Lithium iron phosphate waste treatment technology

A lithium iron phosphate and waste treatment technology, applied in phosphorus compounds, lithium carbonate;/acid carbonate, inorganic chemistry, etc., can solve the problem of reduced performance of lithium iron phosphate, low product added value, long process flow, etc. problems, to achieve the effect of high added value, low cost and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described in detail below in conjunction with the examples.

[0029] A process for treating lithium iron phosphate waste includes the following steps:

[0030] (1) After discharging the waste lithium battery to a voltage of 0, under the condition of isolating the air, destroy the shell of the waste lithium battery, separate the electrolyte, the shell and the tabs, and obtain the dry core package. Separate and pulverize the positive electrode sheet from the dry core package to obtain lithium iron phosphate waste, add the lithium iron phosphate waste to an alkaline solution and stir and dissolve at 75° C. for 5 hours, and then filter to obtain an aluminum-containing solution and a first filter residue;

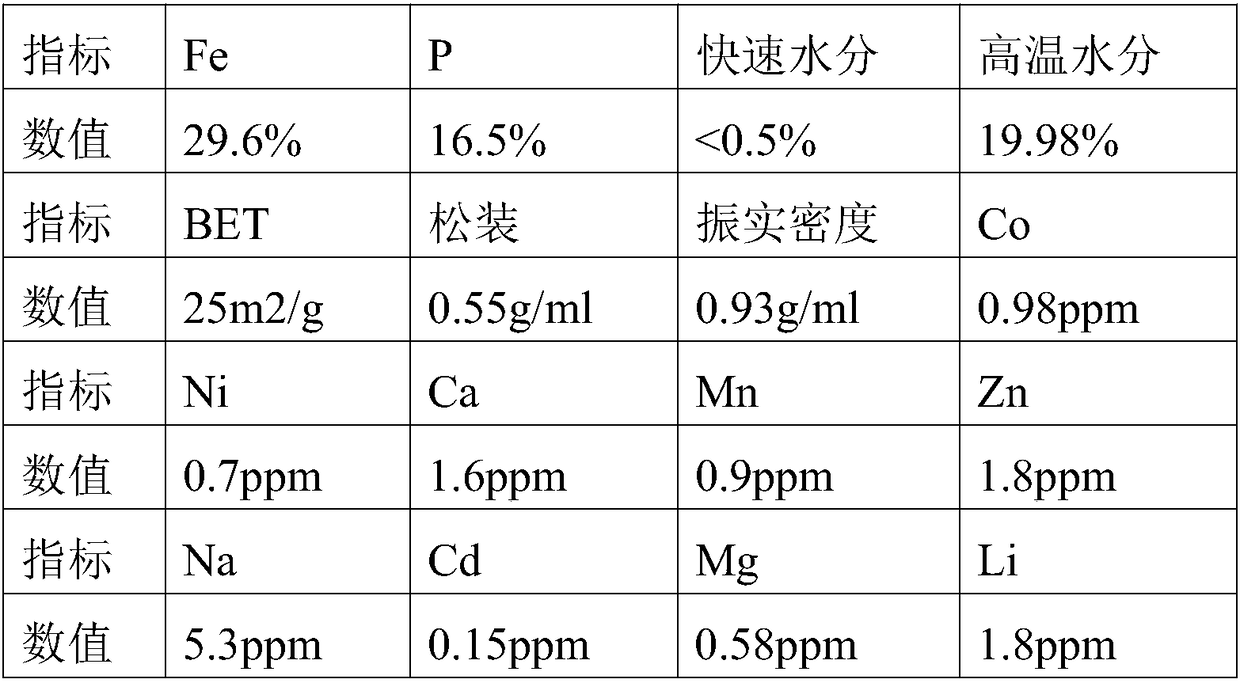

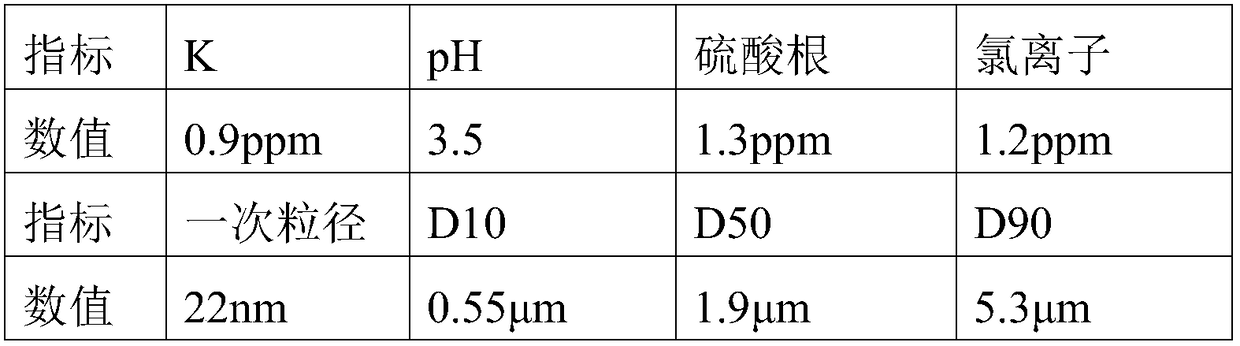

[0031] (2) Add the first filter residue to the sulfuric acid solution, stir and react at 88°C for 5 hours, while adding iron powder at a constant rate during the reaction process until the pH of the solution is 2.5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com