Integrated restaurant-kitchen garbage treatment machine

A kitchen waste and processor technology, applied in filtration separation, liquid separation, fixed filter element filters, etc., can solve the problems of blockage of sewer pipes, inconvenient cleaning, insufficient recycling, etc., to reduce waste and fully recover grease. , the effect of reducing the amount of waste water recovered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is further described.

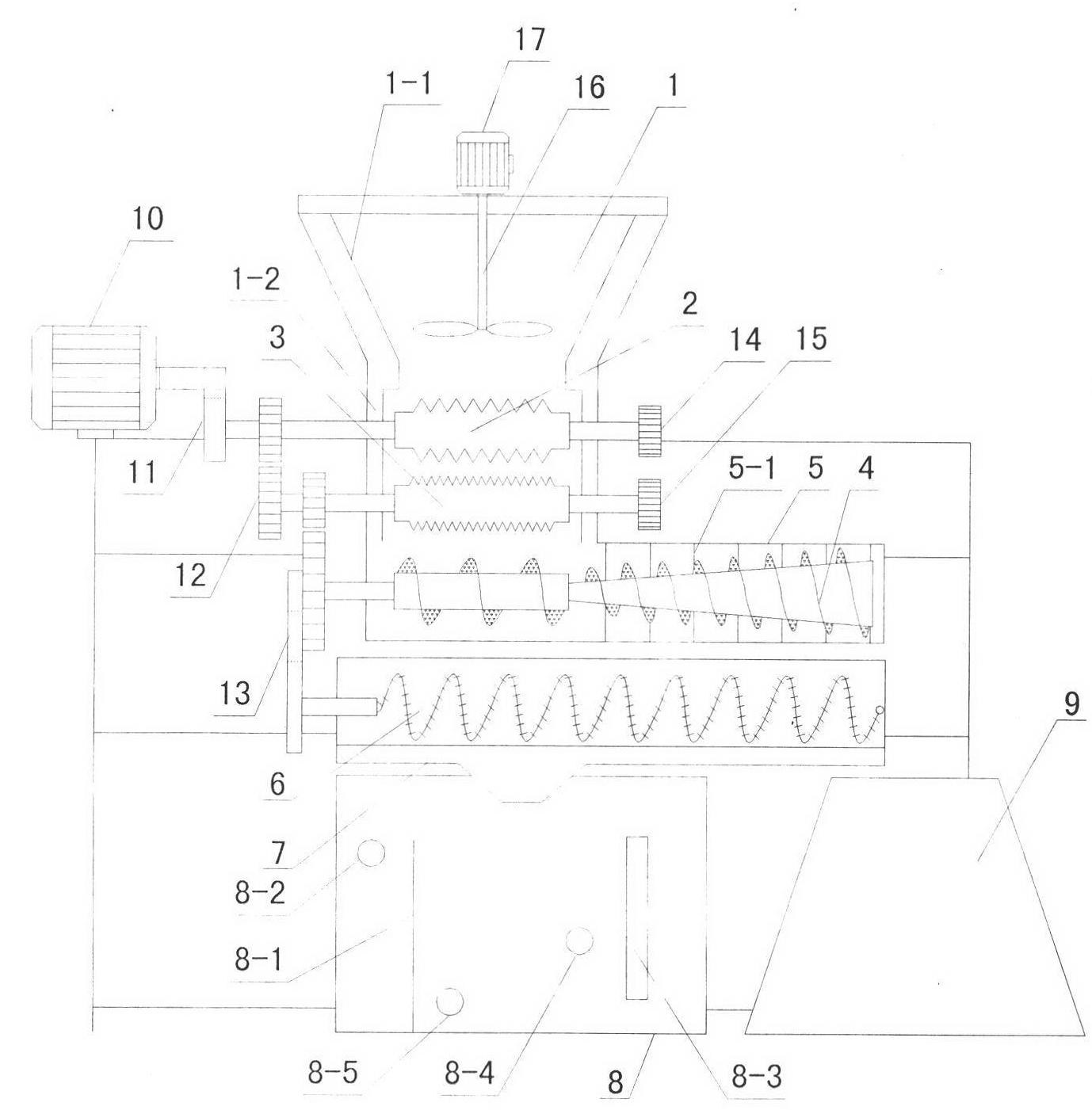

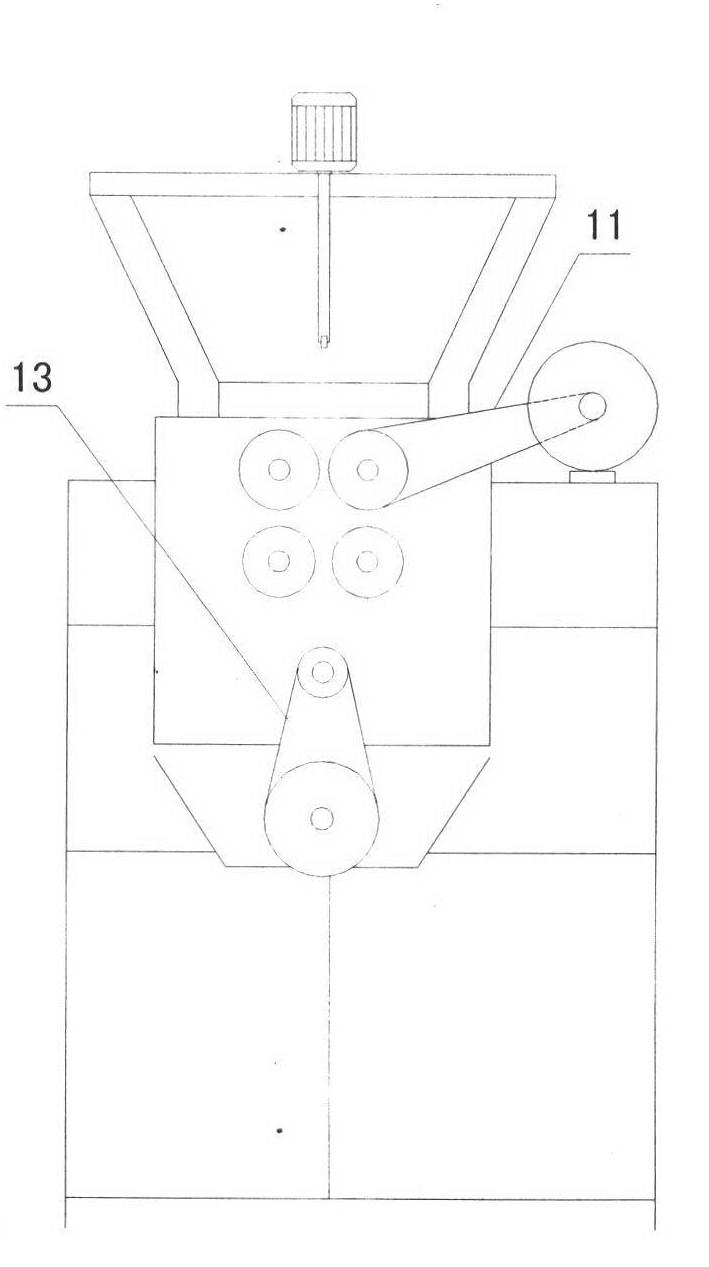

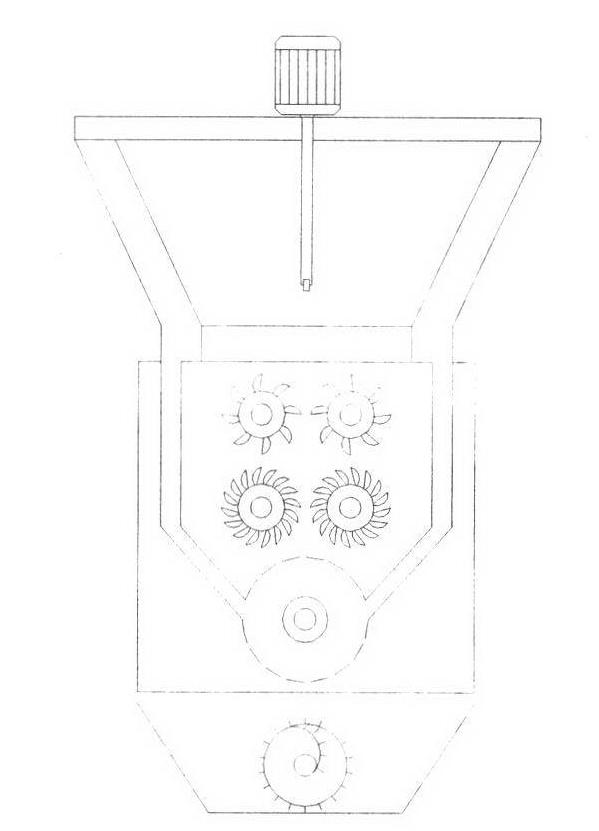

[0020] see Figure 1-4 , a food waste comprehensive processing machine, including a hopper 1, and also includes a crushing device composed of a primary extruding shaft pair 2 and a secondary extruding shaft pair 3, a screw shaft 4, a filter cartridge 5, a spiral brush 6 and a liquid collection The solid-liquid separation device formed by the groove 7, as well as the oil-water separation box 8 and the garbage collection bucket 9; the first-stage extrusion shaft pair 2 is driven by the motor 10 through the pulley 11, and the second-stage extrusion shaft pair 3 is driven by the shaft-pair gear set 12; The screw shaft 4 is driven by the helical gear set 12; the spiral brush 6 is driven by the sprocket 13; the first-stage extrusion shaft pair 2 is meshed by the first-stage gear pair 14; the second-stage extrusion shaft pair 3 is meshed by the second-stage gear pair 15 meshing; the hopper 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com