A kind of processing method of 3D glass panel without flash point

A glass panel and processing method technology, applied in the field of glass surface treatment, can solve the problems of poor uniformity, poor anti-glare effect, disadvantages, etc., and achieve uniform etching, good roughness and atomization value, and good surface roughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

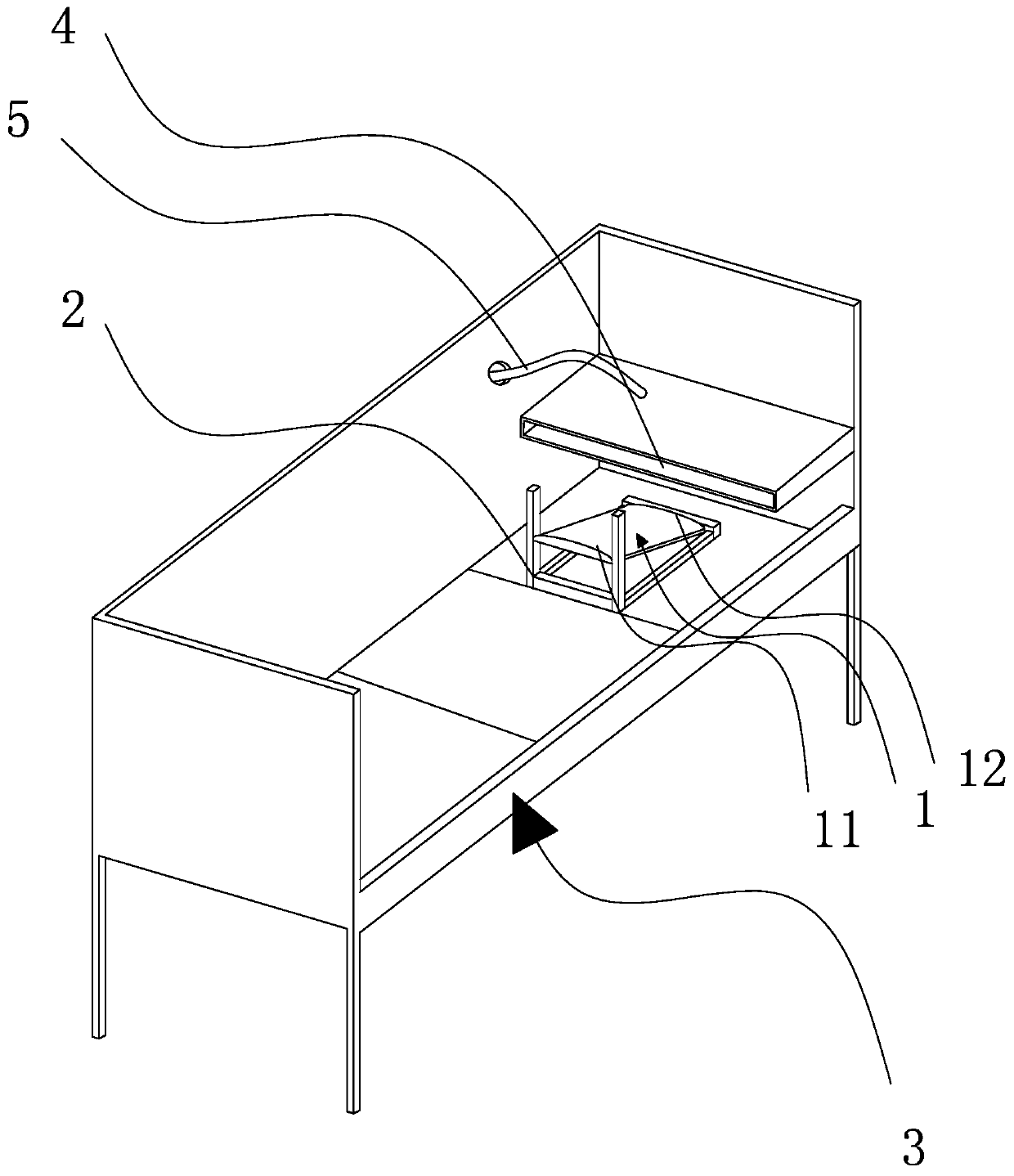

[0026] According to the actual size requirements, select the 3D glass panel 1 of the corresponding size, and then clean the 3D glass panel 1 to be processed, specifically with deionized water, remove the impurities on the surface, and then dry it;

[0027] Then the cleaned 3D glass panel 1 is fixed on the fixture 2, and the curved surface of the 3D glass panel 1 faces outward, that is, the surface that needs to be etched is exposed to the outside, and the surface that does not need to be etched is exposed to the outside. The fixtures 2 can be fitted together or covered with a covering. Among them, ordinary fixtures 2 can be used, as long as the 3D glass panel 1 can be fixed, and at the same time, the fixture 2 can be fixed on the horizontal surface of the workbench 3 On the other hand, of course, the fixed position of the fixture 2 can be adjusted according to the size and size of the 3D glass panel 1, so that when spraying, the spray liquid can be sprayed downwards onto the up...

Embodiment 2

[0033] According to the actual size requirements, select the 3D glass panel 1 of the corresponding size, and then clean the 3D glass panel 1 to be processed, specifically with deionized water, remove the impurities on the surface, and then dry it;

[0034] Then the cleaned 3D glass panel 1 is fixed on the fixture 2, and the curved surface of the 3D glass panel 1 faces outward, that is, the surface that needs to be etched is exposed to the outside, and the surface that does not need to be etched is exposed to the outside. The fixtures 2 can be fitted together or covered with a covering. Among them, ordinary fixtures 2 can be used, as long as the 3D glass panel 1 can be fixed, and at the same time, the fixture 2 can be fixed on the horizontal surface of the workbench 3 On the (fixed surface), of course, the fixed position of the clamp 2 can be adjusted according to the size and size of the 3D glass panel 1, so that when spraying, the spray liquid can be sprayed downward on the up...

Embodiment 3

[0040] According to the actual size requirements, select the 3D glass panel 1 of the corresponding size, and then clean the 3D glass panel 1 to be processed, specifically with deionized water, remove the impurities on the surface, and then dry it;

[0041] Then fix the cleaned 3D glass panel 1 on the fixture, and make the curved surface of the 3D glass panel 1 outward, that is, expose the surface that needs to be etched, and the surface that does not need to be etched and the fixture 2 can be bonded together or covered with a cover. Among them, ordinary fixtures 2 can be used. It only needs to be able to fix the 3D glass panel 1. At the same time, the fixture 2 can be fixed on the horizontal surface of the workbench 3. Of course, the fixed position of the fixture 2 can be adjusted according to the size and size of the 3D glass panel 1, so that when spraying, the spray liquid can be sprayed downwards onto the upper end surface 11 of the 3D glass panel 1, preferably to make the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com