Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Precision manufacturing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

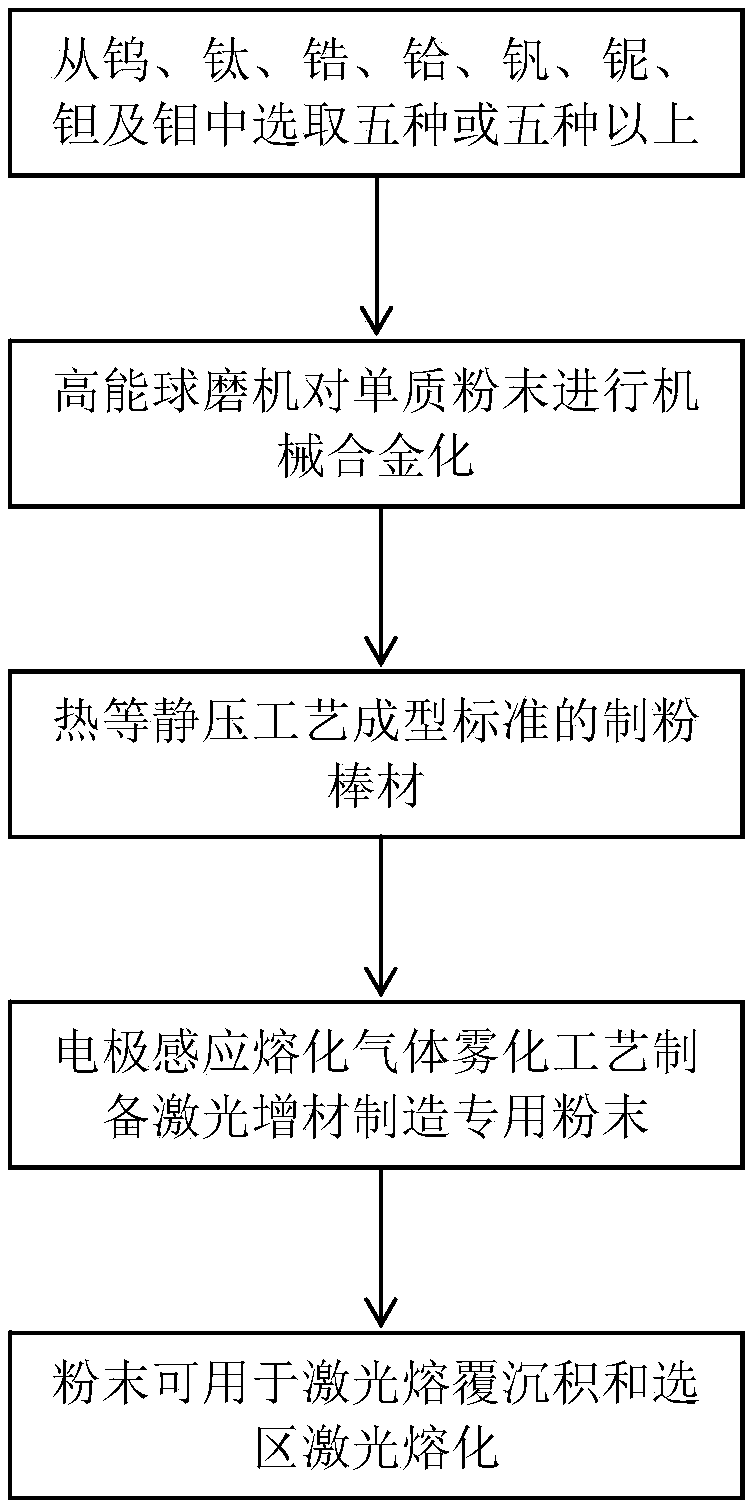

Preparation method of high-melting-point and high-entropy alloy spherical powder based on laser additive manufacturing

ActiveCN107096923AFast preparationPrecision manufacturingAdditive manufacturing apparatusTransportation and packagingHigh energyWear resistant

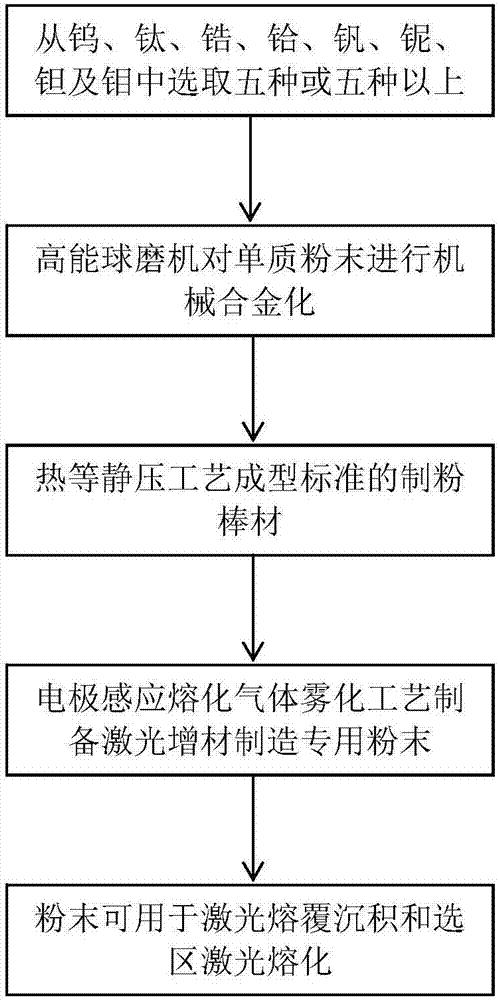

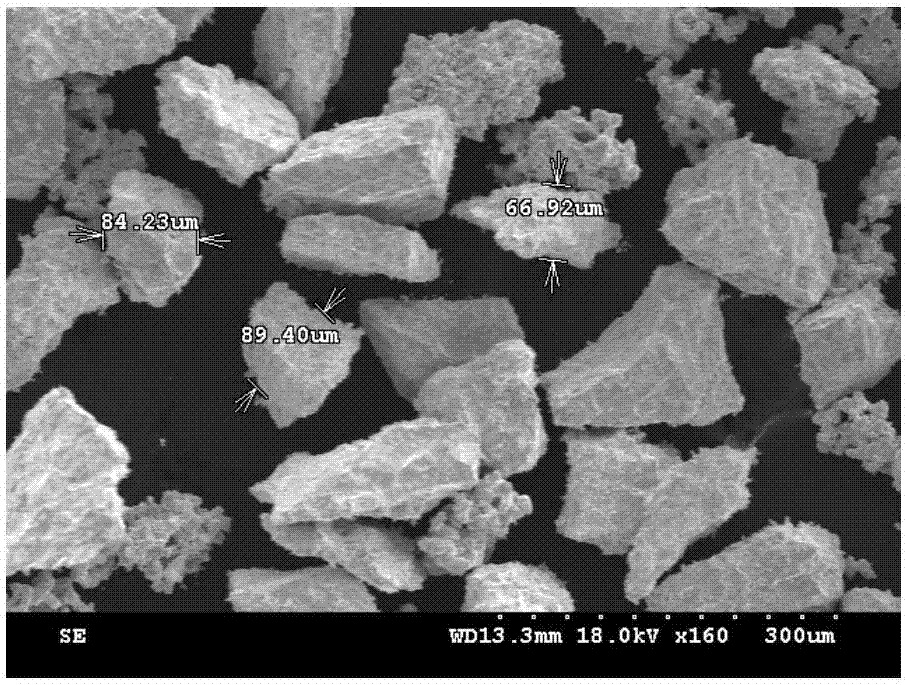

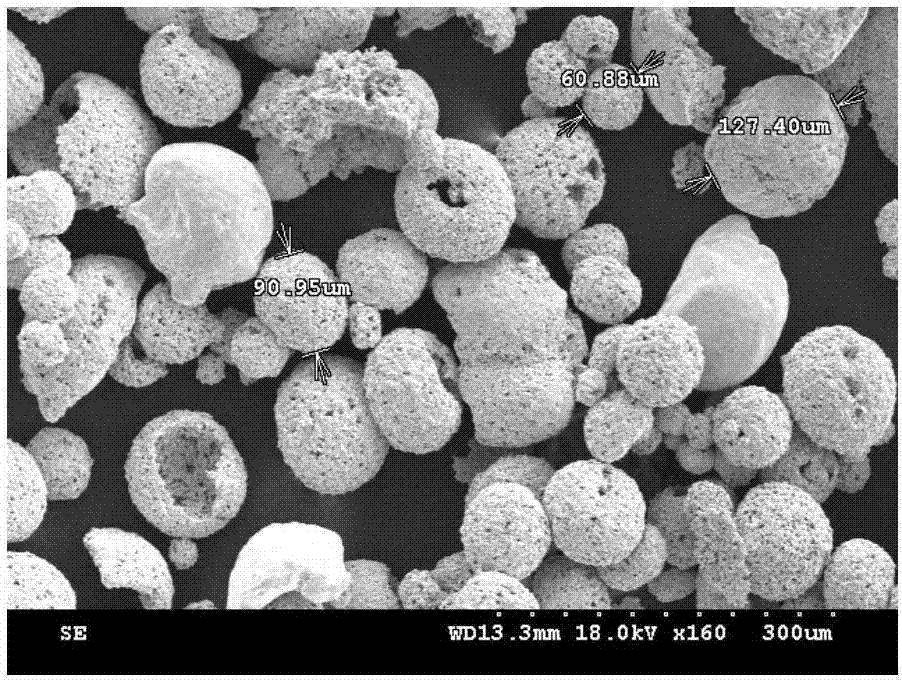

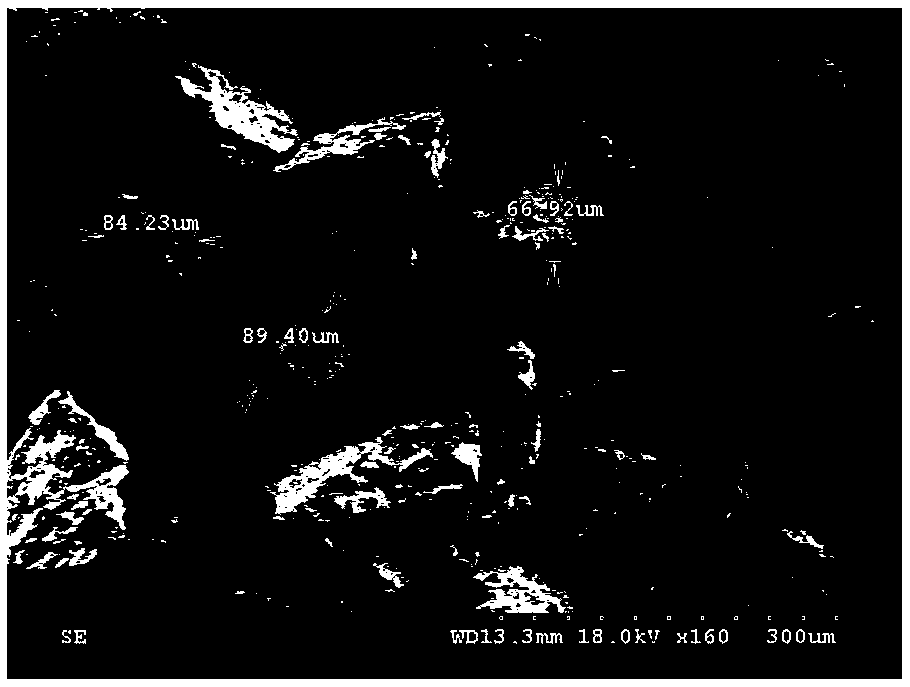

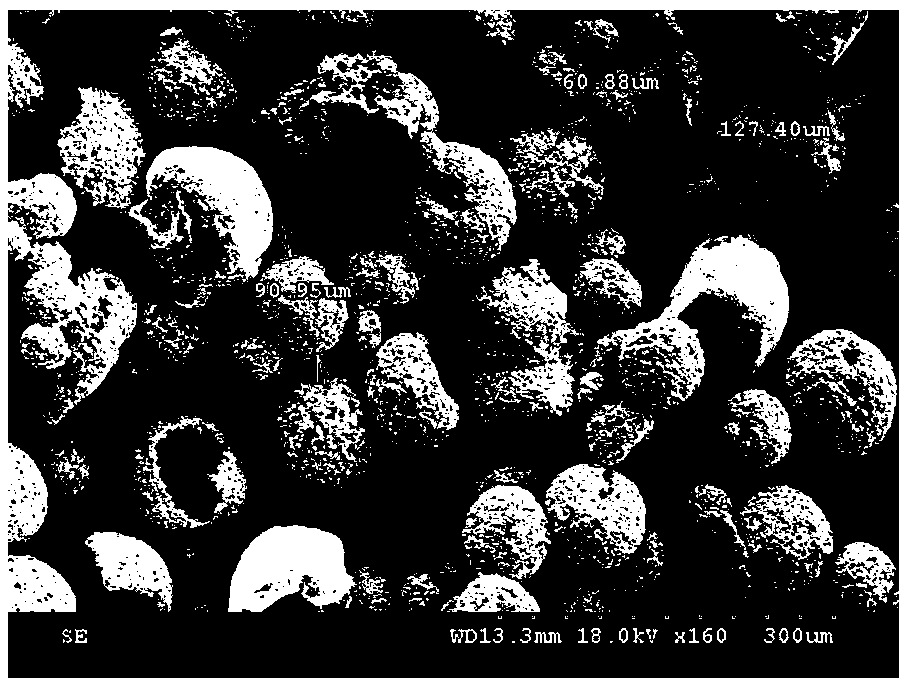

The invention discloses a preparation method of high-melting-point and high-entropy alloy spherical powder based on laser additive manufacturing. The preparation method comprises the steps: randomly selecting powder of five or more from high-melting-point metallic elements including tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum, and mixing the powder according to a certain ratio; then, carrying out mechanical alloying by using a high-energy ball mill to obtain single-phase solid solution powder of a high-melting-point and high-entropy alloy; preparing a powder bar material by adopting the forming standard of a hot isostatic pressing process; and finally, preparing laser directly-formed powder by using an electrode induction melting gas atomization process. By using the single-phase solid solution powder of the high-melting-point and high-entropy alloy, formed by using the preparation method, a series of problems of different burnout rates of different elements due to relatively high difference as well as component microscopic segregation and negative eutectic and the like caused by various elements in the laser additive manufacturing and forming processes of the powder of the high-melting-point metallic elements can be solved, and the rapid and precise manufacture of high-temperature-resistant and wear-resistant parts special for the aerospace and hot end parts of high-performance turbine engines can be more effectively realized.

Owner:XI AN JIAOTONG UNIV

Rapid manufacturing method for laser remelting scanning carbide dispersion strengthened aluminum alloy

ActiveCN105112708APrecision manufacturingShorten the manufacturing cycleAdditive manufacturing apparatusIncreasing energy efficiencyThree dimensional modelMuffle furnace

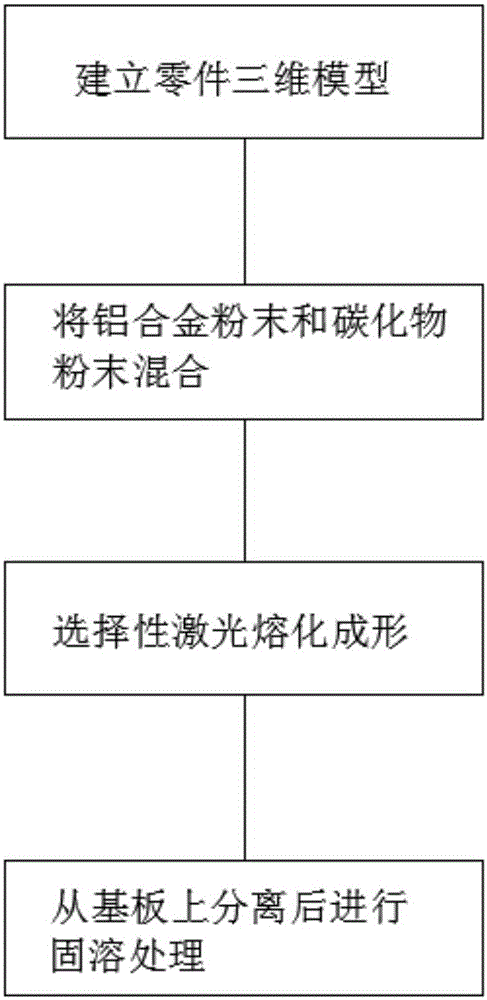

The invention discloses a rapid manufacturing method for laser remelting scanning carbide dispersion strengthened aluminum alloy. The method includes the following steps that (1) a three-dimensional part model is established on a computer, and then the three-dimensional part model is converted to be in an STL format and imported into selective area laser melting forming equipment; (2) aluminum alloy powder and carbide powder are mixed, and then are ball-milled through a ball grinder to be evenly mixed; (3) the ball-milled mixed powder is transferred into the selective area laser melting forming equipment, and the mixed powder is formed according to three-dimensional model data under the protection of inert gases; and (4) a formed part is separated from a substrate by the adoption of the wire-electrode cutting technology, and then is subjected to solution treatment in a muffle furnace, afterwards, quenching is carried out, ceramic bead sand blasting treatment is conducted, and accordingly a finished product is obtained. By the adoption of the method, dispersion strengthening phases can be evenly distributed, and therefore the purposes of obtaining the ceramic phase dispersion strengthened aluminum alloy and improving the high-temperature performance of the aluminum alloy are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

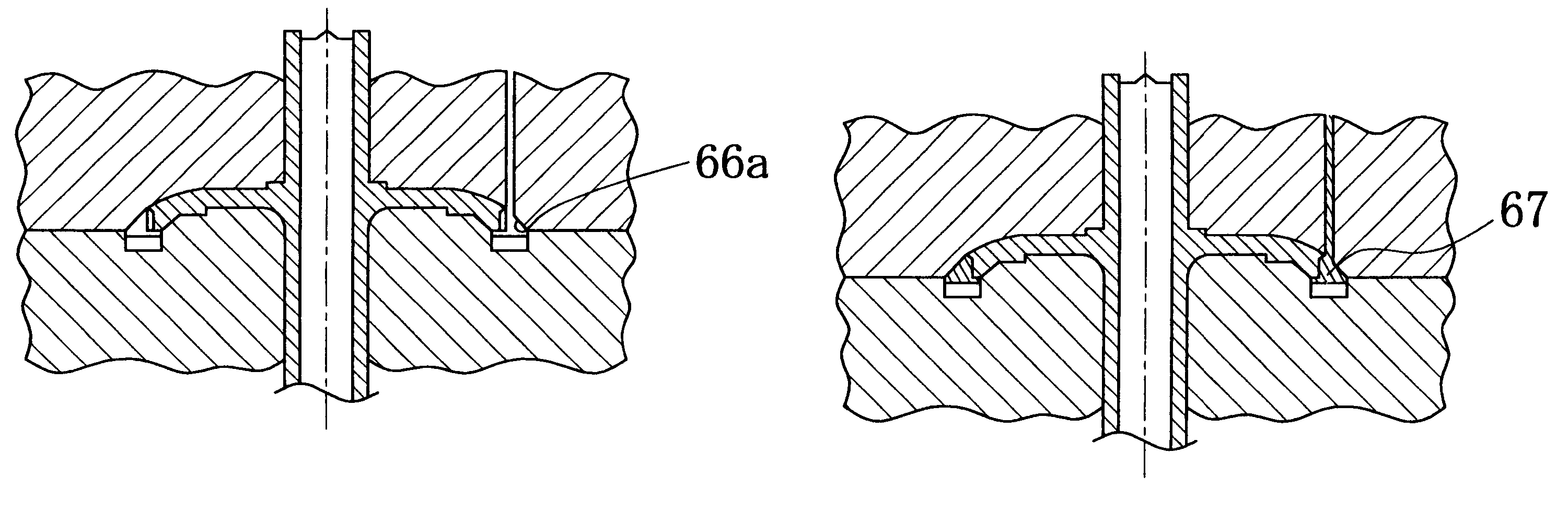

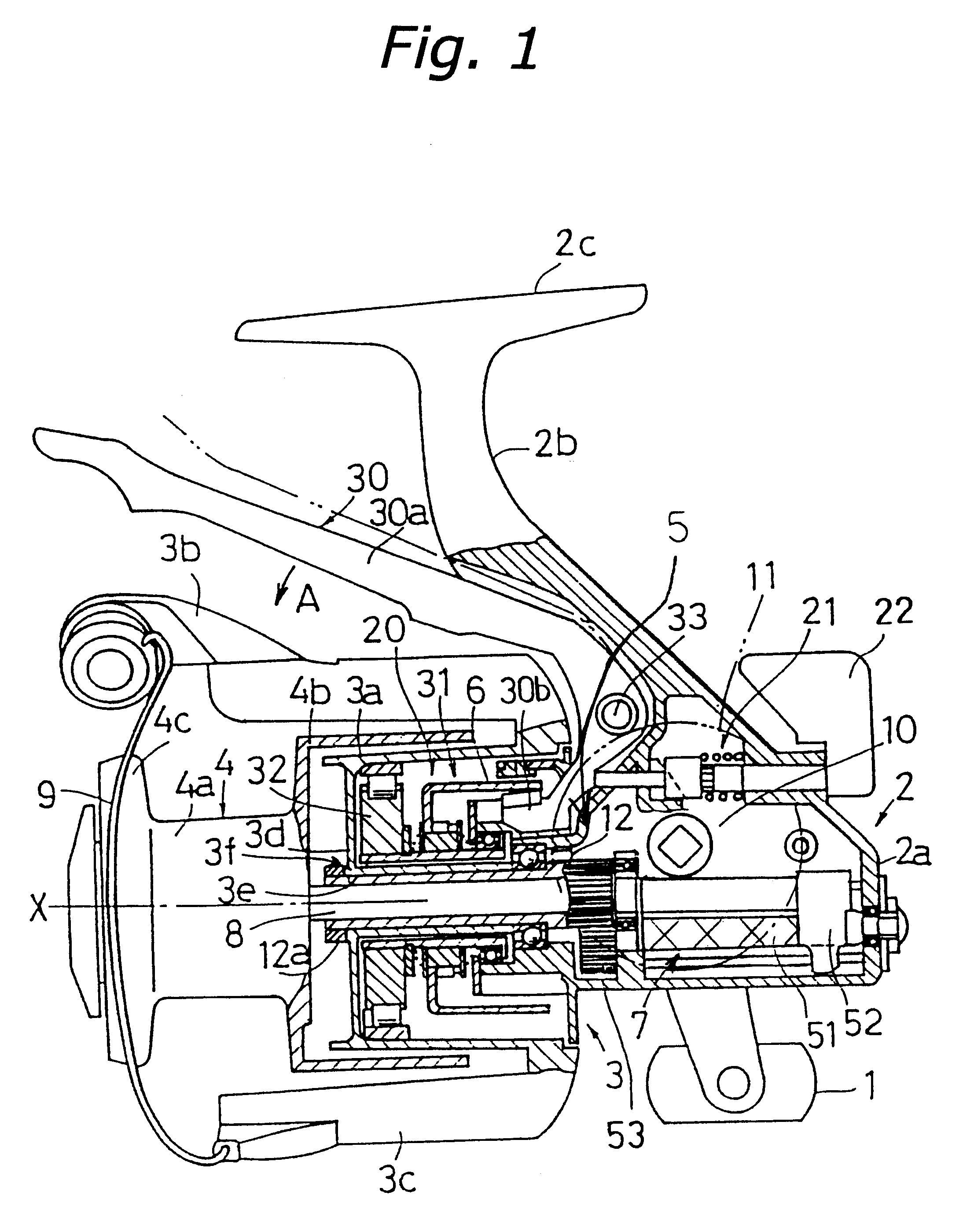

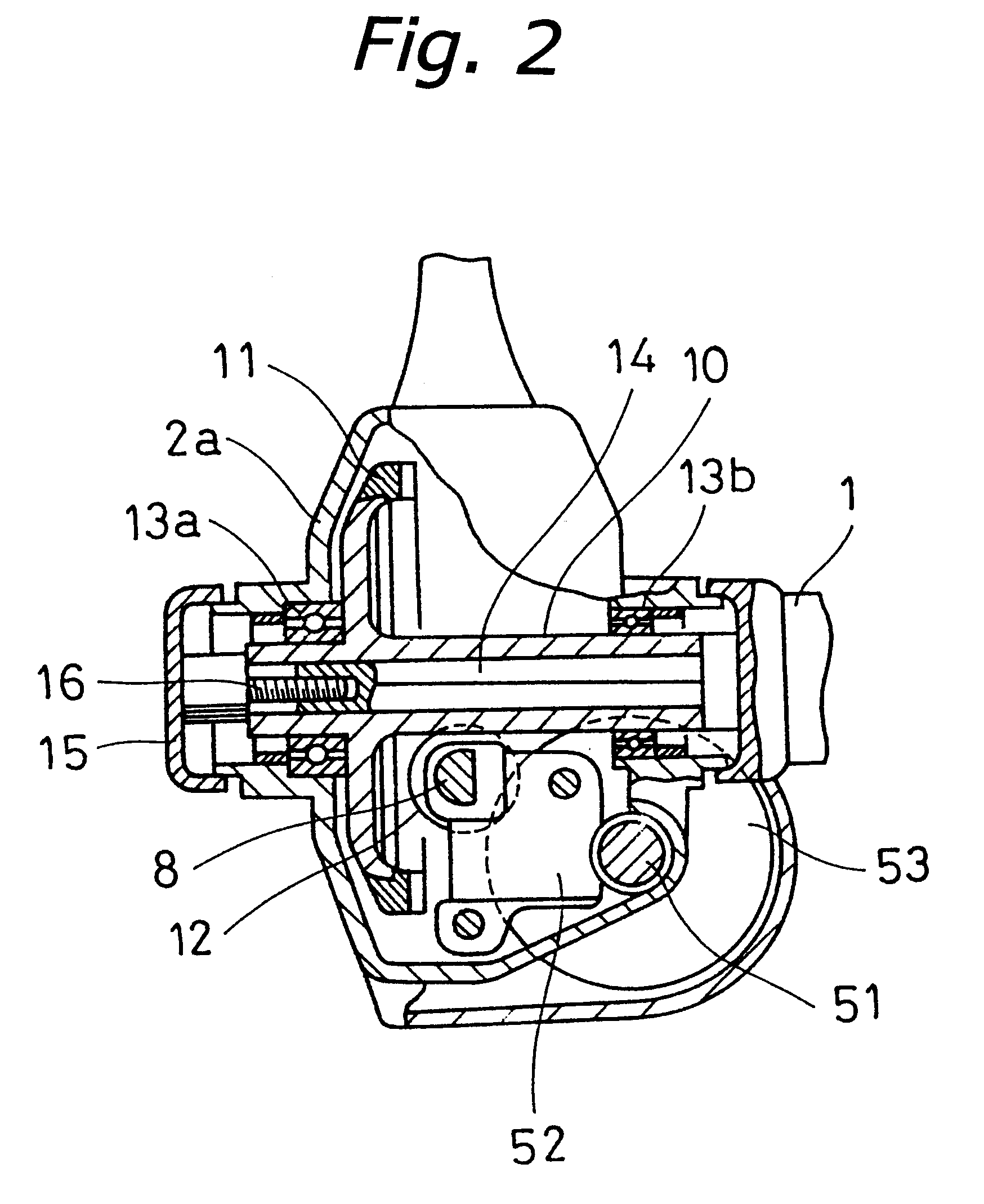

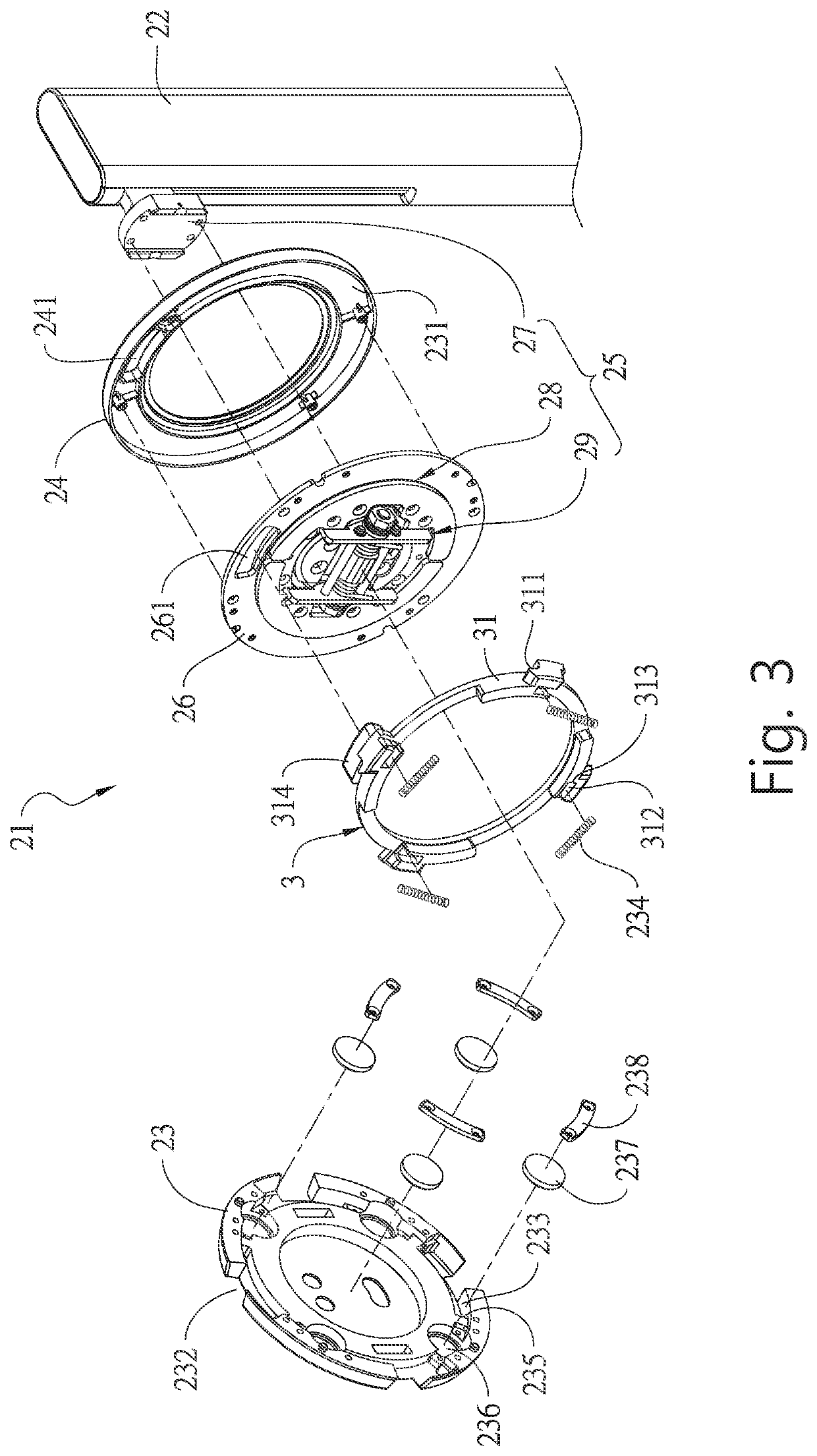

Spinning reel face gear manufacturing method

InactiveUS6343418B1Improve corrosion resistancePrecision manufacturingMetal-working apparatusPortable liftingHigh intensityEngineering

A spinning reel face gear is manufactured by a method of molding tooth-ring bearing, obverse-facing gear teeth onto a separately formed gear disk after the gear disk is made. The gear disk is specially configured with circumferentially spaced peripheral indentations to retain the tooth ring strongly against torque when the face gear meshes with a pinion gear in operation in a spinning reel. Manufacturing the face gear in two separate stages adds a degree of freedom in material selection, allowing a lightweight material to be employed for the gear disk, and a high-strength material for forming precision gear teeth to be employed for the tooth ring. The two-stage manufacturing method also enables the tooth ring to be formed onto the gear disk in a mold that does not leave a parting line on the obverse, teeth-bearing face of the tooth-ring when the mold plates are parted.

Owner:SHIMANO INC

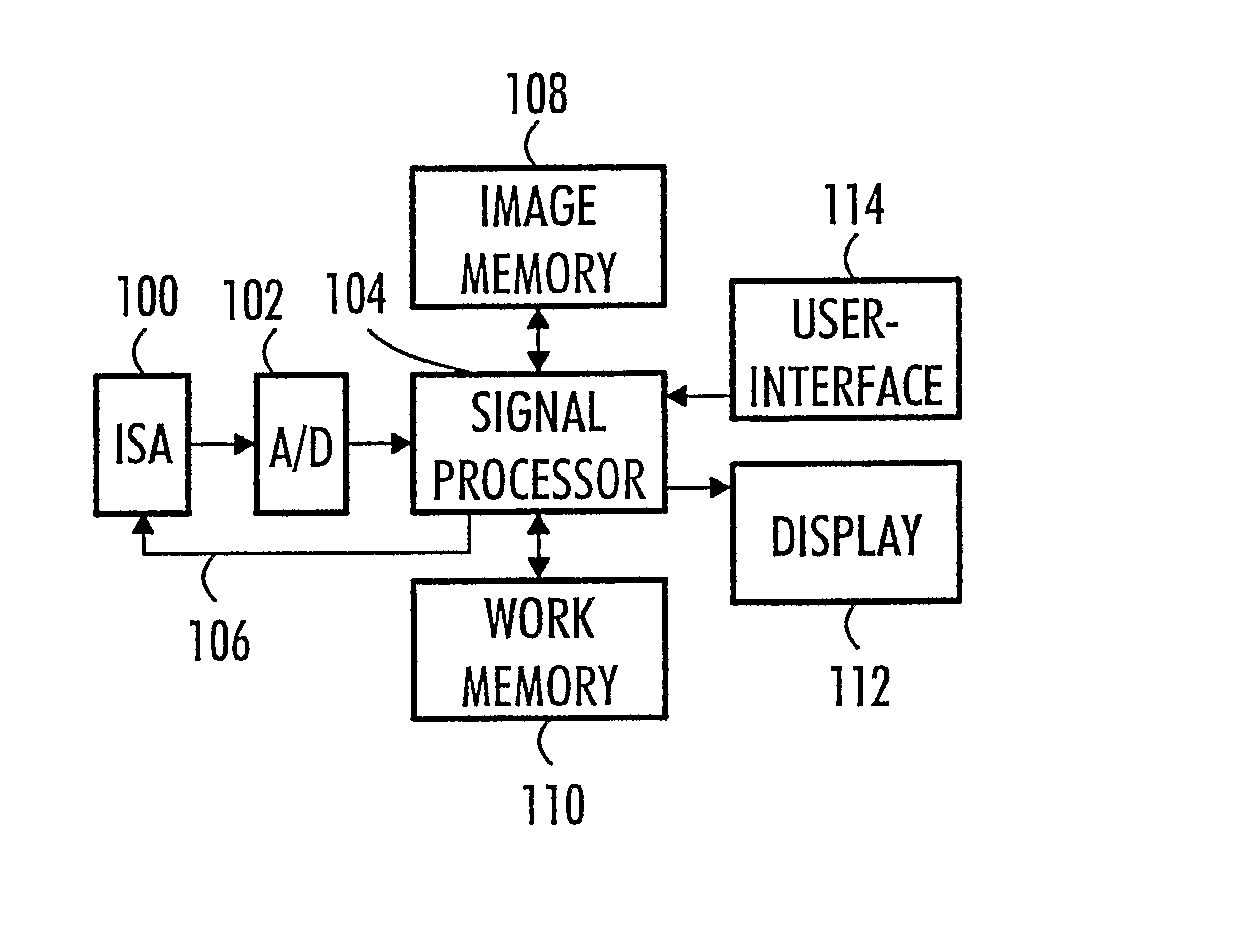

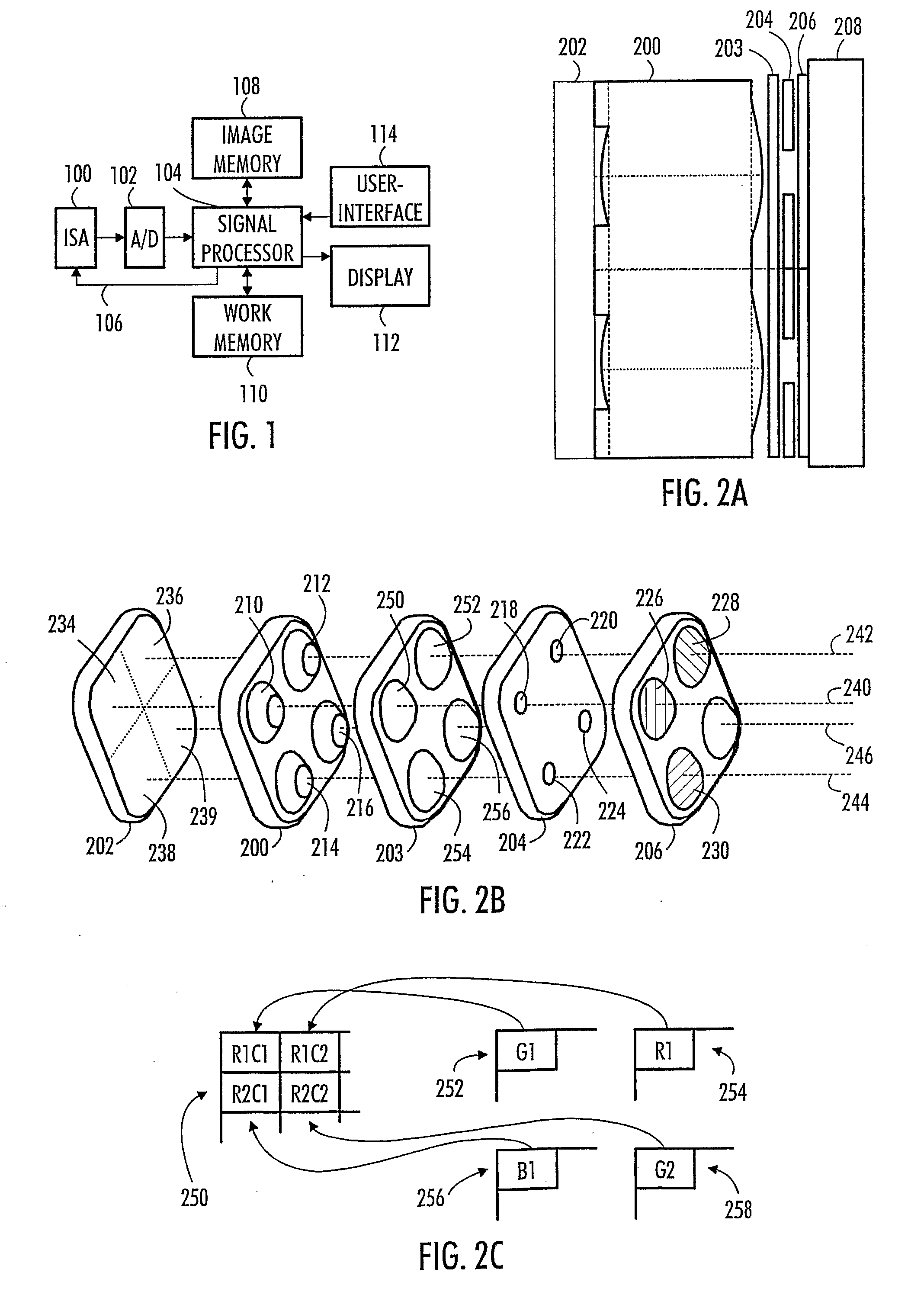

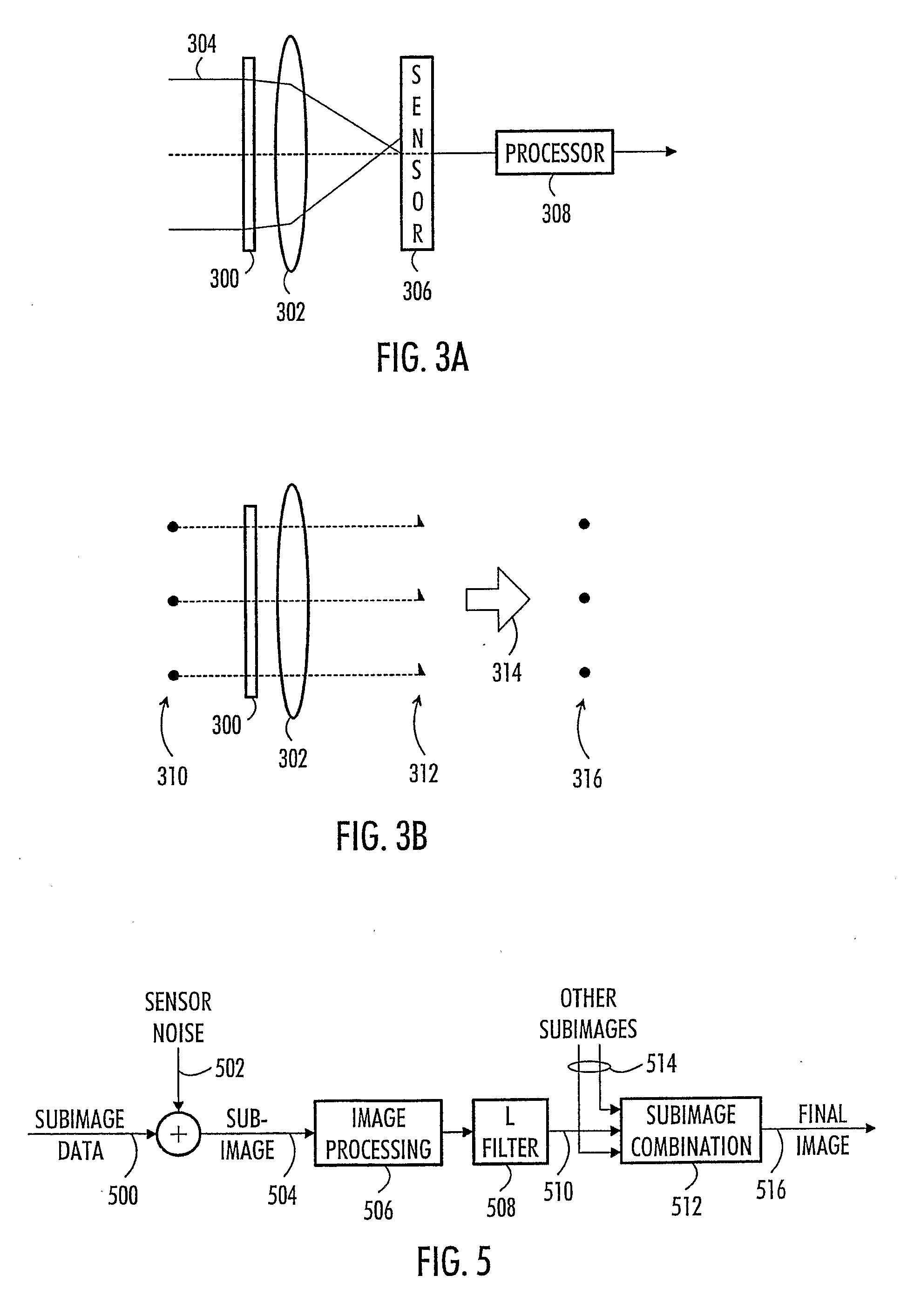

Method of Creating Colour Image, Imaging Device and Imaging Module

InactiveUS20070252908A1Precision requirement related to manufacturing can be avoidedMeet the blocking requirementsTelevision system detailsTelevision system scanning detailsPhase maskColour image

An imaging device comprising at least three image capturing apparatuses is provided. Each apparatus includes a lens system and a sensor and is configured to produce an image. The device further comprises a processor configured to combine at least a portion of the images with each other to produce a colour image. Each lens system comprises a phase mask which modifies the phase of incoming rays of light such that distribution of rays after the lens system is insensitive to the location of the sensor.

Owner:NOKIA CORP

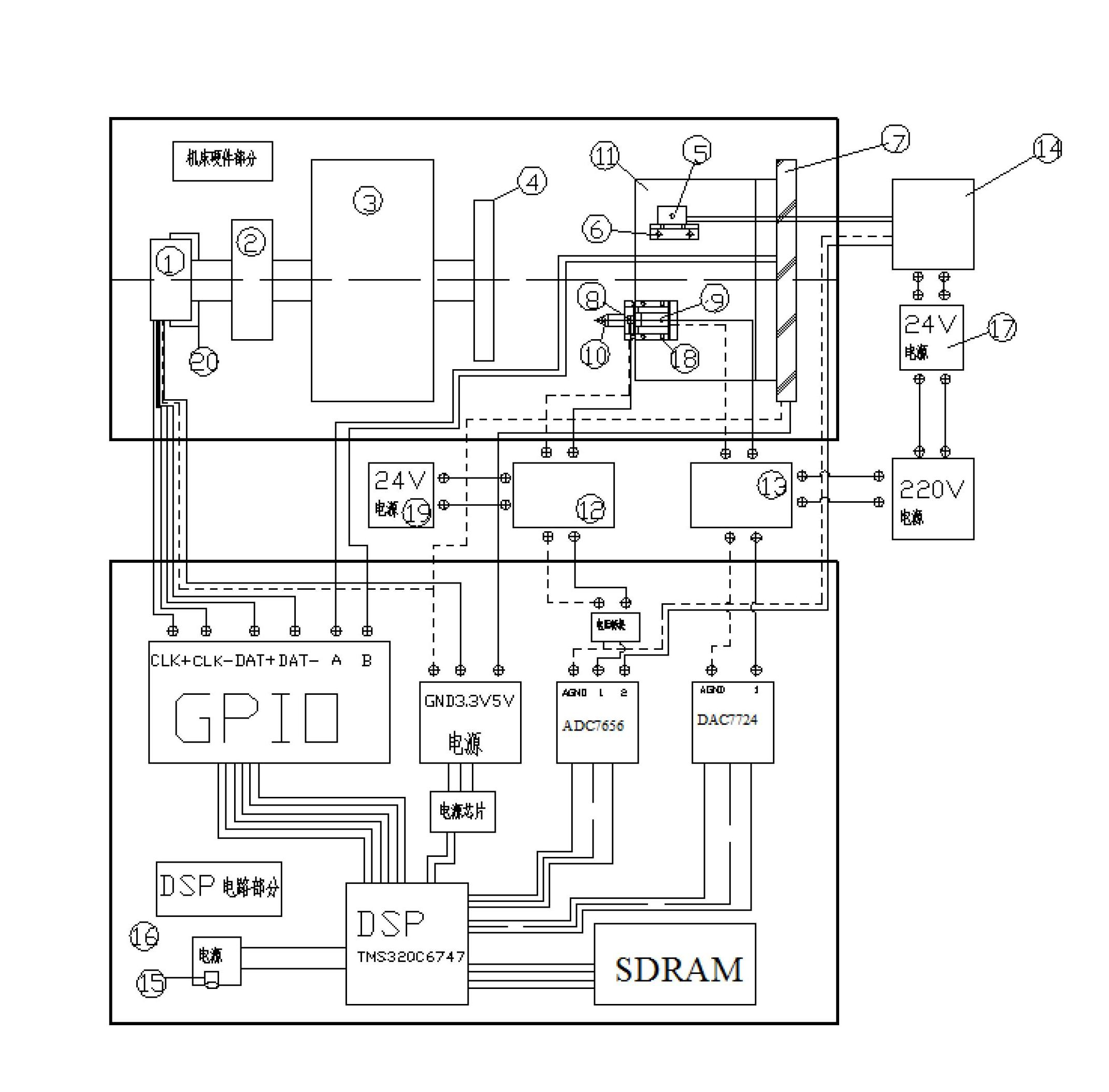

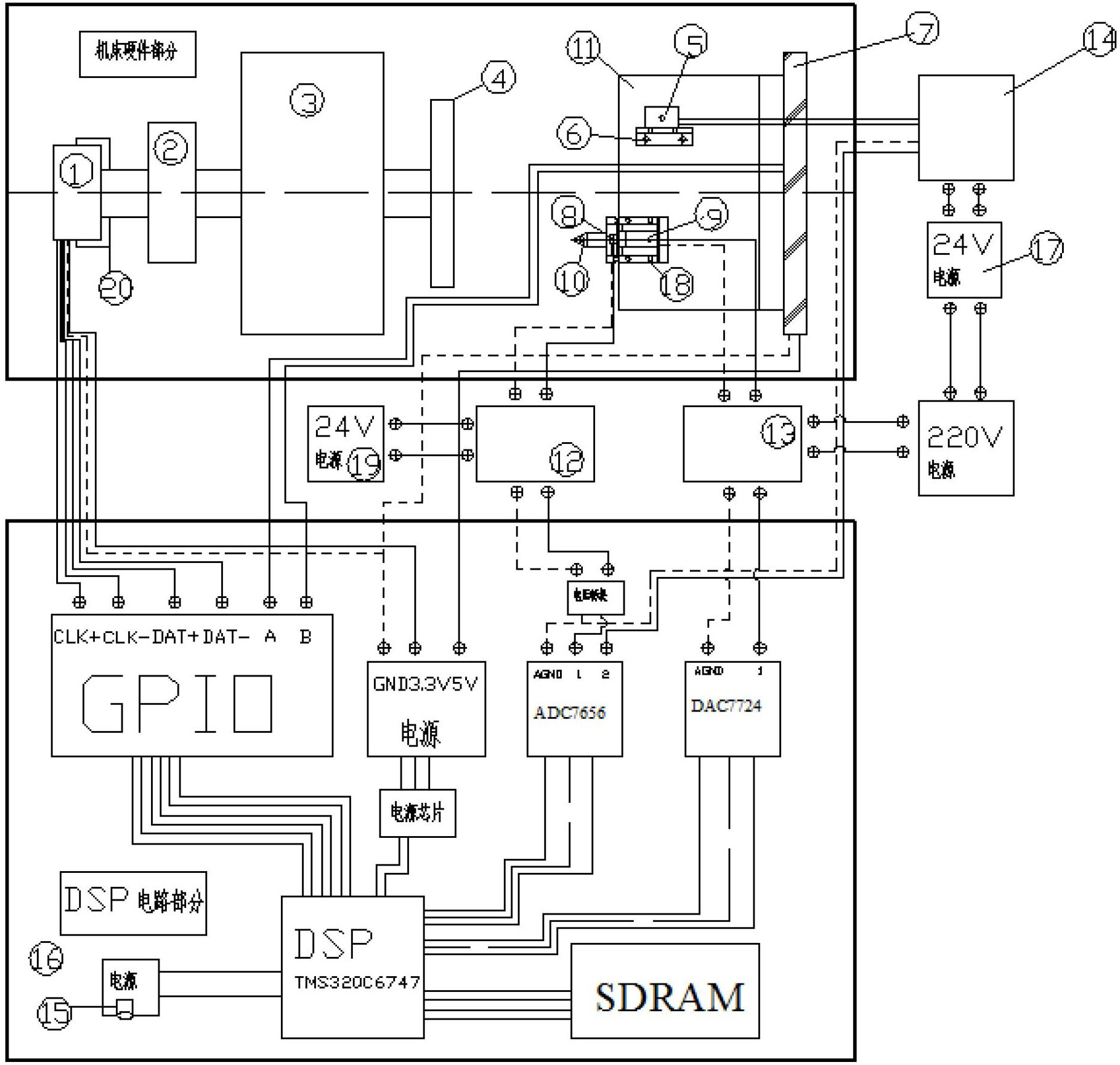

System for measuring surface topography of aerospace thin-wall disc part and machining fixture based on digital signal processor (DSP)

ActiveCN102672540AQuick measurementFast preparationAutomatic control devicesMeasurement/indication equipmentsDigital signal processingGrating

The invention relates to a system for measuring the surface topography of an aerospace thin-wall disc part and machining a fixture based on a digital signal processor (DSP). The system consists of a TMS320C6747 chip, and a DSP development board, a DSP development board 5V power supply, a quick servo tool rest, a piezoelectric ceramic displacement driver, a piezoelectric ceramic power amplifier, a capacitive sensor measuring head, a capacitive sensor signal amplifier, a capacitive sensor power supply, an absolute encoder, a linear grating ruler, a laser displacement sensor measuring head, a laser displacement sensor measuring head retainer, a laser displacement sensor controller, a laser displacement sensor power supply, an absolute encoder bracket, an elastic coupling, a monocrystalline diamond turning tool, a thin-wall workpiece, a fixture mounting platform and an experiment platform which are based on the chip. The system has the functions of quickly measuring the surface topography and manufacturing the fixture at high accuracy, has practical value in the field of machining, and can solve the problems that the deformation of the thin-wall part is large, new deformation is generated in each machining process, accuracy is difficult to ensure, and the fixture cannot meet the clamping requirement in each process.

Owner:BEIHANG UNIV

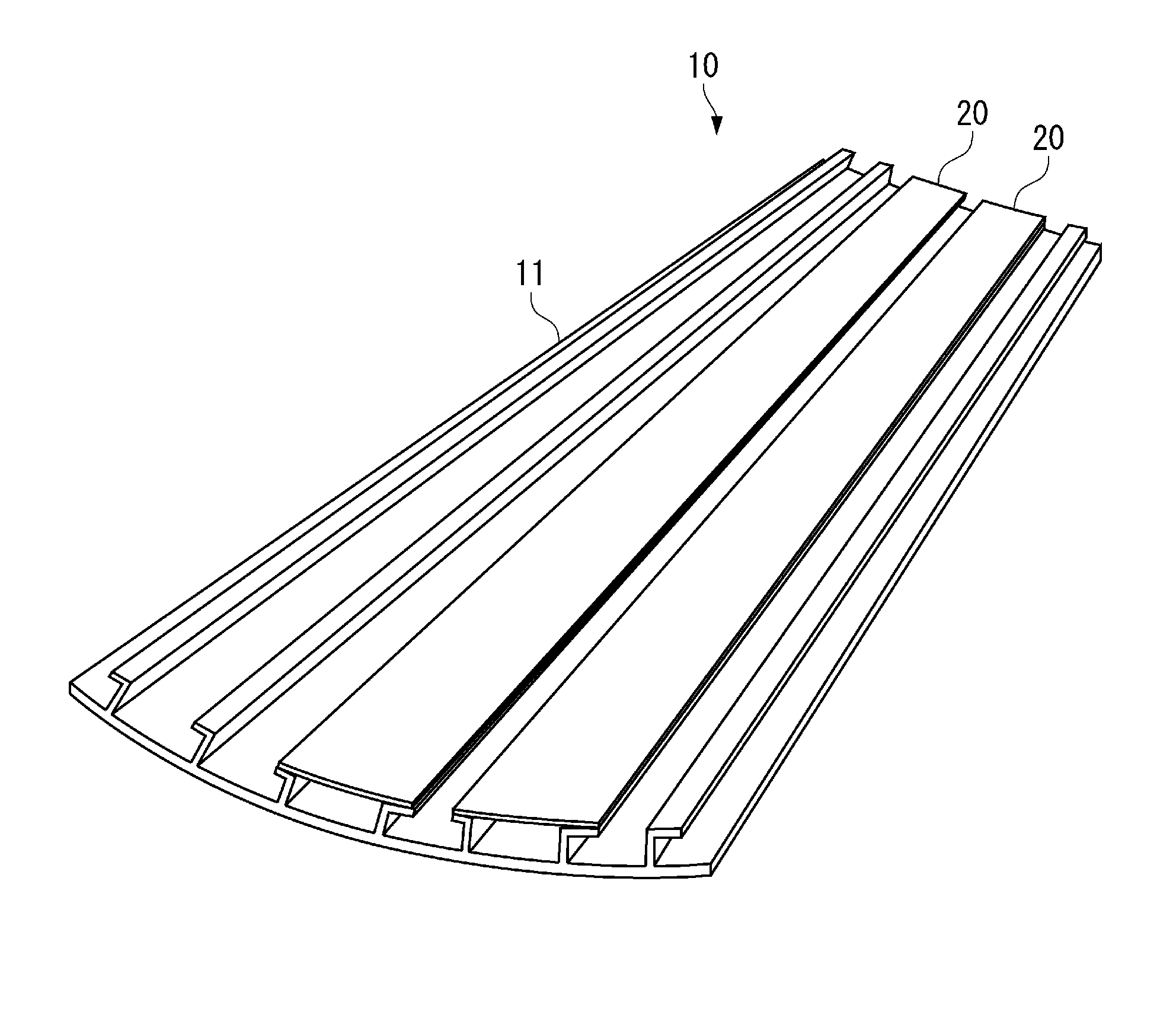

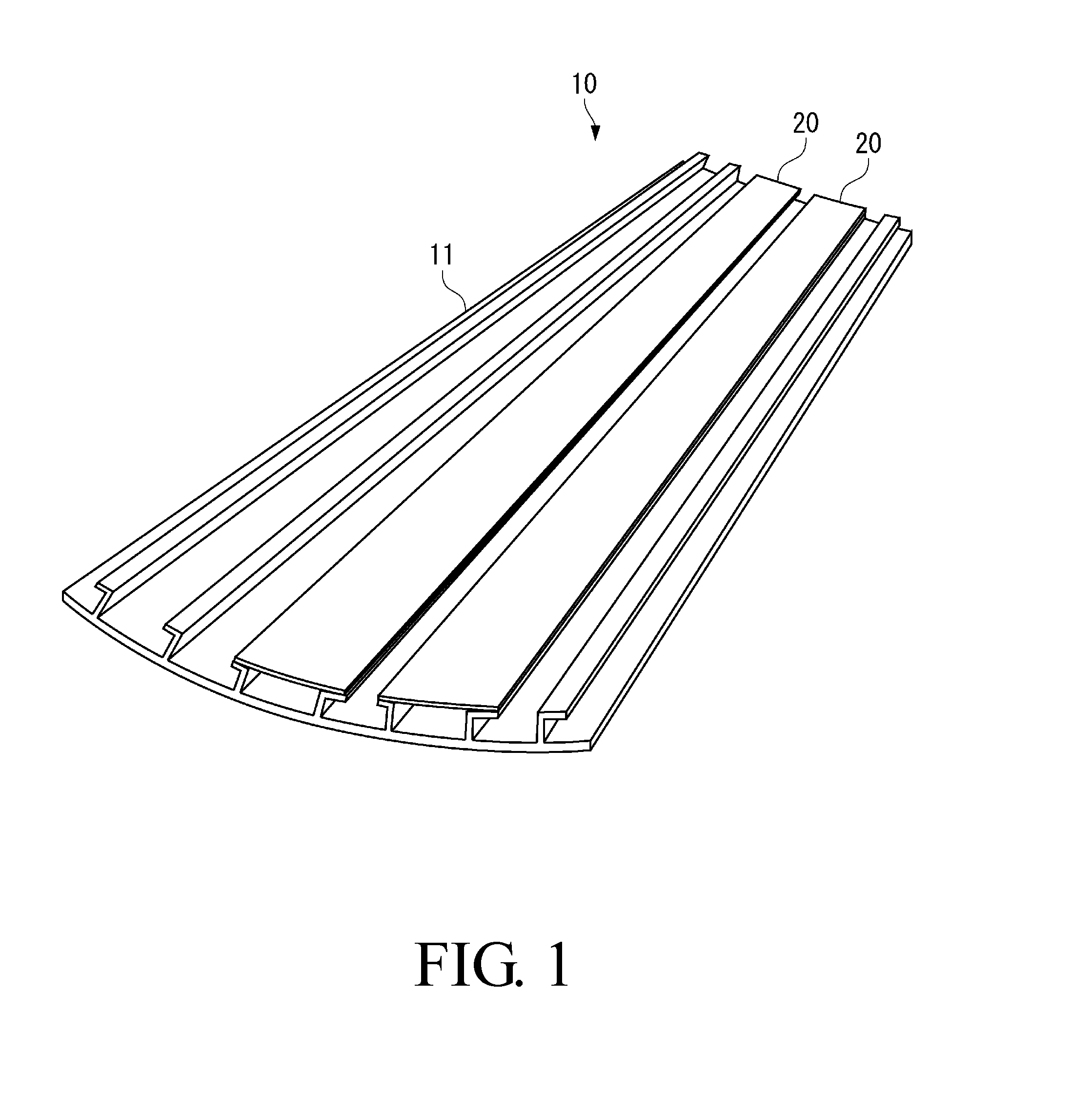

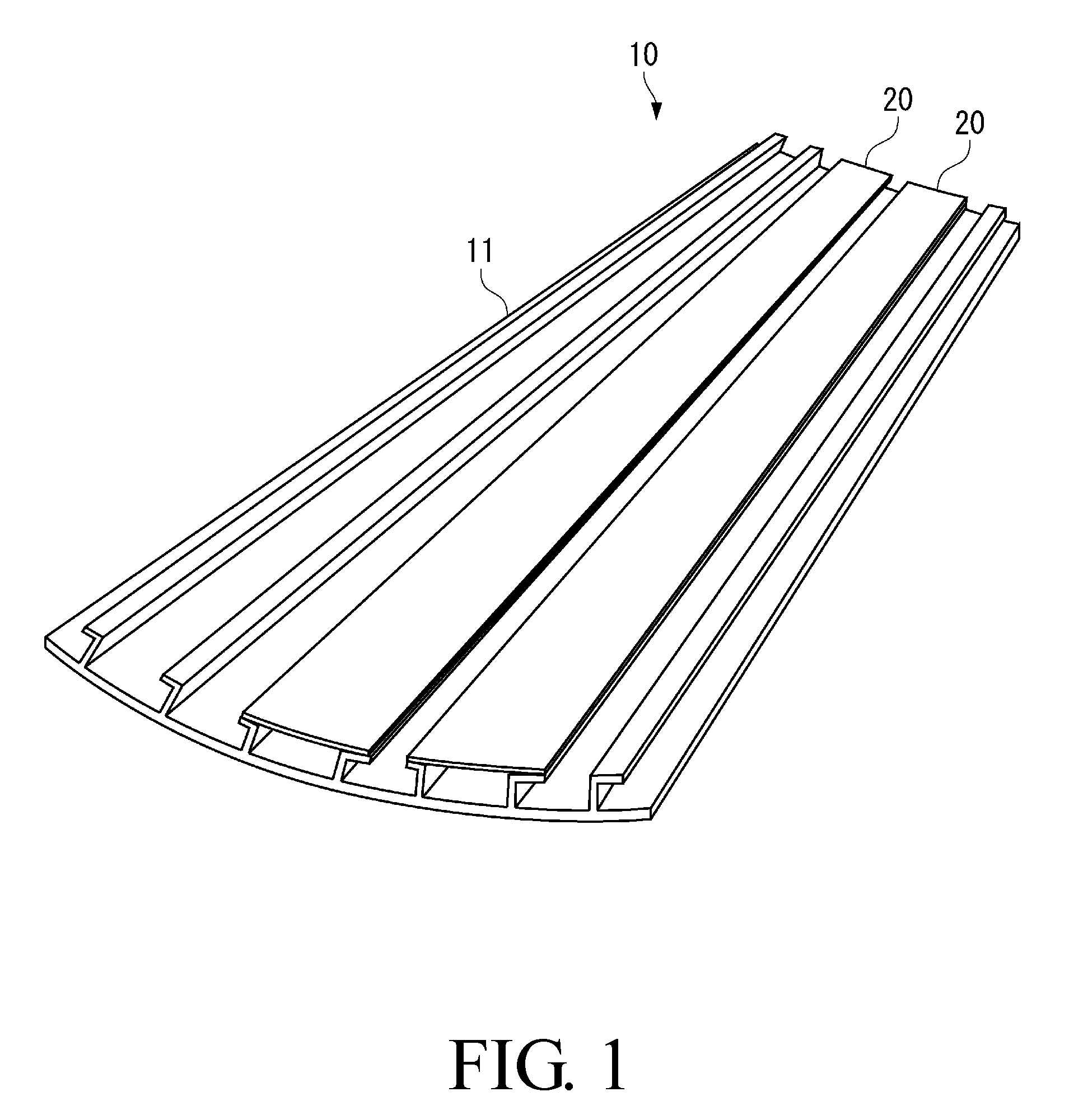

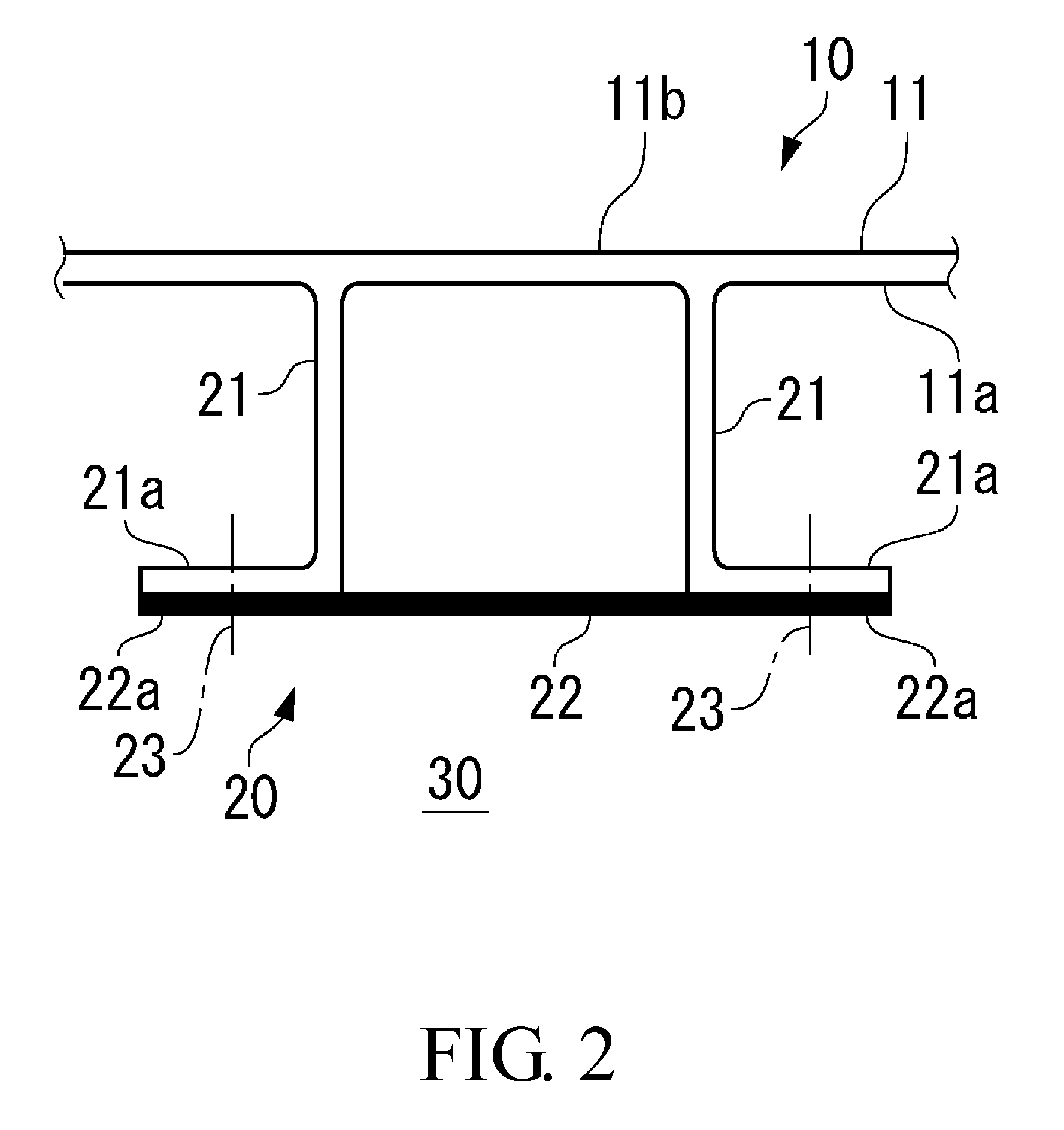

Vent stringer and aircraft main wing

ActiveUS20120187246A1Excellent workabilityHigh accuracyPower plant fuel tanksAircraft stabilisationAirplaneAircraft landing

A vent stringer 20 is formed by a pair of ribs 21 rising in the direction perpendicular to an inner surface 11a of a wing panel 11, and a cover 22 provided in the tip end portions of the ribs 21. With rivets 23 unexposed to an outer surface 1 lb of the wing panel 11, a spark is prevented from occurring in a fuel tank 30, which is provided in a main wing 10, through the rivet 23 at the time of a lightning strike. Formed by being machined integrally with the wing panel 11, the rib 21 is formed with high accuracy so as to match the curved shape of the wing panel 11. The cover 22 has only to be formed by curving a strap member so as to match the shapes of the wing panel 11 and the ribs 21.

Owner:MITSUBISHI AIRCRAFT

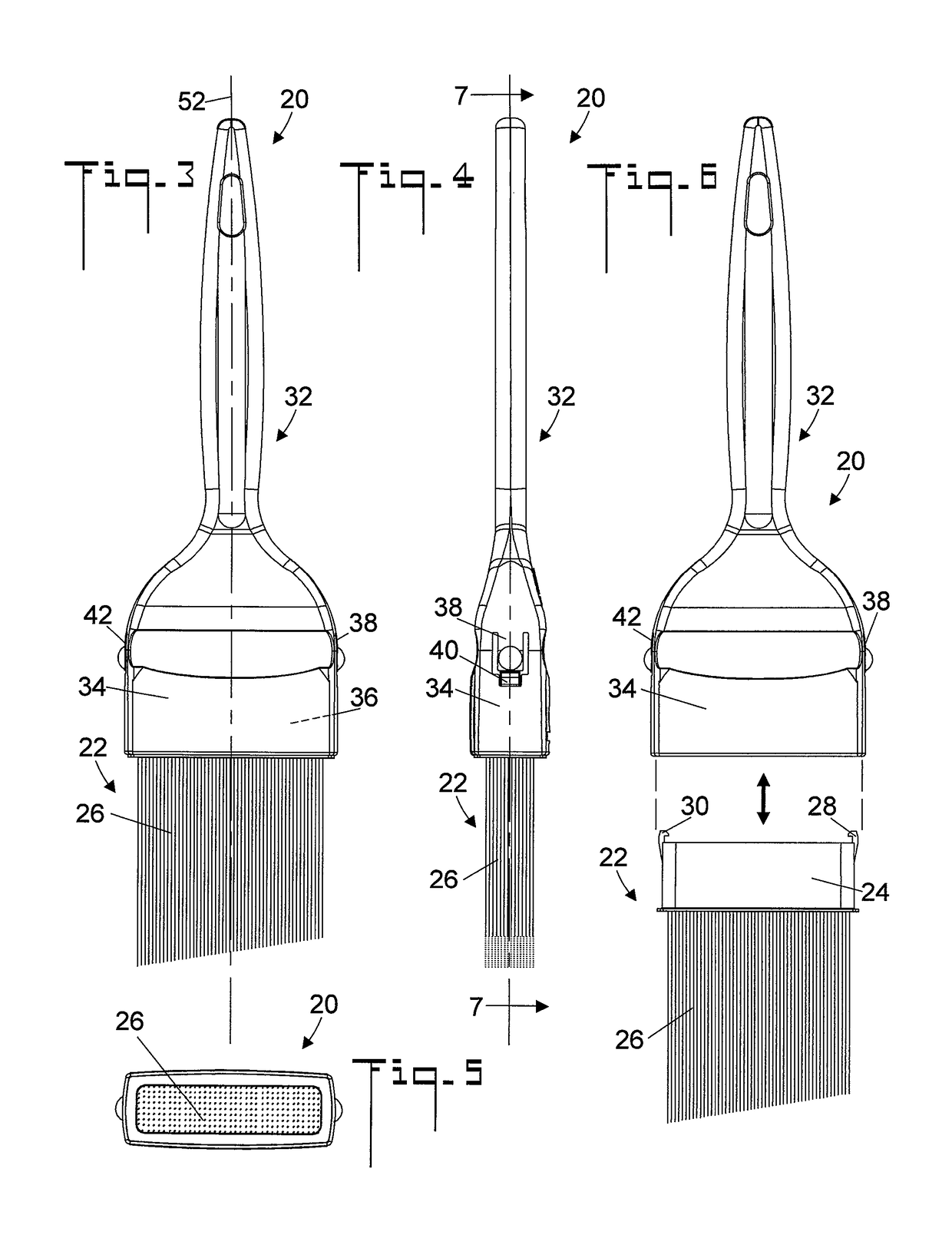

Paintbrush and method of use

ActiveUS10021960B1Manufacturing tolerance can be correctedProcedure is time-consumeLiquid surface applicatorsBristle carriersBristleEngineering

A paintbrush includes a bristle assembly which has a bristle housing to which a plurality of bristles are connected. The bristle housing has a first connector which is spaced apart from a second connector. A handle includes a holder which has cavity which is shaped and dimensioned to removably receive the bristle housing. The handle also includes spaced apart first and second resilient arms, the first resilient arm has a first arm connector and the second resilient arm has a second arm connector. The bristle housing is positionable in the cavity of the holder so that the first connector engages the first arm connector and the second connector engages the second arm connector thereby locking the bristle housing within the cavity. The first resilient arm and the second resilient arm are also positionable to a release position so that the first arm connector is disengaged from the first connector and the second arm connector is disengaged from the second connector so that the bristle housing can be removed from the holder.

Owner:DOUGLAS TERRY RAY +1

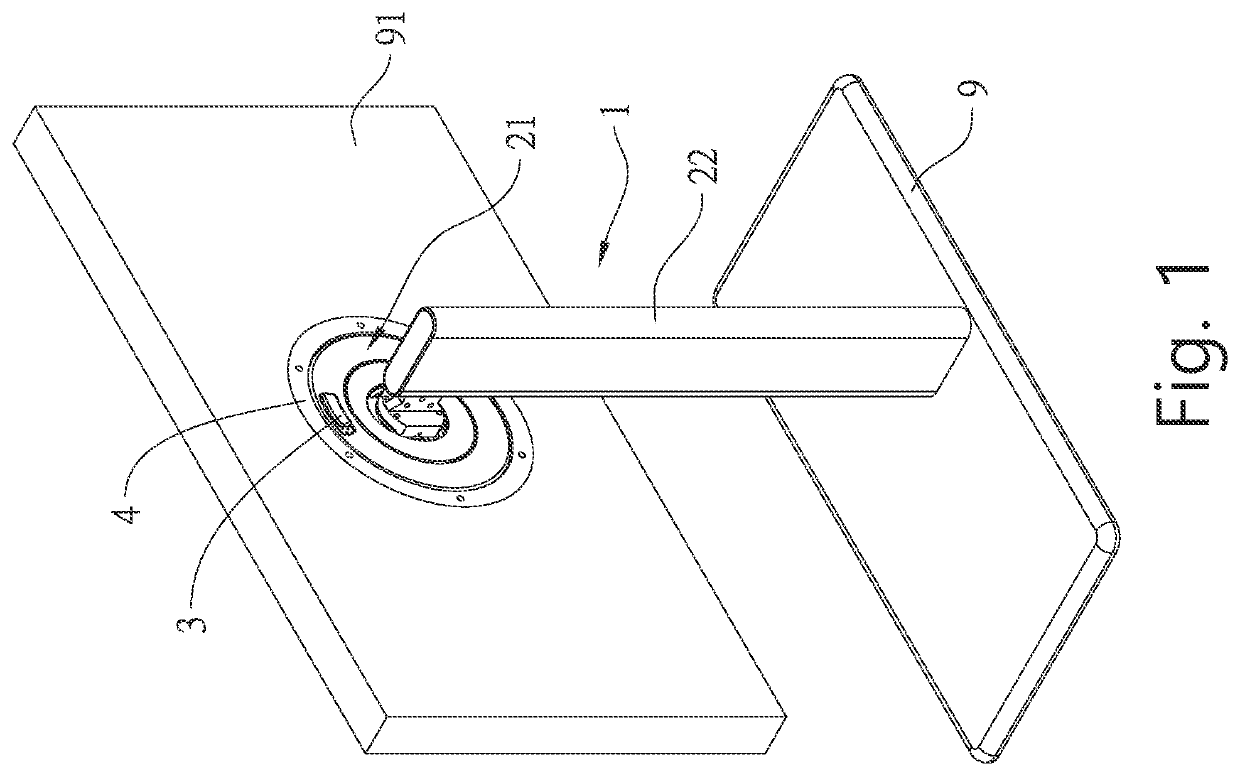

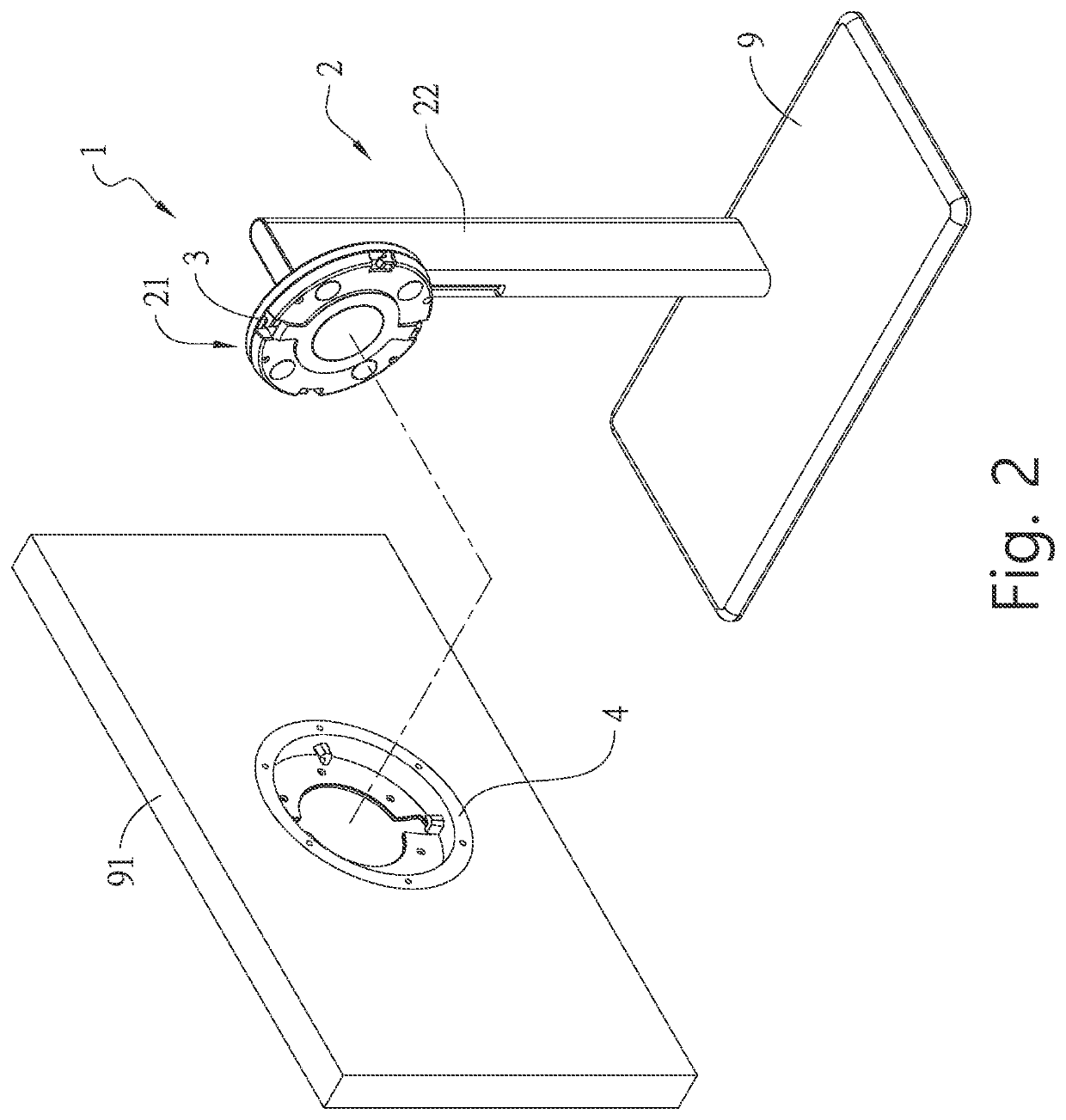

Vent stringer and aircraft main wing

ActiveUS8672269B2Improve lightning protection effectPrecision manufacturingPower plant fuel tanksAircraft stabilisationLightning strikeFuel tank

A vent stringer 20 is formed by a pair of ribs 21 rising in the direction perpendicular to an inner surface 11a of a wing panel 11, and a cover 22 provided in the tip end portions of the ribs 21. With rivets 23 unexposed to an outer surface 11b of the wing panel 11, a spark is prevented from occurring in a fuel tank 30, which is provided in a main wing 10, through the rivet 23 at the time of a lightning strike. Formed by being machined integrally with the wing panel 11, the rib 21 is formed with high accuracy so as to match the curved shape of the wing panel 11. The cover 22 has only to be formed by curving a strap member so as to match the shapes of the wing panel 11 and the ribs 21.

Owner:MITSUBISHI AIRCRAFT

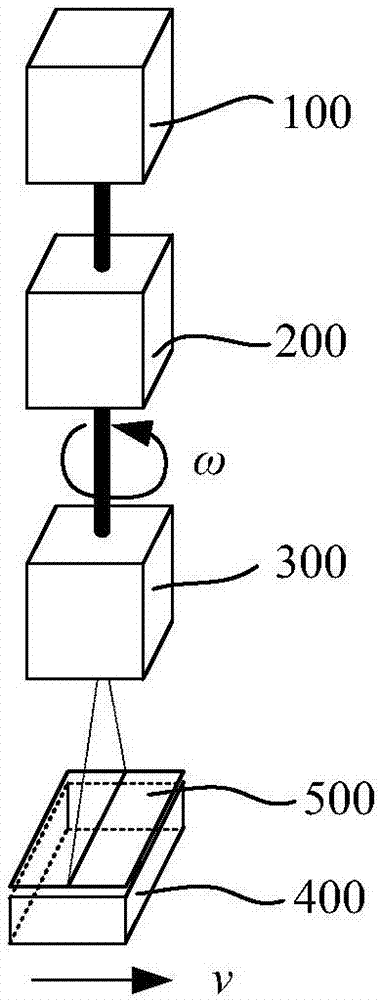

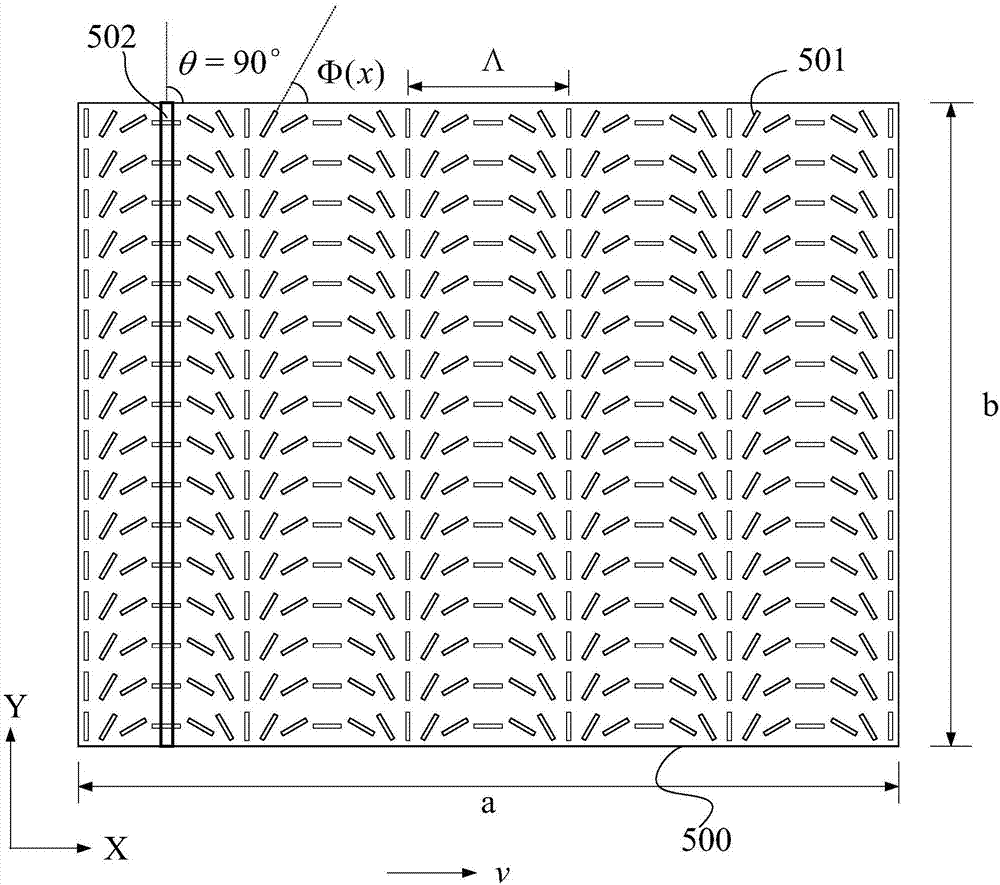

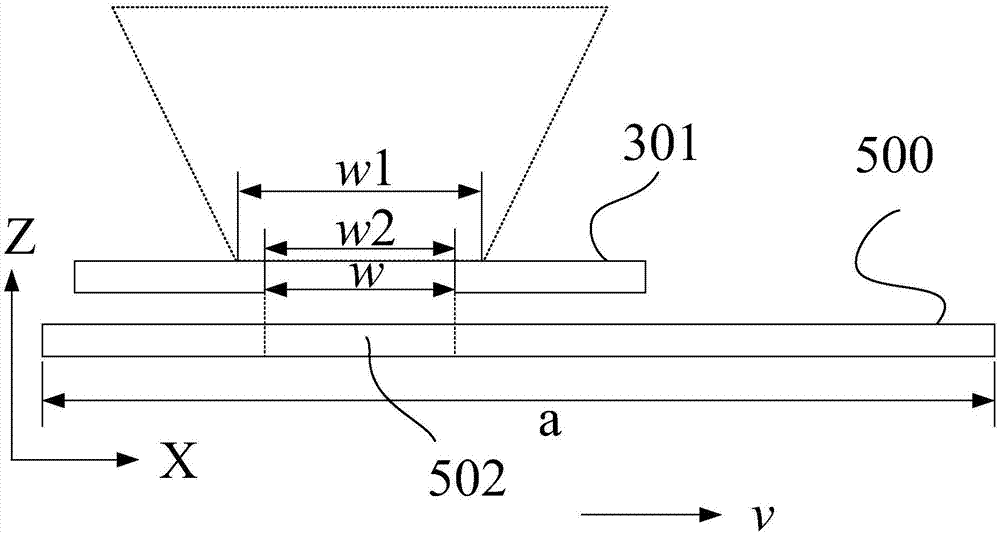

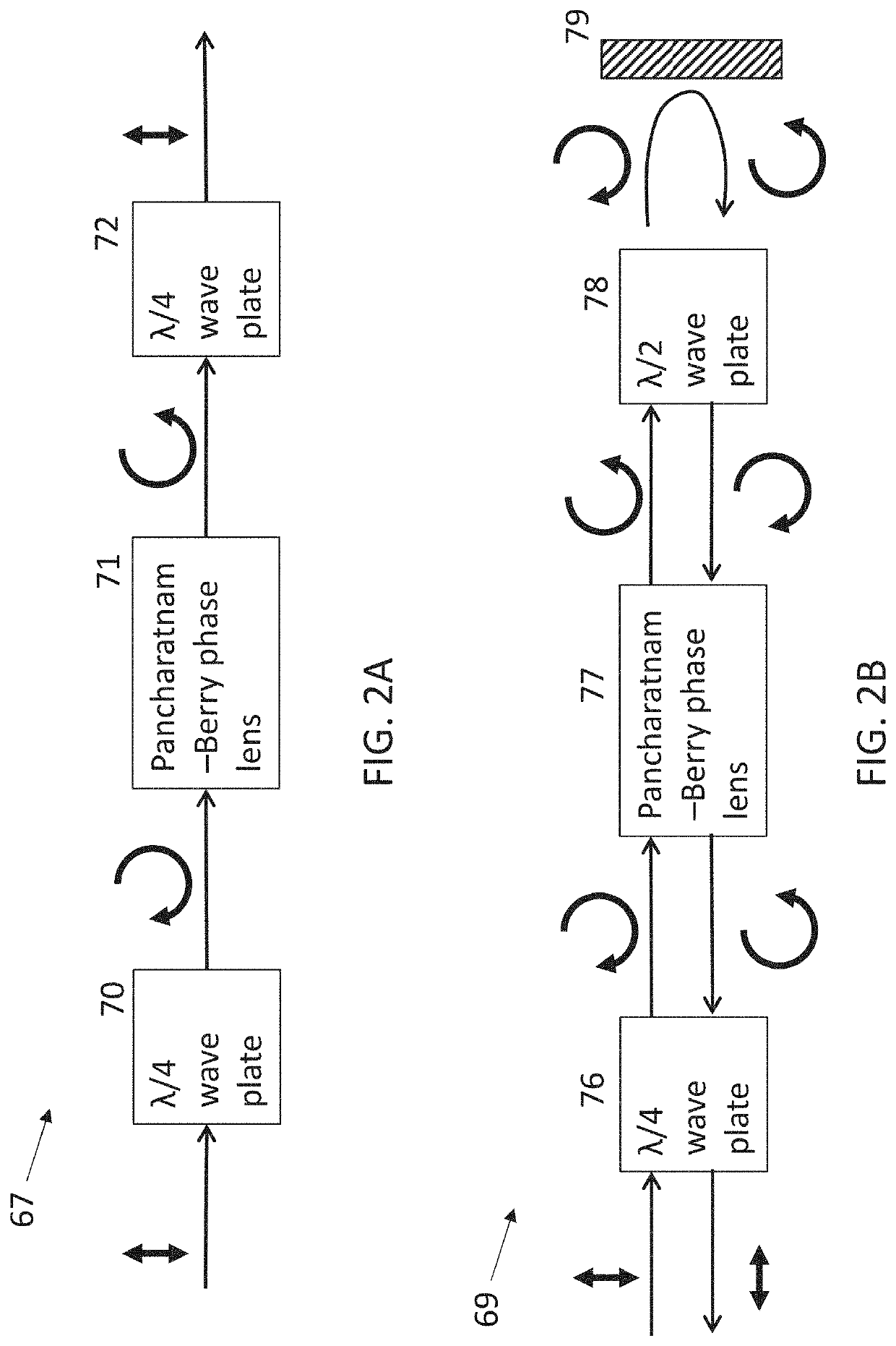

Exposure device and method capable of manufacturing large-aperture liquid crystal polarization grating device

InactiveCN107966885AFast preparationPrecision manufacturingDiffraction gratingsPhotomechanical exposure apparatusGratingLight beam

The invention discloses an exposure device and method capable of manufacturing a large-aperture liquid crystal polarization grating device. The exposure device comprises an exposure light source and is characterized by comprising a polarization state controller, a light beam converter and a sample wafer translation platform, the polarization state controller is used for converting a polarization state of the exposure light source into a rotatable linear polarization state, the light beam converter is used for shaping an incident light beam of the exposure light source to be a uniform elongatedlight beam, the sample wafer translation platform is used for controlling translation scanning movement of an exposed sample wafer, the exposure light source, the polarization state controller, the light beam converter and the sample wafer translation platform are sequentially arranged spatially and spaced, and clear apertures of optical parts contained in the four components are maintained in acoaxial relation along a downward linear transmitting direction of the exposure light source. The exposure device is simple in structure, the method is simple and convenient in process, exposure aperture is large, and precise adjusting range of a grating period is wide. The exposure device is convenient for repair and maintenance.

Owner:CHINA WEAPON EQUIP RES INST

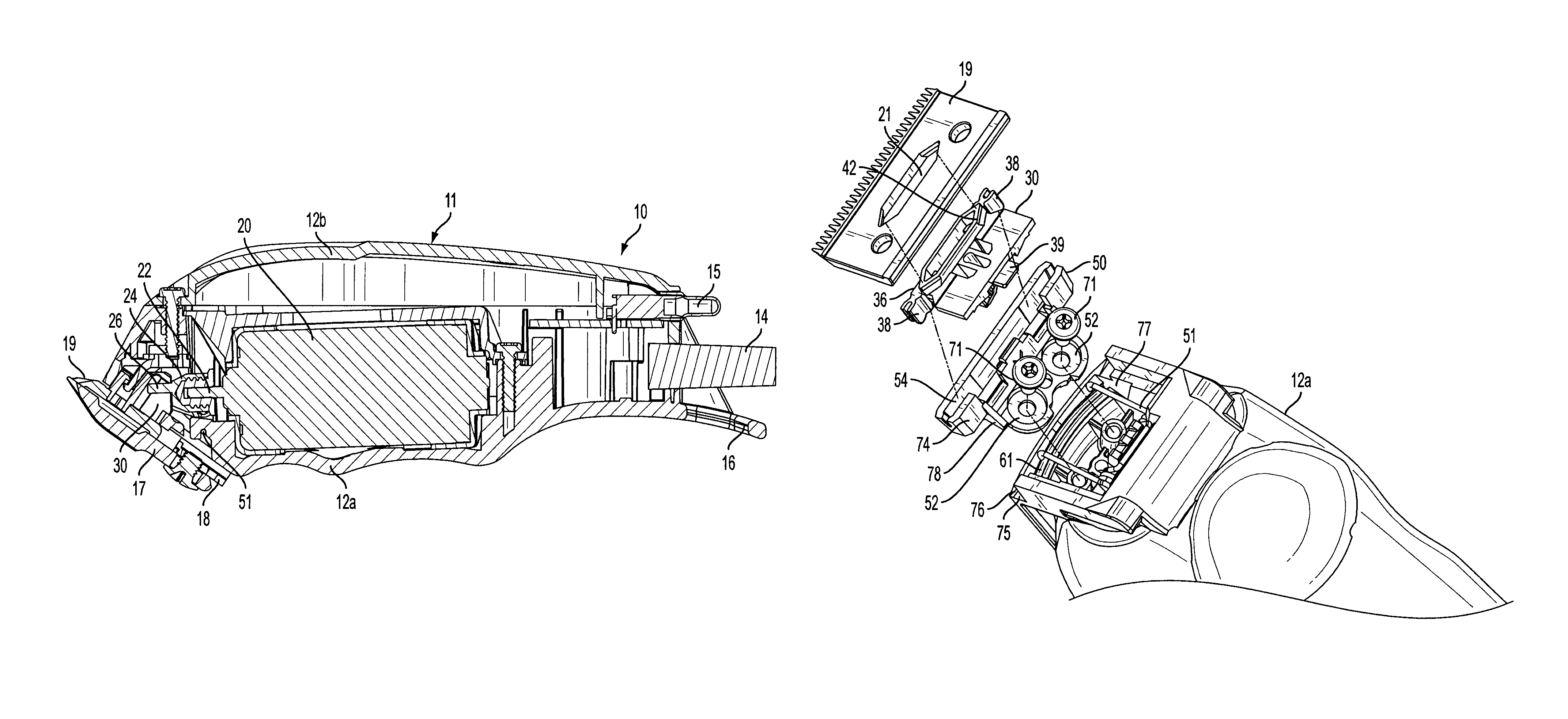

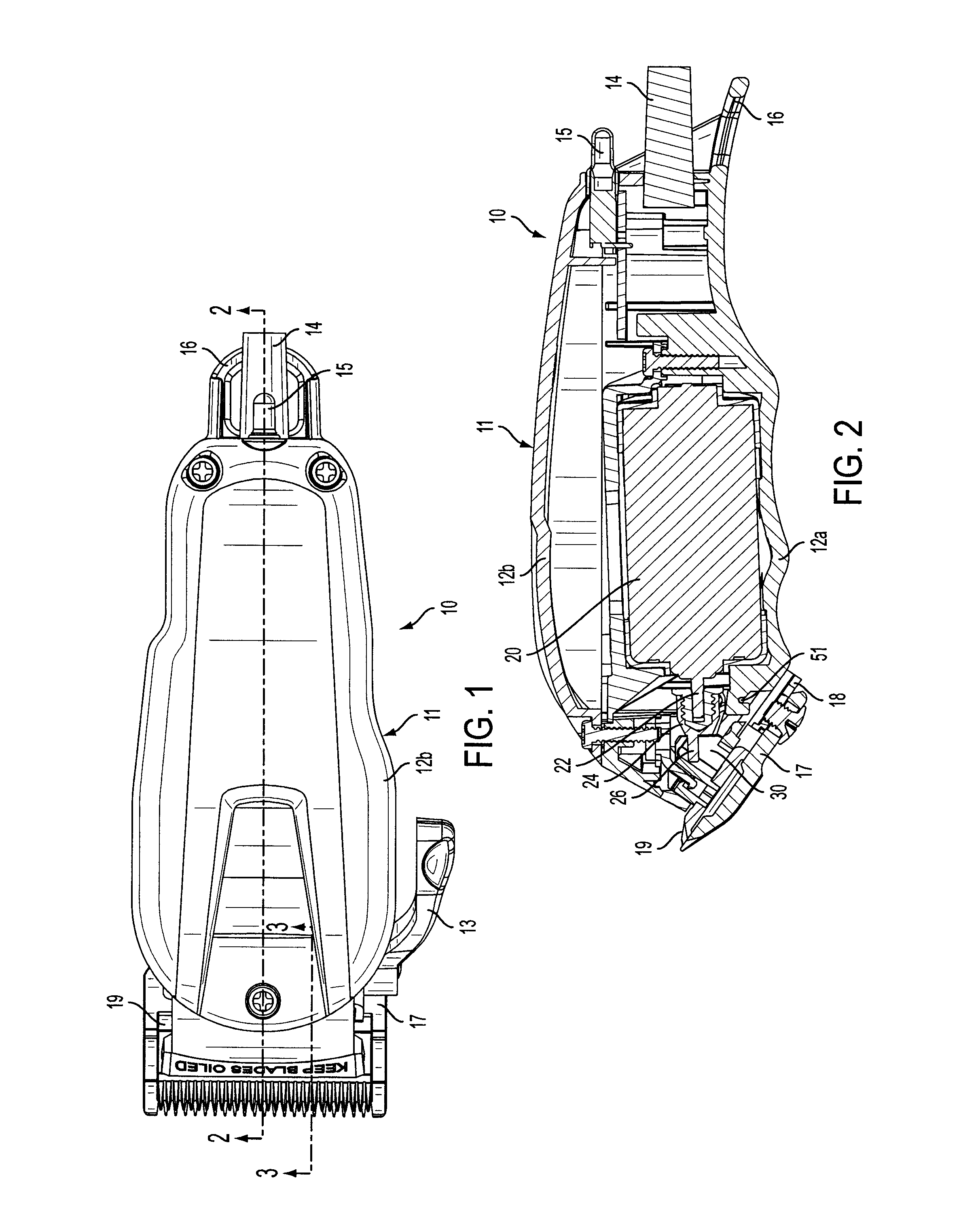

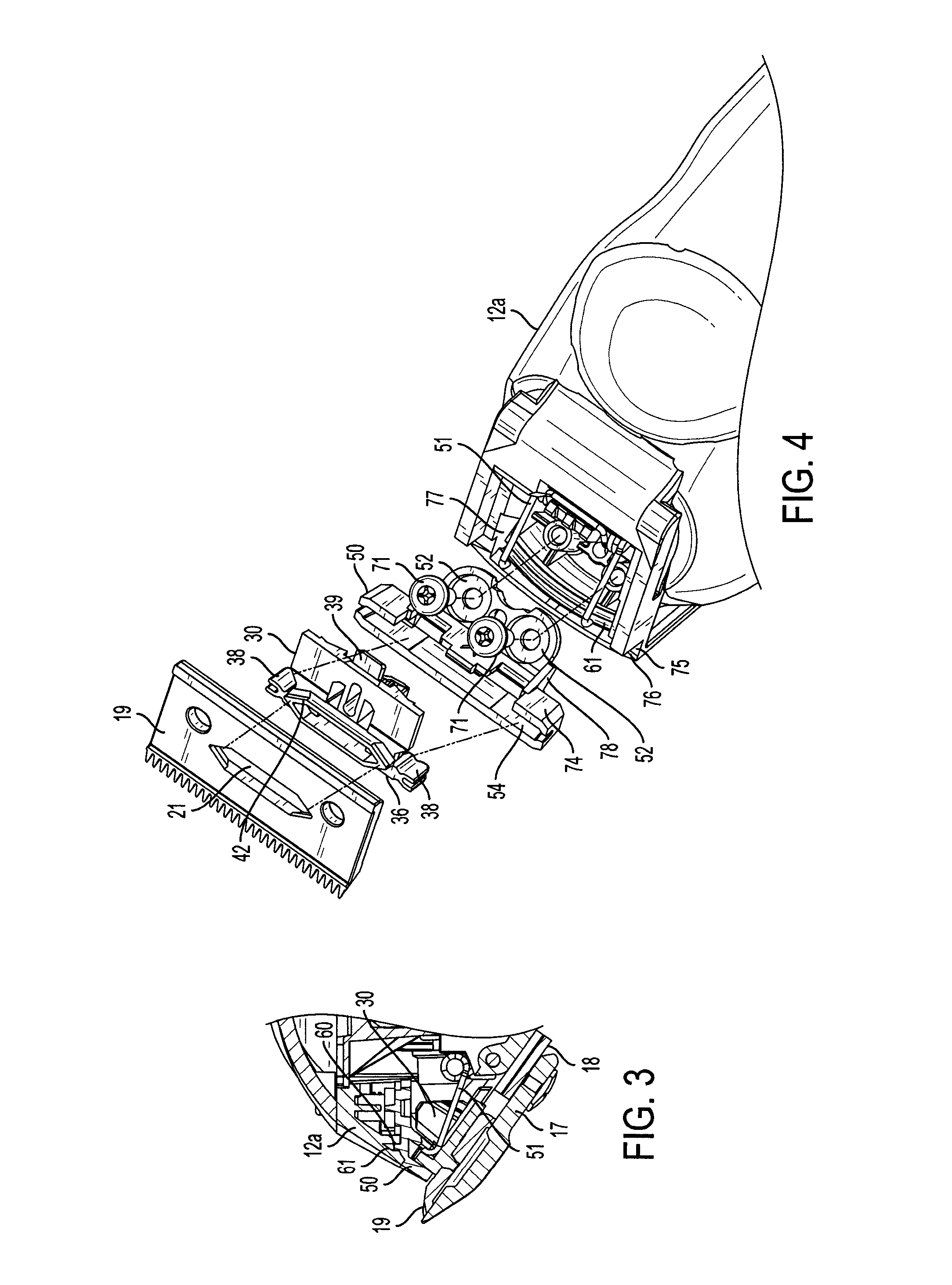

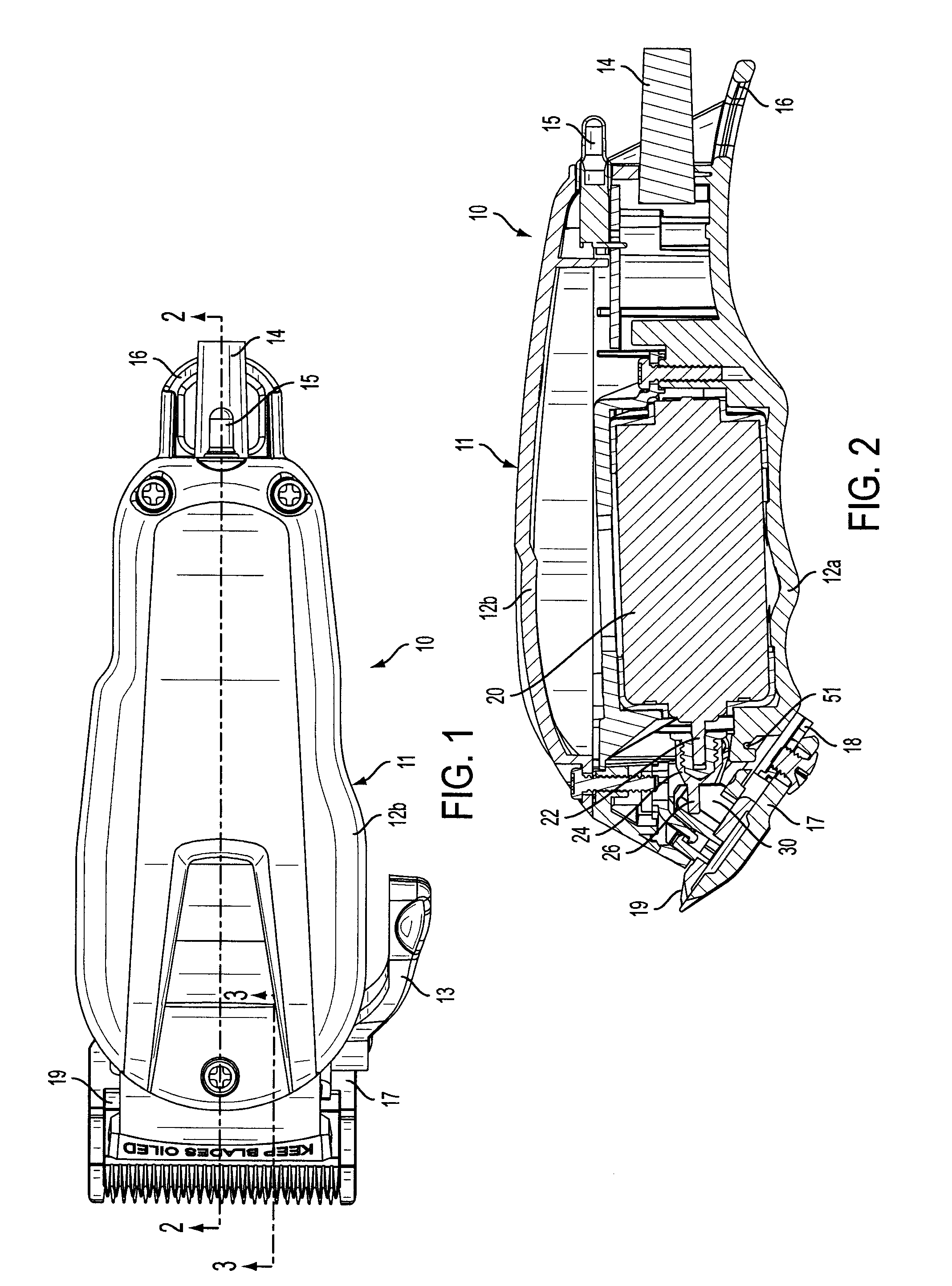

Linear drive system for hair clippers

ActiveUS9144911B2Precision manufacturingEasy alignmentMetal working apparatusEngineeringHair clipper

A hair clipper has a base housing, a secondary housing cover, and a rotary motor or vibrator motor secured between the base housing and the housing cover. The rotary motor has a shaft and a cam secured to an end of the shaft, and the vibrator motor has a drive arm with a drive finger. A cam follower is operably connected to the cam or drive finger on a top side. The top side of the cam follower also has an elongated guide rail that is operably secured to a guide channel in a blade guide, which in turn is secured to the base housing. A reciprocating blade is operably secured to the bottom side of the cam follower, and a stationary blade is secured to the base housing adjacent the reciprocating blade.

Owner:WAHL CLIPPER

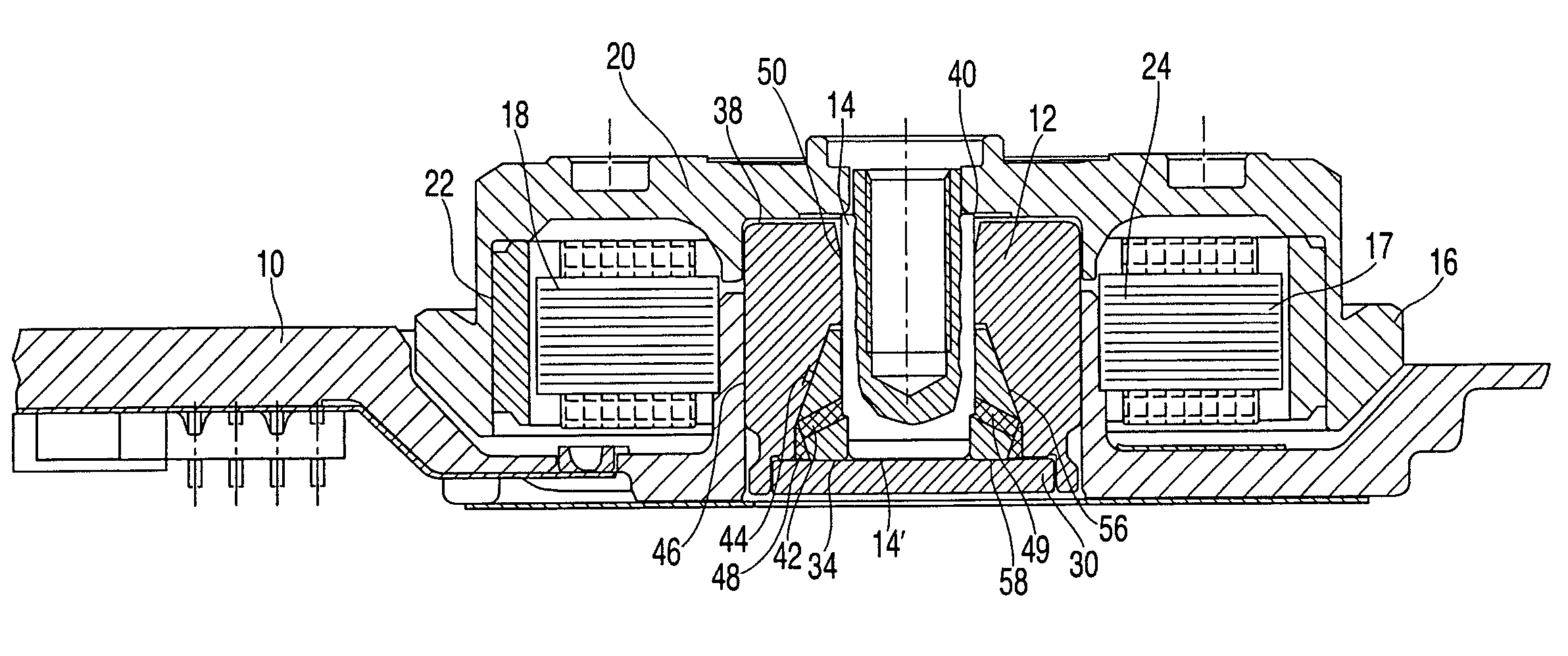

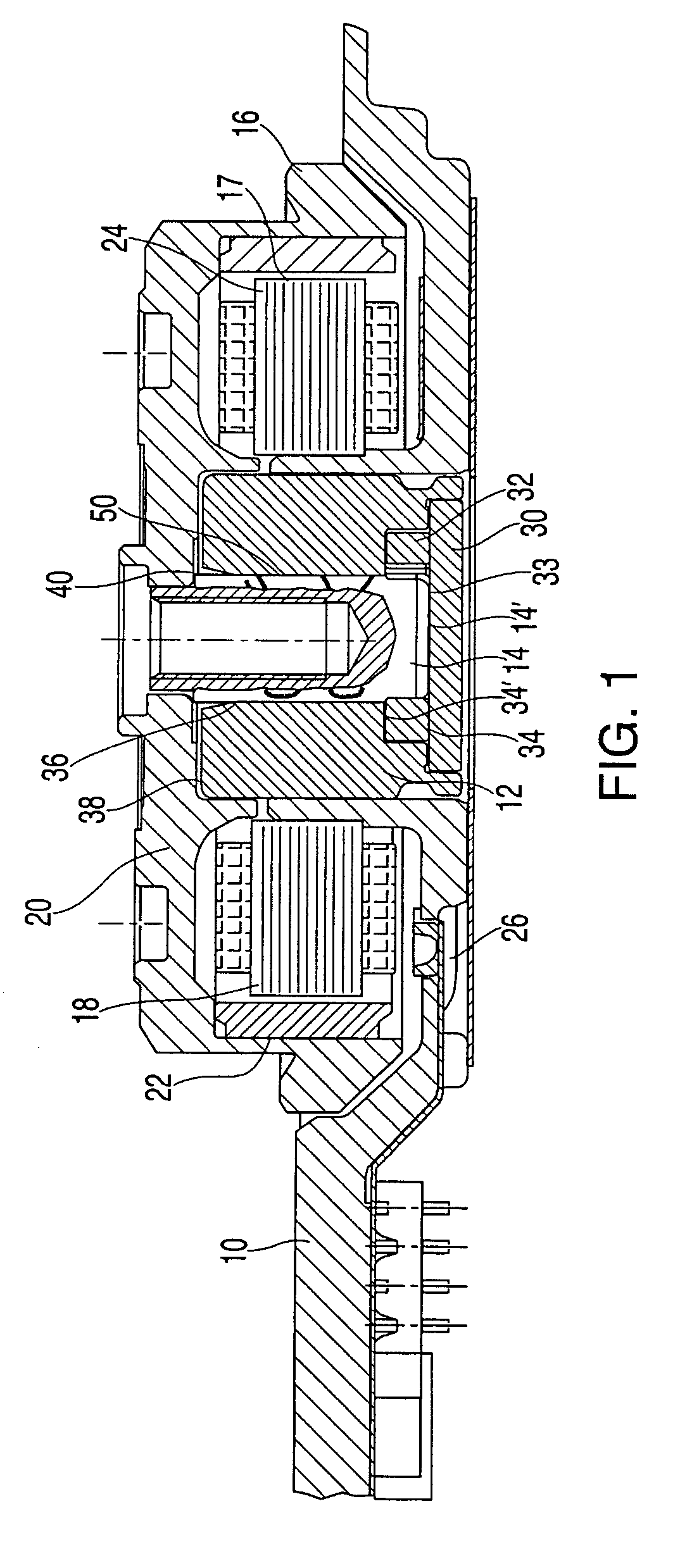

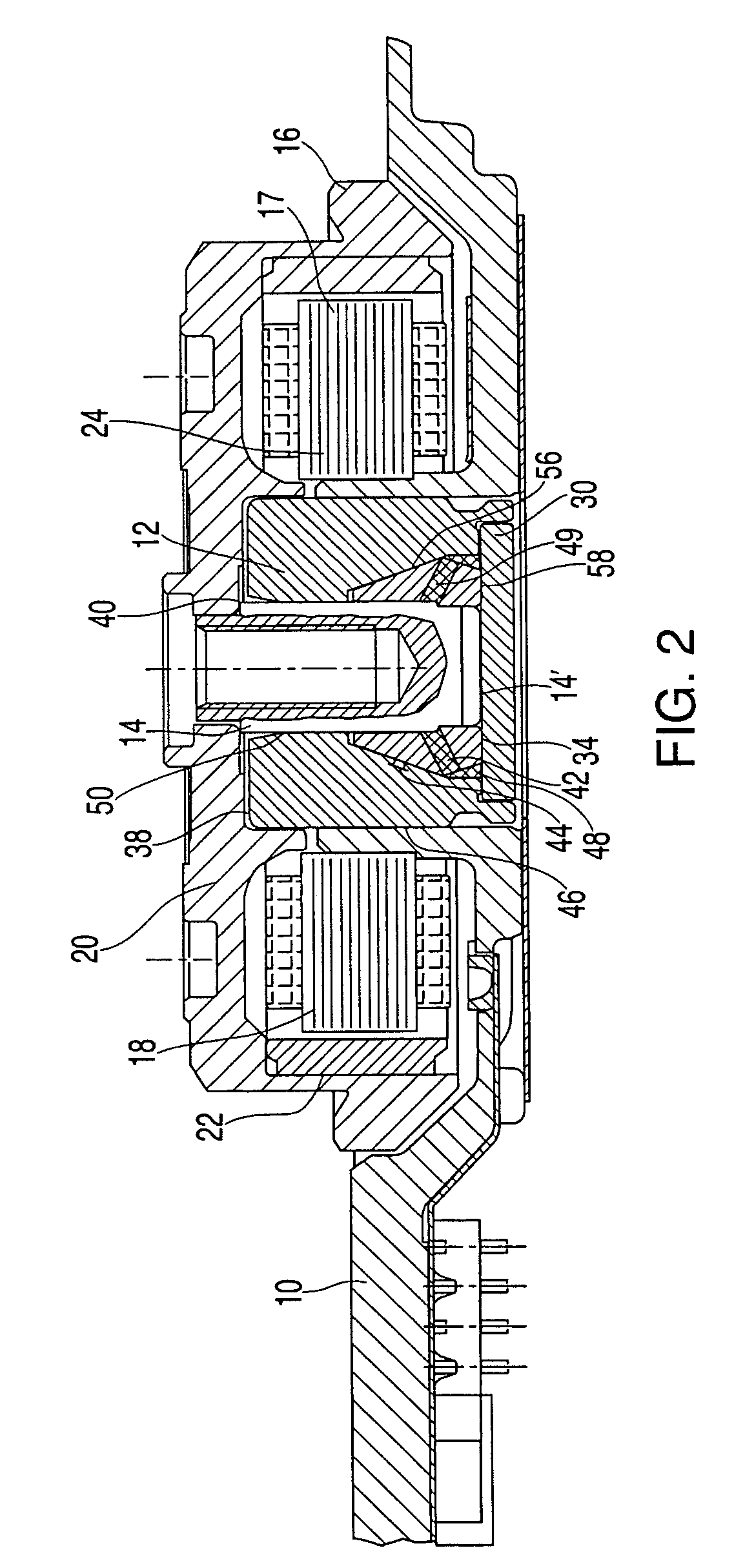

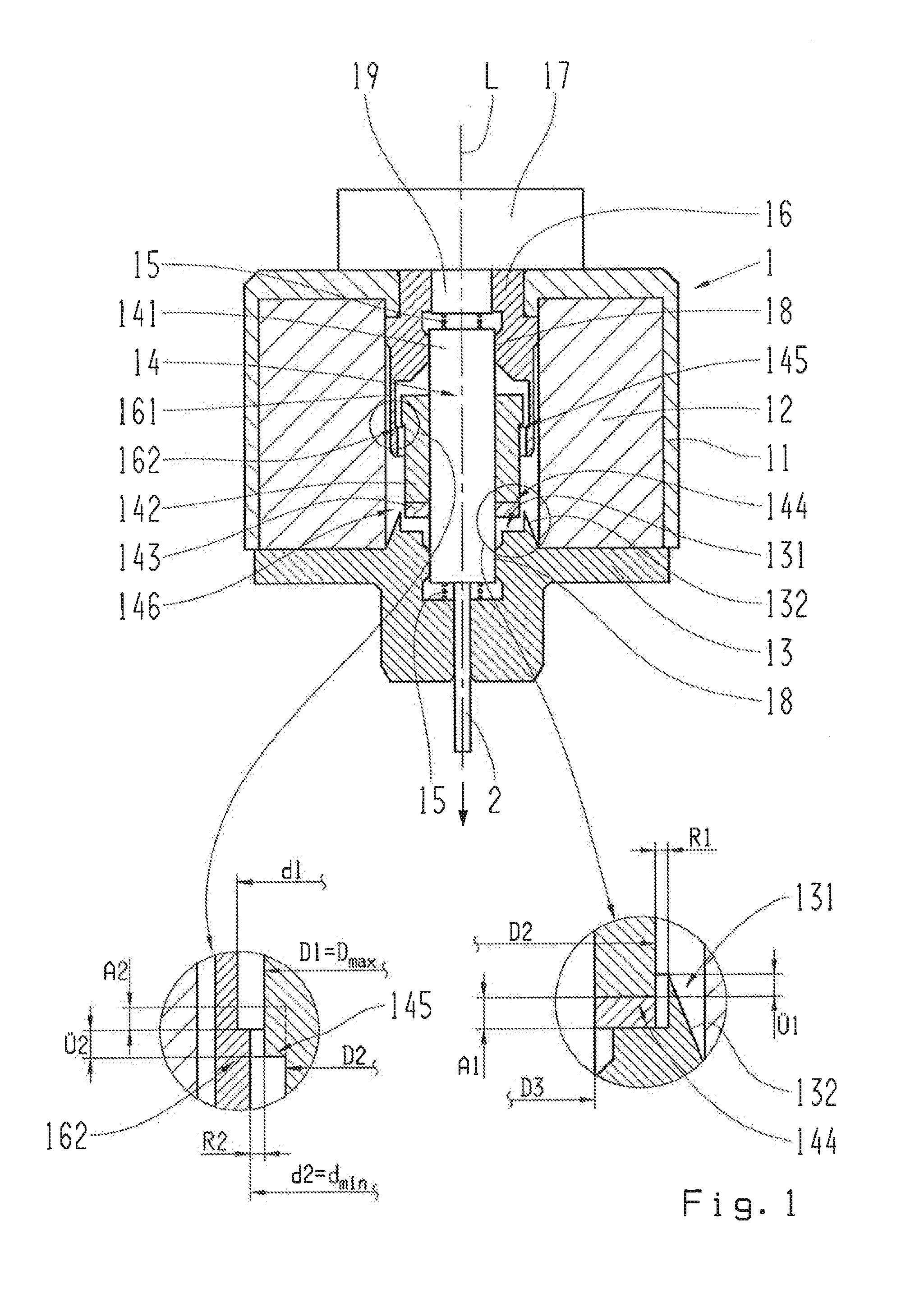

Hydrodynamic bearing for a spindle motor

InactiveUS7097360B2Little power lossImprove efficiencyShaftsRecord information storageDynamic pressureElectric motor

A hydrodynamic bearing for use in a spindle motor, having a shaft, a bearing sleeve encompassing the shaft with a small radial space, and a skewback at one end face of the bearing sleeve which is fixedly connected to the bearing sleeve. The shaft features a thrust plate or a conical or cone-like extension at its end face which faces the skewback. The diameter of the conical extension increases in the direction of the end face of the shaft. A bearing gap formed between the shaft and the bearing sleeve is filled with a bearing fluid. Dynamic pressure generating grooves are provided on one of the outer surface of the shaft and the inner surface of the bearing sleeve to generate an excess pressure in the bearing fluid.

Owner:MINEBEA CO LTD

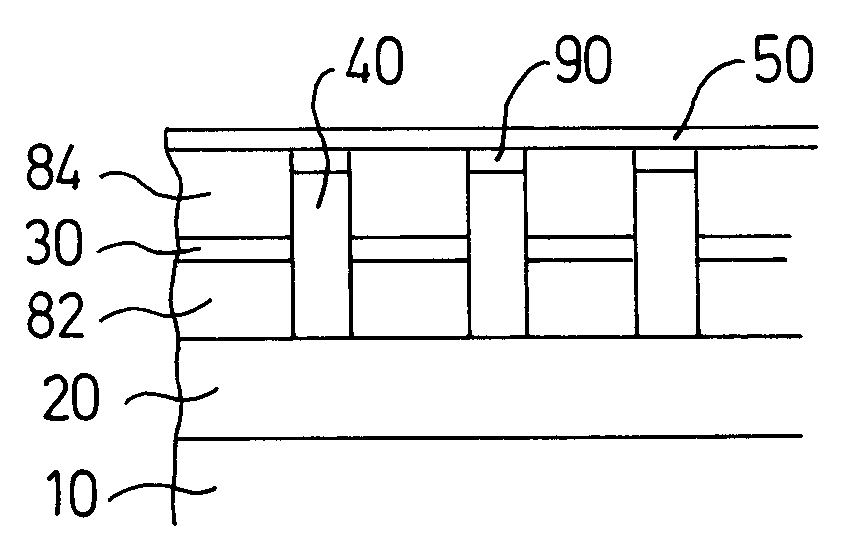

Data memory, writable and readable by microtips, which has a well structure, and manufacturing method

InactiveUS20090173929A1Facilitate amorphous/crystalline change of statePromote crystallizationVariable resistance carrier recordingNanoinformaticsData memoryData storing

The invention relates to data storage memories, that can be written and read by using at least one write or read microtip which comes near to a point zone to be written or to be read on the surface of a substrate, either in order to change the physical state of this zone, when writing or erasing, or in order to determine the physical state of the zone, when reading, the data stored in the zone being defined by the physical state of the zone. The surface of the substrate is subdivided into a set of individual islands (75) of a layer of a first sensitive material capable of changing state under the action of the write microtip, each island (75) being surrounded by a well (80) formed by a second material which is not or not very sensitive to the action of the write microtip, this second material completely separating the individual islands from one another. The material of the wells is the same as that of the islands, but differentiation impurities distinguish them from one another. The organization into islands and into wells may be obtained by photolithography or by a step of self-organization of materials capable of agglomerating spontaneously into islands.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

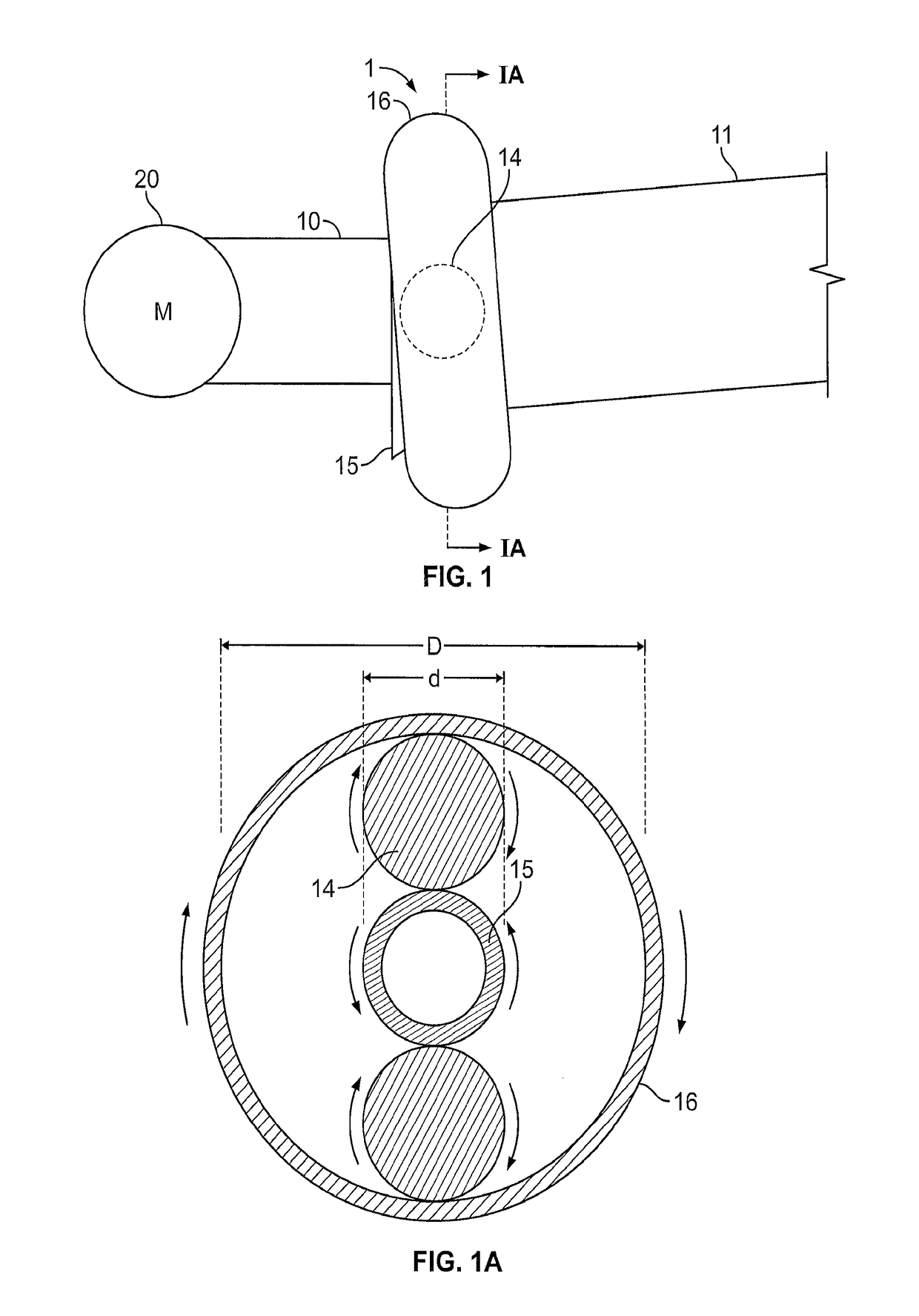

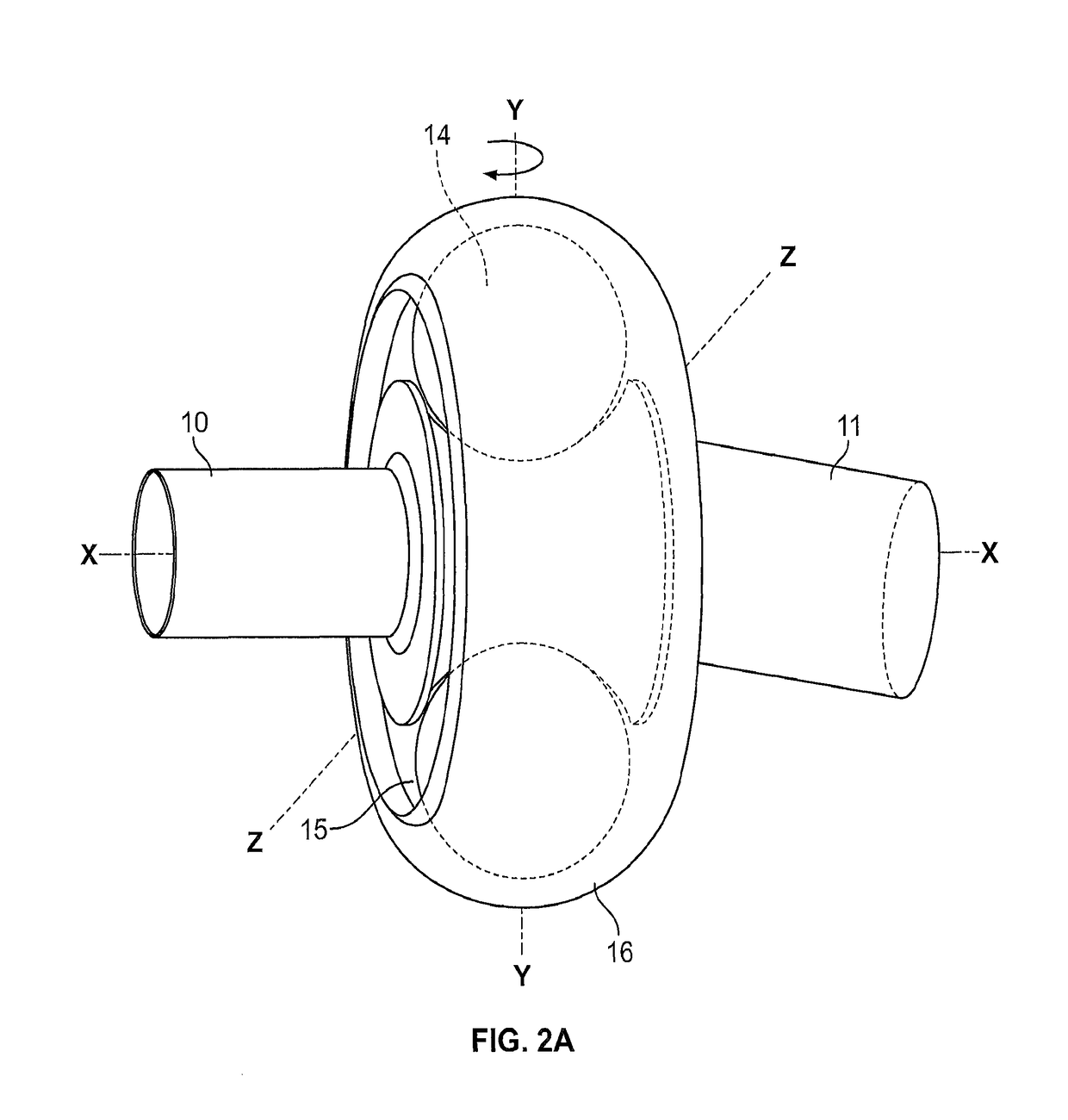

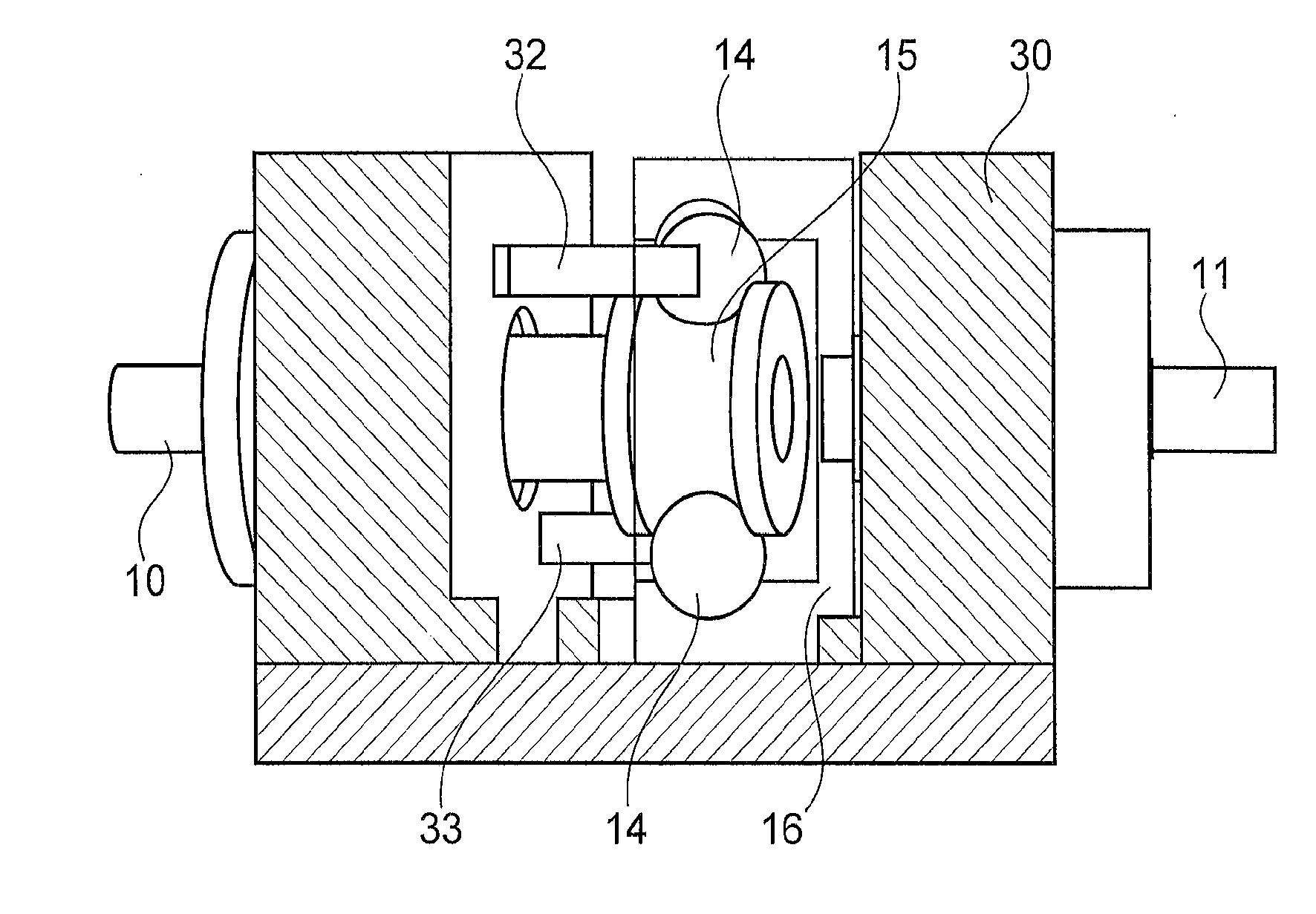

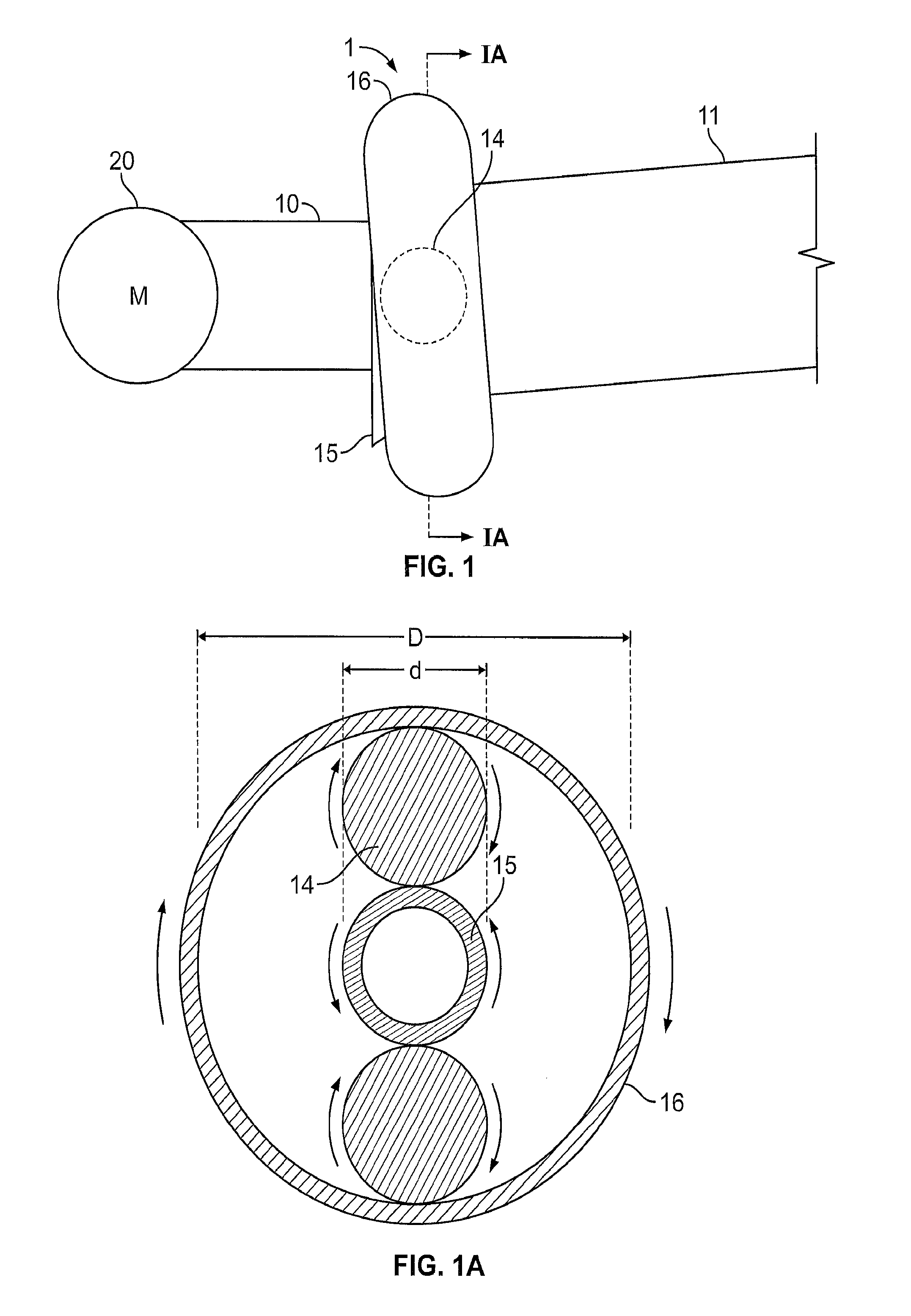

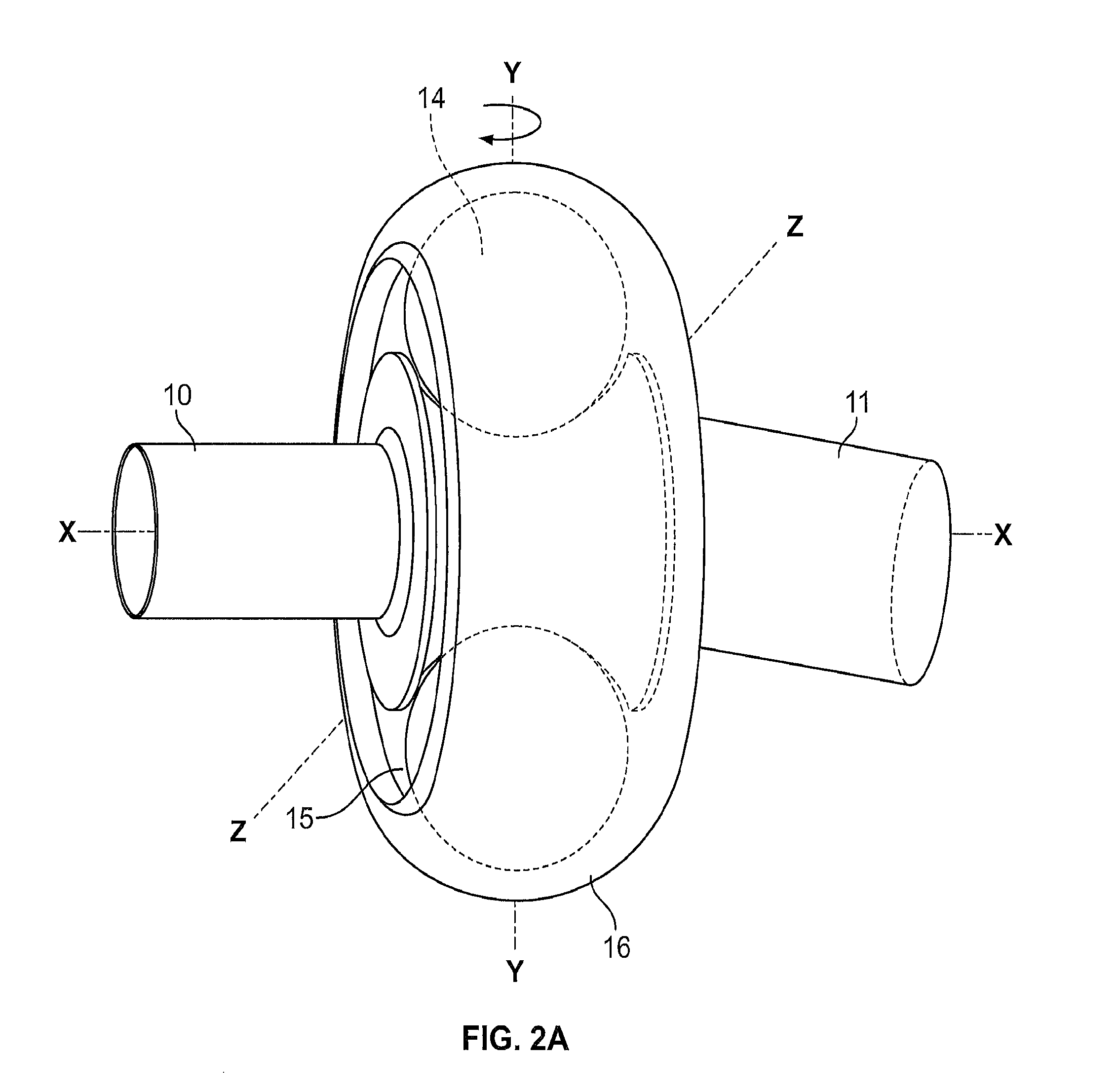

Gearless speed reducer or increaser

A gearless speed reducer or increaser consists of an input shaft, an output shaft, and a motor connected to the input shaft. There is an external race connected to one of the shafts, and an internal race attached to the other shaft. Two ball bearings are disposed between the races and held in place by a finger assist. After the ball bearings have been inserted, the shafts are tilted relative to each other so that the balls become fixed in pockets created between the races and cannot slide within the races.

Owner:MARMALADE TECH LLC

Linear drive system for hair clippers

ActiveUS20140352159A1Precision manufacturingEasy alignmentMetal working apparatusElectric machineryLinear drive

A hair clipper has a base housing, a secondary housing cover, and a rotary motor or vibrator motor secured between the base housing and the housing cover. The rotary motor has a shaft and a cam secured to an end of the shaft, and the vibrator motor has a drive arm with a drive finger. A cam follower is operably connected to the cam or drive finger on a top side. The top side of the cam follower also has an elongated guide rail that is operably secured to a guide channel in a blade guide, which in turn is secured to the base housing. A reciprocating blade is operably secured to the bottom side of the cam follower, and a stationary blade is secured to the base housing adjacent the reciprocating blade.

Owner:WAHL CLIPPER

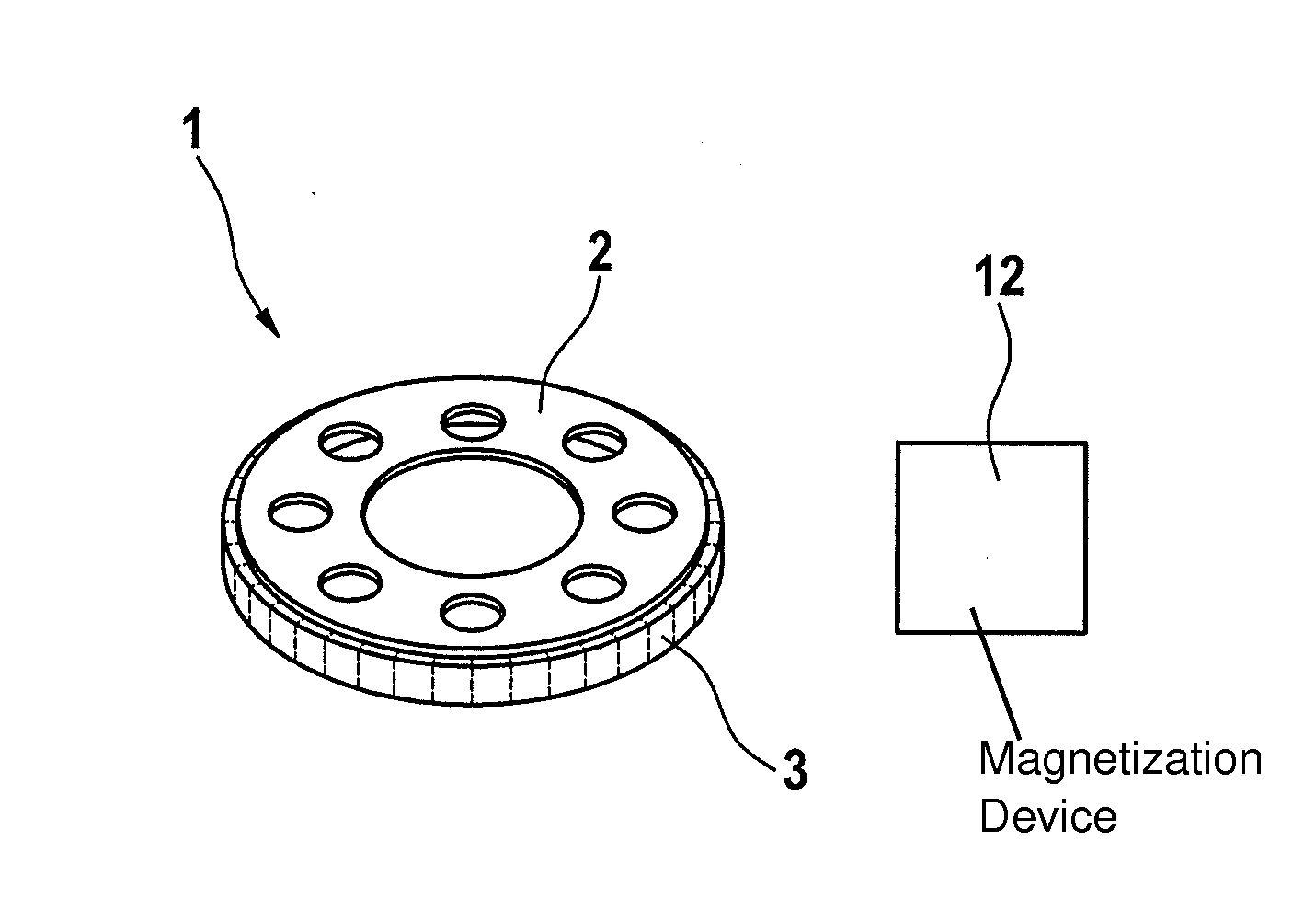

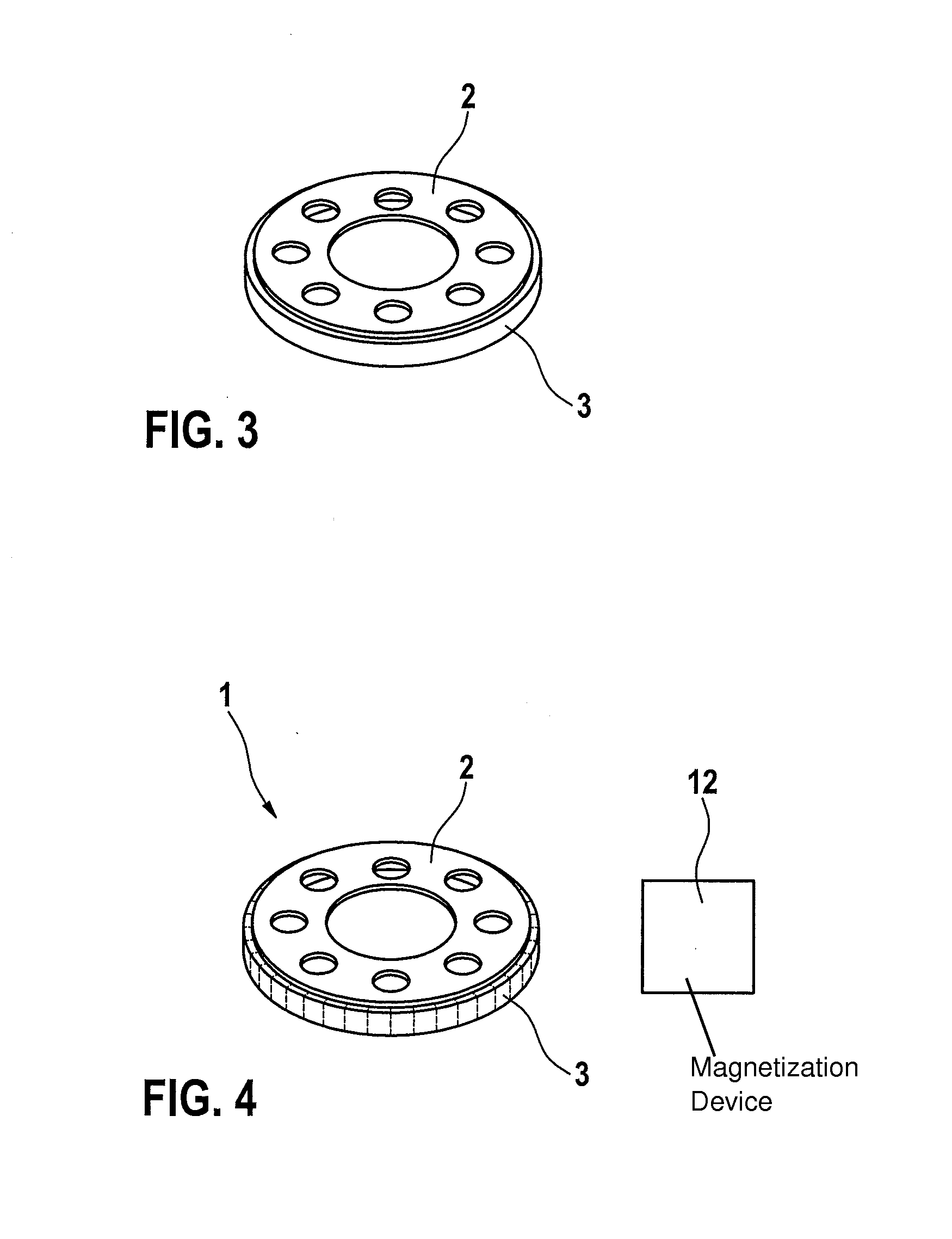

Encoder element and method for the manufacture thereof

InactiveUS20140117978A1Easy and controlled automationMaximum precisionMagnetic measurementsRadiation applicationsEngineeringMagnetic layer

A method is described for manufacturing an encoder element having a base body and a magnetic layer situated on the outer circumference of the base body, including the following steps: providing the base body; providing a magnetic or magnetizable powdery material; directly applying the powdery material to the outer circumference or to an end face of the base body to generate the magnetic layer in such a way that an integral, direct joint is created between the base body and the magnetic layer; and magnetizing the applied magnetic layer.

Owner:ROBERT BOSCH GMBH

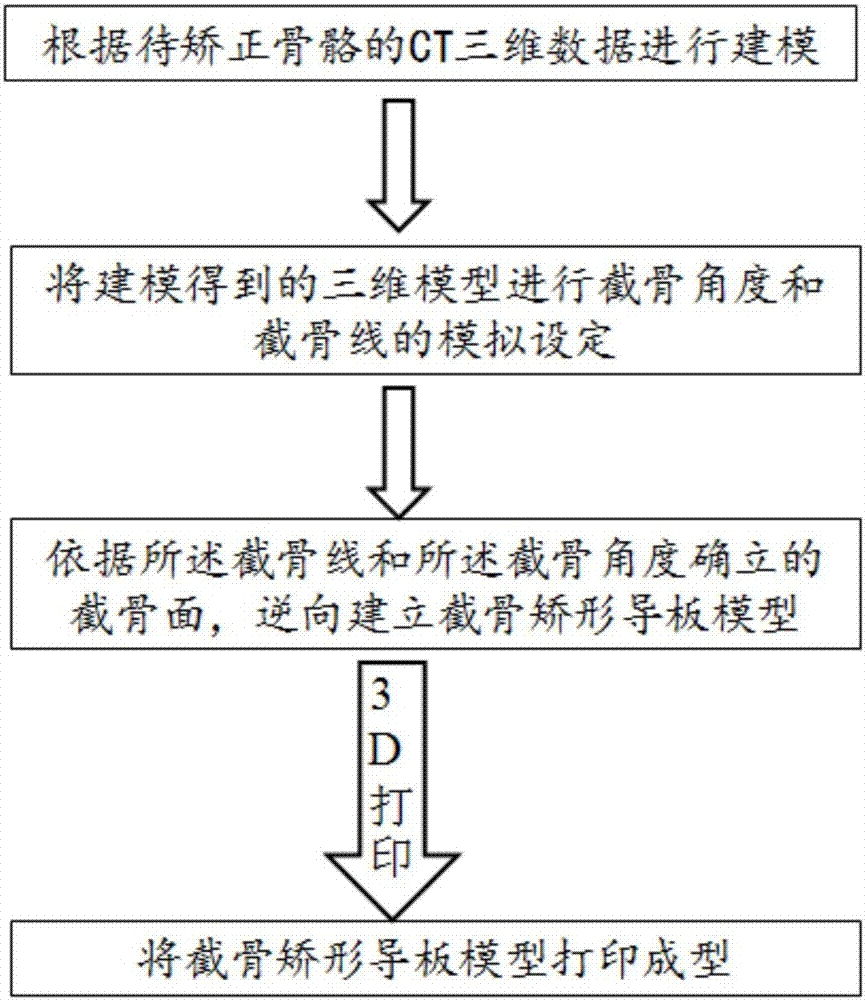

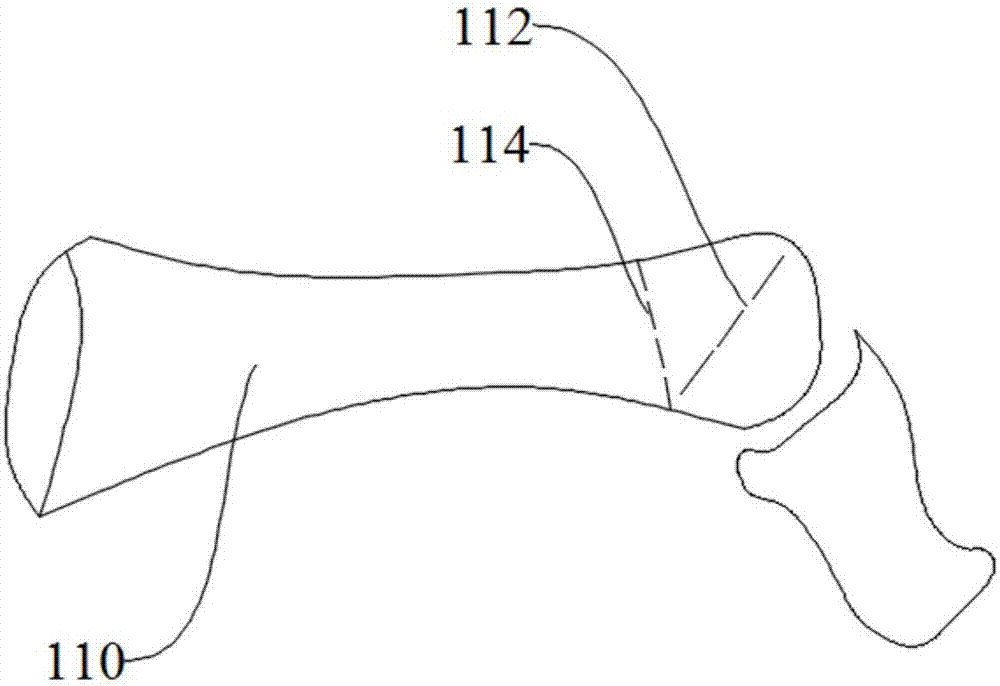

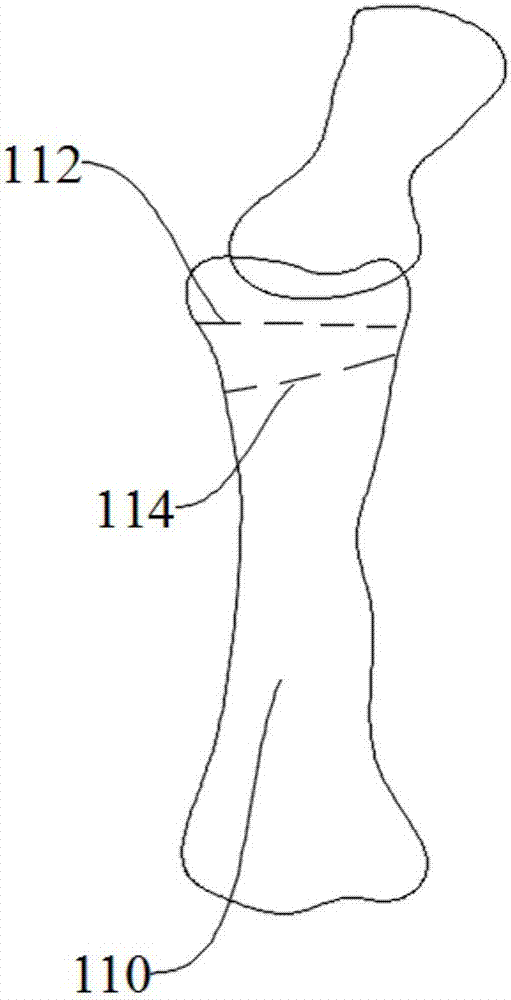

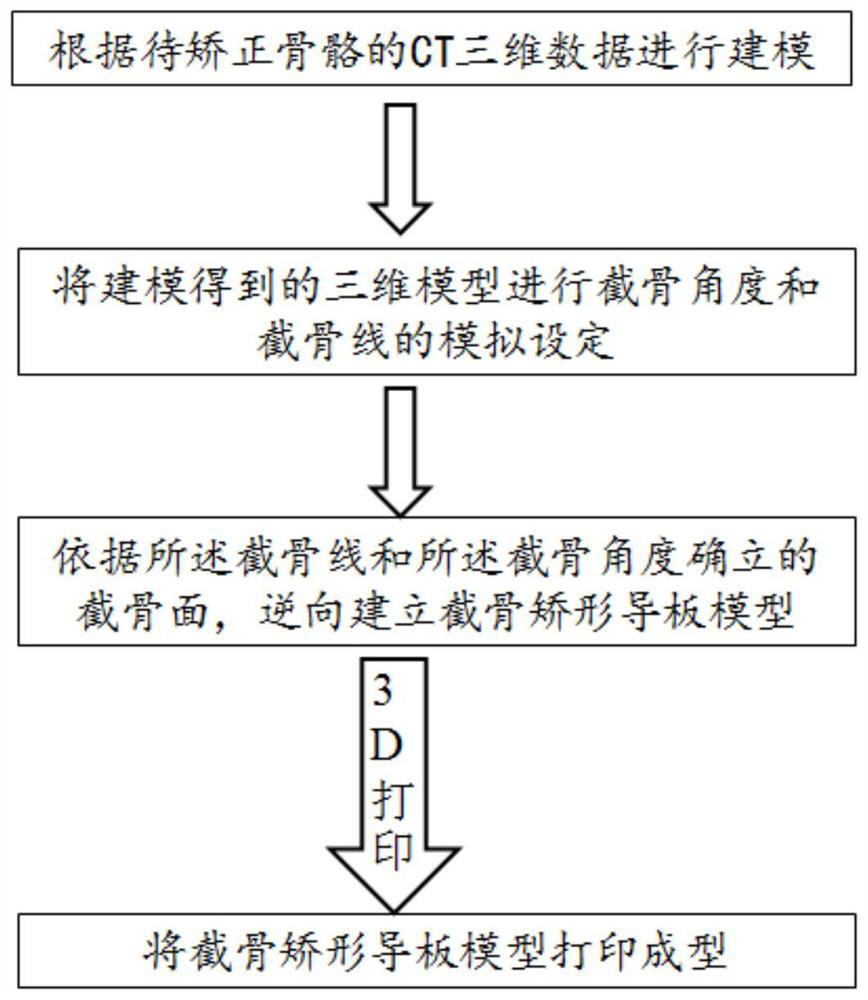

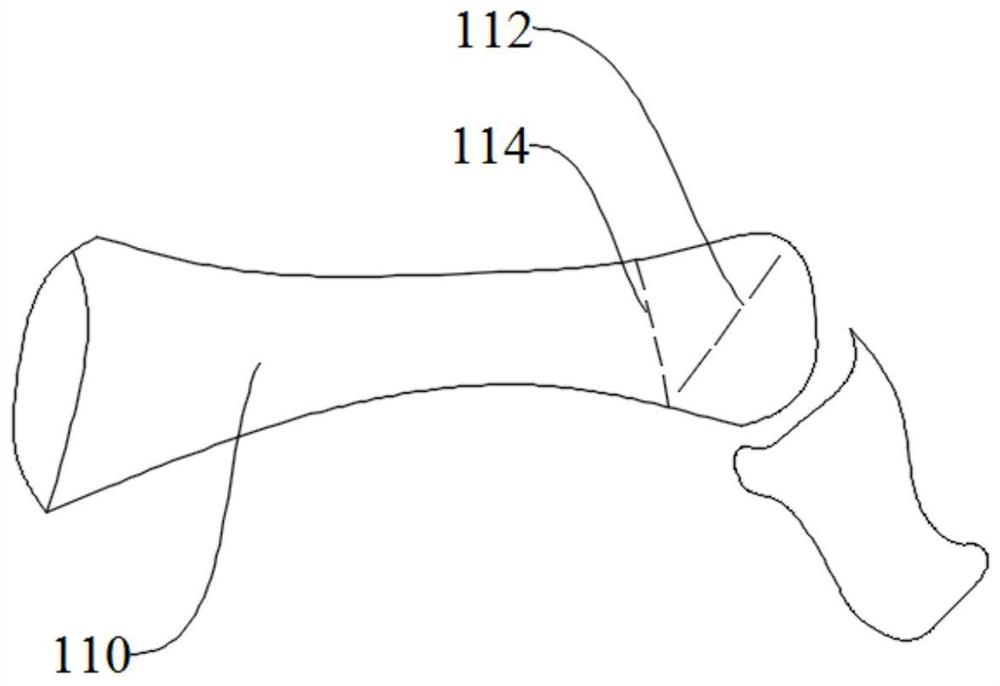

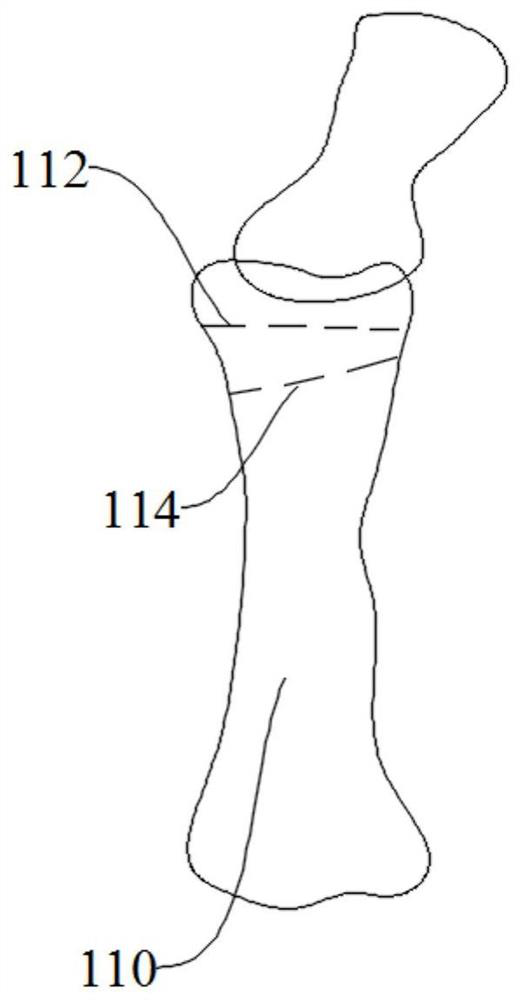

Osteotomy orthopedic guide plate and its manufacturing method

ActiveCN107361815APrecision manufacturingAccurate and reliable orientationAdditive manufacturing apparatusComputer-aided planning/modellingEngineeringOsteotomy

The invention discloses an osteotomy orthopedic guide plate and its manufacturing method, and relates to the field of osteotomy assistant tool design and processing. The manufacturing method of the osteotomy orthopedic guide plate includes steps of building up a data model according to a CT three-dimensional data of a skeleton to be corrected, and accurately matching an osteotomy face built by the surface of the skeleton to be corrected with the osteotomy orthopedic guide plate, so that the osteotomy orthopedic guide plate after the 3D printing and shaping has the accurate and reliable guidance quality. Therefore, the manufacturing method of the osteotomy orthopedic guide plate can accurately and rapidly manufacture the osteotomy orthopedic guide plate in accordance with the operation requirements, help doctors to carry out individual customized design upon specific condition of patients, and realize the technical effects of accurate osteotomy and reliable orthopedic; moreover, the osteotomy orthopedic guide plate manufactured through the manufacturing method can make the practice of the osteotomy more scientific and safer because of its accurate and reliable guidance quality. Therefore, the osteotomy orthopedic guide plate and its manufacturing method have important value of popularization and application.

Owner:张永飞

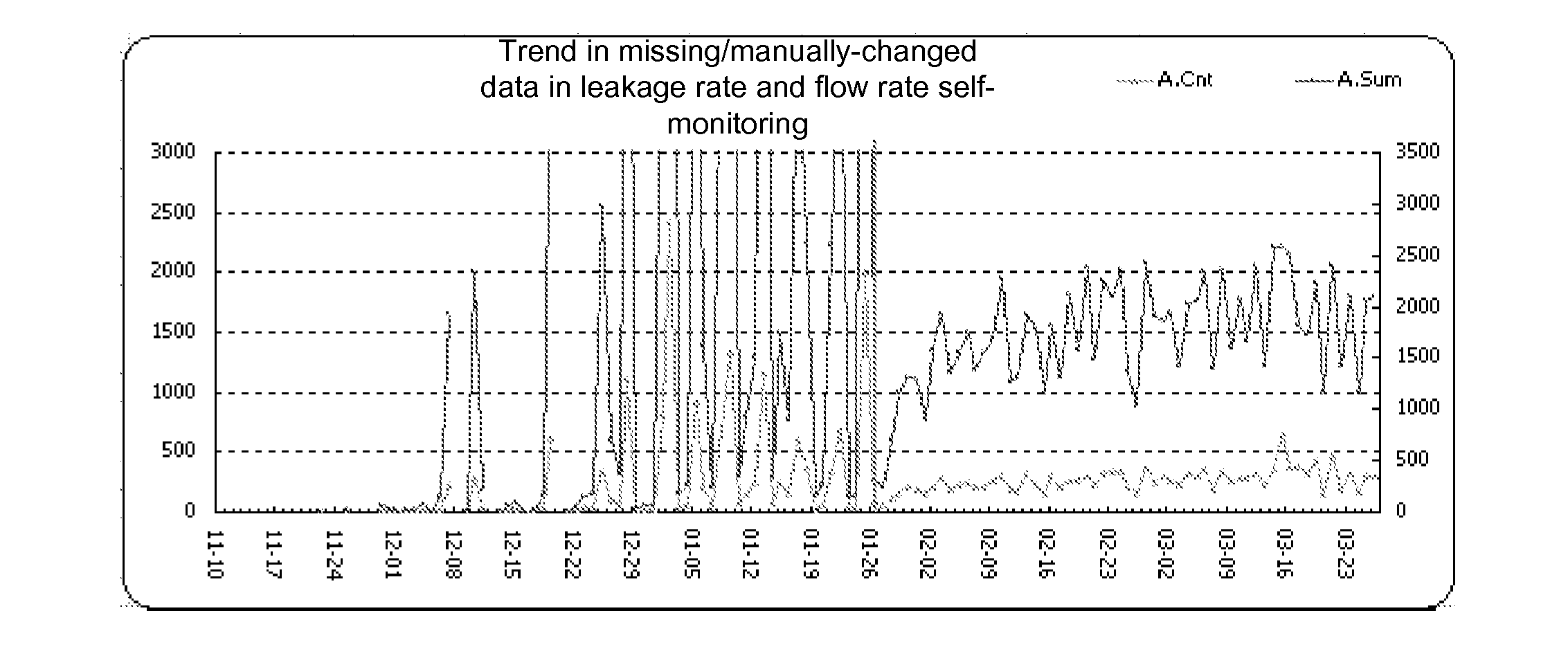

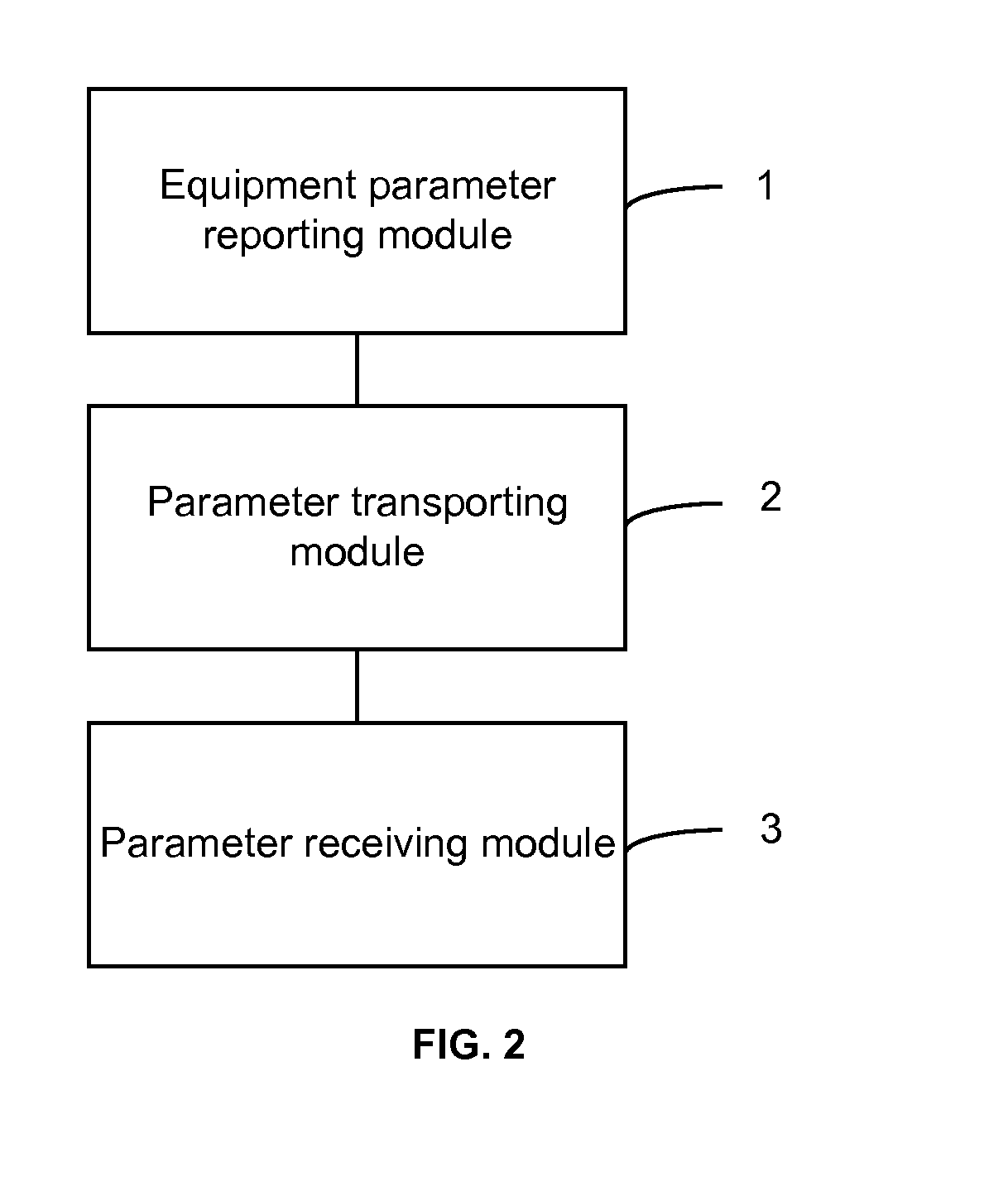

Method and system for automatically collecting semiconductor manufacturing parameters

ActiveUS20150287621A1Precision manufacturingIncrease productivitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingManufacturing execution systemElectronic data

A method for automatically collecting semiconductor manufacturing parameters of a manufacturing equipment is provided. The method includes reporting semiconductor manufacturing parameters obtained by self-monitoring of the manufacturing equipment and obtaining storage locations in an electronic data capture corresponding to reported semiconductor manufacturing parameters and transporting the reported semiconductor manufacturing parameters and corresponding storage locations. The method further includes receiving the reported semiconductor manufacturing parameters and the corresponding storage location and storing each reported semiconductor manufacturing parameters automatically into the electronic data capture of a manufacturing execution system according to the corresponding storage location.

Owner:SEMICON MFG INT (SHANGHAI) CORP

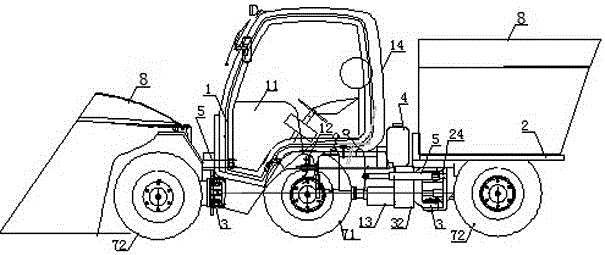

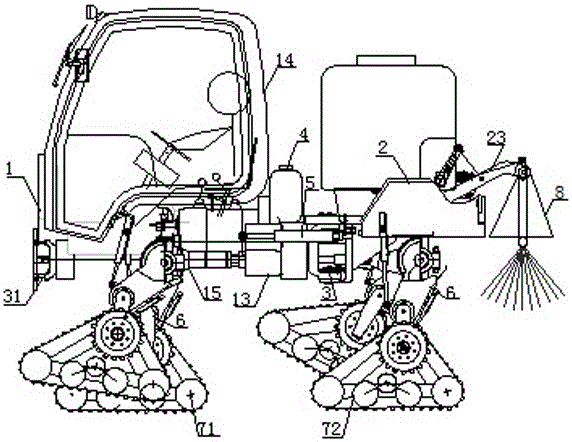

Articulated hillside tractor with cascaded efficiency power transmission system

ActiveCN106585369APrecision manufacturingCompact structureEndless track vehiclesControl devicesClutchTractor

The invention relates to an articulated hillside tractor with a cascaded efficiency power transmission system. A main machine includes power, a clutch, an efficient power transmission system, a cockpit, a front profiled hinge, a rear profiled hinge, a main bridge and a host walking system; an auxiliary machine includes an auxiliary bridge, a rack, a lifter, a steering arm and an auxiliary walking system; a high-power box, a gearbox and a combiner box are connected in series so as to form the efficiency power transmission system; the high-power box includes an input shaft, an input end gear pair, a power output shaft, a front gear pair, an outgoing end gear pair and a front power shaft; a universal gearbox is adopted as the gearbox; and the combiner box includes a power take-off gear pair, a power take-off shaft, a planetary gear train, a differential large gear, a front shaft, a rear shaft, an inter-shaft differential mechanism, a bevel gear pair, a main bridge differential mechanism, a main bridge half shaft, a hydrostatic transmission or a motor and a motor gear. The articulated hillside tractor has the advantages of front and back power interfacing, power stepless speed change, chassis exchange and simple production, and can assist in preventing the burnout of a transmission part.

Owner:廖建群

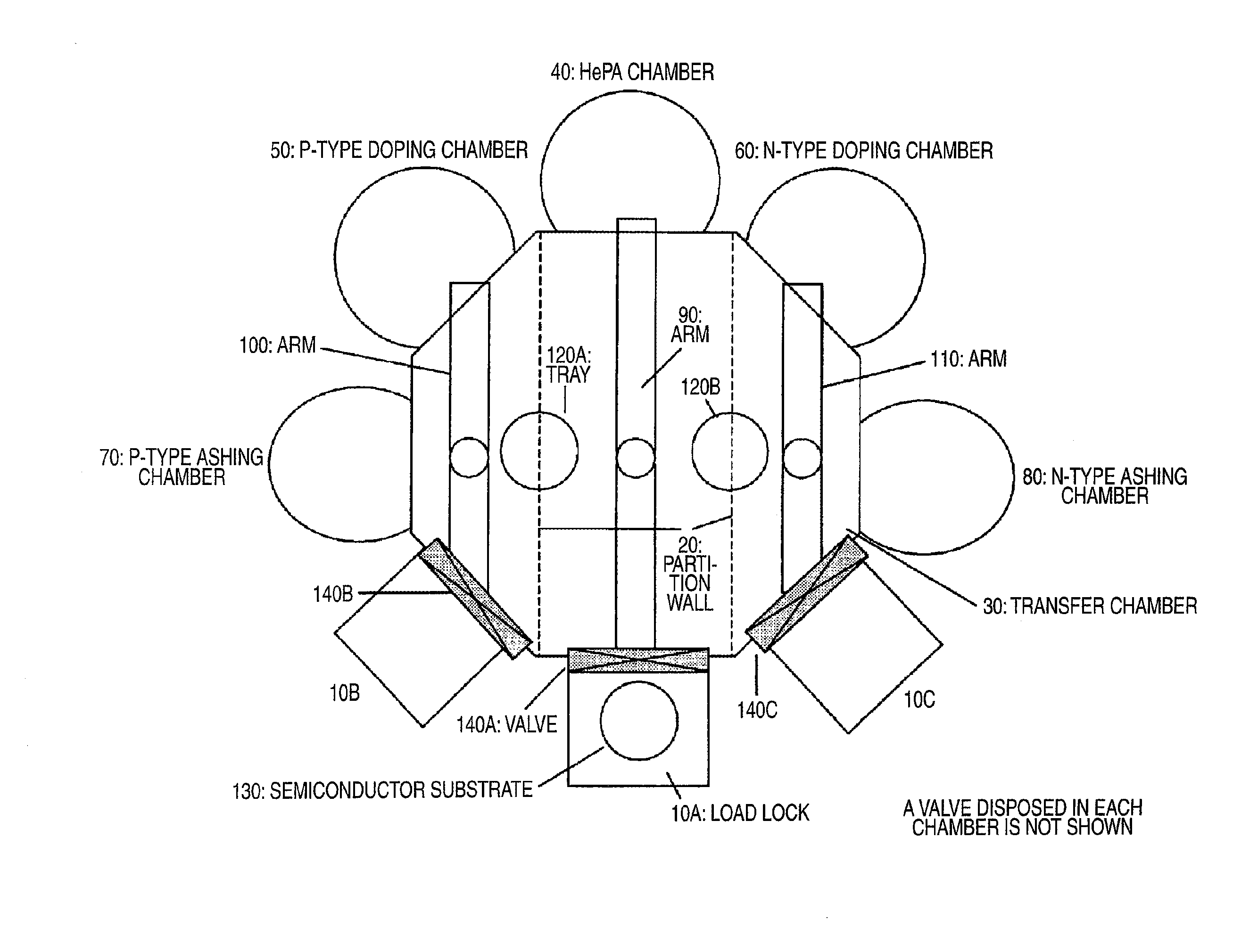

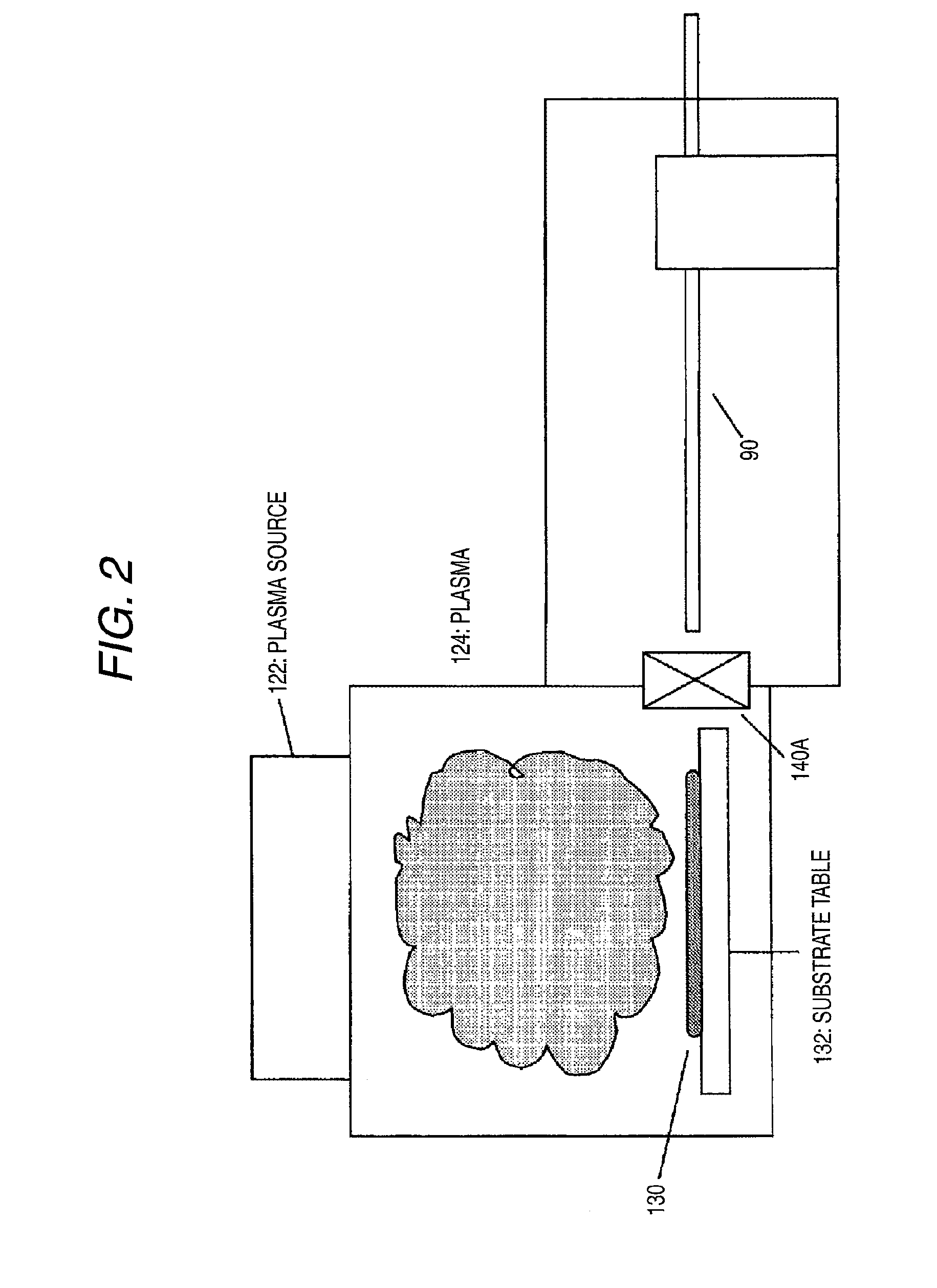

Impurity introducing apparatus and impurity introducing method

InactiveUS20080166861A1Made preciselyHigh energyElectric discharge tubesSemiconductor/solid-state device manufacturingSemiconductorImpurity

It is an object to prevent functions expected originally from being unexhibited when impurities to be introduced into a solid sample are mixed with each other, and to implement plasma doping with high precision. In order to distinguish impurities which may be mixed from impurities which should not be mixed, first of all, an impurity introducing mechanism of a core is first distinguished. In order to avoid a mixture of the impurities in very small amounts, a mechanism for delivering a semiconductor substrate to be treated and a mechanism for removing a resin material to be formed on the semiconductor substrate are used exclusively.

Owner:PANASONIC CORP

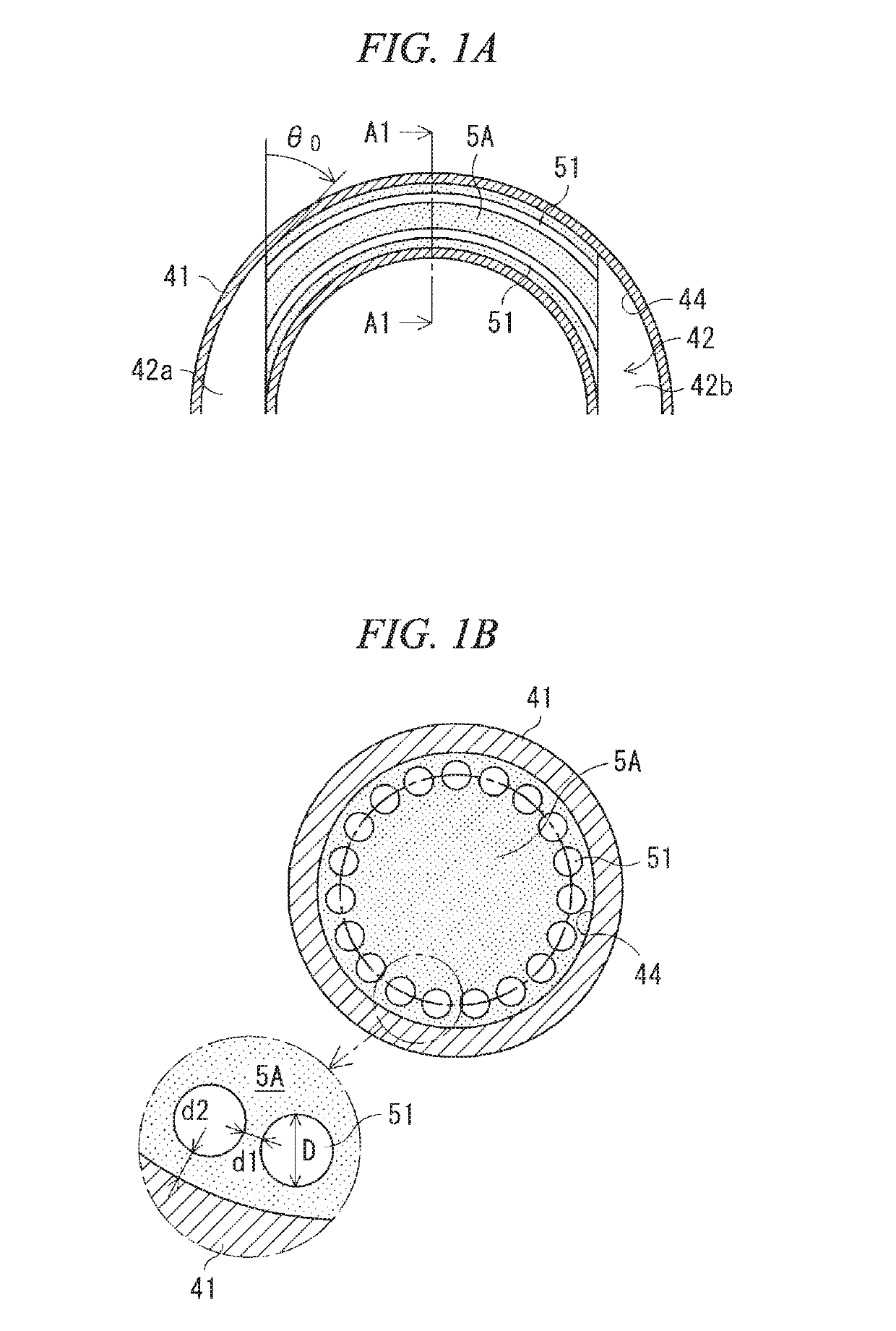

Support member for additive manufacturing, production method and production device for three-dimensional object by additive manufacturing, manufactured object model creation device, control device, and manufacturing method for manufactured object

ActiveUS20190105712A1Secure shape accuracyEasy to disassembleAdditive manufacturing apparatusIncreasing energy efficiencyAdditive layer manufacturingManufactured Object

This support member for additive manufacturing is a support to be disposed below a manufactured portion of a particular overhanging portion of the three-dimensional object which needs the support in the process of additively manufacturing the three-dimensional object. The support member is provided with: the support main body; and a polishing channel which is formed in the support main body so as not to be exposed to an interface with the three-dimensional object, and through which a polisher for polishing and removing the support main body is allowed to pass.

Owner:MITSUBISHI HEAVY IND LTD

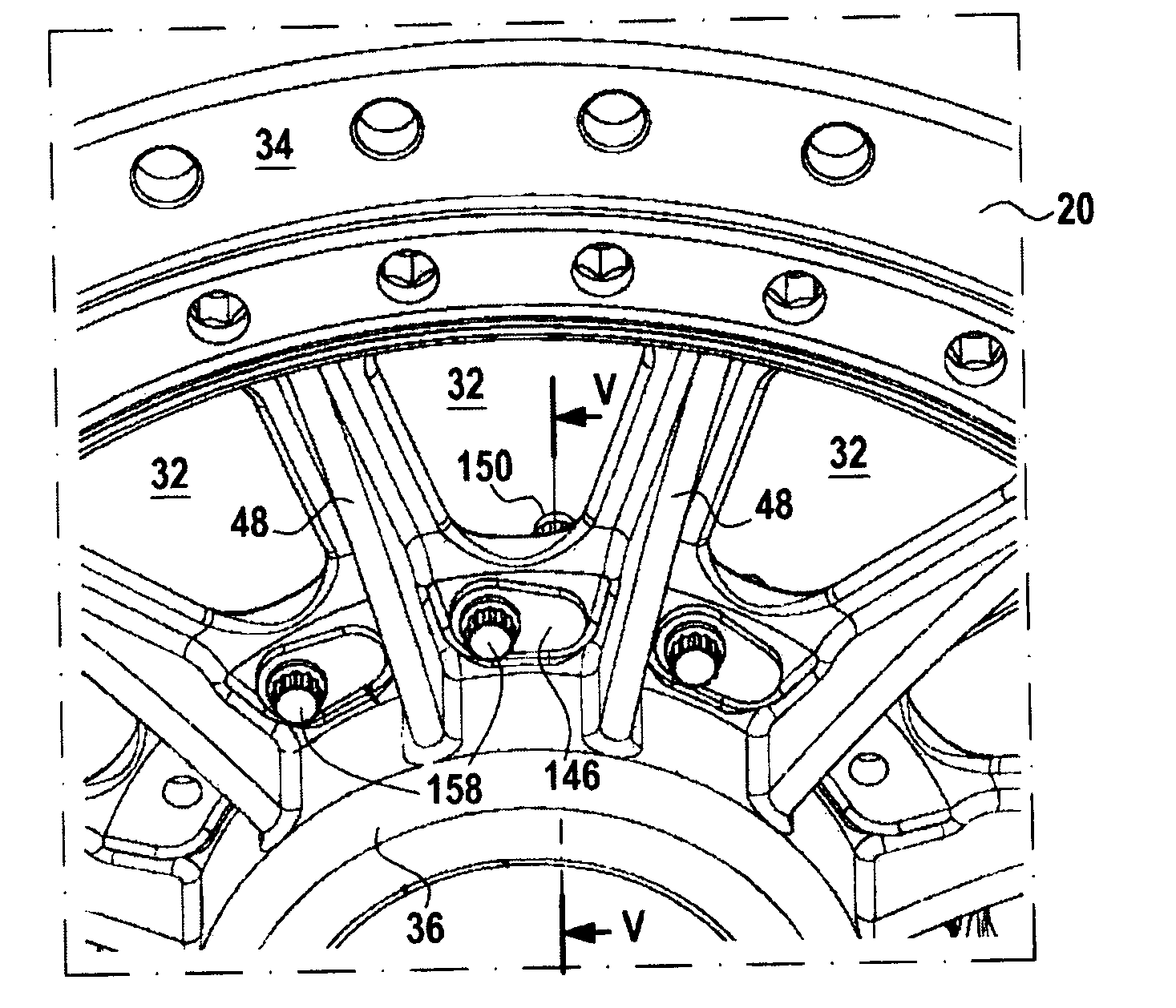

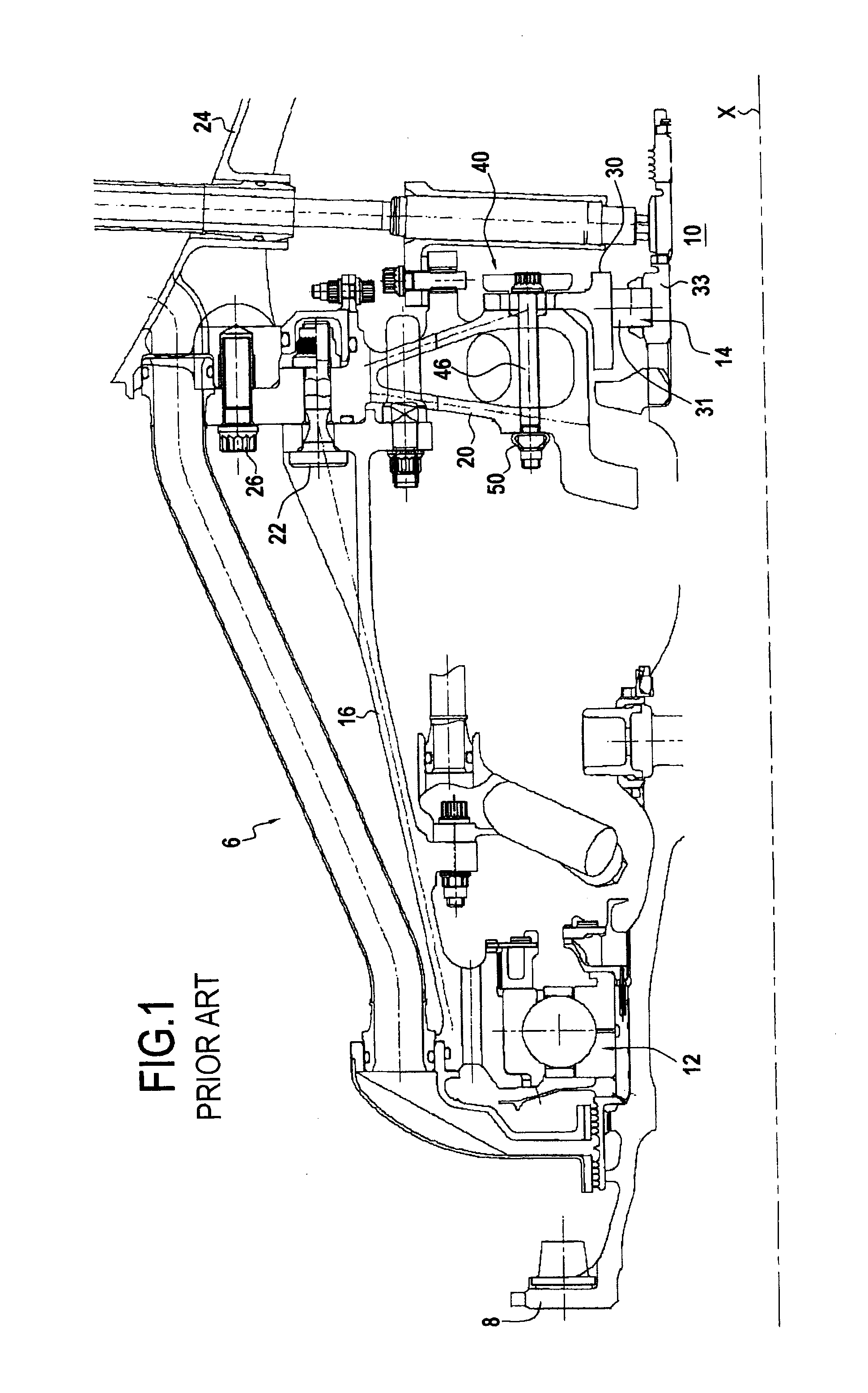

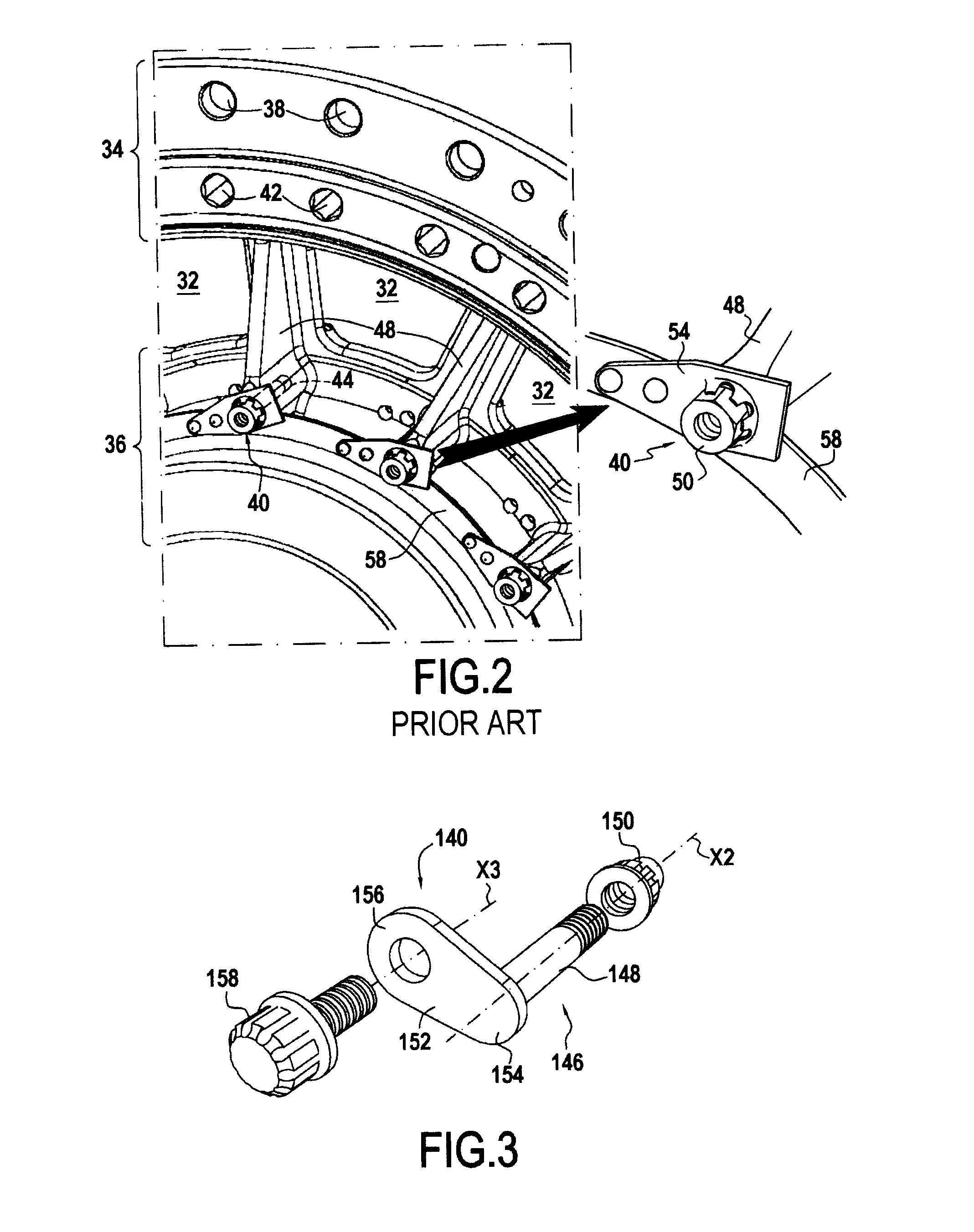

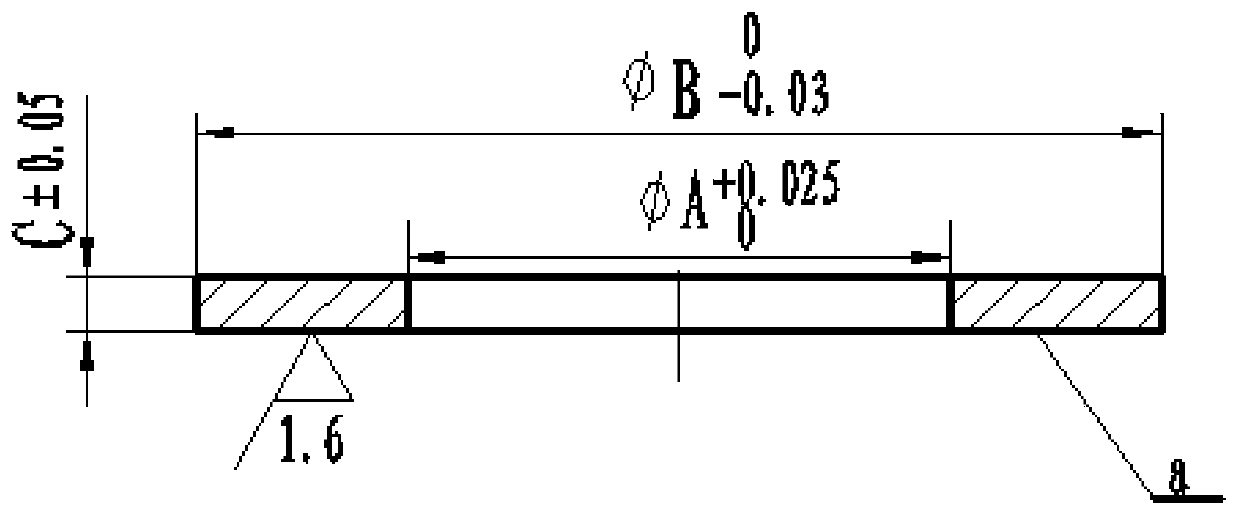

Turbomachine optimized for fastening a rotary shaft bearing. a method of mounting said bearing on said turbomachine

A turbomachine including a shaft, a bearing for supporting the shaft and including an outer ring, and a support for said bearing, the support having a flange to which the outer ring is fastened by fasteners; each fastener comprising a fastener bolt and a nut screwed together; the turbomachine also including for each fastener, position-retention means for retaining the bolt, and suitable for retaining the bolt in a position that is stationary relative to the bearing support or the outer ring, even in the absence of the nut. The head of the fastener bolt and the position-retention means may be of small dimensions, thereby enabling the fastening of the flange to the bearing support to be optimized, and in particular enabling the weight of said fastening to be optimized. The invention also provides a method of mounting said bearing of the turbomachine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Method for processing swirler and method for validating air flow of swirler

ActiveCN110823581APrecision manufacturingImprove machining accuracyEngine testingProcess engineeringIndustrial engineering

The invention provides a method for processing a swirler and a method for validating air flow of the swirler. The processing method comprises the steps of: 1) modeling a theoretical size of the swirler; 2) determining the range of the runner of the model; 3) splitting the swirler into two parts to perform additive manufacturing or subtractive manufacturing; 4) controlling the flatness, the processing benchmark and the perpendicularity of the splitting surfaces of two splitting pieces when processing the splitting surfaces, and separately processing the split parts; and 5) processing and assembling the splitting pieces according to the model. The validating method comprises the steps of: adjusting and validating the flow data by a standard specimen for several times so that the detection data is consistent with the standard specimen; testing the flow of the maximal air runner by a number of assembly parts; testing the flow of the minimal air runner by a number of assembly parts; comparing the average value with the designed theoretical flow value; validating that the size and the tolerance of the designed structure satisfy the flow requirement if the flow detection average value accords with the designed calculated value; and otherwise, validating that the requirement is not satisfied. By adoption the methods provided by the invention, the swirler can be manufactured and measured rapidly and precisely.

Owner:AECC AVIATION POWER CO LTD

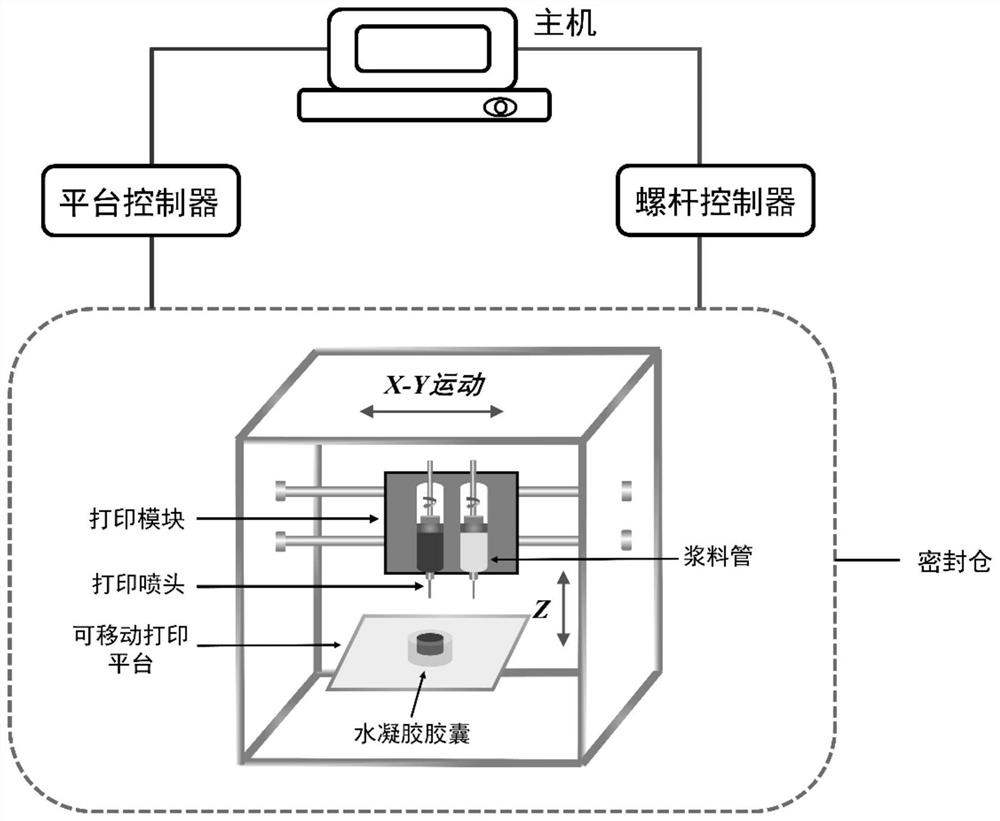

Programmable intelligent controlled-release capsule as well as application and preparation method thereof

ActiveCN112843022APrecision manufacturingImprove personalizationAdditive manufacturing apparatusPharmaceutical non-active ingredientsControlled releasePharmacy medicine

The invention provides a programmable intelligent controlled-release capsule as well as application and a preparation method thereof. The capsule is of a shell-core type structure prepared through 3D printing, a shell of the capsule is hydrogel, and an inner core of the capsule is a medicine with a treatment effect. The capsule can respond in real time through in-vivo environment temperature stimulation, intelligent controlled release is achieved, the preparation process is simple, and personalized customization of specific individuals on the medicine is facilitated.

Owner:JILIN UNIV

Gearless speed reducer or increaser

A gearless speed reducer or increaser consists of an input shaft, an output shaft, and a motor connected to the input shaft. There is an external race connected to one of the shafts, and an internal race attached to the other shaft. Two ball bearings are disposed between the races and held in place by a finger assist. After the ball bearings have been inserted, the shafts are tilted relative to each other so that the balls become fixed in pockets created between the races and cannot slide within the races.

Owner:MARMALADE TECH LLC

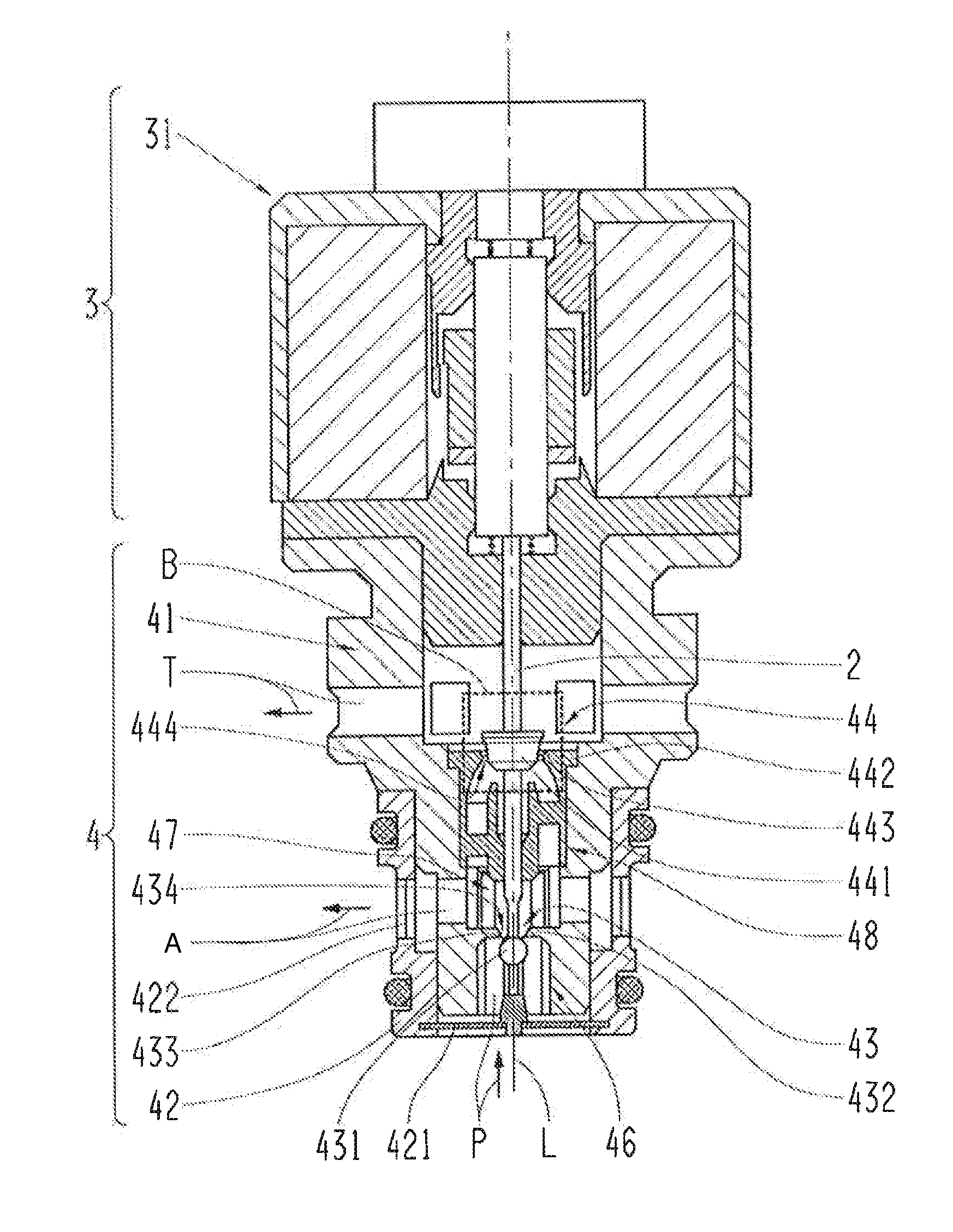

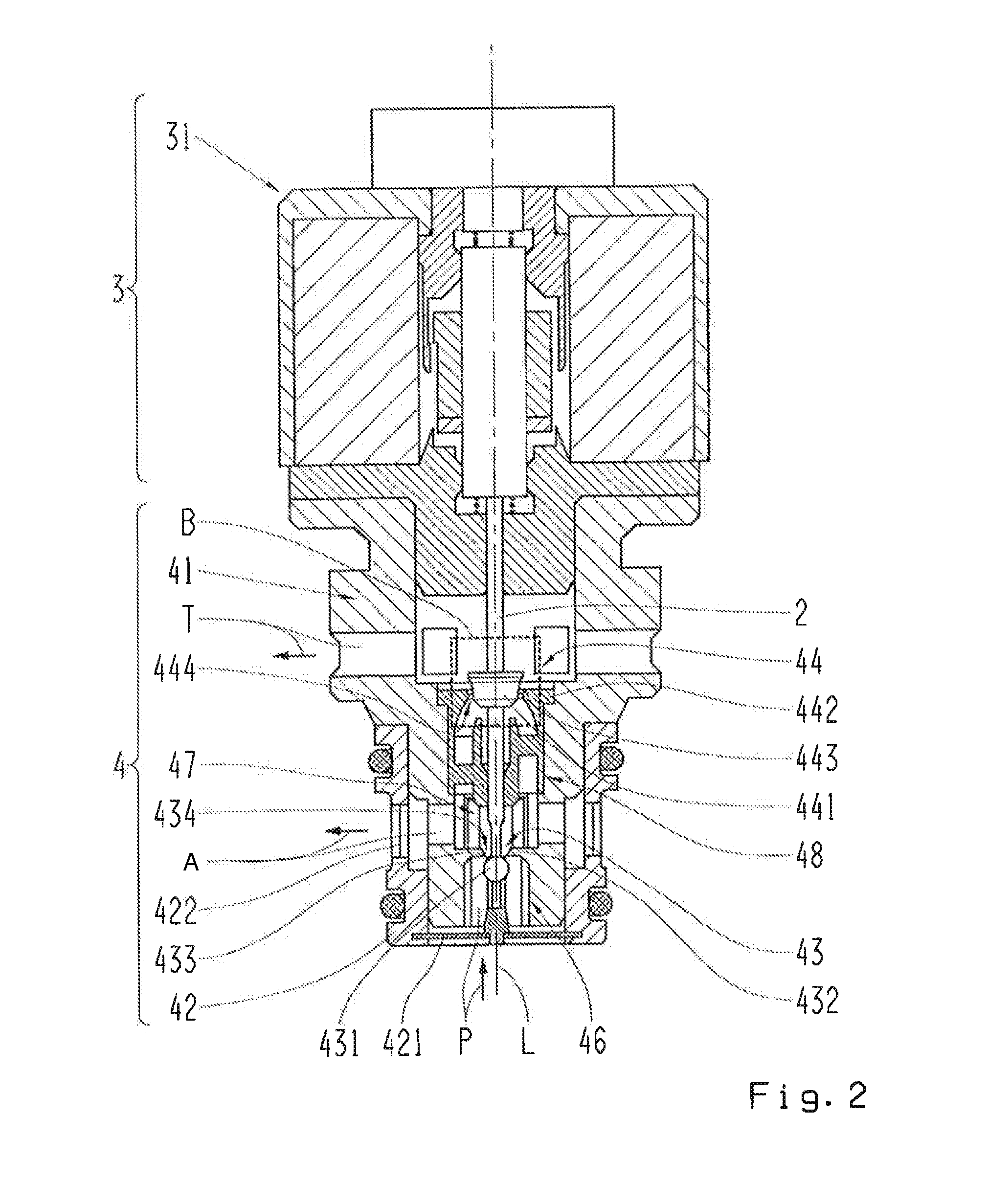

Fluid valve for a vehicle transmission

InactiveUS20150013800A1Easy to produceEasy to manufactureOperating means/releasing devices for valvesCheck valvesEngineeringPressure controlled ventilation

A fluid valve, in particular a pressure control valve in a vehicle transmission, has at least one inlet opening and a first and a second outlet opening, which are connected to each other through two part valves that are mechanically coupled to each other. Whereas, by means of the first part valve, a fluid intake is adjustable from the inlet opening to the first and second outlet opening, and, by means of the second part valve, a fluid discharge is adjustable between the first and second outlet opening. At least the second part valve is designed as a poppet valve, with a cone-shaped closing element that features several taper areas, which have varying taper angles.

Owner:ZF FRIEDRICHSHAFEN AG

Preparation method of high melting point high entropy alloy spherical powder based on laser additive manufacturing

ActiveCN107096923BFast preparationPrecision manufacturingAdditive manufacturing apparatusTransportation and packagingWear resistantHigh energy

The invention discloses a preparation method of high-melting-point high-entropy alloy spherical powder based on laser additive manufacturing. Five or five kinds of high-melting point metal elemental powders are randomly selected from tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum. more than one species and mixed according to a certain ratio; then use a high-energy ball mill for mechanical alloying to obtain a single-phase solid solution powder of a high-melting-point high-entropy alloy; use a hot isostatic pressing process to form a standard powder-making bar; finally use an electrode induction to melt the gas mist The laser direct forming powder is prepared by chemical process; the high melting point high entropy alloy single-phase solid solution powder formed by the present invention can solve the problem of different burning loss rates of different elements caused by the large difference in melting point in the process of laser additive manufacturing of high melting point metal single substance powder And a series of problems such as composition microsegregation and negative eutectic caused by multiple elements can more effectively realize the rapid and precise manufacturing of high-temperature and wear-resistant aerospace special parts and high-performance turbine engine hot-end parts.

Owner:XI AN JIAOTONG UNIV

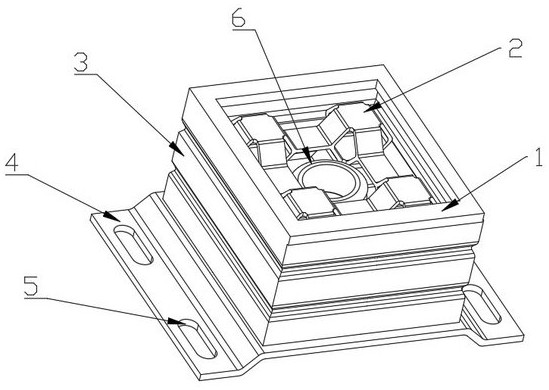

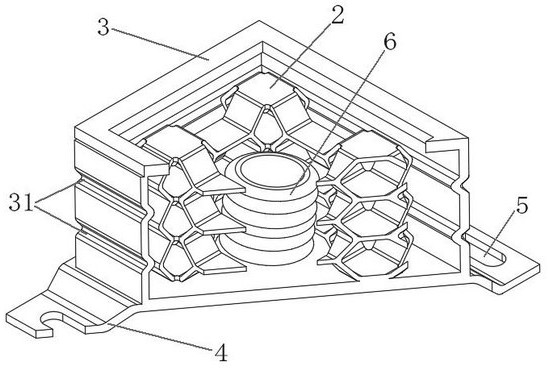

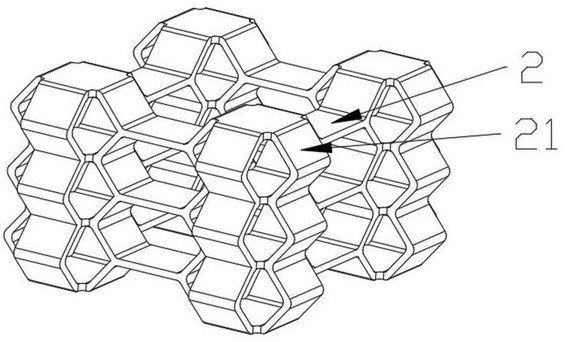

A Recoverable Deformable Automotive Crash Box Based on Additive Manufacturing

ActiveCN112428949BPromote absorptionImprove bearing capacityBumpersEnergy absorptionHigh entropy alloys

The invention discloses a recoverable and deformable energy-absorbing box for automobiles based on additive manufacturing, which comprises an upper end cover, a filling structure, a thin-walled shell, a mounting plate and a thin-walled corrugated pipe, the bottom of the thin-walled shell is provided with a mounting plate, and the mounting plate There are several installation holes on the top, the filling structure is set inside the thin-walled shell, the thin-walled bellows is set inside the filling structure, and the upper end cover is set on the top of the thin-walled shell; the thin-walled shell is detachable from the anti-collision beam of the car through the mounting holes The connection, filling structure, thin-walled shell and thin-walled bellows are integrally printed and formed of high-entropy alloy materials; the invention has excellent energy absorption characteristics, and the filling structure proposed by the invention is a regular hexahedron in which the four sides of the two opposite faces are respectively It is connected with four other unit cell structures in different directions, which improves the energy absorption while improving the bearing capacity of the energy-absorbing box, so that it can maintain the stability and continuity of energy absorption, high bearing capacity, good stability, and can be reused. Reduce car maintenance costs.

Owner:JILIN UNIV

Quick-Release Structure for a Display

ActiveUS20220003355A1Precision manufacturingPrecise positioningStands/trestlesDigital processing power distributionFast releaseDisplay device

The present invention provides a quick-release structure for a display, comprising a stand, a first buckle ring and a second buckle ring. The stand includes a top base, and the top base is connected with a side of a top end of a support frame, where the top base has a front cover and a rear cover that cover oppositely each other. A clamping space is provided between the front cover and the rear cover, and the front cover has an outer periphery having a plurality of notches. The first buckle ring, accommodated and limited in the clamping space in a manner that the first buckle ring can be restored after being rotated, where the first buckle ring is provided with a pushing portion passed through the first limiting hole to push the first buckle ring to be rotated.

Owner:JARLLYTEC CO LTD

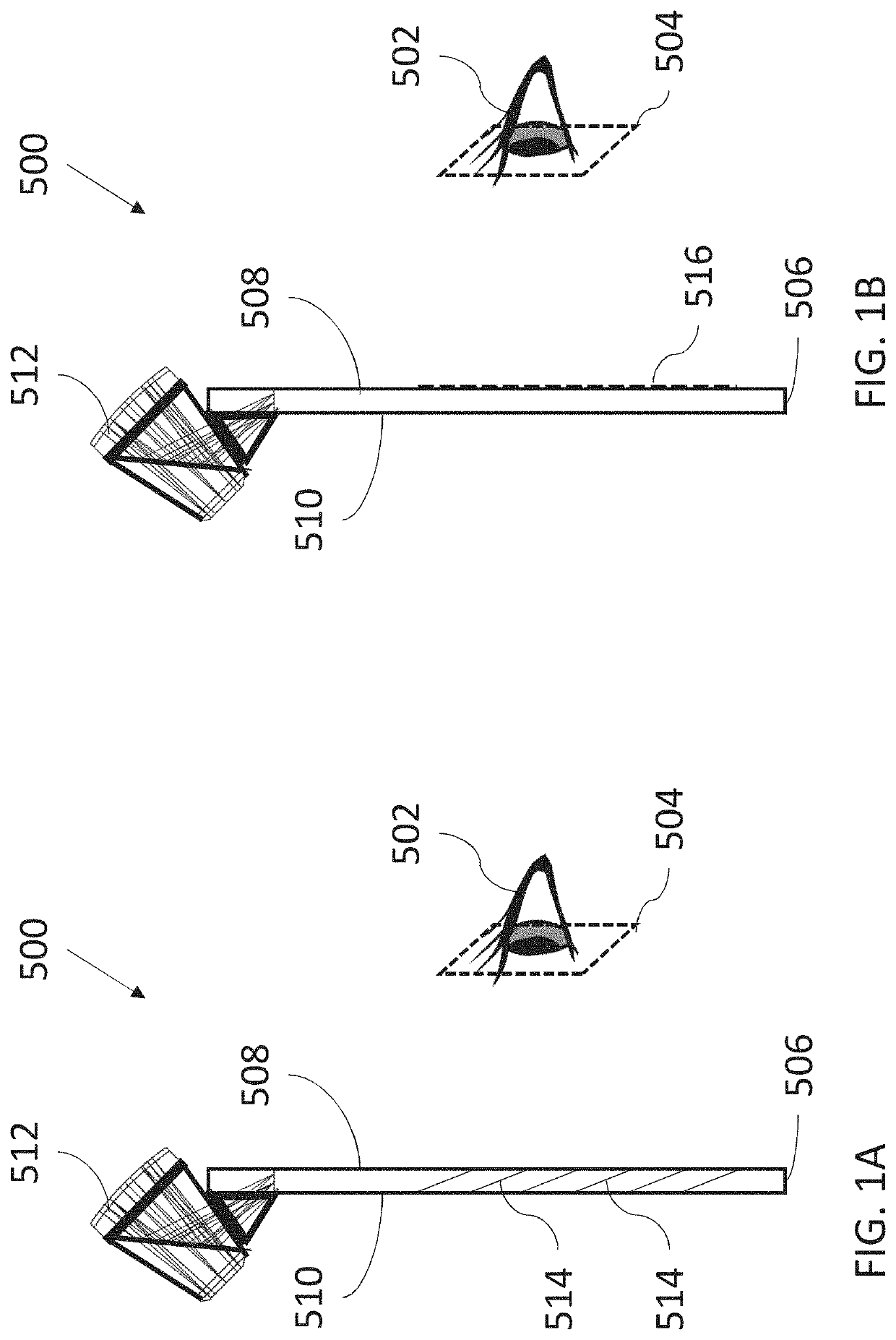

Display with foveated optical correction

PendingUS20220350219A1Reduce optical aberrationPrecision manufacturingInput/output for user-computer interactionMechanical apparatusOphthalmologyImage content

A display system (500) for displaying an image to an eye of a user includes a light-guide optical element (LOE) (506) and an image projector (512) projecting image illumination of a collimated image into the LOE. The image projector includes an electrically-controllable variable lens (10, 13, 71, 77, 58A, 58B, 59, 58C, 58D, 58E, 58F1, 58F2, 58G1, 58G2, 58H, 1223). A controller (18) determines a current region of interest of the image, either from tracking of the user's eye or by analysis of the image content, and controls the variable lens so as to reduce aberrations in the current region of interest at the expense of increased aberration in at least one area of the image outside the current region of interest.

Owner:LUMUS LTD

A kind of osteotomy orthopedic guide plate and its manufacturing method

ActiveCN107361815BPrecision manufacturingAccurate and reliable orientationAdditive manufacturing apparatusComputer-aided planning/modellingOsteotomyReoperative surgery

The invention discloses an osteotomy orthopedic guide plate and its manufacturing method, and relates to the field of osteotomy assistant tool design and processing. The manufacturing method of the osteotomy orthopedic guide plate includes steps of building up a data model according to a CT three-dimensional data of a skeleton to be corrected, and accurately matching an osteotomy face built by the surface of the skeleton to be corrected with the osteotomy orthopedic guide plate, so that the osteotomy orthopedic guide plate after the 3D printing and shaping has the accurate and reliable guidance quality. Therefore, the manufacturing method of the osteotomy orthopedic guide plate can accurately and rapidly manufacture the osteotomy orthopedic guide plate in accordance with the operation requirements, help doctors to carry out individual customized design upon specific condition of patients, and realize the technical effects of accurate osteotomy and reliable orthopedic; moreover, the osteotomy orthopedic guide plate manufactured through the manufacturing method can make the practice of the osteotomy more scientific and safer because of its accurate and reliable guidance quality. Therefore, the osteotomy orthopedic guide plate and its manufacturing method have important value of popularization and application.

Owner:张永飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com