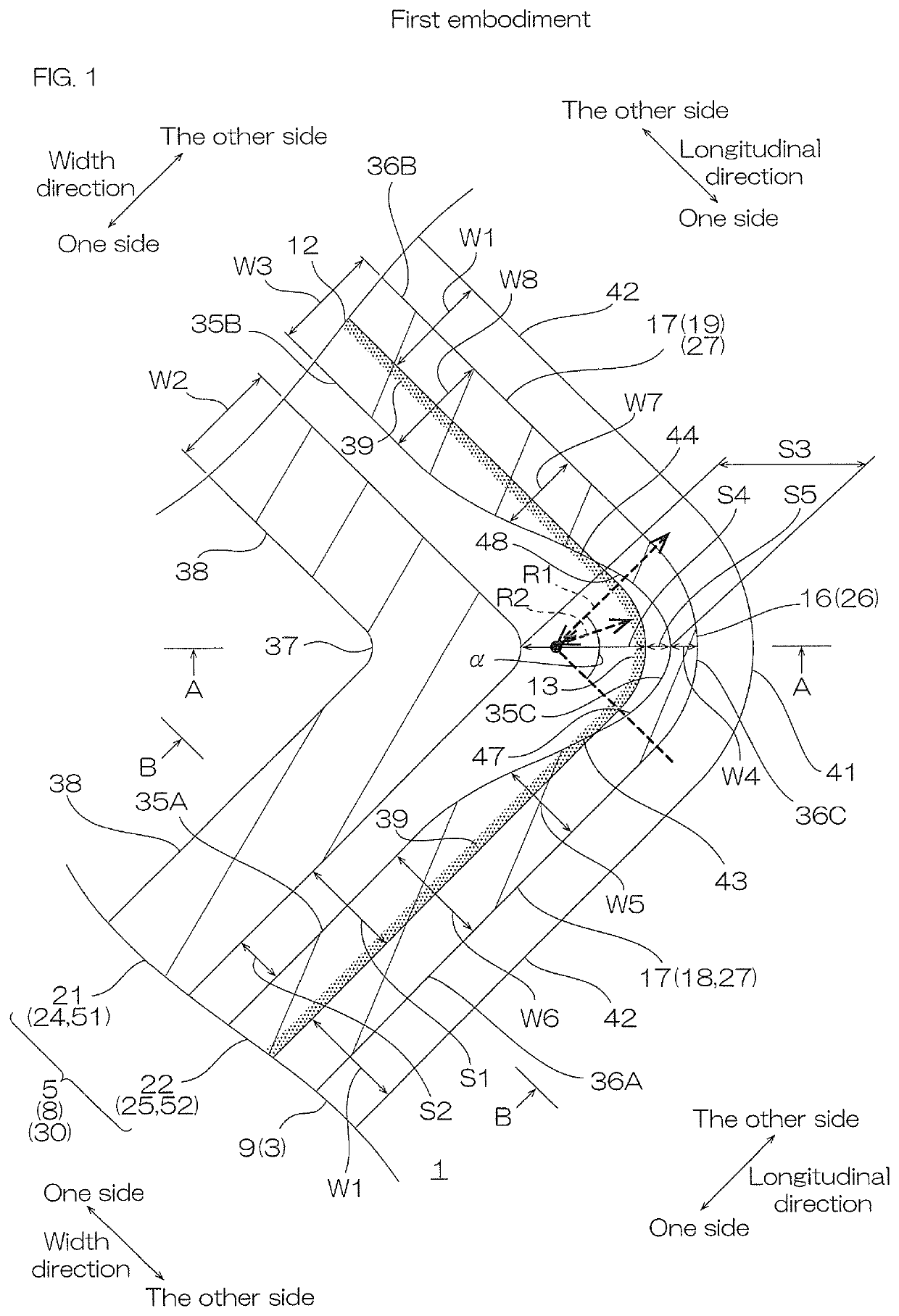

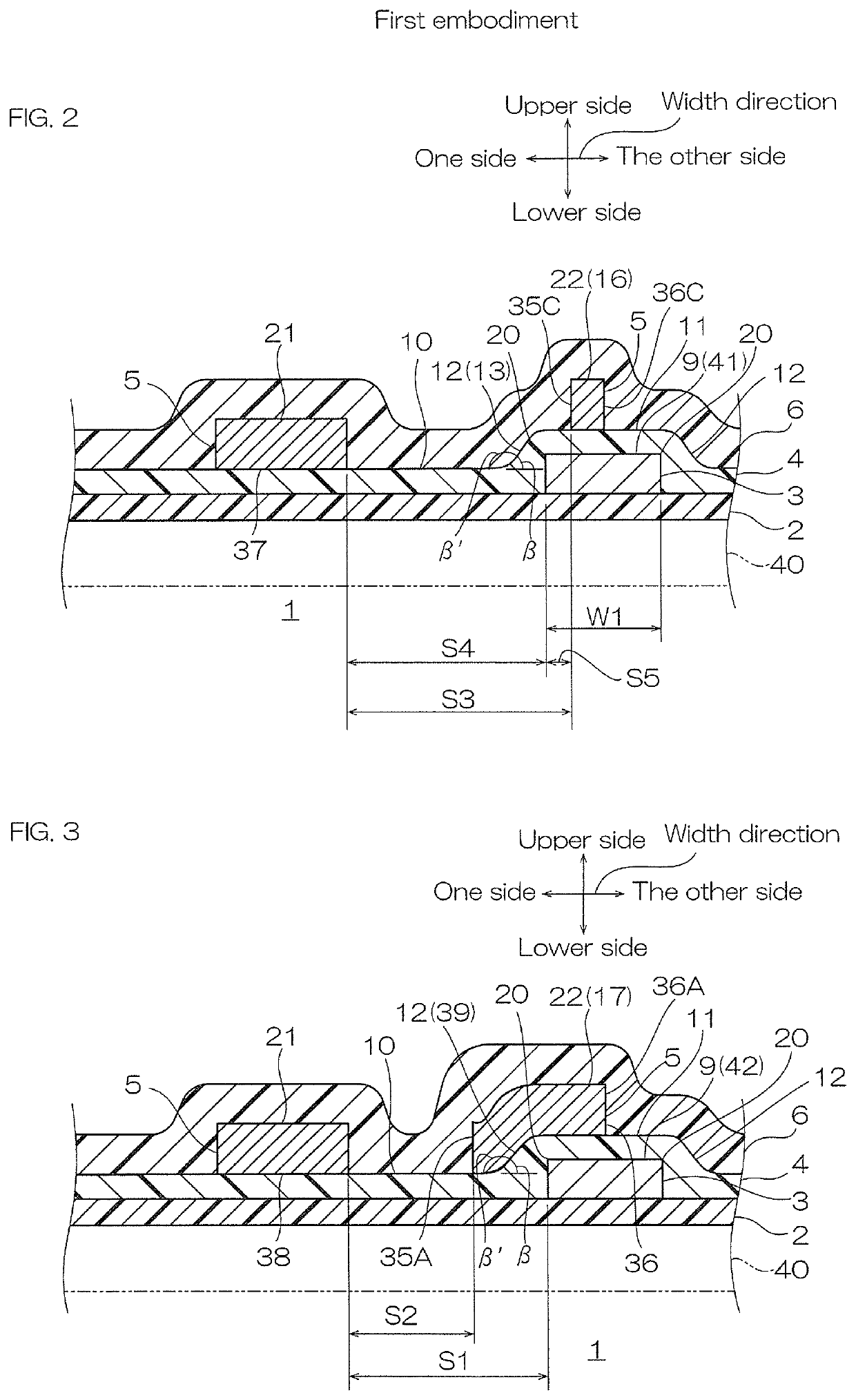

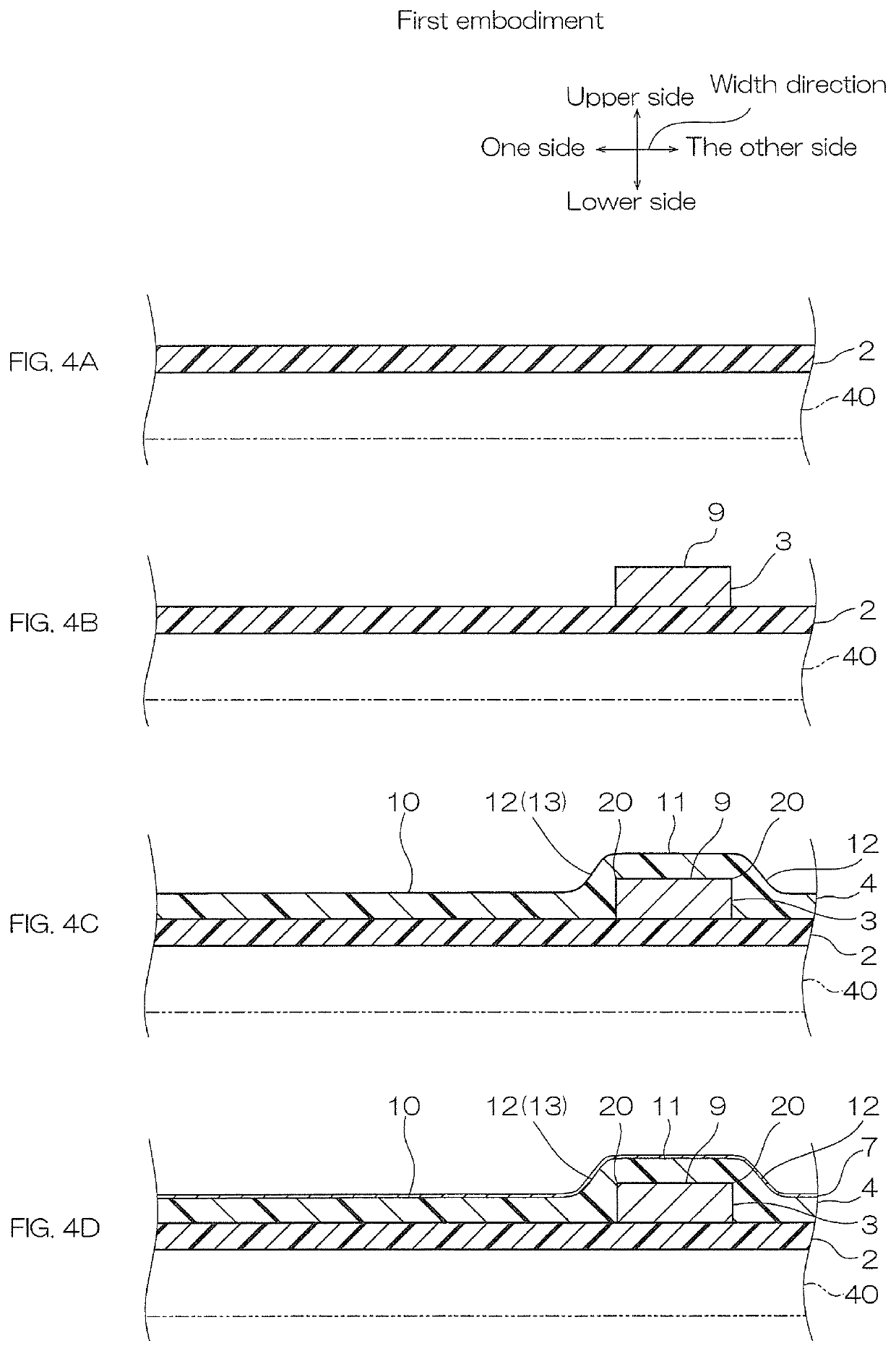

Method for producing wired circuit board

ActiveUS10143088B2Inadequate formation of conductive pattern can be suppressedImprove connection reliabilityResist detailsPrinted circuit aspectsThin membraneEngineering

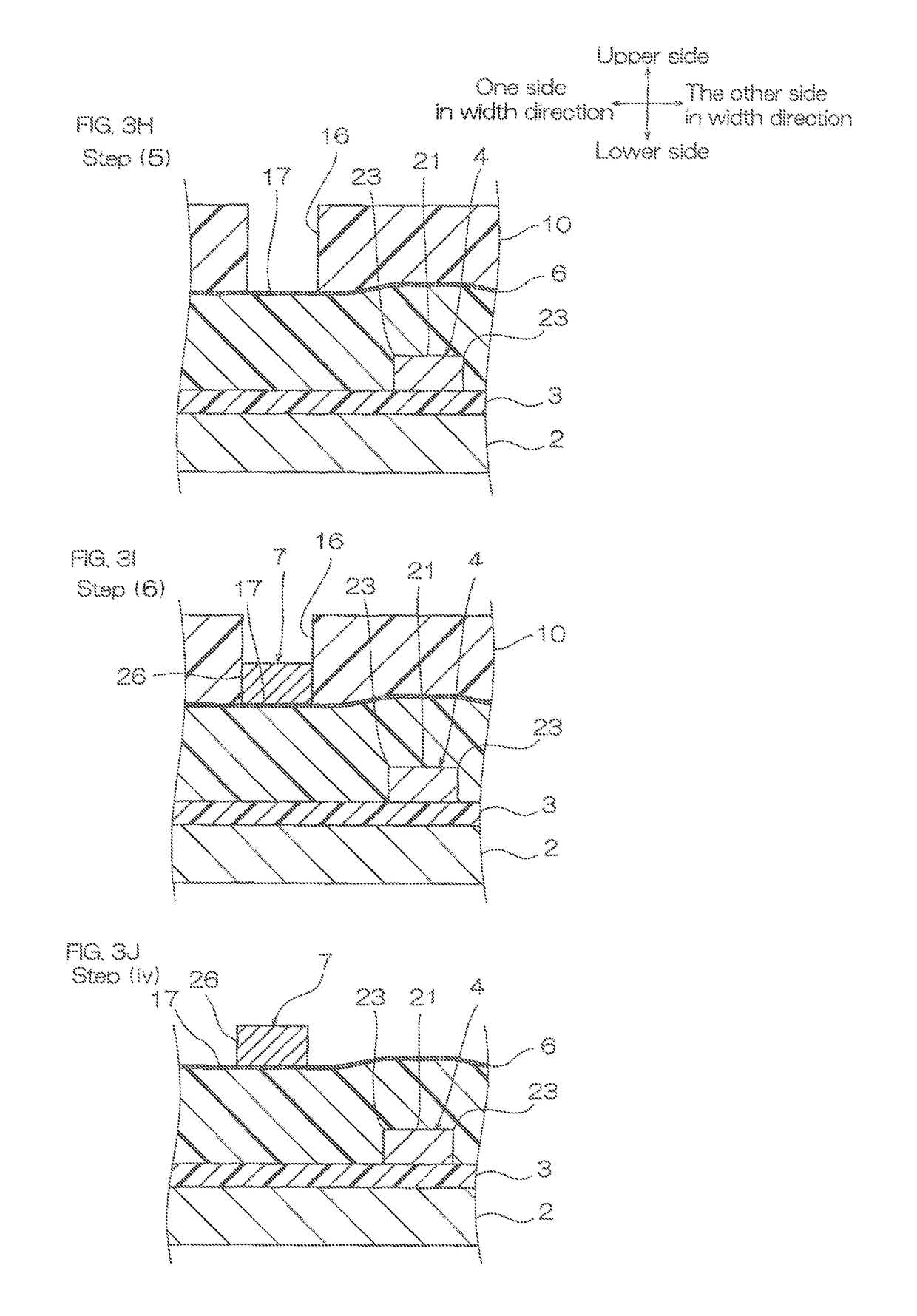

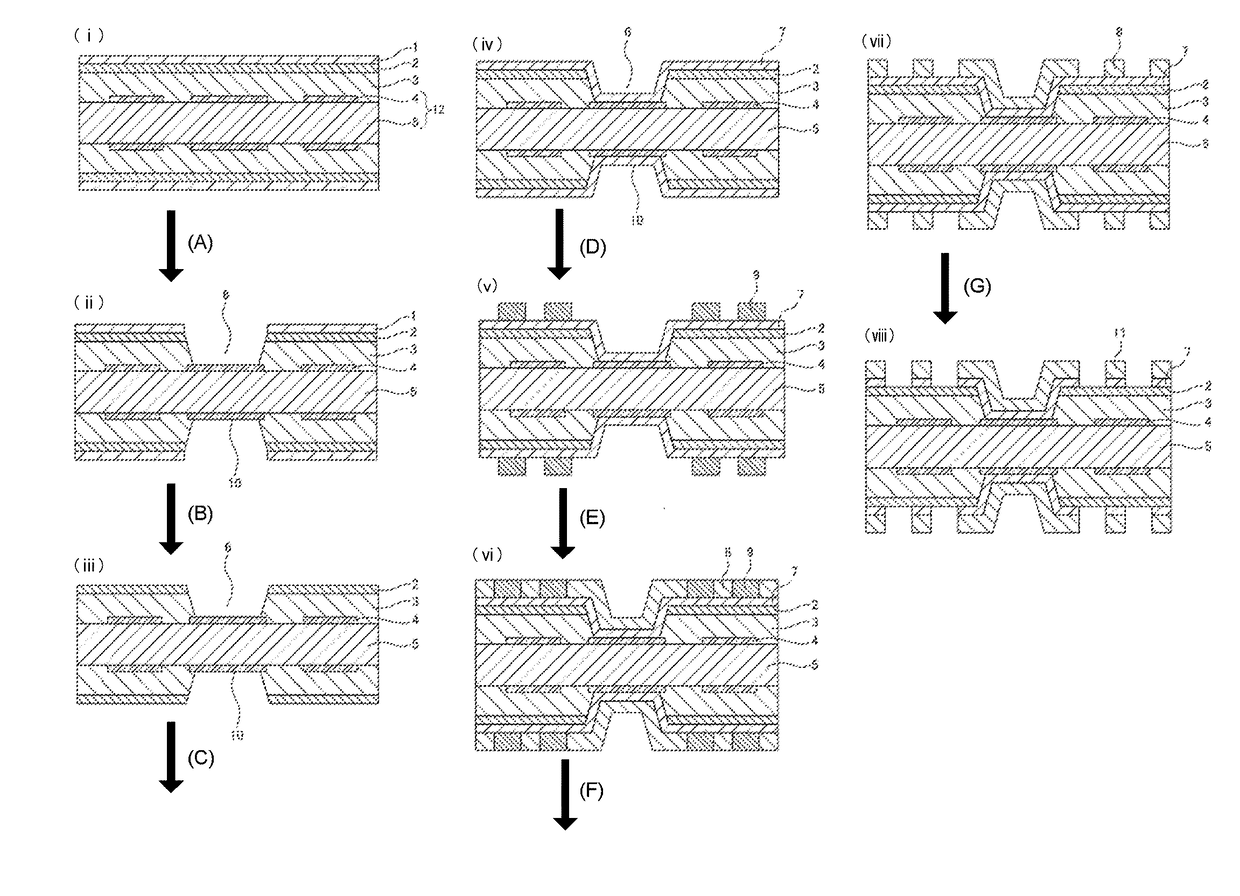

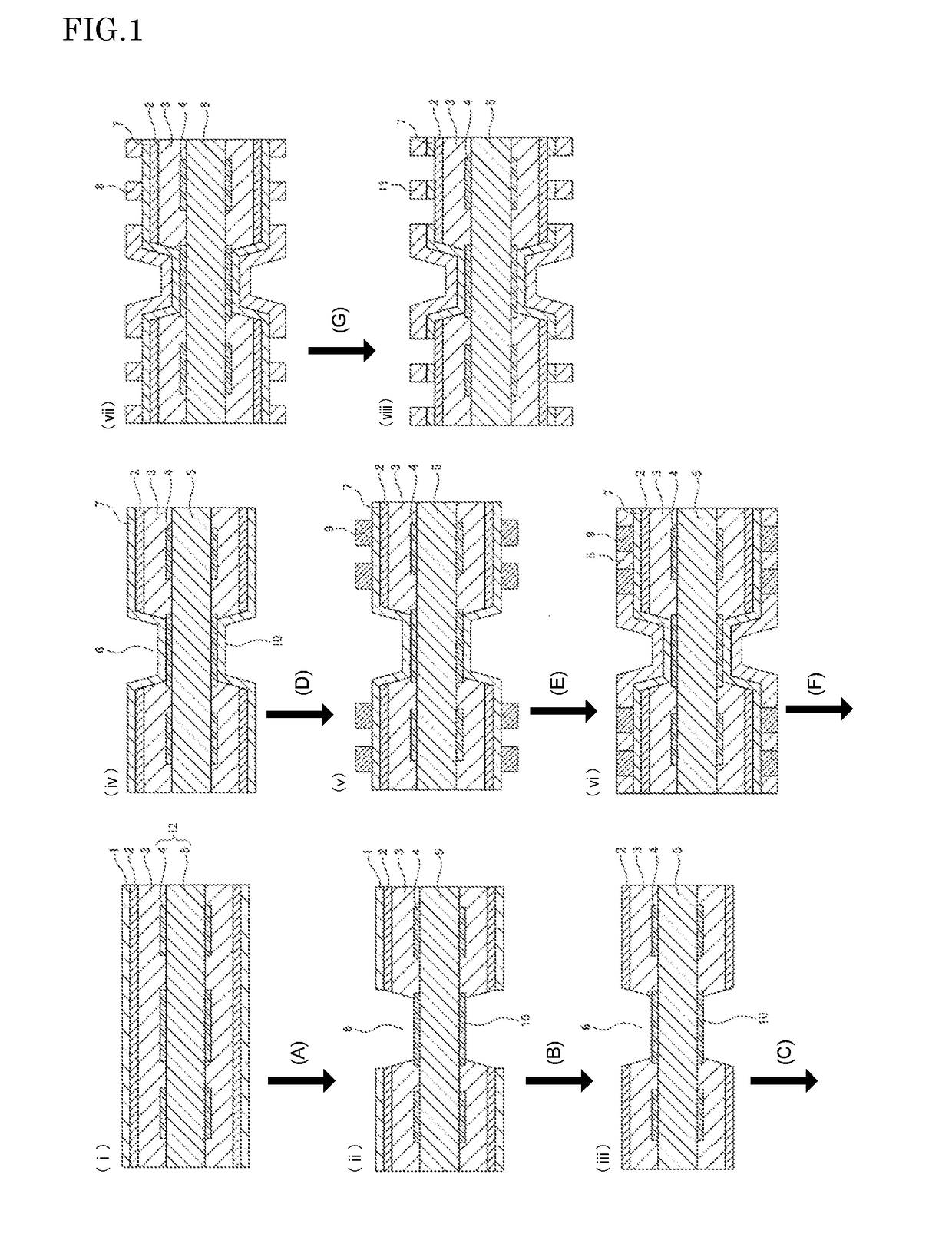

The method for producing a wired circuit board including an insulating layer and a conductive pattern provided on the insulating layer includes the steps of the following: a step (1), in which the insulating layer is provided; a step (2), in which a metal thin film is provided on an inclined face of the insulating layer; a step (3), in which a photoresist is provided on the metal thin film; a step (4), in which a photomask is disposed so that in the photoresist, a portion where the conductive pattern is to be provided is shielded from light, and the photoresist is exposed to light through the photomask; a step (5), in which the portion of the photoresist shielded from light by the photomask is removed to expose the metal thin film corresponding to the portion; and a step (6), in which the conductive pattern is provided on the metal thin film exposed from the photoresist. When exposing the photoresist, reflection is caused by the metal thin film positioned on the inclined face to reduce light projected to the portion.

Owner:NITTO DENKO CORP

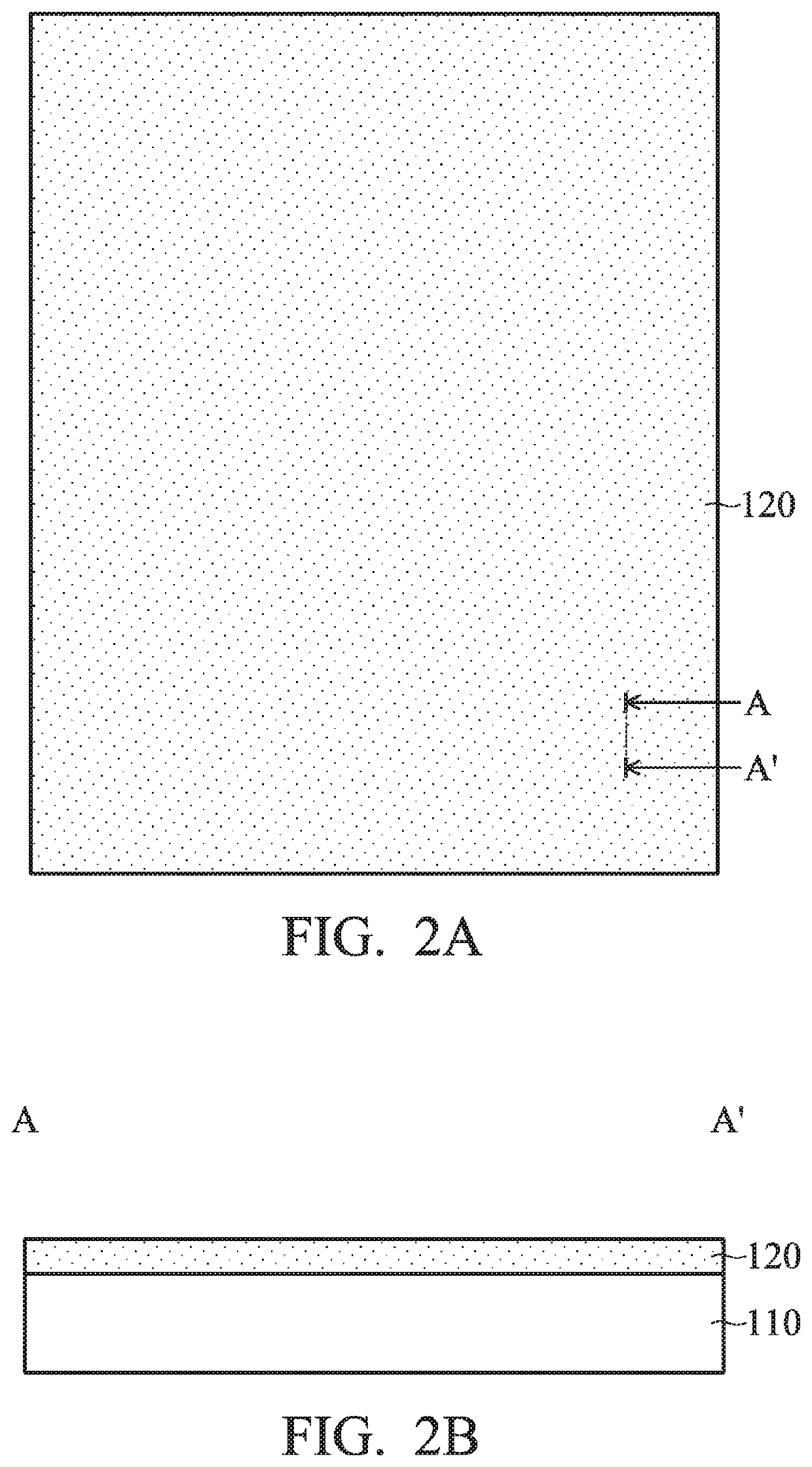

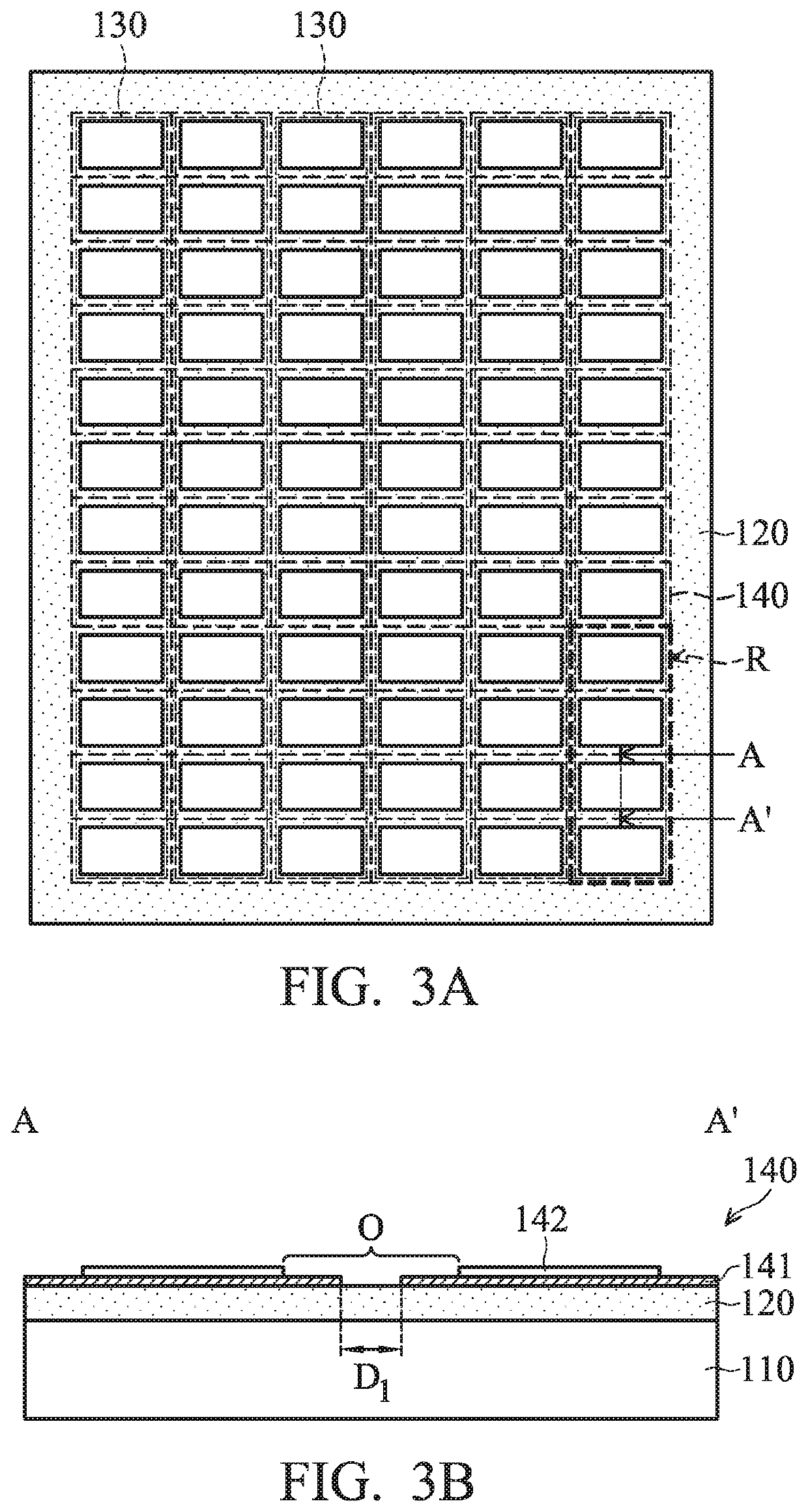

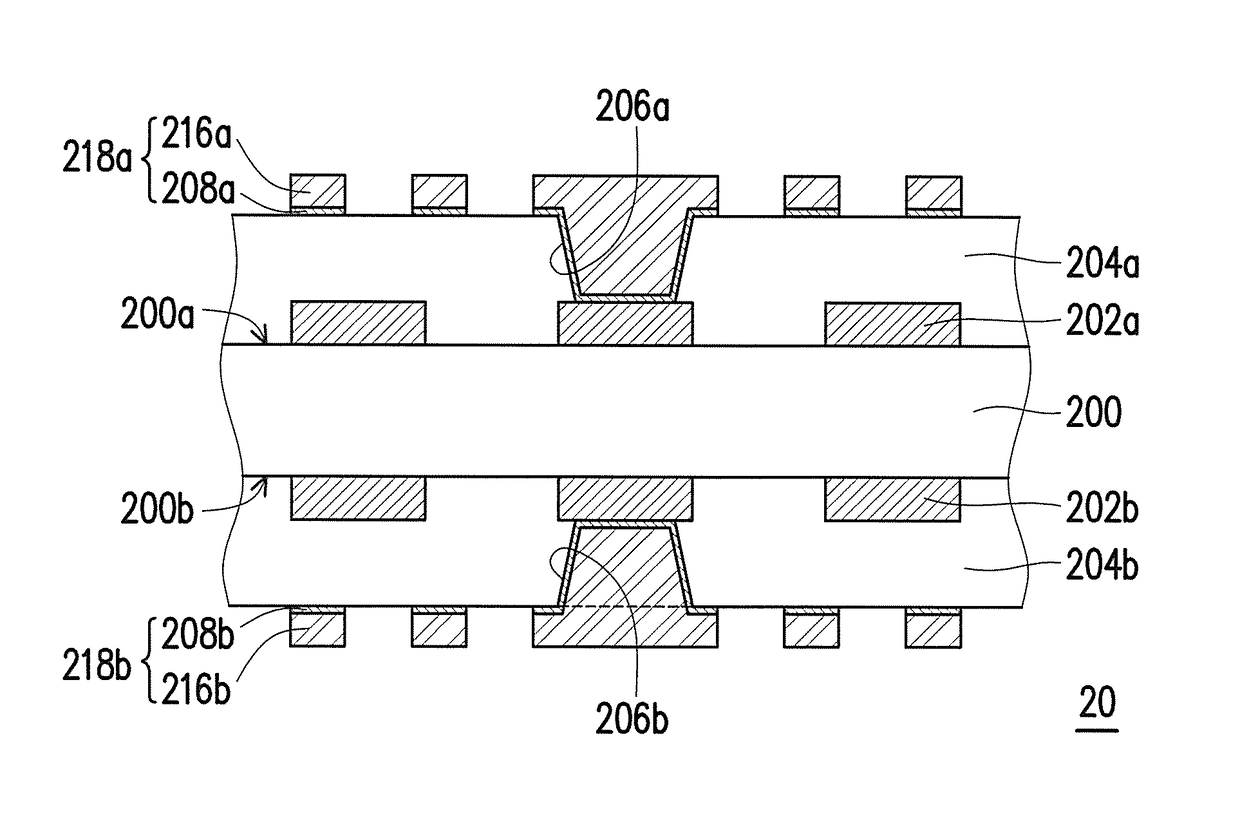

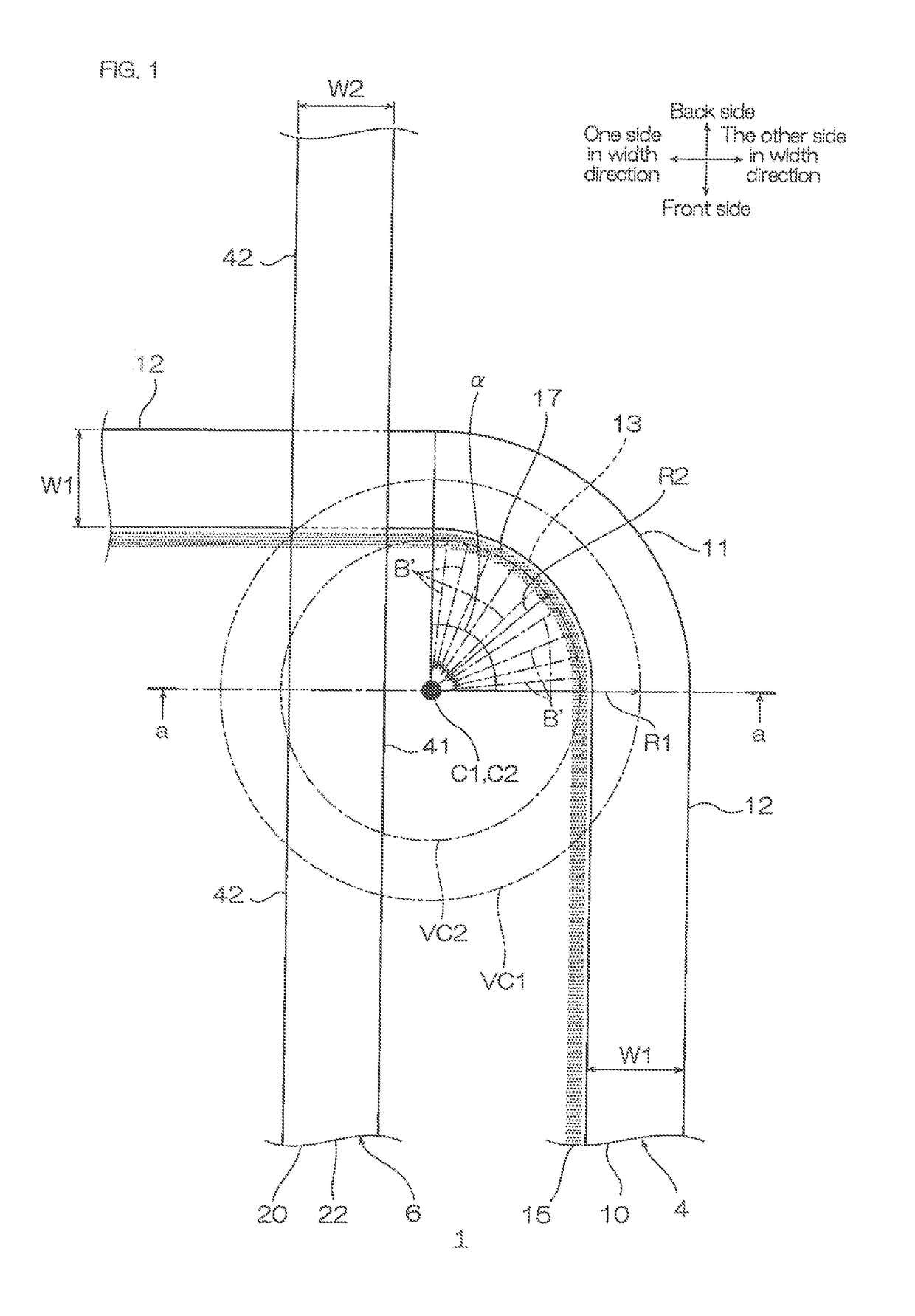

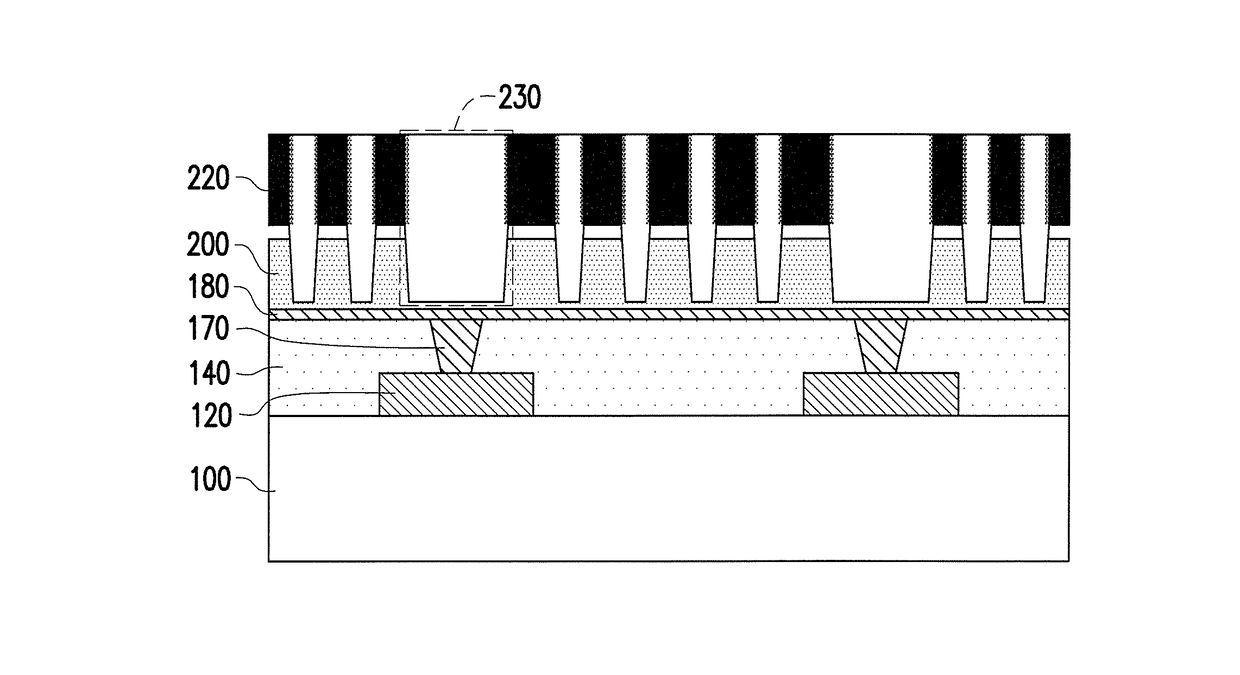

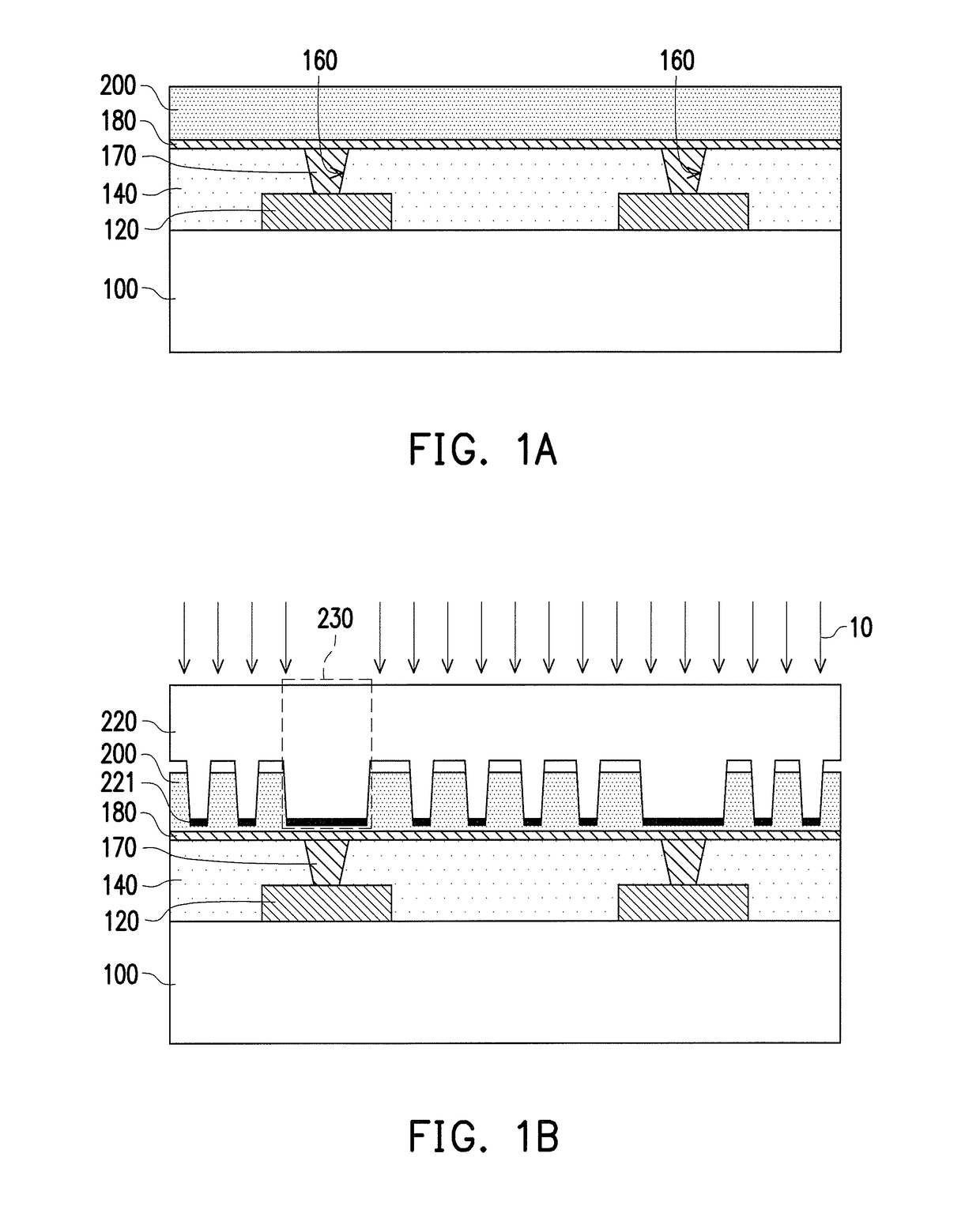

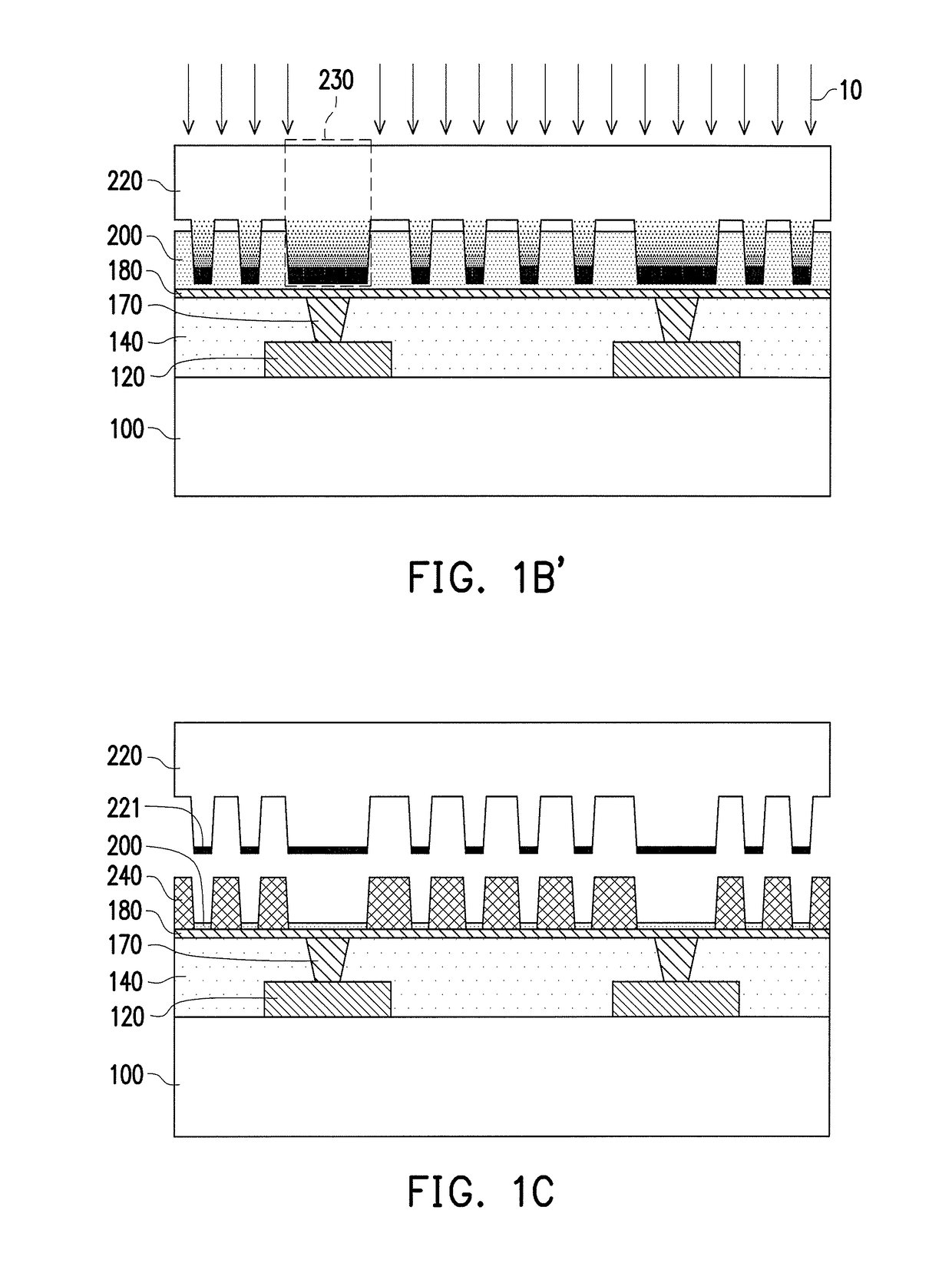

Circuit board and manufacturing method thereof

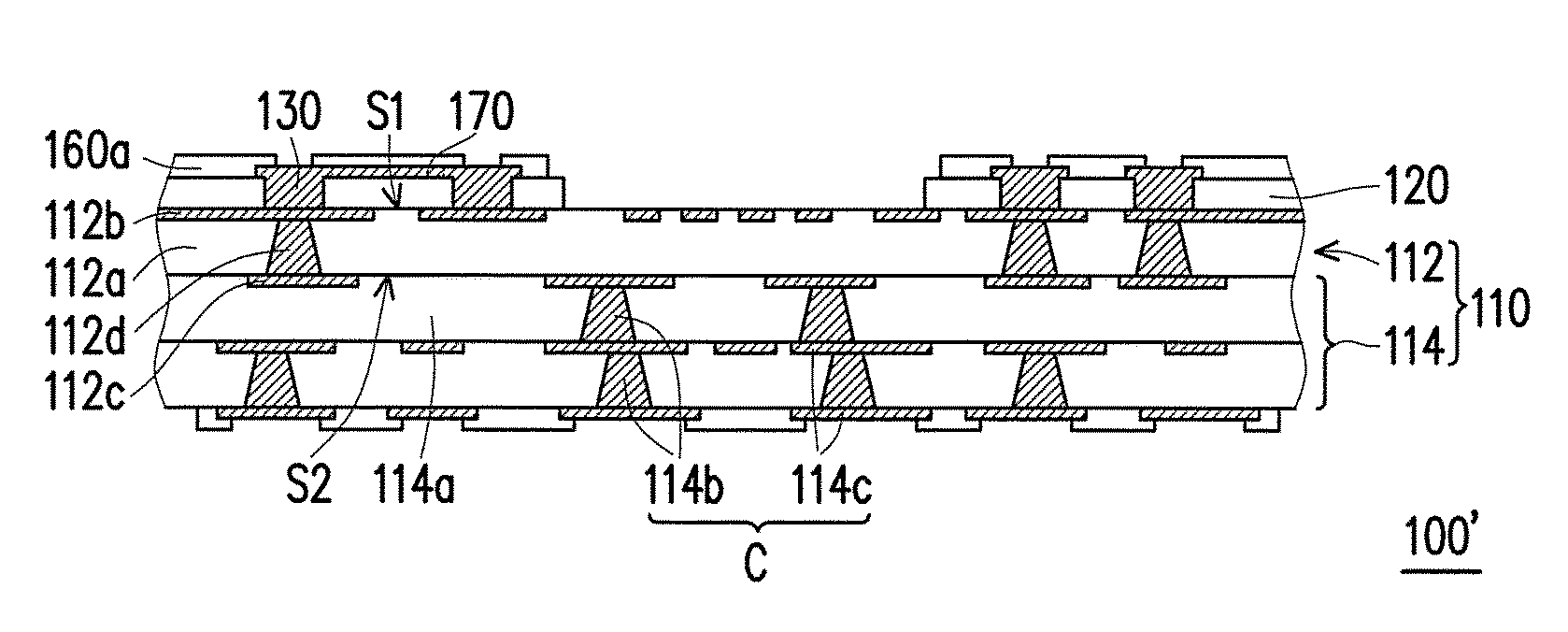

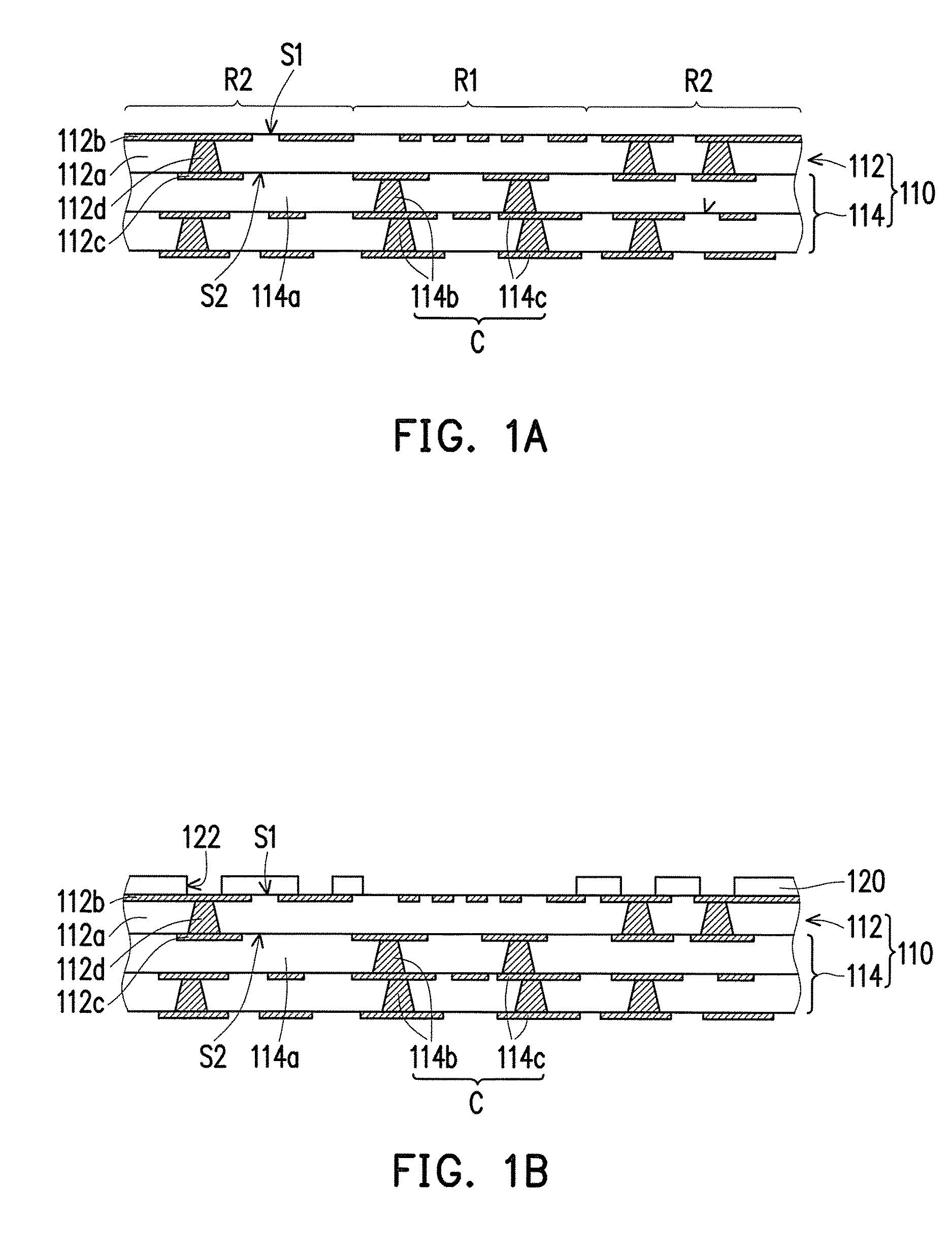

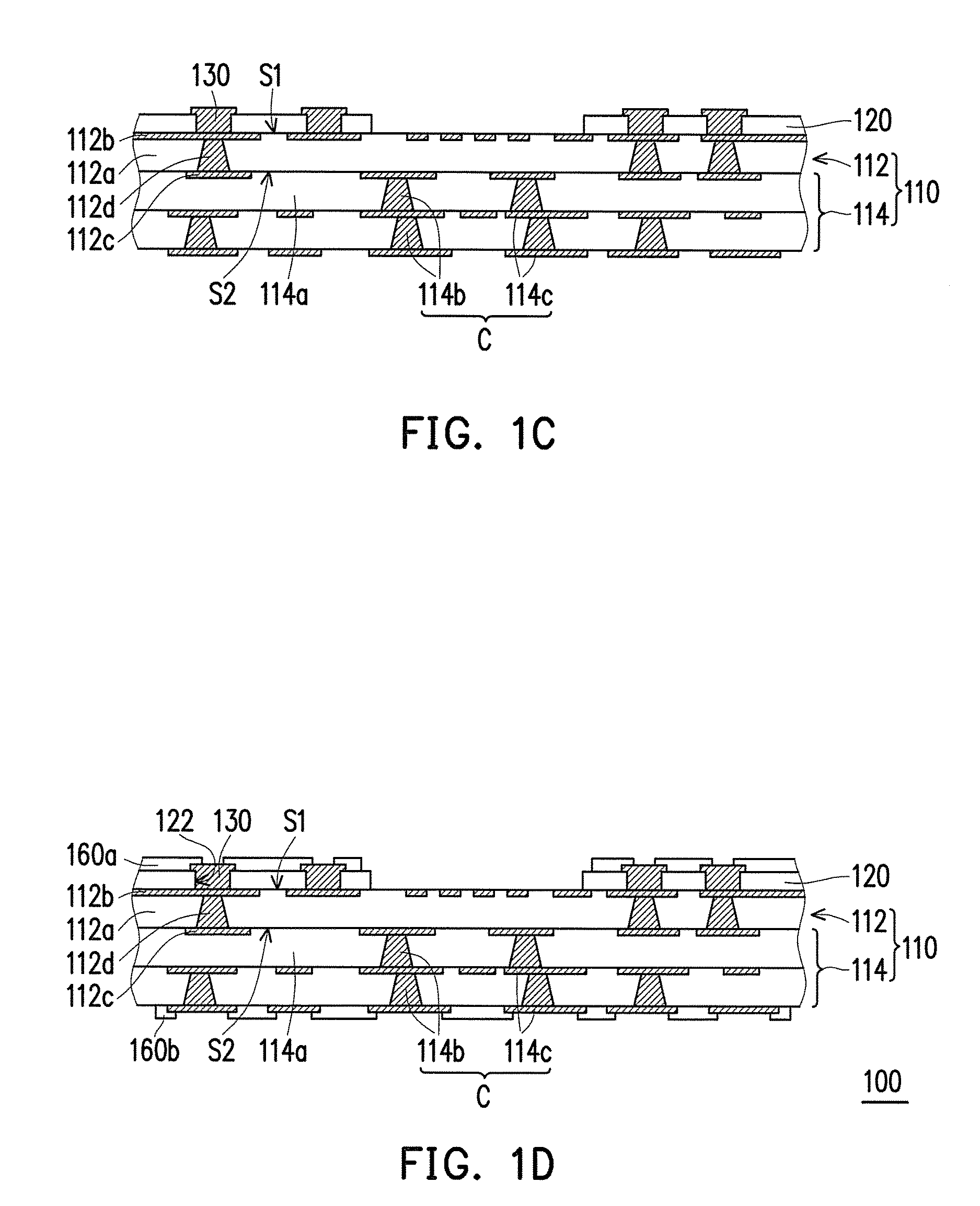

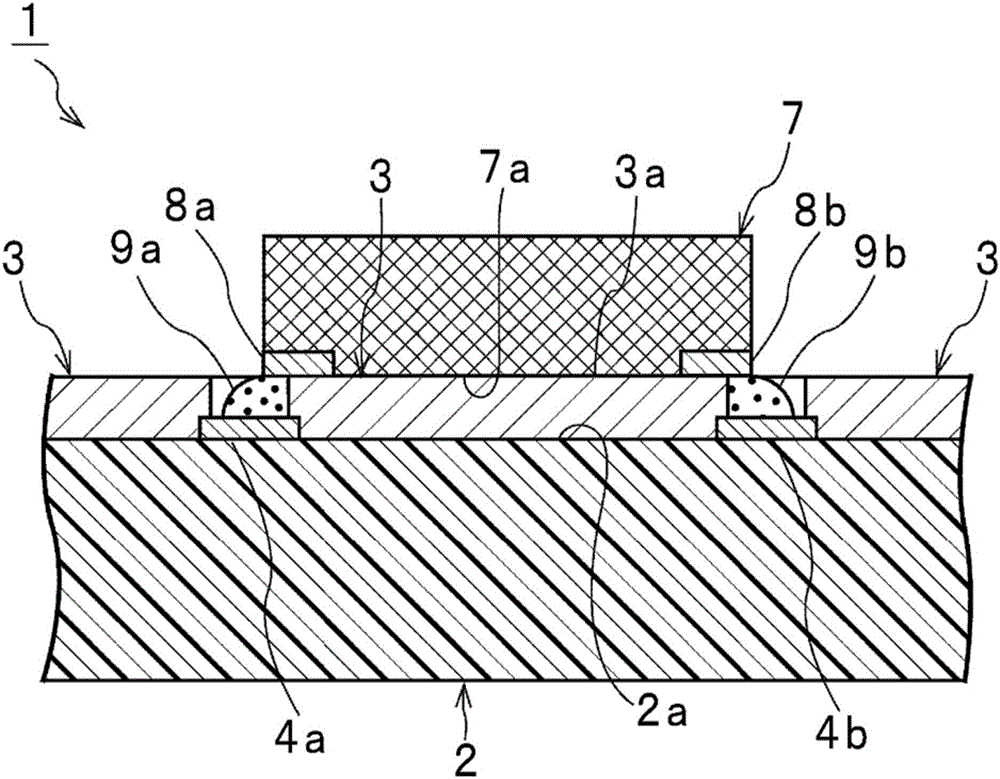

ActiveUS20170042026A1Precision manufacturingReduce chanceFinal product manufactureResist detailsElectrical connectionDielectric layer

A circuit board including a substrate, a photo imageable dielectric layer and a plurality of conductive bumps is provided. The substrate has a first surface and a first circuit layer, wherein the first surface has a chip disposing area and an electrical connection area, and the first circuit layer is embedded in the first surface. The photo imageable dielectric layer is disposed on the electrical connection area and has a plurality of openings, wherein parts of the first circuit layer is exposed by the openings. The conductive bumps are disposed at the openings respectively and connected to the first circuit layer, wherein a side surface of each of the conductive bumps is at least partially covered by the photo imageable dielectric layer. In addition, a manufacturing method of the circuit board is also provided.

Owner:UNIMICRON TECH CORP

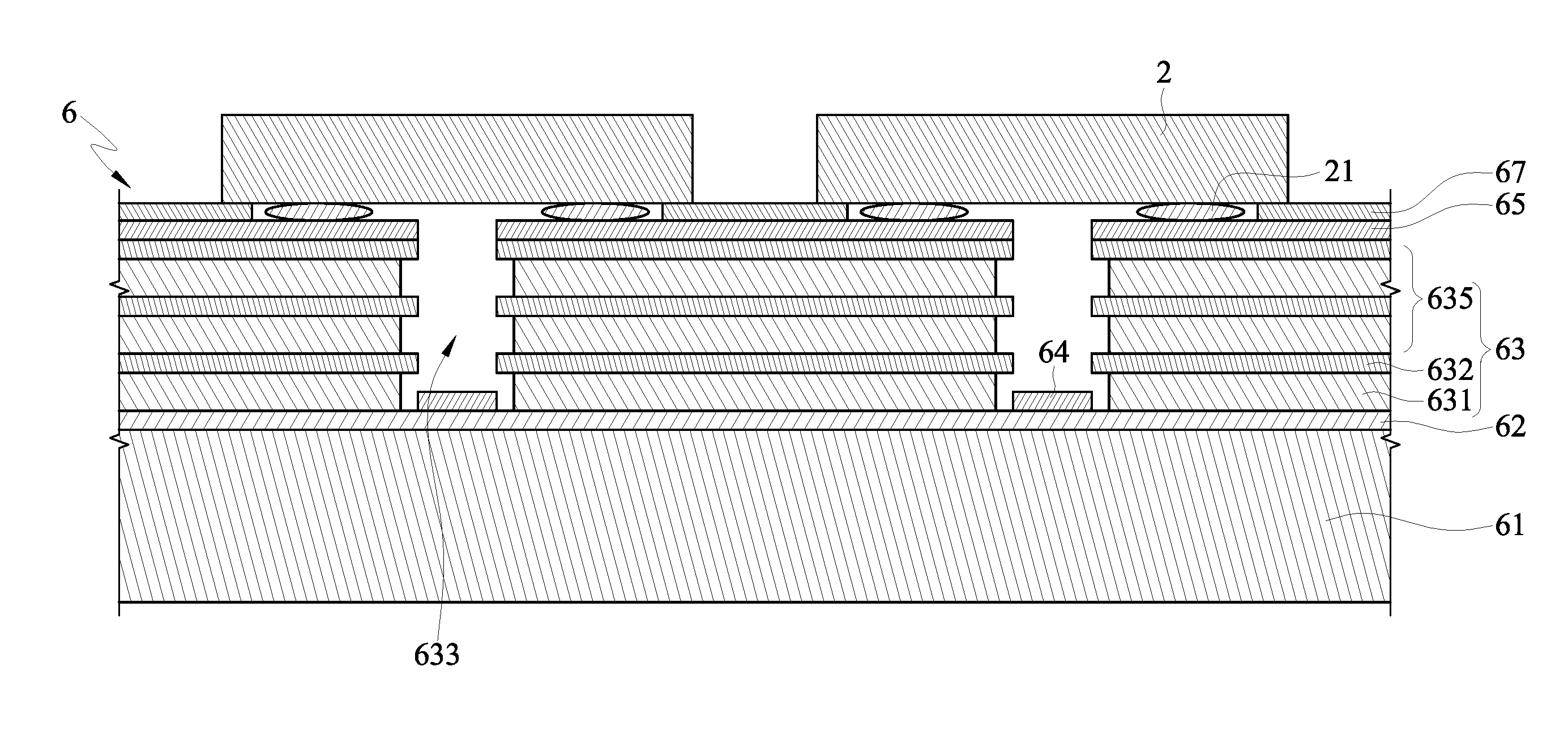

Light emitting diode load board and manufacturing process thereof

InactiveCN106058025AImprove thermal conductivityAvoid touching each otherResist detailsPrinted circuit aspectsEngineeringLight-emitting diode

Disclosed are a light emitting diode load board and a manufacturing process thereof. The light emitting diode load board includes a substrate, a first dielectric layer, a second dielectric layer, a first conductive pad and a second conductive pad. The second dielectric layer includes a first structure part, a second structure part and a third structure part. The first dielectric layer is disposed on the substrate. The first structure part is disposed on the first dielectric layer and has a first sidewall. The second structure part is disposed on the first structure part and has a second sidewall. The third structure part is disposed on the second structure part and has N sidewalls. The second sidewall is more prominent than the first sidewall. The first sidewall, the second sidewall and the N sidewalls define the first etched part, and the part of the first dielectric layer is exposed from the first etched part. The first conductive pad is disposed in the first etched part. The second conductive is disposed on the second dielectric layer, covers part of the second dielectric and exposes the open of the first etched part.

Owner:TM TECHNOLOGY INC

Method for manufacturing flexible circuit board

Owner:INNOLUX CORP

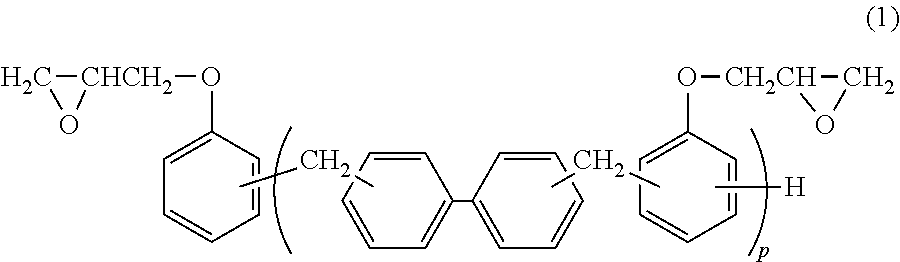

Liquid solder resist composition and covered-printed wiring board

ActiveUS20180210336A1Improve reflectivityPrevent degradationRadiation applicationsResist detailsResistCyclic ether

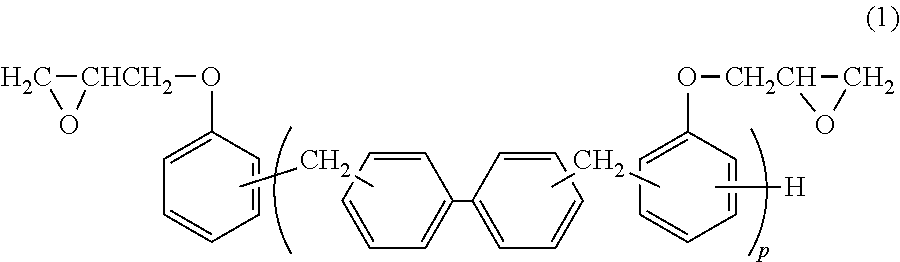

A liquid solder resist composition contains a carboxyl group-containing resin, a photopolymerizable compound containing at least one compound selected from a group consisting of a photopolymerizable monomer and a photopolymerizable prepolymer, a photopolymerization initiator, a titanium dioxide, and a compound having a cyclic ether skeleton. The titanium dioxide contains both of a rutile titanium dioxide manufactured by a sulfuric acid method and a rutile titanium dioxide manufactured by a chlorine method.

Owner:GOO CHEM IND

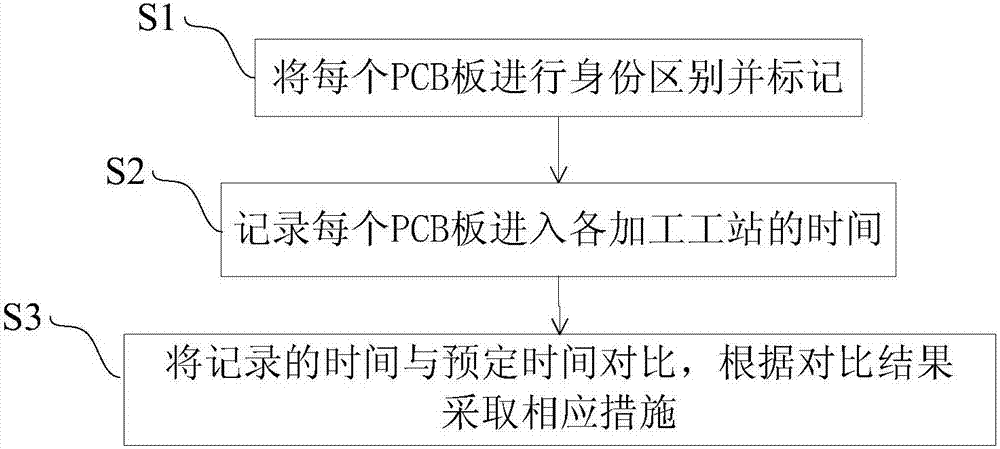

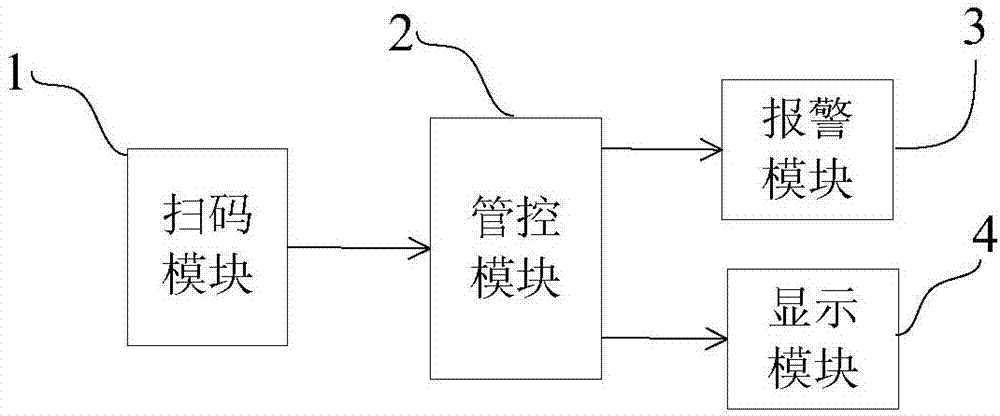

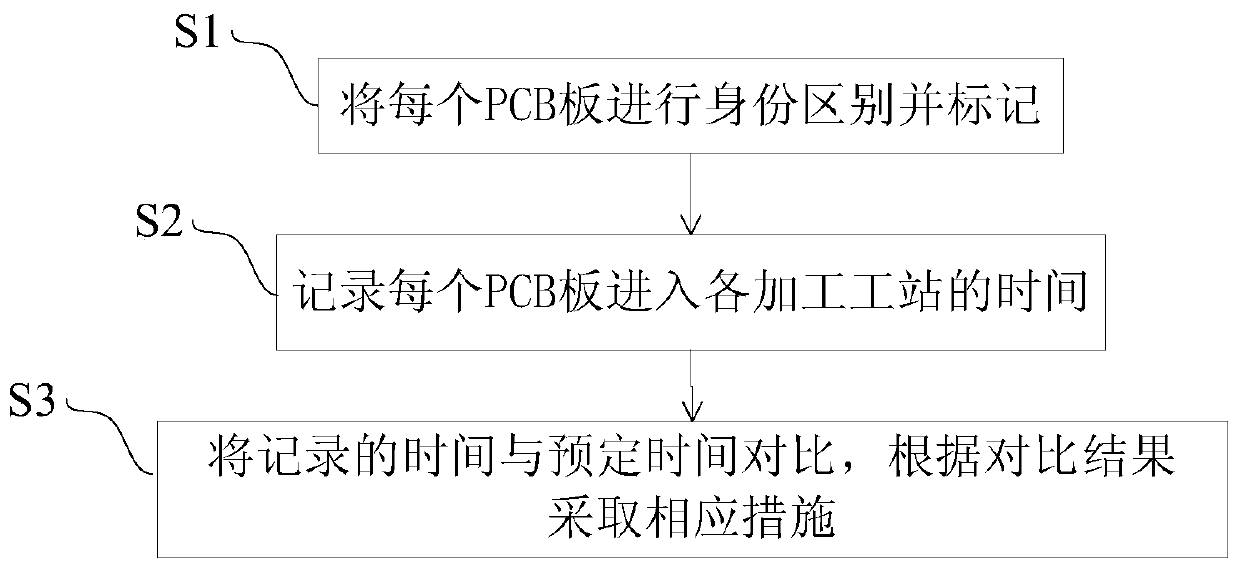

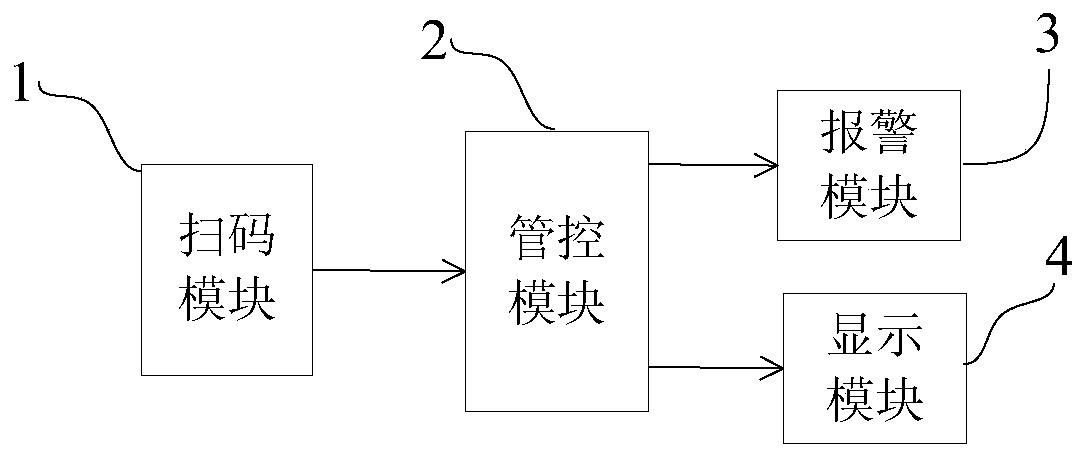

Time control method and system for organic solderability preservatives (OSP) surface processing on printed circuit board (PCB)

ActiveCN107404809AQuality assuranceReduce return rateResist detailsNon-metallic protective coating applicationState of artSolderability

The invention discloses a time control method and system for organic solderability preservatives (OSP) surface processing on a printed circuit board (PCB). The method comprises the steps of performing identification on each PCB, and marking each PCB; recording time of each PCB entering each processing station; and comparing recorded time with preset time, and taking corresponding measure according to a comparison result. The system comprises a scanning module, a control module, a warning module and a display module, wherein an output end of the scanning module is connected with an input end of the control module, and an output end of the control module is connected with the warning module and the display module. Compared with the prior art, the processing time of the PCB is strictly controlled, the quality of the PCB leaving from a factory is ensured, the return rate is greatly reduced, manual control is omitted, and the production cost is reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

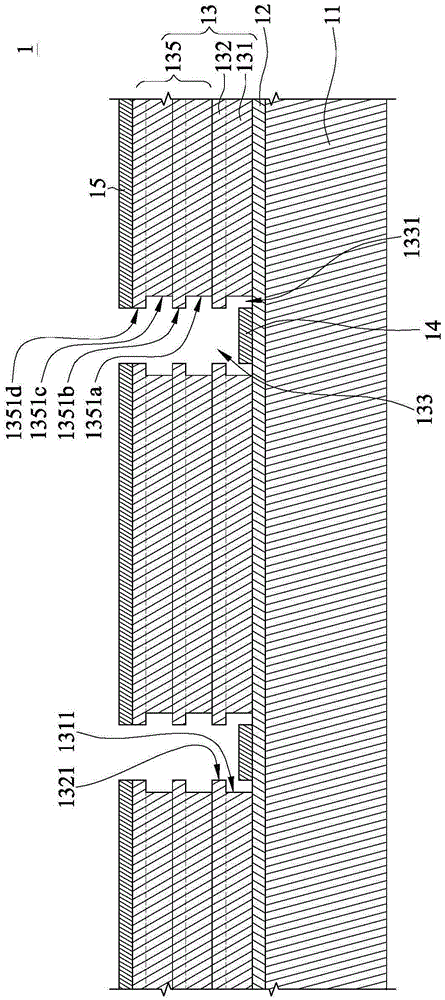

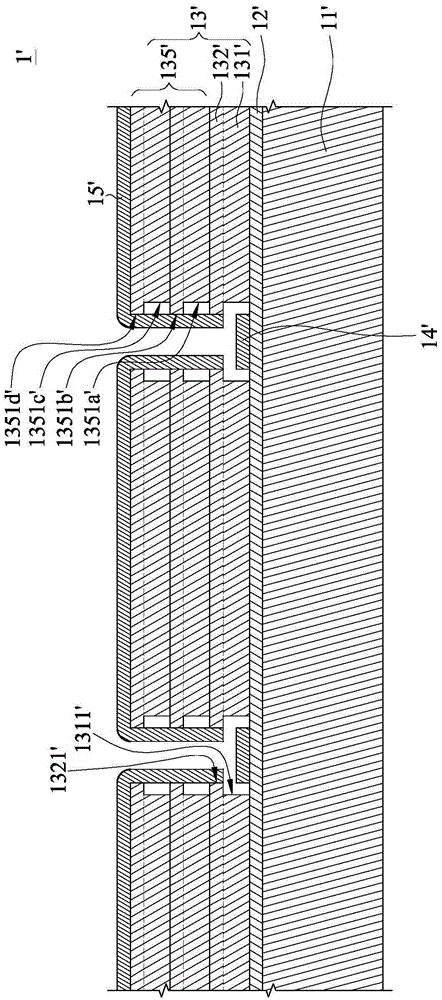

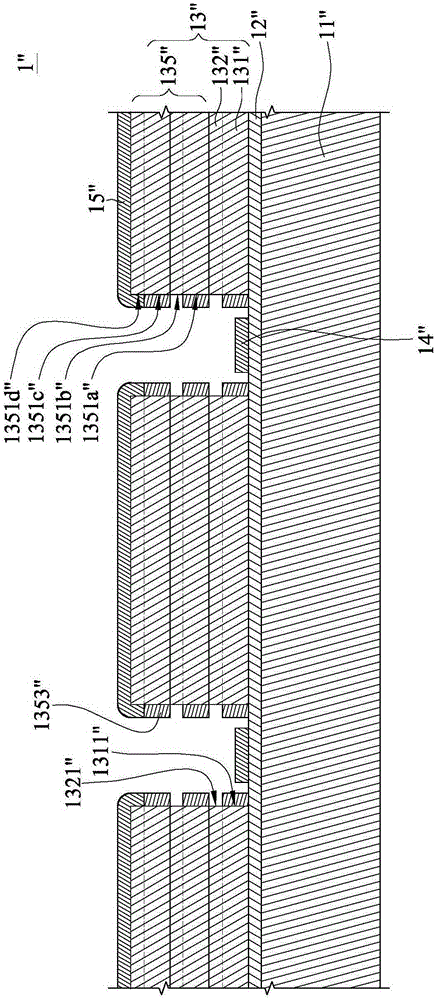

Light emitting diode load board and manufacturing process thereof

InactiveUS9560753B2Improve efficiencyImprove thermal conductivityResist detailsPrinted circuit aspectsDielectric layerLight-emitting diode

A light emitting diode load board includes a substrate, a first dielectric layer, a second dielectric layer and a first conductive pad and a second conductive pad. The second dielectric layer includes a first structure part, a second structure part and a third structure part. The first dielectric layer is disposed on the substrate. The first structure part is disposed on the first dielectric layer and has a first sidewall. The second structure part is disposed on the first structure part and has a second sidewall. The third structure part is disposed on the second structure part and has N sidewalls. The second sidewall is more prominent than the first sidewall. The first sidewall, the second sidewall and the N sidewalls define the first etched part, and the part of the first dielectric layer is exposed from the first etched part. The first conductive pad is disposed in the first etched part. The second conductive is disposed on the second dielectric layer, covers part of the second dielectric and exposes the open of the first etched part.

Owner:TM TECHNOLOGY INC

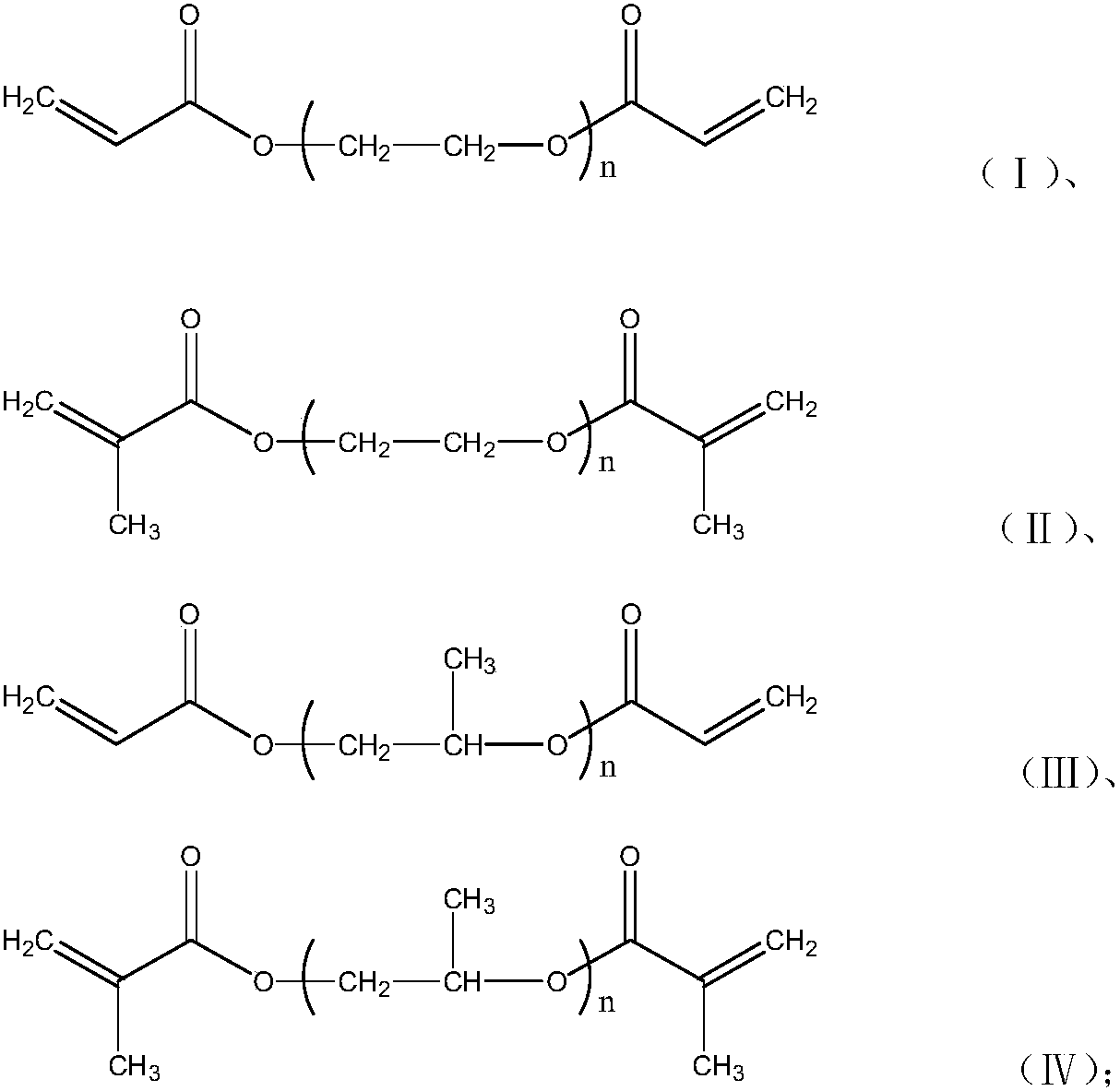

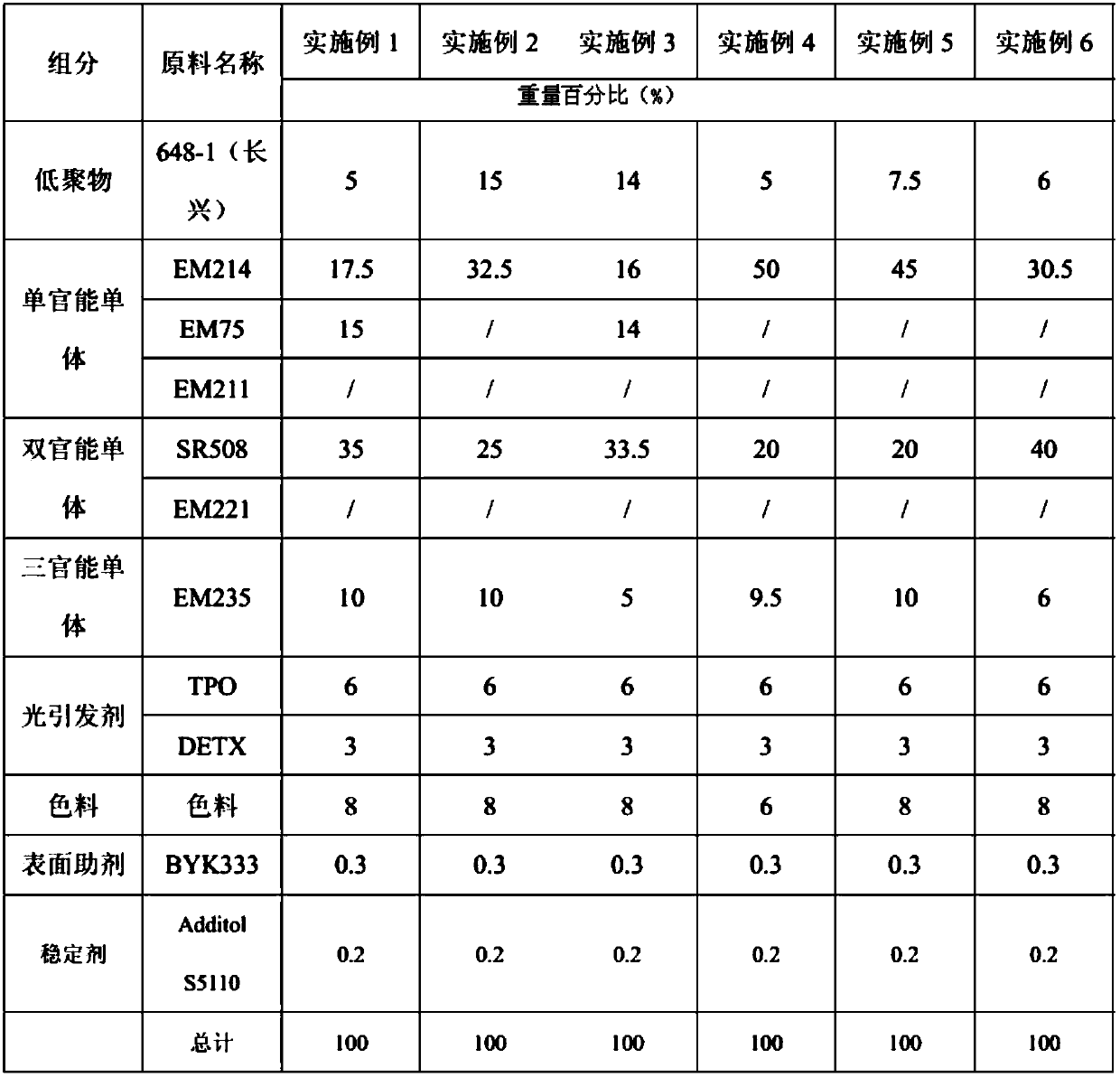

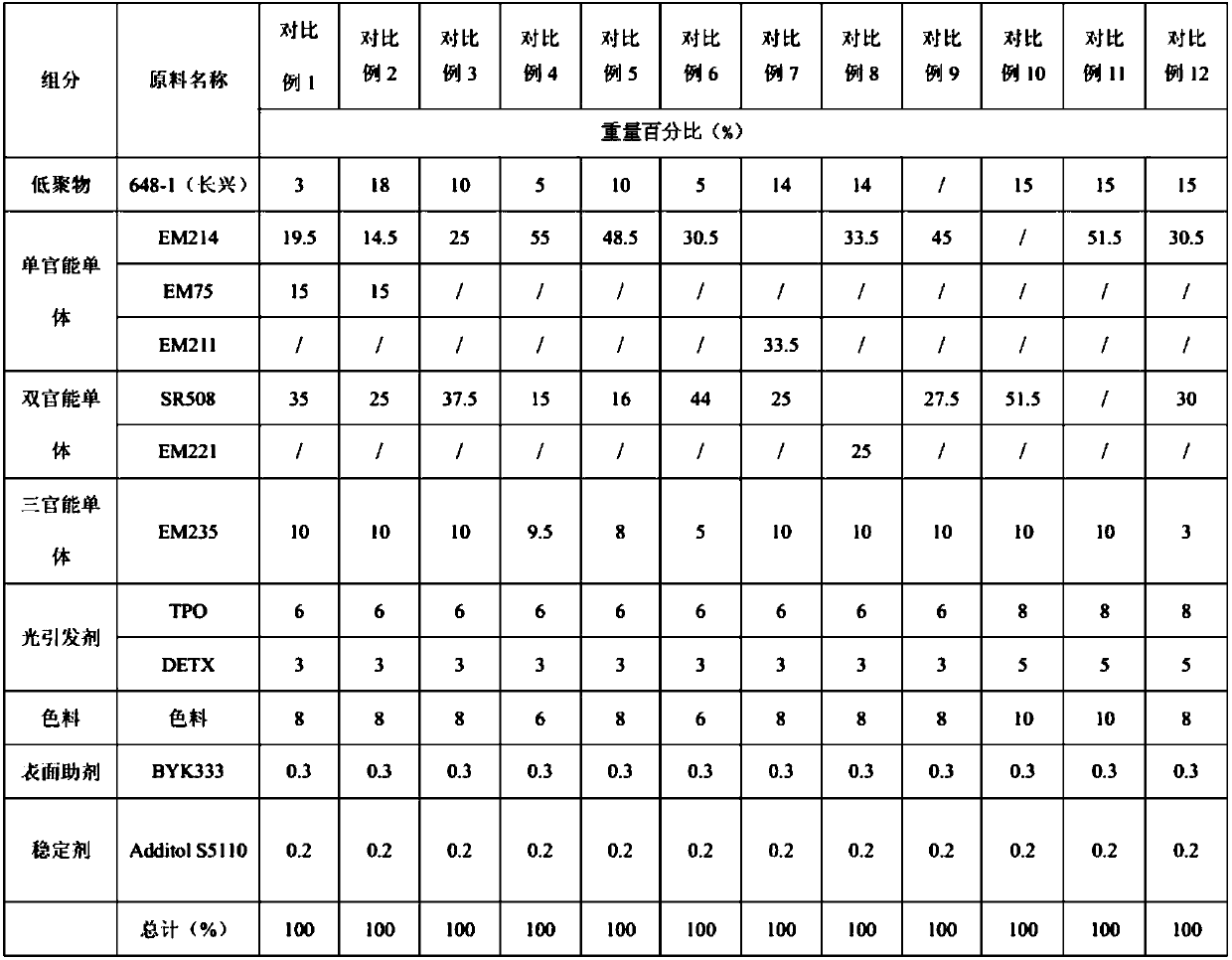

A kind of anti-etching ink-jet ink and its application

ActiveCN105733361BImprove liquidityStable printing performanceResist detailsInksMethacrylatePolymer science

The invention provides etching-resistant jet ink and provides a method for preparing a conductive circuit by using the etching-resistant jet ink. The etching-resistant jet ink comprises a photocuring monomer, an oligomer, a pigment and a photoinitiator, wherein the photocuring monomer comprises at least one of monofunctional (methyl) acrylate, bidirectional (methyl) acrylate and tri-functional acrylate; the bidirectional (methyl) acrylate comprises at least one of bidirectional (methyl) acrylate with a glycol structure or propylene glycol structure in the molecular structure. The etching-resistant jet ink is good in flowability, applicable to jet ink technique and good in stable jet printing property, a temporary protecting layer formed after the jet ink is cured can meet the process requirements of the circuit board in the production process and is resistant to corrosion of an etching liquid without dropping, and rapid stripping can be achieved in an alkali liquid after the etching process is completed.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

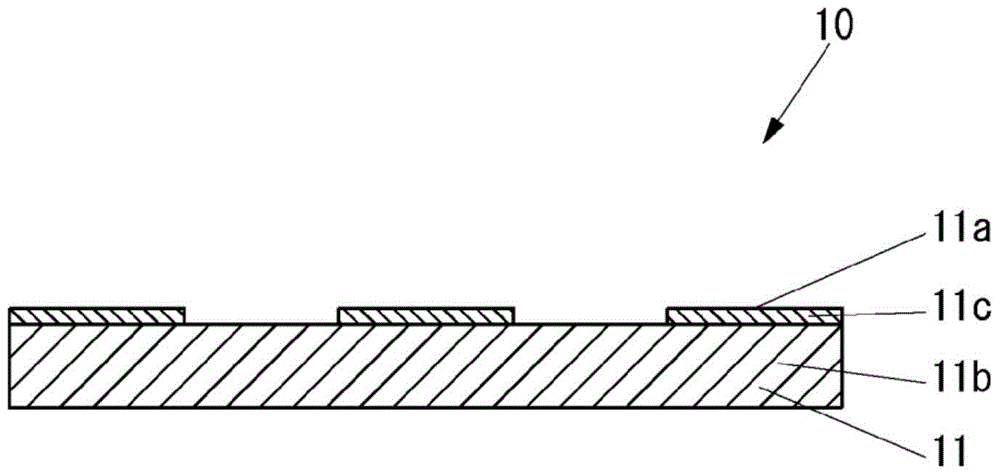

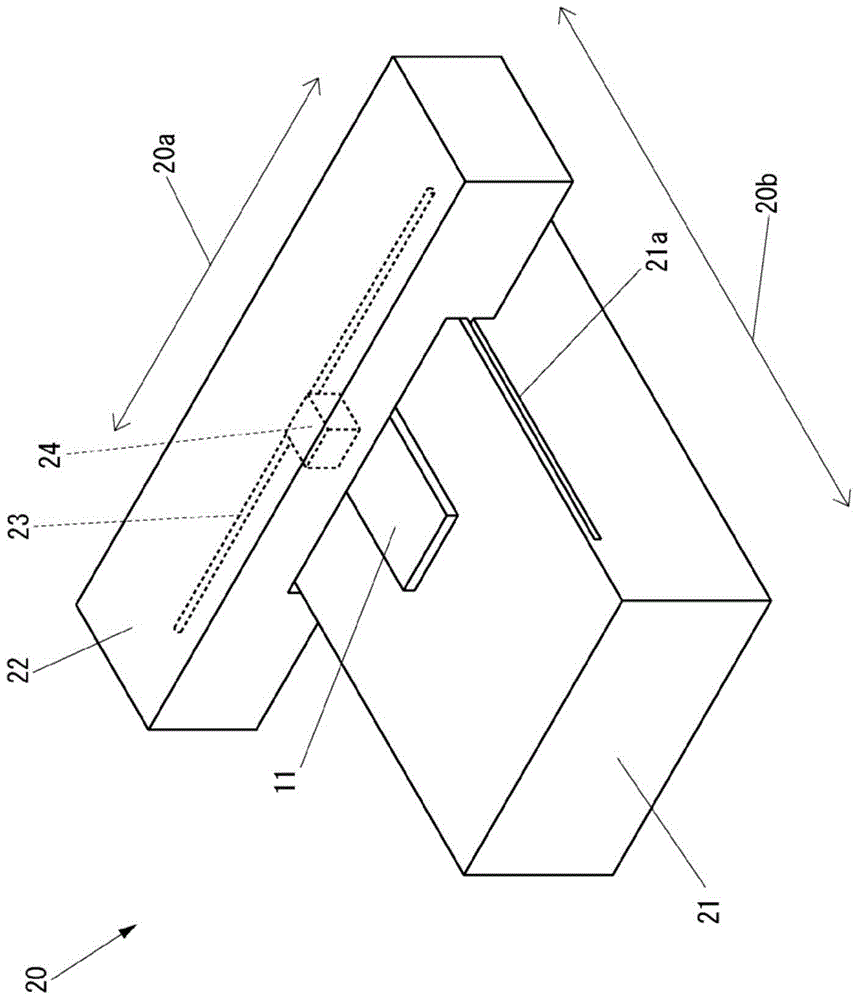

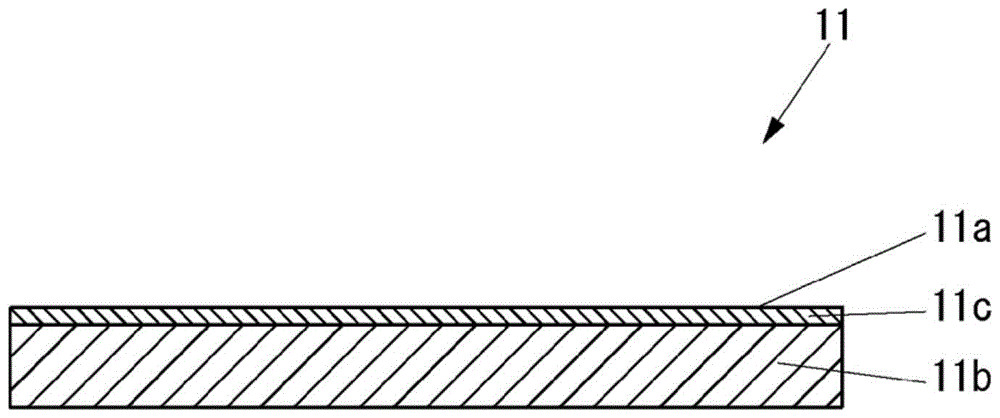

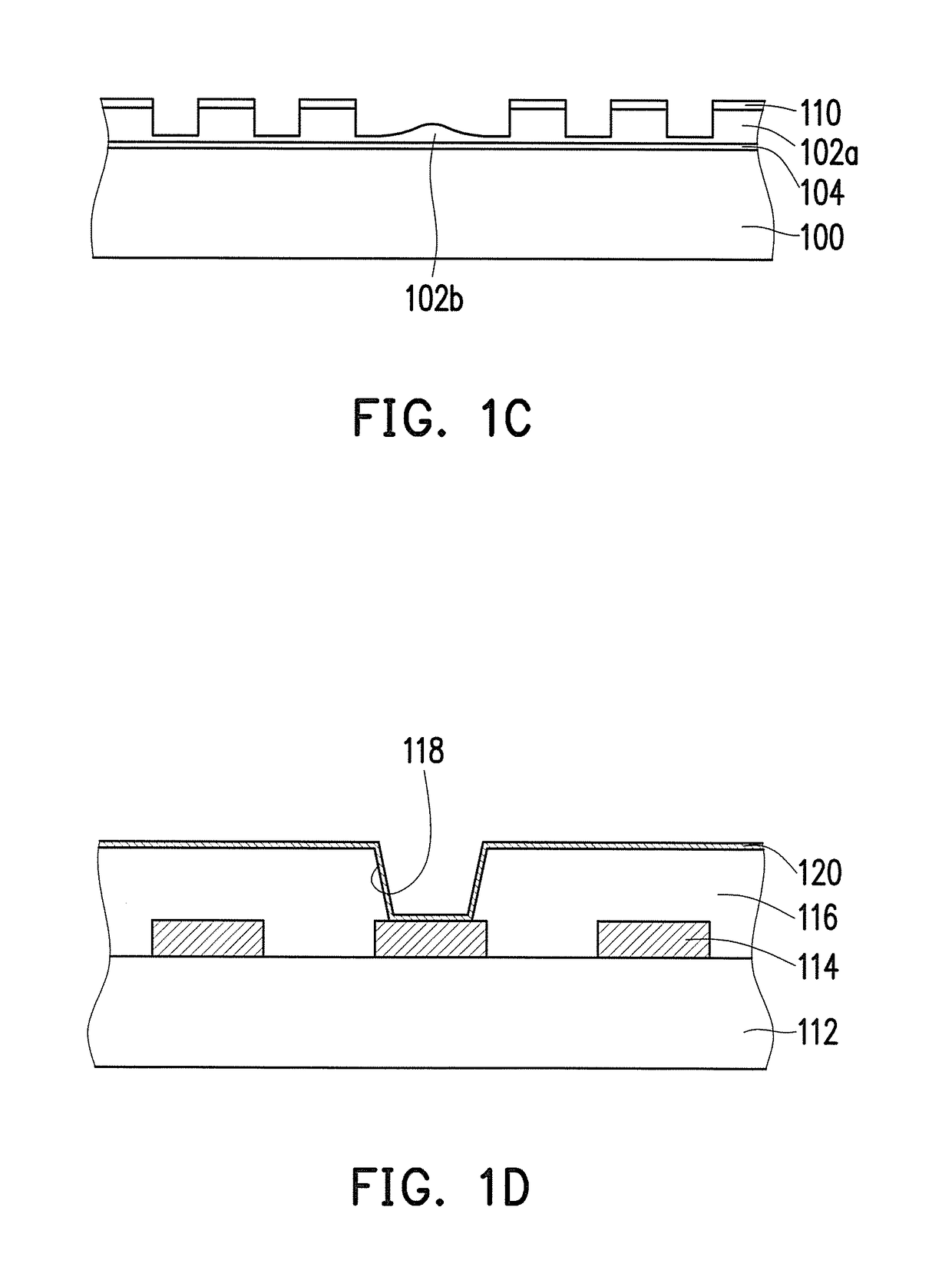

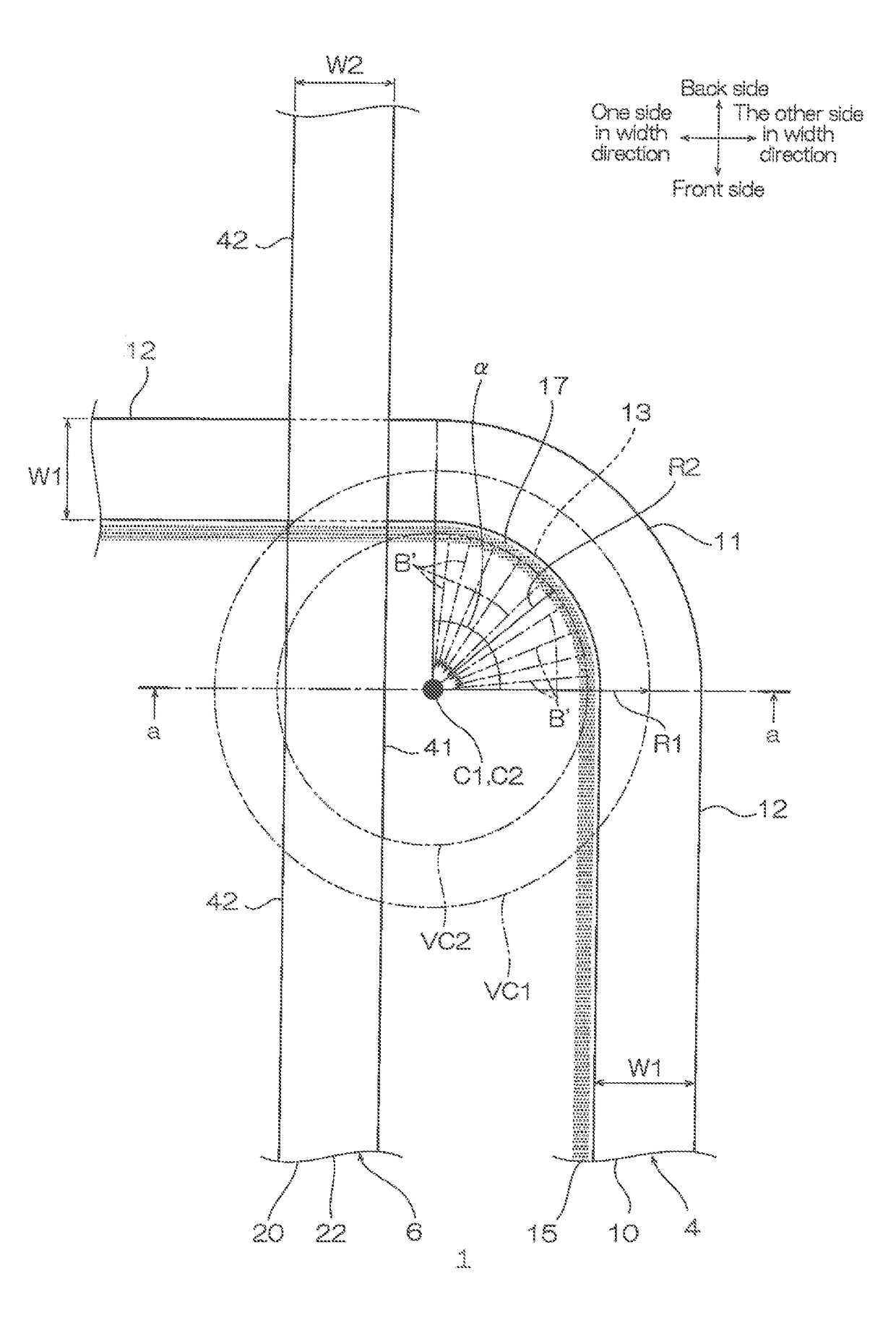

Etching method

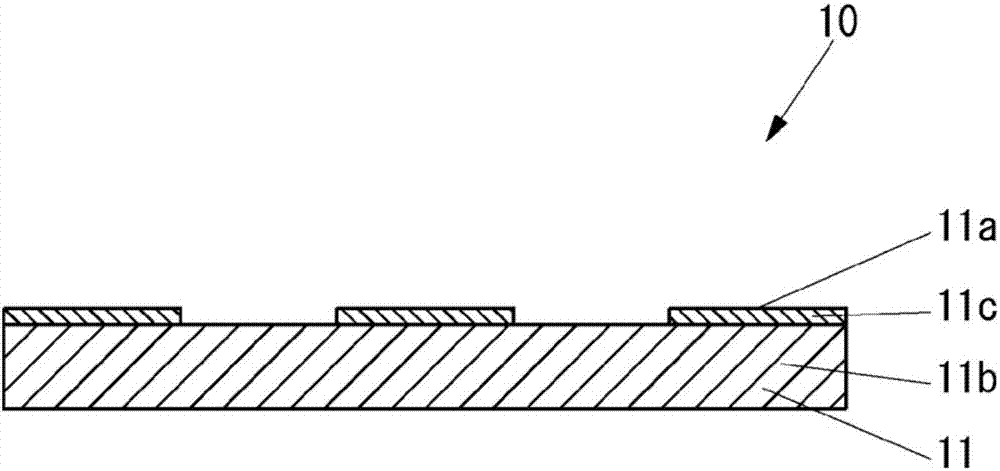

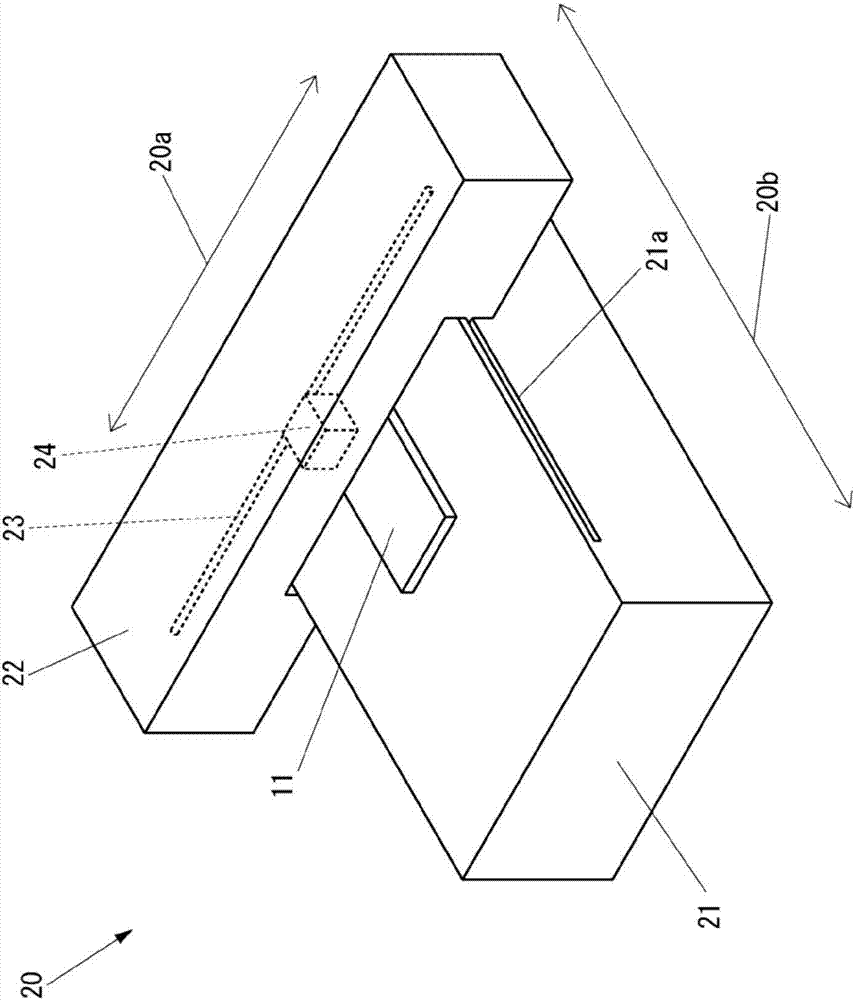

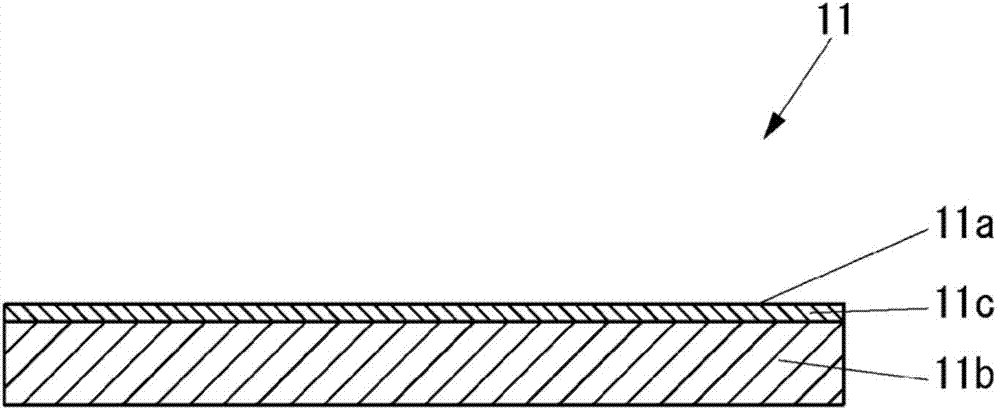

In this etching method, the surface (11a) of a target object (11) is processed by using a corrosive agent to corrode said surface (11a) as a means of solving the problem addressed by the present invention. The etching method comprises: a resist formation step in which resist liquid is inkjet-printed on the surface (11a) so that the resist liquid forms a resist (12); a surface corrosion step in which the side (11a) of the target object (11) on which the resist (12) was formed by the resist formation step is brought into contact with a corrosive agent so that the part of the surface (11a) not having the resist (12) formed thereon is corroded; and a resist peeling step in which the resist (12) is peeled from the surface (11a) after the surface corrosion step. The etching method is characterized by the resist formation step being a step in which the resist (12) is formed using a resist liquid containing a monofunctional monomer or a monofunctional oligomer and a polyfunctional monomer or a polyfunctional oligomer.

Owner:MIMAKI ENG

Large-makeup high-ounce copper solder resist one-time printing ink process

PendingCN111770645AImprove yield rateSolve sheddingResist detailsNon-metallic protective coating applicationMetallurgyPrinting ink

The invention discloses a large-makeup high-ounce copper solder resist one-time printing ink process. The process comprises the following steps: S1, preparing solder resist ink; S2, performing soldermask primary printing; S3, performing pre-drying and carrying out primary exposure; and S4, performing developing and polishing. The large-makeup high-ounce copper solder resist one-time printing inkprocess is simple and easy to implement, short in process, high in production efficiency and low in production cost, the yield of produced finished products is high, the problems of circuit ink bubbles and ink falling can be effectively solved, and the quality and the grade of a PCB are improved.

Owner:KUNSHAN DAYANG PRINTED CIRCUIT BOARD

Liquid solder resist composition and covered-printed wiring board

ActiveUS10234758B2Improve reflectivityPrevent degradationRadiation applicationsResist detailsResistCyclic ether

A liquid solder resist composition contains a carboxyl group-containing resin, a photopolymerizable compound containing at least one compound selected from a group consisting of a photopolymerizable monomer and a photopolymerizable prepolymer, a photopolymerization initiator, a titanium dioxide, and a compound having a cyclic ether skeleton. The titanium dioxide contains both of a rutile titanium dioxide manufactured by a sulfuric acid method and a rutile titanium dioxide manufactured by a chlorine method.

Owner:GOO CHEM IND

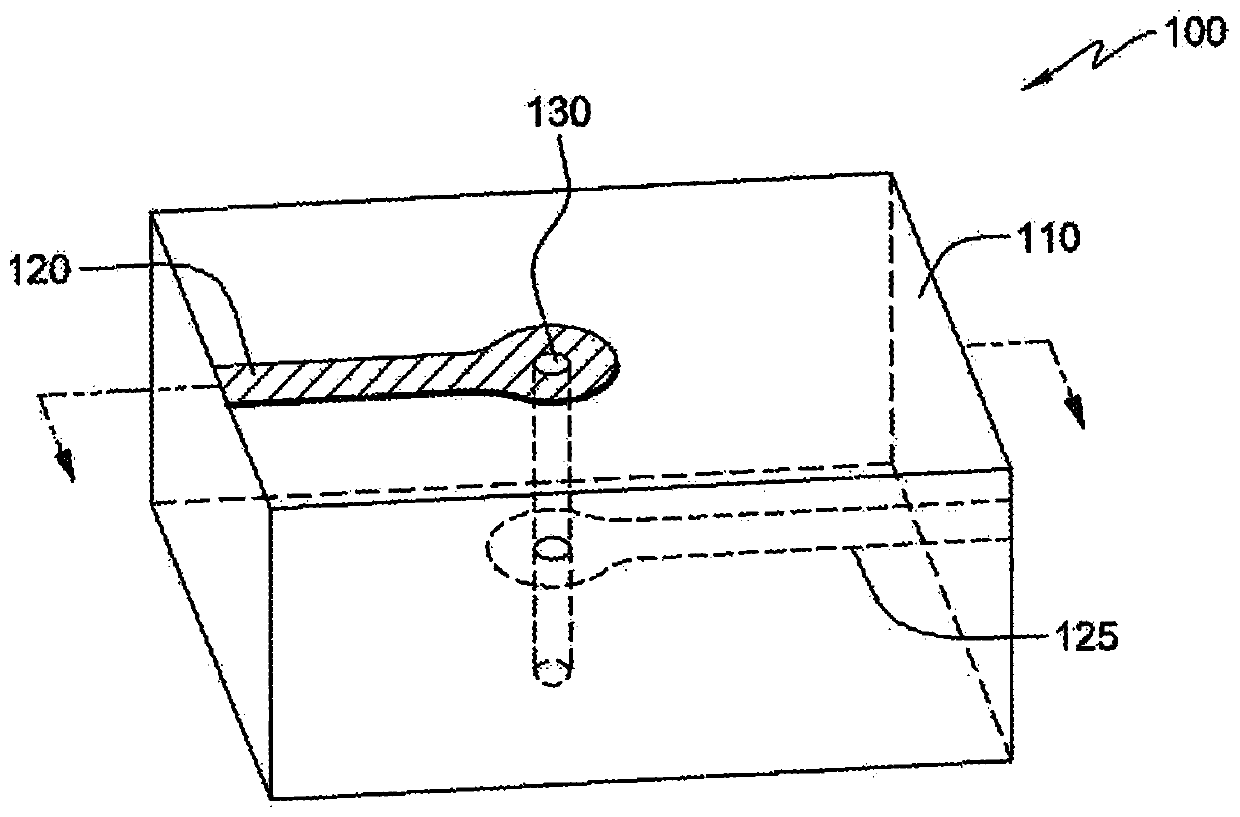

Forming conductive vias using a light guide

The present invention provides a process and a structure of forming conductive vias using a light guide. In an exemplary embodiment, the process includes providing a via in a base material in a direction perpendicular to a plane of the base material, applying a photoresist layer to an interior surface of the via, inserting a light guide into the via, exposing, by the light guide, a portion of thephotoresist layer to light, thereby resulting in an exposed portion of the photoresist layer and an unexposed portion of the photoresist layer, removing a portion of the photoresist layer, and platingan area of the via, where the photoresist has been removed, with a metal, thereby resulting in a portion of the via plated with metal and a portion of the via not plated with metal.

Owner:IBM CORP

Multilayer printed wiring board production method, adhesive layer-equipped metal foil, metal-clad laminate, and multilayer printed wiring board

ActiveUS20180235090A1Improve adhesionStructuredInsulating substrate metal adhesion improvementResist detailsResistCopper plating

Disclosed is a production method of a multi-layered printed wiring board, including the following steps 1 to 3:Step 1: a step of laminating, on a substrate with inner layer circuit, a metal foil with adhesive layer including a support, a metal foil having a thickness of 3 μm or less and ⅙ or less relative to the thickness of the inner layer circuit, and an organic adhesive layer having a thickness of 10 μm or less in this order, via an organic insulating resin layer such that the organic insulating resin layer and the organic adhesive layer are opposed to each other, and then releasing the support to form a laminated sheet (a) having the metal foil as an outer layer metal foil layer;Step 2: a step of irradiating the laminated sheet (a) with a laser to bore the outer layer metal foil layer, the organic adhesive layer, and the organic insulating resin layer to form a bored laminated sheet (b) having a blind via hole; andStep 3: a step of forming an outer layer circuit connected with the inner layer circuit through the following steps 3-1 to 3-4:Step 3-1: a step of etching removing the outer layer metal foil layer of the bored laminated sheet (b) formed in the step 2 and then forming an outer layer copper layer having a thickness of 2 μm or less on the bored laminated sheet (b);Step 3-2: a step of forming a resist pattern by a resist applied on the outer layer copper layer;Step 3-3: a step of forming a circuit layer on the surface of the outer layer copper layer on which the resist pattern is not formed, by electrolytic copper plating; andStep 3-4: a step of removing the resist pattern and then removing the exposed outer layer copper layer by etching, thereby forming an outer layer circuit connected with the inner layer circuit.

Owner:RESONAC CORP

First liquid and second liquid of two-liquid mixing type and method for manufacturing printed wiring board

PendingCN106019828AGood storage stabilitySuppression of variation in reflectanceResist detailsPhotosensitive materials for photomechanical apparatusHybrid typeOrganic solvent

The invention provides a first liquid and a second liquid of a two-liquid mixing type, wherein the first liquid and the second liquid have excellent storage stability and can prevent deviation of the reflectivity of an anti-corrosion film. The first liquid and the second liquid are used for obtaining a mixture, that is, a first liquid and a second liquid of a two-liquid mixing type of a photo-sensitive composition. The first liquid contains a carboxyl-containing polymerizable polymer, a polymerization initiator, titanium oxide, inorganic filler and an organic solvent. The second liquid contains a cyclic-ether-containing compound, titanium oxide and inorganic filler, and is free of an organic solvent. No more than 10% by weight of the photo-sensitive composition contains the organic solvent based on that the photo-sensitive composition contains 100% by weight of the whole organic solvent.

Owner:SEKISUI CHEM CO LTD

Manufacturing method of circuit board

ActiveUS10098234B2Improve reliabilityHigh yieldLithography/patterningResist detailsDielectric substrateTransmittance

A manufacturing method of a circuit board and a piezochromic stamp are provided. A circuit pattern is formed on a dielectric substrate. A dielectric layer having a hole or a conductive via and covering the circuit pattern is formed on the dielectric substrate. A conductive seed layer is formed on the dielectric layer. A photoresist layer is formed on the conductive seed layer. A piezochromic stamp is imprinted on the photoresist layer, wherein when the pressing side of the piezochromic stamp is in contact with the conductive seed layer, the light transmittance effect thereof is changed to blocking or allowing light having a specific wavelength to pass through. A patterned photoresist layer is formed by using the piezochromic stamp as a mask. A patterned metal layer is formed on the exposed conductive seed layer. The patterned photoresist layer and the conductive seed layer are removed.

Owner:UNIMICRON TECH CORP

Etching method

A solution is characteristic in being an etching method that processes a surface of a target object by corroding the surface by a corrosive, and the etching method includes: a resist forming step of forming a resist on the surface using resist liquid by ink jet printing the resist liquid on the surface; a surface corroding step of corroding a portion of the surface where the resist is not formed by bringing the corrosive into contact with a surface side of the target object where the resist has been formed in the resist forming step; and a resist detaching step of detaching the resist from the surface after the surface corroding step, wherein the resist forming step is a step of forming the resist by the resist liquid containing monofunctional monomers or monofunctional oligomers, and polyfunctional monomers or polyfunctional oligomers.

Owner:MIMAKI ENG

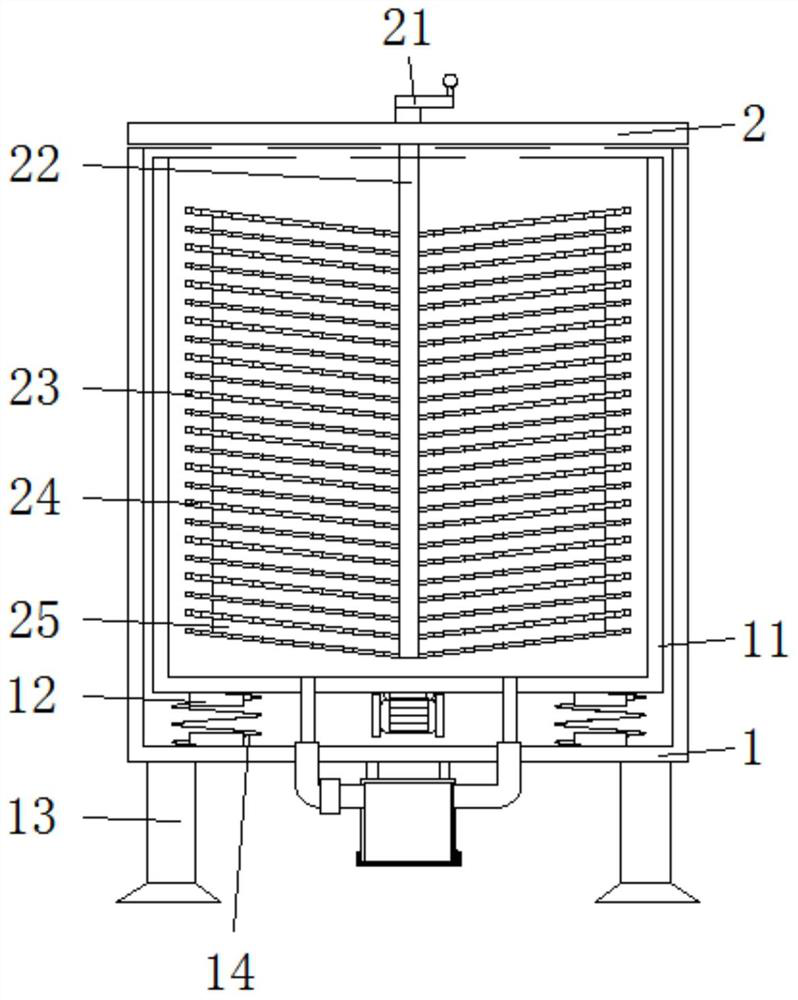

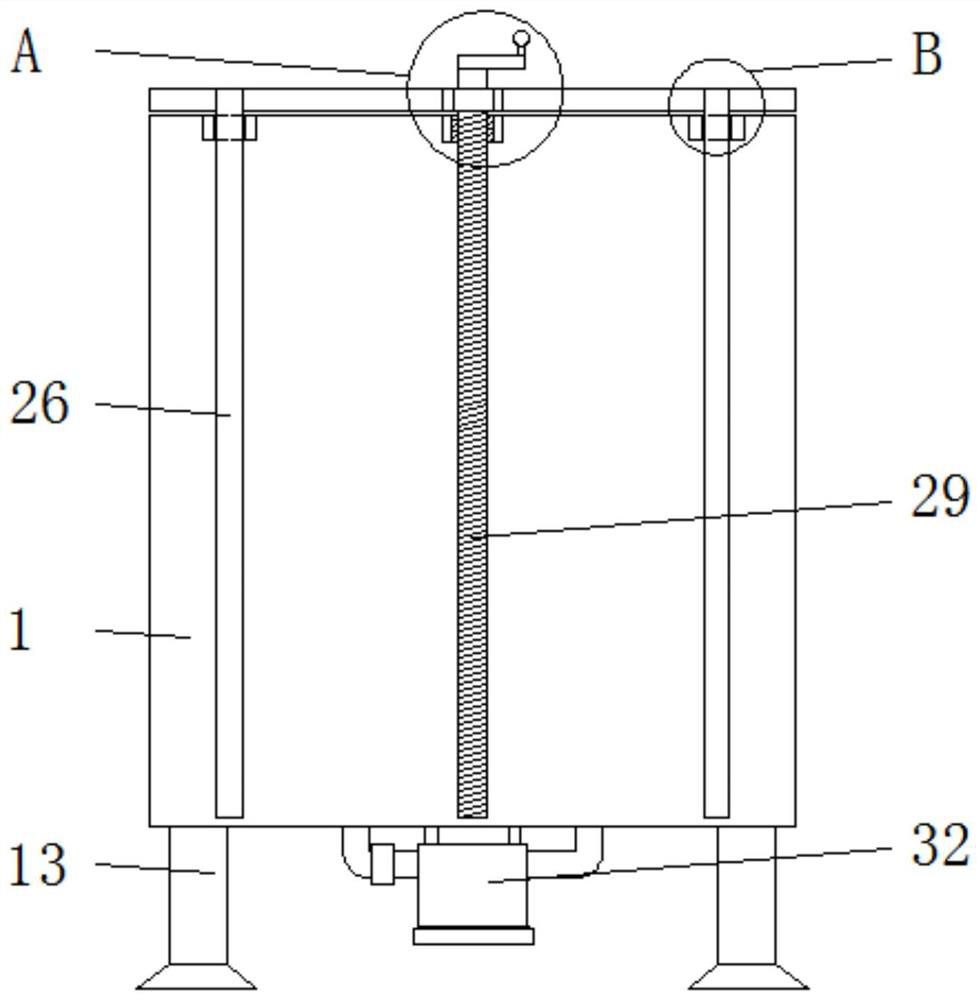

Micro-strip circuit board etching method and improved device

ActiveCN113163611AAchieve the effect of etchingEasy to moveResist detailsConductive material chemical/electrolytical removalElectric machineStructural engineering

The invention discloses a micro-strip circuit board etching method and an improved device. The device comprises a shell, a cover plate, a connecting pipe, a through hole and a screw hole. The shell is internally provided with a water storage bin, a vibration motor is installed on one side of the outer wall of the lower end of the water storage bin, and a first rubber hose and a second rubber hose are inserted into the lower end of the inner wall of the water storage bin. The cover plate is arranged on one side of the outer wall of the upper end of the shell; the vibration motor is installed on one side of the outer wall of the lower end of the water storage bin; the connecting pipe is inserted into one side of the outer wall of the lower end of the shell; and the outer walls of the two ends of the connecting pipe penetrate through the shell to be connected with the first rubber hose and the second rubber hose correspondingly. By arranging the vibration motor, a spring and the water storage bin, the effect of removing bubbles on the surface of a circuit board is achieved, it is guaranteed that etching liquid can make full contact with the circuit board, the etching effect of the etching liquid on the circuit board is guaranteed, and the etching quality of the circuit board is guaranteed.

Owner:江苏艾诺信电路技术有限公司

Manufacturing method of circuit board and stamp

ActiveUS20170273191A1Easy to disassembleLithography/patterningLithographic masksDielectric substratePhotoresist

A manufacturing method of a circuit board and a stamp are provided. The method includes the following steps. A circuit pattern and a dielectric layer covering the circuit pattern are formed on a dielectric substrate. A conductive via connected to the circuit pattern is formed in the dielectric layer. A photoresist material layer is formed on the dielectric layer. An imprinting process is performed on the photoresist material layer using a stamp to form a patterned photoresist layer, wherein the pressing side of the stamp facing the circuit pattern becomes sticky when subjected to pressure so as to catch photoresist residue from the photoresist material layer in the imprinting process. A patterned metal layer is formed on a region exposed by the patterned photoresist layer. The patterned photoresist layer is removed.

Owner:UNIMICRON TECH CORP

Time control method and system for osp surface treatment of pcb

ActiveCN107404809BQuality assuranceReduce return rateResist detailsNon-metallic protective coating applicationControl engineeringProcess engineering

The invention discloses a time control method and system for organic solderability preservatives (OSP) surface processing on a printed circuit board (PCB). The method comprises the steps of performing identification on each PCB, and marking each PCB; recording time of each PCB entering each processing station; and comparing recorded time with preset time, and taking corresponding measure according to a comparison result. The system comprises a scanning module, a control module, a warning module and a display module, wherein an output end of the scanning module is connected with an input end of the control module, and an output end of the control module is connected with the warning module and the display module. Compared with the prior art, the processing time of the PCB is strictly controlled, the quality of the PCB leaving from a factory is ensured, the return rate is greatly reduced, manual control is omitted, and the production cost is reduced.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

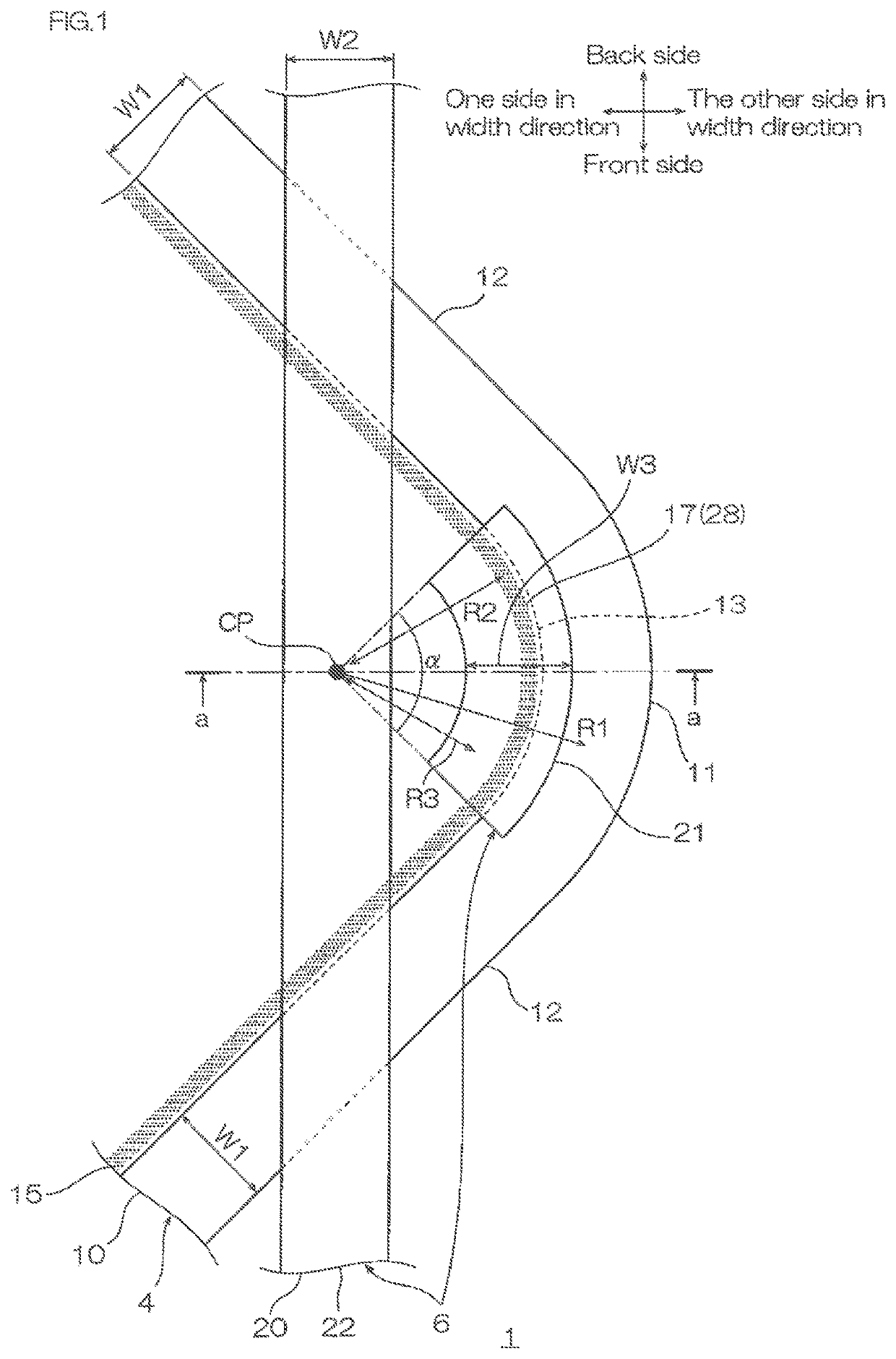

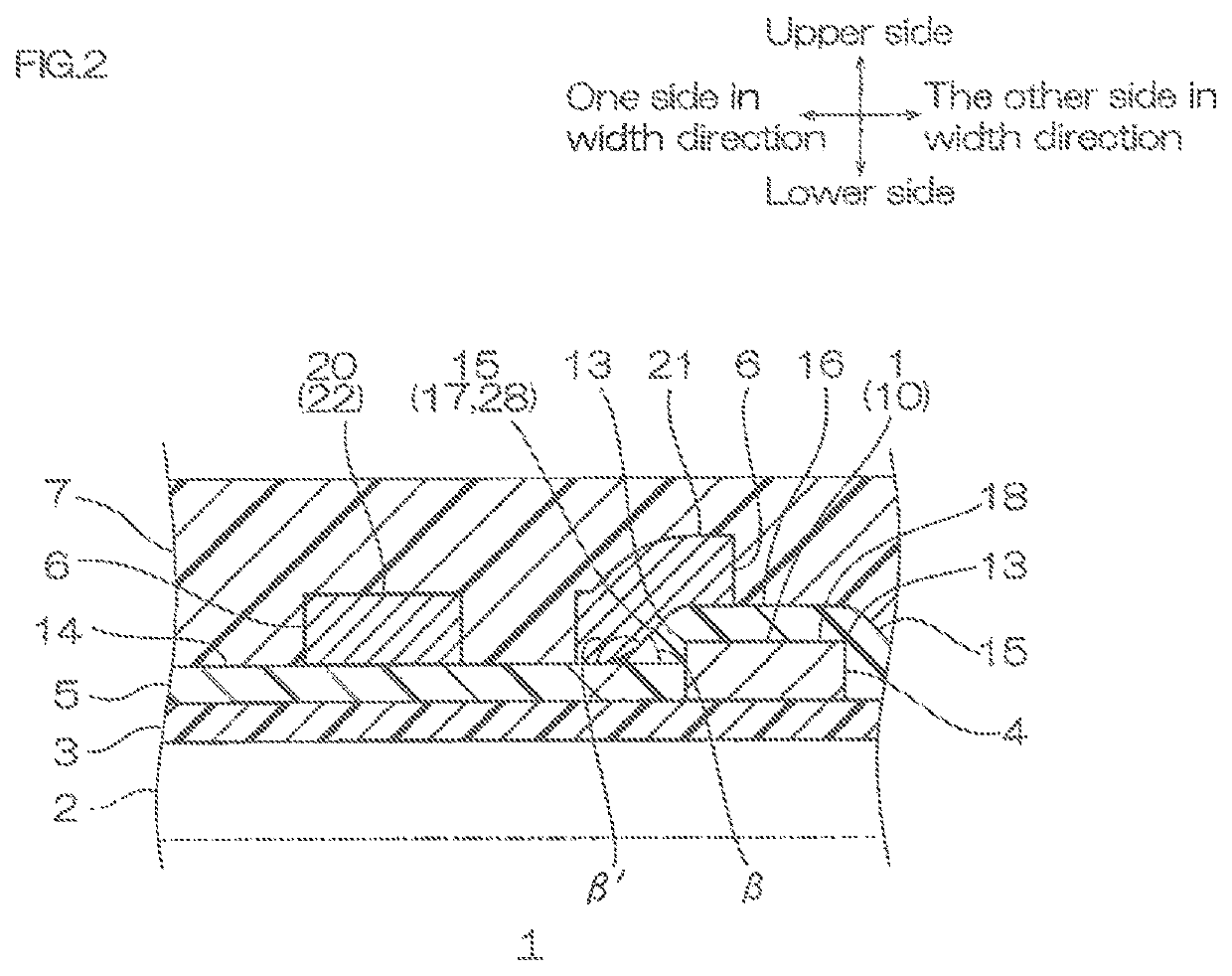

Wired circuit board including a conductive pattern having a wire and a dummy portion

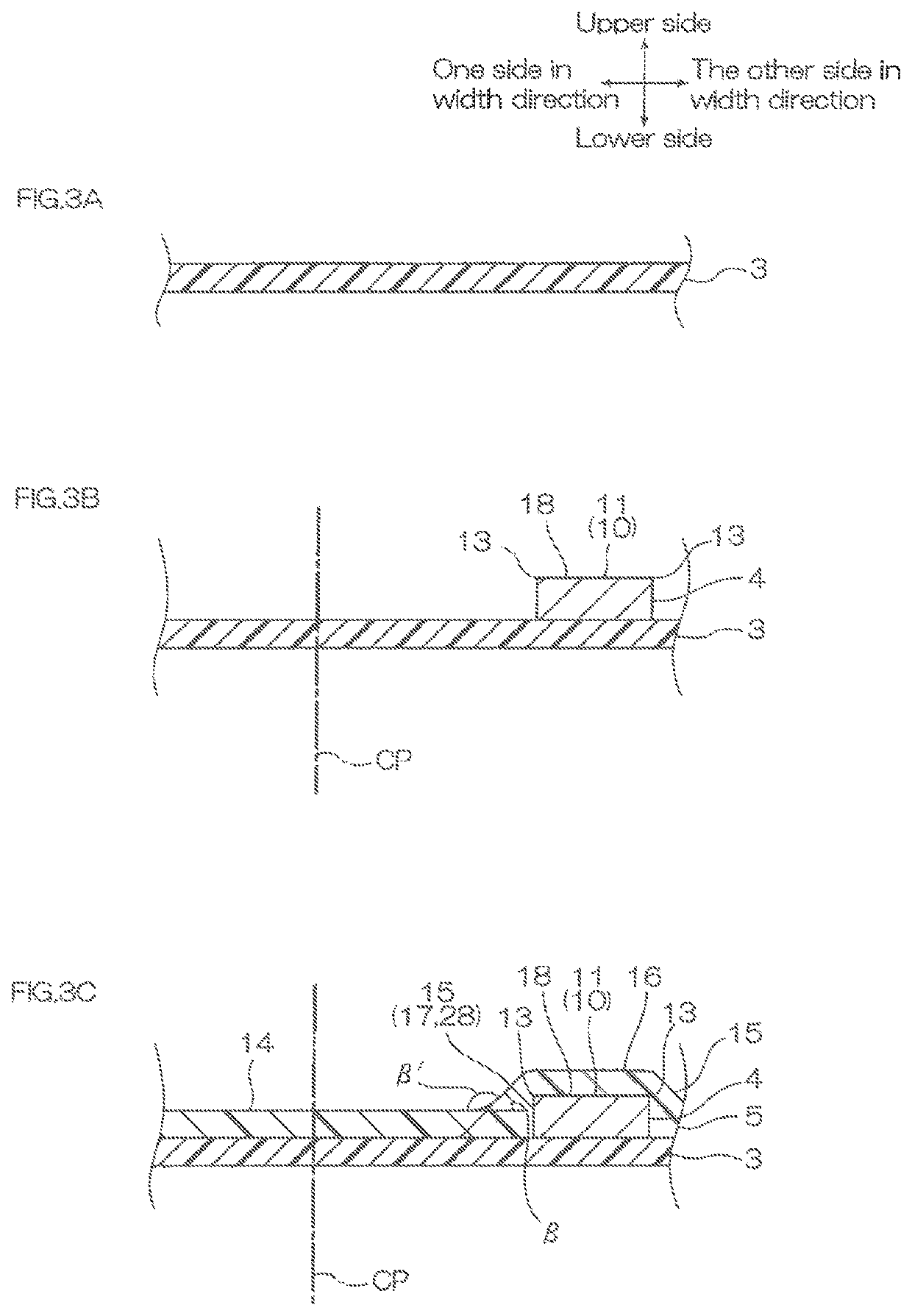

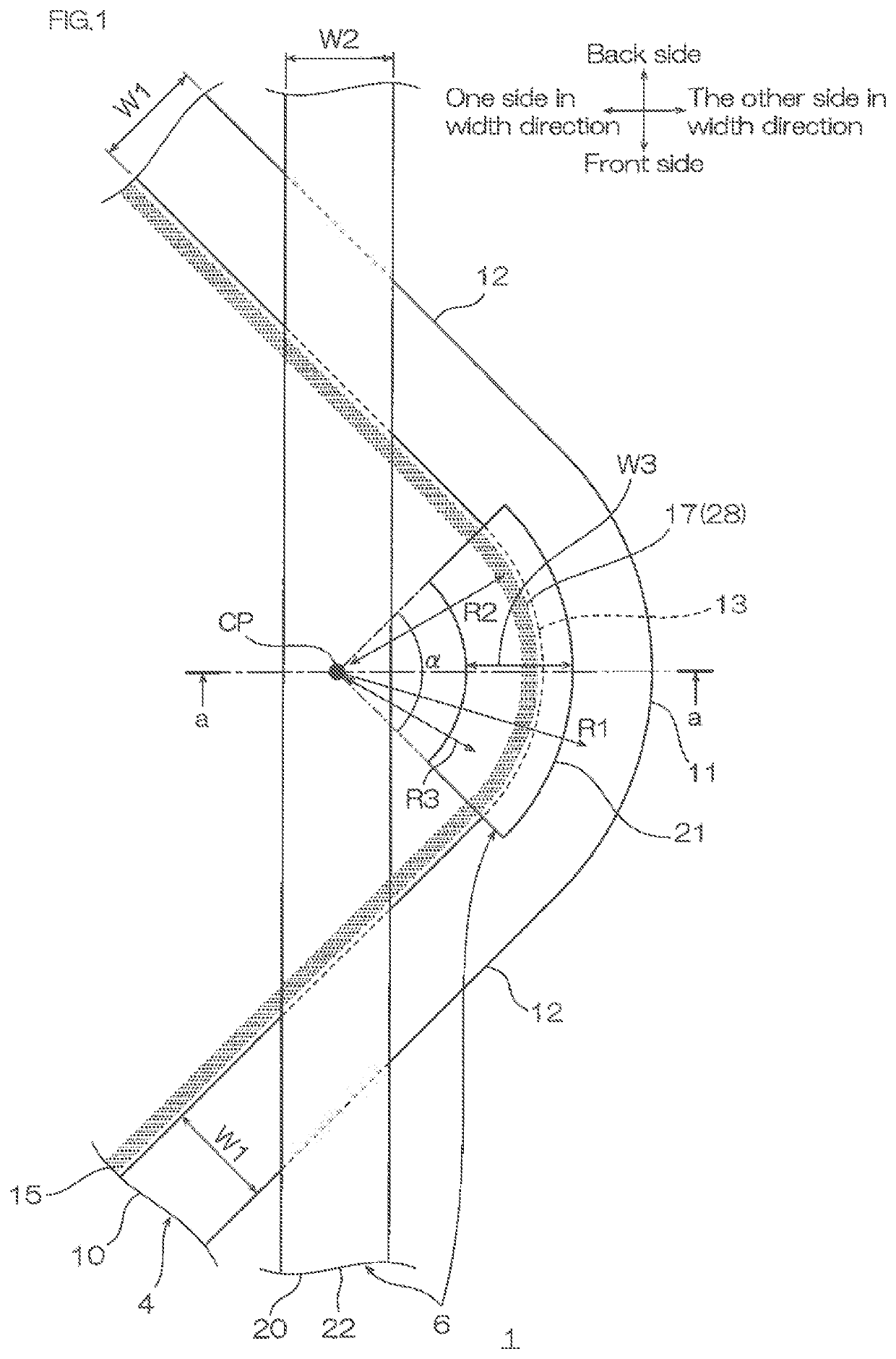

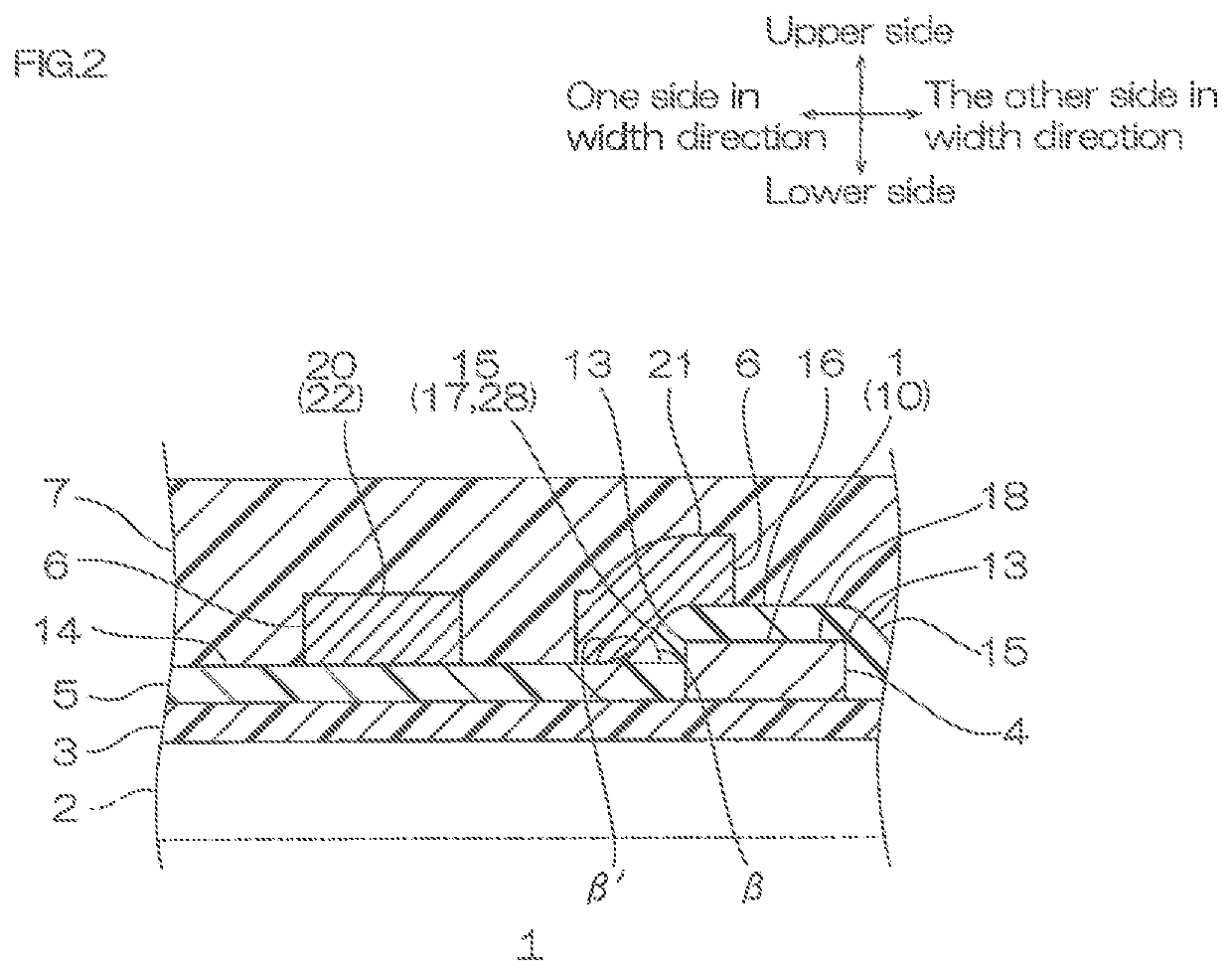

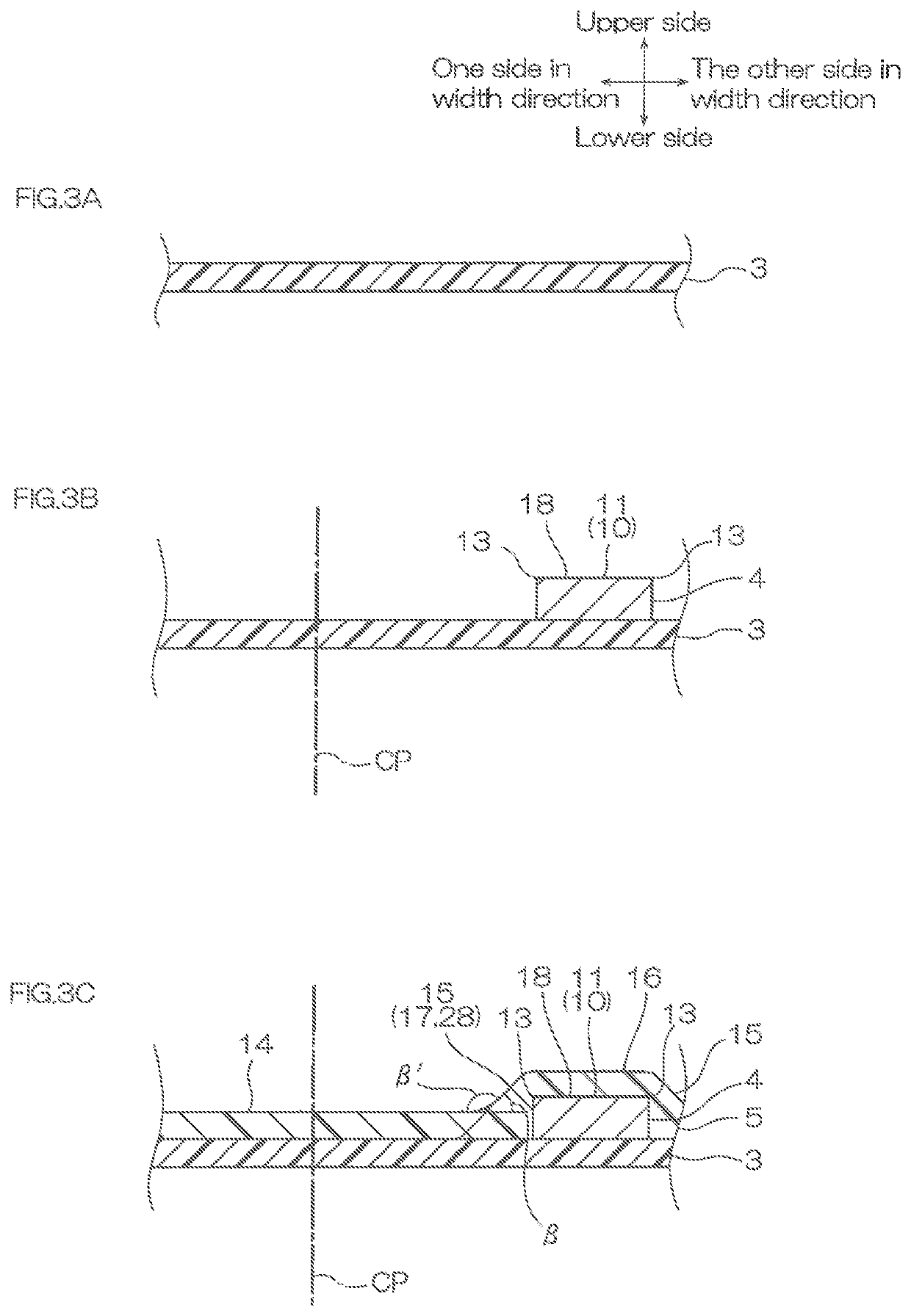

ActiveUS10687427B2Improve reliabilityIncrease freedomCircuit bendability/stretchabilityResist detailsThin membranePhotoresist

Owner:NITTO DENKO CORP

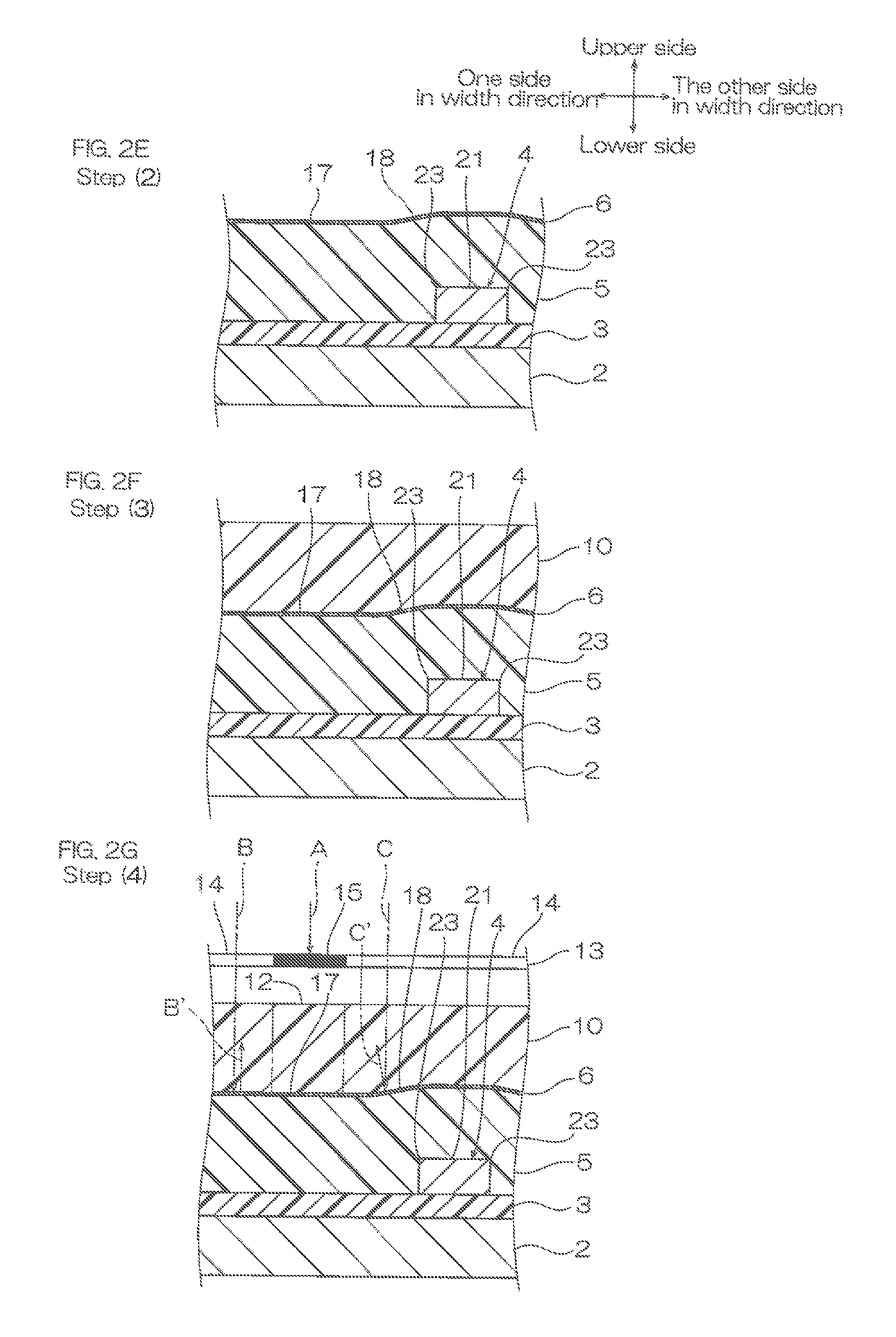

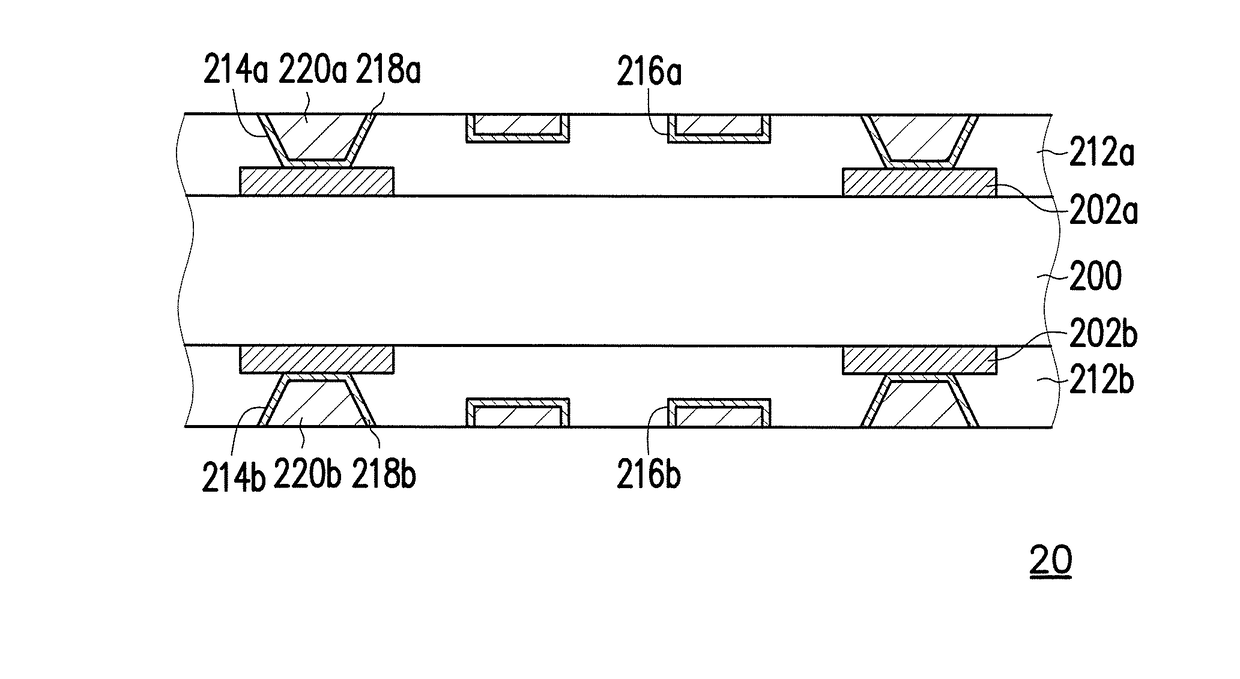

Wired circuit board and producing method thereof

ActiveUS20200260588A1Improve reliabilityIncrease freedomCircuit bendability/stretchabilityResist detailsThin membranePhotoresist

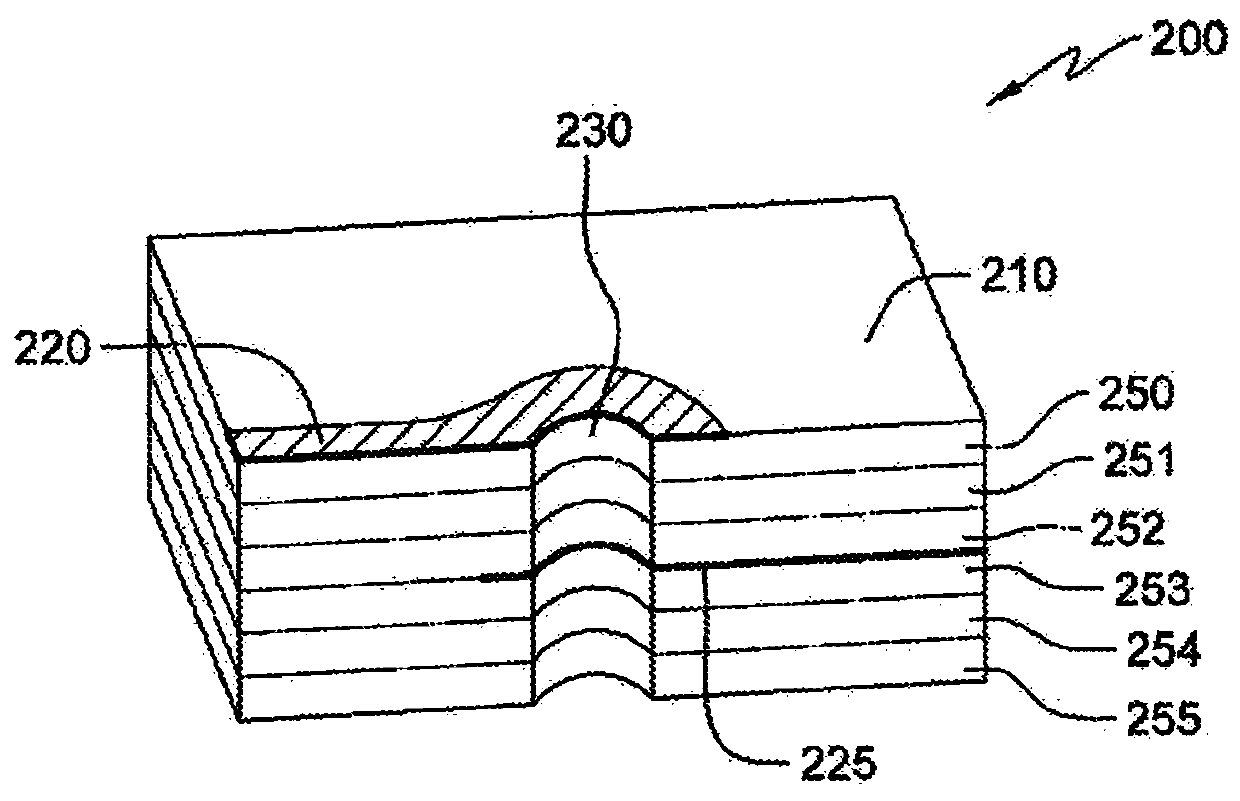

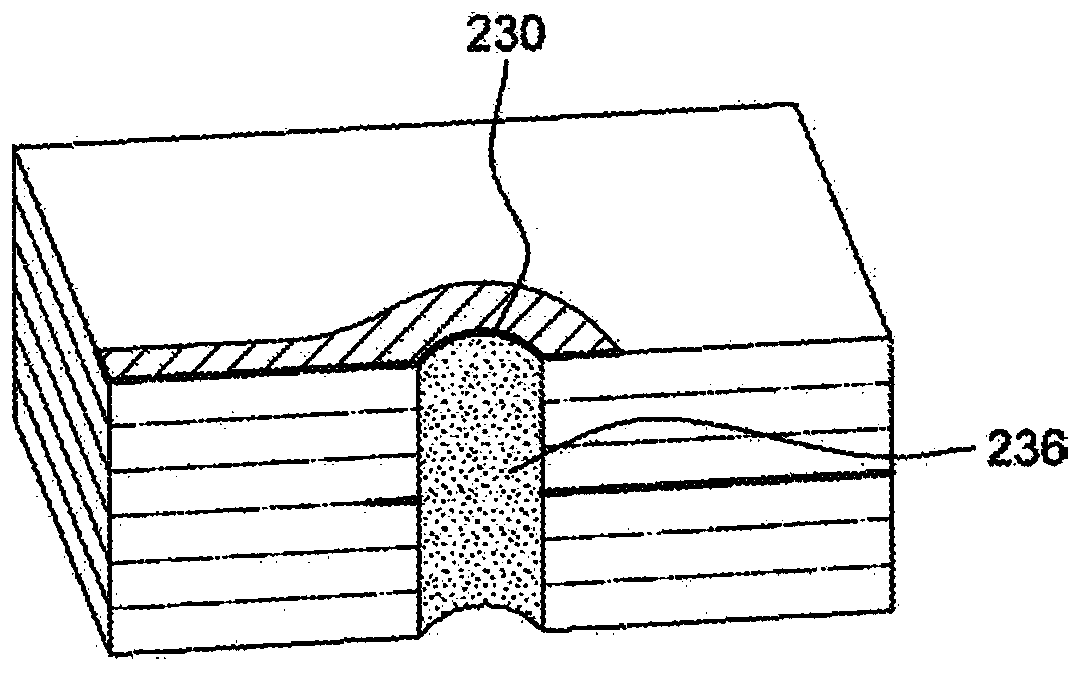

A method for producing a wired circuit board including an insulating layer and a conductive pattern, including (1), providing the insulating layer having an inclination face; (2), providing a metal thin film at least on the surface of the insulating layer; (3), providing a photoresist on the surface of the metal thin film; (4), disposing a photomask so that a first portion, where the conductive pattern is provided in the photoresist, is shielded from light, and the photoresist is exposed to light through the photomask; (5), removing the first portion to expose the metal thin film corresponding to the first portion; and (6), providing the conductive pattern on the surface of the metal thin film exposed from the photoresist. The inclination face has a second portion that allows the light reflected at the metal thin film to reach the first portion.

Owner:NITTO DENKO CORP

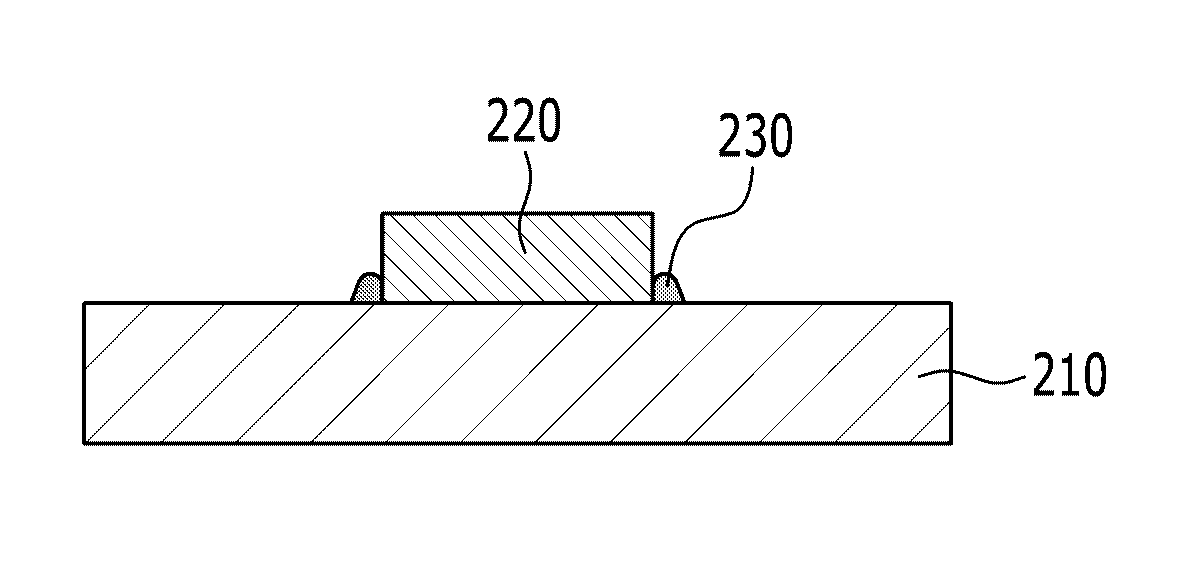

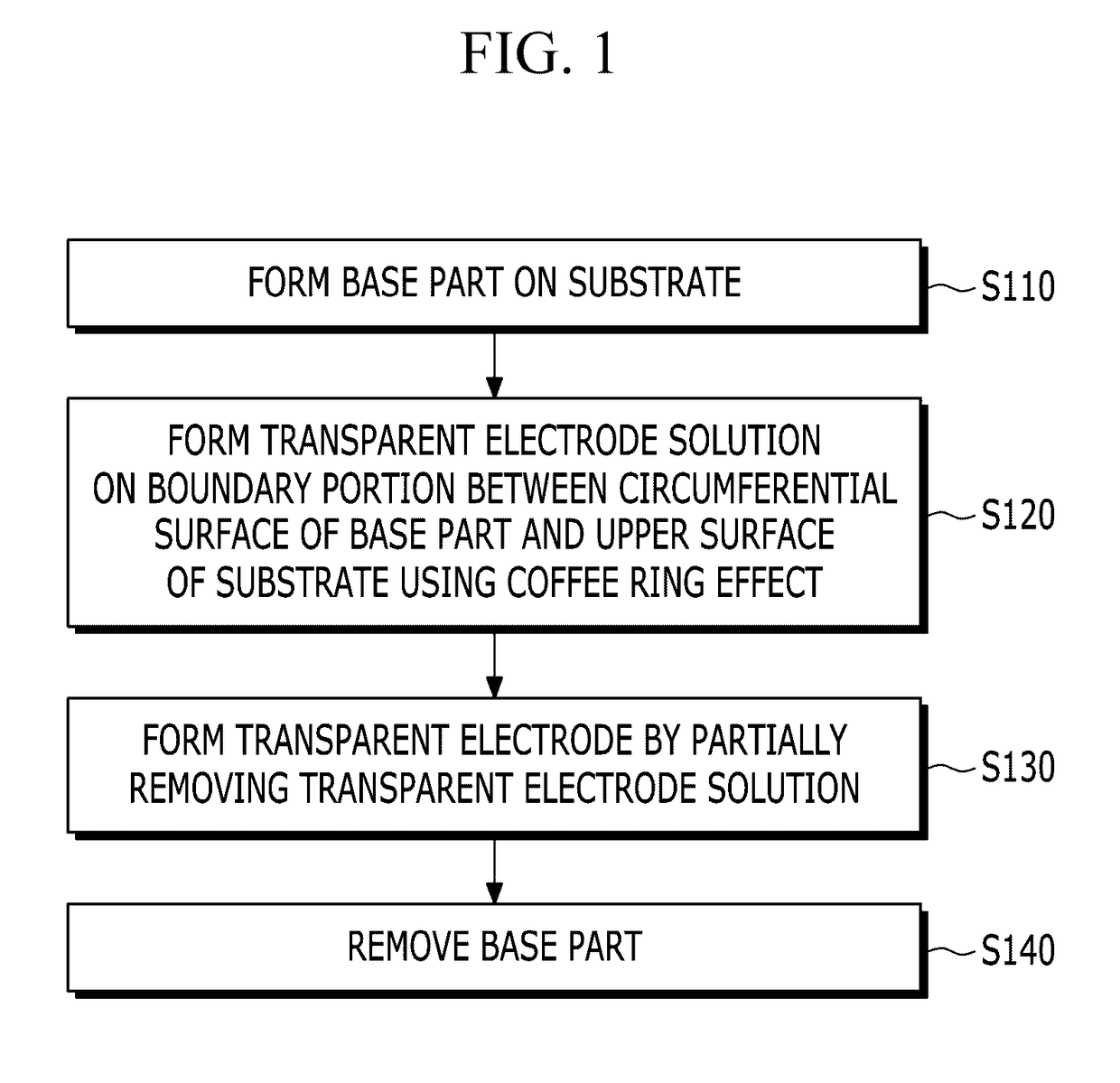

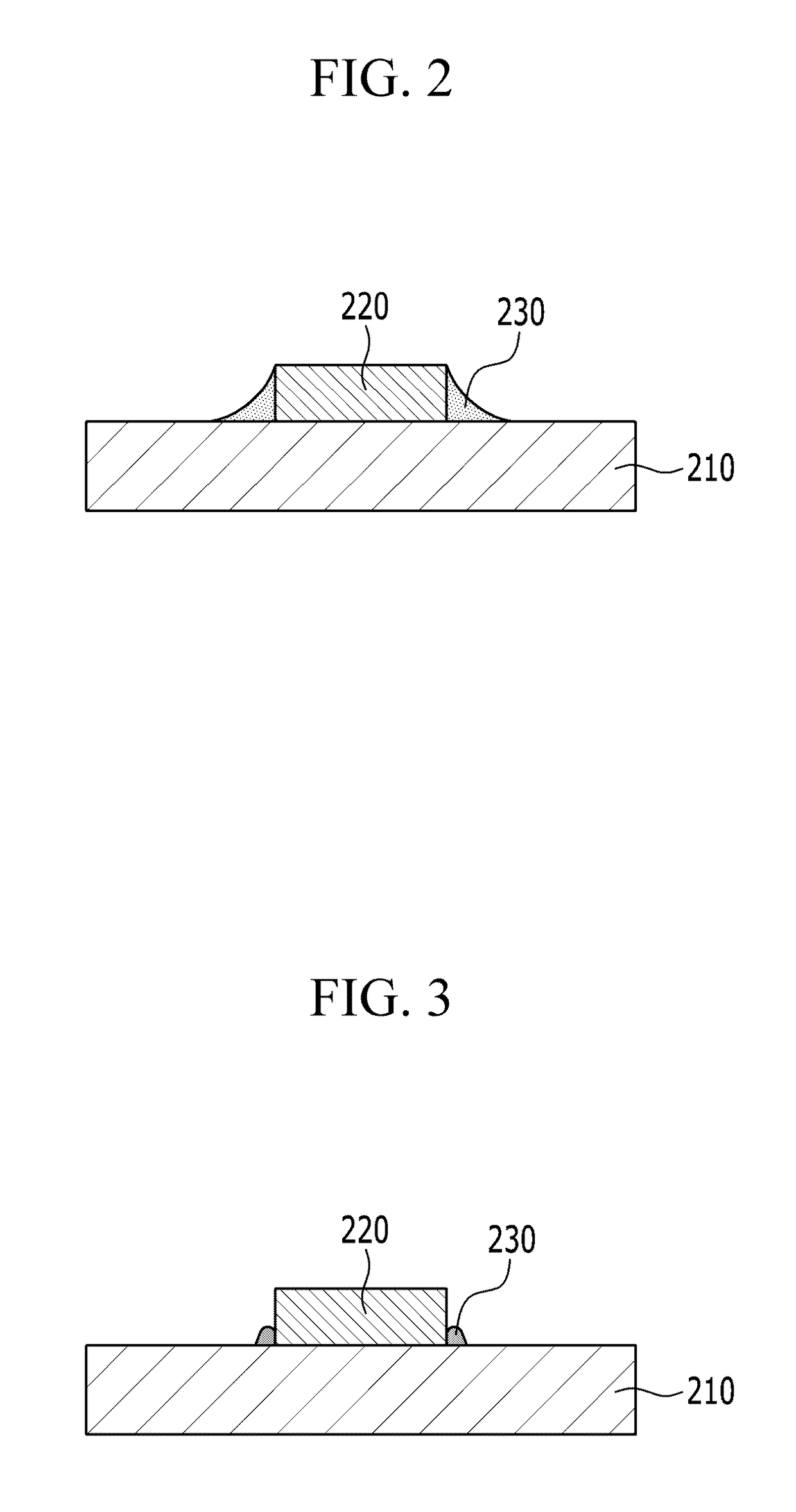

Method of forming fine electrode for flat panel display

InactiveUS9674951B2Simple and cheap processResist detailsPrinted circuit aspectsDisplay deviceFlat panel display

A method of forming a fine electrode, including: forming a base part on a substrate; disposing a transparent electrode solution at a boundary portion between a circumferential surface of the base part and an upper surface of the substrate; forming a transparent electrode by partially removing the transparent electrode solution; and removing the base part from the substrate.

Owner:SAMSUNG DISPLAY CO LTD

Manufacturing method of circuit board

ActiveUS20170273186A1Flexible choiceLess adhesiveLithography/patterningLithographic masksDielectric substrateEngineering

A manufacturing method of a circuit board including the following steps is provided. A carrier substrate is provided. A patterned photoresist layer is formed on the carrier substrate. An adhesive layer is formed on the top surface of the patterned photoresist layer. A dielectric substrate is provided. A circuit pattern and a dielectric layer covering the circuit pattern are formed on the dielectric substrate, wherein the dielectric layer has an opening exposing a portion of the circuit pattern. The adhesive layer is adhered to the dielectric layer in a direction that the adhesive layer faces of the dielectric layer. The carrier substrate is removed. A patterned metal layer is formed on a region exposed by the patterned photoresist layer. The patterned photoresist layer is removed. The adhesive layer is removed.

Owner:UNIMICRON TECH CORP

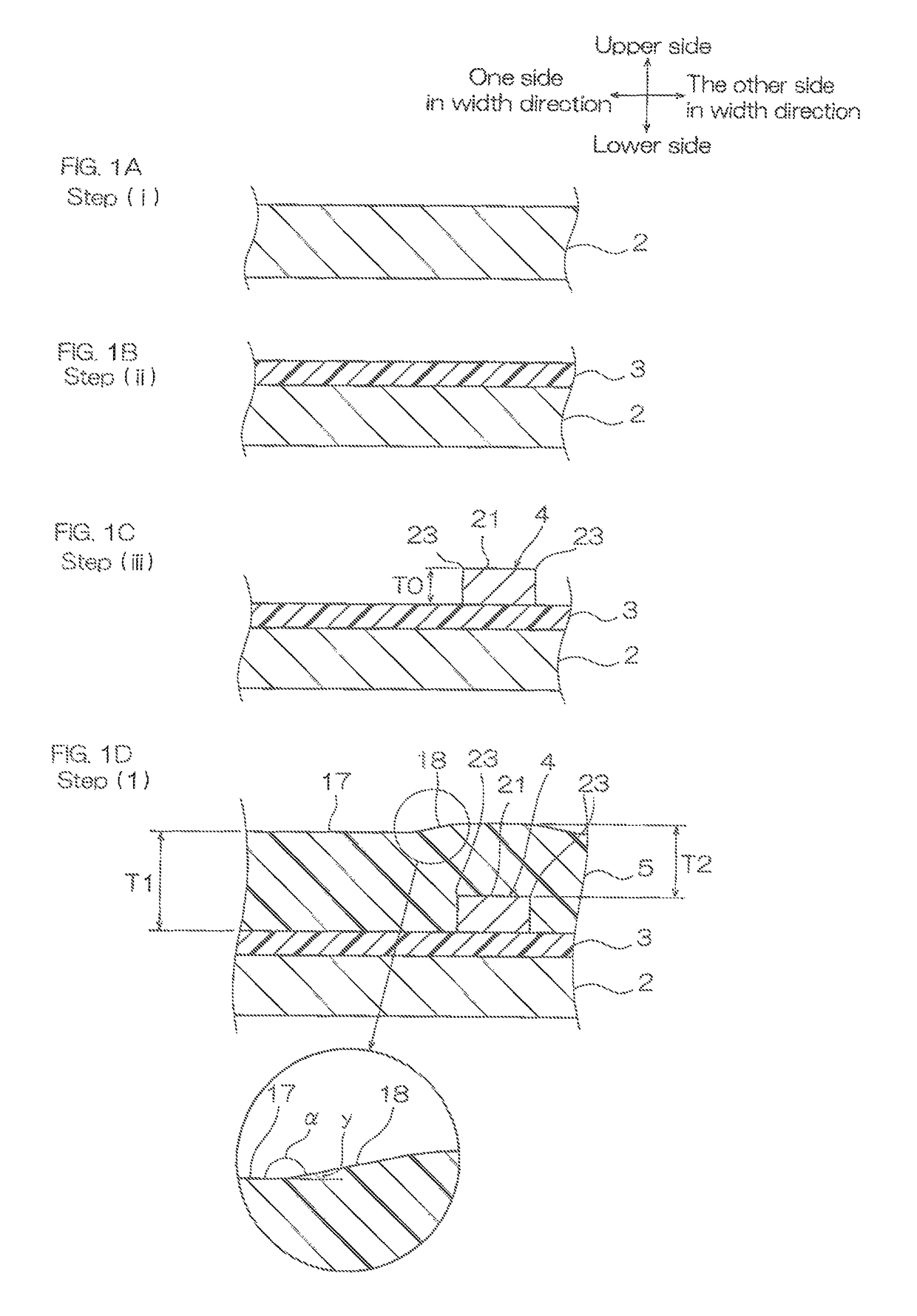

Wired circuit board and producing method thereof

ActiveUS20180014401A1Avoid focusImprove connection reliabilityCircuit bendability/stretchability3D rigid printed circuitsResistEngineering

A method of producing a wired circuit board including an insulating layer and a conductive pattern, including: (1), an insulating layer having an inclination face, (2), a metal thin film provided at least on the inclination face, (3), a photoresist provided on the surface of the metal thin film, (4), a light shield portion of a photomask disposed so that a first portion, where the conductive pattern is to be provided in the photoresist, is shielded from light, and the photoresist is exposed to light through the photomask, (5), the first portion of the photoresist is removed to expose the metal thin film corresponding to the first portion, and (6), the conductive pattern is provided on the surface of the metal thin film exposed from the photoresist.

Owner:NITTO DENKO CORP

Multilayer printed wiring board production method, adhesive layer-equipped metal foil, metal-clad laminate, and multilayer printed wiring board

ActiveUS10893616B2Improve adhesionStructuredResist detailsSemiconductor/solid-state device manufacturingAdhesive cementMetal foil

Disclosed is a production method of a multi-layered printed wiring board, including the following steps 1 to 3:Step 1: a step of laminating, on a substrate with inner layer circuit, a metal foil with adhesive layer including a support, a metal foil having a thickness of 3 μm or less and ⅙ or less relative to the thickness of the inner layer circuit, and an organic adhesive layer having a thickness of 10 μm or less in this order, via an organic insulating resin layer such that the organic insulating resin layer and the organic adhesive layer are opposed to each other, and then releasing the support to form a laminated sheet (a) having the metal foil as an outer layer metal foil layer;Step 2: a step of irradiating the laminated sheet (a) with a laser to bore the outer layer metal foil layer, the organic adhesive layer, and the organic insulating resin layer to form a bored laminated sheet (b) having a blind via hole; andStep 3: a step of forming an outer layer circuit connected with the inner layer circuit through the following steps 3-1 to 3-4:Step 3-1: a step of etching removing the outer layer metal foil layer of the bored laminated sheet (b) formed in the step 2 and then forming an outer layer copper layer having a thickness of 2 μm or less on the bored laminated sheet (b);Step 3-2: a step of forming a resist pattern by a resist applied on the outer layer copper layer;Step 3-3: a step of forming a circuit layer on the surface of the outer layer copper layer on which the resist pattern is not formed, by electrolytic copper plating; andStep 3-4: a step of removing the resist pattern and then removing the exposed outer layer copper layer by etching, thereby forming an outer layer circuit connected with the inner layer circuit.

Owner:RESONAC CORPORATION

Method for producing wired circuit board

ActiveUS10524363B2Short circuitAvoid long lightResist detailsPrinted circuit aspectsPrinted circuit boardMetal thin film

Owner:NITTO DENKO CORP

Manufacturing method of circuit board and piezochromic stamp

ActiveUS20170273189A1Improve circuit reliabilityHigh yieldLithography/patterningResist detailsTransmittanceDielectric substrate

A manufacturing method of a circuit board and a piezochromic stamp are provided. A circuit pattern is formed on a dielectric substrate. A dielectric layer having a hole or a conductive via and covering the circuit pattern is formed on the dielectric substrate. A conductive seed layer is formed on the dielectric layer. A photoresist layer is formed on the conductive seed layer. A piezochromic stamp is imprinted on the photoresist layer, wherein when the pressing side of the piezochromic stamp is in contact with the conductive seed layer, the light transmittance effect thereof is changed to blocking or allowing light having a specific wavelength to pass through. A patterned photoresist layer is formed by using the piezochromic stamp as a mask. A patterned metal layer is formed on the exposed conductive seed layer. The patterned photoresist layer and the conductive seed layer are removed.

Owner:UNIMICRON TECH CORP

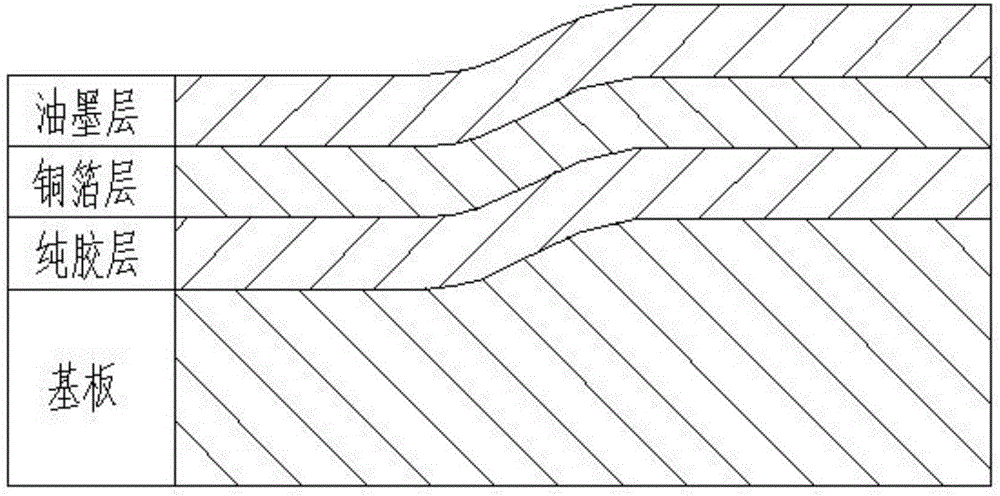

Flexible-rigid combined plate

InactiveCN106455304AAvoid it happening againPrinted circuit detailsResist detailsEngineeringCopper foil

The invention discloses a flexible-rigid combined plate, comprising a base plate, a pure rubber layer, a copper foil layer and an ink layer; the pure rubber layer is disposed on the base plate, the copper foil layer is arranged on the pure rubber layer, and the ink layer is arranged on the copper foil layer. In this way, high and low parts of the flexible-rigid combined plate can be avoided generating bubbles, such that circuit breaking is after etching avoided.

Owner:苏州市华扬电子有限公司

Popular searches

Multilayer circuit manufacture Printed element electric connection formation Photomechanical exposure apparatus Photosensitive material processing Microlithography exposure apparatus Directly printed exposure masks Metal core circuit manufacture Conductive pattern formation Electrical connection printed elements Printed circuit simultaneous processing

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com