Rapid manufacturing method for laser remelting scanning carbide dispersion strengthened aluminum alloy

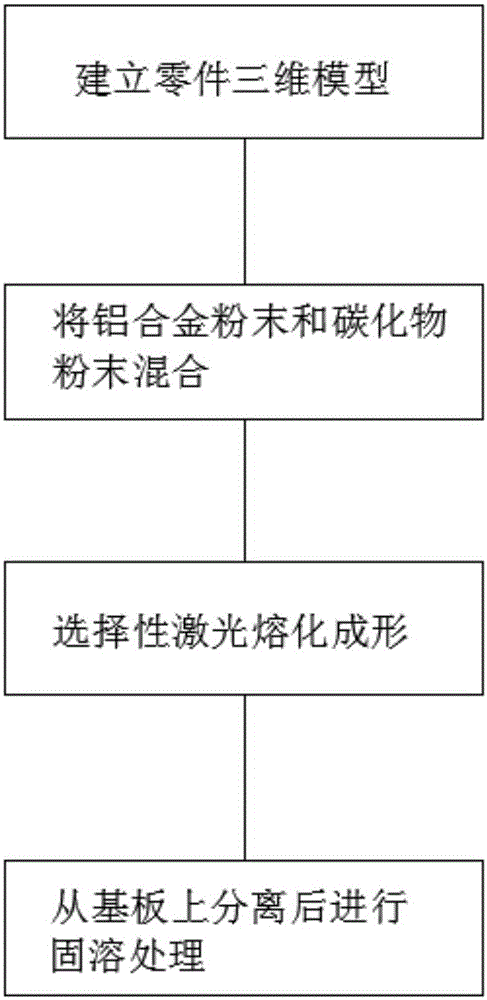

A technology of laser remelting and dispersion enhancement, which is applied in the field of additive manufacturing, can solve problems such as forming failure, and achieve the effects of improving high temperature performance, shortening manufacturing cycle, and precise manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Establish a complex part CAD model according to the actual application needs, and convert the model file into an STL format file for SLM processing.

[0031] (2) Weigh 1.9kg of aluminum alloy powder Al-15Si by SLM forming process. The powder is spherical or nearly spherical, the powder particle size distribution is 20-50 μm, and the oxygen content is lower than 1000 ppm; 0.1 kg of TiC powder with a purity of more than 99.9% is weighed, and the particle size distribution is 100 nm-10 μm. Under the protection of an inert gas, a ball mill is used for ball milling and mixing;

[0032] (3) The laser source is a Yb fiber laser with a wavelength of 1070±10nm, a maximum power of 400W, and a spot diameter of 0.12mm. Under the protection of argon, the mixed powder of aluminum alloy and TiC was formed in three dimensions according to the CAD model, and the remelting scanning strategy was used in the forming process. After the workpiece is cooled, remove the floating powder o...

Embodiment 2

[0035] (1) Establish a part CAD model according to the actual application needs, and convert the model file into an STL format file for SLM processing.

[0036](2) Weigh 1.8kg of aluminum alloy powder AlSi10Mg of SLM forming process. The powder is spherical or nearly spherical, the particle size distribution of the powder is 20-40 μm, and the oxygen content is lower than 1000 ppm. Weigh 0.2 kg of SiC powder with a purity of more than 99.95%, and a particle size distribution of 100 nm-10 μm. Under the protection of an inert gas, a ball mill is used for ball milling and mixing;

[0037] (3) The laser source is Yb fiber laser, the wavelength is 1070±10nm, the maximum power is 400W, and the spot diameter is 0.1mm. Under the protection of argon, the mixed powder of aluminum alloy and SiC is three-dimensionally formed according to the CAD model. During the forming process, the remelting scanning strategy is used to reduce the degree of spheroidization of the parts. After the work...

Embodiment 3

[0040] (1) Establish a part CAD model according to the actual application needs, and convert the model file into an STL format file for SLM processing.

[0041] (2) Weigh 1.98kg of aluminum alloy powder Al-20Si by SLM forming process. The powder is spherical or nearly spherical, the powder particle size distribution is 10-40μm, and the oxygen content is lower than 1000ppm. Weigh 0.02 kg of TiC powder with a purity of more than 99.99%, and a particle size distribution of 100 nm-10 μm. Under the protection of an inert gas, a ball mill is used for ball milling and mixing;

[0042] (3) The laser source is Yb fiber laser, the wavelength is 1070±10nm, the maximum power is 400W, and the spot diameter is 0.15mm. Under the protection of argon, the mixed powder of aluminum alloy and TiC is three-dimensionally formed according to the CAD model, and the remelting scanning strategy is used in the forming process to reduce the degree of spheroidization of the parts. After the workpiece i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com