Novel de-cap method of rigid-flex board

A new type of technology for flexible and rigid boards, applied in chemical/electrolytic methods to remove conductive materials, multi-layer circuit manufacturing, anti-corrosion parts, etc. Cleaning and other issues, to achieve the effect of protecting product quality, convenient operation, simple process

Inactive Publication Date: 2017-03-22

江苏弘信华印电路科技有限公司

View PDF4 Cites 15 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The disadvantages of the original technology are: printing and peelable adhesive curing - during the lamination pressure transmission process, the product will be deformed with the curing process of the peelable adhesive, and the peelable adhesive is not resistant to high temperature. After the outer layer is made, it needs to be peeled off manually

During the stripping process, there is a phenomenon of dirty stripping, which will affect the post-manufacturing process

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0024] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

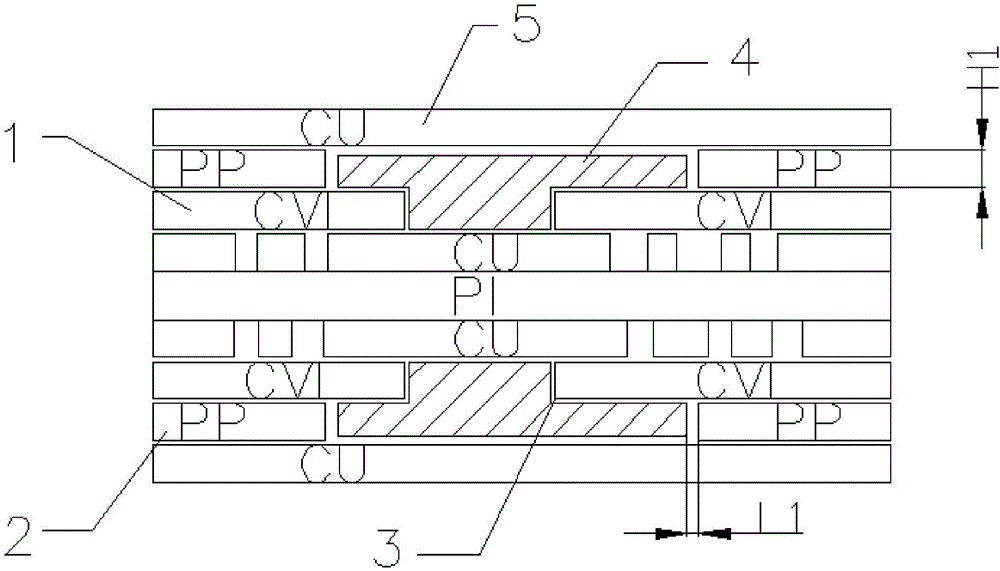

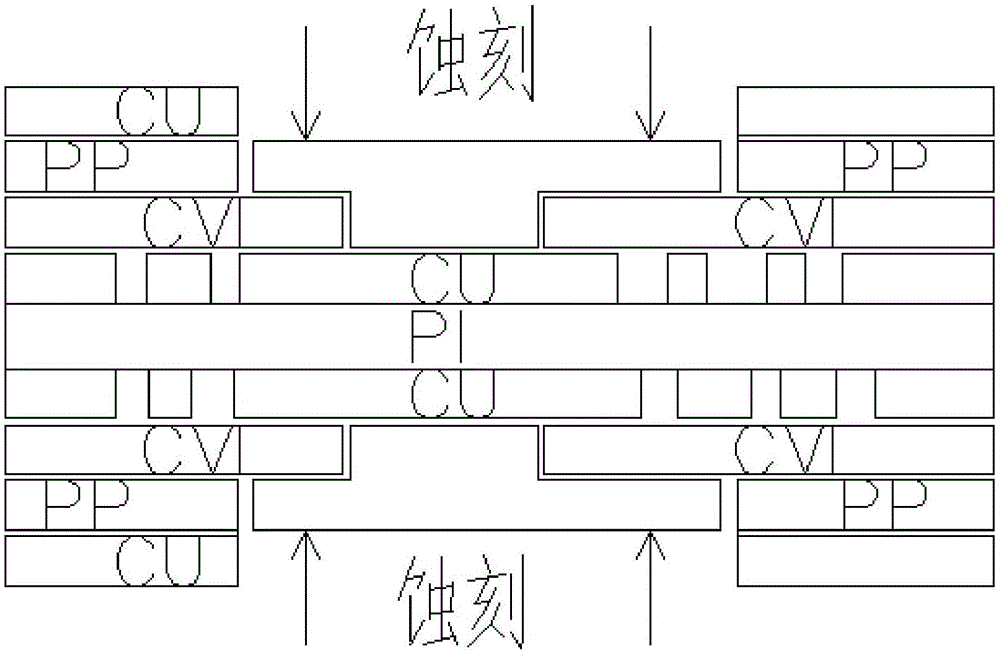

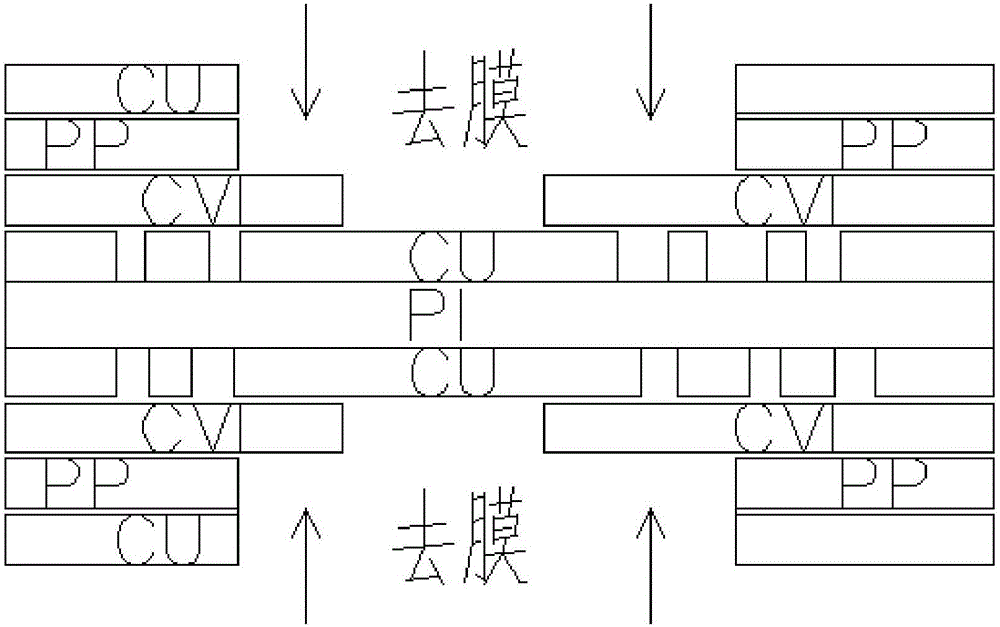

The invention relates to a novel de-cap method of a rigid-flex board. The method includes the following steps that: (1) after the inner layer covering film of the rigid-flex board is bonded, and the inner layer covering film is covered with a layer of PP prepregs, a layer of cleanable printing ink is printed through screen printing at interdigital windows or grounding points , and a cleanable printing ink protection film is formed; (2) a copper-clad film is laminated and pressed, the copper-clad film is pressed for 3 hours under 180 DEC C; (3) drilling, electroplating, dry film attachment, exposure and development are carried out after pressing and molding; (4) etching processing is carried out by means of an acid etching solution after the development; and (5) an alkaline solution is adopted to carry out film removal after etching is completed, and the cleanable printing ink protection film is dissolved. The novel de-cap method of the invention has the advantages of simple process, convenient operation and cost-saving performance.

Description

technical field [0001] The invention relates to a method of uncovering, in particular to a method for uncovering a novel rigid-flex board. Background technique [0002] Now the types of soft-rigid combination boards are showing a trend of diversity. There are more and more types of openings for plugging or grounding at the inner layer of flexible boards of soft-rigid combination boards. Technology has also become a hot topic. [0003] The original technical process is: cutting of the inner soft board - drilling - pretreatment - dry film - exposure - development - etching circuit - cover film - printing peelable glue (a liquid ink, which acts as a protection after curing) or strip Paste high temperature resistant tape - pressure transmission of the outer laminated board. [0004] The disadvantages of the original technology are: printing and peelable adhesive curing - during the lamination pressure transmission process, the product will be deformed with the curing process o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H05K3/46H05K3/06

CPCH05K3/4691H05K3/06H05K2203/0562

Inventor 王俊涛

Owner 江苏弘信华印电路科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com