Light emitting diode load board and manufacturing process thereof

A technology of light-emitting diodes and manufacturing methods, applied in printed circuit manufacturing, pattern and photolithography, printed circuits, etc., to achieve the effects of increasing efficiency, improving thermal conductivity, and increasing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The detailed features of the present invention are described in the following embodiments, which are sufficient to enable any person familiar with the relevant art to understand the technical content of the present invention and implement it accordingly. Those skilled in the art can easily understand the related objects and advantages of the present invention. The following examples further illustrate various aspects of the present invention, but do not limit the scope of the present invention in any aspect.

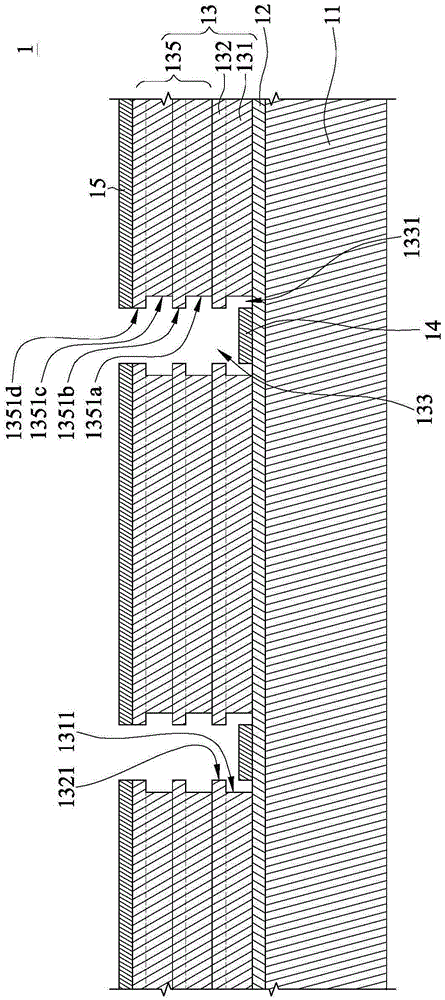

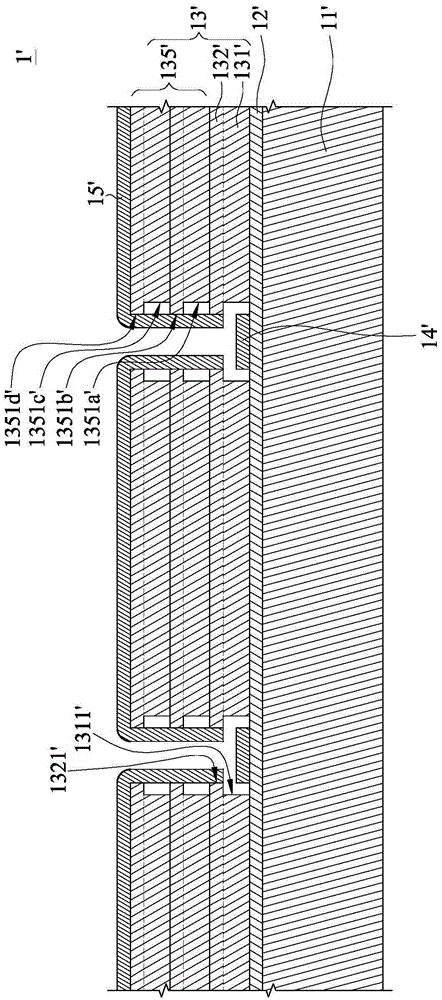

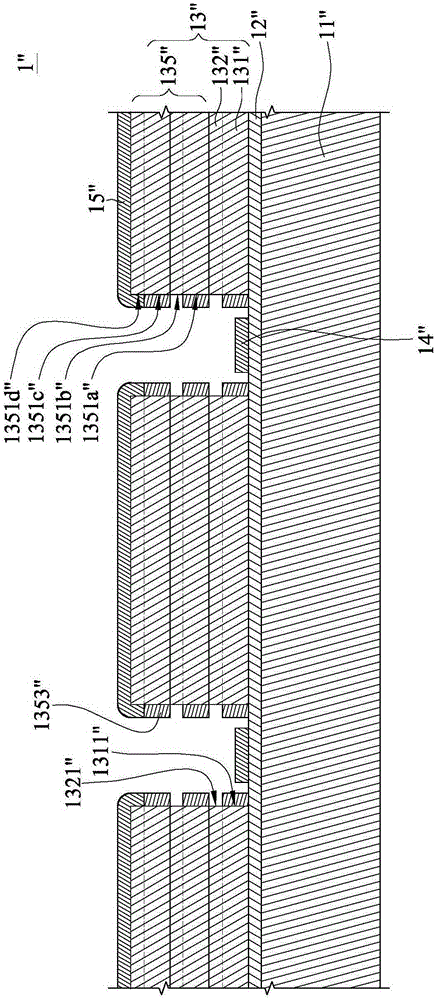

[0057] Please refer to Figure 1A , Figure 1A A schematic structural diagram of a light emitting diode carrier in an embodiment of the present invention. Such as Figure 1AAs shown, the LED carrier 1 includes a substrate 11 , a first dielectric layer 12 , a second dielectric layer 13 , a first conductive pad 14 and a second conductive pad 15 . The second dielectric layer 13 includes a first structure part 131 , a second structure part 132 and a third structure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com