Method for processing swirler and method for validating air flow of swirler

A processing method and air flow technology, which are used in the testing, instruments, and measuring devices of machines/structural parts, etc., can solve the problems of large fluctuation, poor consistency, difficult to guarantee blade shape, thickness and size, and achieve accurate measurement, reduce Machining difficulty and the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

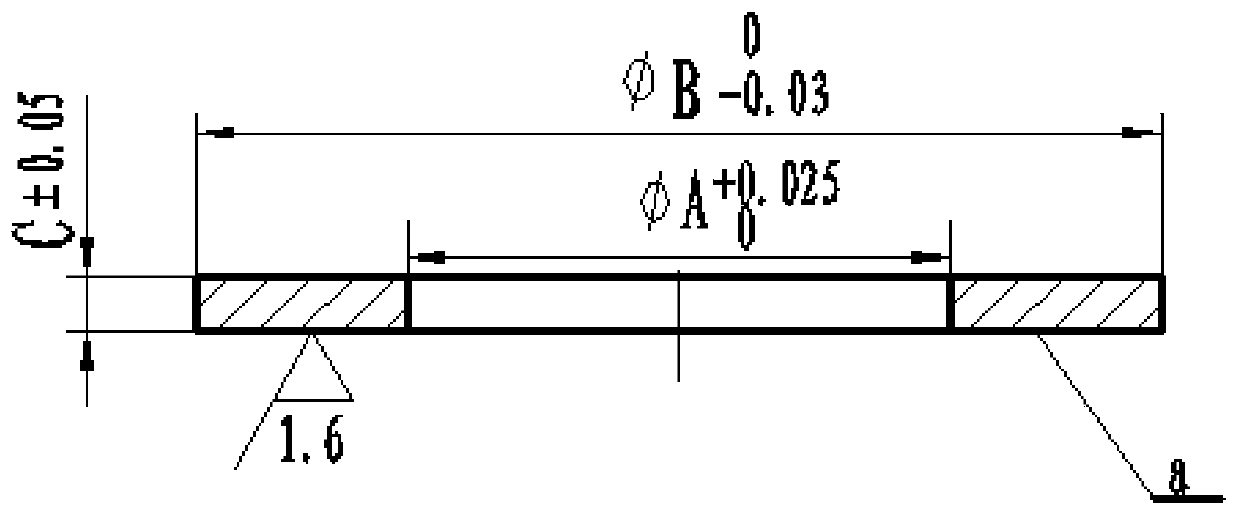

[0042] For a certain type of engine vortex, the material is K536, such as Figure 1-3 Shown, adopt the present invention to carry out the method for verification of theoretical air flow as follows:

[0043] (1) Modeling of vortex generator: use UG for theoretical size modeling

[0044] (2) Determination of the model runner range:

[0045] In this embodiment, a computer is used to construct a theoretical model of flow rate based on dimensional tolerances on the flow channel model of the three-dimensional digital model;

[0046] Maximum flow model: the maximum difference in the height of the flow channel, the minimum value of the blade thickness and the radius of the intake and exhaust.

[0047] The minimum flow model: the minimum height of the flow channel, the maximum blade thickness, and the maximum radius of the intake and exhaust.

[0048] (3) Split the vortex into two parts along the radial section of the part at the position of the flow channel for additive and subtrac...

Embodiment 2

[0056] A certain type of engine has a vortex with a venturi tube, the material is K536, and the method of the present invention is used to verify the theoretical air flow of the vortex. The specific method is as follows:

[0057] (1) Modeling of the vortex: UG is used to model the theoretical size. For the convenience of modeling, the Venturi structure is removed.

[0058] (2) Determination of the range of the flow path of the model: use the computer to construct the theoretical model of the flow rate, the maximum flow model, and the minimum flow model according to the dimensional tolerances on the flow channel model of the three-dimensional digital model.

[0059] Maximum flow model: the maximum difference in the height of the flow channel, the minimum value of the blade thickness and the radius of the intake and exhaust.

[0060] The minimum flow model: the minimum height of the flow channel, the maximum blade thickness, and the maximum radius of the intake and exhaust.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com