Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

314 results about "Waste treatment technologies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

There are a number of different waste treatment technologies for the disposal, recycling, storage, or energy recovery from different waste types.

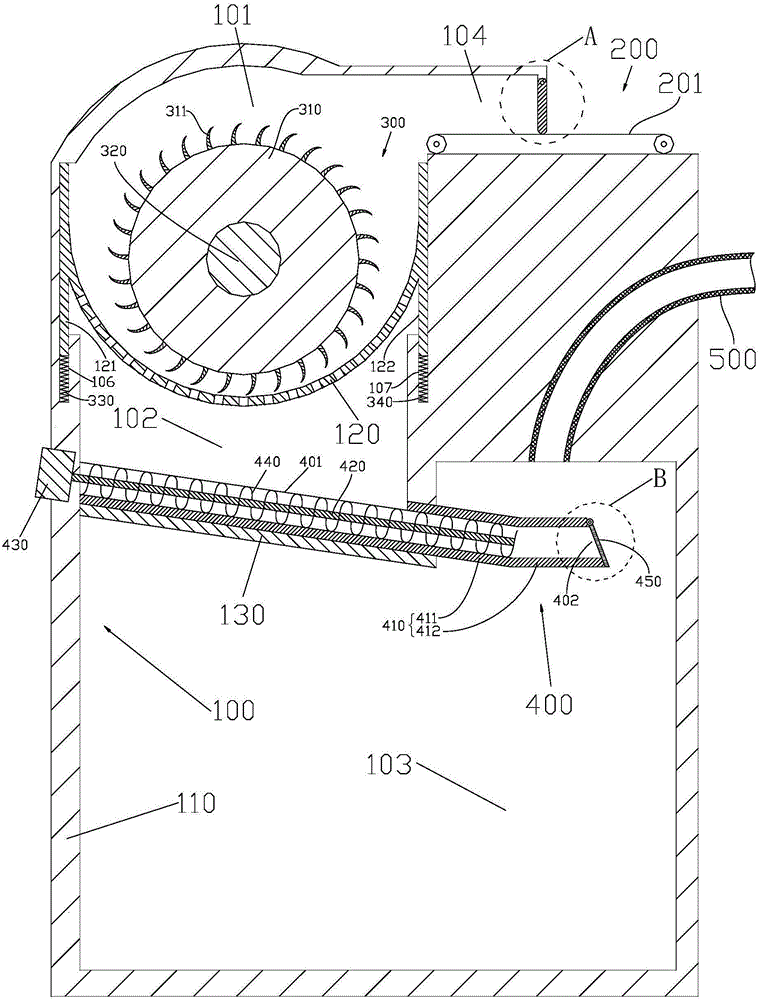

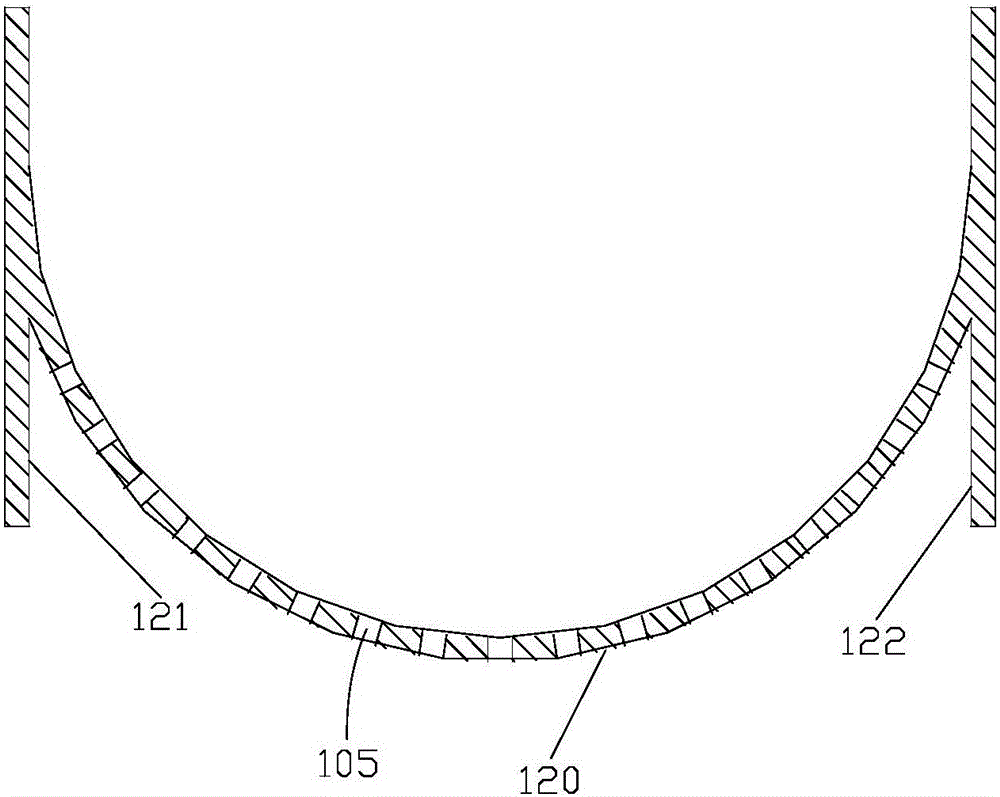

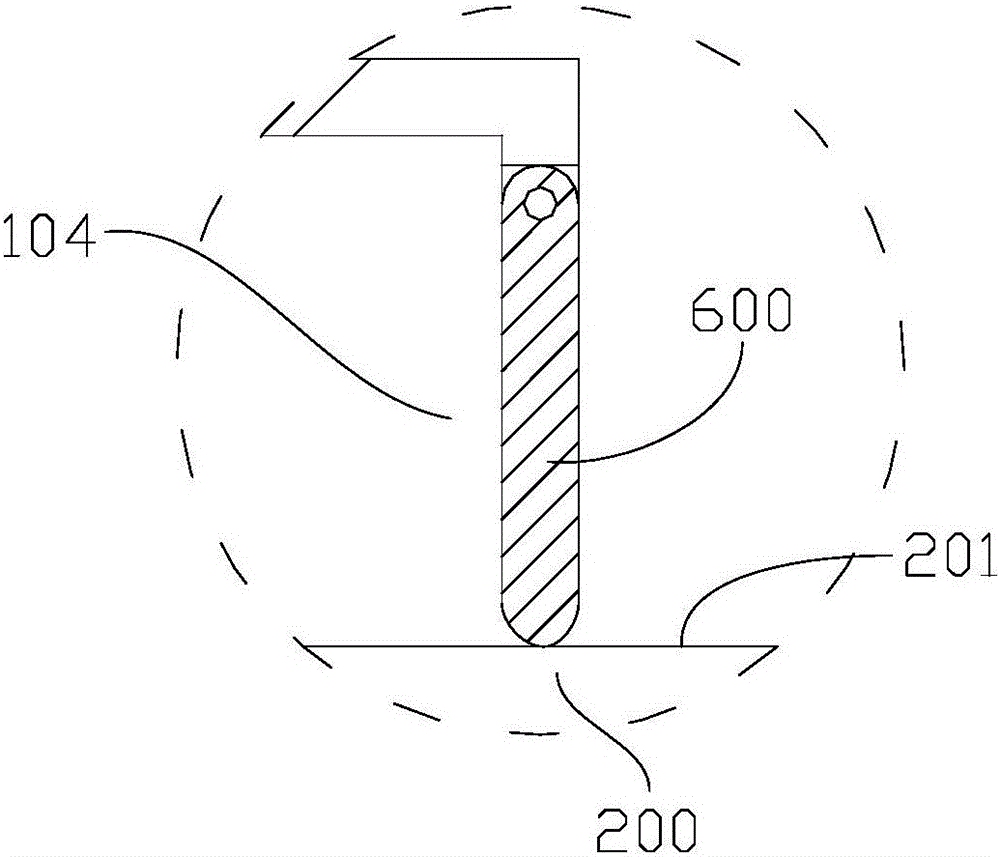

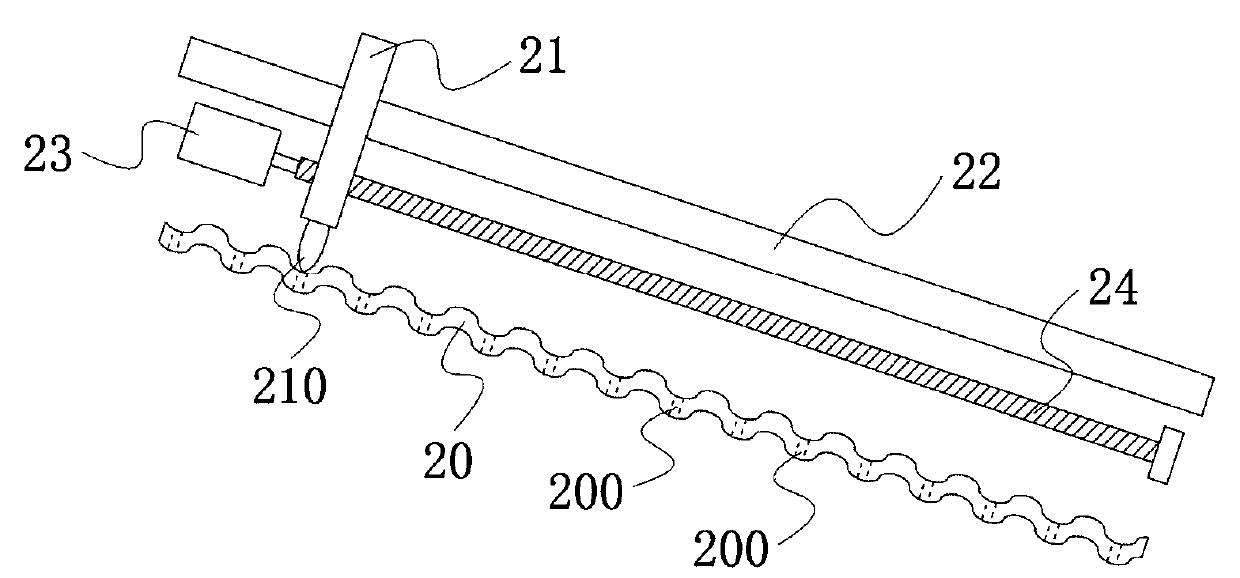

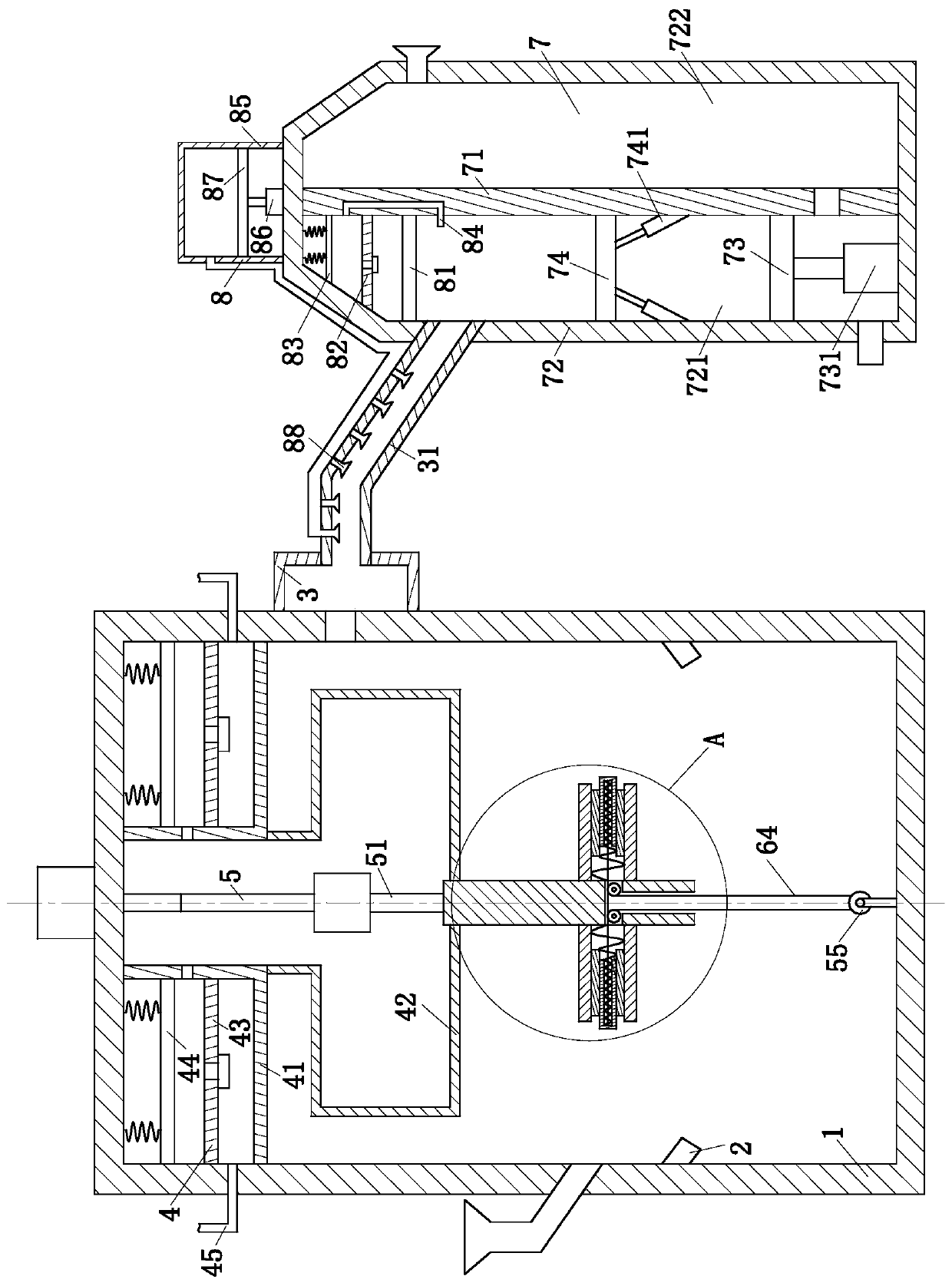

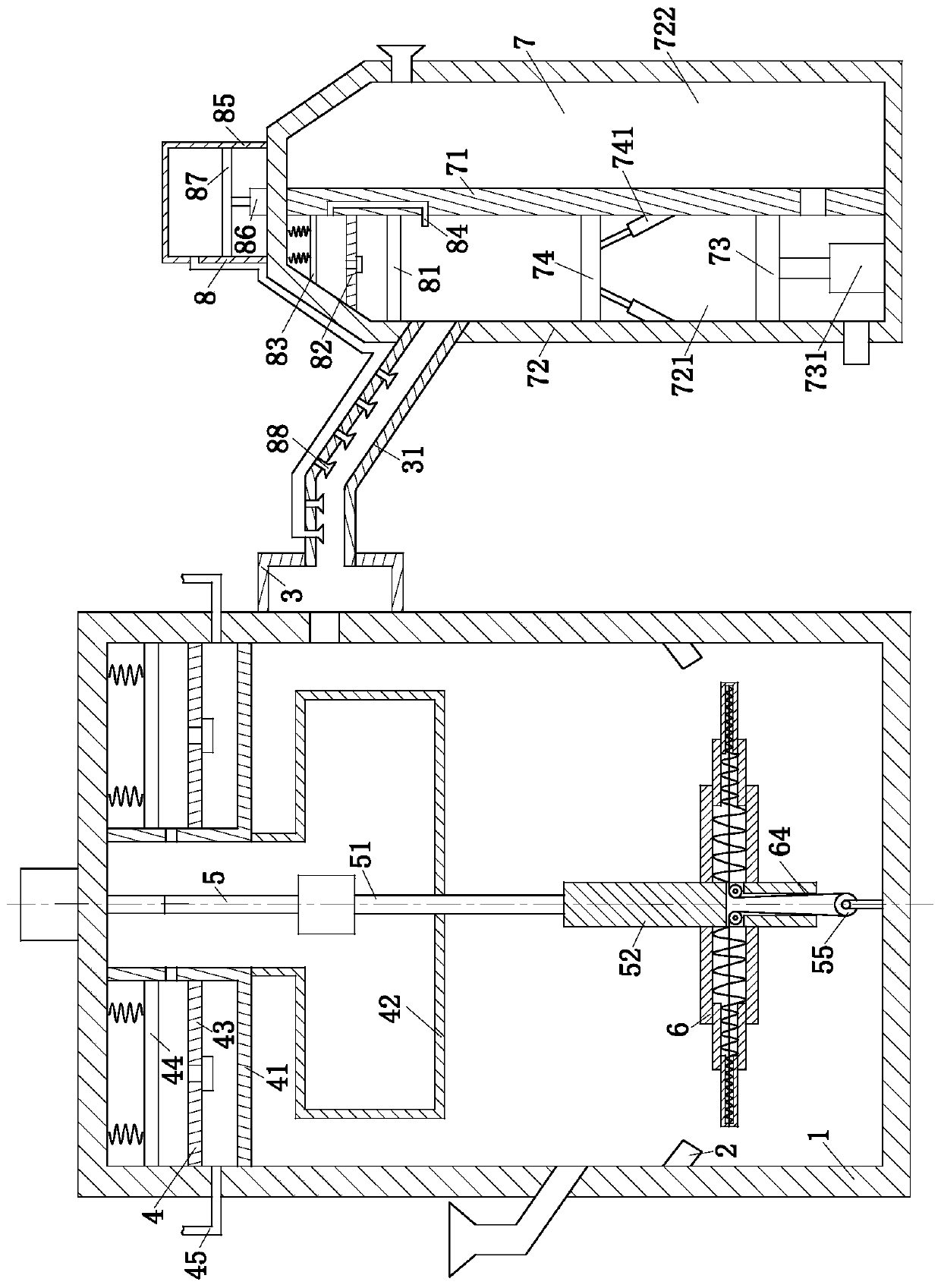

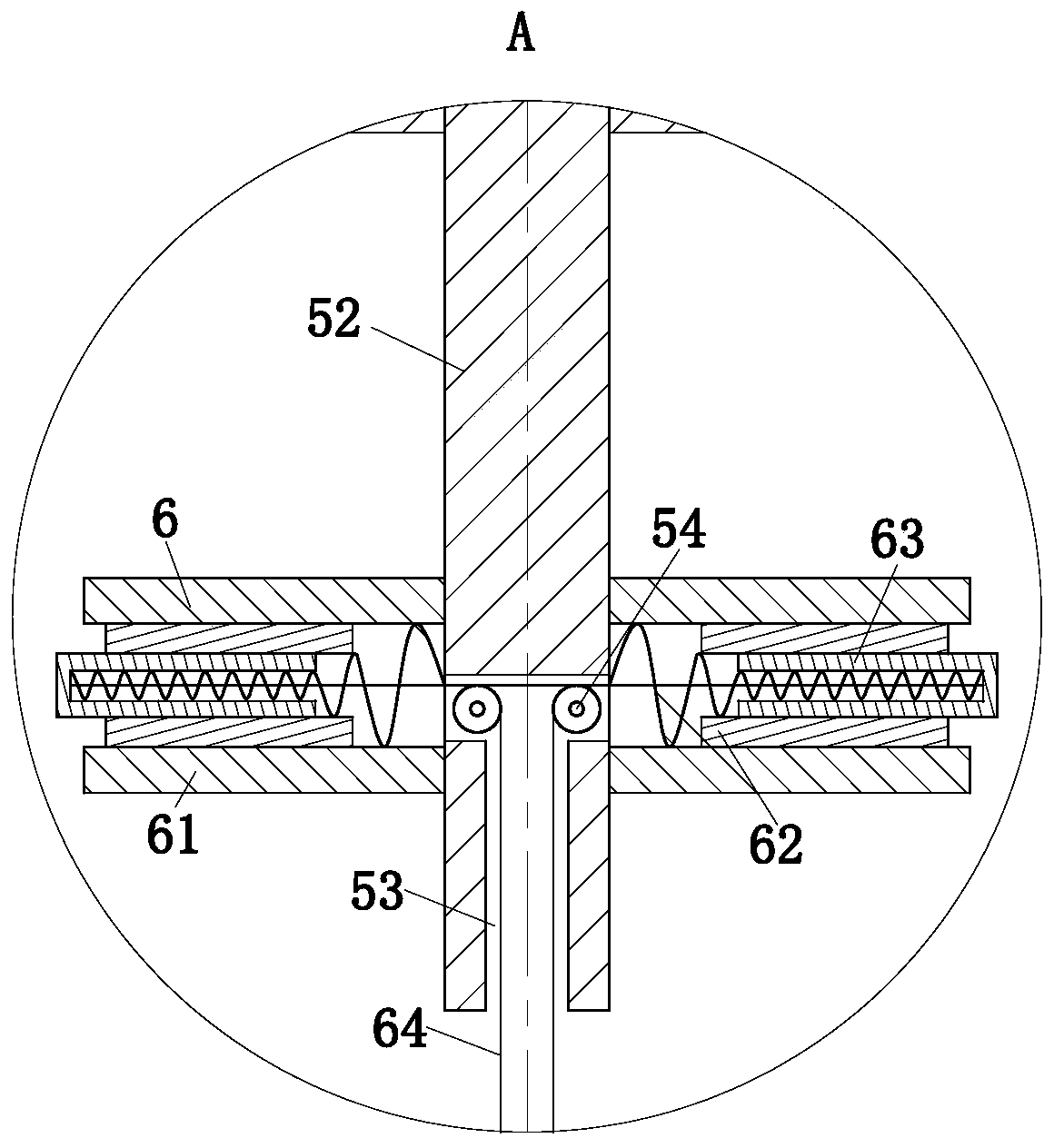

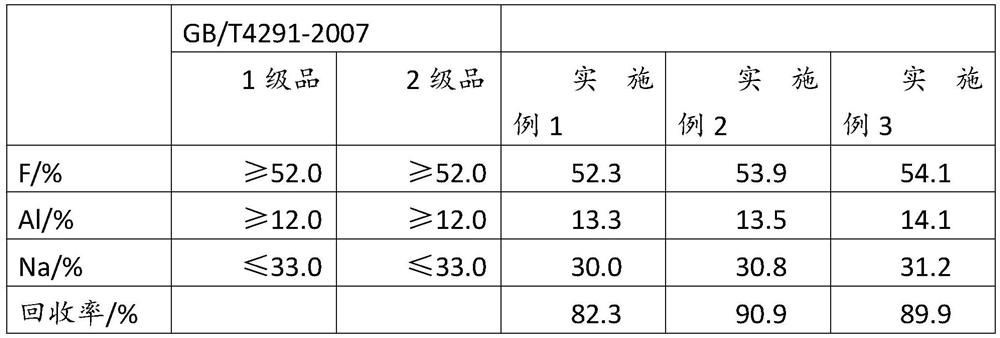

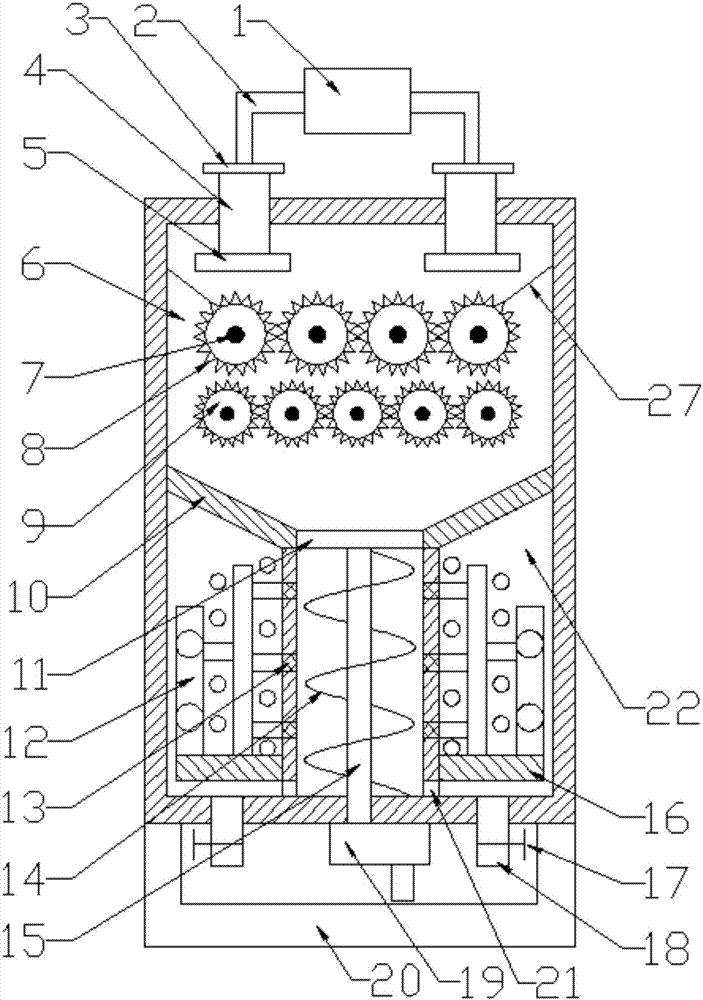

High-temperature continuous treatment system for disposing waste cathode of electrolytic aluminum

ActiveCN106185818ASimple structureEasy to operateFluoride preparationEnergy inputParticulatesResource utilization

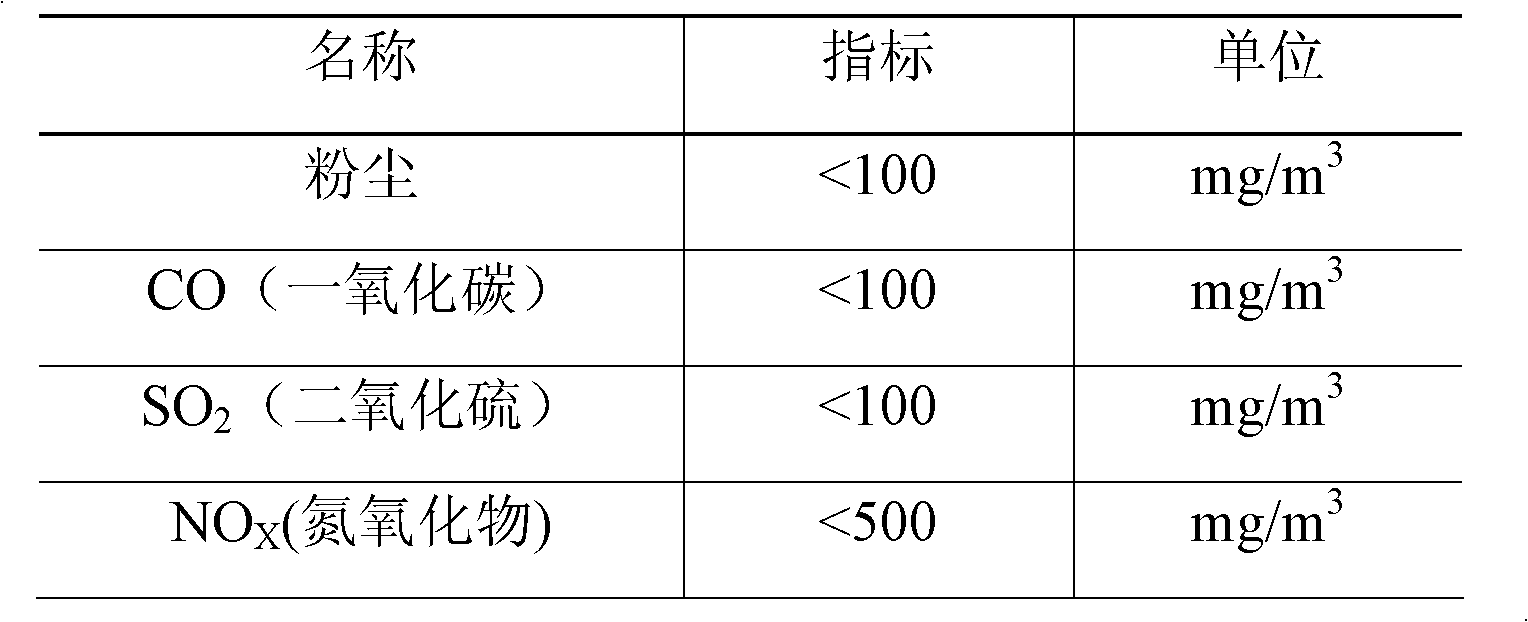

The invention relates to the technical field of the treatment of solid waste substances, and particularly relates to a high-temperature continuous treatment system for disposing a waste cathode of electrolytic aluminum. The invention provides the high-temperature continuous treatment system for disposing the waste cathode of the electrolytic aluminum. The high-temperature continuous treatment system comprises a crushing system, a feed system, a roasting system, a fume treatment system and a solid particulate matter treatment system, wherein the crushing system is used for crushing a charcoal block of the waste cathode of the electrolytic aluminum to form particulate material and conveying the particulate material to the roasting system by the feed system; the roasting system comprises an electric calcining furnace, a gas discharge opening is formed in the upper end of the electric calcining furnace, and a solid discharge opening is formed in the lower end of the electric calcining furnace; the fume treatment system is connected with the gas discharge opening; the solid particulate matter treatment system is connected with the solid discharge opening. By the system, a fluoride salt and a carbon product which are high in quality and further have economic value added are obtained; further, the system is simple in structure, convenient to operate and low in energy consumption and cost, has innocent treatment, and improves the treatment efficiency and the resource utilization efficiency of the charcoal block of the waste cathode of the electrolytic aluminum.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

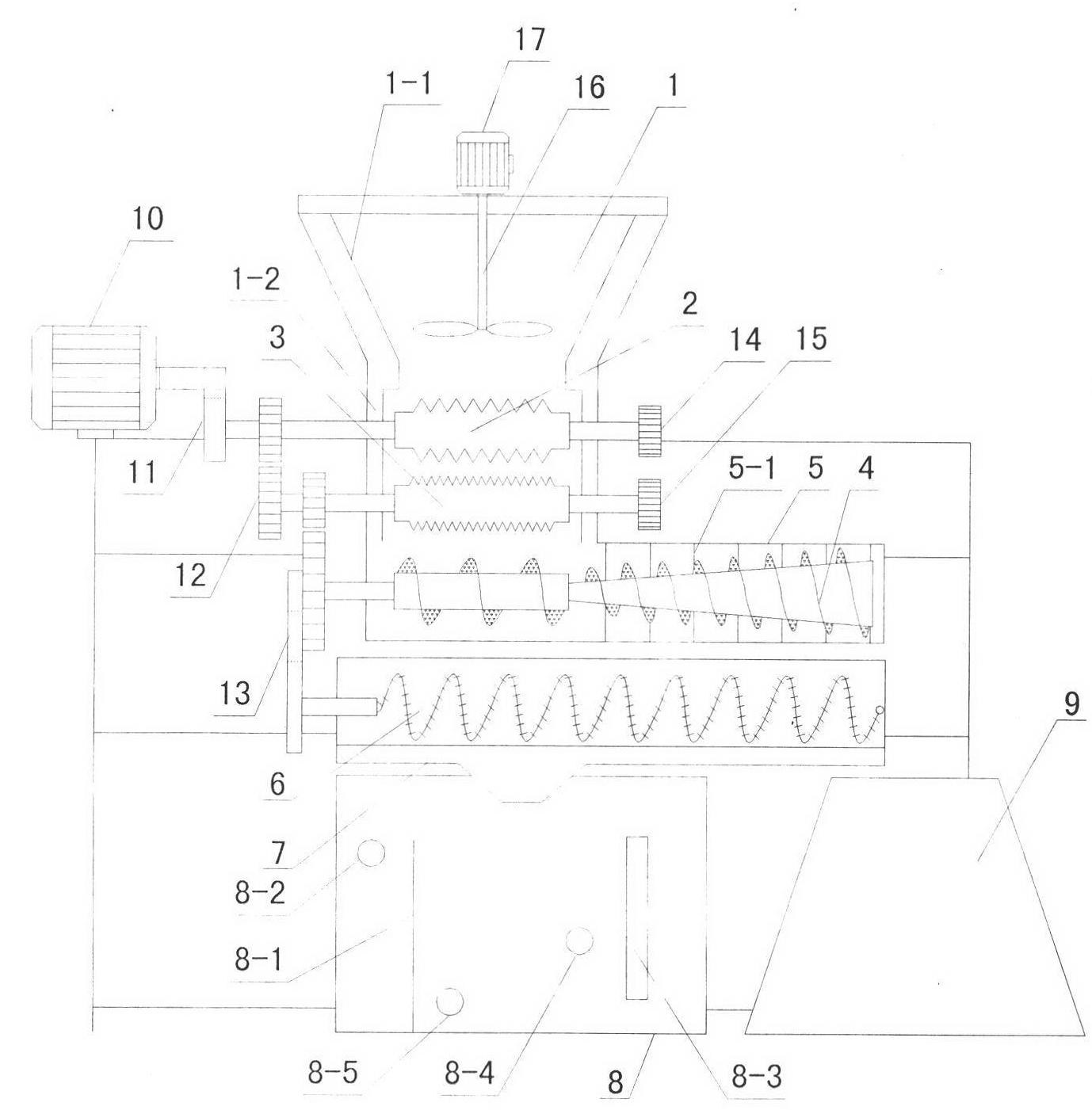

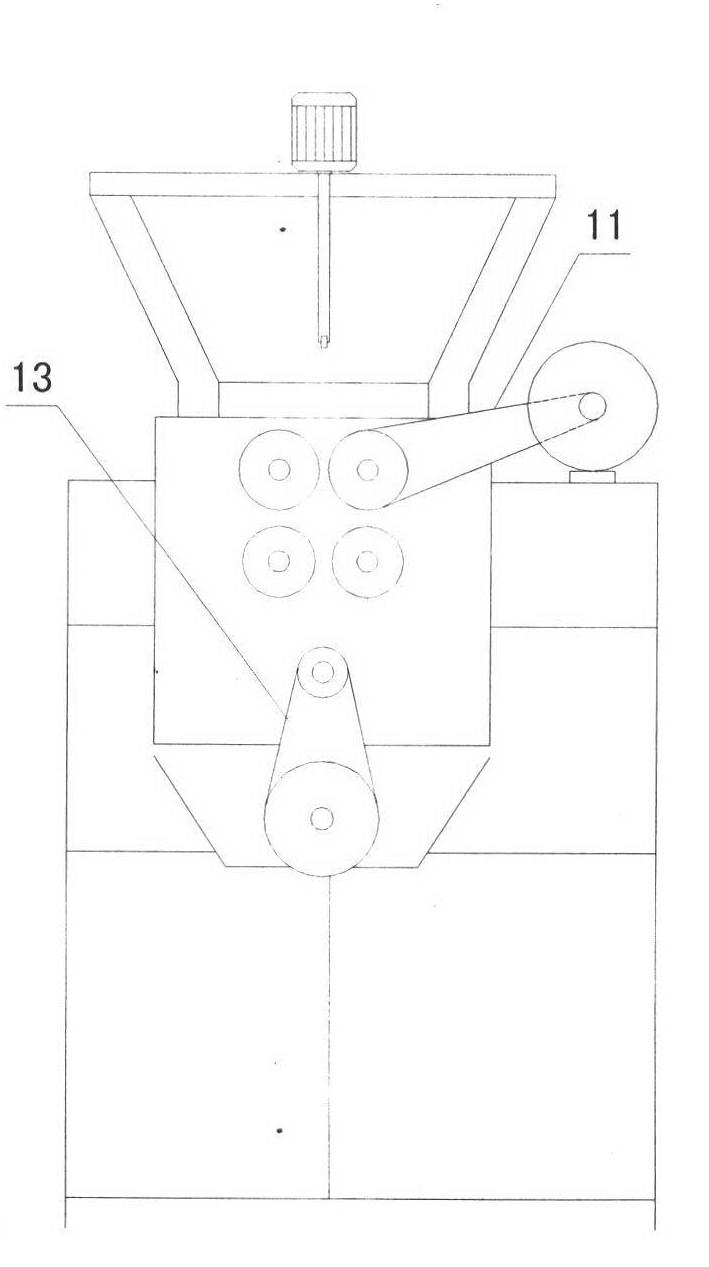

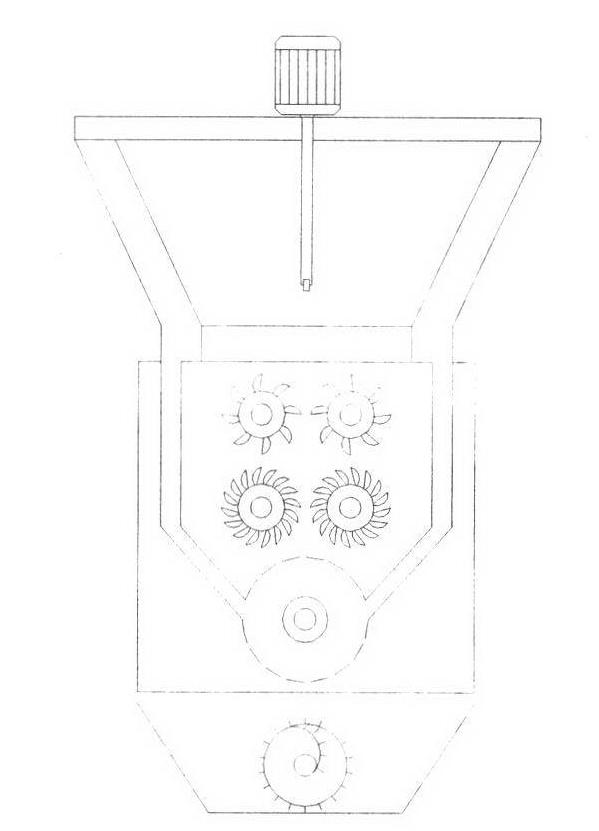

Integrated restaurant-kitchen garbage treatment machine

InactiveCN102198345AFast and effective instant separationReduce wasteLiquid separationStationary filtering element filtersRefuse collectionWaste collection

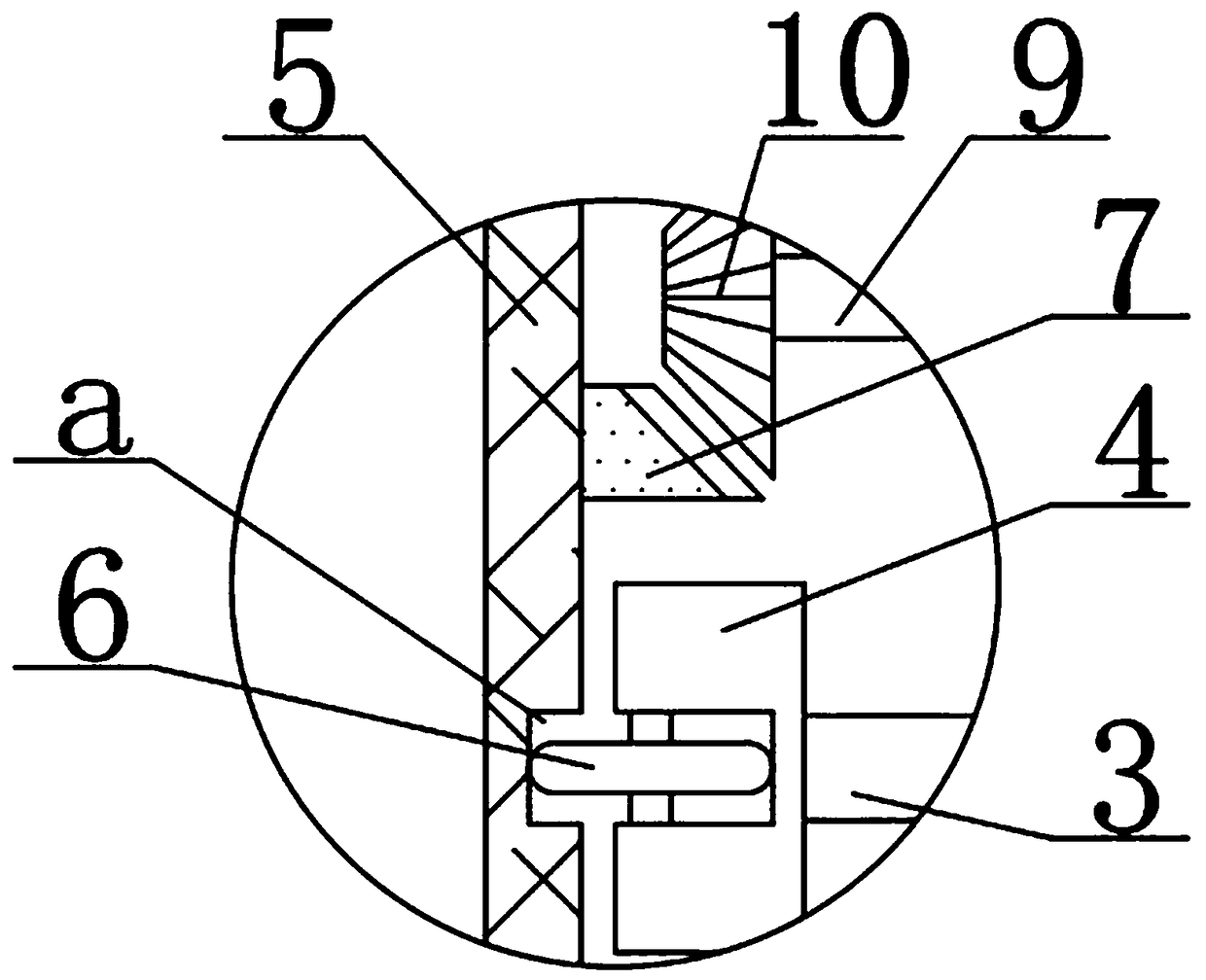

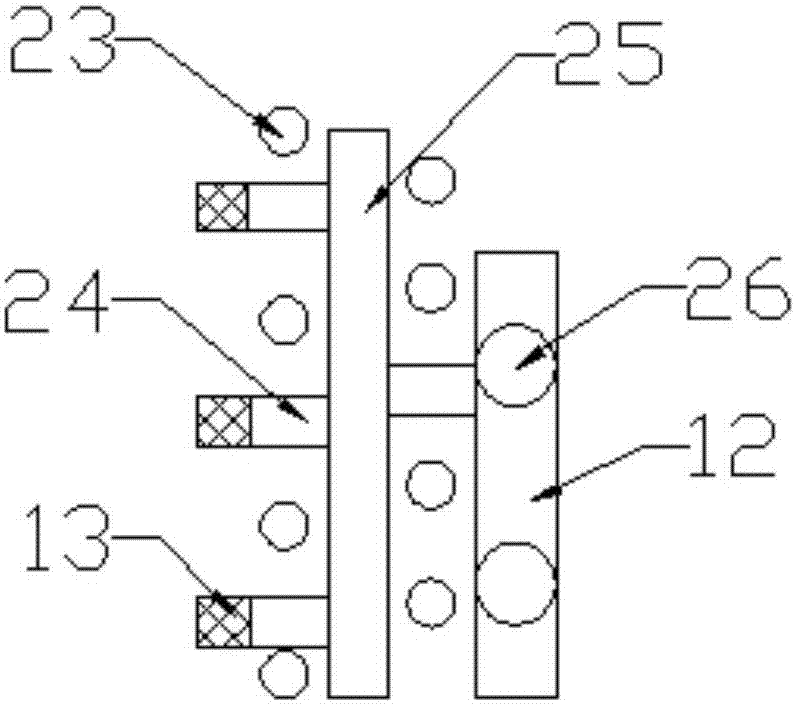

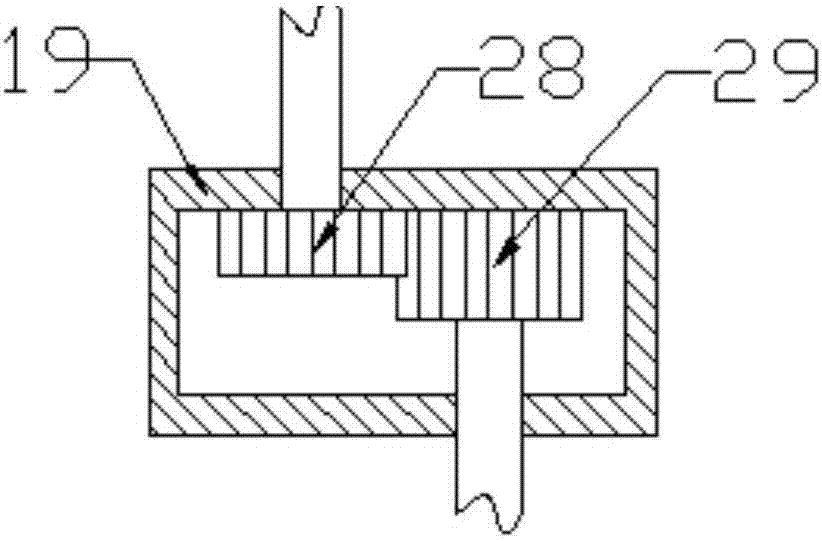

The invention discloses an integrated restaurant-kitchen garbage treatment machine and belongs to the technical field of waste treatment. The machine comprises a hopper, a crushing device consisting of a primary extrusion shaft pair and a secondary extrusion shaft pair, a solid-liquid separation device consisting of a spiral shaft, a filter cartridge, a spiral brush and a collecting tank, an oil-water separation tank and a garbage collecting barrel, wherein the primary extrusion shaft pair is driven by a motor through a belt pulley and the secondary extrusion shaft pair is driven by a shaft pair gear set; the spiral shaft is driven by a spiral gear set; the spiral brush is driven by a chain wheel; the primary extrusion shaft pair is engaged through a primary gear pair; the secondary extrusion shaft pair is engaged through a secondary gear pair; the hopper is a double-layer primary filtrate type hopper; a gap is formed in an inner layer of the hopper; and a liquid guiding pipe connected with a filter cartridge is arranged on the lower part of the hopper. The treatment machine rapidly and effectively separates restaurant-kitchen residues timely and reduces the waste of organic substances, and pigwash recovery is reduced by over 70 percent. The equipment is not blocked and is convenient to clean; grease is fully recovered; the equipment has high treatment capacity and high degree of automation; and the machine is suitable for various restaurants, dining halls and other places.

Owner:成都市城卫环保科技有限公司

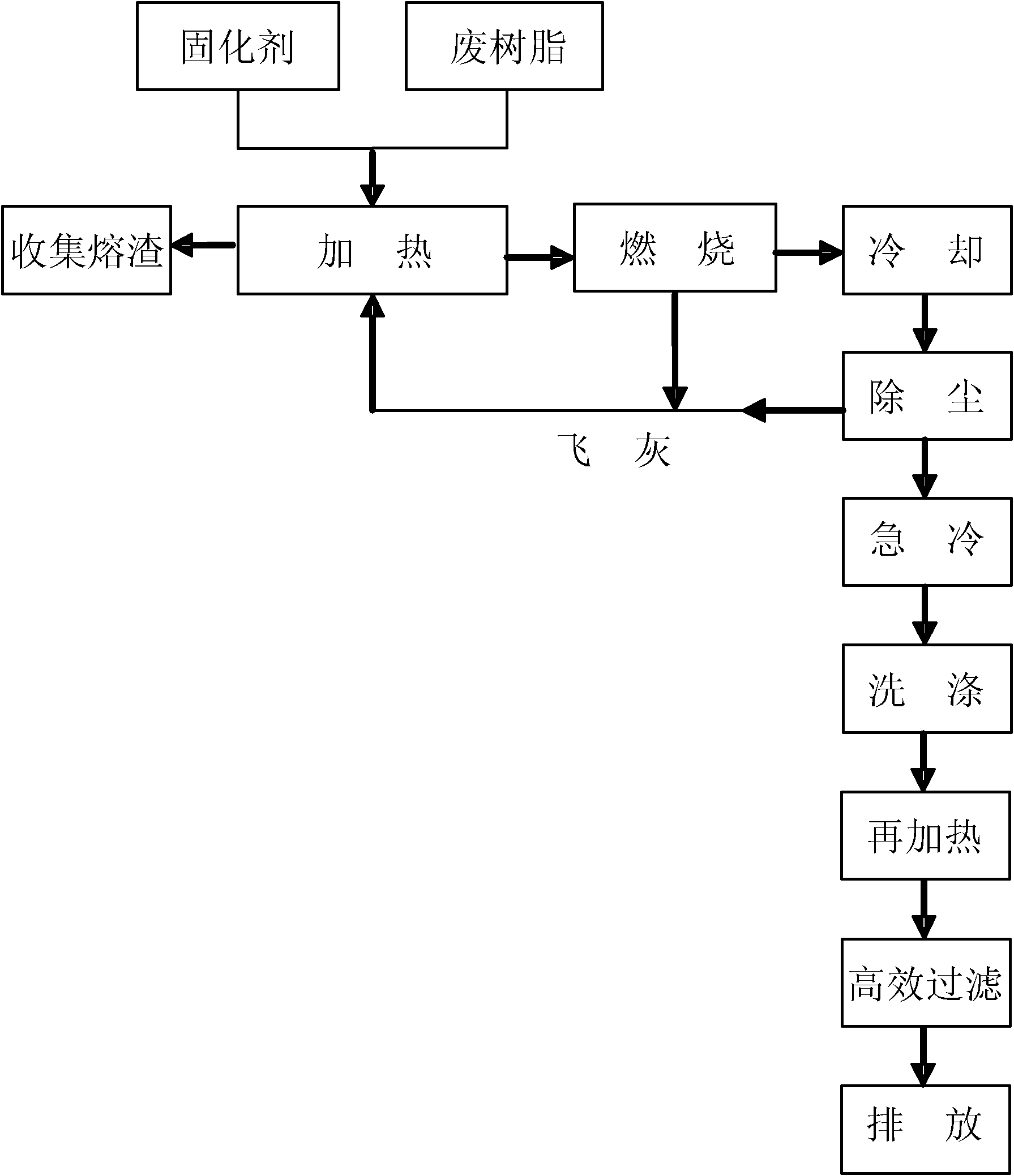

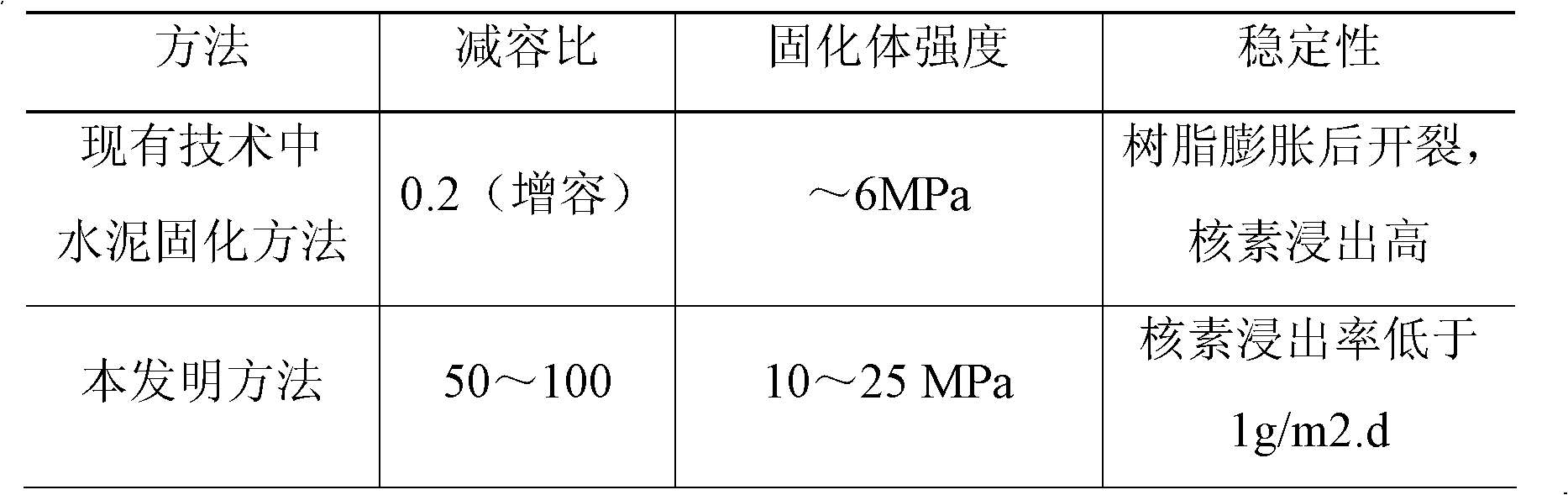

A high-temperature incineration and solidification method for radioactive waste resin plasma

InactiveCN102723117ALarge capacity reduction ratioLow leaching rateRadioactive decontaminationSlagCombustible gas

The invention belongs to the plasma waste treatment technology field and relates to a high-temperature incineration and solidification method for radioactive waste resin plasma. The method comprises the following steps: mixing a waste resin with a curing agent and heating the obtained product, with organic ingredient generating combustible gas and inorganic ingredient collecting slag; cooling the obtained product to form a vitreous body; subjecting the combustible gas and air to co-combustion to generate fume; cooling the generated fume and filtering out dust; spraying lye into the obtained product, removing the dust, and cooling the fume; and heating the fumes and discharging the remaining fumes. The method in the invention solves technology problems of a small volume-reduction ratio and unstable products in technology of the prior art, and achieves beneficial effects of a large volume-reduction ratio and stable products.

Owner:SOUTHWESTERN INST OF PHYSICS

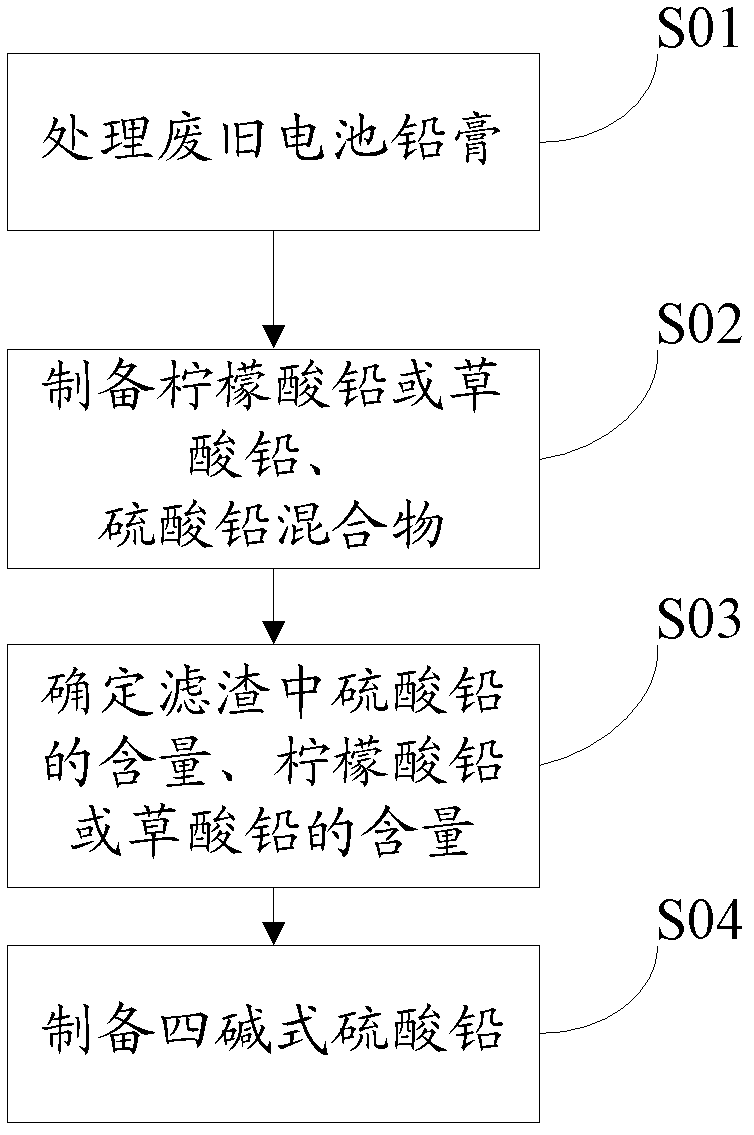

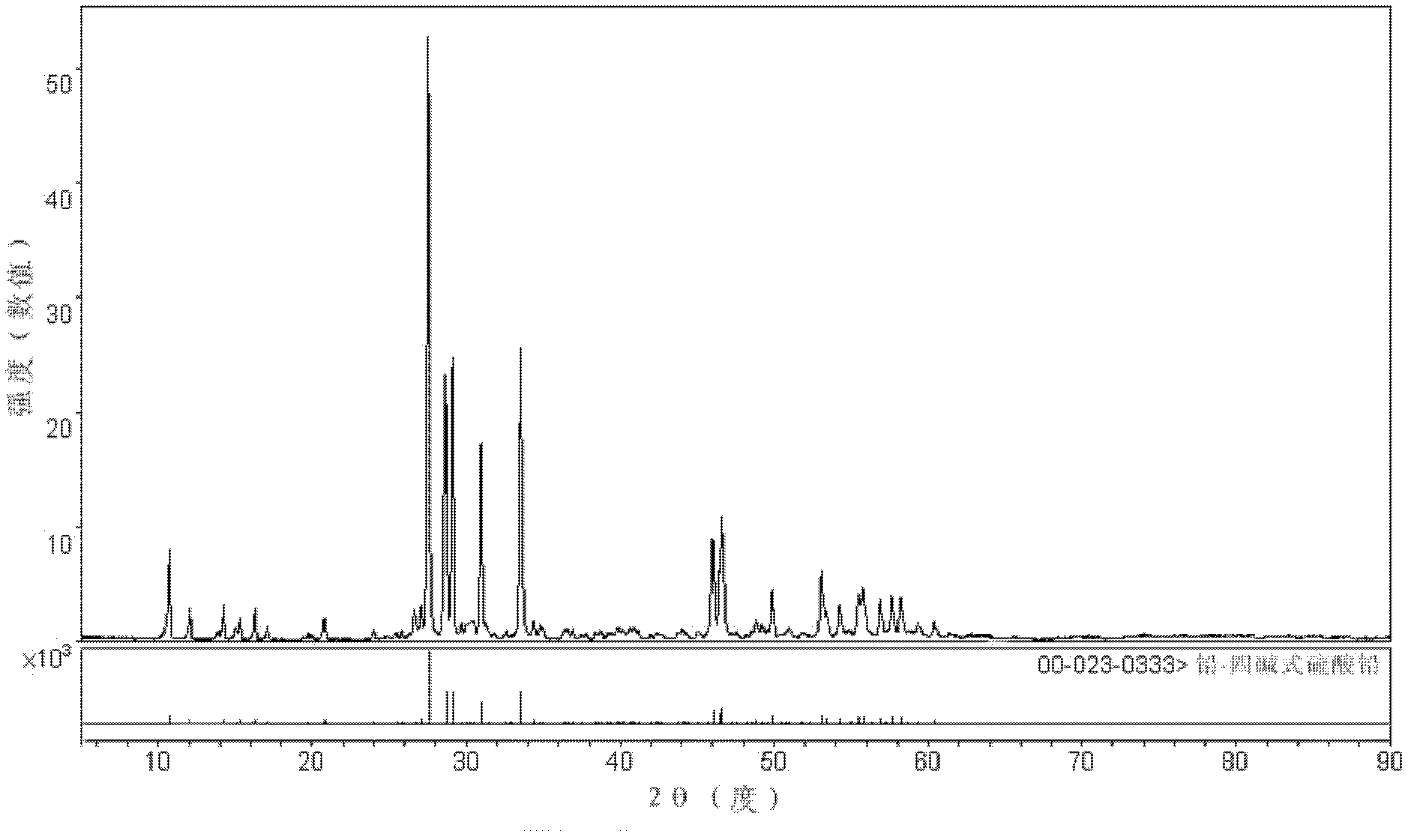

Method for preparing tetrabasic lead sulfate from waste batteries and application of tetrabasic lead sulfate

ActiveCN103022594AEasy to operateLow costWaste accumulators reclaimingLead sulfatesEconomic benefitsEnvironmental engineering

The invention is applicable to the field of waste treatment technologies and provides a method for preparing tetrabasic lead sulfate from waste batteries and the application of the prepared tetrabasic lead sulfate in batteries. The method comprises the steps of processing lead plaster of the waste batteries, preparing a lead citrate or lead oxalate and lead sulfate mixture, determining the content of lead oxalate and the content of the lead citrate or lead oxalate in filter residue, preparing the tetrabasic lead sulfate, and the like. According to the method for preparing the tetrabasic lead sulfate from the waste batteries and the application of the tetrabasic lead sulfate, the lead plaster is recovered from the waste batteries and used for preparing the tetrabasic lead sulfate, so that the battery recovery processing has a great economic benefit, and substances polluting the environment are not generated, thereby being environment-friendly; and the method is simple in operation and low in cost, thereby being very applicable to industrialized production.

Owner:SHENZHEN CENT POWER TECH

Curing agent for curing radioactive wastes containing borate and method thereof

InactiveCN101935200AAvoid non-condensingAvoid the cracking of the cement solidified body after soaking in waterSolid waste managementRadioactive decontaminationNuclear powerFirming agent

The invention discloses a curing agent for curing radioactive wastes containing borate, belonging to the technical field of a waste treatment. The curing agent is the mixture of cement and sodium silicate, wherein the weight ratio of the cement to the sodium silicate is 100 to (1-15). The invention also discloses a method for curing the radioactive wastes containing the borate by utilizing the curing agent. The mixture of the cement and the sodium silicate in the invention can be used for curing the radioactive wastes generated in a nuclear power station, avoiding the phenomenon of non-condensing cement slurry because of the delayed coagulation of the borate adsorbed in the wastes on the cement and cracking of cement curing bodies after being soaked in water, enhancing the capacity, shortening the initial coagulation time of the cement slurry, and ensuring that no crack is generated on the surfaces of the curing bodies and various performance indexes can meet the requirements of the national standard GB14569.1-93.

Owner:TSINGHUA UNIV

Solid waste recycling treatment technology

ActiveCN106180136ASimple processImprove insulation effectTransportation and packagingSolid waste disposalGas phaseGas passing

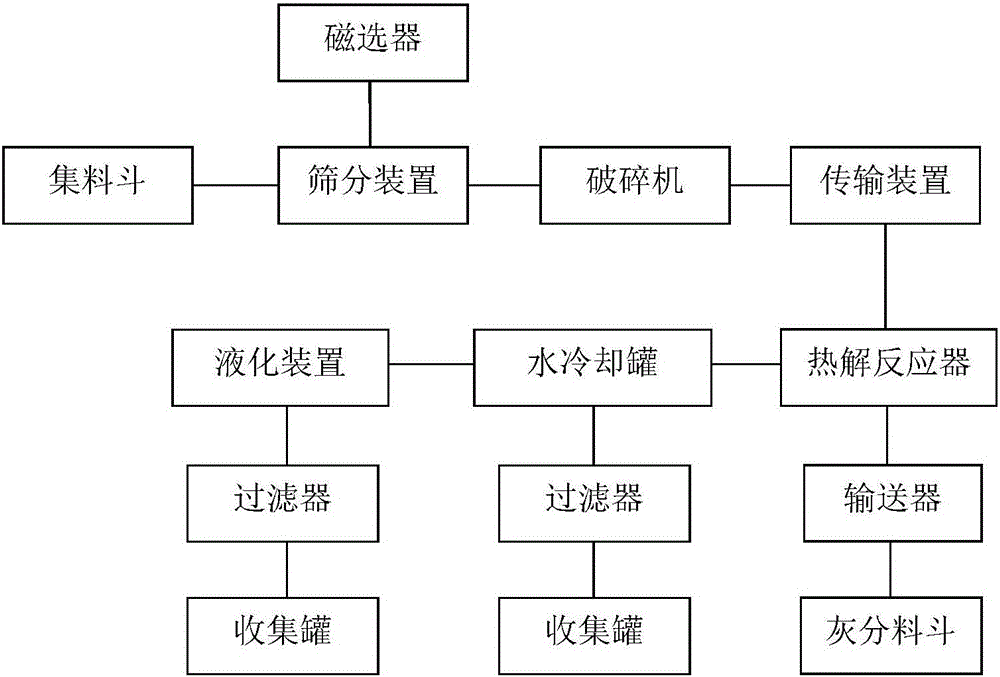

The invention discloses a solid waste recycling treatment technology. The technology comprises a solid waste pretreatment stage, a pyrolysis stage, a condensation stage and a classified collection stage. The technology specifically comprises the steps that solid wastes are loaded into a collection hopper to be subject to preliminary screening, magnetic metal is sorted out, smashed and fed into a pyrolysis reactor to be subject to pyrolysis, steam, liquid fractions and gas generated after pyrolysis are cooled through a water cooling tank, components condensed into liquid in the water cooling tank are collected, the condensed gas is subject to low-temperature liquefying through a liquefying device and is collected, and solid residue obtained after pyrolysis is conveyed to an ash dividing hopper; the solid waste treatment technology is simplified, anaerobic heating is carried out through a spiral stirring heating pipe, the pyrolysis steps are simplified, the solid phase, the liquid phase and the gas phase generated after pyrolysis are collected in a classified manner, gas fuel, liquid fuel and solids used for building materials can be obtained, waste disposal is reduced, natural resources are sufficiently utilized, and emissions of harmful substances are reduced.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

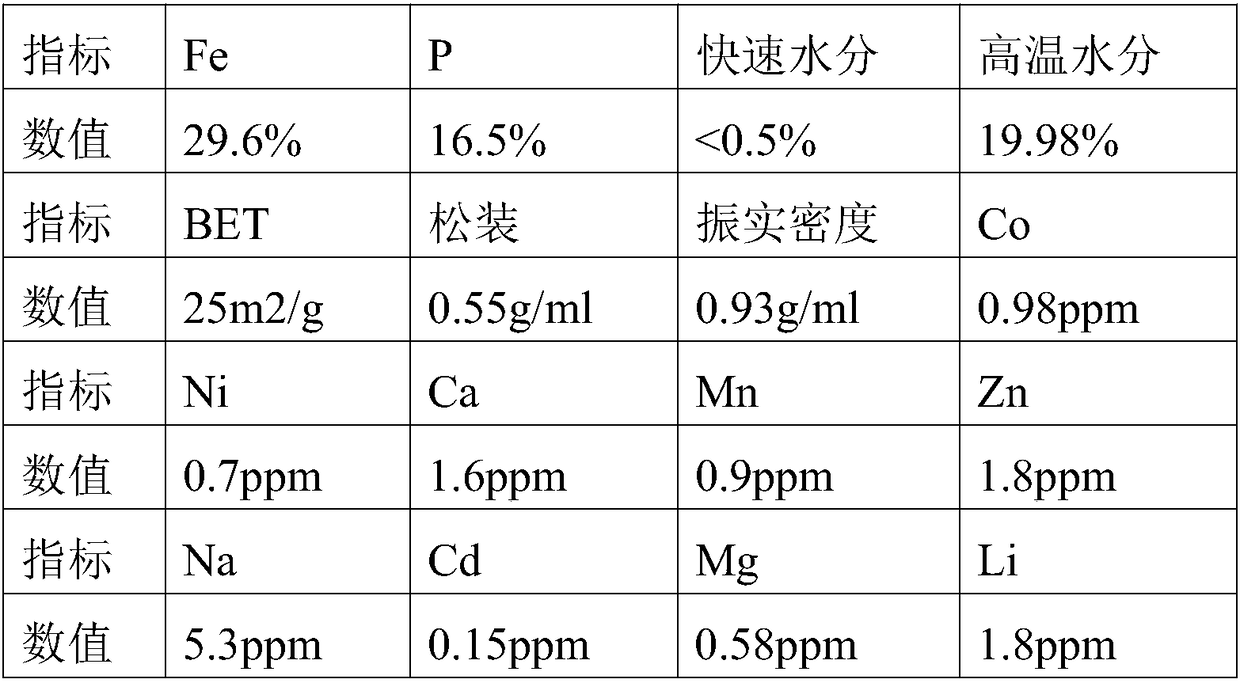

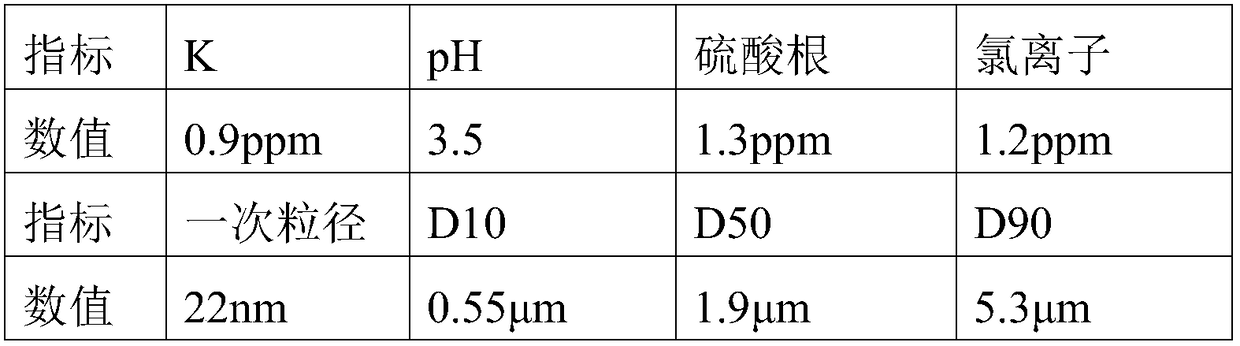

Lithium iron phosphate waste treatment technology

InactiveCN108483418AAchieve recyclingHigh recovery ratePhosphorus compoundsLithium carbonates/bicarbonatesPhosphoric acidEngineering

The invention discloses a lithium iron phosphate waste treatment technology. The lithium iron phosphate waste treatment technology comprises the following steps: (1), discharging a waste lithium battery until the voltage is 0, then destroying an outer shell of the waste lithium battery in the case of air isolation, separating out an electrolyte, the outer shell and electrode lugs to obtain a dry core package, separating out a positive electrode sheet from the dry core package, crushing to obtain lithium iron phosphate waste, adding the lithium iron phosphate waste into an alkali solution, stirring for dissolving the lithium iron phosphate waste at 75 DEG C for 5 hours, and then filtering to obtain an aluminum-containing solution and a first filter residue; (2), adding the first filter residue into a sulfuric acid solution, stirring for reaction at 88 DEG C for 5 hours, continuously adding iron powder at a constant rate during the reaction, and reacting until the pH of the solution is 2.5. By the lithium iron phosphate waste treatment technology, the design is reasonable, the cost is low and the technological flow is short; in addition, battery-grade iron phosphate and battery-gradelithium carbonate can be obtained, so that recycling of all components is achieved; moreover, and recycled products are high in added values and are all raw materials of the lithium iron phosphate; the recycling rate of each component is high.

Owner:何长才

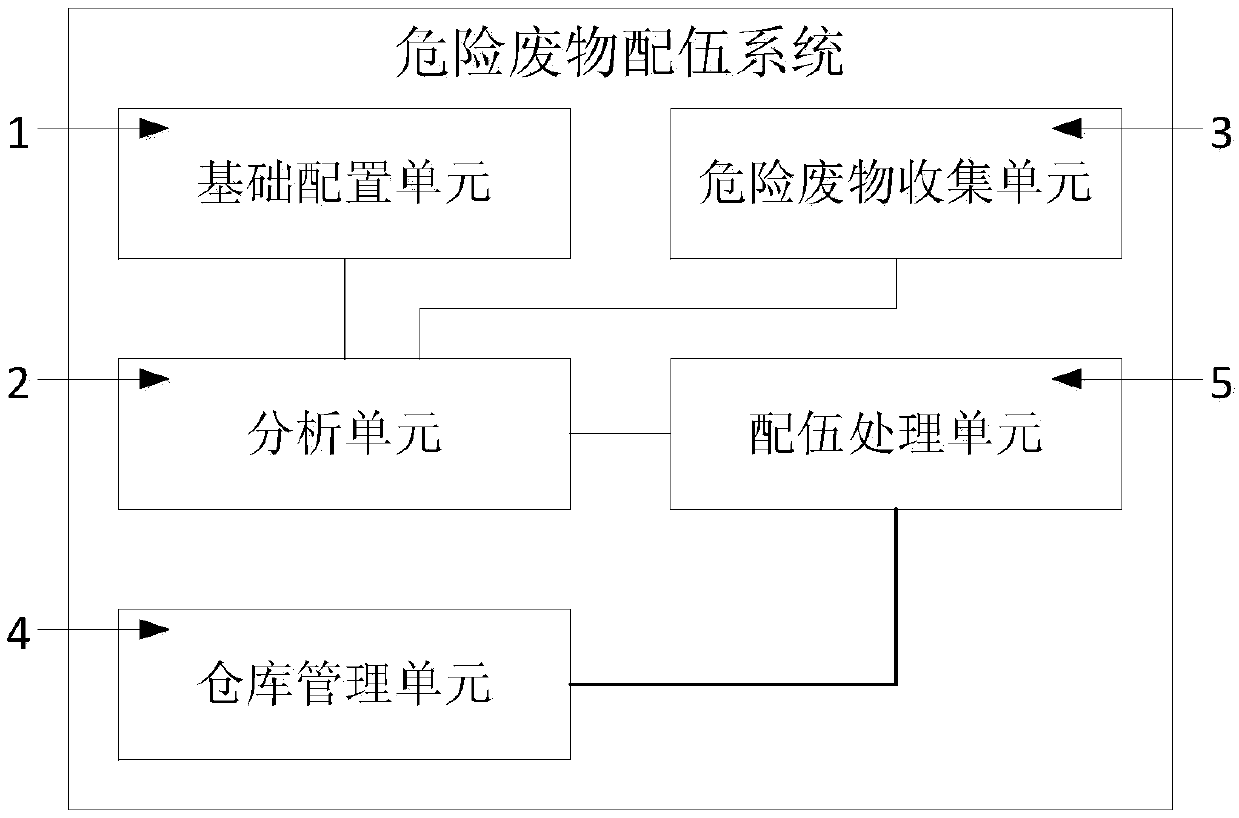

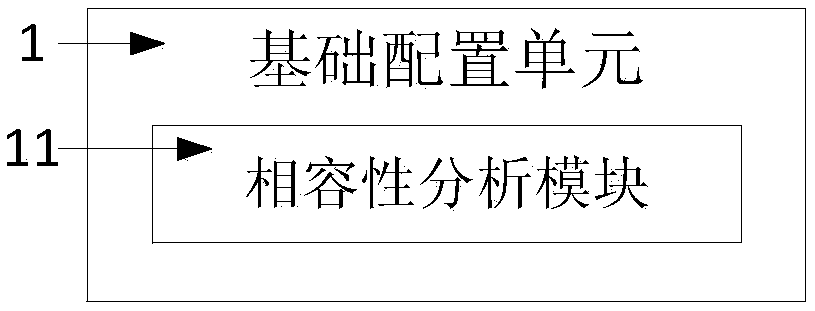

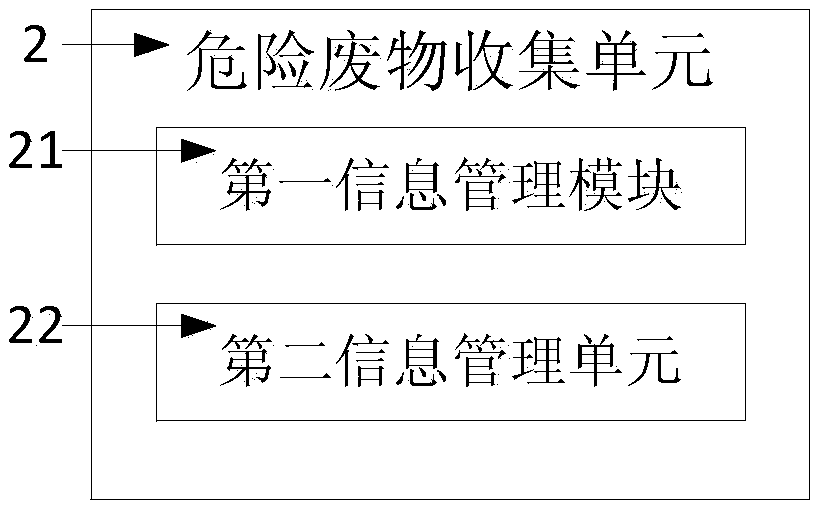

Hazardous waste compatibility system

InactiveCN107705235AEnsure safetyRealize automatic compatibilityData processing applicationsIncinerator apparatusWaste treatment technologiesToxic industrial waste

The present invention discloses a hazardous waste compatibility system, and belongs to the technical field of waste treatment. The hazardous waste compatibility system comprises a basic configurationunit for configuring and modifying basic data; a hazardous waste collection unit for implementing order check and a contamination composition record on the collection process of the hazardous waste; an analysis unit for establishing a database associated with all stored hazardous wastes; a warehouse management unit for implementing functions such as accounting entry of hazardous wastes, inbound / outbound inquiries, and the like; and a compatibility processing unit for performing compatibility processing on the to-be-compatibility processed hazardous waste, in order to obtain at least a compatibility scheme, wherein the waste disposal station staff selects a to-be-compatibility processed hazardous waste from at least one compatibility schemes for compatibility and incineration. Beneficial effects of the technical scheme of the present invention are as follows that: the automatic compatibility of industrial wastes is achieved, the detection function of the waste compatibility is provided,the safety of the compatibility scheme is ensured, and the environmental pollution after waste incineration is reduced.

Owner:SHANGHAI ELECTRICGROUP CORP

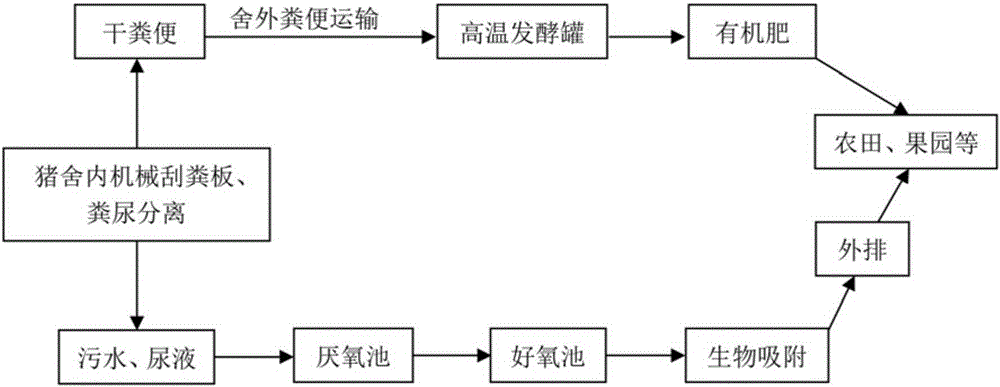

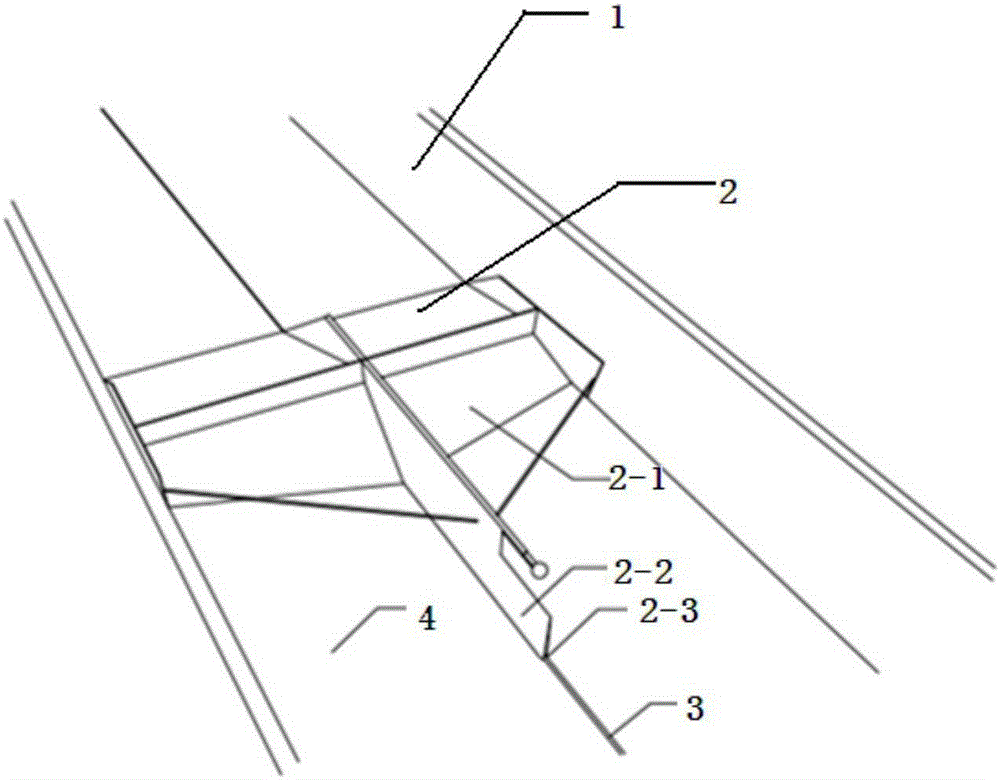

Automatic pig breeding farm waste treatment system and method

The present invention discloses an automatic pig breeding farm waste treatment system and method. The system comprises inside-pigsty feces and urine separation mechanical manure scraping equipment, outside-pigsty manure automatic transporting equipment, manure fermentation equipment and sewage purification treatment equipment. According to the large-scale pig farm automatic waste treatment technology provided by the present invention, automatic control can be realized, and working efficiency of feeders is raised; with utilization of a mechanical manure scraper, water using amount of a large-scale pig farm is saved, and sewage treatment burdens are also reduced; and an electric transportation dung-cart is used for transporting the manure to a fermentation tank, and organic fertilizers obtained after the fermentation are applied to fields, thereby reducing the using amount of chemical fertilizers.

Owner:南京绿辉牧业科技有限公司

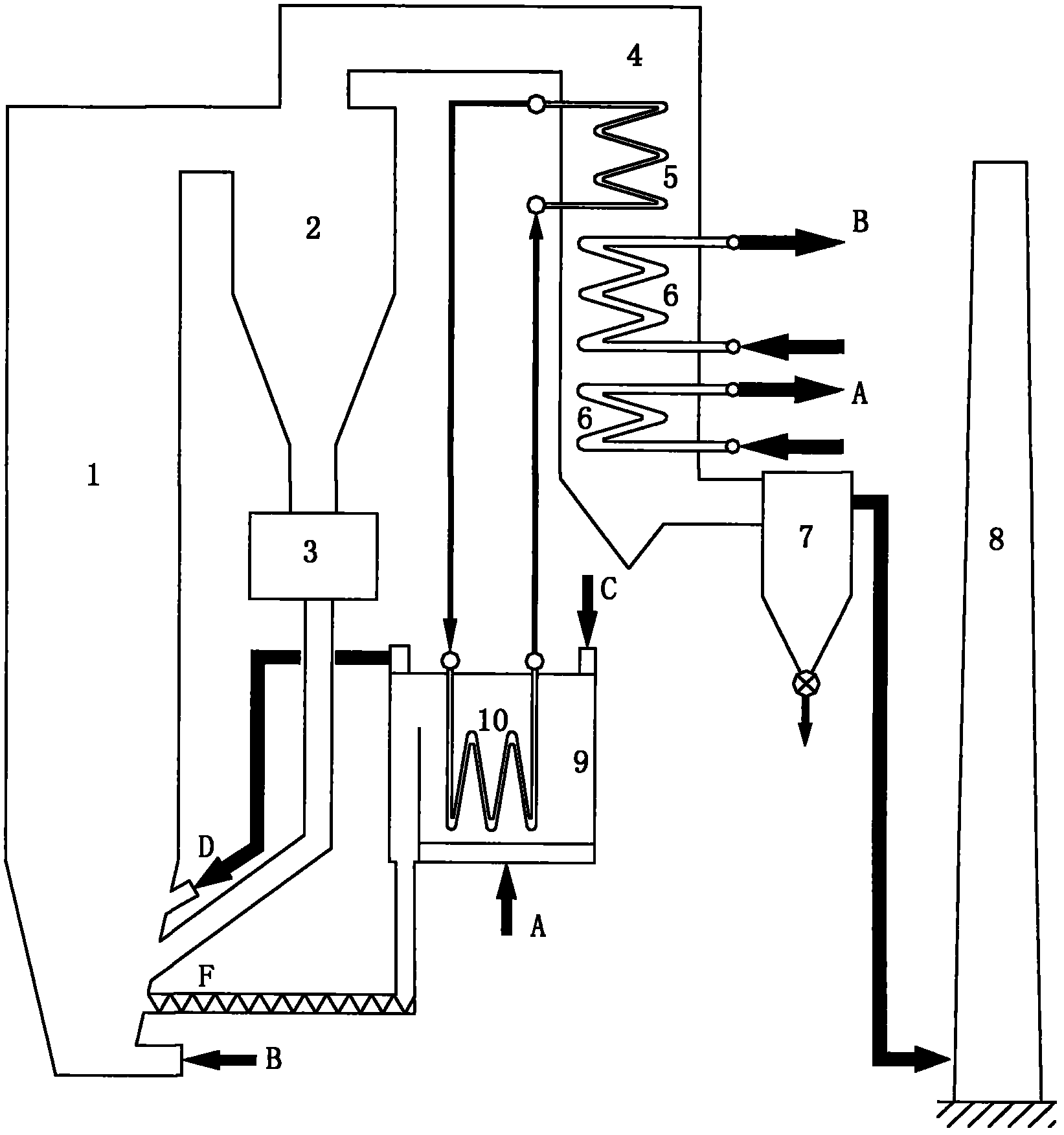

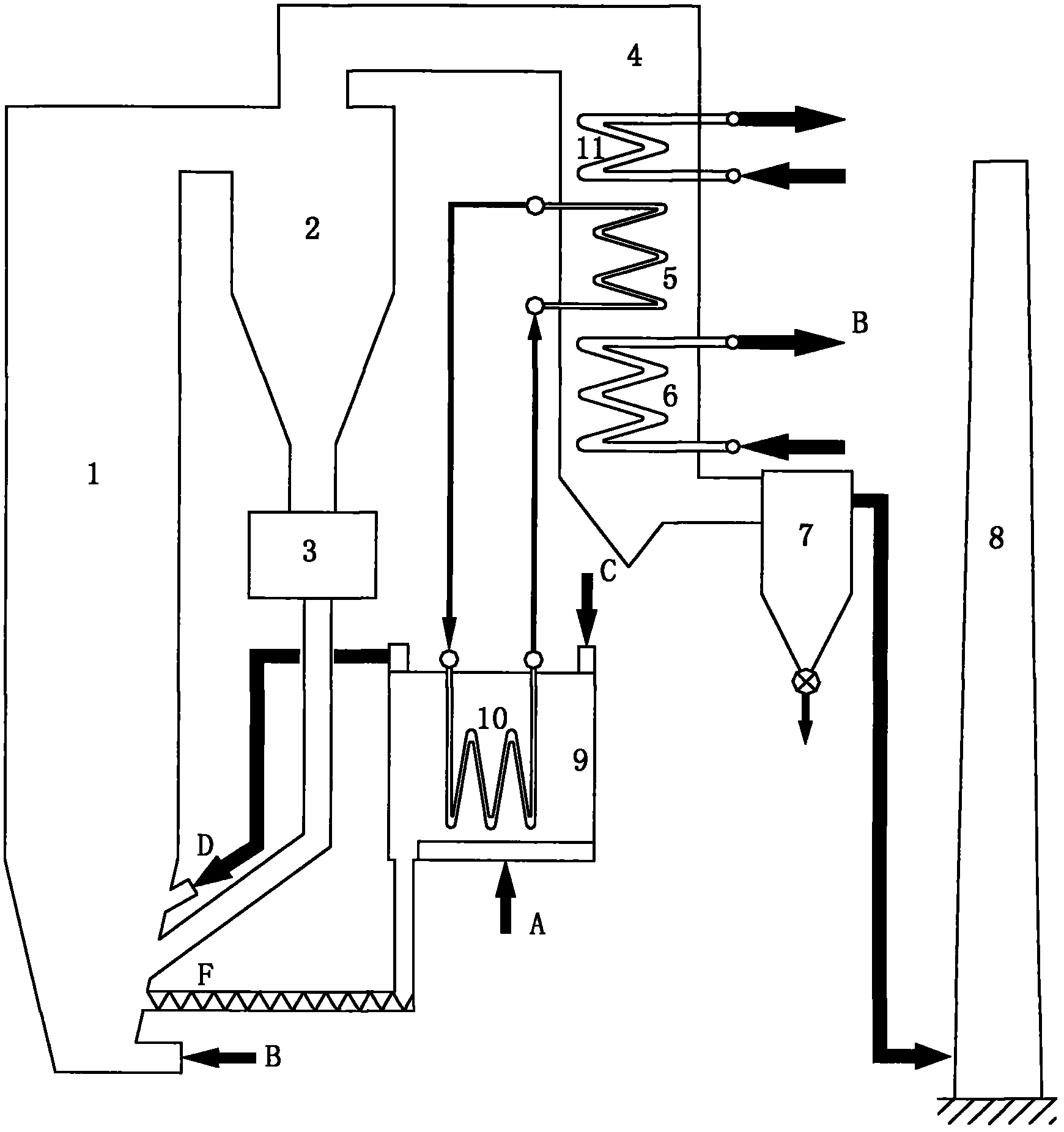

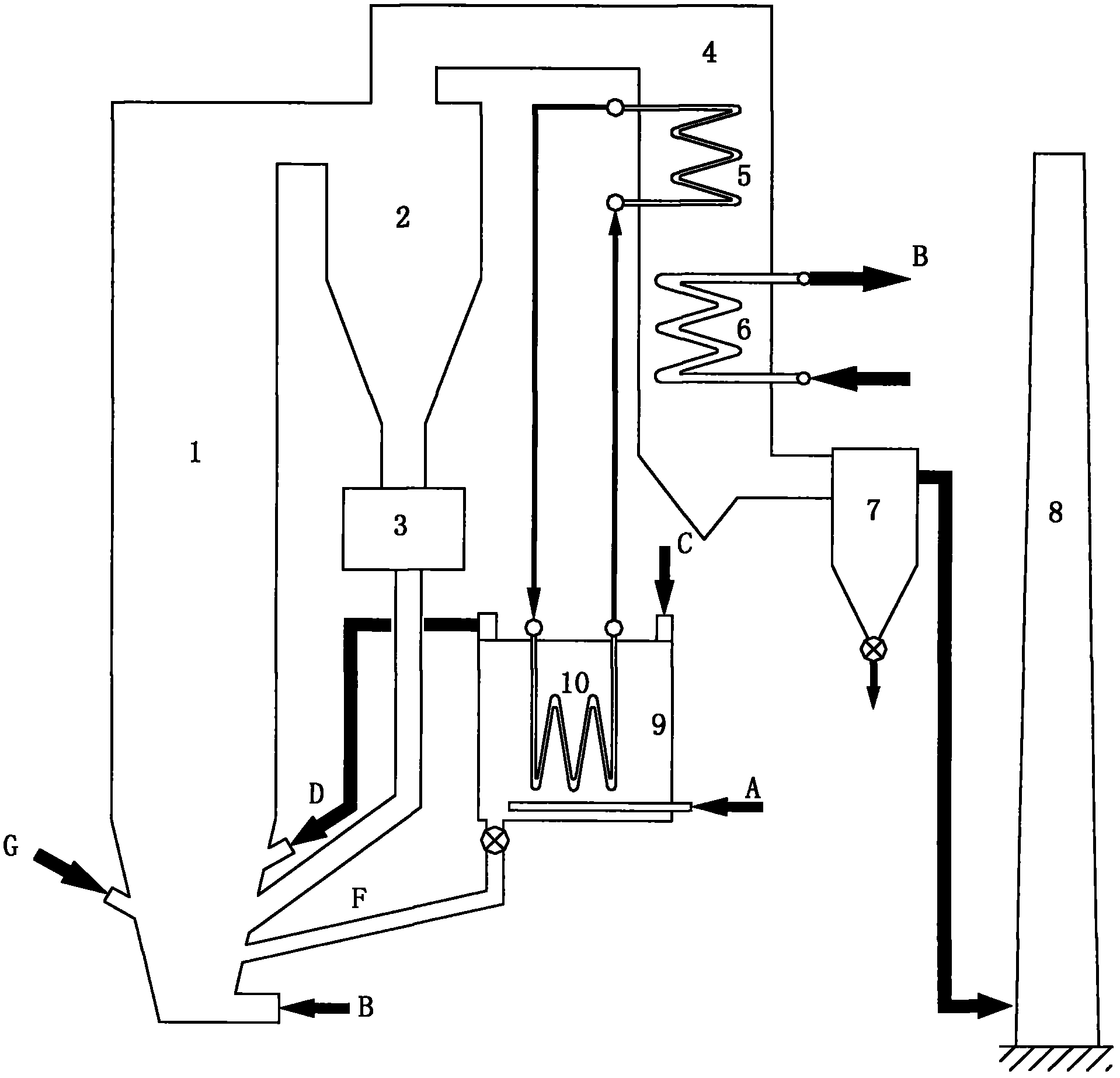

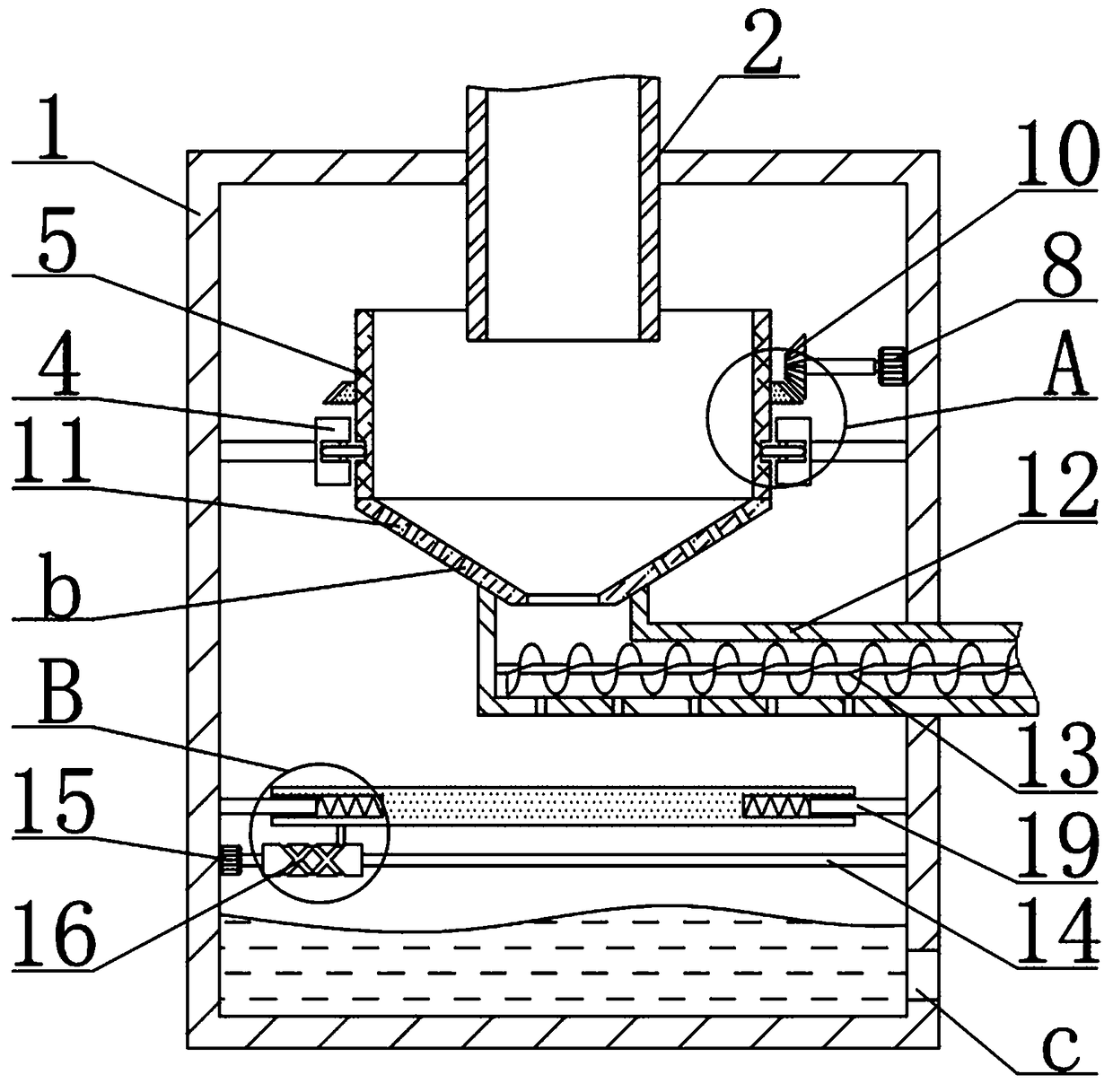

Wet sludge drying and incinerating treatment device

ActiveCN102531324ARealize deodorization and harmlessnessSuppress generationSludge treatment by de-watering/drying/thickeningIncinerator apparatusAir preheaterFluidized bed

The invention relates to a wet sludge incinerating treatment device and relates to the waste treatment technology. The treatment device comprises a circulating fluidized bed hearth, a separator, a material returning device, a tail flue, a duster, a chimney and a fluidized bed type sludge drier, wherein an exhaust outlet and a wet sludge inlet are arranged at the top of the sludge drier, an air distributing device and a dry sludge outlet are arranged at the bottom of the sludge drier, and a heat release coil filled with a heat transfer medium is arranged inside the sludge drier; an air preheater and a heat exchanger are arranged in the tail flue; the heat exchanger is communicated with the heat release coil in the sludge drier; a secondary air port, a material returning port and a dry sludge inlet are arranged at the lower part of the sidewall of the circulating fluidized bed hearth; and the dry sludge inlet is communicated with the dry sludge outlet of the sludge drier, and the secondary air port is communicated with the exhaust outlet of the sludge drier. By adopting the device provided by the invention, the heat from sludge incineration is recovered as much as possible by a process as simple as possible, the wet sludge is incinerated with low energy consumption, and the gas is simultaneously subjected to deodorization and harmless treatment.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

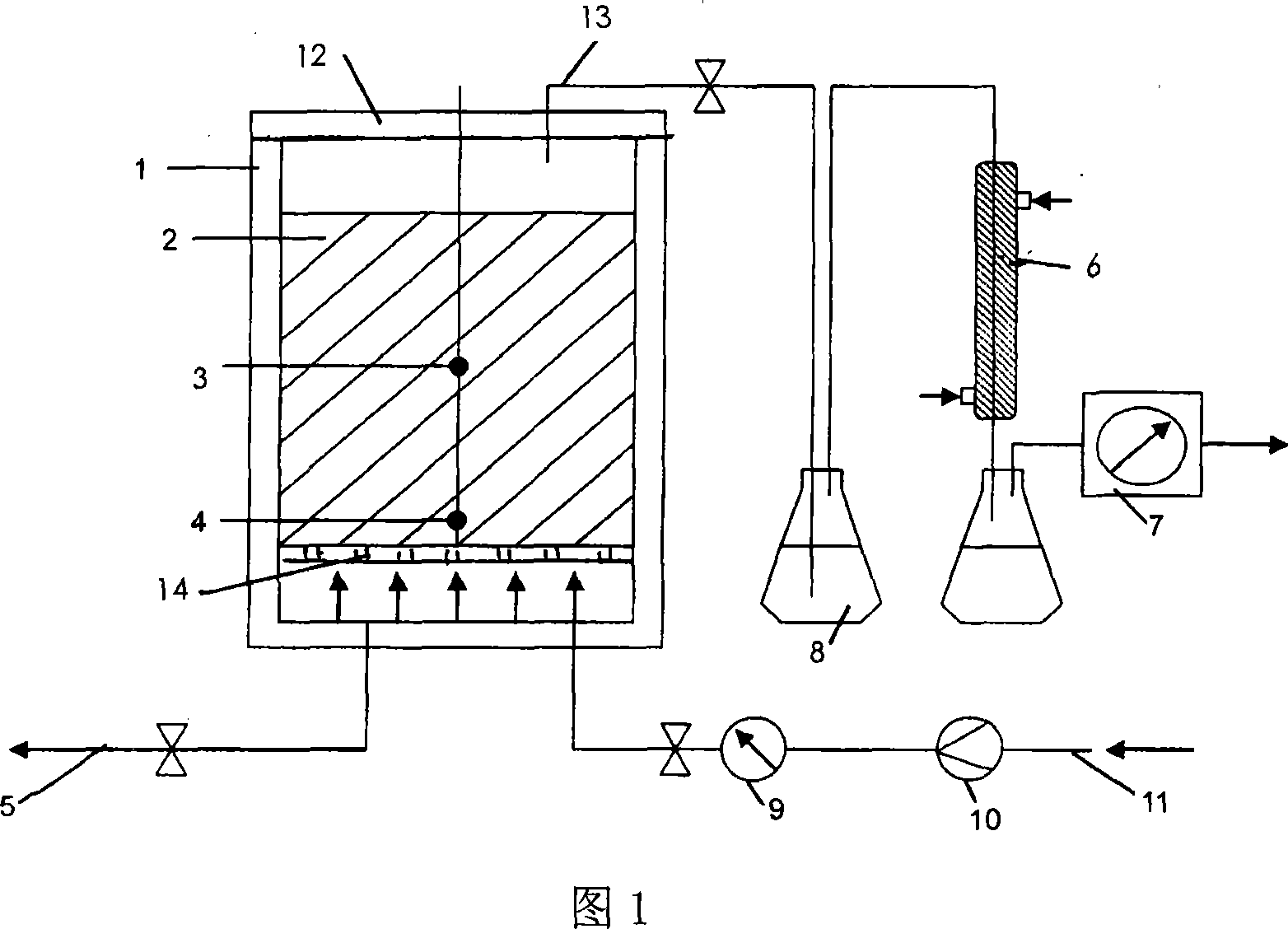

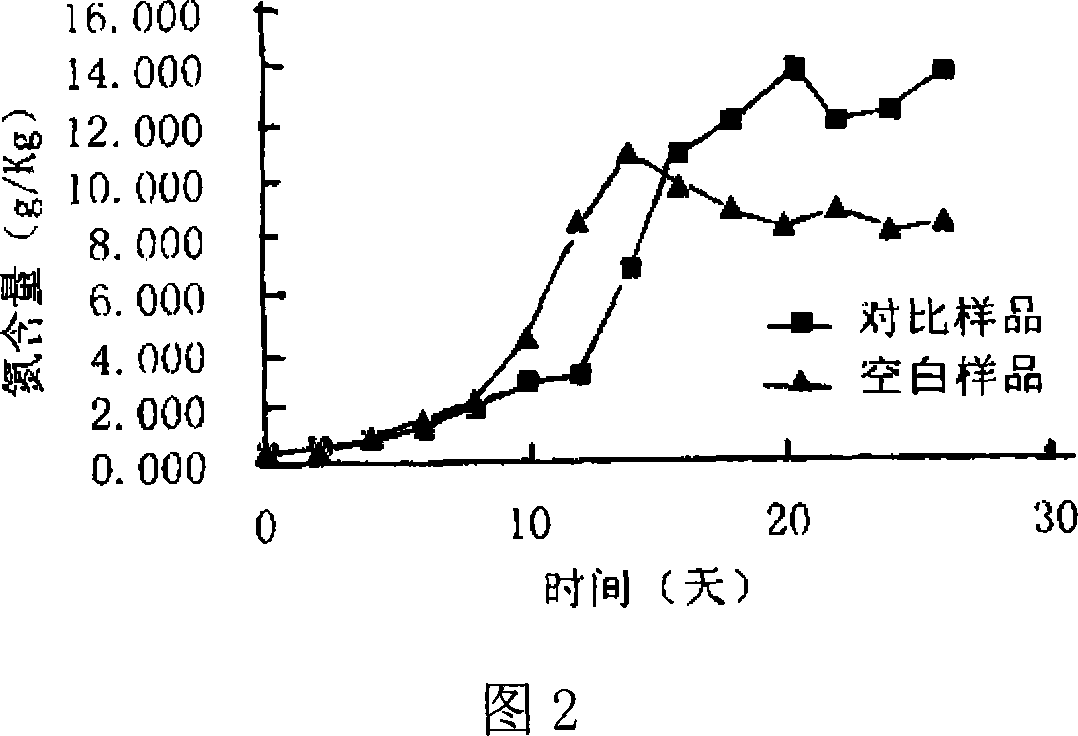

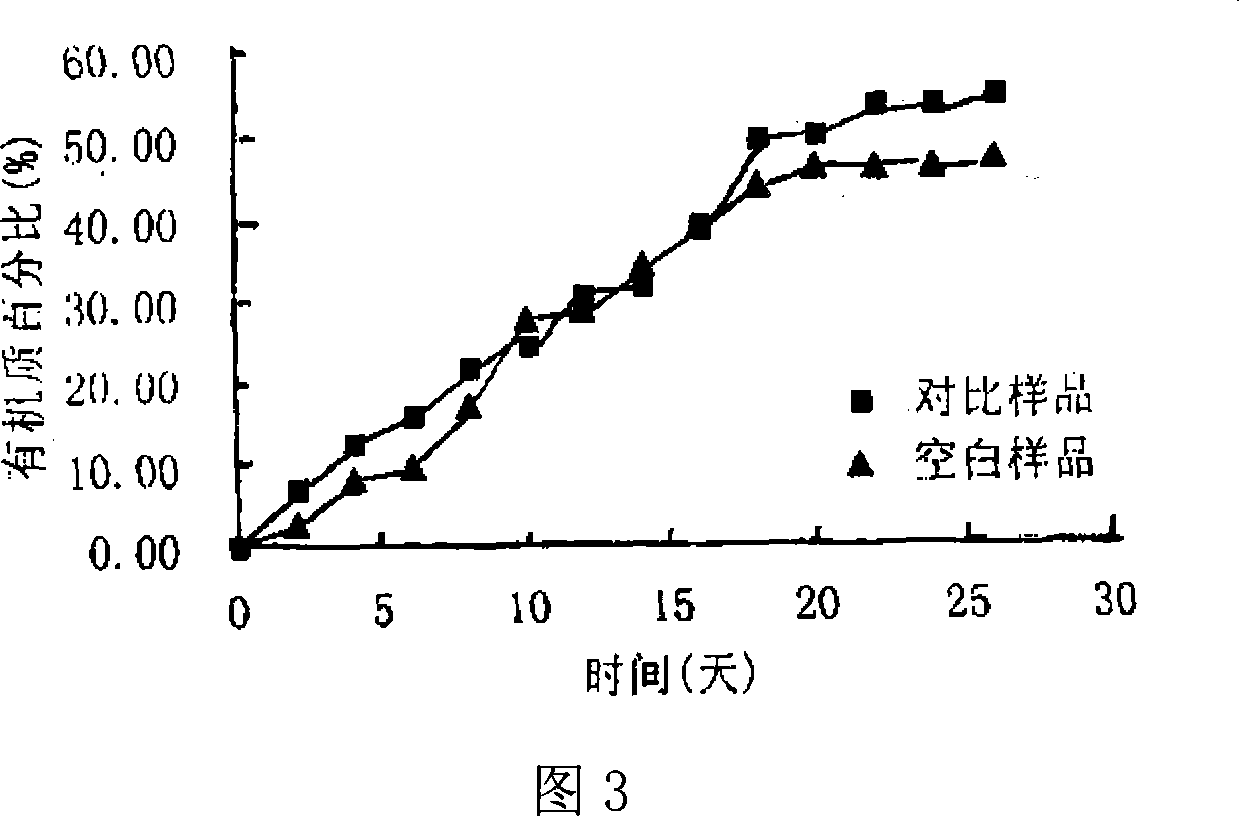

Method and device for fast composting kitchen residual by catalytic decomposing agent

InactiveCN101033154AIncreased rate of organic matter degradationImprove the degree of organic matter degradationBio-organic fraction processingClimate change adaptationRoom temperatureEngineering

This invention discloses a method and a device for composting rest materials of kitchens by corrosion-catalyst, which adds a corrosion-catalyst solution into an analog rest material of kitchen composed of potatos, rice, carrots, leaves, meat, soya and plant soil in a certain proportion to process them and keep the compost system under room temperature and ventilation, in which, the application of corrosion-catalyst can increase the degradation rate and degree of organic matters and increases the effect of the compost products, the degradation rate is increased by 76%, the degradation degree of organic matters of the compost products is increased by 16.3% and content of NH4+-N is increased by 62.4%.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

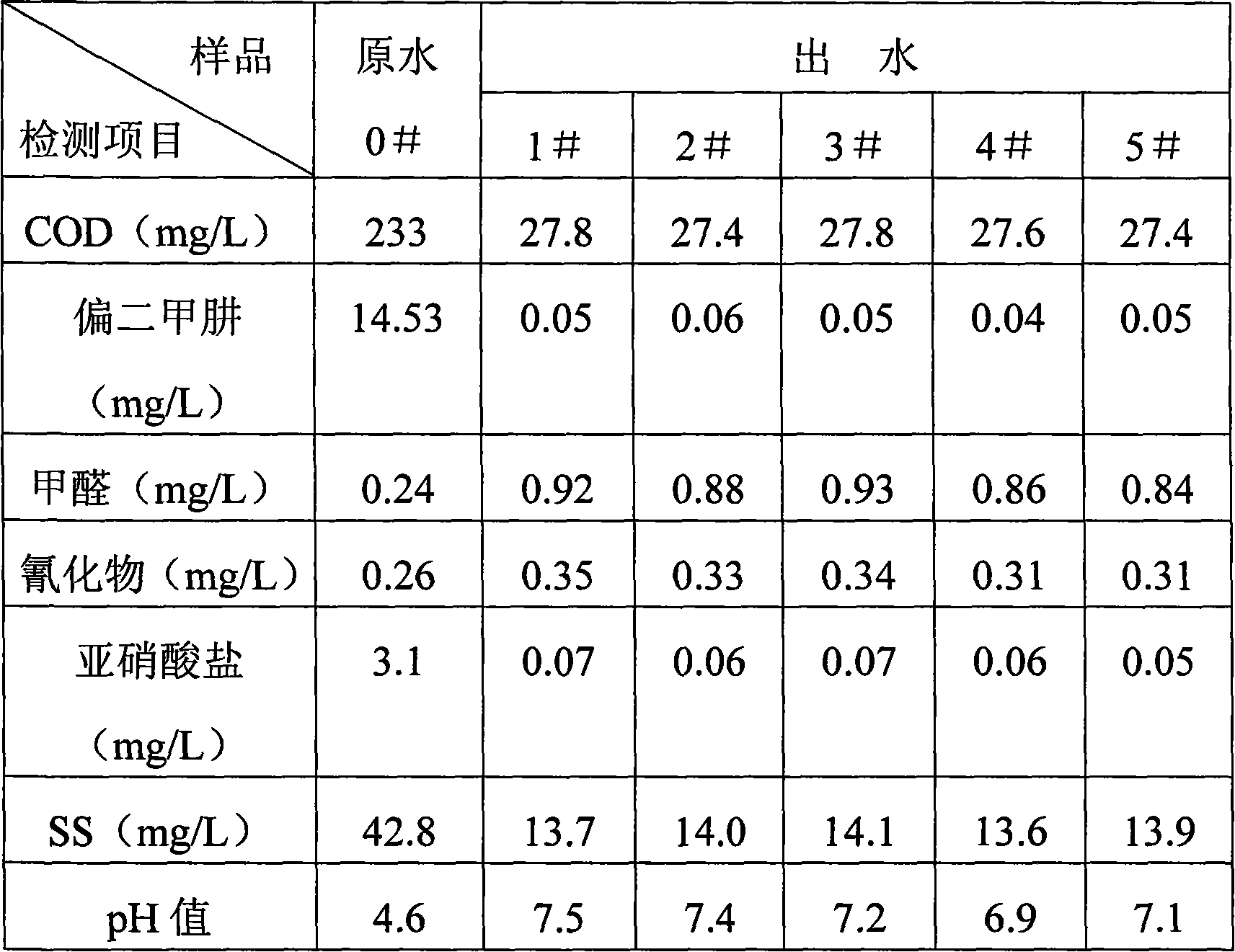

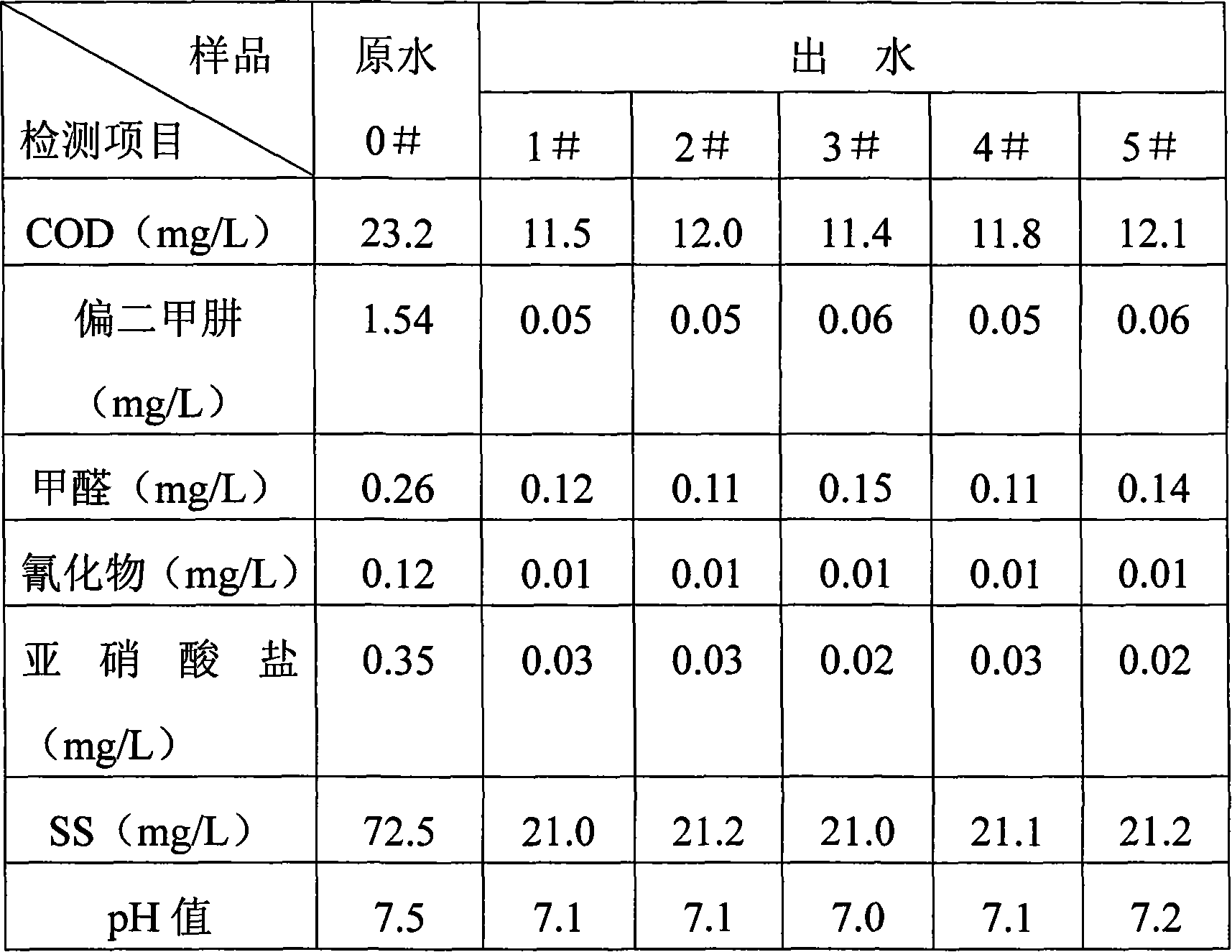

Treatment method of missile propellant waste water and mobile processing vehicle

InactiveCN101249997AEmission complianceImprove processing efficiencyWater/sewage treatment by irradiationMultistage water/sewage treatmentWastewaterWaste treatment technologies

The invention relates to an environmental protection waste treatment technique, in particular providing a processing method for space propellant wastewater and a movable treatment trolley, employing plasma oxidation technology to combine with process for photo-oxidation to treat propellant wastewater. The movable treatment trolley mainly comprises a trolley body, a working cabin and a treatment device, and the propellant wastewater of each station is treated according to the above method. The invention has the advantages that the treatment technique is reliable in technique and high in treatment efficiency, and is capable of meeting the standard for discharge of the propellant wastewater and reducing the treatment cost greatly, further as employing the movable treatment trolley, the technical problems of mounting and using on the trolley of the device is resolved, and the movable treatment trolley is sound in mobility and simple in management of the operation, which is adapted for pollution treatment of multi-stations of launch site.

Owner:ENG DESIGN & RES INST OF GENERAL ARMAMENTS DEPT +1

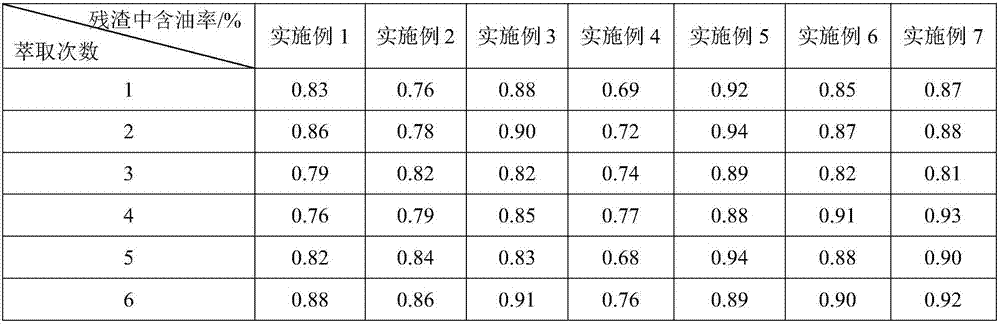

Extracting solvent, method for treating waste based on same and application of method

InactiveCN107050916ARealize recycling and reuseImprove extraction efficiencySolvent extractionLiquid hydrocarbon mixture productionAlkaneSludge

The invention provides an extracting solvent, a method for treating waste based on the same and application of the method. The extracting solvent is prepared from halogenated hydrocarbons and alkanes. The method comprises the following steps: mixing and stirring the extracting solvent with oil-containing waste; then separating solid-liquid phases through centrifuging; pouring a separated solid phase into a distillation device for heating and drying, and recycling water and the extracting solvent in the solid phase; pouring a separated liquid phase into the distillation device, and recycling the water, oils and the extracting solvent. According to the extracting solvent, the method and the application, provided by the invention, the problems that an oil-containing waste treatment technology in the prior art is narrow in application range, high in energy consumption, complicated in technology, high in cost, easy to cause secondary pollution and the like are solved; the extracting solvent, the method and the application, provided by the invention, have the advantages that not only can oil-based drillings generated during a drilling process be treated, but also oil-containing sludge generated during oil field exploitation and transportation can be treated, recycling and reutilization of the oil and the extracting solvent can be realized, a technological process is relatively simple, the extracting efficiency is high, centralized treatment is suited, harmlessness and reclamation can be realized, the secondary pollution cannot be caused, and the like.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

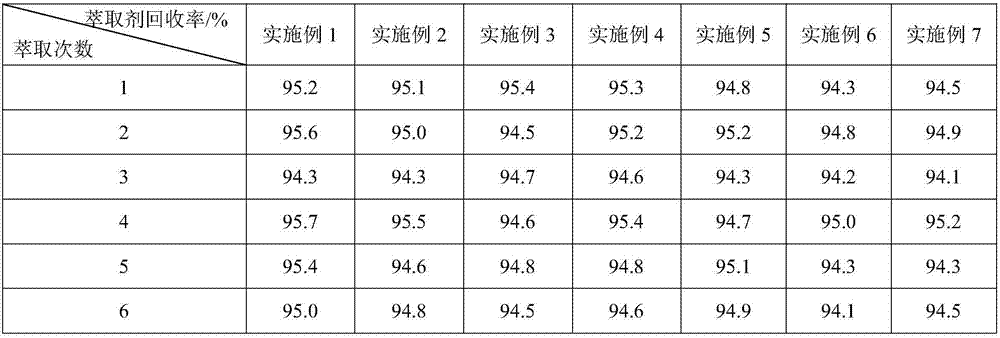

Coarse TDI (toluene diisocynate) treating method

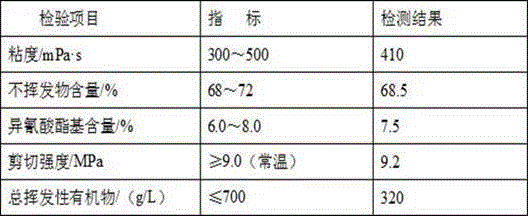

ActiveCN106753180AEasy to useImprove performancePolyureas/polyurethane adhesivesPolyurethane adhesivePolymeric MDI

The invention relates to the technical field of synthesizing of TDI (toluene diisocynate), in particular to the technical field of treatment of wastes in the synthesizing process, and discloses a coarse TDI treatment method. The method is characterized in that coarse TDI is modified through polymerized MDI (methylene diphenyl diisocyanate), and thus novel modified isocyanate can be produced and can be used as a raw material for producing a polyurethane adhesive. The production method is simple; the prepared polyurethane adhesive is high in performances. With the adoption of the method, the technical problems in the prior art that the cost of treating coarse TDI in the TDI synthesizing process is high, the generated tar solid wastes are hardly treated and the environment is polluted can be solved; the tar solid wastes can be effectively reduced, and thus the environmental pollution is reduced; and the economic benefit is high.

Owner:CANGZHOU DAHUA CO LTD

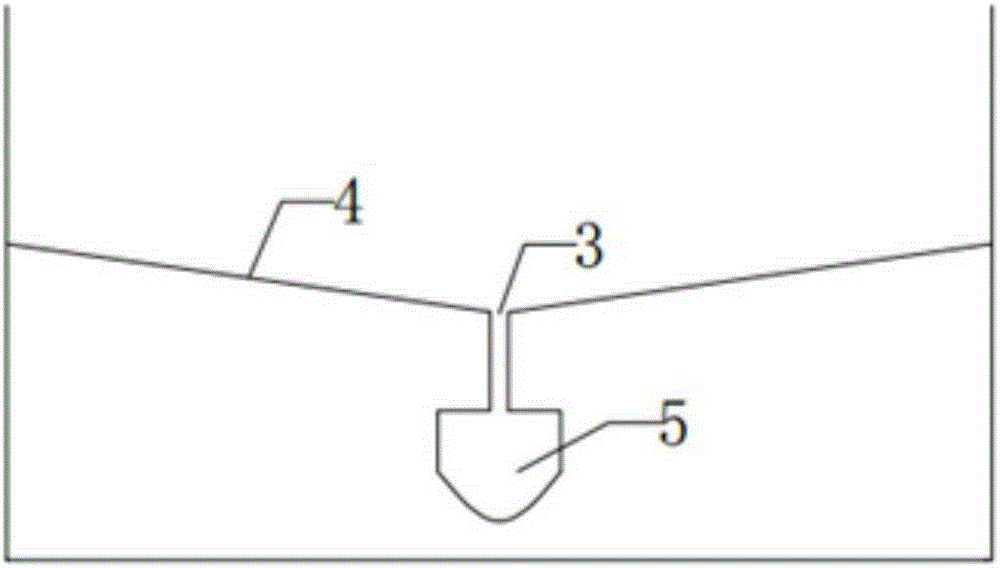

Oil-water separator

InactiveCN101947399AEfficient managementReduce pollutionLiquid separationFiltration circuitsOil and greaseChemical industry

The invention discloses an oil-water separator, which belongs to the technical field of waste treatment. The oil-water separator comprises a case, wherein the upper part of the case is a filter cavity and the lower part of the case is a separating cavity; and a combined tank consisting of an oil storage tank, a mixing tank and a water storage tank, connecting pipelines and valves are arranged in the separating cavity. The oil-water separator has the advantages of high separation efficiency, complete oil-water separation, no need of loading or transporting waste cooking oil, no need of chemical agent or energy source, no secondary pollution, low cost and convenient use. The separator can treat the waste cooking oil produced by catering services in situ; one equipment can simultaneously realize solid-liquid separation and oil-water separation; the recovered grease can be used as a raw material for the chemical industry; and the discharged sewage meets the national emission standard. The separator can retain food residues and grease of kitchen wastes of canteens, hotels and restaurants from the source and reduce grease content in the sewage. The separator realizes effective management of the kitchen wastes, enhances operability of the management, prevents the waste cooking oil from returning to dining tables, ensures food safety and effectively reduces pollution of kitchen sanitary sewage to environment.

Owner:四川省中明新能源科技有限公司

Biomass waste treatment device

ActiveCN106345788AImprove filtration efficiencySolid waste disposalPulp and paper industryWaste treatment technologies

The invention relates to the technical field of organic waste treatment and provides a biomass waste treatment device. The biomass waste treatment device comprises a main body, a conveying mechanism, a cutting mechanism and an injection mechanism, wherein the main body comprises a shell, an extrusion plate and a partition plate; the shell encloses to form a working cavity with a feeding opening; the working cavity is divided into a cutting cavity, a material falling cavity and a fermentation cavity by the extrusion plate and the partition plate; the feeding opening is communicated with the cutting cavity; the extrusion plate is provided with a plurality of extrusion meshes; the conveying mechanism is arranged at the feeding opening and is used for feeding raw materials into the cutting cavity; the cutting mechanism comprises a roller and a first motor; the first motor is arranged on the shell; the roller is coaxially arranged on an output shaft of the first motor and positioned in the cutting cavity. According to the embodiment of the invention, the biomass waste is fermented after being shredded, so the fermentation efficiency is greatly improved.

Owner:JIANGSU SIKU INFORMATION TECH CO LTD

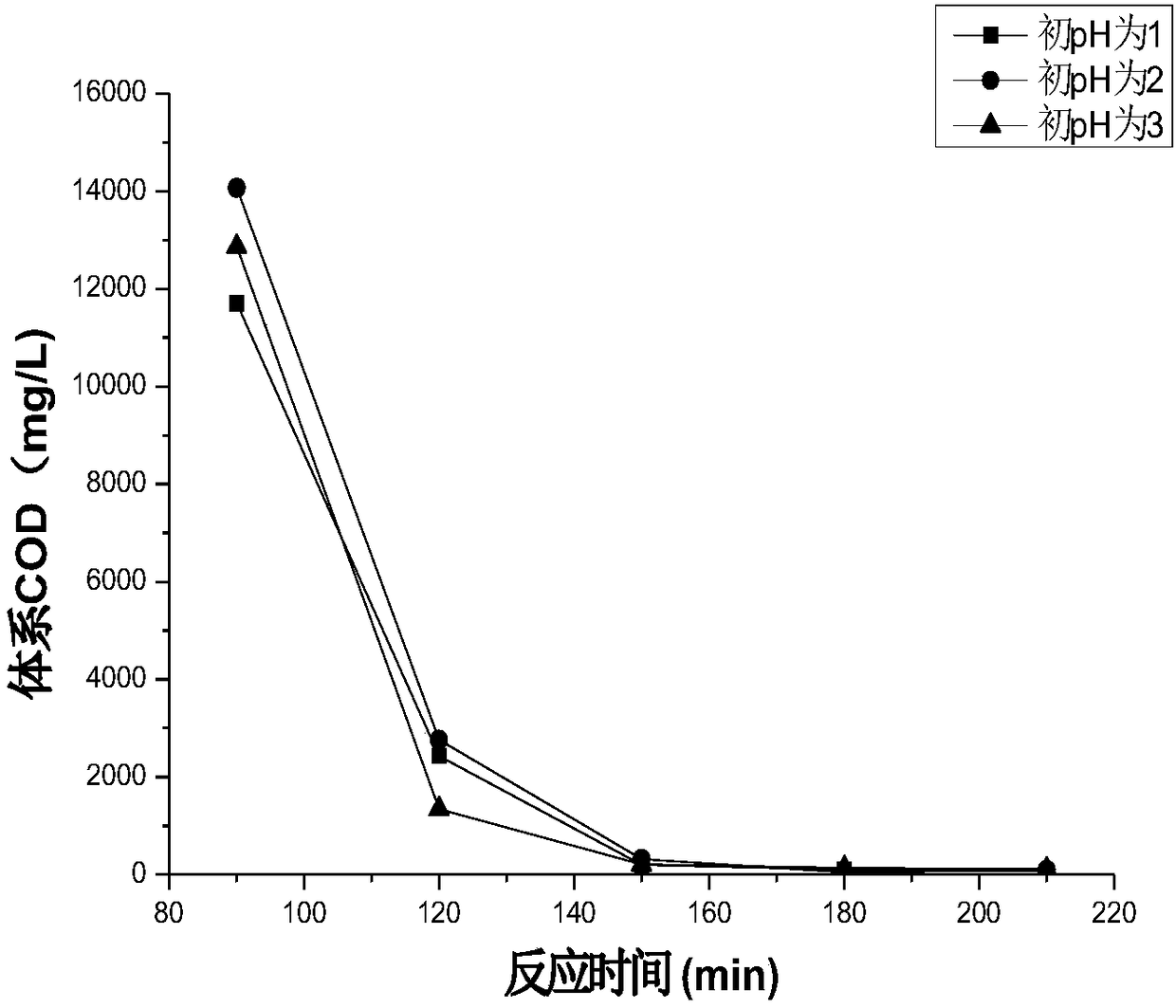

Treatment method of radioactive waste negative ion exchange resin

PendingCN108538420AImprove oxidative degradation efficiencyIncrease profitRadioactive decontaminationHydrogenRadioactive waste

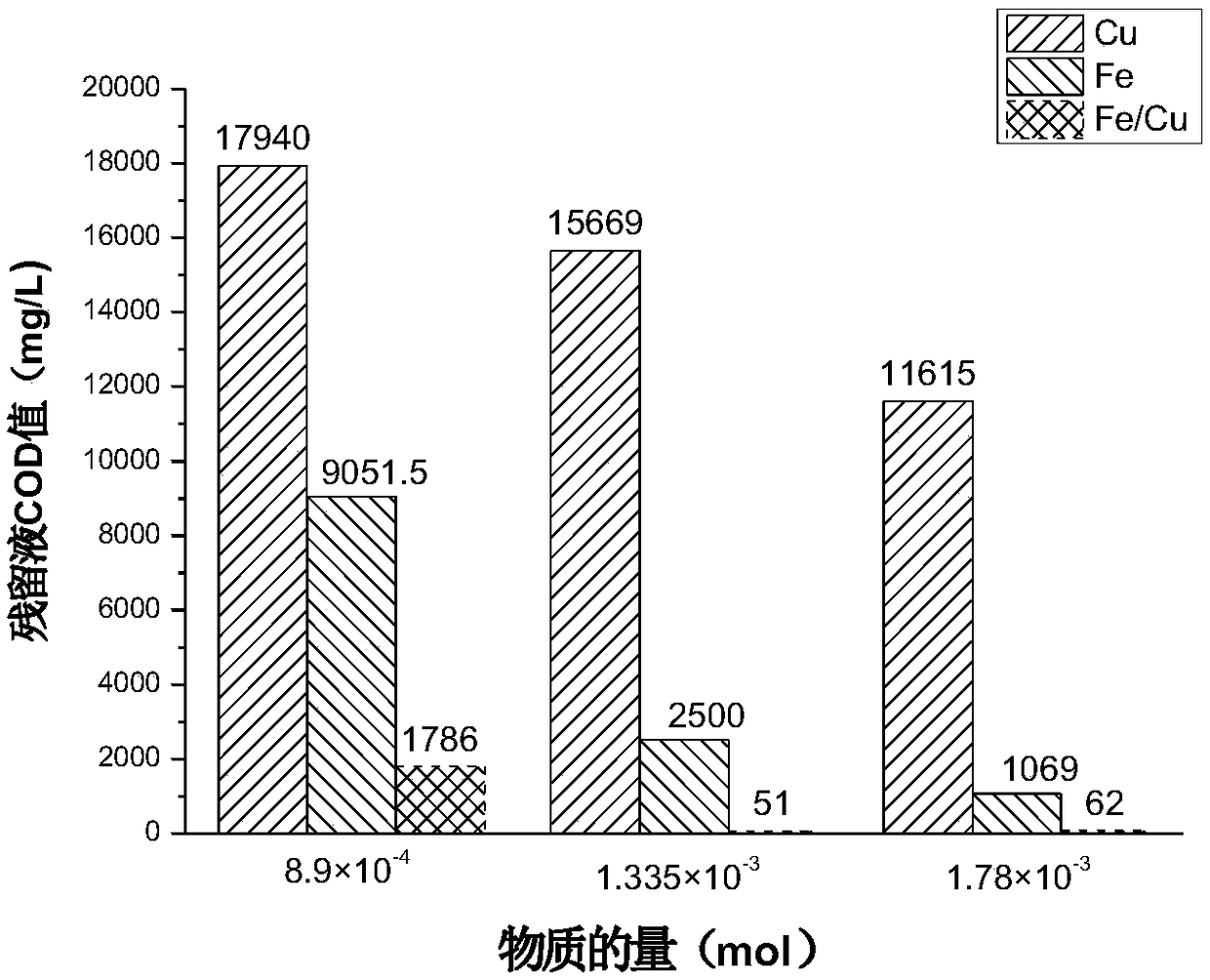

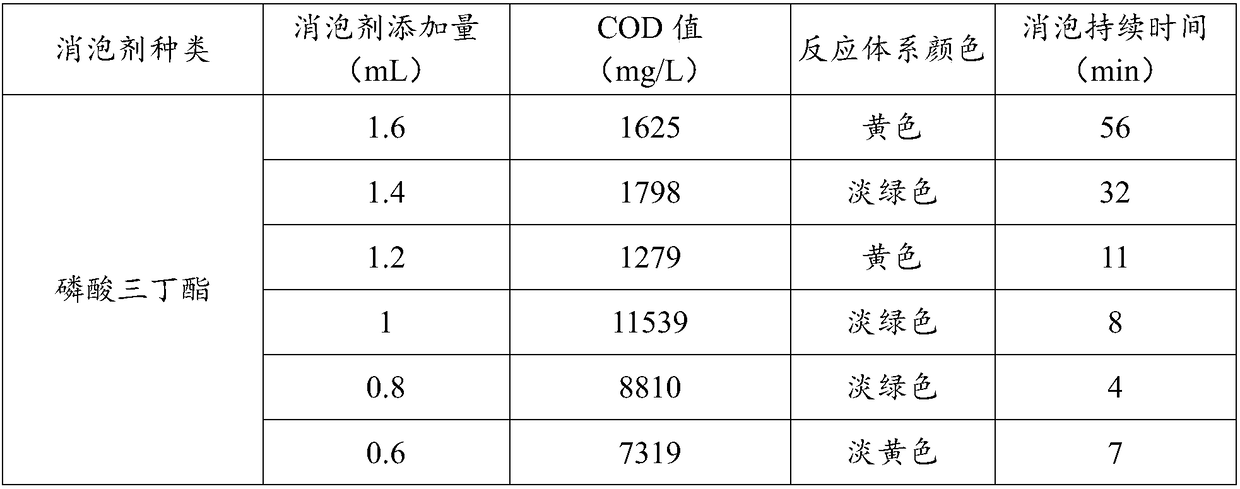

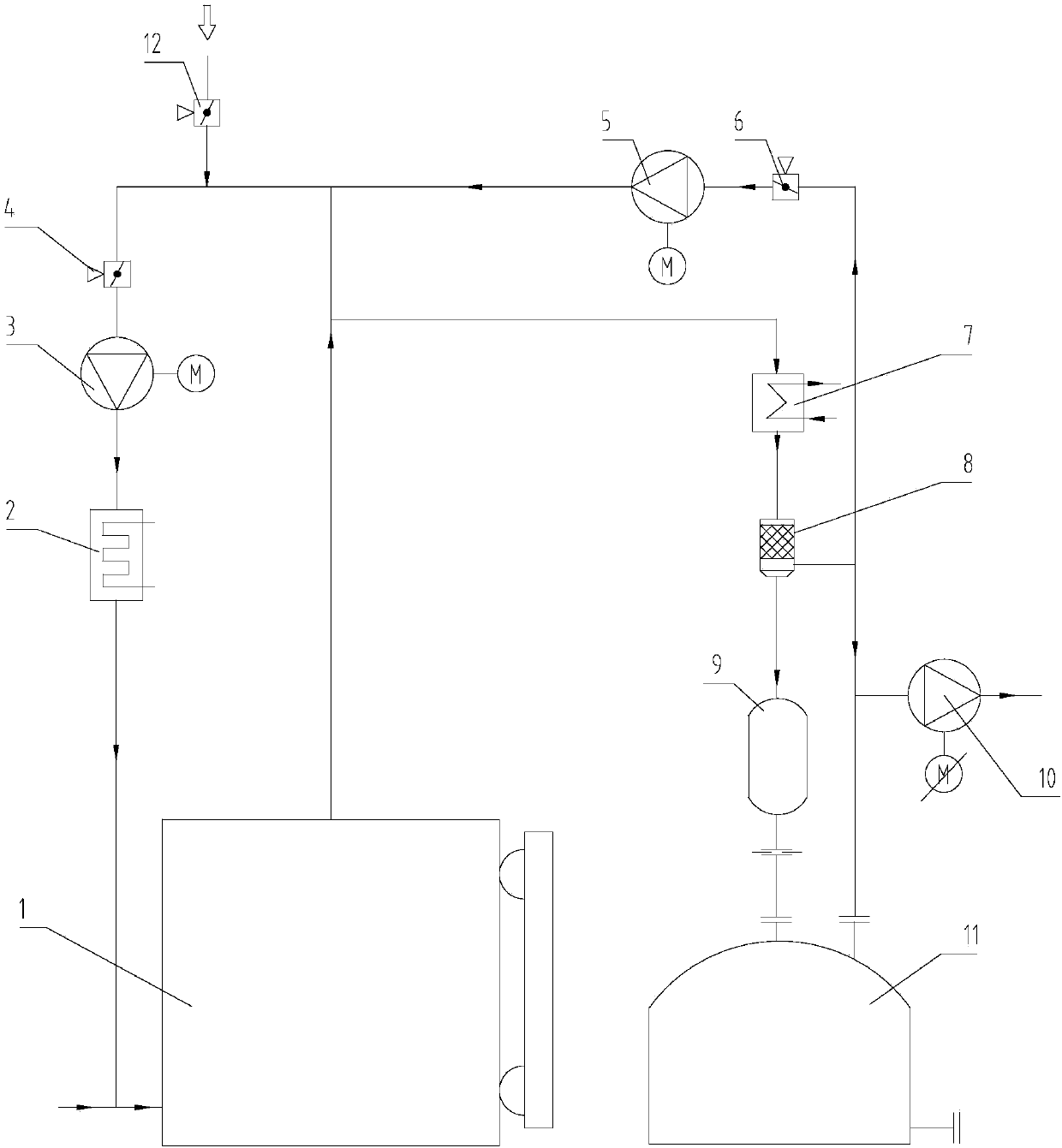

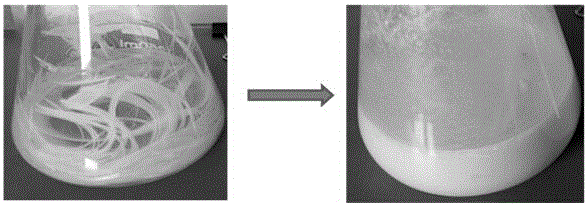

The invention belongs to the technical field of nuclear waste treatment, and relates to a treatment method of radioactive waste negative ion exchange resin. The method includes the steps: adding oxidizing agent hydrogen peroxide solution, catalysts and defoaming agents into the radioactive waste negative ion exchange resin; inorganically treating organic components in the radioactive waste negative ion exchange resin by controlling temperature and pH (potential of hydrogen) of reaction. The catalysts are mixture of Fe2+ and Cu2+. By the treatment method of the radioactive waste negative ion exchange resin, oxidative degradation efficiency of the radioactive waste negative ion exchange resin can be improved within a short reaction time, usage amount of the defoaming agents is reduced in thetreating process, and the utilization rate of oxidizing agents is increased in the treatment process.

Owner:CHINA INST FOR RADIATION PROTECTION

Drying system in radioactive solid waste furnace and drying method

InactiveCN107830698APrevent leakageAvoid effluxDrying solid materials without heatDrying gas arrangementsRadioactive gasVacuum pumping

The invention relates to a drying system in a radioactive solid waste furnace, meanwhile relates to a corresponding drying method, and belongs to the technical field of radioactive waste treatment. The system comprises a drying furnace and a condensate box; the drying furnace is provided with a main circulation loop and a flow dividing pipeline, wherein the top of the main circulation loop is connected to one side of the drying furnace through a heating draught fan and a heater which are in series connection, and the flow dividing pipeline is connected to the condensate box through a cooler, asteam and water separator and a metering device, a gas outlet of the steam and water separator is connected to the main circulation loop through a cooling draught fan to form an air returning pipeline, the cooling draught and the heating draught fan are each provided with a corresponding adjusting valve, and the condensate box and a gas outlet of the gas and water separator are connected with a vacuum pumping device to form a vacuum generation passage. Discharging of radioactive gas in the drying process can be effectively avoided, air utilization rate is improved, energy consumption is saved, and secondary pollutions can be obviously reduced.

Owner:AEROSUN CORP +1

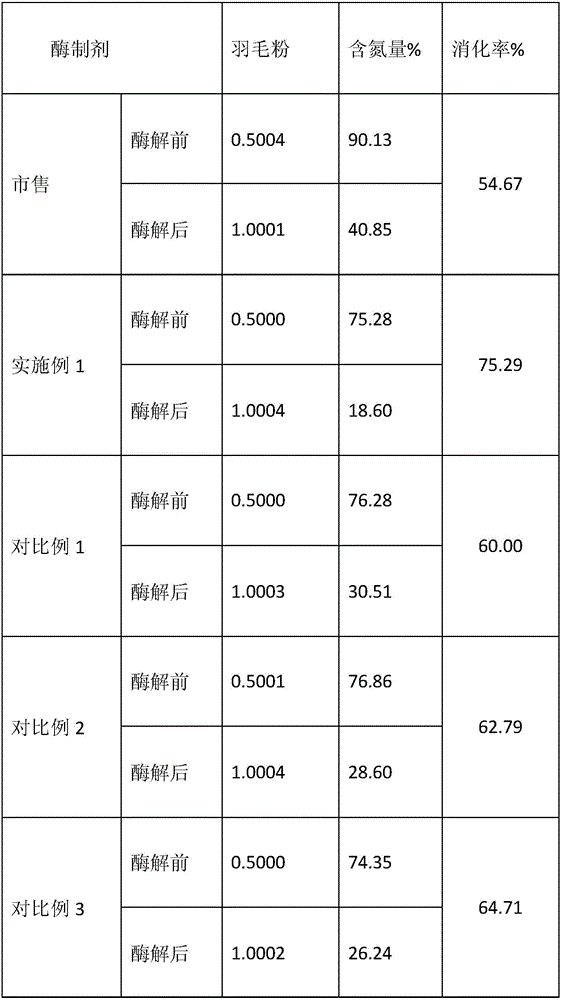

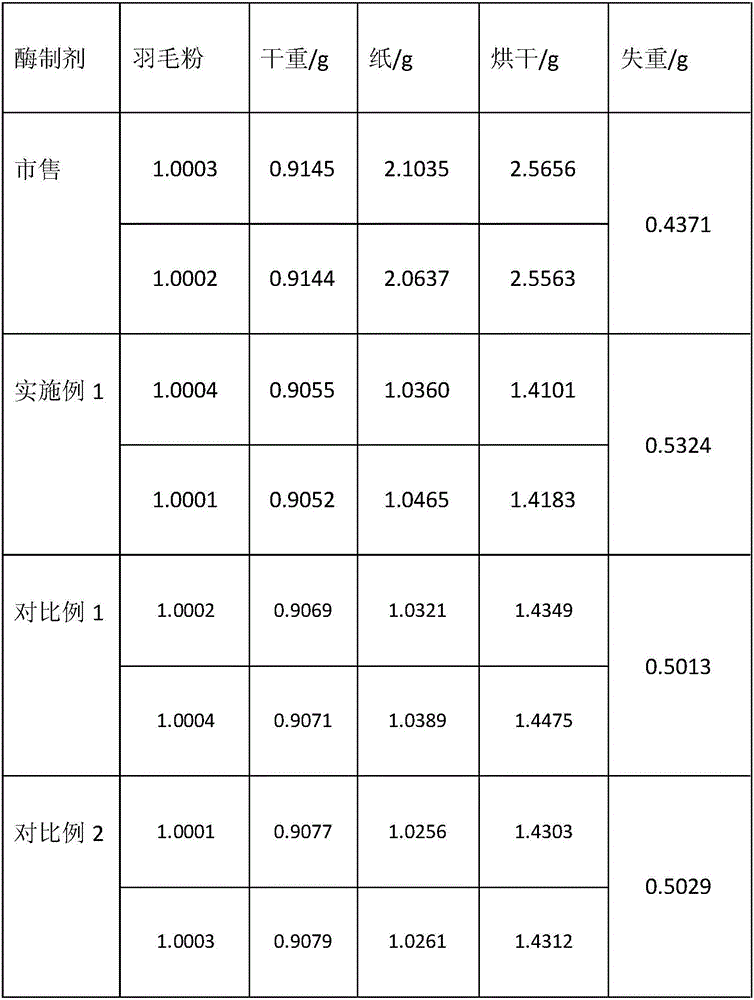

Processing and treating method of feathers

The invention belongs to the technical field of treatment of waste in poultry industry, and particularly relates to a processing and treating method of feathers. The processing and treating method of the feathers comprises the following steps of (1) taking feathers, adding water in the weight ratio of materials to liquid being 1 to (5-9), and performing uniform mixing; (2) adjusting the temperature of a mixed solution obtained in the step (1) to 40-55 DEG C, adjusting the pH to 8.0-9.0, adding protease for enzymolysis, wherein the dosage of the protease is 0.5-2.5% of the weight of the feathers, performing enzymolysis for 10-14h, and performing enzyme deactivation treatment at 95-100 DEG C for 5 minutes; and (3) drying enzymatic hydrolysate obtained in the step (2) in a drying oven. The processing and treating method disclosed by the invention has the beneficial effects that when the method disclosed by the invention is used for processing and treating the feathers, the content of small peptides in prepared feather powder is 20.94%, which is greatly increased compared with the content of small peptides in common feather powder sold in the market only being 0.9%, and compared with the digestion rate of the feather powder sold in the market being 54.67%, the digestion rate of the feather powder obtained by the method disclosed by the invention is 79.29% and is also greatly increased.

Owner:JINANBESTZYME BIO ENG CO LTD

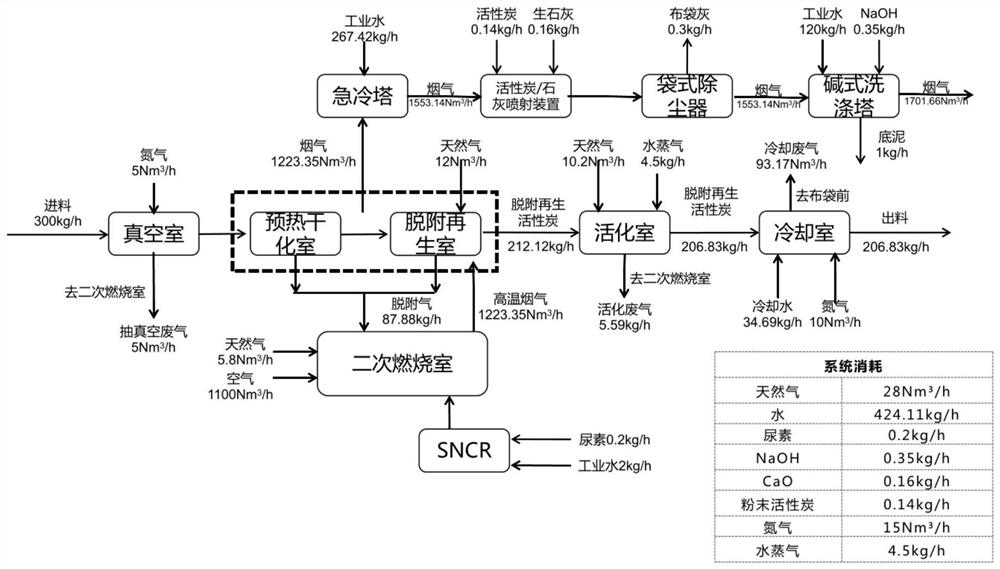

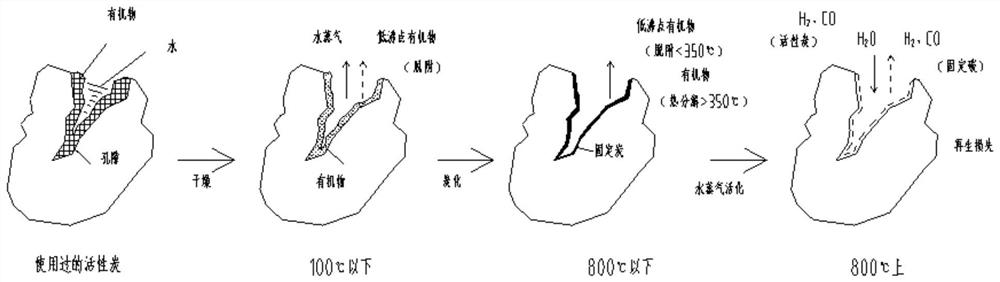

Waste honeycomb activated carbon regeneration process

InactiveCN111632584ARestore adsorption capacityGuaranteed anaerobic atmosphereGas treatmentDispersed particle separationActivated carbonHoneycomb

Owner:马月生

Garbage disposal process

The invention belongs to the technical field of waste disposal and particularly provides a garbage disposal process.The garbage disposal process comprises the following steps of screening garbage, then crushing the garbage, conducting magnetic separation on the crushed garbage, picking out metal garbage, picking out sandstone and plastic garbage out of the remaining garbage through air separation, making the sandstone into building materials, and conducting crushing, washing, drying, splitting, fractionation and condensation on the plastic garbage, so that solid wax is obtained.The garbage disposal process is simple in structure, low in cost and high in efficiency, the garbage is effectively separated without being dumped or incinerated, environmental pollution is avoided, the sandstone and waste plastic obtained through separation are effectively recycled, and the waste materials are changed into things of value.

Owner:周口市丰泉环保电力有限公司

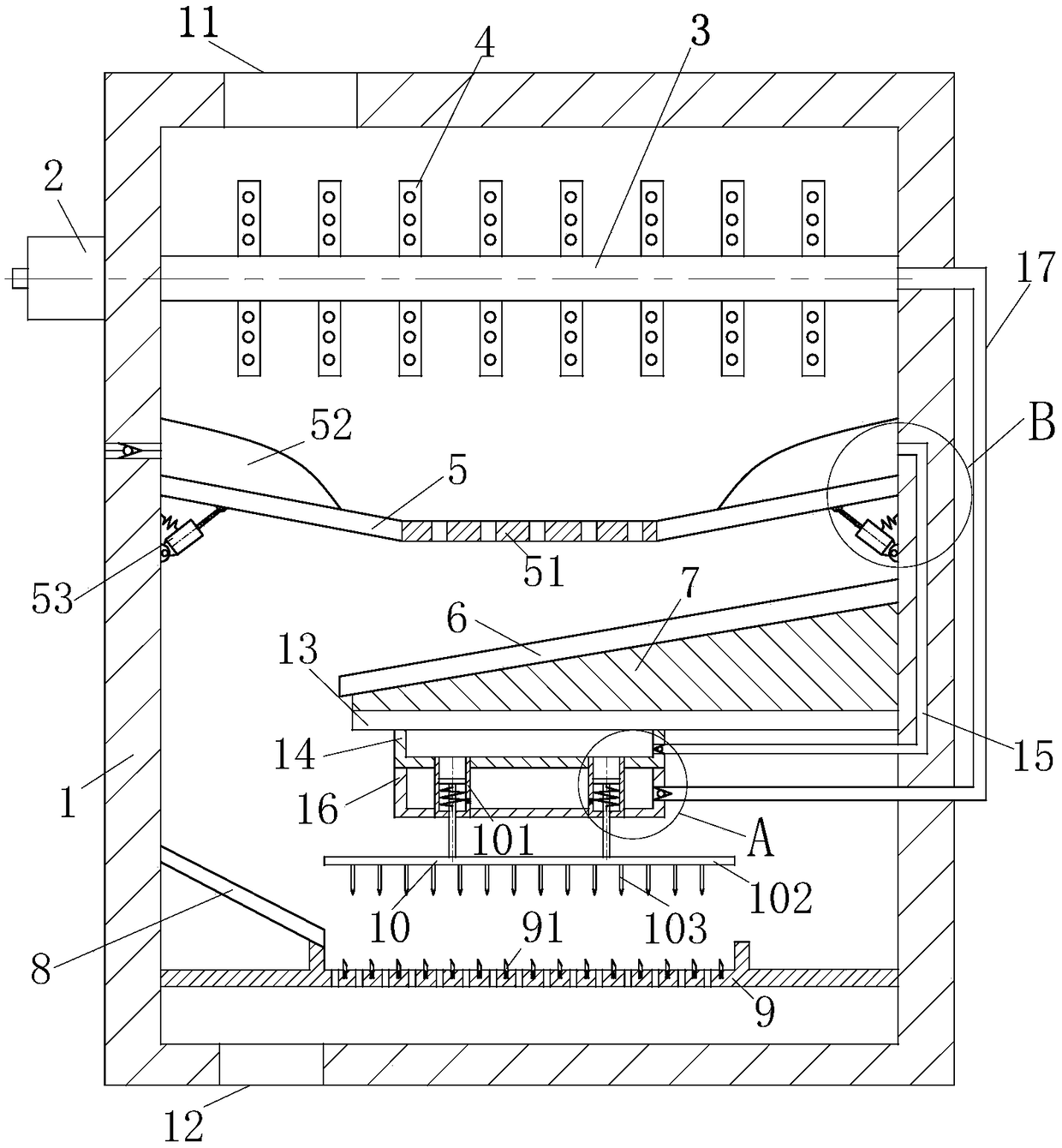

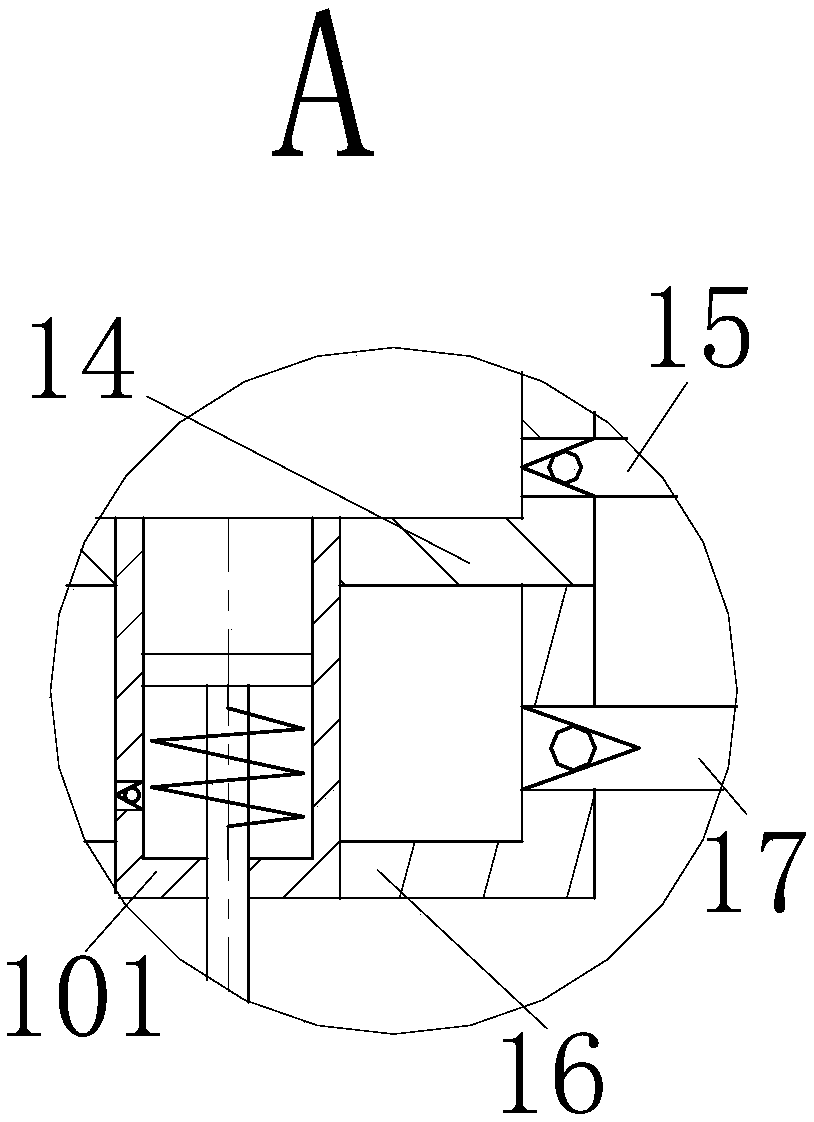

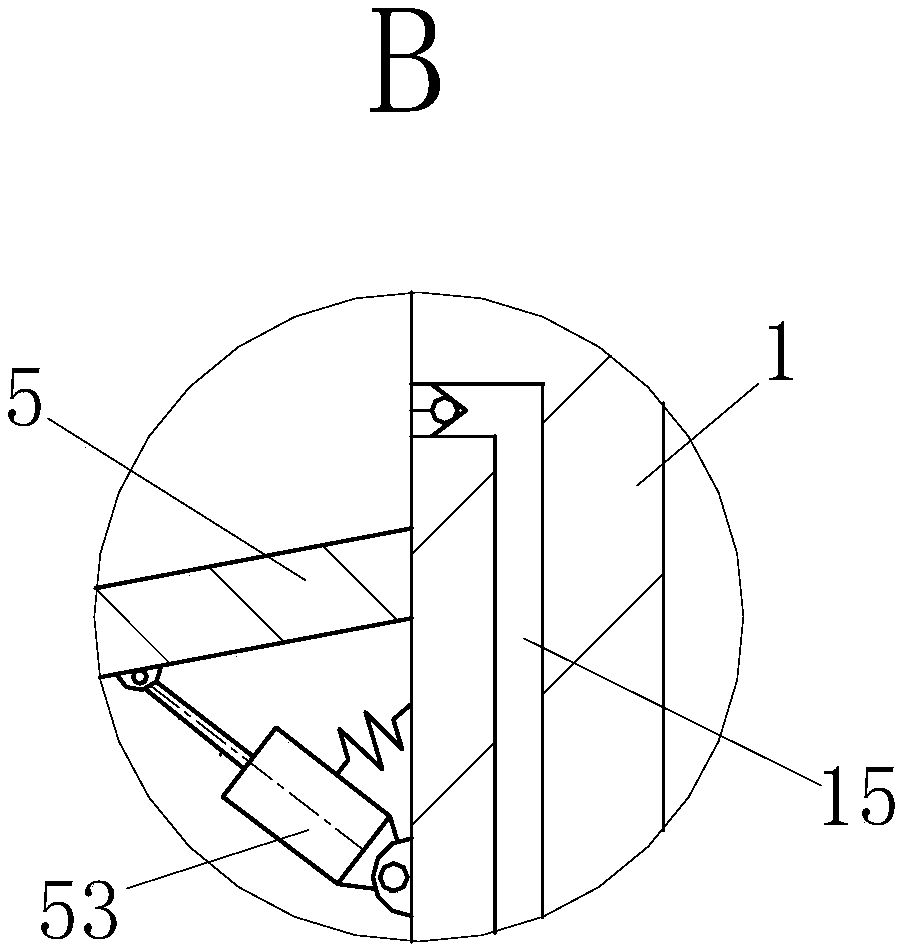

Urban solid waste treatment device

ActiveCN109092861AEnsure normal dischargeWon't blockSolid waste disposalEngineeringWaste treatment technologies

The invention belongs to the technical field of waste treatment, and particularly relates to an urban solid waste treatment device. The urban solid waste treatment device comprises a box, a motor, a connecting shaft, smashing rods, a partition plate, a first slideway, a high-temperature disinfection module, a second slideway, a first filtering net and an extruding module. The motor is fixed to theupper left portion of the box, and the connecting shaft is located in the box. The connecting shaft and an output shaft of the motor are connected, and the smashing rods are evenly mounted on the connecting shaft. The partition plate is mounted in the box and located below the smashing rods. A second filtering net is arranged in the middle of the partition plate, and the first slideway is fixed into the box. The high-temperature disinfection module is located below the first slideway and makes contact with the bottom of the first slideway. The second slideway is located in the box and locatedbelow the first slideway. The first filtering net is located in the box, mounted on the lower portion of the second slideway, and connected with the second slideway. The extruding module is located between the first filtering net and the high-temperature disinfection module.

Owner:深鹏环保工程有限公司

Oil field waste classification recovery processing device

InactiveCN108499749AEasy to sort and collectEasy to recycleCentrifugesMoving filtering element filtersWaste processingSlag

The invention relates to the technical field of oil field waste processing, in particular to an oil field waste classification recovery processing device. The oil field waste classification recovery processing device comprises a shell, a feeding hopper, a slag outlet pipe and a filtering net; and a connecting pipe which is vertically arranged is fixedly connected to the center position of the topend of the shell, a supporting frame which is arranged horizontally is fixedly connected to the inner side of the shell, a fixing pipe which is arranged vertically is arranged on the inner side of thesupporting frame, the feeding hopper is fixedly connected to the bottom end of the fixing pipe, the slag outlet pipe is rotationally connected to the outer side of the bottom end of the feeding hopper, a connecting rod which is horizontally arranged is fixedly connected to the inner side of the bottom end of the shell, a multi-groove cam is rotationally connected to the left end of the connectingrod, and the filtering net is horizontally arranged over the connecting rod. According to the oil field waste classification recovery processing device, solid residues which are separated out can bedischarged, the device can conveniently classify and collect the oil field waste, meanwhile, impurities can be filtered out more completely through the filtering net, waste recovering and using are facilitated, the huge economic benefits and the wide market prospects are achieved, and the device is worthy of use and popularization.

Owner:DIMENSION TECH

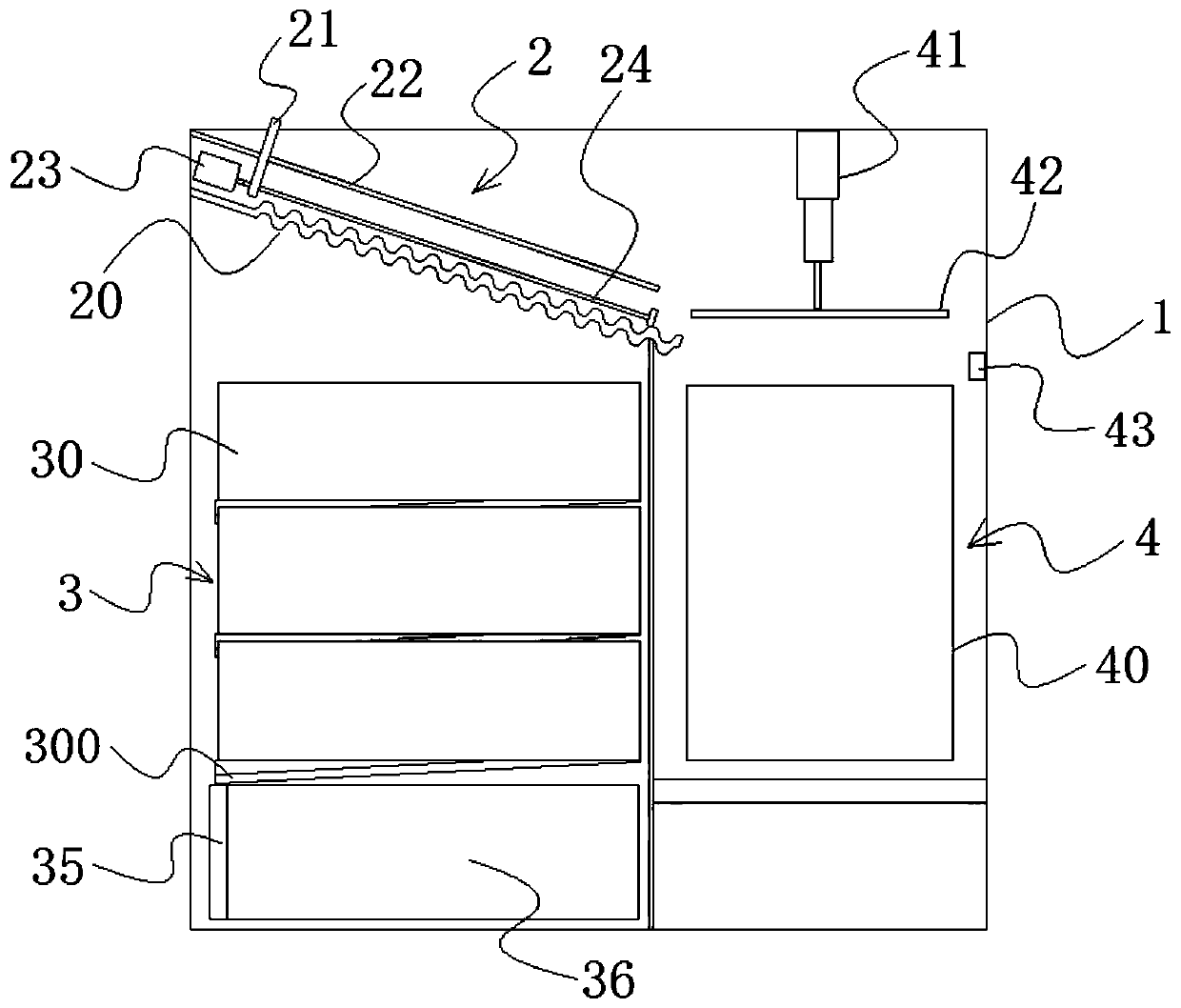

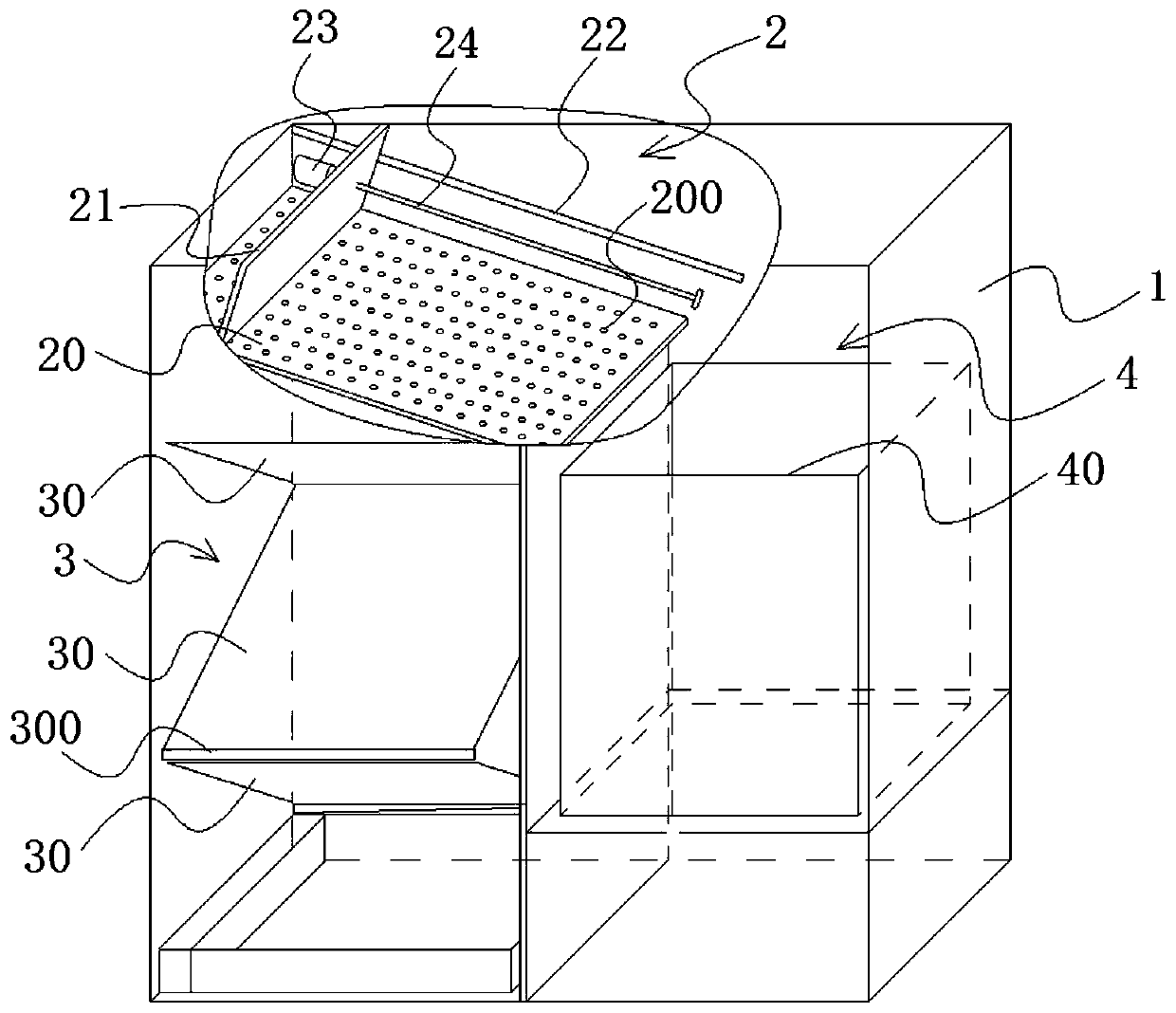

Kitchen garbage treatment device

InactiveCN110694343AThorough separationReduce processing timeFiltration circuitsWater storage tankProcess engineering

The invention provides a kitchen garbage treatment device and relates to the field of waste treatment technologies. The kitchen garbage treatment device comprises a solid-liquid separation bin, an oil-water separation bin and a garbage compression bin, wherein a filter plate is arranged in the solid-liquid separation bin, filtrate holes are formed in the filter plate, the oil-water separation binis arranged at the lower side of the filter plate, a water-seeping oil-isolating layer, an oil storage tank and a water storage tank are arranged in the oil-water separation bin, the water-seeping oil-isolating layer is arranged obliquely, an oil discharging groove is formed in a bottom edge position of the water-seeping oil-isolating layer, the oil discharging groove communicates with the oil storage tank, the water storage tank is located at the lower side of the water-seeping oil-isolating layer, the garbage compression bin is arranged at the outer side of the filter plate and communicateswith the solid-liquid separation bin, an inner cylinder is movably installed in the garbage compression bin, an opening is formed in the top of the inner cylinder, a driving mechanism and an extrudingplate are arranged, corresponding to the opening, at the top of the garbage compression bin, and the extruding plate is matched with the opening of the inner cylinder in shape.

Owner:广州邑拓商务发展有限公司

Environment-friendly waste incineration treatment device

ActiveCN109737414AImprove incineration efficiencyReduce generationCombustion technology mitigationIncinerator apparatusWaste treatment technologiesIncineration

The invention belongs to the technical field of waste treatment, and particularly discloses an environment-friendly waste incineration treatment device. The environment-friendly waste incineration treatment device comprises an incinerator, a feeding opening, an igniter, a motor, a smoke discharging cabin and a controller; the igniter is located on one side of the lower side of the incinerator; themotor is located at the top of the incinerator; the output end of the motor penetrates through the top of the incinerator and extends into the incinerator; a heat collection unit is arranged at the top inside the incinerator; a stirring unit is arranged below the heat collection unit; and a filtering unit is arranged on one side of the incinerator. By the aid of the environment-friendly waste incineration treatment device, the waste incineration efficiency can be improved, and heat and smoke produced by waste incineration can be utilized, so that the utilization rate of resources is increased.

Owner:LISHUI INST OF ECOLOGY ENVIRONMENT NANJING UNIV

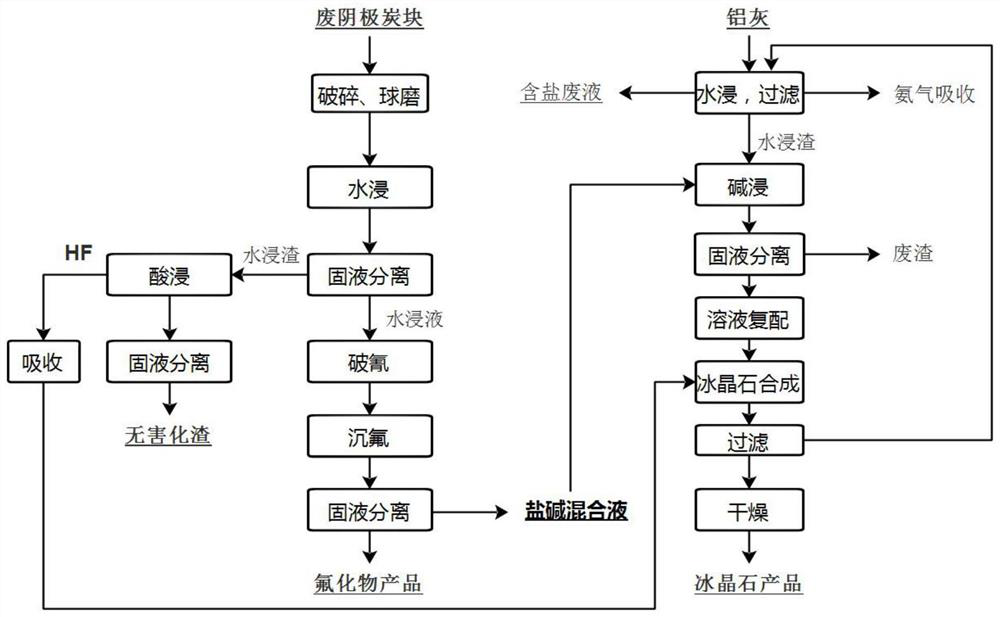

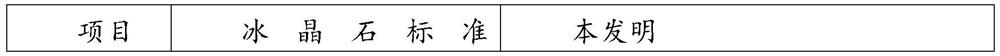

Method for recycling cryolite through combined treatment of aluminum electrolysis overhaul slag and aluminum ash

ActiveCN113072089AHigh recovery rateHarmlessCalcium/strontium/barium fluoridesAluminium fluoridesSodium aluminatePhysical chemistry

The invention discloses a method for recycling cryolite through combined treatment of aluminum electrolysis overhaul slag and aluminum ash, and relates to an aluminum electrolysis solid waste treatment technology. The method comprises the following steps: (1) carrying out water leaching and acid leaching on the overhaul slag; (2) soaking aluminum ash in water; (3) carrying out alkaline leaching on the aluminum ash water leaching residues: reacting the salt-alkali mixed solution obtained in the step (1) with the water leaching residues to obtain a mixed solution of sodium aluminate and salt; (4) detecting the aluminum content and the salt content of the mixed solution in the step (3), and compounding the mixed solution of sodium aluminate and salt to obtain a mixed compound solution for later use; and (5) mixing the mixed compound liquid obtained in the step (4) and the hydrofluoric acid obtained in the step (1) to carry out cryolite synthesis reaction. The overhaul slag and the aluminum ash are subjected to innocent treatment, fluorine in the overhaul slag and aluminum in the aluminum ash are recycled, cryolite is synthesized and returned to the aluminum electrolysis cell, resource recycling of harmful waste slag is achieved, the production cost of electrolytic aluminum is reduced, and the method is suitable for application and popularization.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

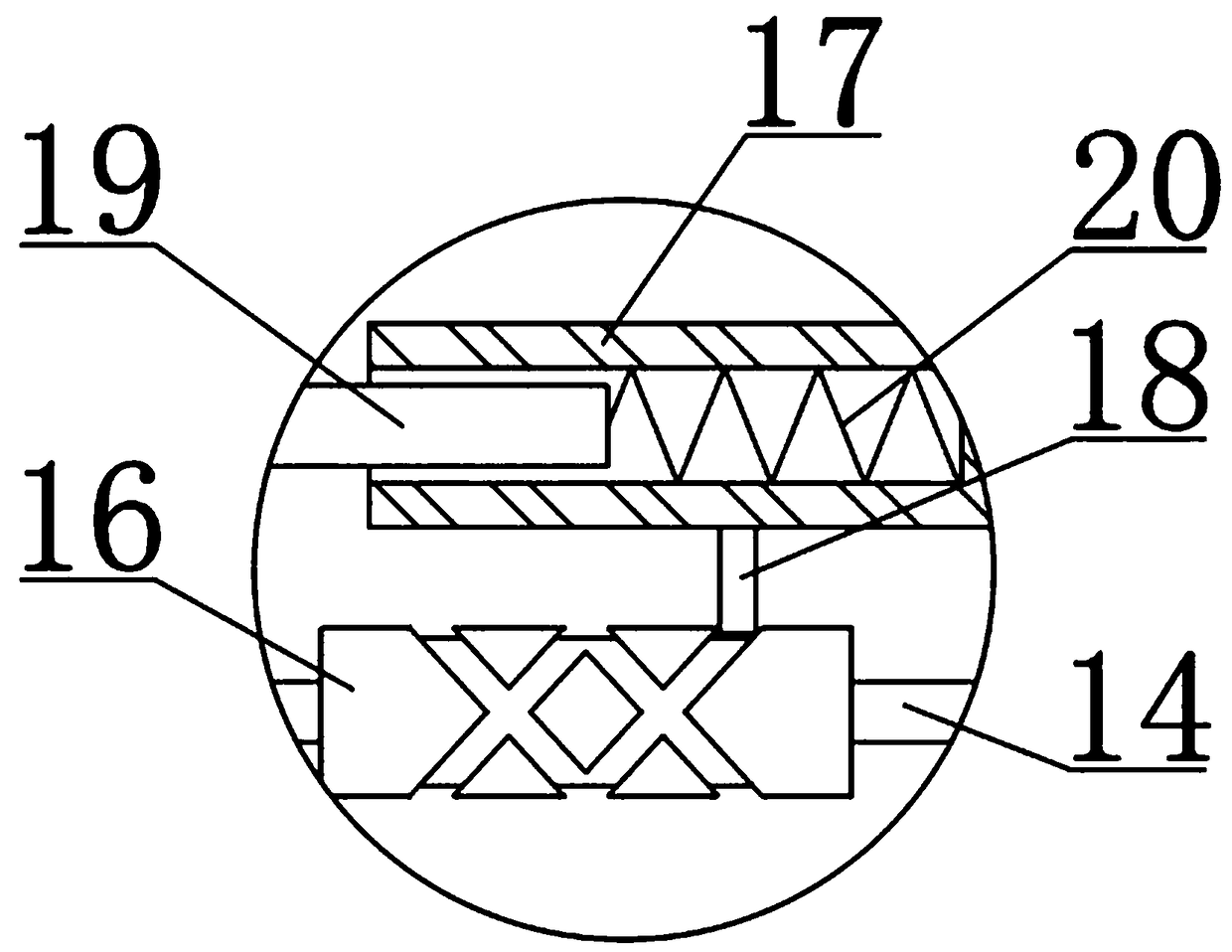

Apparatus and method for completely-mixed fermentation treatment of kitchen/bathroom organic wastes

ActiveCN101948336ASimplify fermentation processing equipmentEasy to operateClimate change adaptationOrganic fertilisersEngineeringEnvironmental engineering

The invention relates to an apparatus and a method for the completely-mixed fermentation treatment of kitchen / bathroom organic wastes, belonging to the field of organic waste treatment technology and characterized in that: a fermentation groove is divided into a feeding pileup groove, a mixing groove, a primary fermentation groove, a secondary fermentation groove, a decomposing groove and a finished product groove; corrugated sheltering plates are arranged on the top of factory workshops; gaps and water collecting trenches are arranged around the factory workshops; and air inflation oxygen supply pipes inside the factory workshops are communicated with porous stainless pipelines of the grooves. The mixed fermentation treatment comprises the following steps of: mixing and stirring organic wastes; air inflation and oxygen supply, fermenting the organic wastes in the primary fermentation groove and the secondary fermentation groove in case of everyday turning; stably decomposing the organic wastes in the decomposing groove; and turning piles to transfer the organic wastes into the finished product groove. The equipment and the method have the advantages of: no need of embedding air inflation oxygen supply pipes in advance, maintaining the ground flat, convenient turning operation by manpower or vehicle, oxygen supply in a manner of air blowing and no return of water drop to composts owing to the sheltering plates on roof, thus the entire fermentation process is shortened and the efficiency is enhanced. In addition, both environmental protection benefit and economical benefit of the organic wastes fermentation treatment are realized.

Owner:上海汀滢环保科技有限公司 +1

Waste treatment method adopting brick making process

The invention relates to a technology for making environment-friendly composite pavement bricks and in particular relates to a waste treatment technology for making composite pavement bricks by utilizing domestic wastes and construction wastes. The waste treatment technology is characterized by drying, screening and grinding the domestic wastes to prepare solid wastes, grinding the construction wastes into powder or fine granules after screening the construction wastes, grinding fluorine gypsum and fly ash into powder, adding 25-35% of domestic wastes, 25-35% of construction wastes, 10-15% of fly ash, 15-20% of fluorine gypsum, 5-10% of cement, 3-5% of aluminium potassium sulfate and 2-5% of acrylic construction gelatine powder to a stirrer and fully stirring the materials uniformly, then sprinkling water and stirring the materials until the raw materials are moist and loose and have certain viscosity, throwing the raw materials into a brick making machine to undergo press forming, curing the formed bricks for 5-7 days in a storeroom with relatively stable temperature and humidity, and delivering the bricks.

Owner:宁士谦

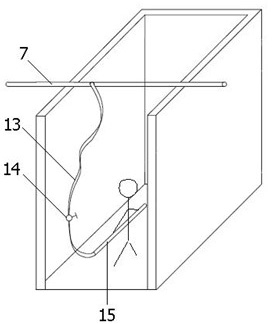

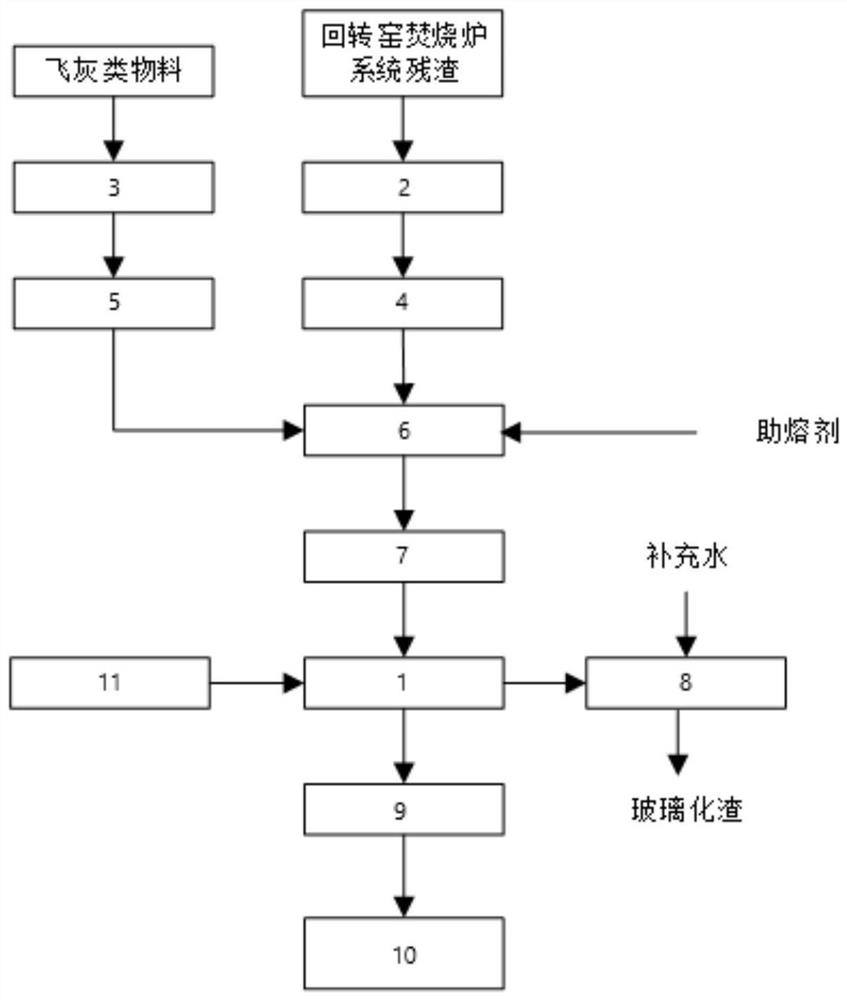

Hazardous waste plasma melting treatment system

InactiveCN112122307AImprove removal efficiencyReduce productionSolid waste disposalTransportation and packagingCombustion chamberSlag

The invention discloses a hazardous waste plasma melting treatment system, and relates to the technical field of hazardous waste treatment. The system comprises a plasma melting furnace, a crusher, agranulator, an incineration residue bin, a fly ash particle bin, a mixing conveyor, a feeding buffer bin, a residue salvaging machine, a flue gas regulator, a rotary kiln incinerator secondary combustion chamber and a plasma torch. The plasma melting furnace is adopted for hazardous waste incineration treatment, incineration residues, fly ash and other materials serve as main treatment materials,and cullet and lime serve as auxiliary materials (fluxing agents). After the technical scheme is adopted, the method has the beneficial effects that a, toxic, harmful, dangerous and non-dangerous waste, including organic, inorganic, gaseous, liquid and solid waste, can be treated; b, the generation amount of dioxin in the treatment process is extremely small; c, treated furnace slag is non-toxic and harmless vitrified slag, is an inert substance, is extremely low in permeability and can be used as a roadbed material; and d, the waste breaking efficiency is up to 99% or above.

Owner:SHANGHAI CANZHOU ENVIRONMENTAL ENG

Plastic garbage smashing and drying device

InactiveCN107876541AAvoid damageEvenly crushedSolid waste disposalTransportation and packagingSpiral bladeLitter

The invention provides a plastic garbage smashing and drying device and belongs to the technical field of waste treatment. The plastic garbage smashing and drying device comprises two feeding holes, asmashing cavity, a drying cavity and a base, wherein the two feeding holes are formed in the upper end of a box; an air inlet pipe is arranged at the upper ends of the feeding holes; tremie pipes arearranged at the lower ends of the feeding holes; an air compressor is arranged at the upper end of the air inlet pipe; and the air inlet pipe is connected with the air compressor. When the plastic garbage smashing and drying device is used, plastic garbage is put into the device from the feeding holes; the air compressor drives the plastic garbage to enter into dispersing discharging pipes; the plastic garbage is uniformly discharged through the dispersing discharging pipes to prevent too-fast discharging from damaging smashing teeth; the plastic garbage is smashed through smashing rollers; the internal diameters of each of upper-end smashing rollers and each of lower-end smashing rollers are different, and the smashing degrees of the upper-end smashing rollers and the lower-end smashingrollers are different, so that thorough smashing is ensured; the plastic garbage falls down on a spiral blade through a partition board, and the spiral blade conveys and smashes the plastic garbage; during the conveying process, the drying device dries the plastic garbage; and the conveying is uniform to ensure complete drying.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com