Waste honeycomb activated carbon regeneration process

A honeycomb activated carbon and activated carbon technology, which is applied in filter regeneration, petroleum industry, filtration and separation, etc., can solve problems such as waste of resources, save energy and ensure production safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

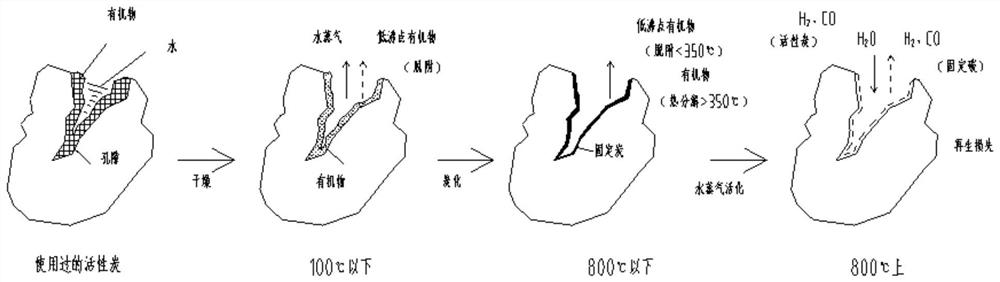

Method used

Image

Examples

Embodiment 1

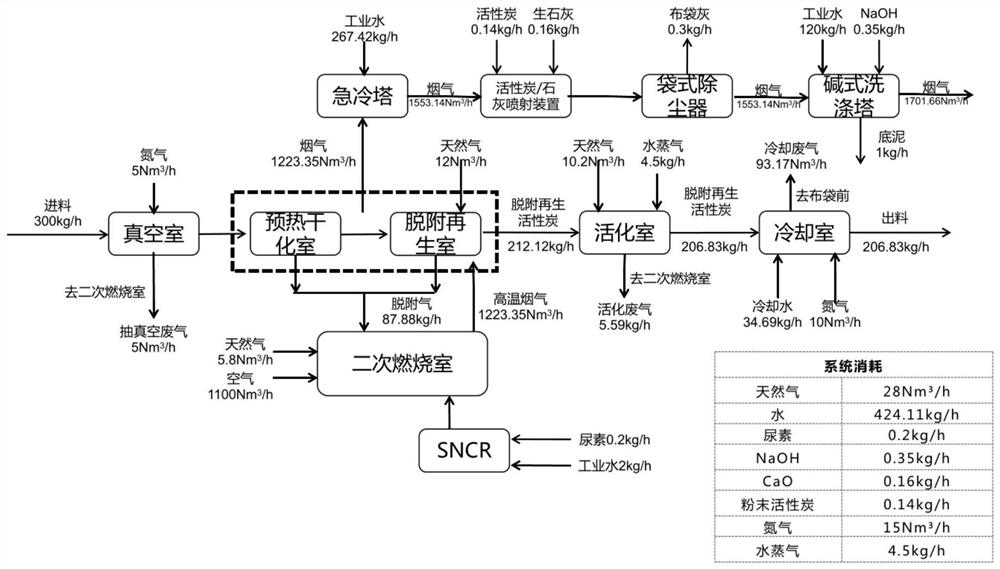

[0030] 1. Regenerative processing unit

[0031] (1) Feed the waste honeycomb activated carbon into the vacuum chamber, the feed rate is 300kg / h, the vacuum chamber is made of anti-corrosion steel material, the working size is (1000*1000*600)mm, the thickness is 8mm to make a closed chamber with reinforcing ribs, There are two vacuum doors for entry and exit, and the opening and closing of the vacuum doors are completed by hydraulic cylinders. The seal adopts high temperature resistant rubber ring, and is equipped with vacuum pumping solenoid valve and nitrogen gas inlet solenoid valve. The evacuated gas is introduced into the secondary combustion chamber for harmless treatment. Vacuuming by a vacuum pump and introducing nitrogen as a replacement gas ensures an oxygen-free atmosphere during the thermal desorption process and ensures production safety. The intake volume of nitrogen gas is 5Nm 3 / h, the output of vacuum exhaust gas is 5Nm 3 / h. Vacuum exhaust gas passes into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com