Micro-strip circuit board etching method and improved device

A technology of microstrip circuits and circuit boards, which is applied in printed circuits, removal of conductive materials by chemical/electrolytic methods, and printed circuit manufacturing. Support frame, guaranteed etching effect, easy to move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

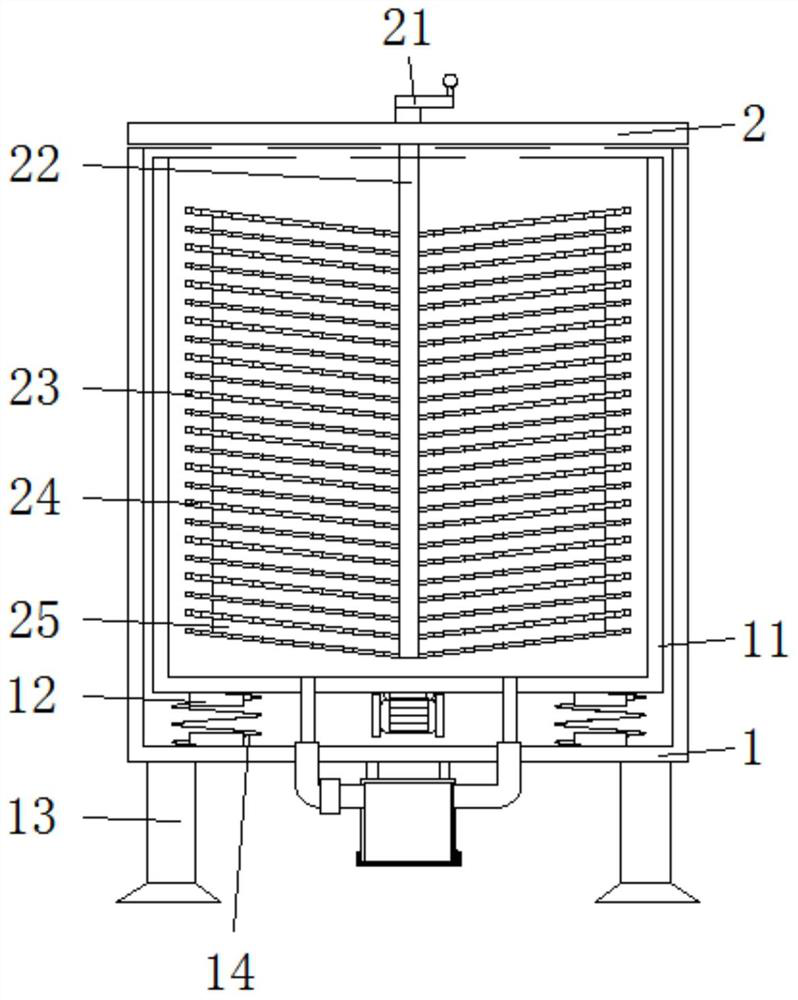

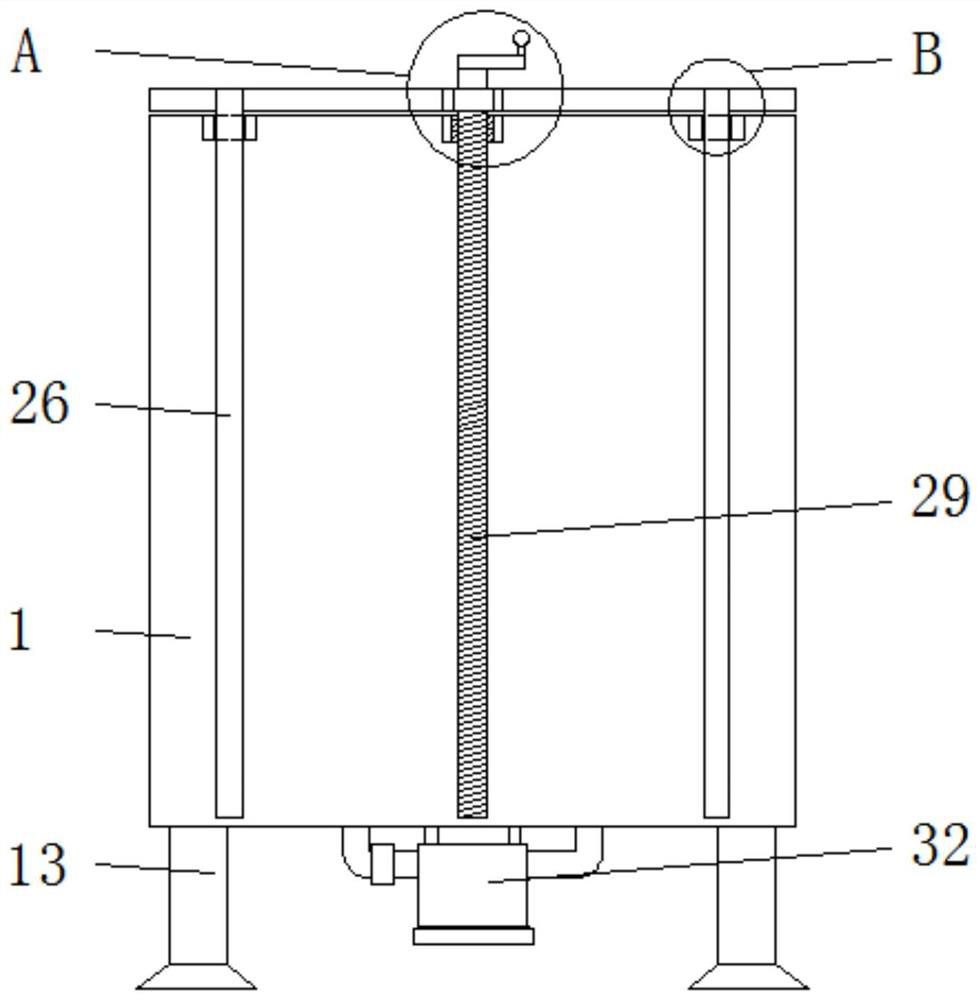

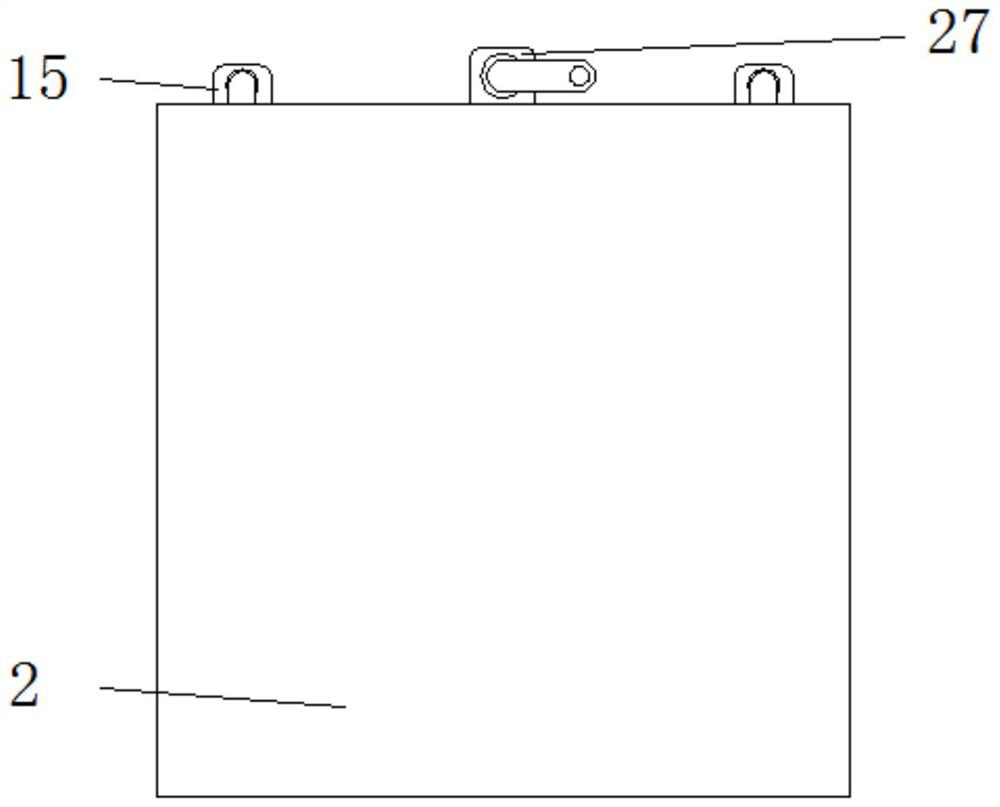

[0041] Embodiment 1: A microstrip circuit board etching method and improved device, including a housing 1, a cover plate 2, a connecting pipe 3, a through hole 16 and a screw hole 18, a water storage tank 11 is arranged inside the housing 1, and the outer wall of the lower end of the water storage tank 11 is on one side A vibrating motor 111 is installed, the lower end of the inner wall of the water storage bin 11 is respectively plugged with a first rubber hose 19 and a second rubber hose 110, the outer wall side of the upper end of the shell 1 is provided with a cover plate 2, and the outer wall side of the lower end of the water storage bin 11 is installed with a vibration Motor 111, the outer wall of the lower end of the housing 1 is plugged with a connecting pipe 3, the outer wall at both ends of the connecting pipe 3 runs through the outer wall of the housing 1 and is respectively connected with the first rubber hose 19 and the second rubber hose 110, and the upper end of ...

Embodiment 2

[0048] Embodiment 2: A microstrip circuit board etching method and improved device, including a housing 1, a cover plate 2, a connecting pipe 3, a through hole 16 and a screw hole 18, a water storage bin 11 is arranged inside the housing 1, and the outer wall of the lower end of the water storage bin 11 is on one side A vibrating motor 111 is installed, the lower end of the inner wall of the water storage bin 11 is respectively plugged with a first rubber hose 19 and a second rubber hose 110, the outer wall side of the upper end of the shell 1 is provided with a cover plate 2, and the outer wall side of the lower end of the water storage bin 11 is installed with a vibration Motor 111, the outer wall of the lower end of the housing 1 is plugged with a connecting pipe 3, the outer wall at both ends of the connecting pipe 3 runs through the outer wall of the housing 1 and is respectively connected with the first rubber hose 19 and the second rubber hose 110, and the upper end of th...

Embodiment 3

[0052] Embodiment 3: A microstrip circuit board etching method and improved device, including a housing 1, a cover plate 2, a connecting pipe 3, a through hole 16 and a screw hole 18, a water storage tank 11 is arranged inside the housing 1, and the outer wall of the lower end of the water storage tank 11 is on one side A vibrating motor 111 is installed, the lower end of the inner wall of the water storage bin 11 is respectively plugged with a first rubber hose 19 and a second rubber hose 110, the outer wall side of the upper end of the shell 1 is provided with a cover plate 2, and the outer wall side of the lower end of the water storage bin 11 is installed with a vibration Motor 111, the outer wall of the lower end of the housing 1 is plugged with a connecting pipe 3, the outer wall at both ends of the connecting pipe 3 runs through the housing 1 and is connected with the first rubber hose 19 and the second rubber hose 110 respectively, and the outer wall of the connecting pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com