System for measuring surface topography of aerospace thin-wall disc part and machining fixture based on digital signal processor (DSP)

A surface topography measurement and processing system technology, applied in metal processing, metal processing equipment, measuring/indicating equipment, etc., to achieve the effect of low cost, fast and high-precision surface topography measurement and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

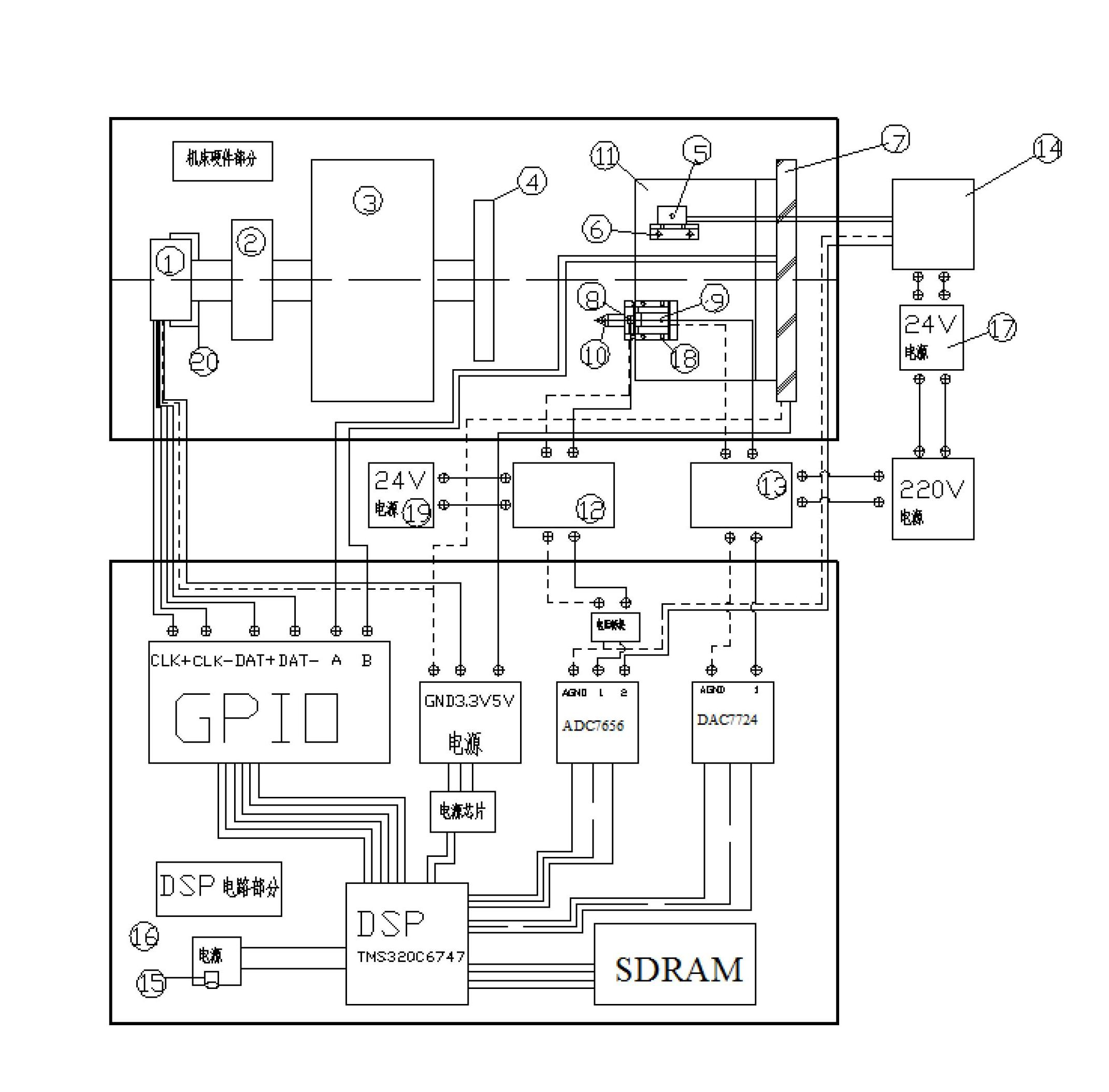

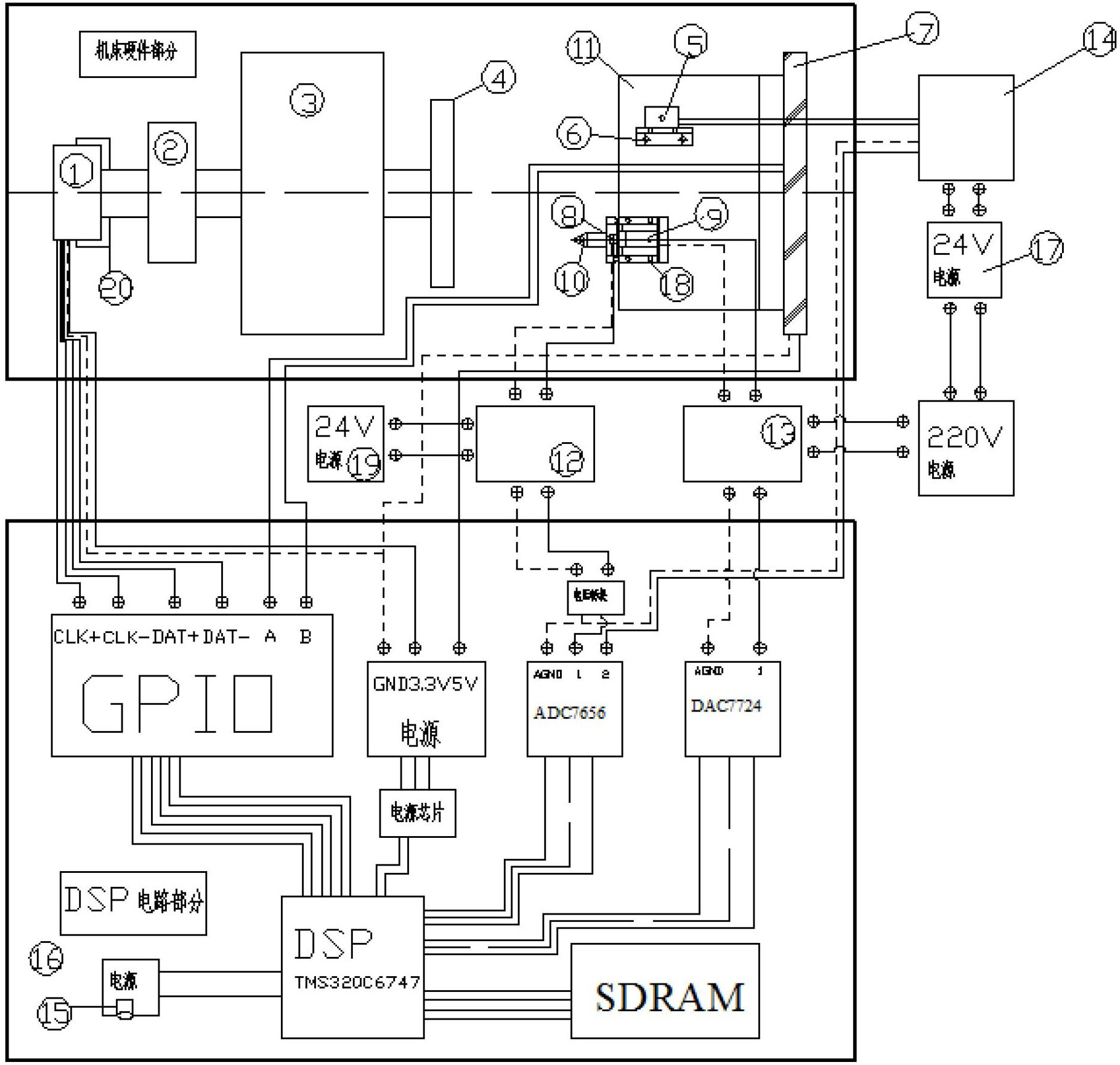

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0040] See figure 1 , figure 2 , the present invention is based on a DSP aviation thin-walled disc surface profile measurement and fixture processing system, which is composed of an absolute encoder 1, an elastic coupling 2, an experimental platform 3, a thin-walled workpiece 4, and a laser displacement sensor Measuring head 5, laser displacement sensor measuring head holder 6, linear grating ruler 7, capacitive sensor measuring head 8, piezoelectric ceramic displacement driver 9, single crystal diamond turning tool 10, fixture installation platform 11, capacitive sensor signal amplifier 12, pressure sensor Electric ceramic power amplifier 13, laser displacement sensor controller 14, DSP development board 5V power supply 15, DSP development board 16, laser displacement sensor power supply 17, fast servo tool holder 18, capacitive sensor power supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com