Method for recycling cryolite through combined treatment of aluminum electrolysis overhaul slag and aluminum ash

A combined treatment and overhaul slag technology, applied in chemical instruments and methods, aluminum fluoride, aluminum halide, etc., can solve problems such as difficult product outlets, environmental pollution, and inability to obtain economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

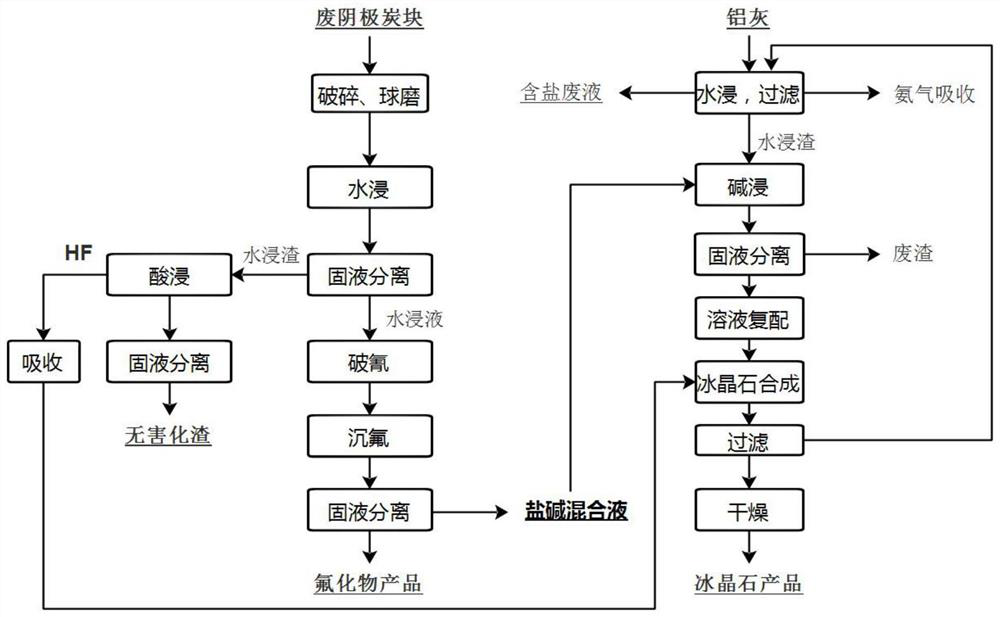

Method used

Image

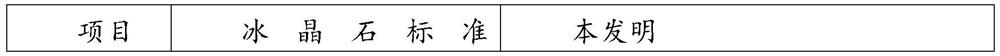

Examples

Embodiment 1

[0032] A method for joint processing of aluminum electrolysis overhaul slag and aluminum ash to reclaim cryolite, comprising the following processing steps:

[0033] (1) Harmless treatment of overhaul slag

[0034] a) crushing and grinding: the overhaul slag is crushed and powdered, and the particle size of the ground powder obtained is 18 mesh;

[0035] b) Water immersion: Throw the ground powder into the water immersion reaction tank, add water in the water immersion reaction tank for stirring reaction, wherein the mass ratio of water to the ground powder is 6:1, and the water immersion reaction The time is 3h. After the reaction is completed, solid-liquid separation is carried out to obtain water leaching residue and water immersion liquid;

[0036] c) Cyanide breaking and fluorine sinking in the water immersion solution: add a cyanide breaking agent to the water immersion solution to carry out the cyanide breaking reaction, and then add calcium chloride twice the fluorid...

Embodiment 2

[0044] A method for joint processing of aluminum electrolysis overhaul slag and aluminum ash to reclaim cryolite, comprising the following processing steps:

[0045] (1) Harmless treatment of overhaul slag

[0046] a) crushing and pulverizing the overhaul slag, so that the particle size of the ground powder is 120 mesh;

[0047] b) Water immersion: Throw the ground powder into the reaction tank, add water for stirring reaction, wherein the mass ratio of water to the ground powder is 10:1, and the water immersion reaction time is 0.5h. After the reaction is completed, solid-liquid separation is carried out to obtain water leaching residue and water immersion liquid;

[0048] c) Cyanide breaking and fluorine sinking in water immersion solution: oxidant is added to water immersion solution 1 to carry out cyanide breaking reaction, after cyanide breaking, calcium chloride with 3 times the fluoride content in water immersion solution 1 is added to carry out fluoride sinking, and t...

Embodiment 3

[0056] A method for joint processing of aluminum electrolysis overhaul slag and aluminum ash to reclaim cryolite, comprising the following processing steps:

[0057] (1) Harmless treatment of overhaul slag

[0058] a) crushing and grinding the overhaul slag to obtain a particle size of the ground powder is 200 mesh;

[0059] b) Water immersion: put the ground powder into the reaction tank, add water for stirring reaction, wherein the mass ratio of water to the ground powder is 3:1, and the water immersion reaction time is 6h. After the reaction is completed, solid-liquid separation is carried out to obtain water immersion residue 1 and water immersion liquid 1;

[0060] c) Water immersion solution 1 for cyanide breaking and fluorine sinking: add oxidant to water immersion solution 1 for cyanide breaking reaction, after cyanide breaking, add water immersion solution 1 with 5 times the fluoride content of aluminum chloride for fluorine sinking and defluorination reaction The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com