Hazardous waste plasma melting treatment system

A plasma and hazardous waste technology, applied in solid waste removal, chemical instruments and methods, transportation and packaging, etc., can solve problems such as environmental pollution, achieve low permeability, high waste removal efficiency, and dioxin production. small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

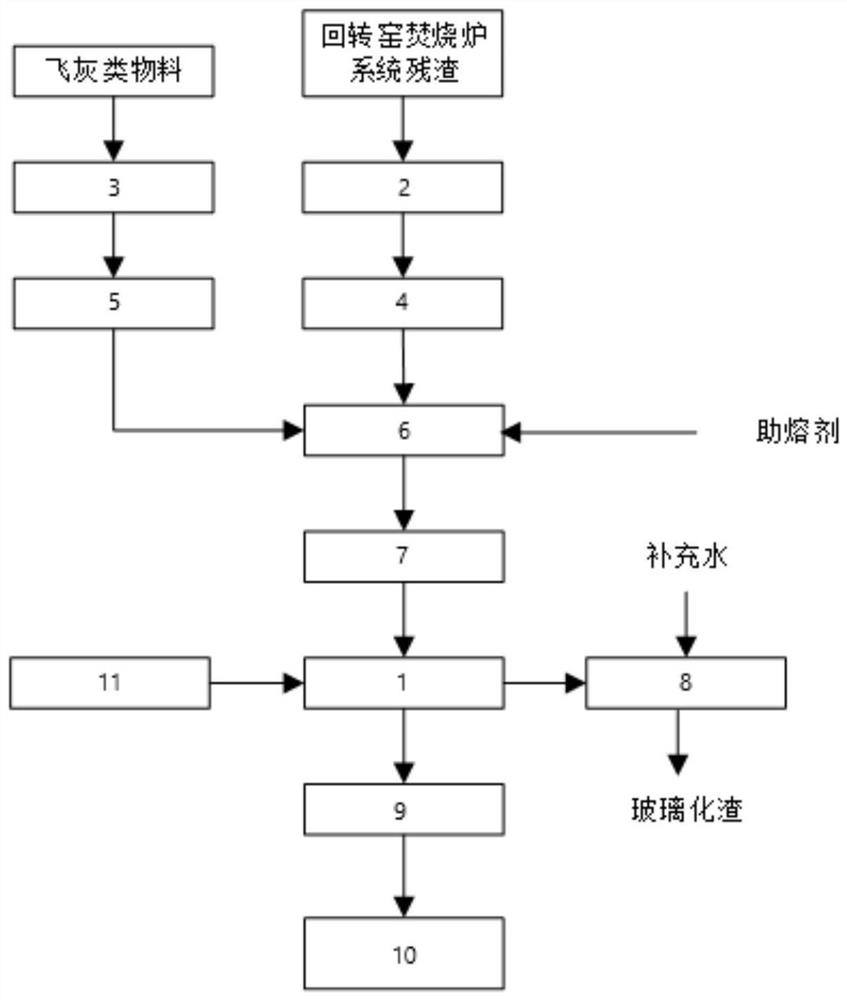

[0014] see figure 1 As shown, the technical solution adopted in this specific embodiment is: a hazardous waste plasma melting treatment system, which includes a plasma melting furnace 1, a crusher 2, a granulator 3, an incineration slag bin 4, a fly ash bin 5, a mixing bin Material conveyor 6, material feeding buffer bin 7, slag removal machine 8, flue gas regulator 9, rotary kiln incinerator secondary combustion chamber 10, plasma torch 11; it uses plasma melting furnace for hazardous waste incineration treatment, mainly processing materials For incineration residue, fly ash and other materials, auxiliary materials (flux) are mainly cullet and lime;

[0015] Its technological process steps are: a. The incineration residue is removed through the water-sealed slag discharger, and then lifted to the crusher by the hoist for crushing pretreatment. The particle size after crushing is generally below 50mm, and the crushed residue enters the slag buffer warehouse storage; b. The ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com