Wet sludge drying and incinerating treatment device

A treatment device and wet sludge technology, applied in dehydration/drying/thickened sludge treatment, incinerator, combustion method, etc., can solve problems such as heat waste, achieve the effects of reduced consumption, simple device, and concise system flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

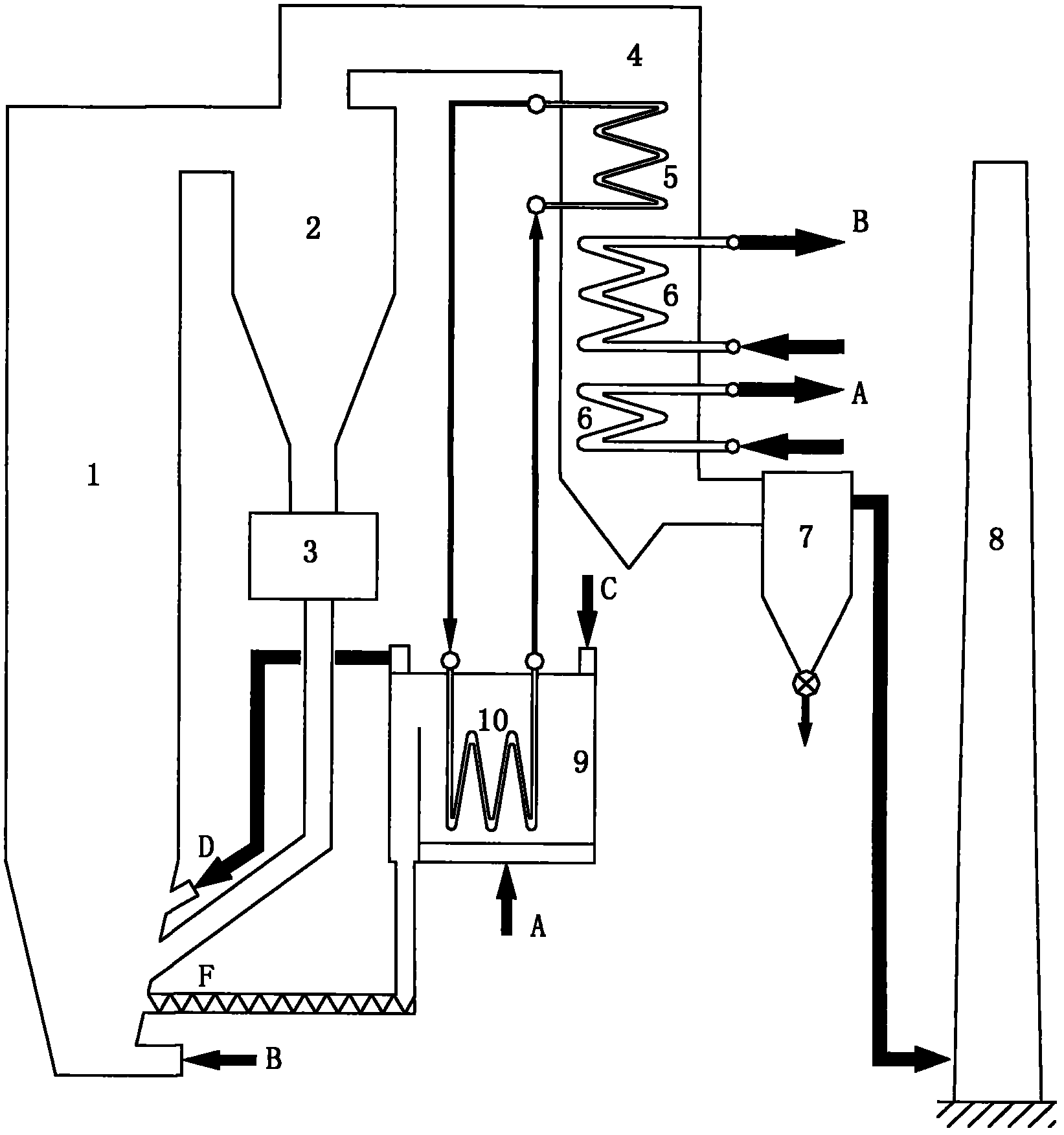

[0040] see figure 1 :

[0041] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5 and the air preheater 6 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0042] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0043] The furnace 1 is insulated, and the side wall is provided with a secondary tuyere, a feeding port, and a dry sludge inlet.

[0044] The sludge dryer 9 is a fluidized bed type, with a wind cap and an air distribution plate at the ...

Embodiment 2

[0053] see figure 1 :

[0054] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 60% and a calorific value of 3000kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5 and the air preheater 6 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0055] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0056] A water-cooled heating surface is provided in the furnace 1, and its side wall is a membrane water-cooled wall, and the lower part of the side wall is provided with a secondary tuyere, a feeding port, and a dry sludge inlet.

[0...

Embodiment 3

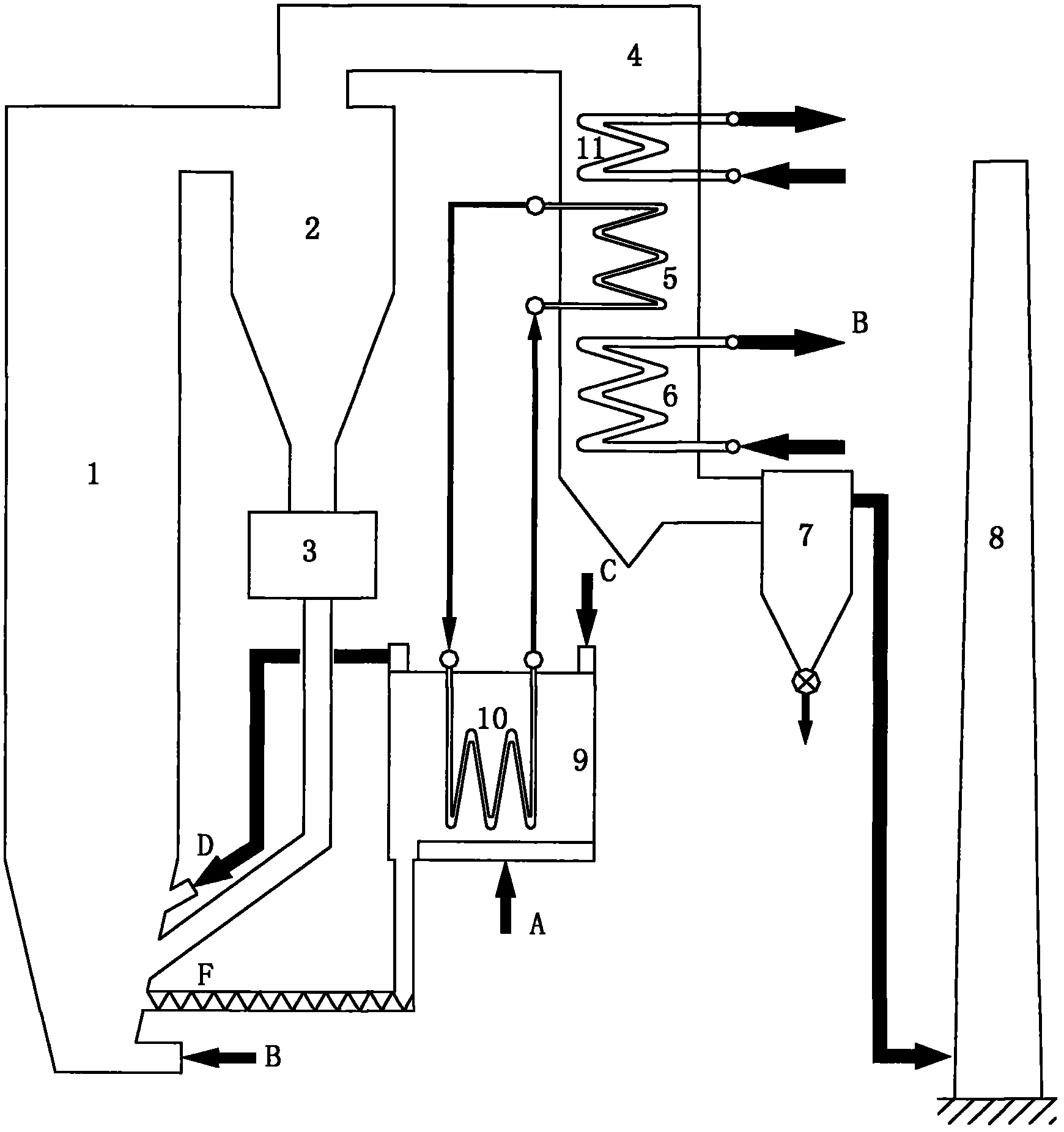

[0065] see figure 2 :

[0066] A circulating fluidized bed incinerator is used to incinerate wet sludge with a moisture content of 76% and a calorific value of 3500kcal / kg on a dry basis. After the wet sludge C is dried in the sludge dryer 9, it is incinerated in the furnace 1, and the incineration produces The high-temperature flue gas is cooled by the heat exchanger 5, the air preheater 6 and the waste heat boiler 11 in the tail flue 4, and the dust is removed by the dust collector 7, and then discharged through the chimney 8.

[0067] The circulating fluidized bed incinerator includes a circulating fluidized bed furnace 1, a separator 2, a feeder 3, a tail flue 4, a dust collector 7, a chimney 8 and an auxiliary system, as well as a fluidized bed sludge dryer 9.

[0068] The furnace 1 is insulated, and the lower part of the side wall is provided with a secondary tuyere, a material return port and a dry sludge inlet.

[0069] The sludge dryer 9 is a fluidized bed type, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com