Preparation method of high melting point high entropy alloy spherical powder based on laser additive manufacturing

A high-entropy alloy and laser additive technology, applied in the field of high-entropy alloys, can solve the problems of uneven composition content, different burning loss rates without comprehensive consideration, and affecting the comprehensive performance of formed parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

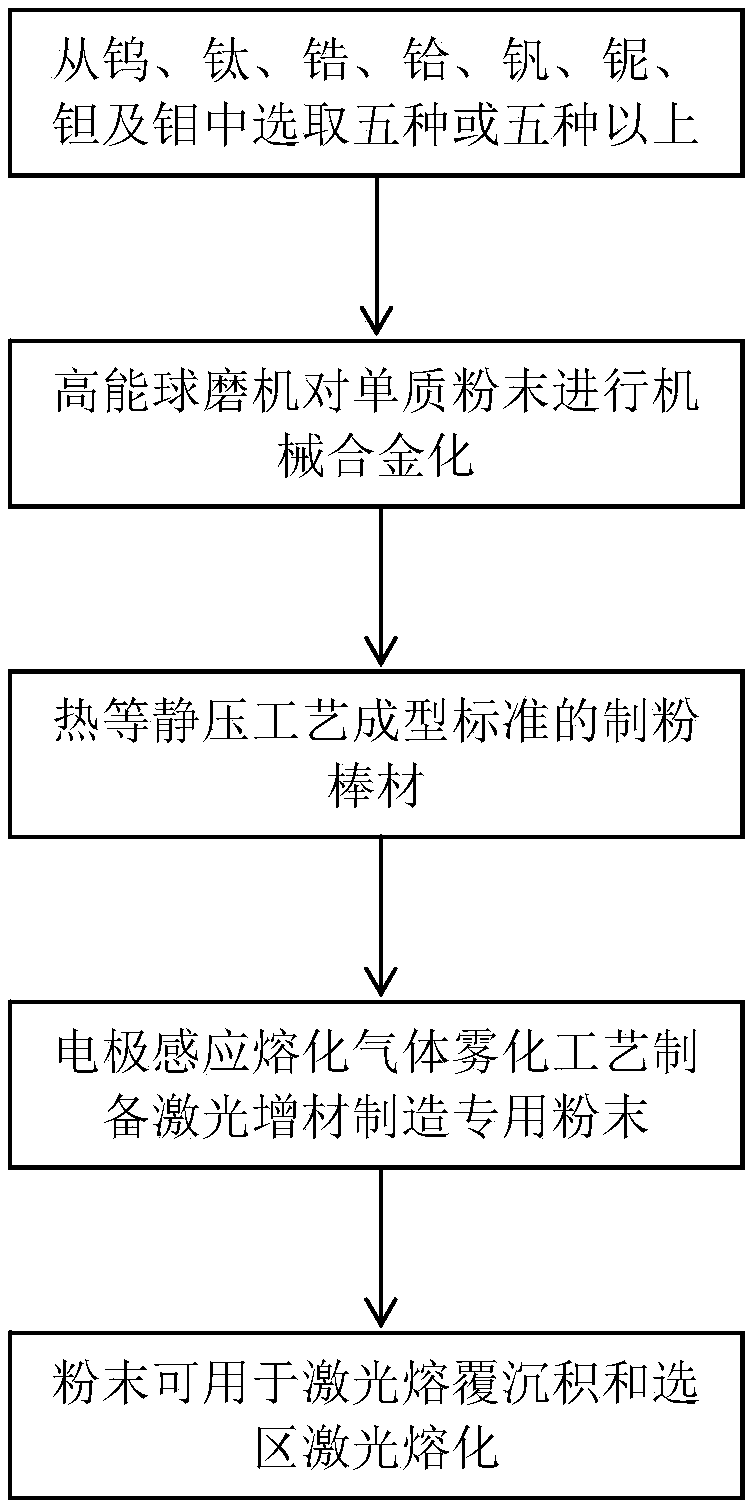

[0030] refer to figure 1 , the present invention is based on the preparation method of high-melting-point high-entropy alloy spherical powder manufactured by laser additive manufacturing, comprising the following steps:

[0031] 1) Select tungsten, titanium, hafnium, vanadium and molybdenum five kinds of high-melting point metal elemental powders from the initial particle size not greater than 270 mesh (53μm) and purity greater than 99.9wt.%, weigh them in sequence and mix them uniformly according to a certain proportion, mix The atomic percentage of each element is between 5% and 30%;

[0032] Five or more can be arbitrarily selected from high-melting point metal elemental powders of tungsten, titanium, zirconium, hafnium, vanadium, niobium, tantalum and molybdenum.

[0033] 2) Use a planetary high-energy ball mill for mechanical alloying. During mechanical alloying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com