Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Soot deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soot build-up, also called “black soot deposition”, is most likely the reason behind a black filter. Black soot deposition inside your home is more than likely caused by: Burning scented candles. A gas furnace that isn’t burning properly. A gas water heater that isn’t burning properly.

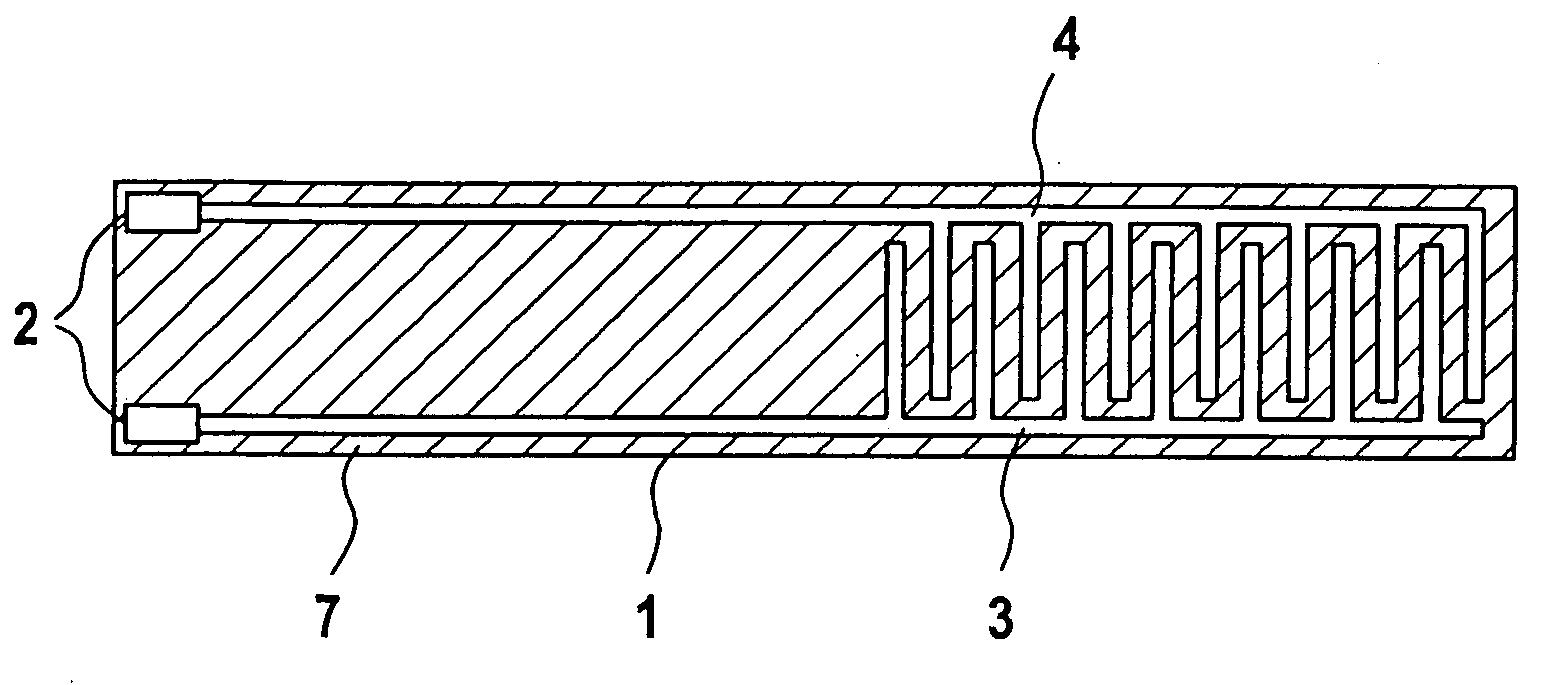

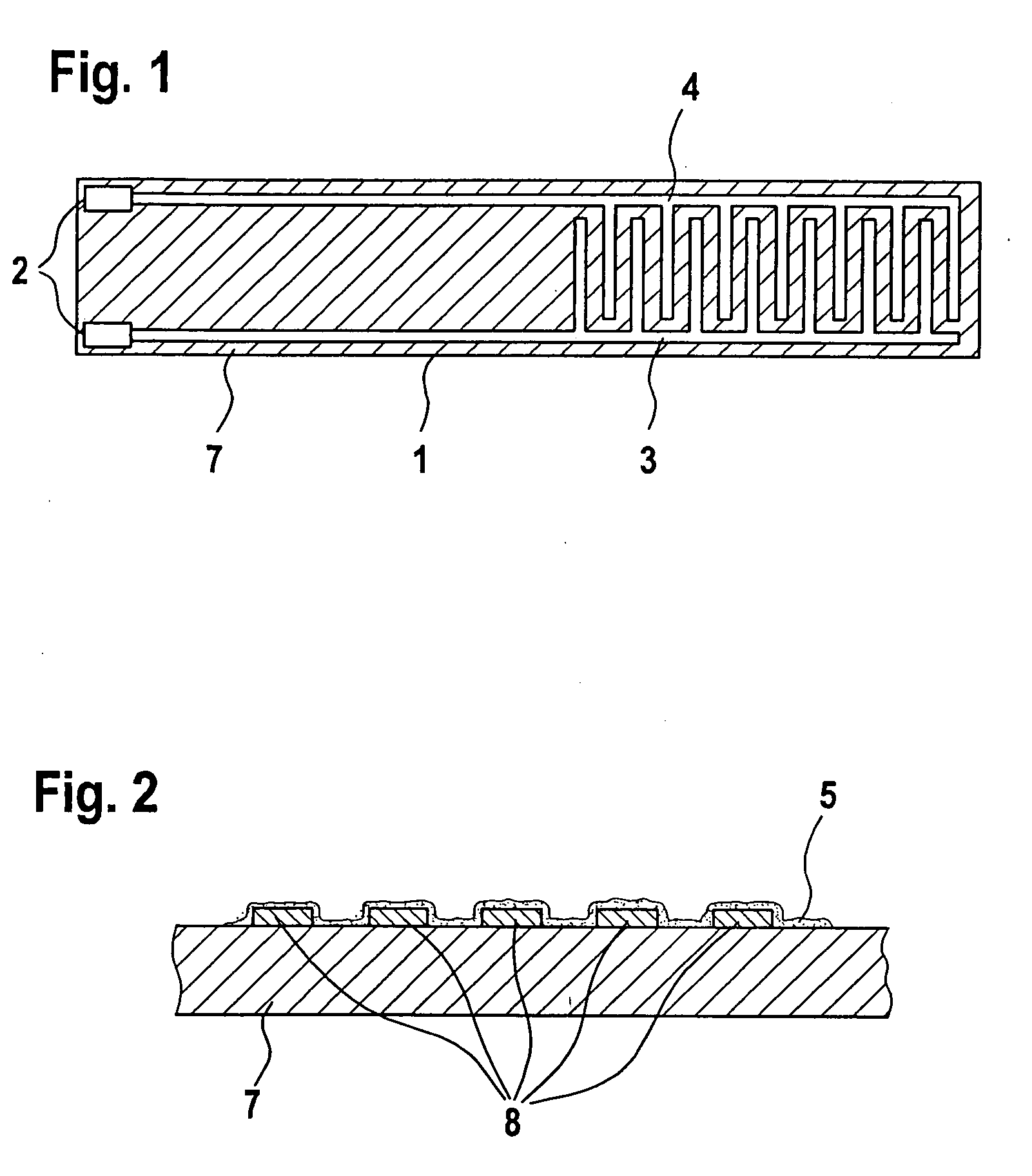

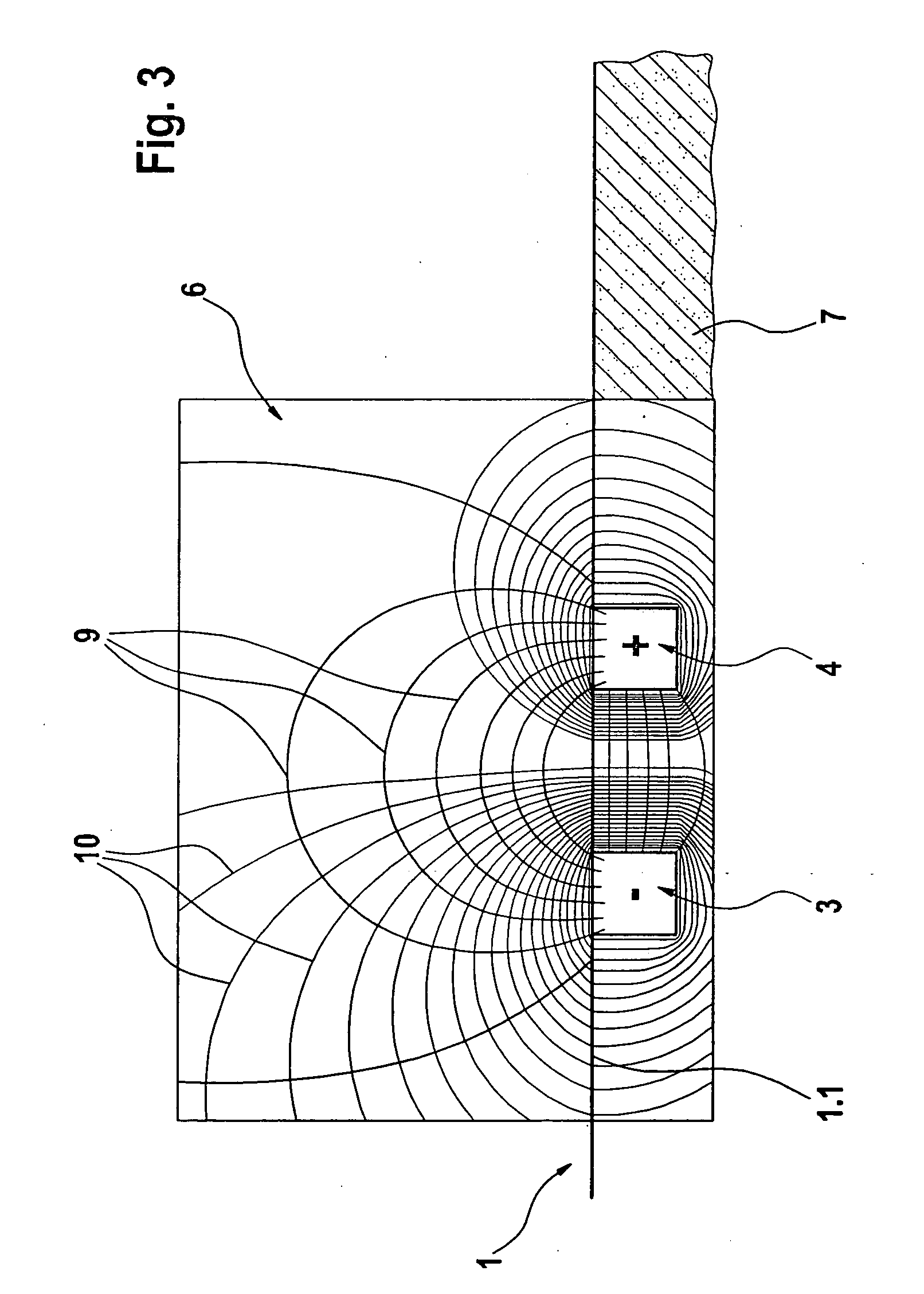

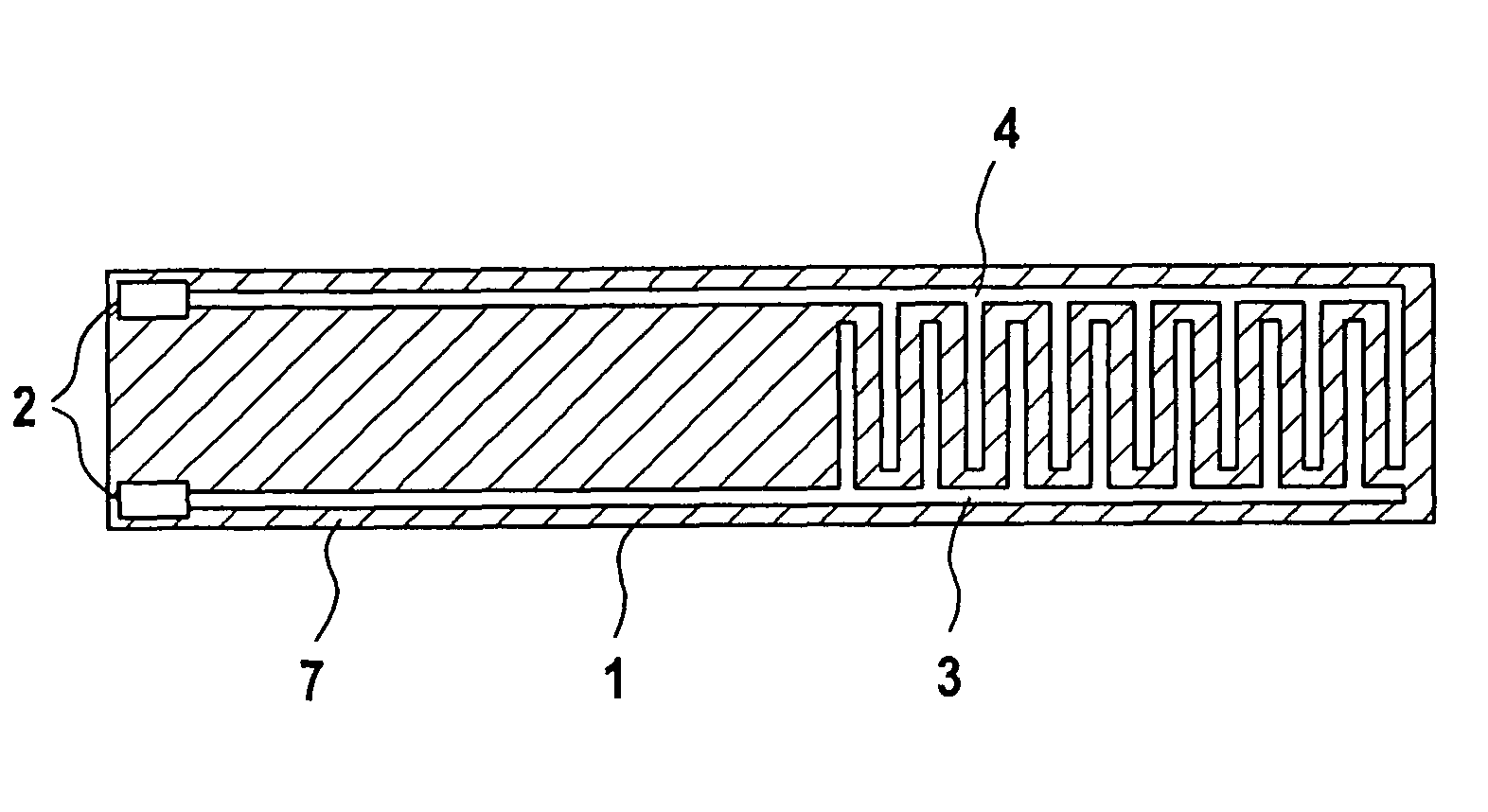

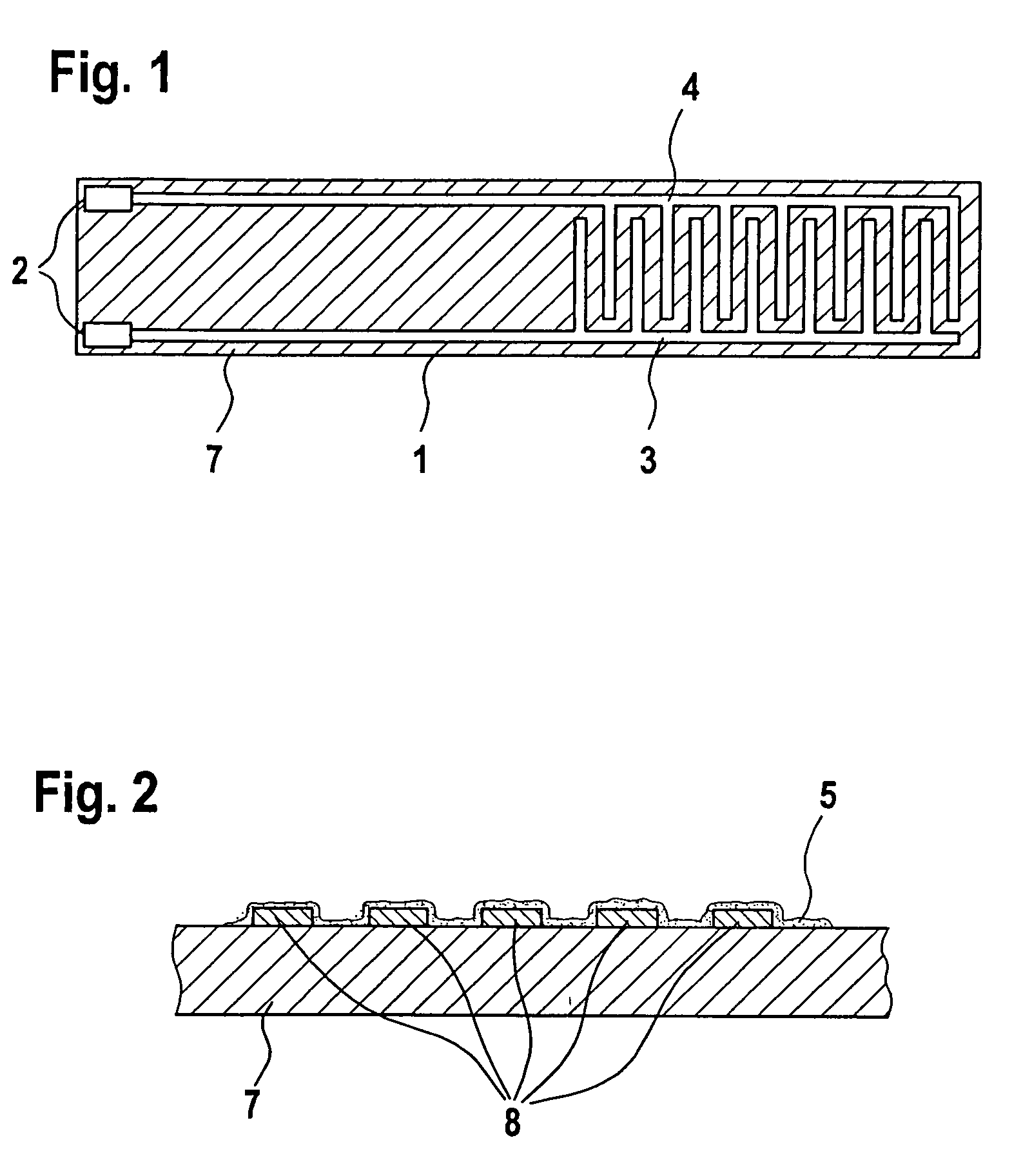

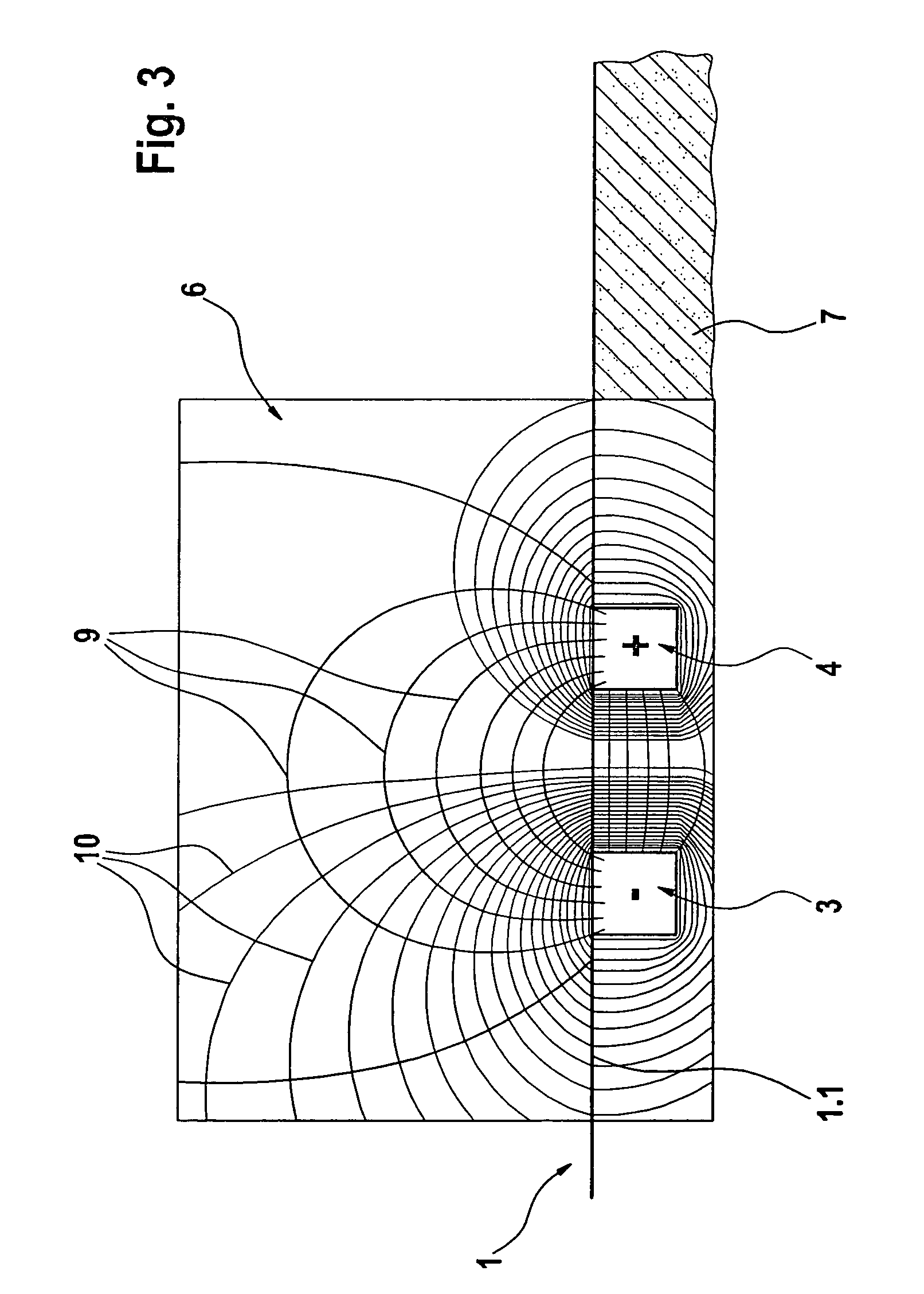

Method for influencing soot deposits on sensors

ActiveUS20090051376A1Improve reliabilityAccurate measurementResistance/reactance/impedenceMaterial analysis by electric/magnetic meansEngineeringHigh voltage

A method is described for controlling the soot deposition on sensors. A sensor element is provided, which includes a first electrode and a second electrode. Different measuring voltages U1 and U2 can be applied to the sensor element. During a first time period t1, the sensor element is operated at a higher voltage U1 until a triggering threshold AP of the sensor element is exceeded, while it is operated at a voltage U2, which is different from higher voltage U1, U2 being lower than voltage U1, during a second time period t2.

Owner:ROBERT BOSCH GMBH

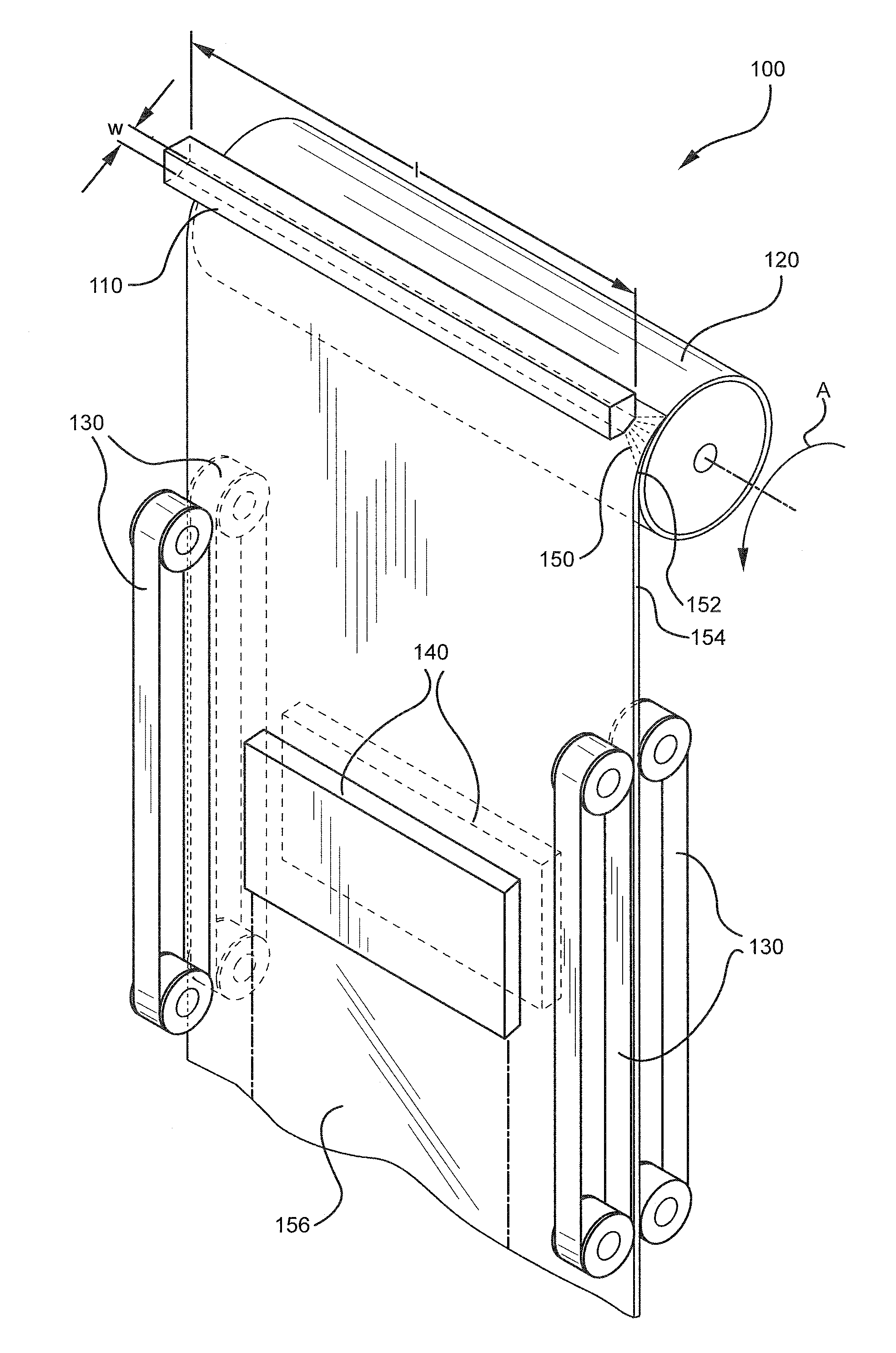

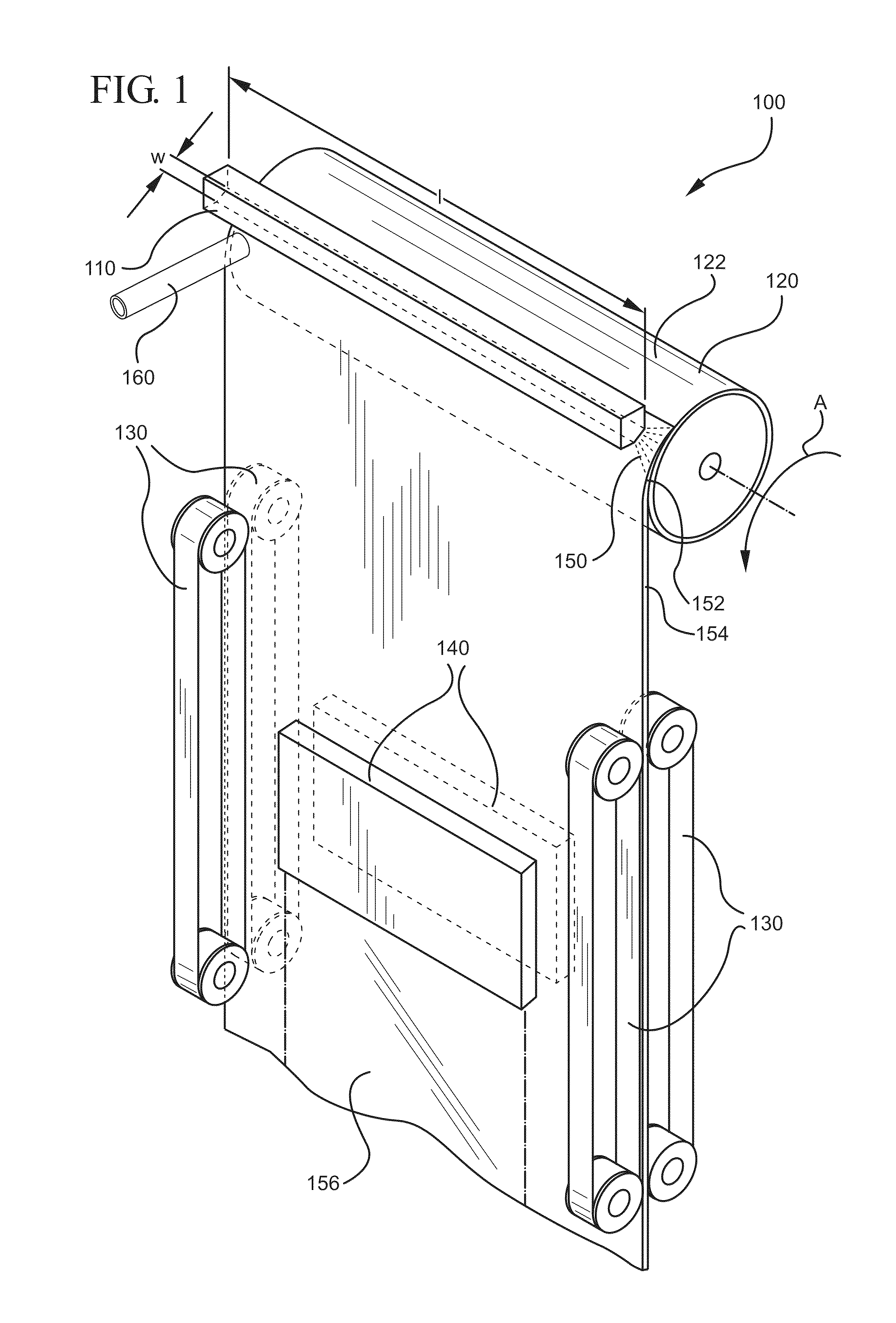

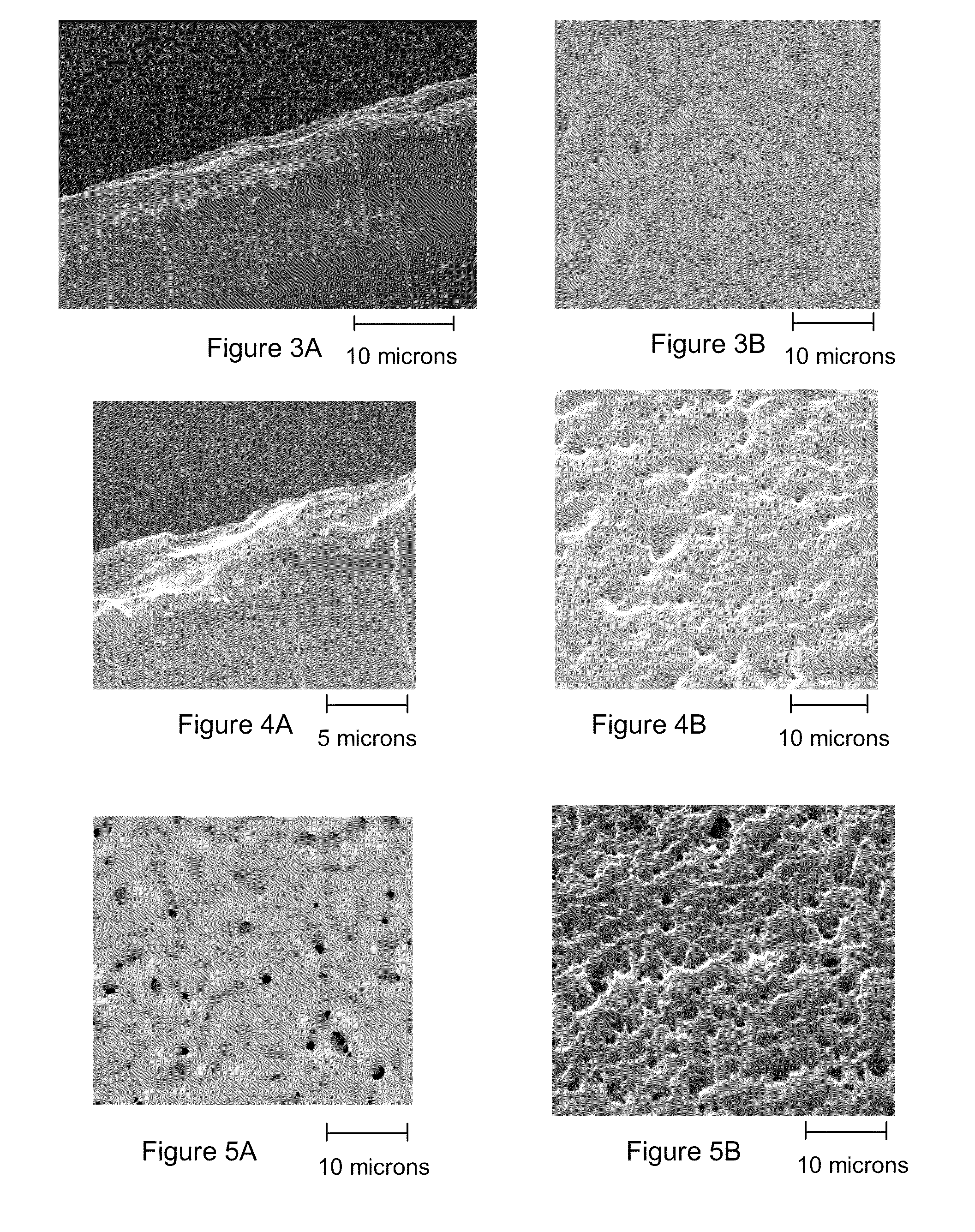

Roll-to-roll glass material attributes and fingerprint

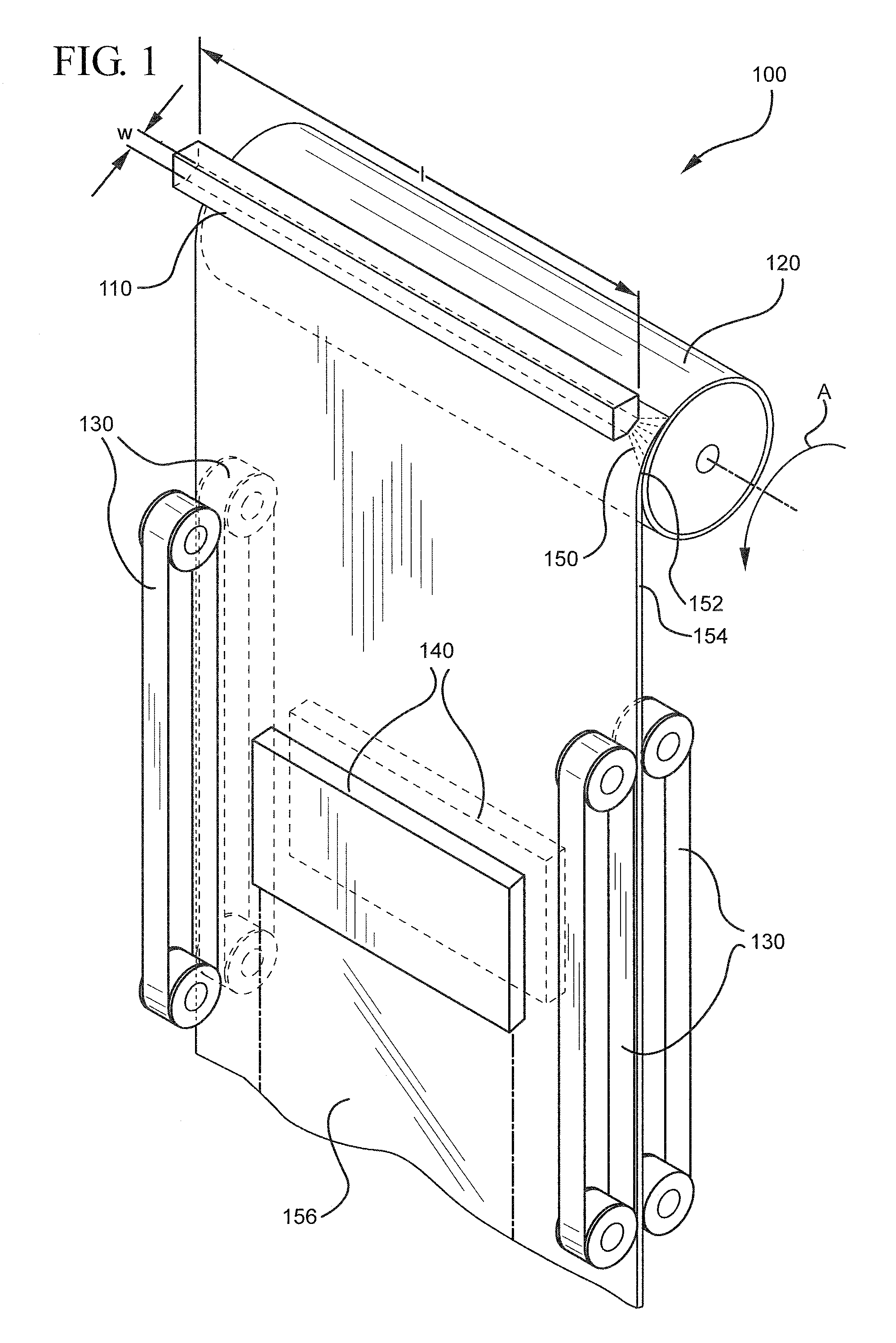

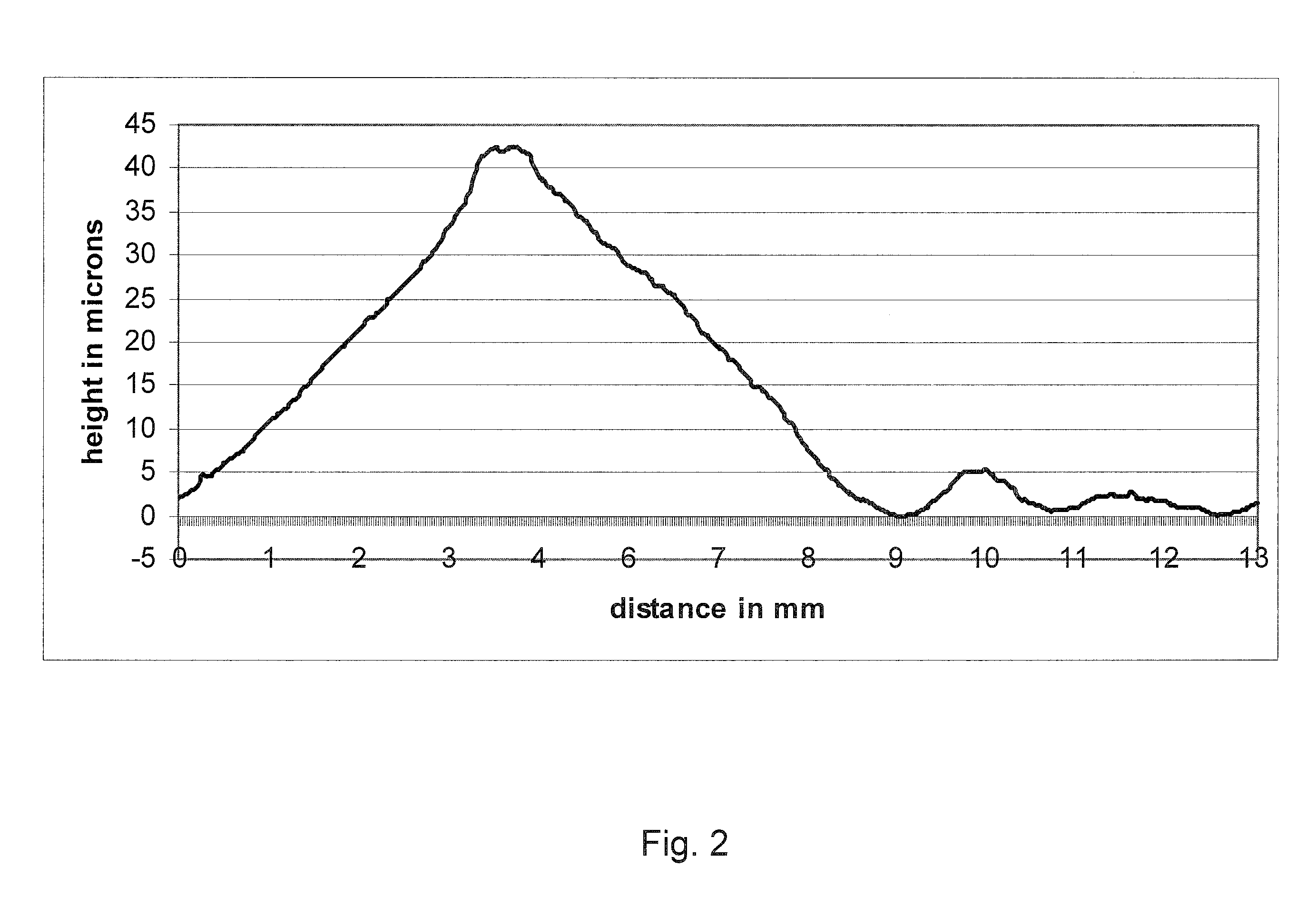

ActiveUS20100291346A1Improve surface qualitySynthetic resin layered productsRecord information storageSurface roughnessHigh silica

A high-silica glass sheet has an average thickness of less than 150 microns and an average surface roughness over one or both of its two major surfaces of less than 1 nm. The glass sheet is formed using a roll-to-roll glass soot deposition and sintering process. The glass sheet may comprise a plurality of substantially parallel surface protrusions, which are visible only when a major surface of the glass sheet is viewed at an angle sufficiently removed from normal incidence.

Owner:CORNING INC

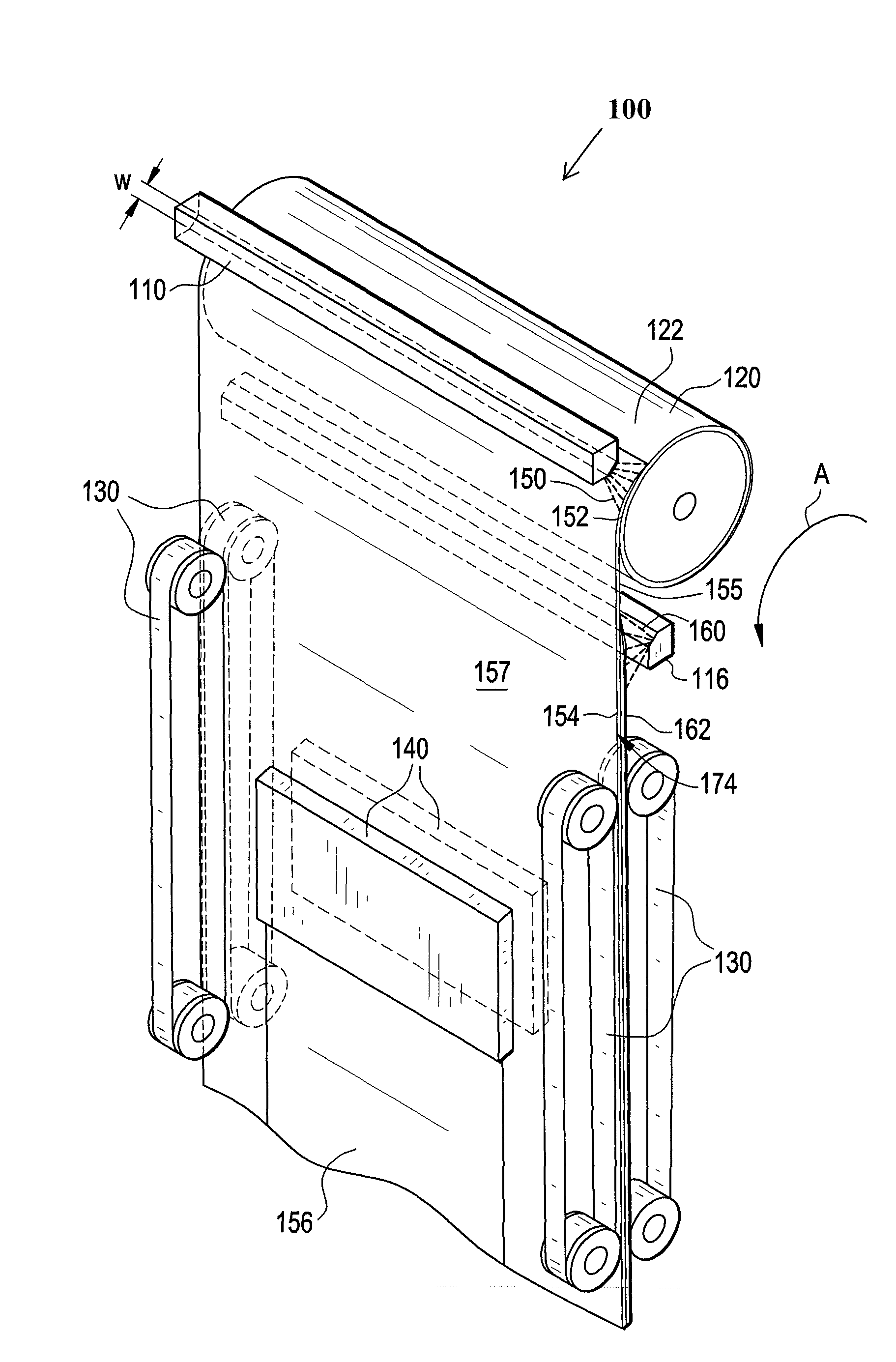

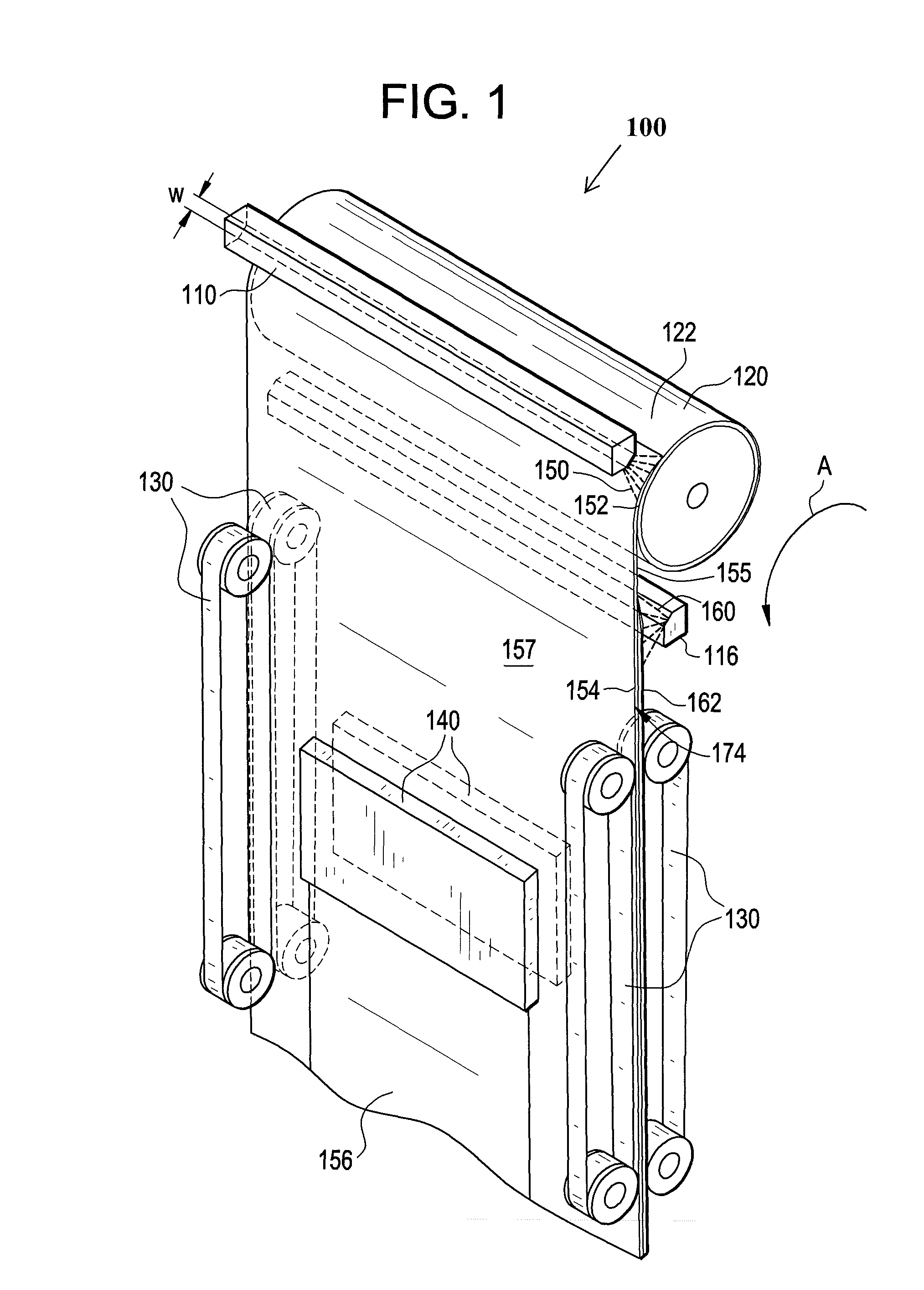

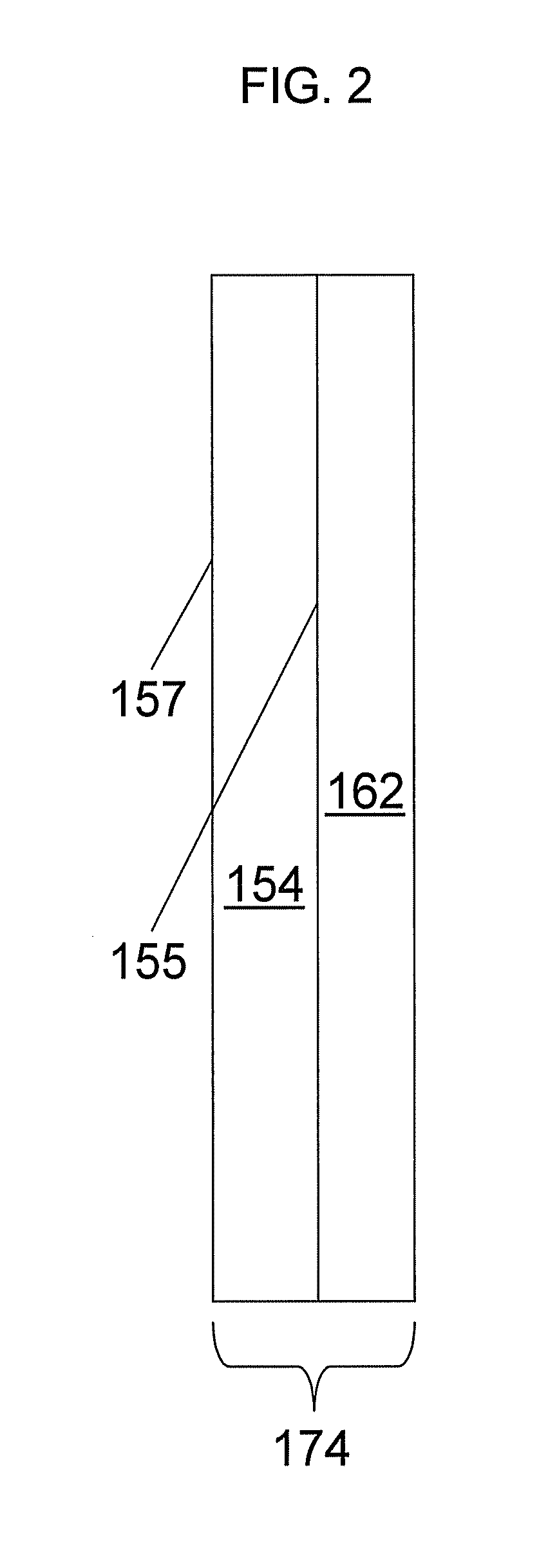

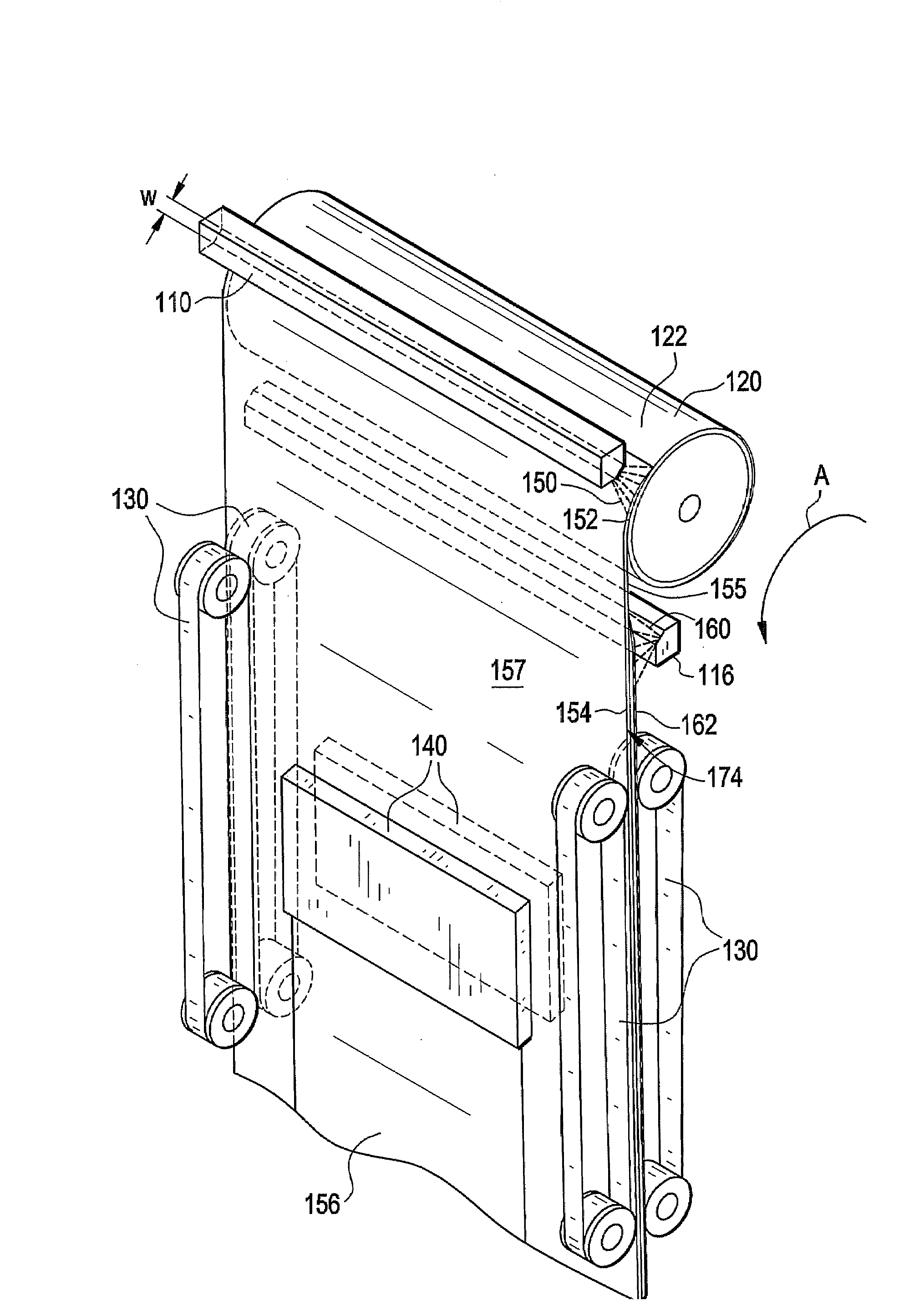

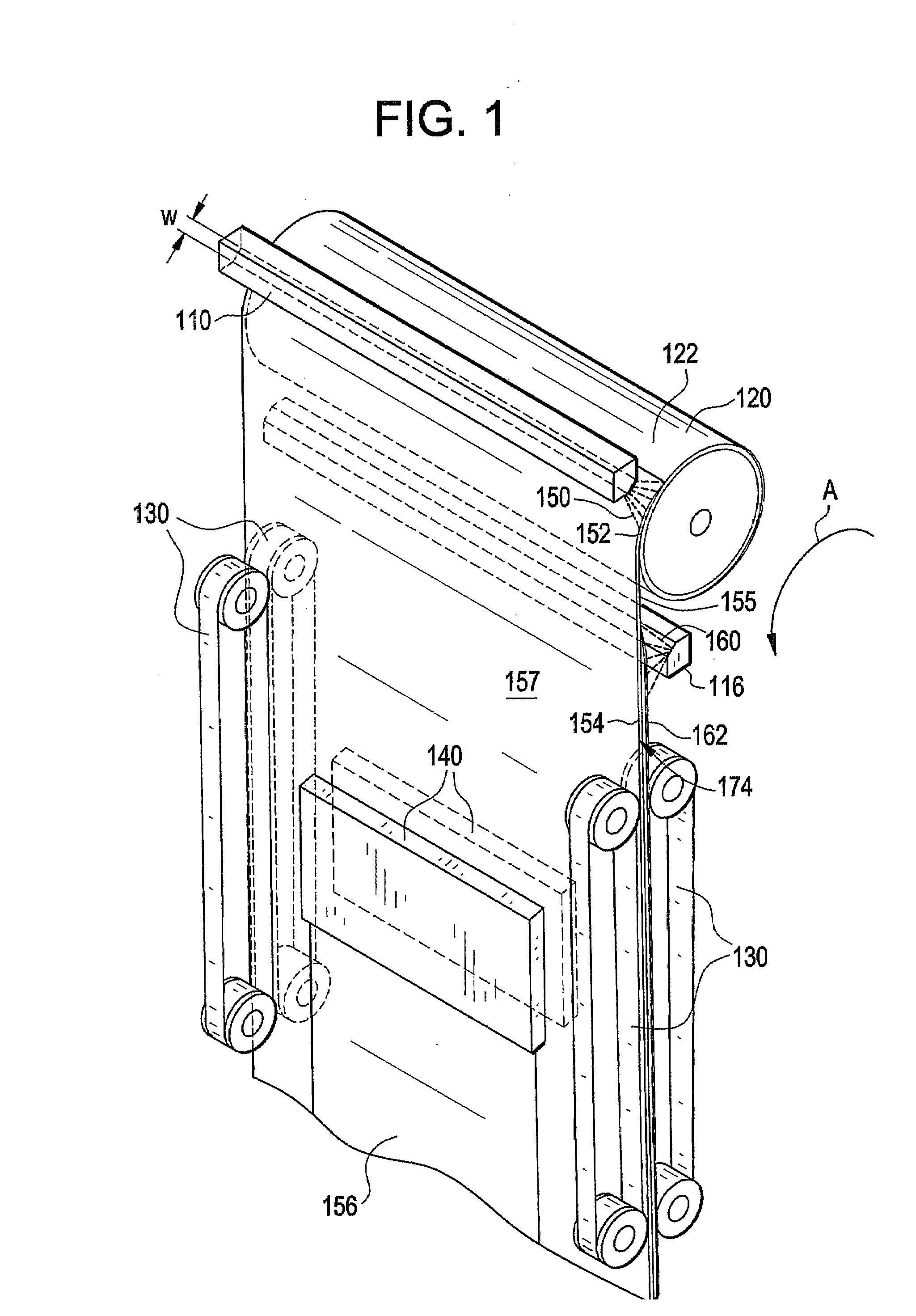

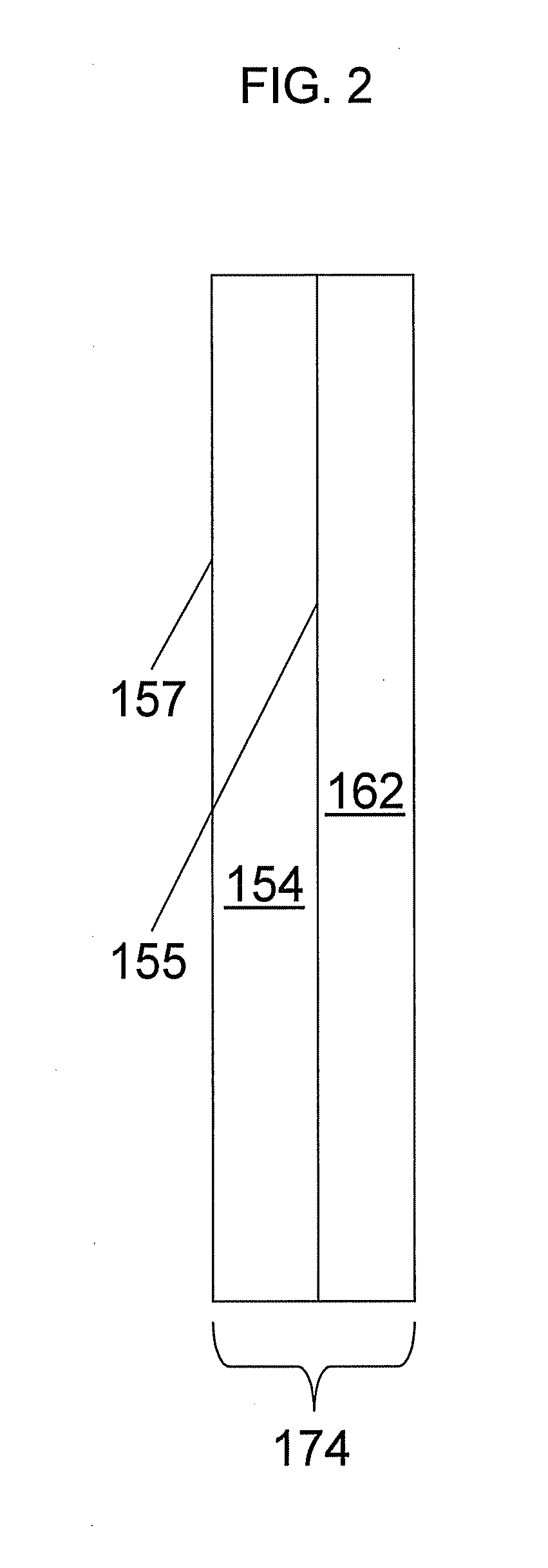

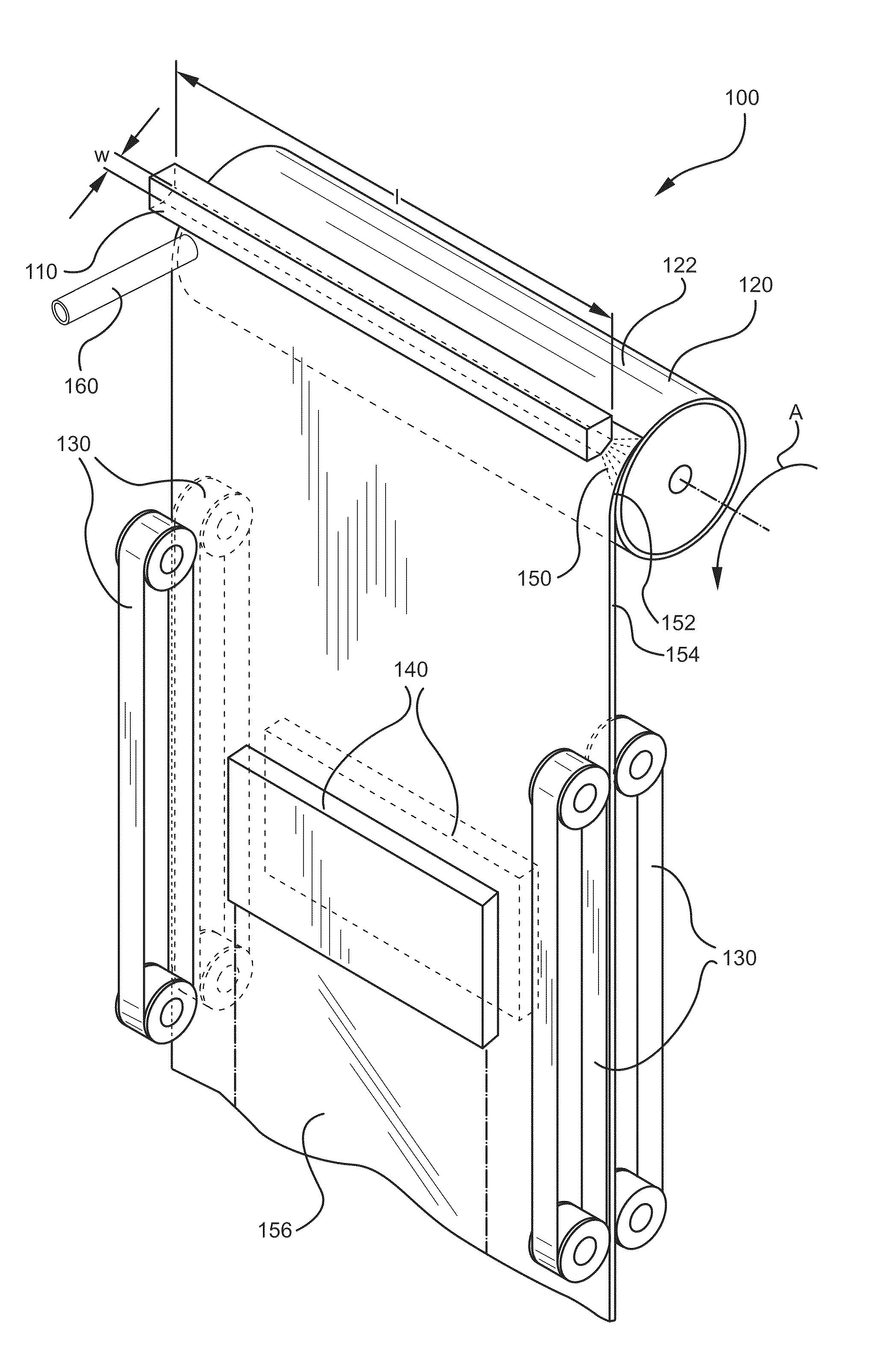

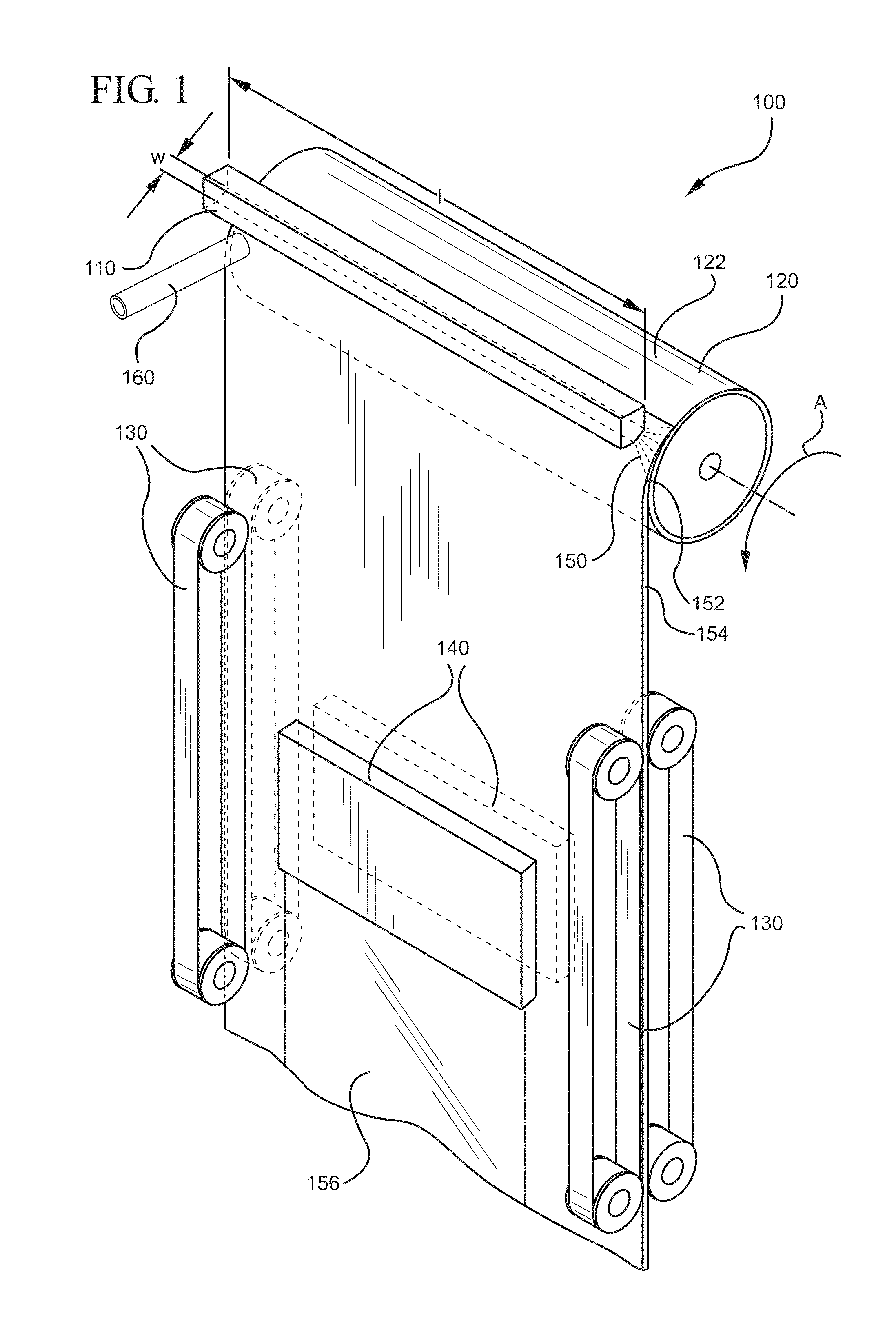

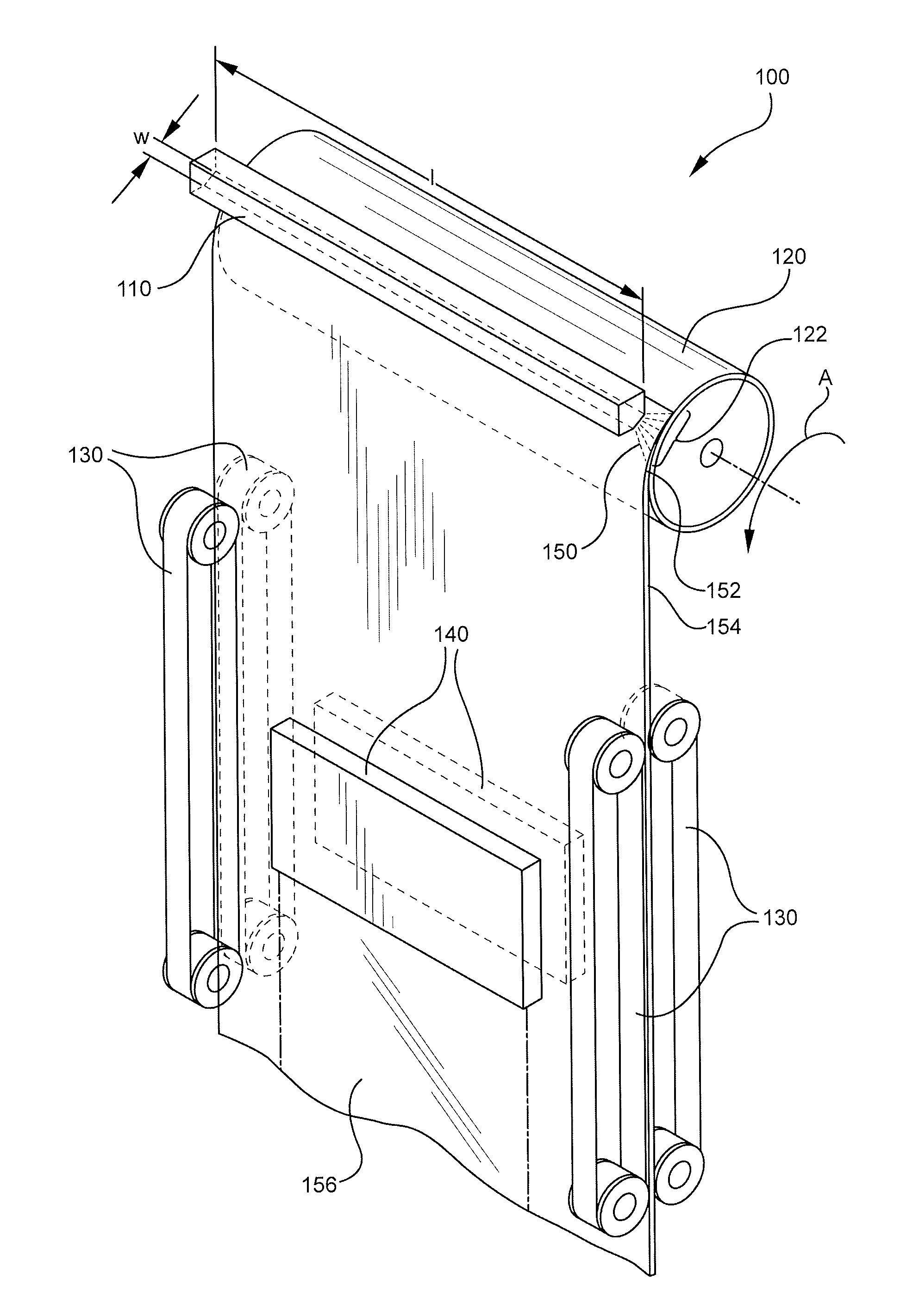

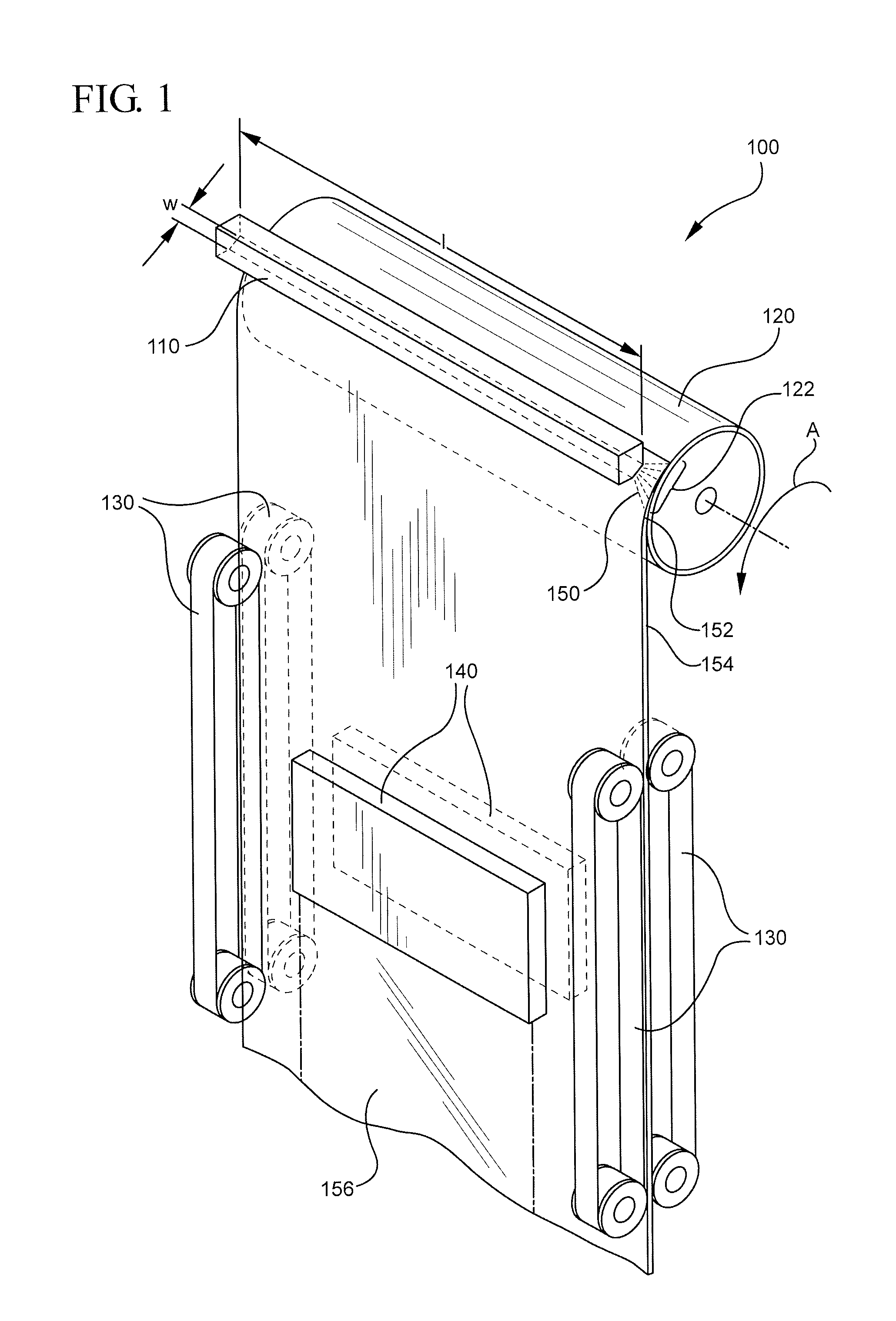

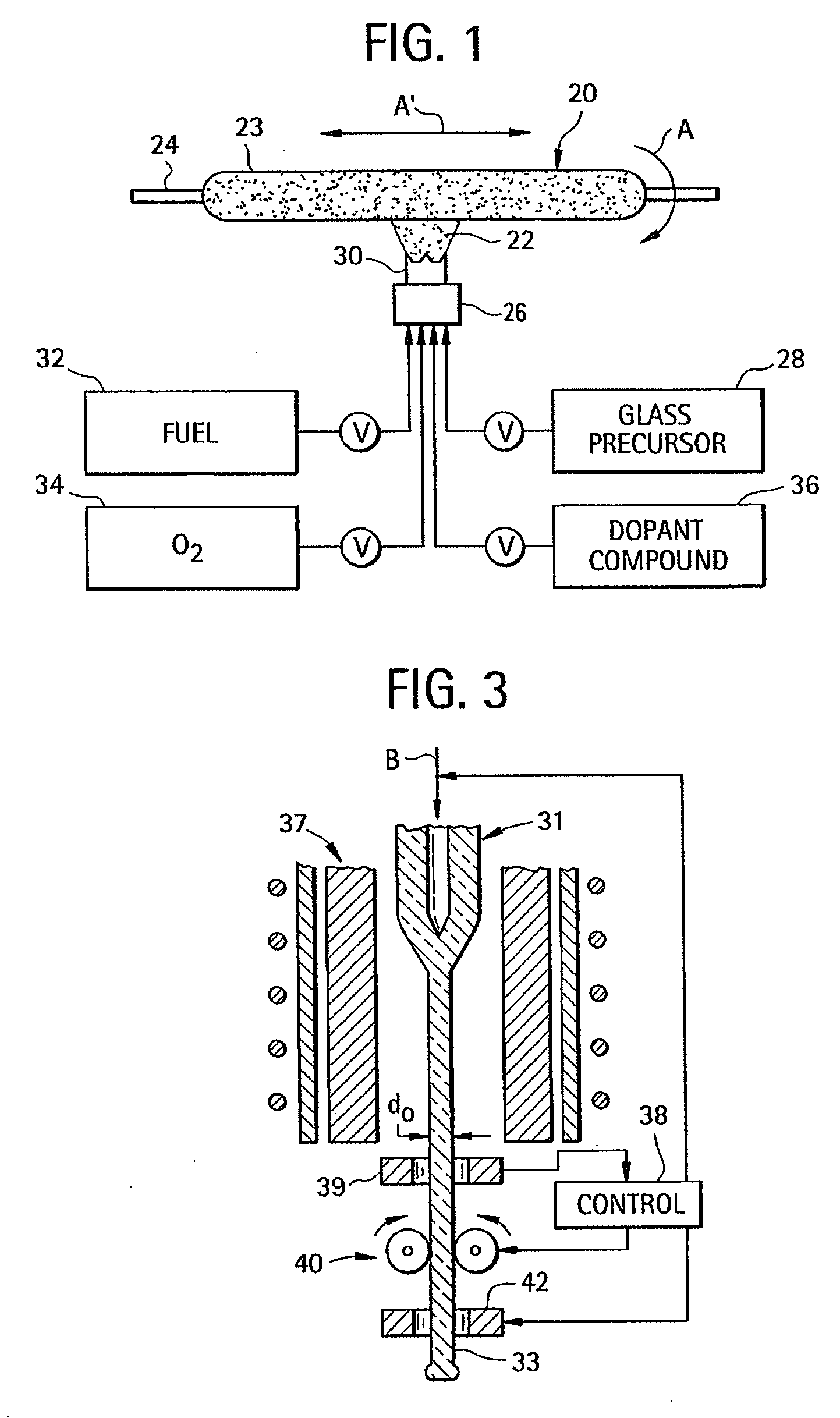

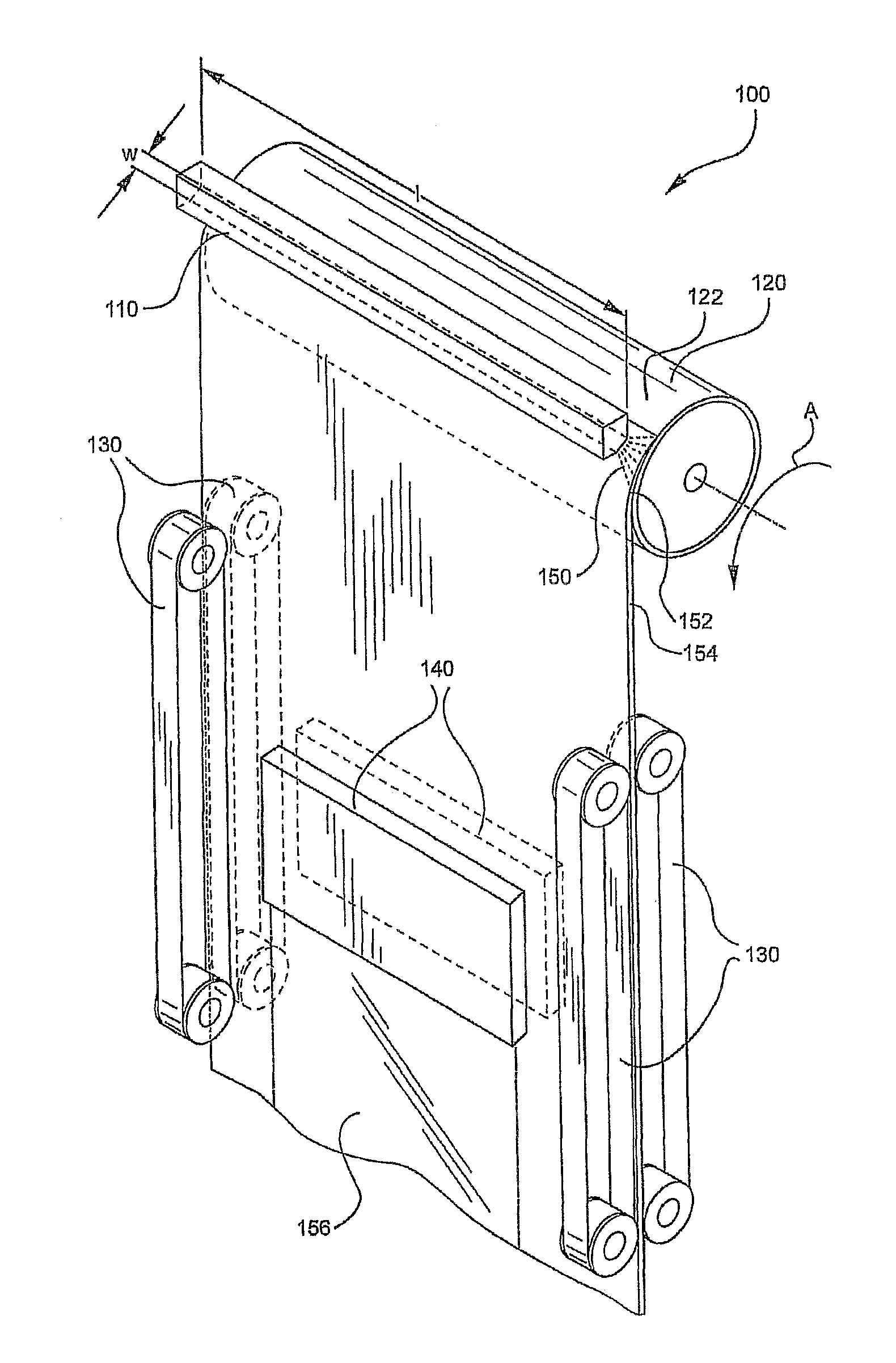

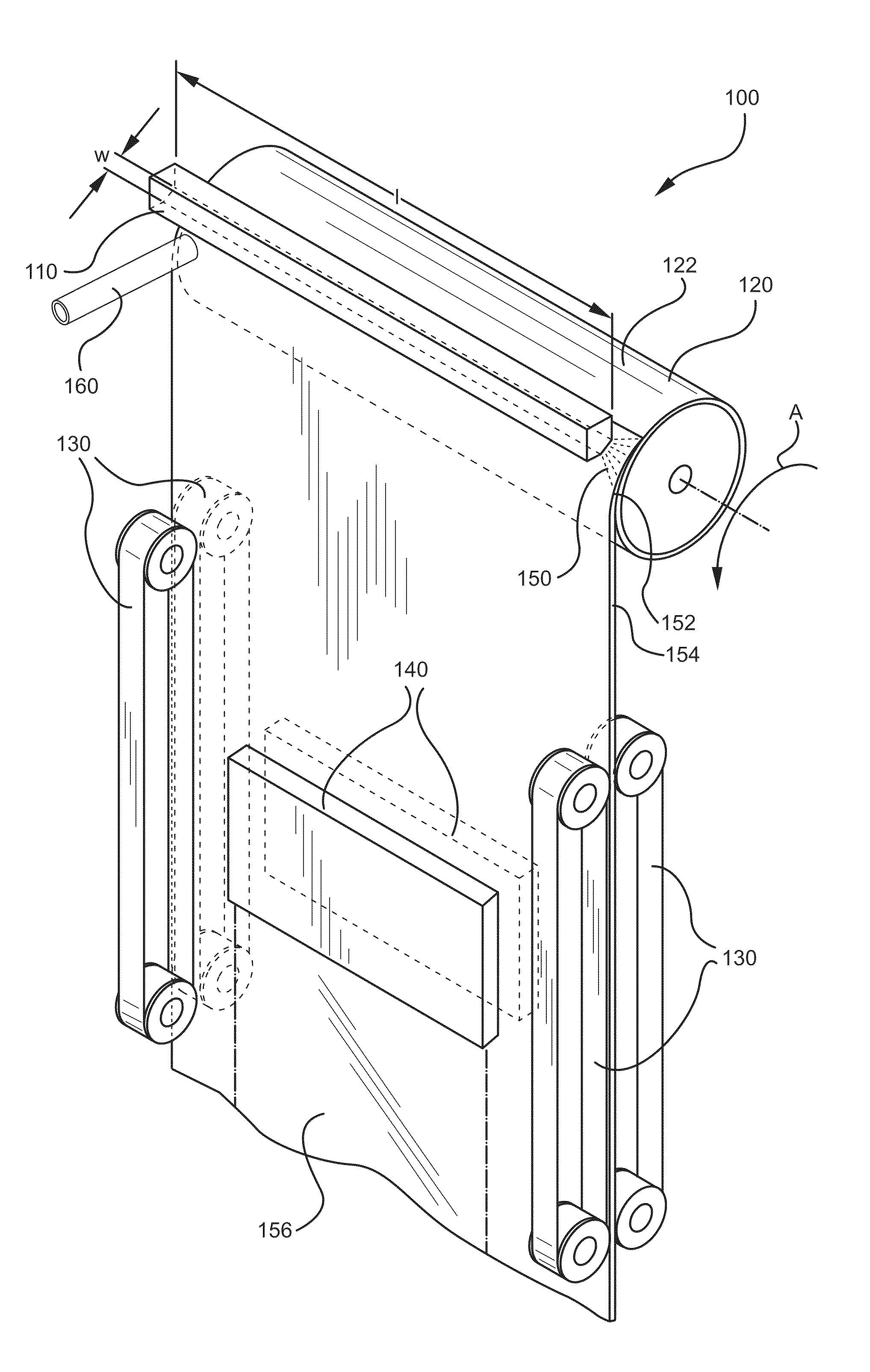

Roll-to-roll glass: touch-free process and multilayer approach

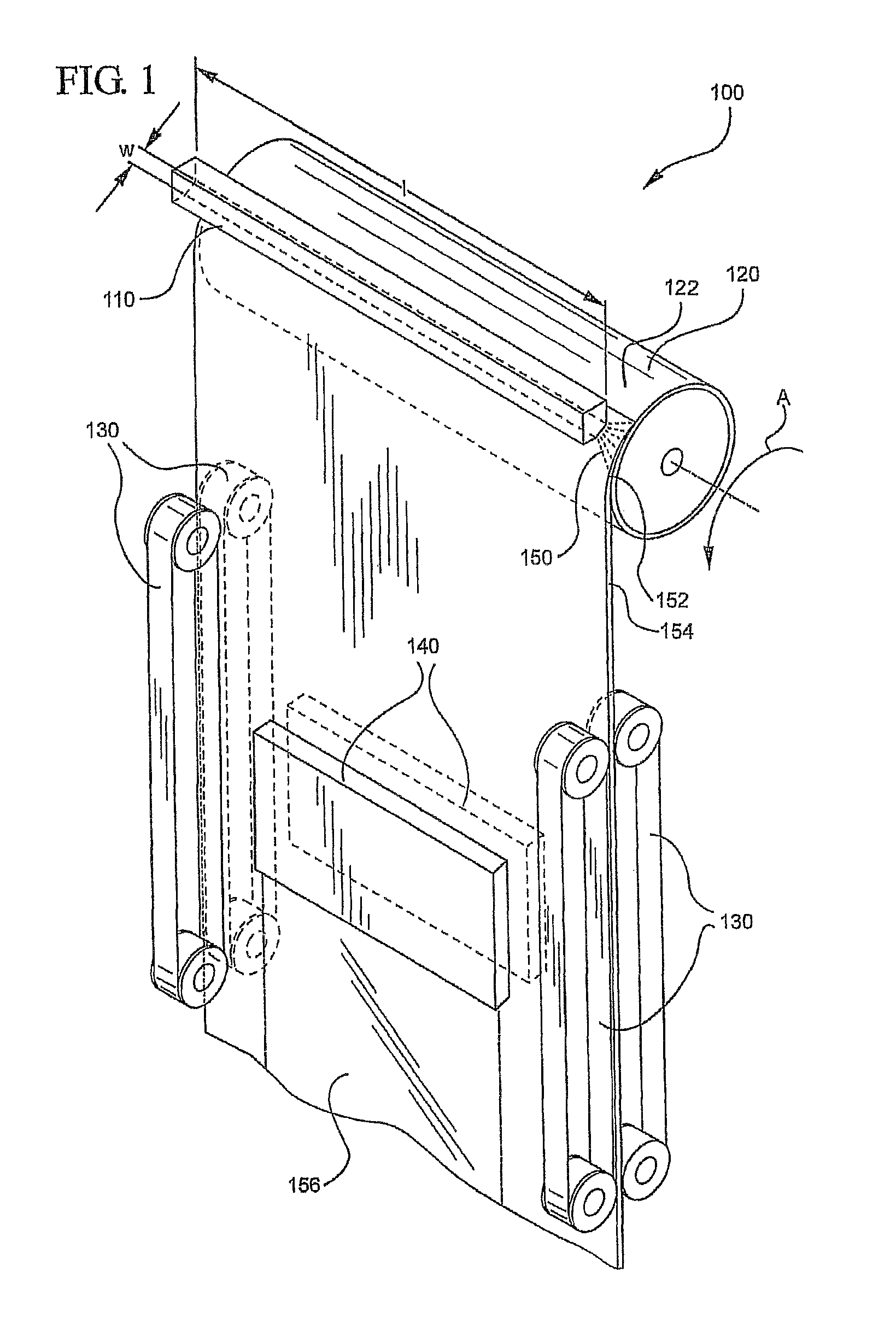

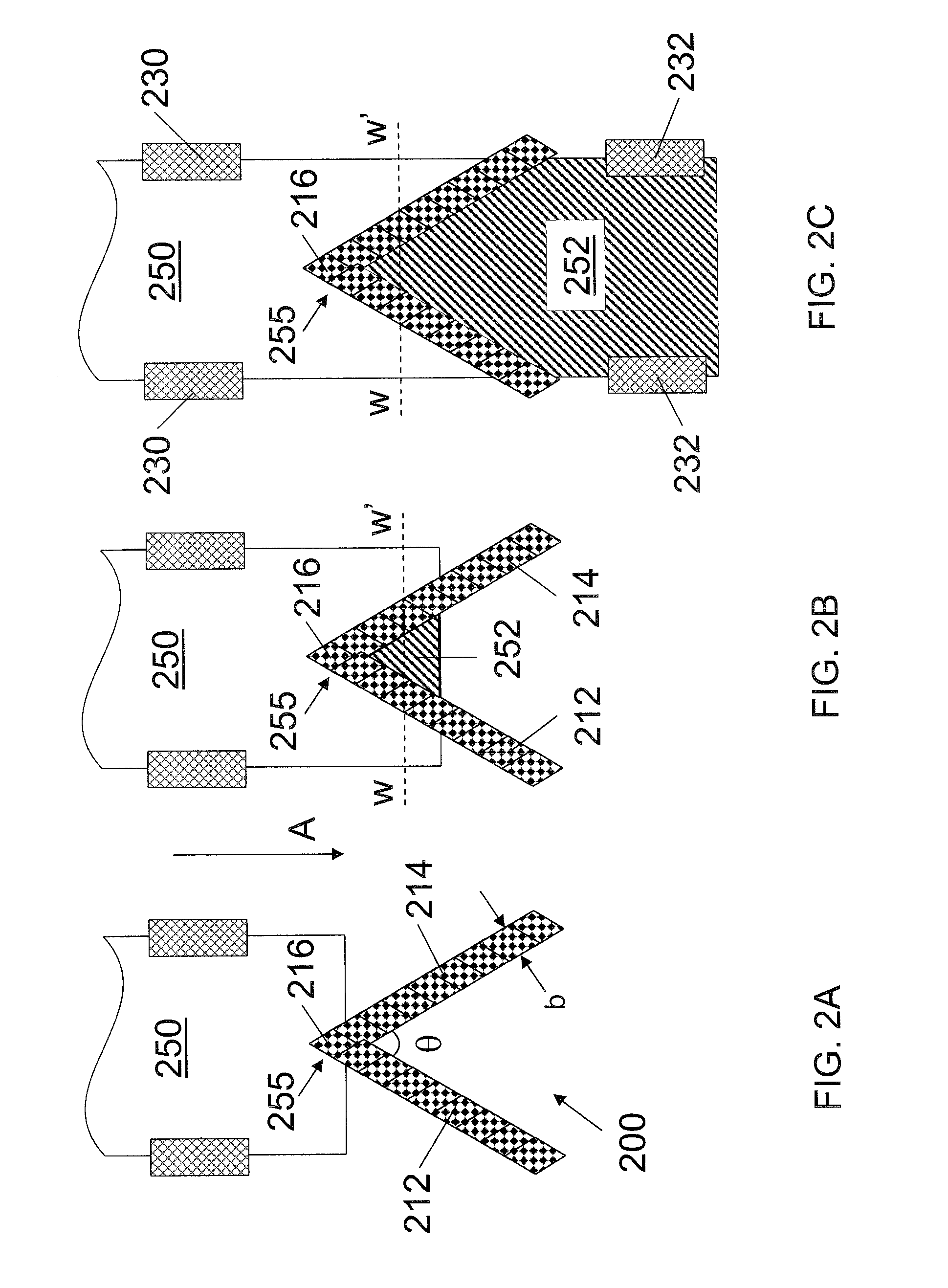

ActiveUS8359884B2Improve surface qualityMolten spray coatingGlass rolling apparatusMetallurgyGlass sheet

A glass sheet is formed using a roll-to-roll glass soot deposition and sintering process. The glass sheet formation involves forming a first glass soot layer on a deposition surface of a soot-receiving device, removing the first glass soot layer from the deposition surface, and forming a second glass soot layer on the unsupported first glass soot layer. The resulting composite glass soot sheet is heated to form a sintered glass sheet. The glass sheet can be a substantially homogeneous glass sheet or a composite glass sheet having layer-specific attributes.

Owner:CORNING INC

Roll-to-roll glass: touch-free process and multilayer approach

ActiveUS20110014445A1Improve surface qualityMolten spray coatingSynthetic resin layered productsMetallurgyGlass sheet

A glass sheet is formed using a roll-to-roll glass soot deposition and sintering process. The glass sheet formation involves forming a first glass soot layer on a deposition surface of a soot-receiving device, removing the first glass soot layer from the deposition surface, and forming a second glass soot layer on the unsupported first glass soot layer. The resulting composite glass soot sheet is heated to form a sintered glass sheet. The glass sheet can be a substantially homogeneous glass sheet or a composite glass sheet having layer-specific attributes.

Owner:CORNING INC

Method for influencing soot deposits on sensors

ActiveUS8035404B2Improve reliabilityAccurate measurementResistance/reactance/impedenceMaterial analysis by electric/magnetic meansHigh voltageSoot deposition

A method is described for controlling the soot deposition on sensors. A sensor element is provided, which includes a first electrode and a second electrode. Different measuring voltages U1 and U2 can be applied to the sensor element. During a first time period t1, the sensor element is operated at a higher voltage U1 until a triggering threshold AP of the sensor element is exceeded, while it is operated at a voltage U2, which is different from higher voltage U1, U2 being lower than voltage U1, during a second time period t2.

Owner:ROBERT BOSCH GMBH

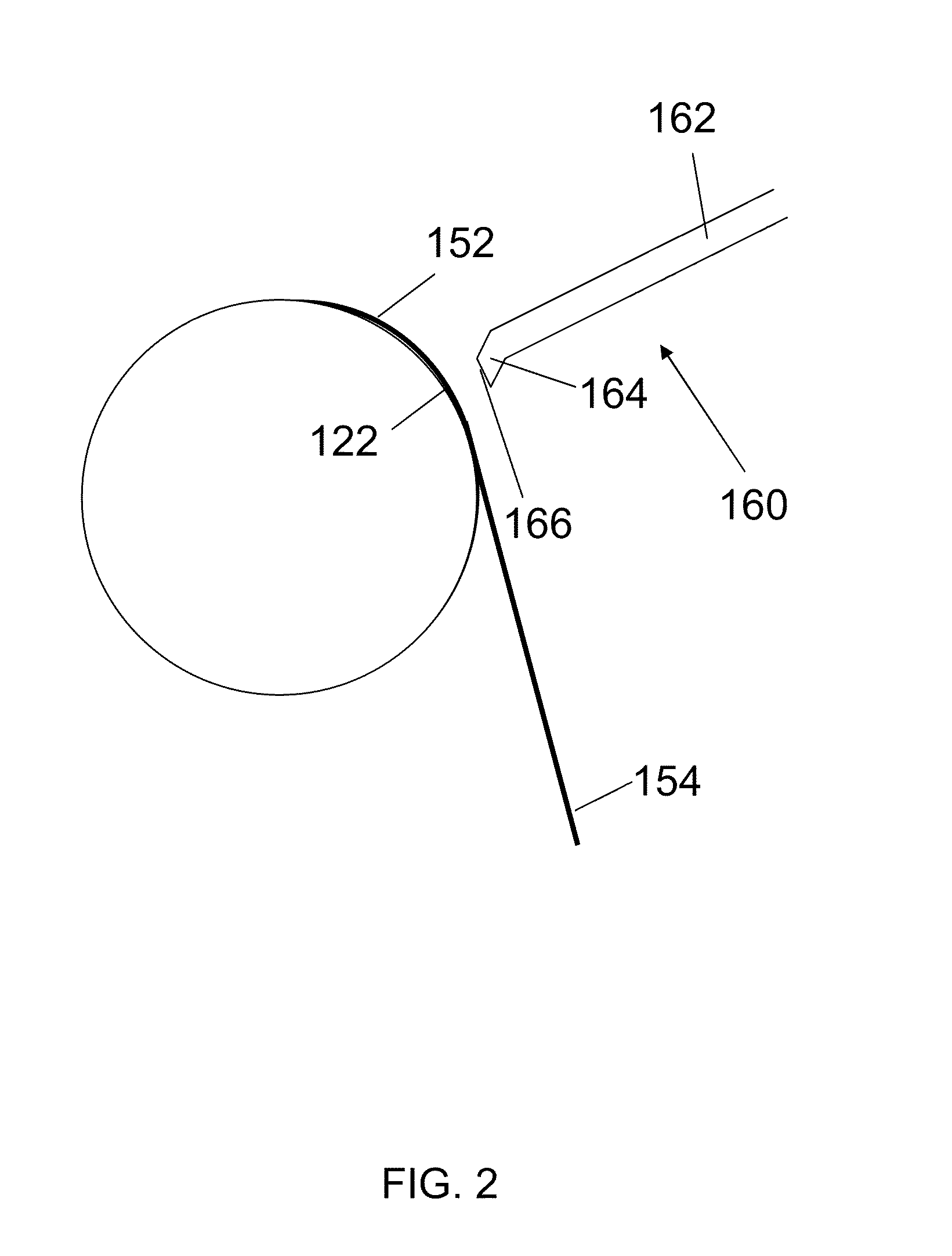

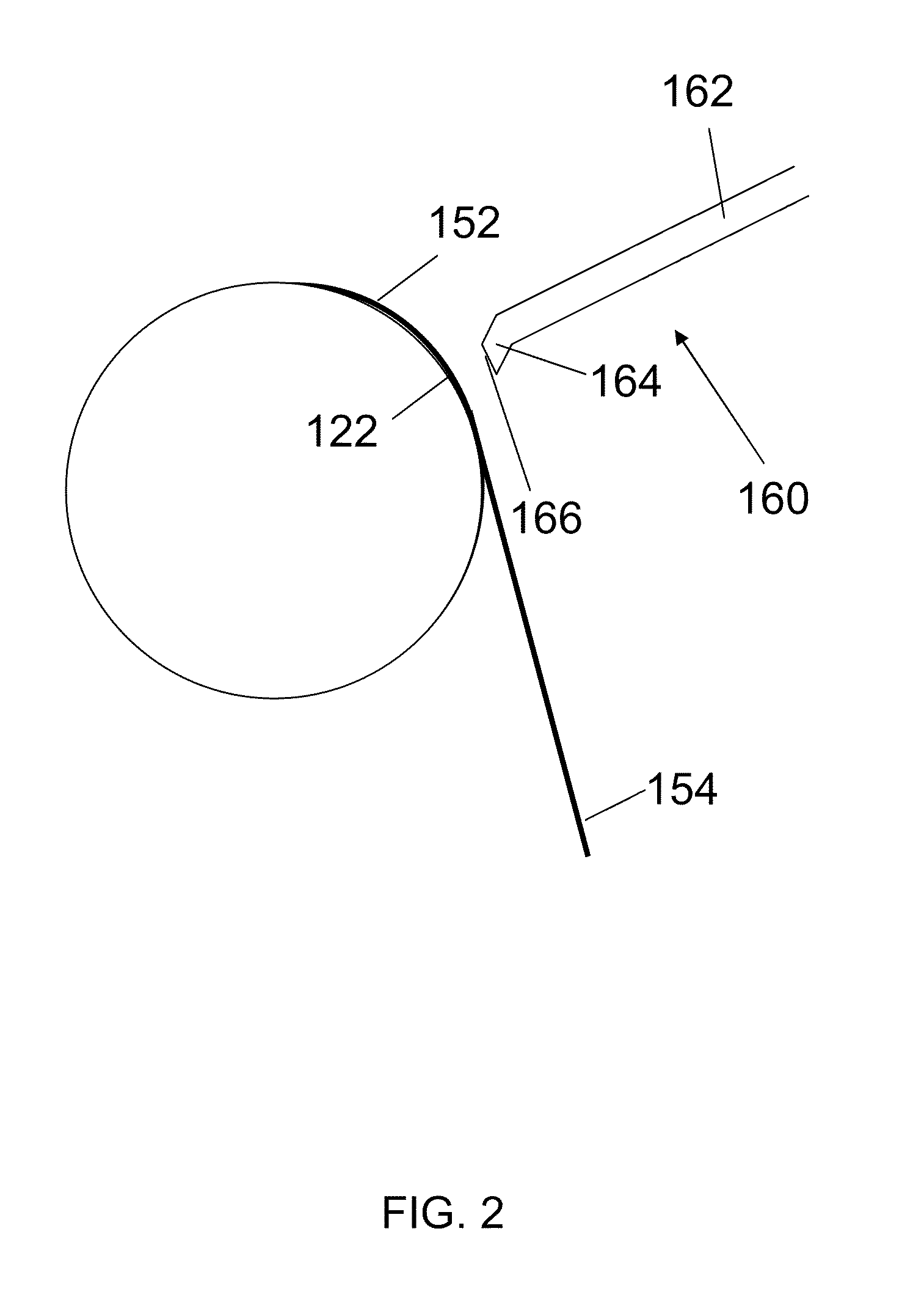

Method and apparatus for removing glass soot sheet from substrate

As a precursor to forming a glass sheet, a soot layer is formed on a deposition surface using a roll-to-roll glass soot deposition process. A soot layer-separating device is configured to bring a stream of gas into contact with at least a portion of a free surface of the soot layer. The impinging gas stream affects local thermal expansion stresses at the soot layer / deposition surface interface, which separates the soot layer from the deposition surface.

Owner:CORNING INC

Roll-to-roll glass material attributes and fingerprint

ActiveUS8062733B2Improve surface qualitySynthetic resin layered productsRecord information storageSurface roughnessHigh silica

Owner:CORNING INC

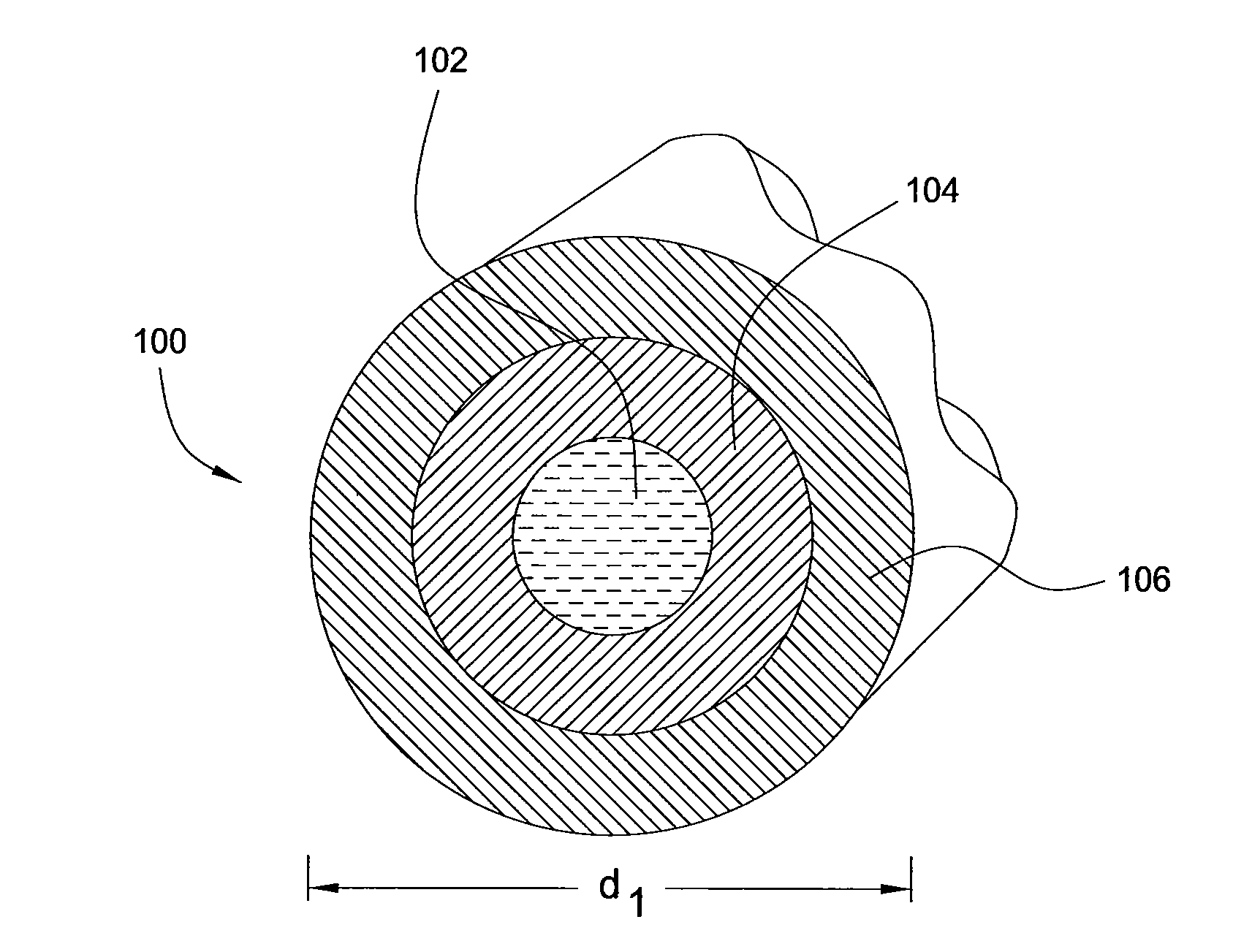

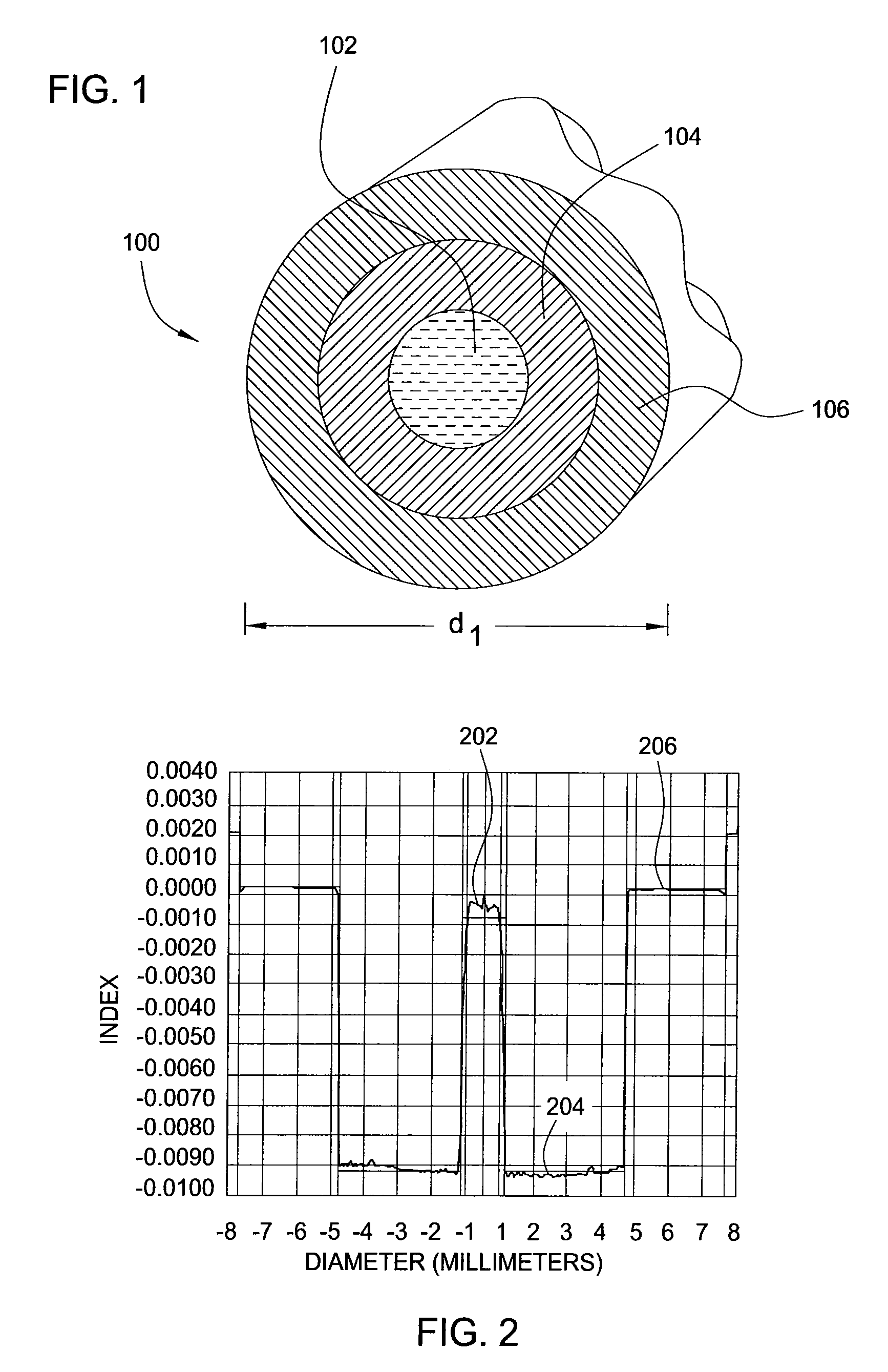

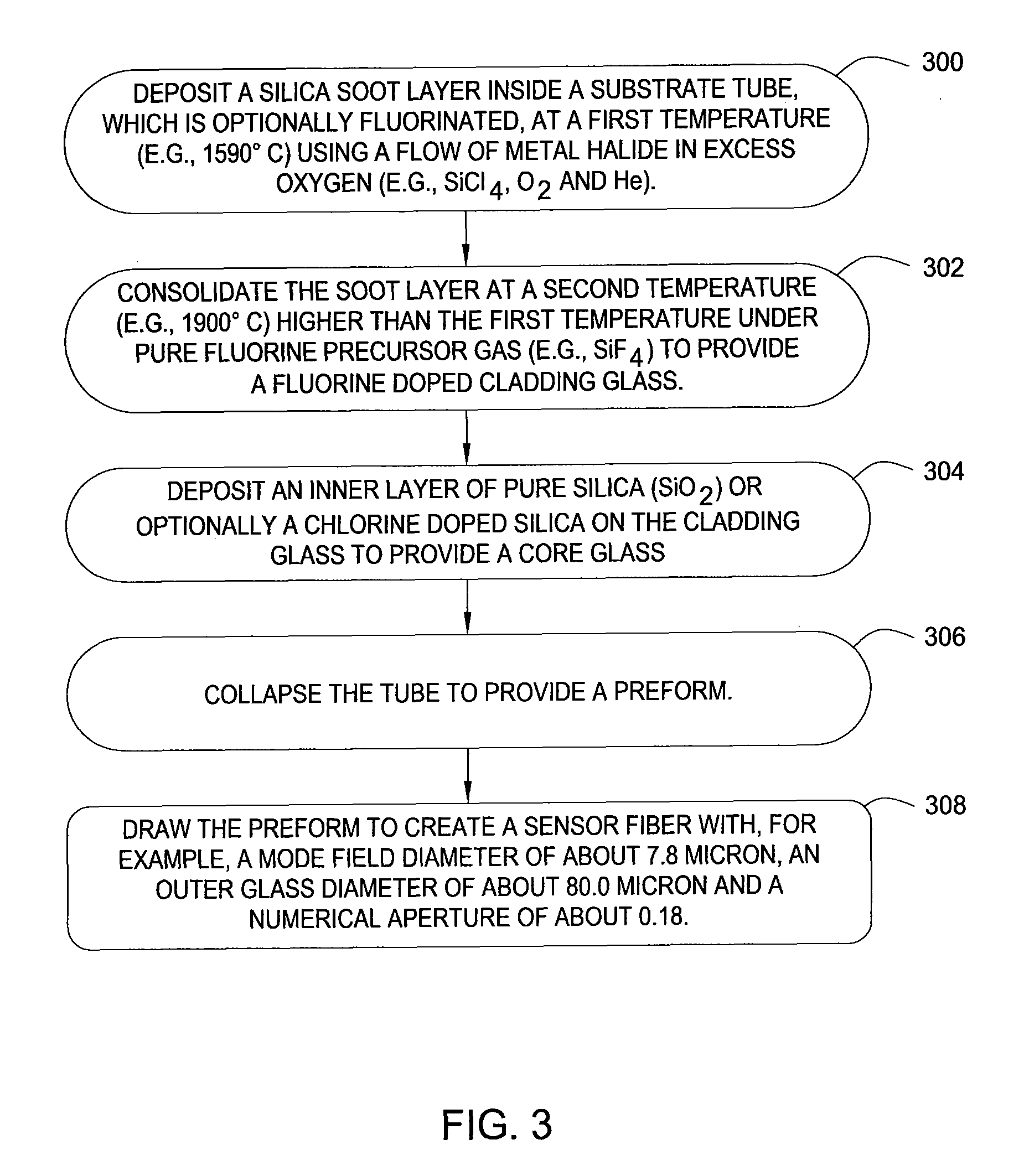

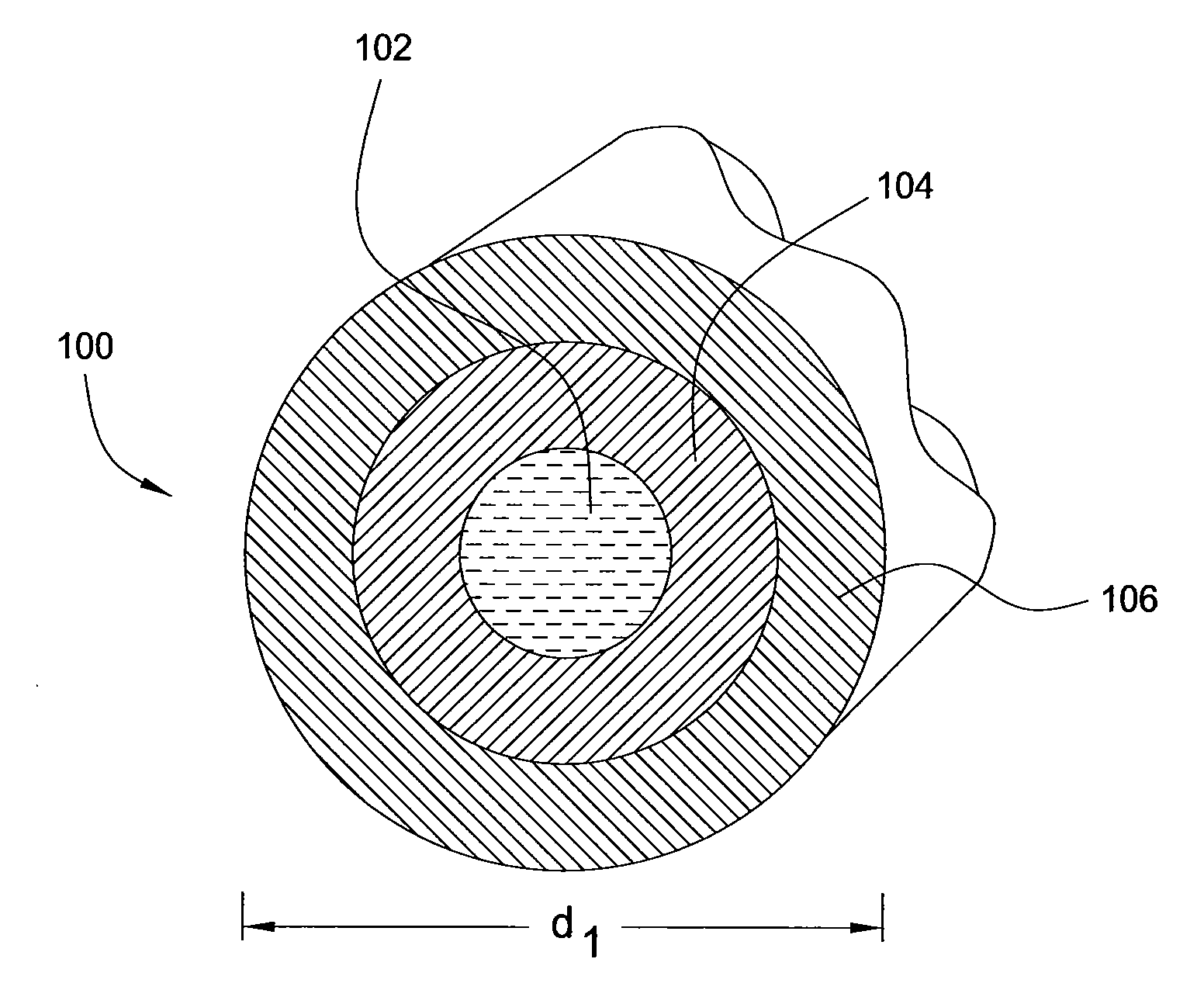

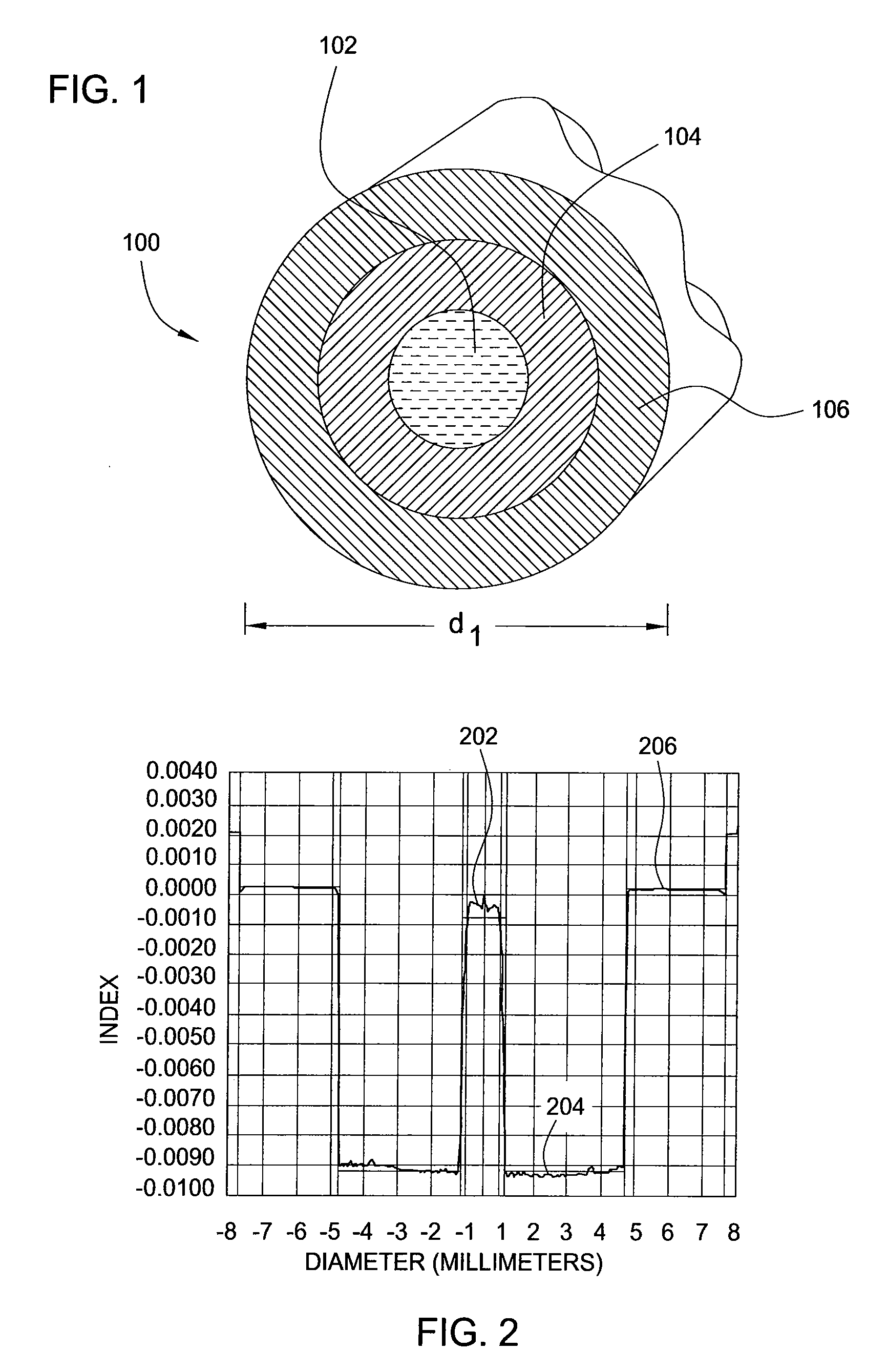

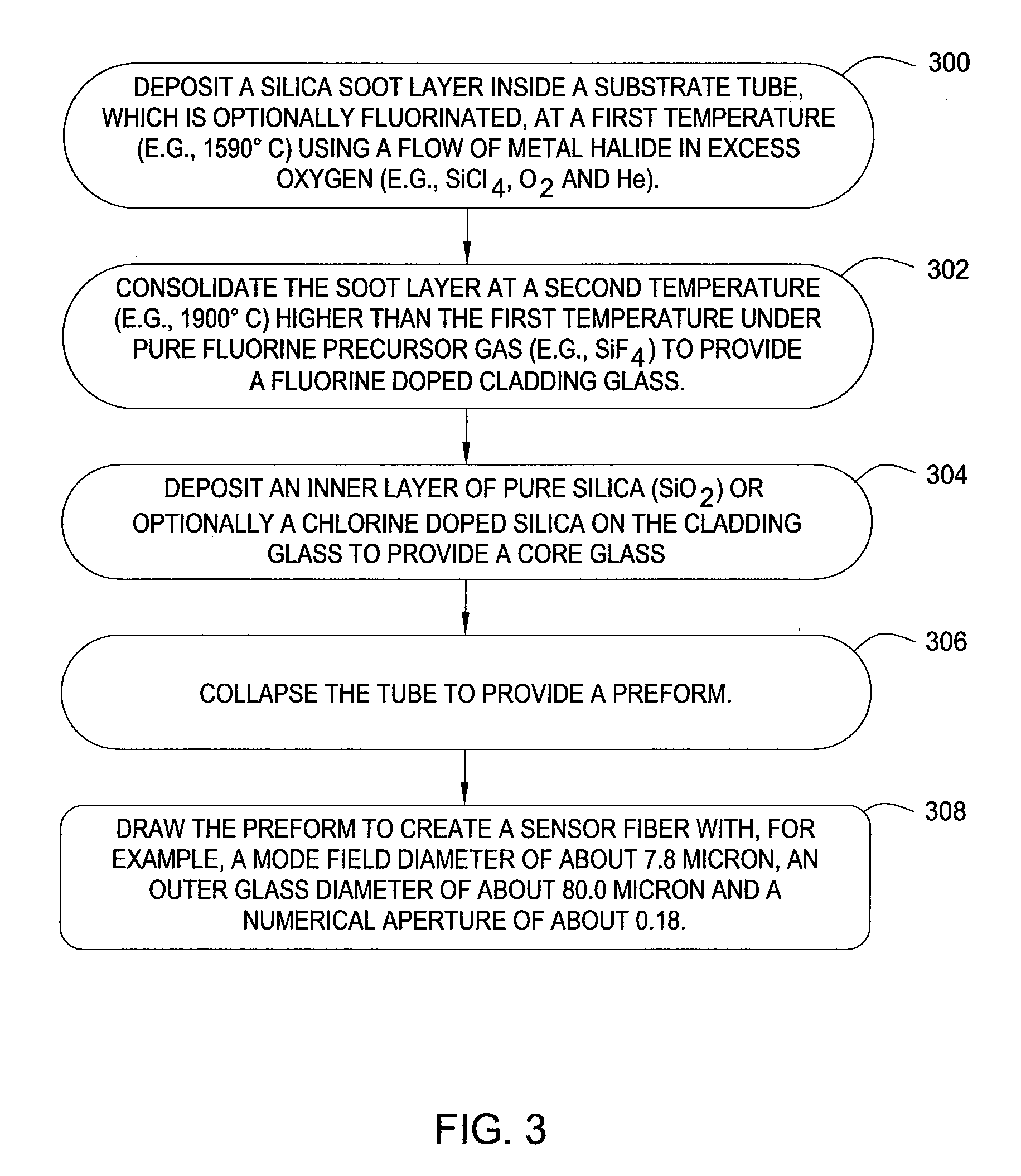

Single mode optical fiber with improved bend performance

InactiveUS7805039B2Glass making apparatusOptical fibre with multilayer core/claddingSilicon dioxideConsolidation process

Owner:WEATHERFORD TECH HLDG LLC

Microstructured optical fibers and methods

InactiveUS20080276650A1Improve bending performancePromote lowerGlass fibre drawing apparatusGlass fibre productsCombustorNitrogen

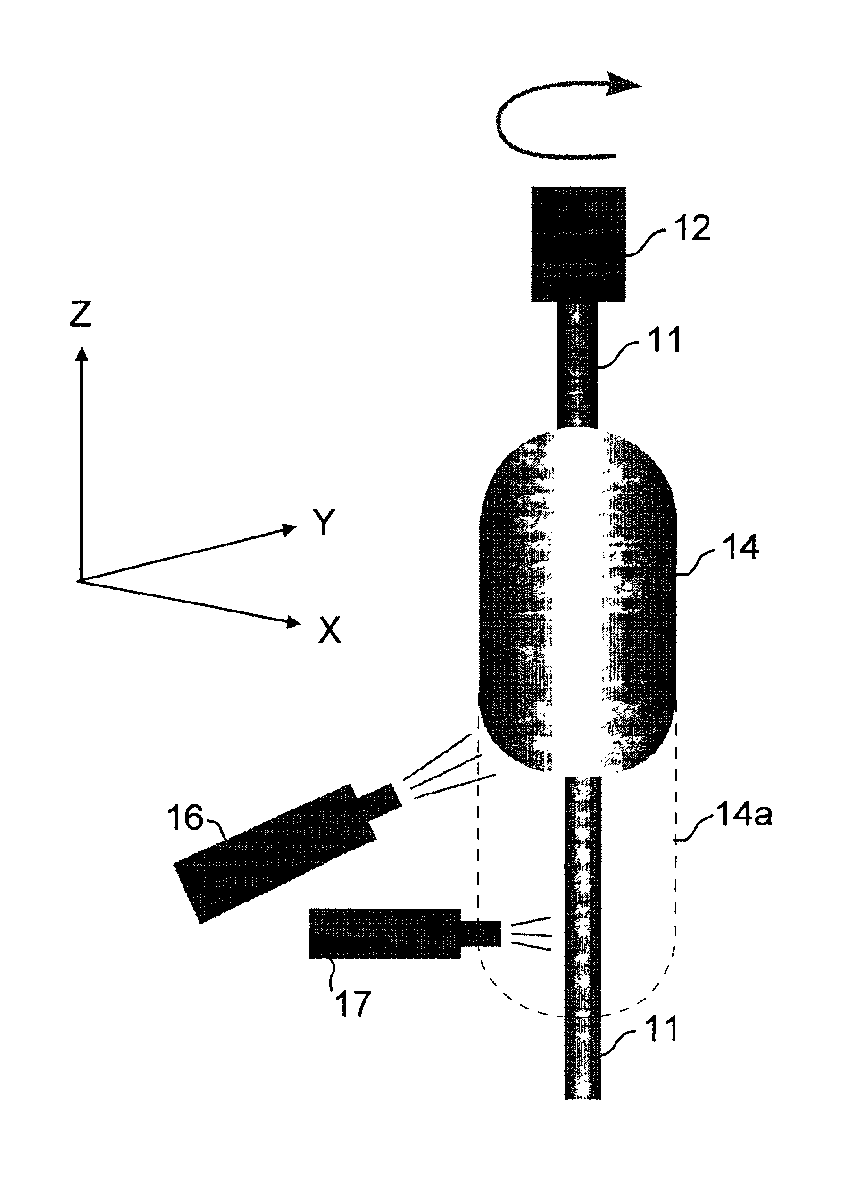

Method of making a microstructured optical fiber. Silica glass based soot is deposited on a substrate to form at least a portion of an optical fiber preform by traversing a soot deposition burner with respect to said substrate at a burner traverse rate greater than 3 cm / sec, thereby depositing a layer of soot having a thickness less than 20 microns for each of a plurality of burner passes. At least a portion of the soot preform is then consolidated inside a furnace to remove greater than 50 percent of the air trapped in said soot preform, said consolidating taking place in a gaseous atmosphere containing krypton, nitrogen, or mixtures thereof under conditions which are effective to trap a portion of said gaseous atmosphere in said preform during said consolidation step, thereby forming a consolidated preform which when viewed in cross section will exhibit at least 50 voids therein.

Owner:CORNING INC

Roll-to-roll glass soot sheet sintering method and apparatus

InactiveUS8181485B2Improve surface qualityGlass drawing apparatusGlass forming apparatusMetallurgyFritted glass

Owner:CORNING INC

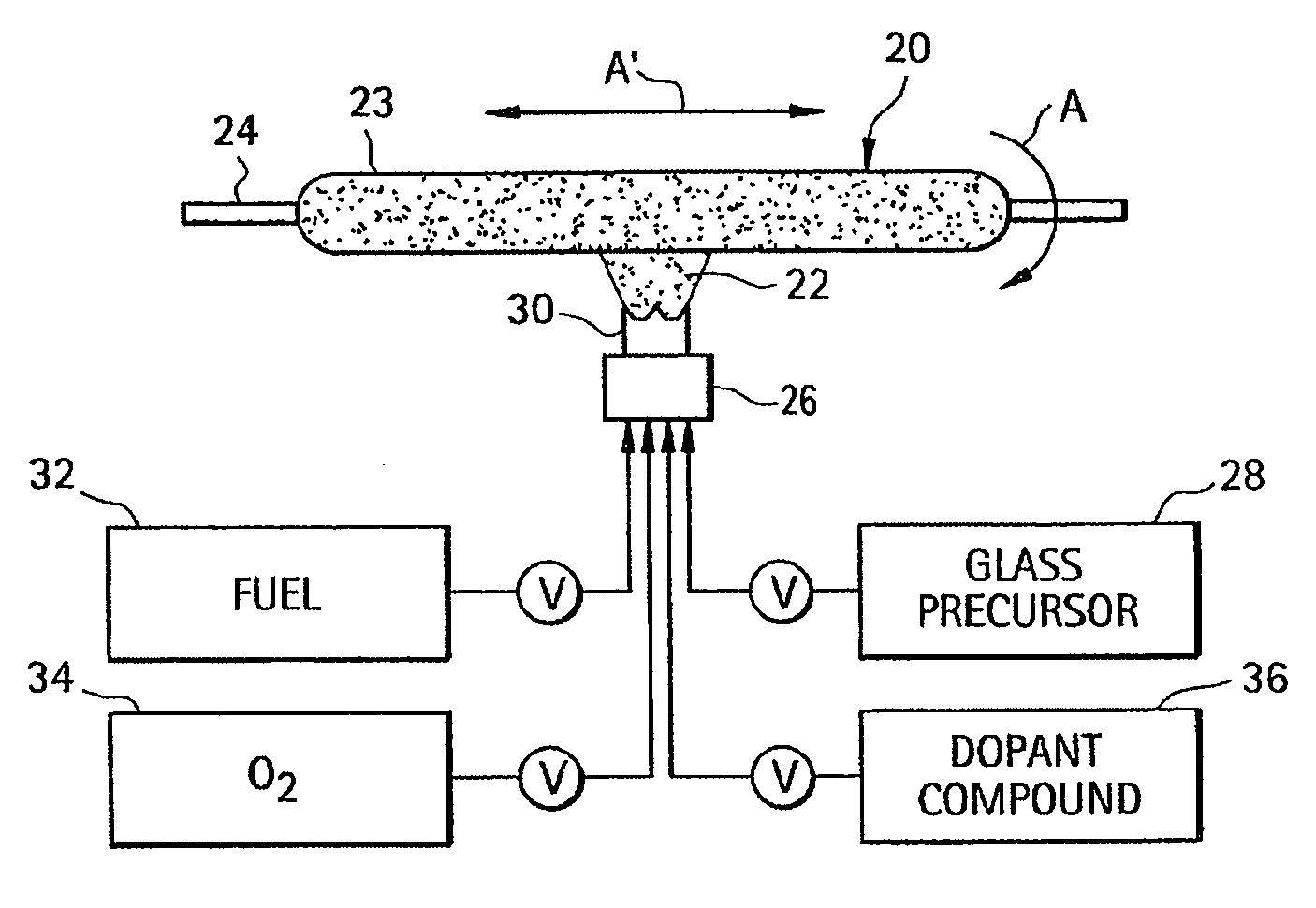

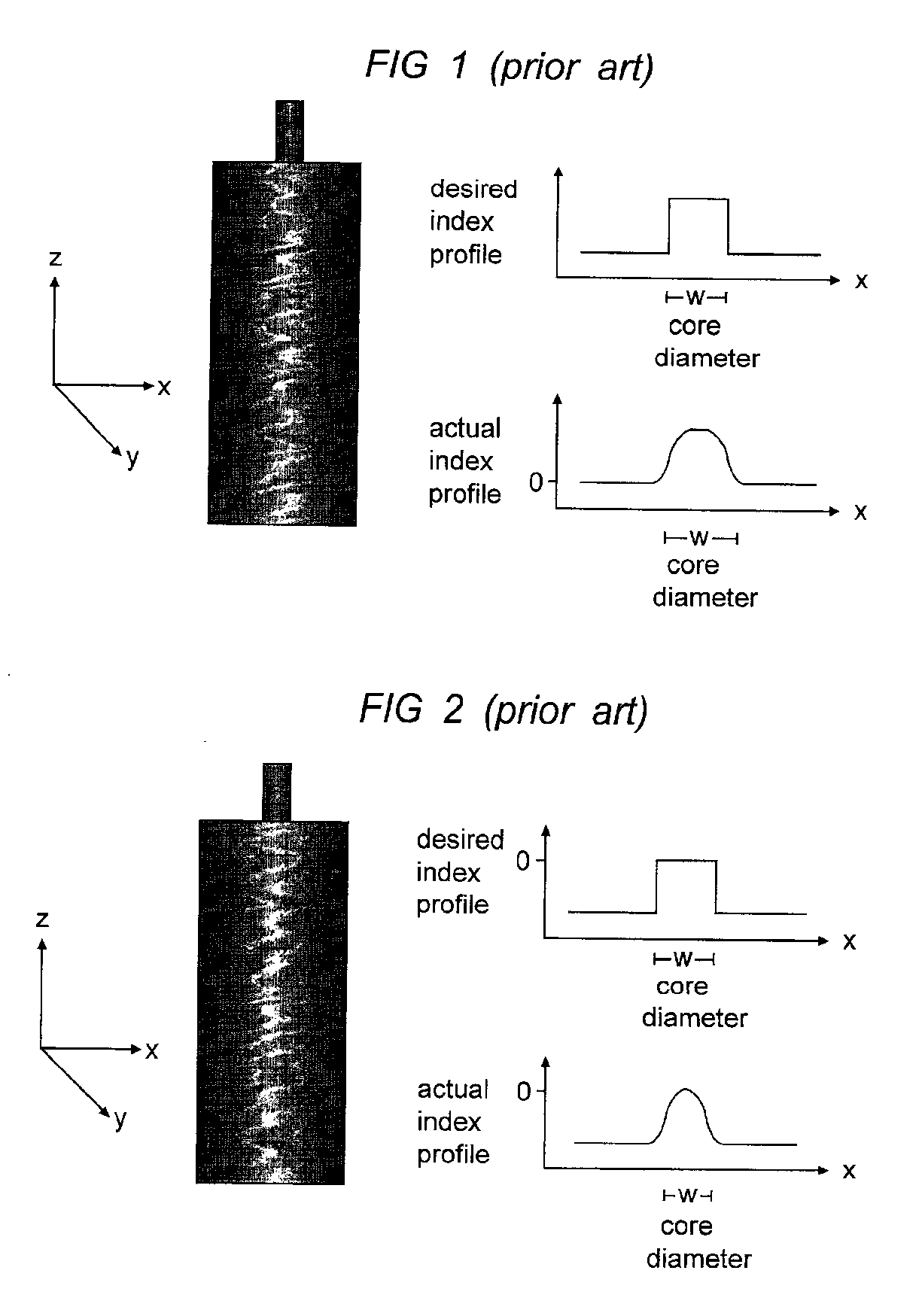

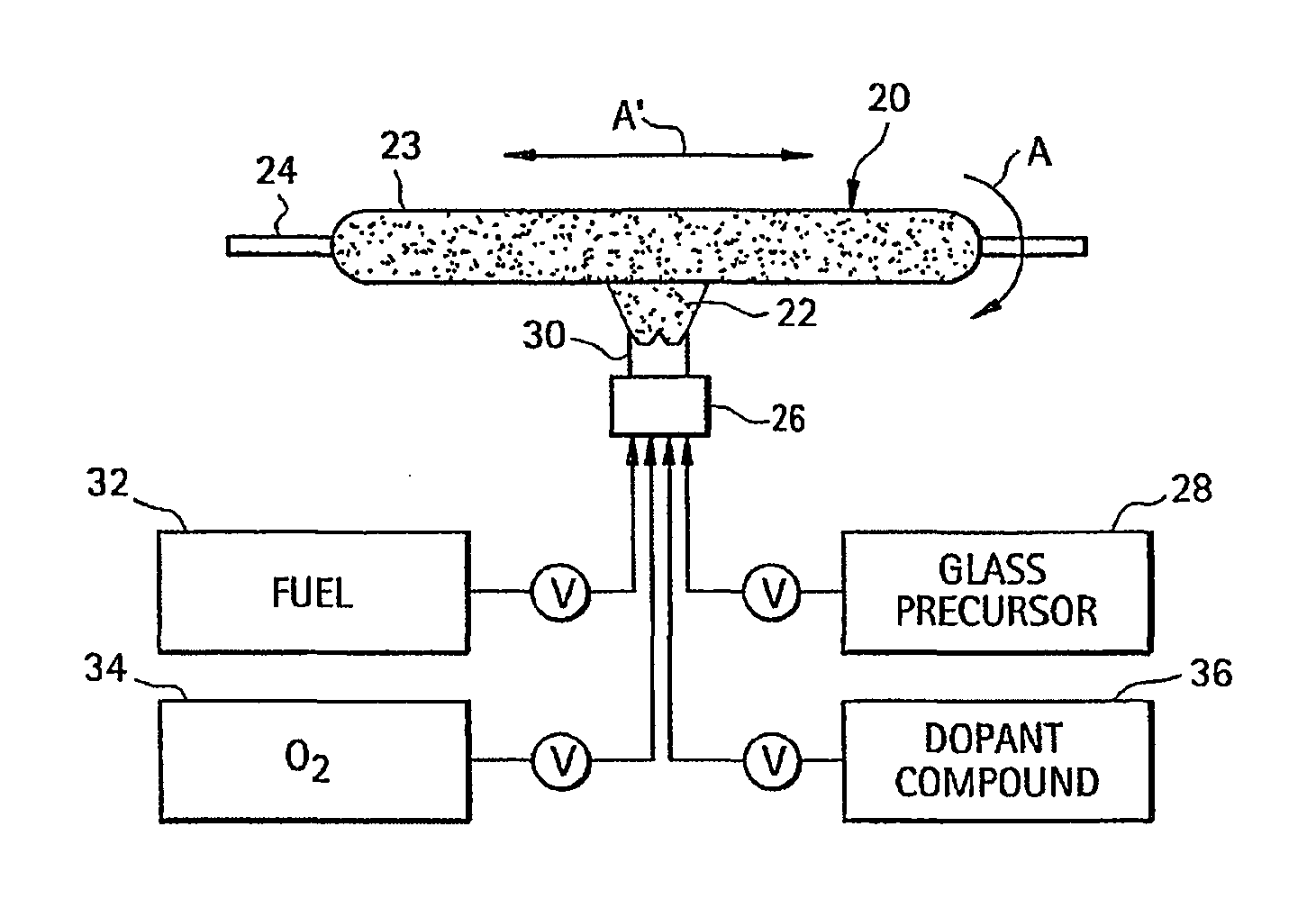

Optical fiber preform manufacture using improved VAD

InactiveUS6928841B2Solve the real problemGlass making apparatusDecorative surface effectsDopantRefractive index

The specification describes a VAD method for producing optical fiber preforms by depositing soot onto a solid core rod. The solid core rod preferably has a uniform composition, doped or undoped, suitable for the center core region of the preform. The primary cladding layer, and additional cladding layers if desired, are produced by depositing soot on the center core rod. The surface of the center core rod is treated with an etchant torch that traverses the center core rod in front of the soot deposition torch. This produces a clean interface between the core and primary cladding. This soot-on-center-core-rod method allows the production of sharp index profiles by reducing the diffusion of dopants into and out of the center core portion of the preform that occurs in soot-on-soot processes.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

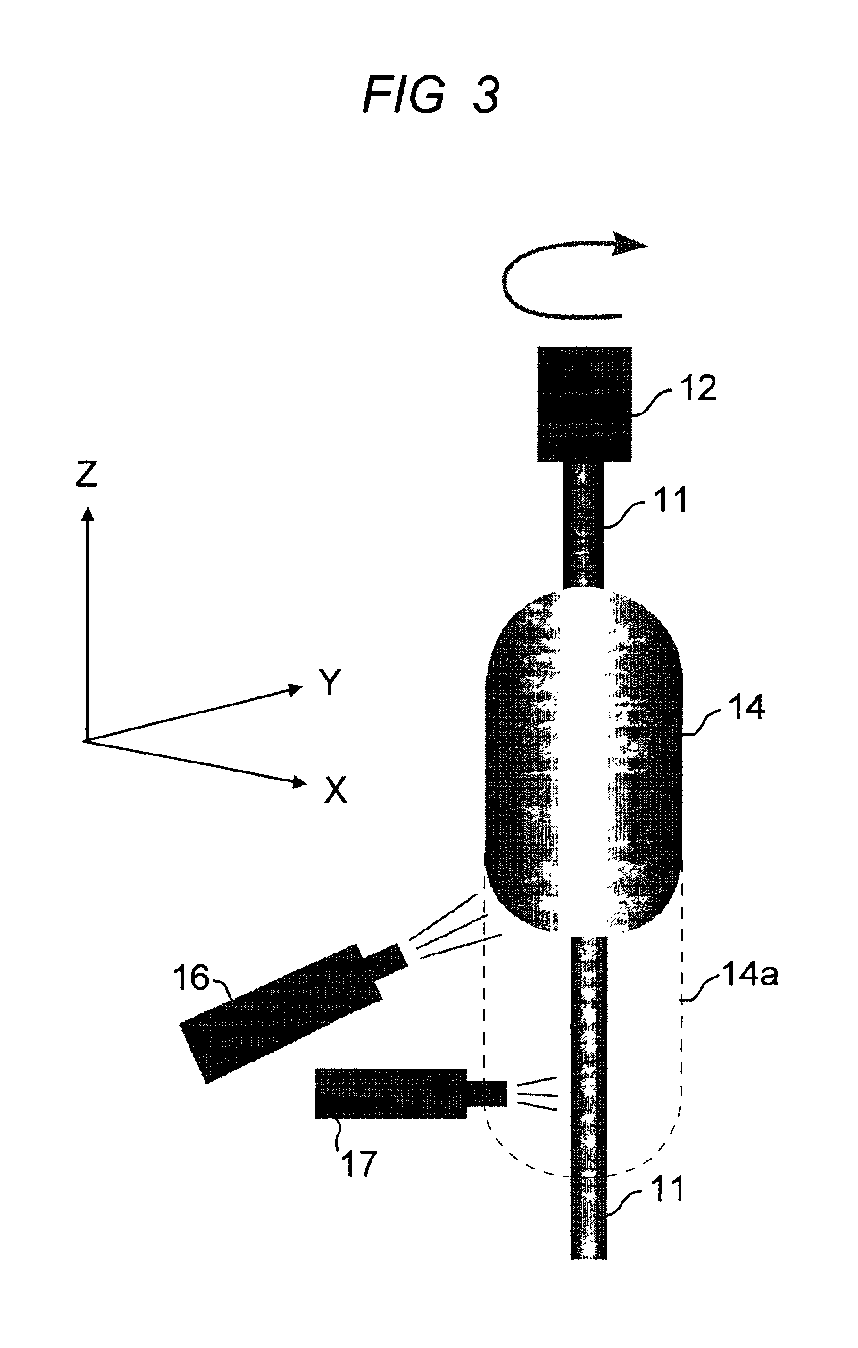

Single mode optical fiber with improved bend performance

InactiveUS20080273849A1Glass making apparatusOptical fibre with multilayer core/claddingSilicon dioxideConsolidation process

Methods and apparatus relate to optical fibers suitable for use in sensing applications exposed to radiation environments. The fibers include a core of pure silica or chlorine doped silica surrounded by a fluorinated silica cladding. These glasses for the core and cladding utilize dopants that resist radiation-induced attenuation. A two step process for forming the cladding can achieve necessary concentrations of the fluorine by performing a soot deposition process in a different environment from a consolidation process where the soot is sintered into a glass. Concentration of fluorine doped into the cladding layer enables obtaining a numerical aperture that confines a mono-mode of the fiber to resist bend-induced attenuation. Dimensions of the fiber further facilitate bending ability of the fiber.

Owner:WEATHERFORD TECH HLDG LLC

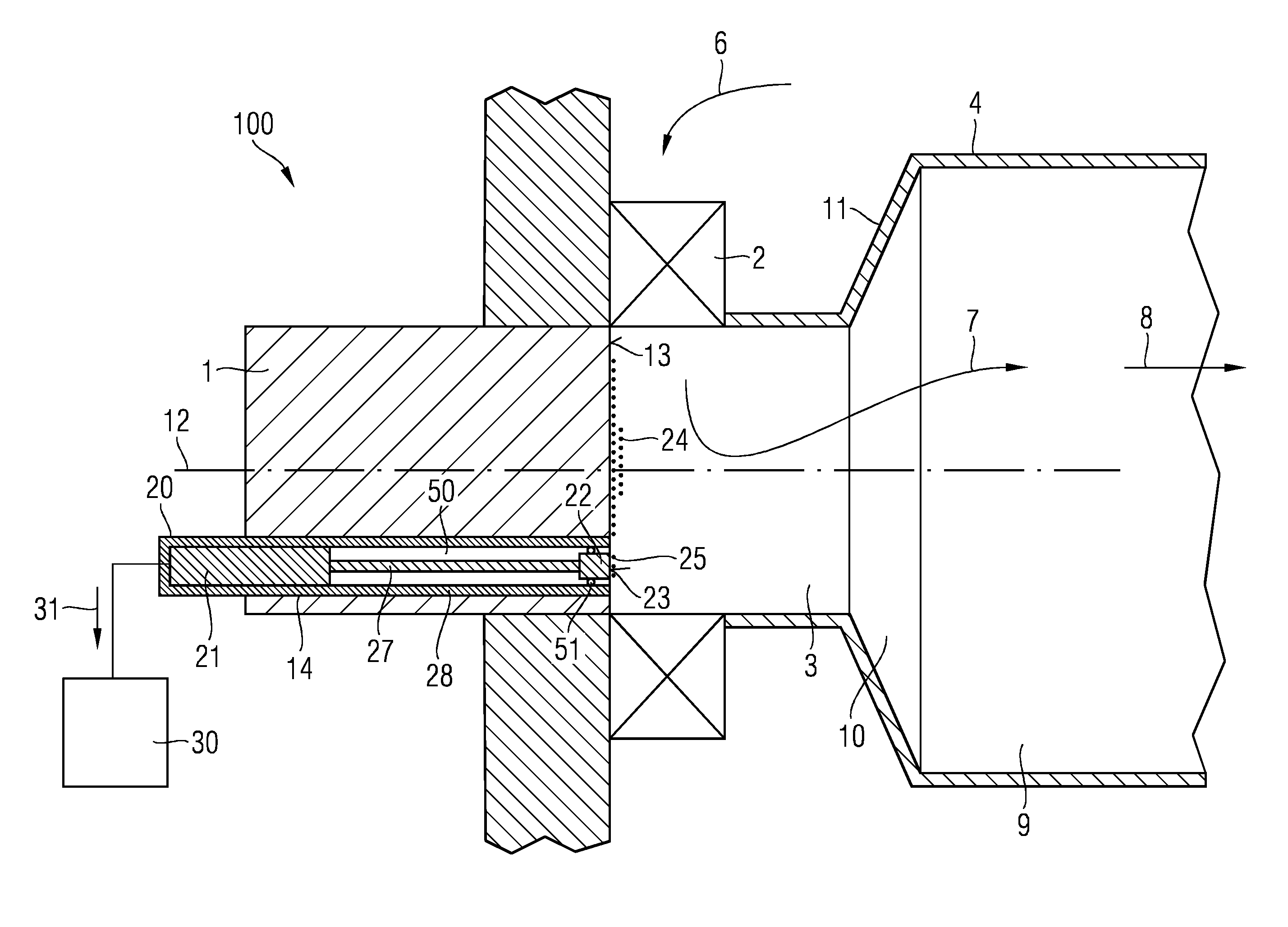

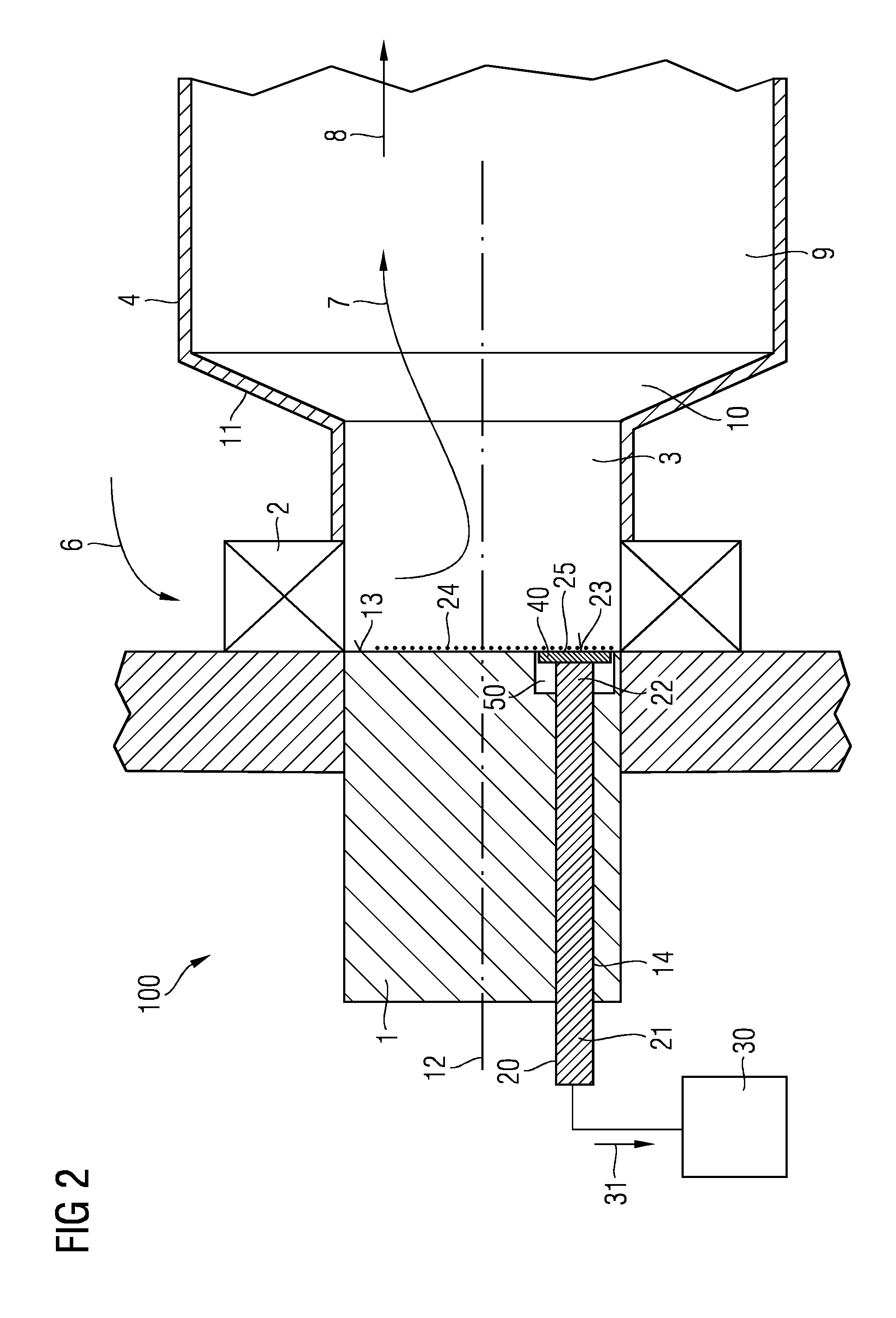

Burner arrangement, combustor, gas turbine engine and method for determining a rate of soot deposition in gas turbine combustors

InactiveUS20150292405A1Increase volumeFaster build-upTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustorGas turbines

A burner arrangement for a combustor of a gas turbine engine including a burner body is provided. The burner arrangement includes a cut-out and a burner face, the cut-out piercing the burner face, a sensor device installed in the cut-out and a first part fixed to the burner body and a second part having a tip surface, the sensor device being configured such that the second part is able to move relative to the burner face, and further including a data evaluation unit. The sensor device generates information signals corresponding to a magnitude and / or a period of the oscillation of the second part relative to the first part, the data evaluation unit collects the received information signals and determines a grade of deposition of combustion residues on the burner face by evaluating the collected information signals.

Owner:SIEMENS AG

Manufacturing method of optical fiber base material possessing low refractive index portion distantly-positioned from core

Owner:SHIN ETSU CHEM IND CO LTD

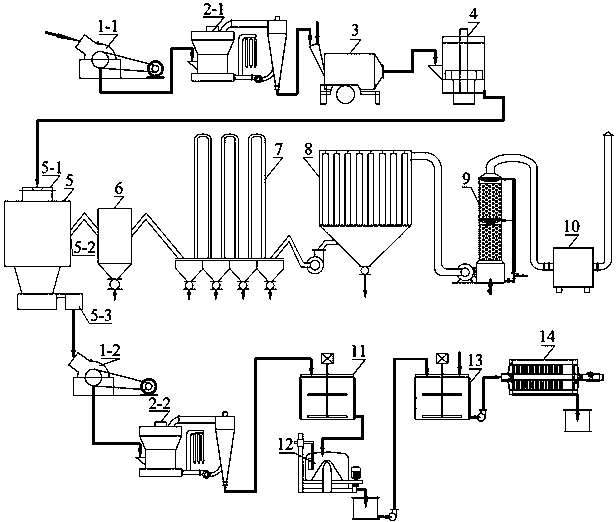

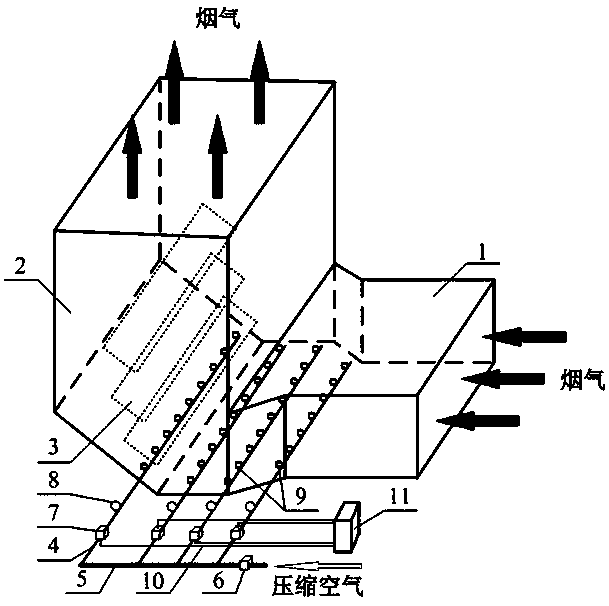

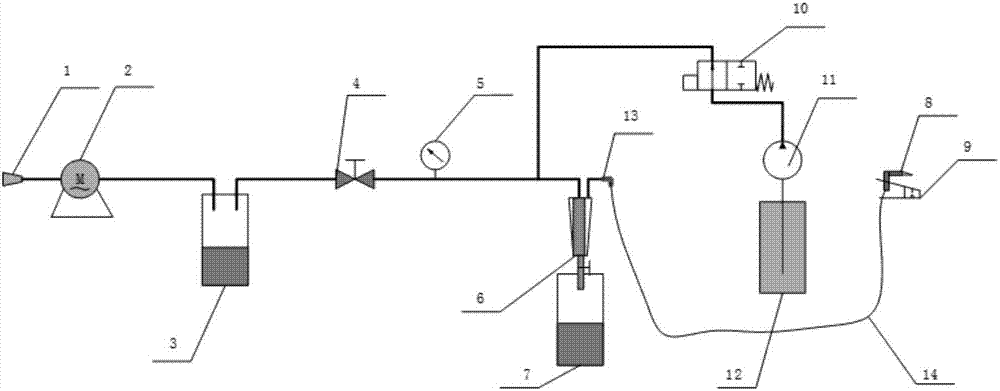

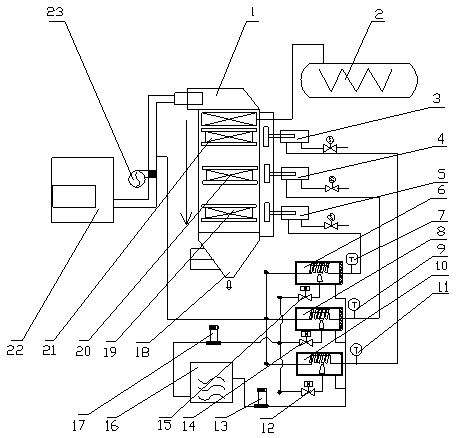

Device and method for jointly treating antimony-smelting arsenic soda slag through pyrogenic process and wet process

The invention relates to a device and method for jointly treating antimony-smelting arsenic soda slag through a pyrogenic process and a wet process. The device comprises a pretreatment unit, an arsenic pyrogenic process volatilization unit and a wet process deep arsenic removing unit; the pretreatment unit comprises a breaking machine, a fine grinding device, a mixing device and a pelletizing machine which are sequentially connected; the arsenic pyrogenic process volatilization unit comprises an arsenic volatilization furnace, a soot deposition chamber, a surface cooling device and a bag collector which are sequentially connected; the wet process deep arsenic removing unit comprises a breaking machine, a fine grinding device, a leaching reaction tank, a centrifuge, a deep arsenic removal reaction tank and a filter press which are sequentially connected; the pelletizing machine is connected with a feeding port of the arsenic volatilization furnace; an air outlet of the arsenic volatilization furnace is connected with the soot deposition chamber; and a discharging port of the arsenic volatilization furnace is connected to the breaking machine in the wet process deep arsenic removingunit. The invention also discloses the method for jointly treating the antimony-smelting arsenic soda slag through the pyrogenic process and the wet process. The device is simple, control is easy andconvenient, and the processing capability is strong; and by means of the method, the arsenic and antimony volatilization rate is high, cost is low, and the method is suitable for industrial production.

Owner:刘义冬

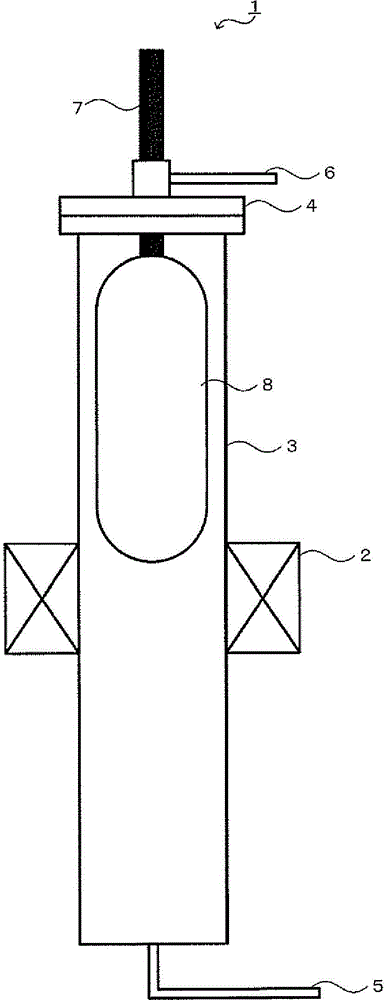

Sintering apparatus

InactiveCN104098255AImprove qualityMaintainance of heating chambersGlass shaping apparatusEngineeringHeating furnace

The invention provides a sintering apparatus for manufacturing quartz glass by heating and sintering a soot deposition body formed of a powder containing silicon dioxide. The sintering apparatus comprises a furnace core tube having an opening in a top end through which the soot deposition body is inserted, and has atmospheric gas introduced therein from below and expelled upward; a shaft from which the soot deposition body hangs; a lid that has the shaft inserted therethrough and can cover the opening; a heating furnace that heats the soot deposition body; an internal lid in a top portion of the furnace core tube that divides the top portion of the furnace core tube into an upper region and a lower region; and a gas flow path that connects the two regions to each other and has the atmospheric gas flow therethrough. Total cross-sectional area, relative to movement direction of the atmospheric gas, of the gas flow path is less than cross-sectional area, relative to movement direction of the atmospheric gas, of the furnace core tube.

Owner:SHIN ETSU CHEM CO LTD

Dust deposition inhibitor for dust removal water system in steelworks

The dust deposition inhibitor of the dedusting water system of the steelworks is an ideal water treatment agent that can be used for descaling, scale inhibition and dust suppression of the dedusting water system of the steelworks. It is a comprehensive multifunctional chemical descaling, antiscaling and dust inhibitor composed of materials such as polyphosphonate and organic polymer with descaling, antiscaling and dispersing properties as the main agent, and inorganic salts and various additives as auxiliary agents. . Descaling, anti-scaling, dust suppression, good effect. No hydrogen embrittlement, no corrosion, no poison, no smell, no pollution. The dust deposition inhibitor product of the dedusting water system of a steel plant of the present invention can be used in the dedusting water system to achieve: the scale inhibition rate is 100%. The descaling rate is 99.5%. The ring erosion rate is 99.6%. When the dedusting water system through scale removal, scale inhibition and dust suppression is running without scale, there is no need to stop production for cleaning and maintenance, which reduces huge economic losses and achieves greater economic benefits.

Owner:北京天森壹清科技有限公司

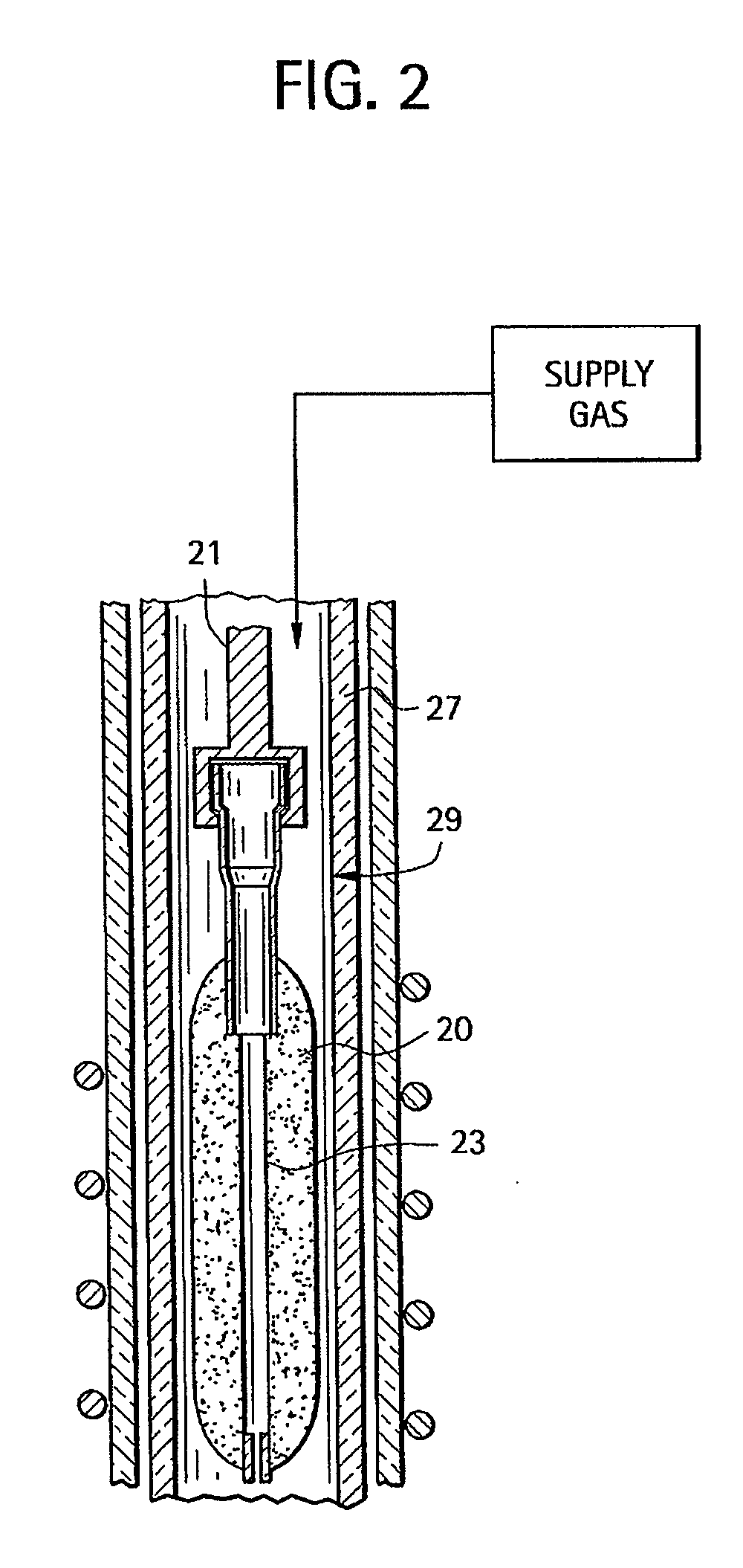

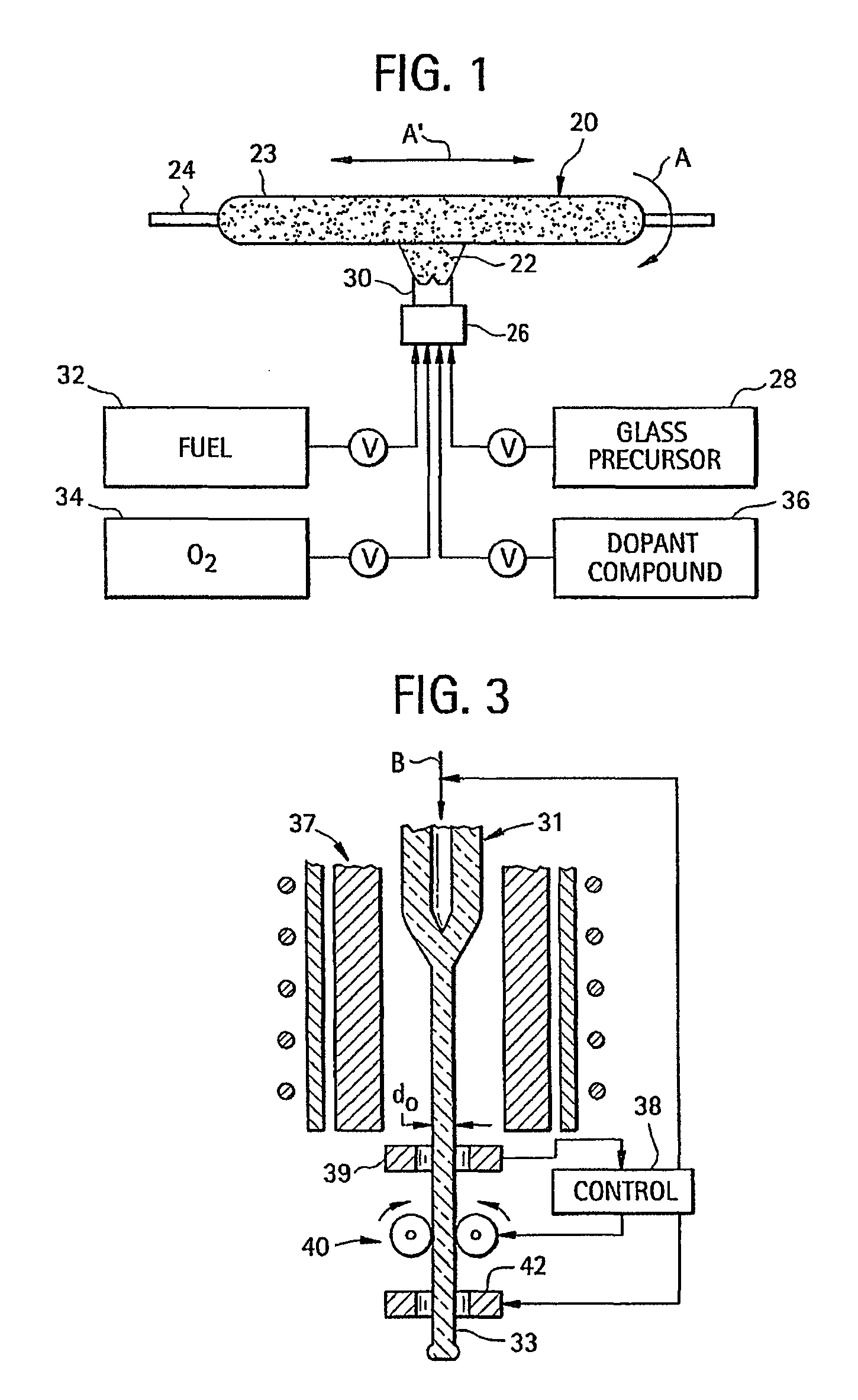

Method of producing optical fiber preform

InactiveUS6895783B2Reduce the generation of voidsLow costCladded optical fibrePretreated surfacesCombustorGlass particle

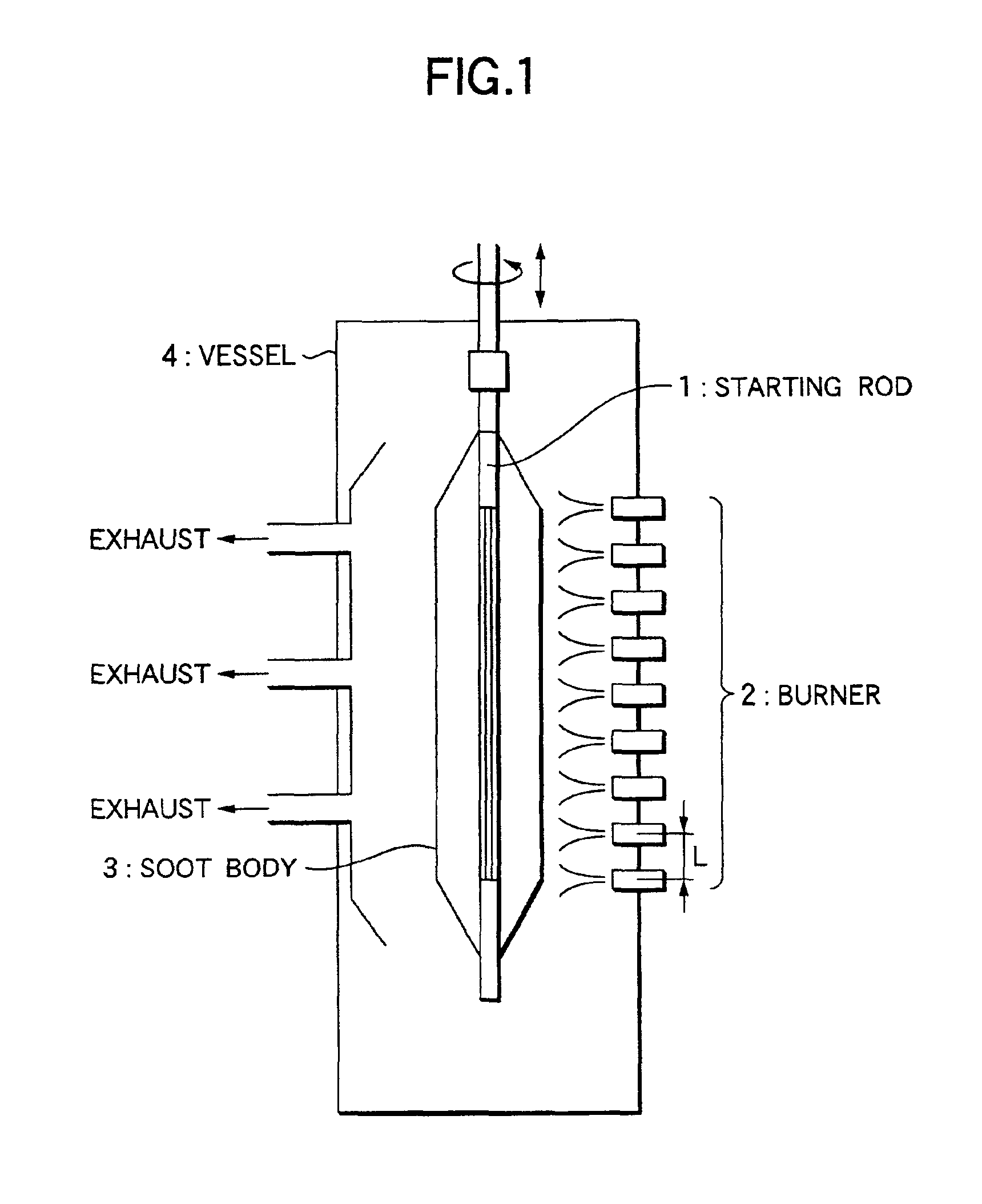

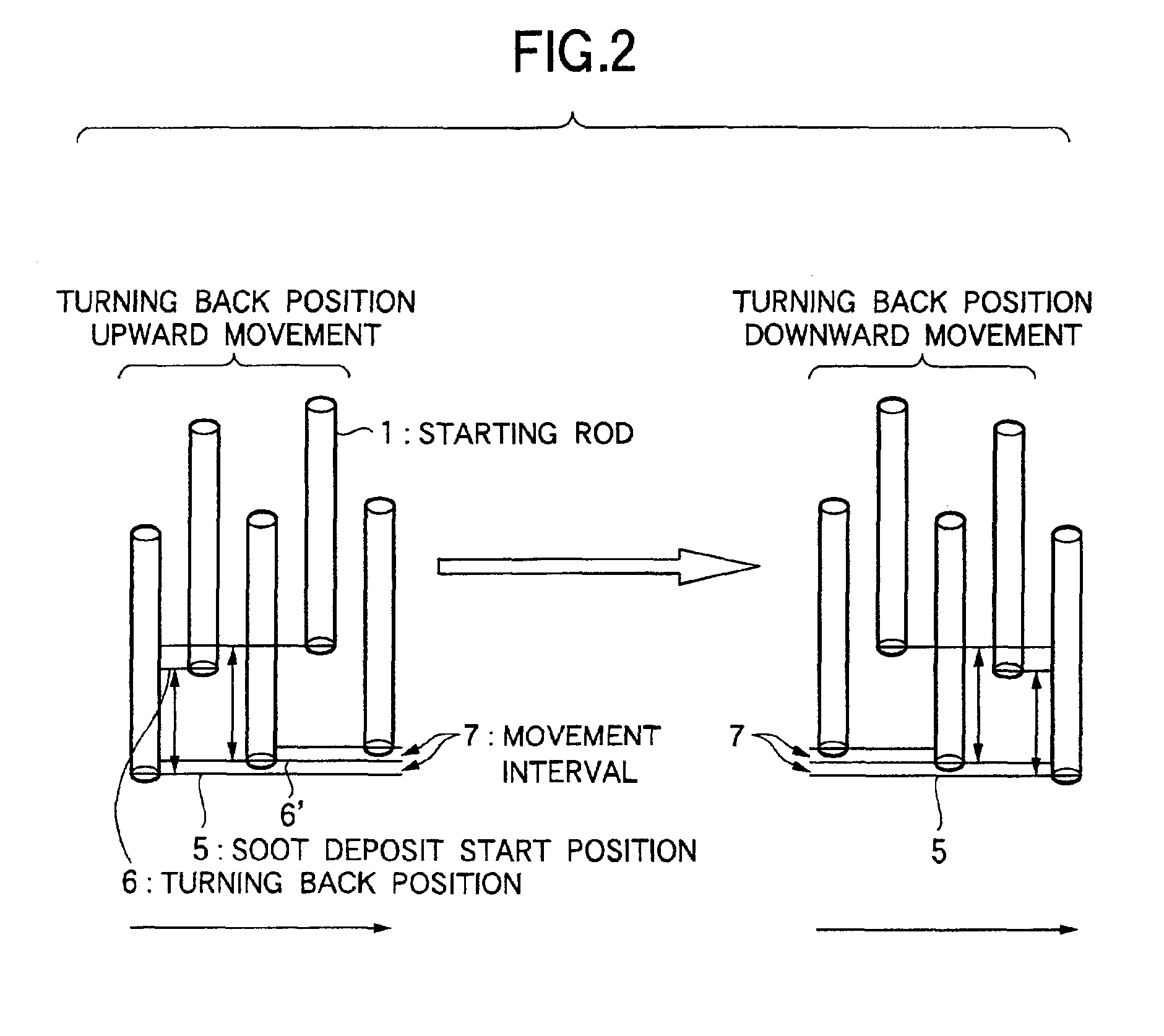

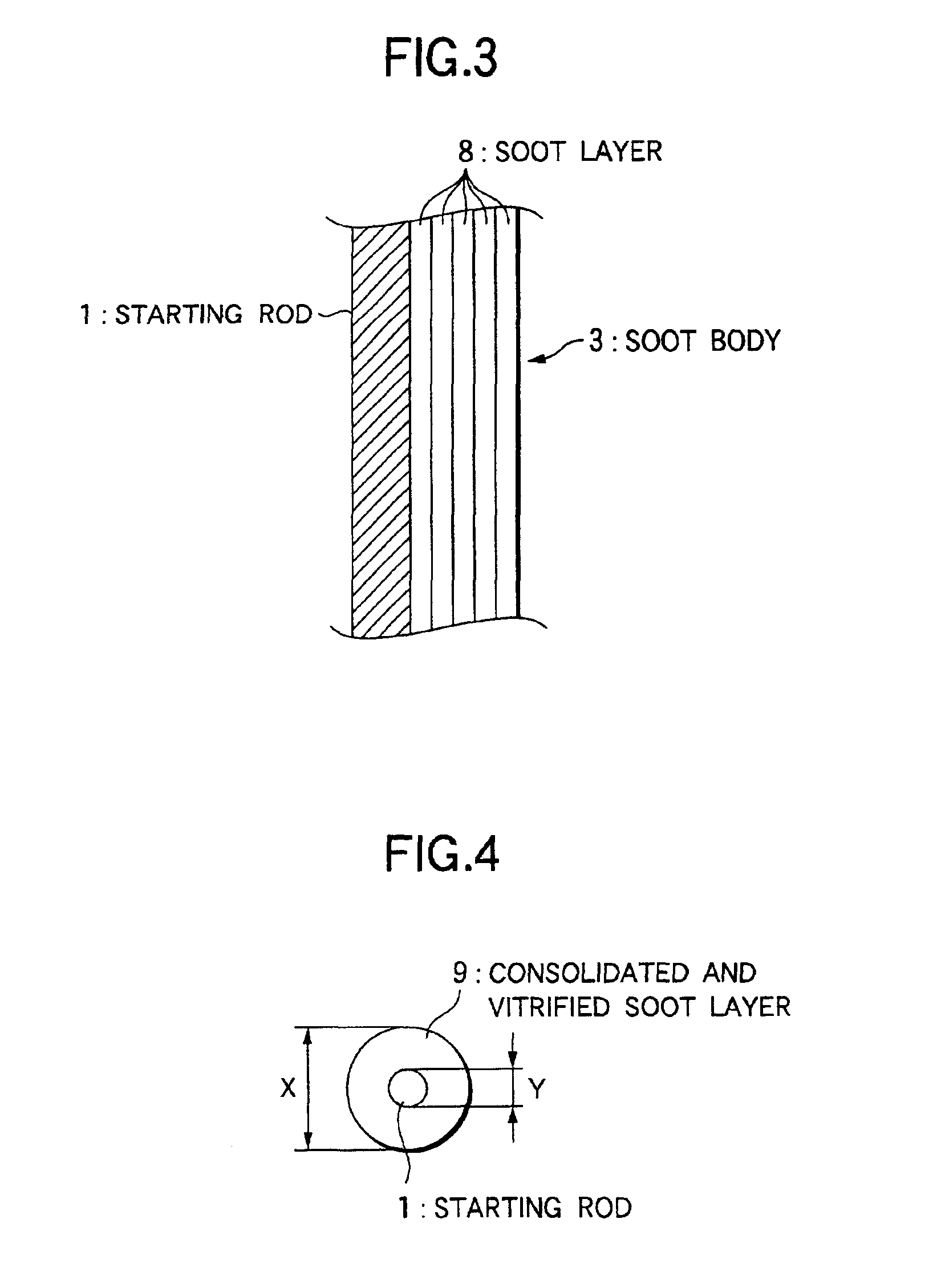

A plurality of glass particles synthesizing burners are arranged at a predetermined burner interval opposite to a rotating starting rod. The starting rod and the glass particles synthesizing burners are relatively parallely reciprocally moved, and the soot deposition is conducted. A reciprocating speed v(mm / minute), axis rotating speed r (rpm), and burner interval L (mm) are set so that a value A expressed by the expression A=(r / v)×L is in a range 40≧A≧8.

Owner:SUMITOMO ELECTRIC IND LTD

Method and apparatus for removing glass soot sheet from substrate

As a precursor to forming a glass sheet, a soot layer is formed on a deposition surface using a roll-to-roll glass soot deposition process. A soot layer-separating device is configured to bring a stream of gas into contact with at least a portion of a free surface of the soot layer. The impinging gas stream affects local thermal expansion stresses at the soot layer / deposition surface interface, which separates the soot layer from the deposition surface.

Owner:CORNING INC

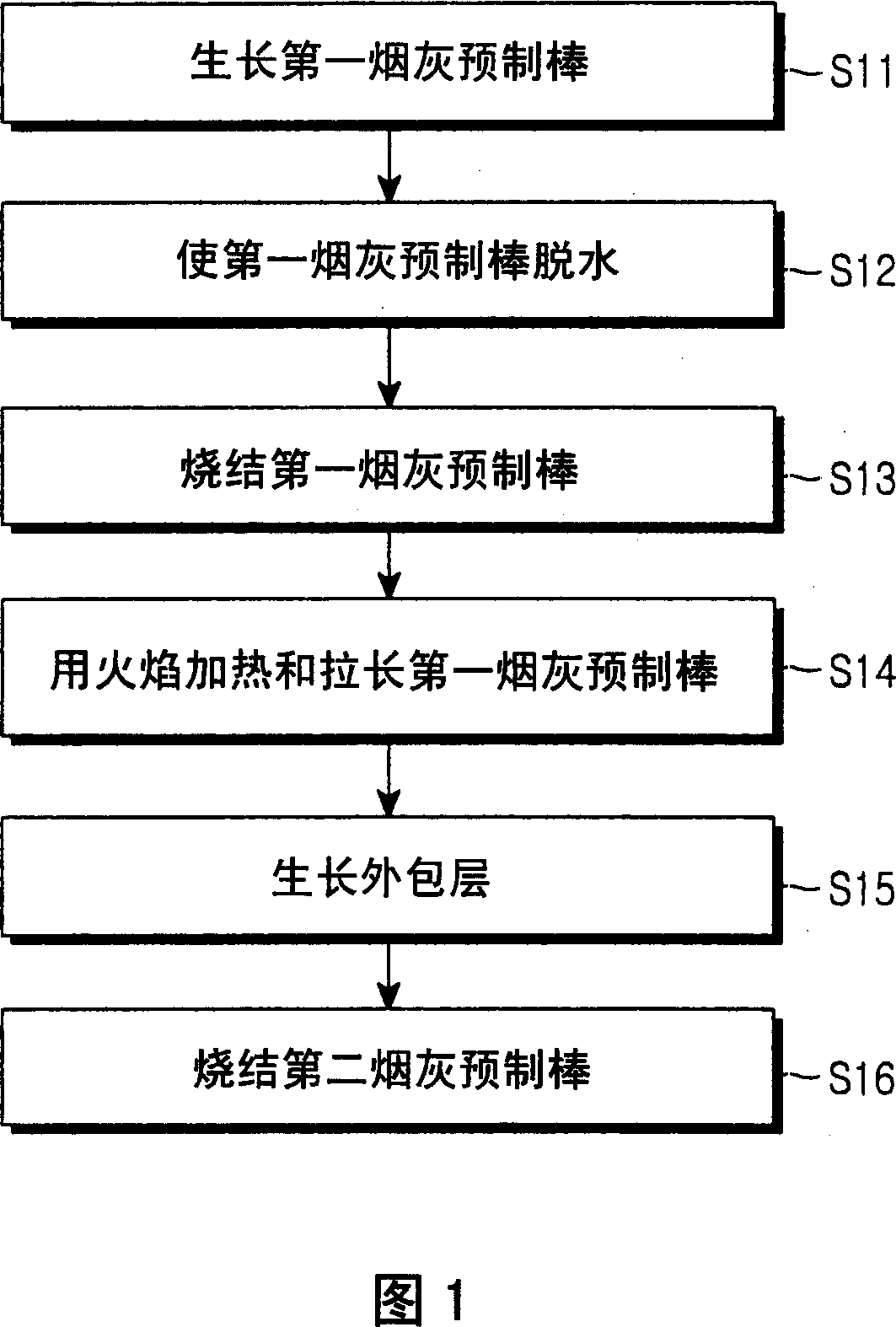

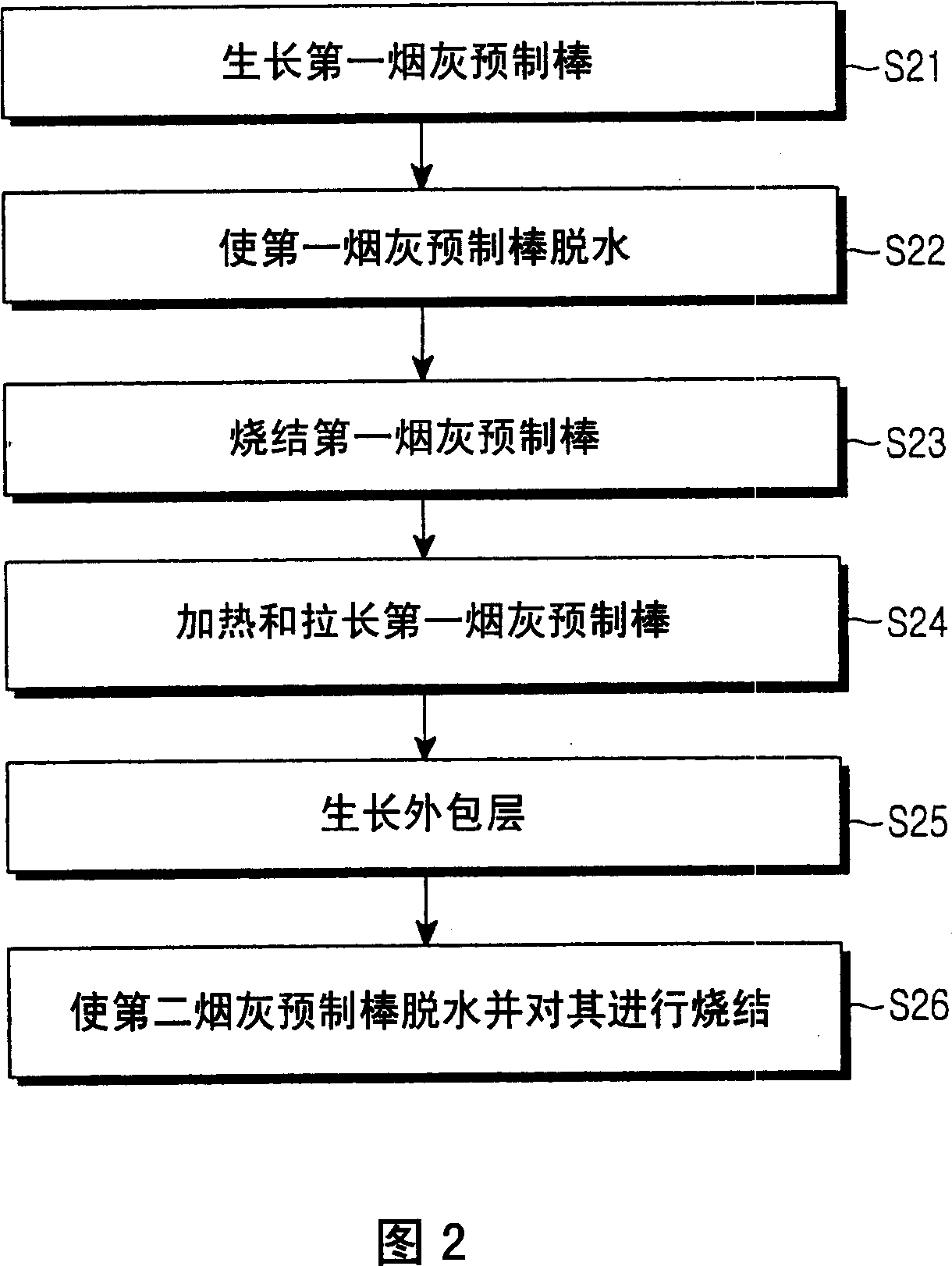

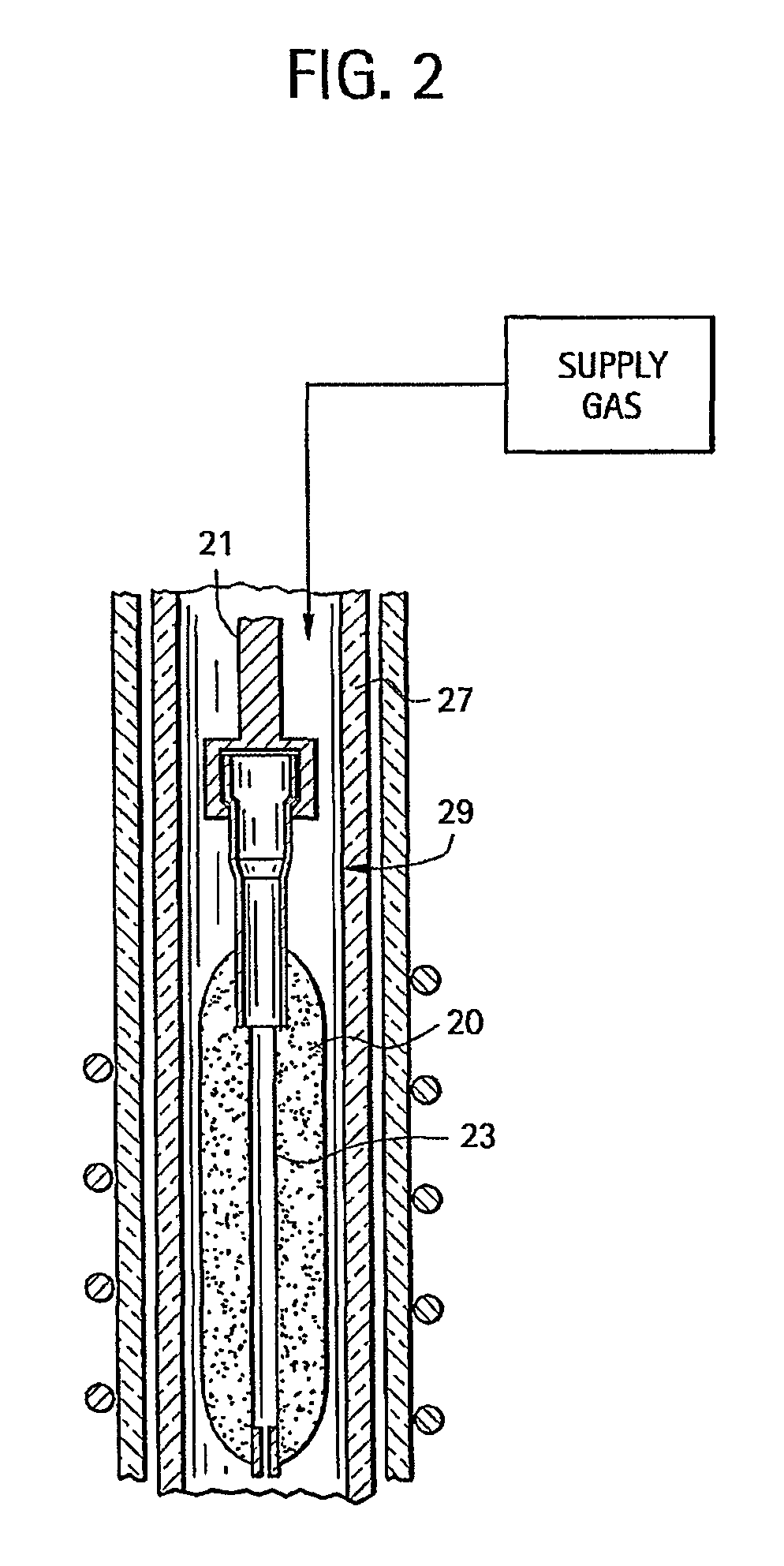

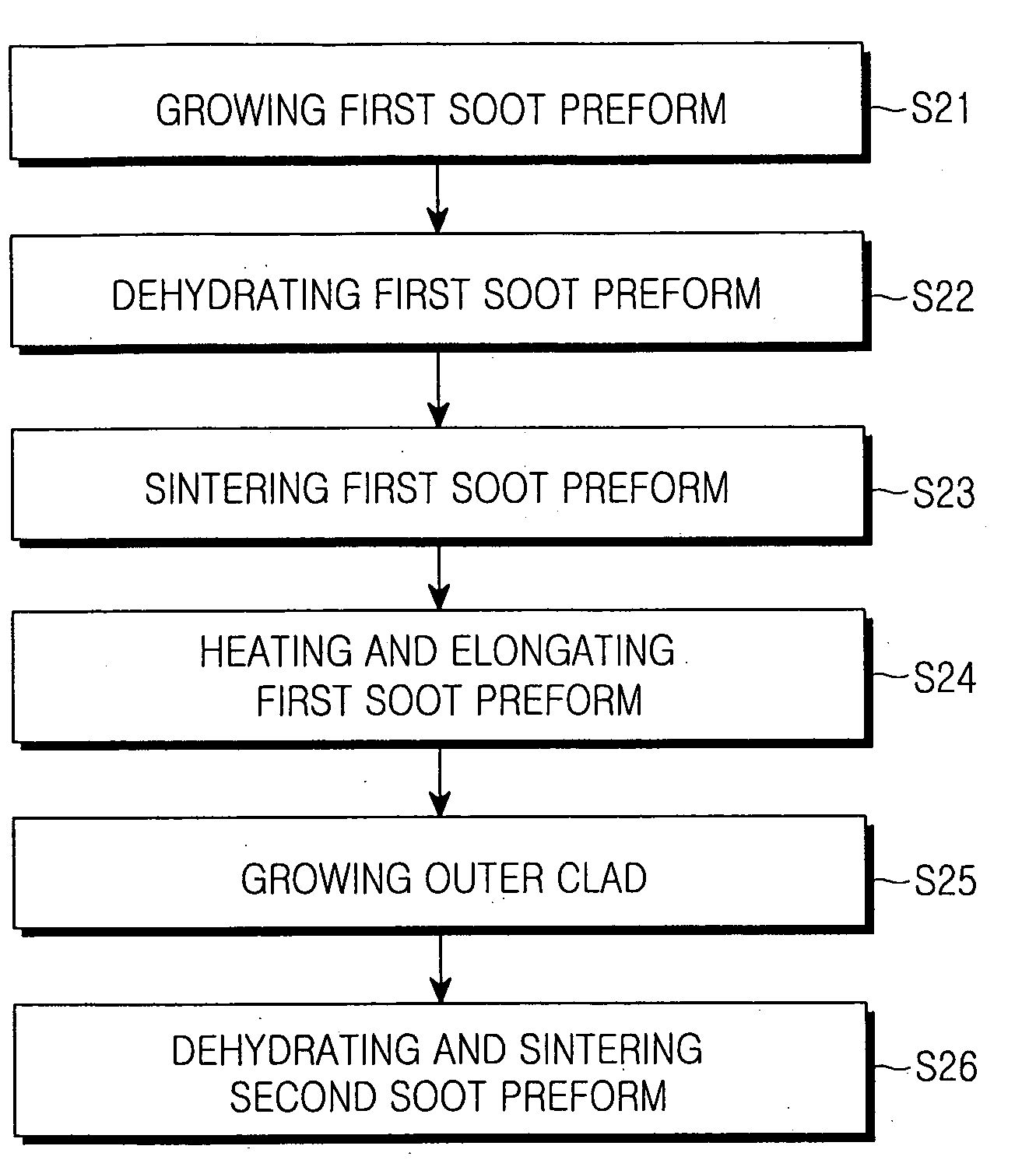

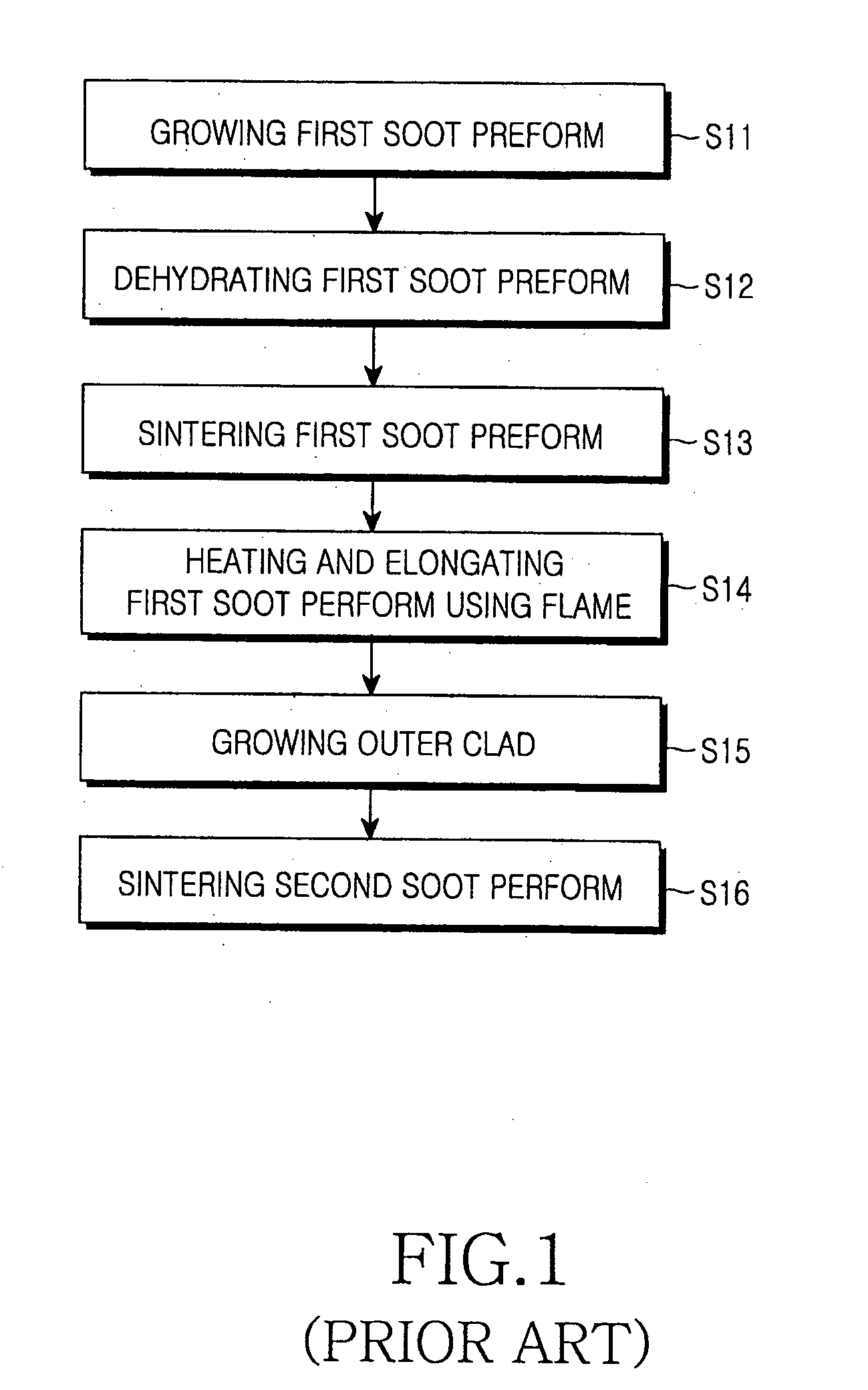

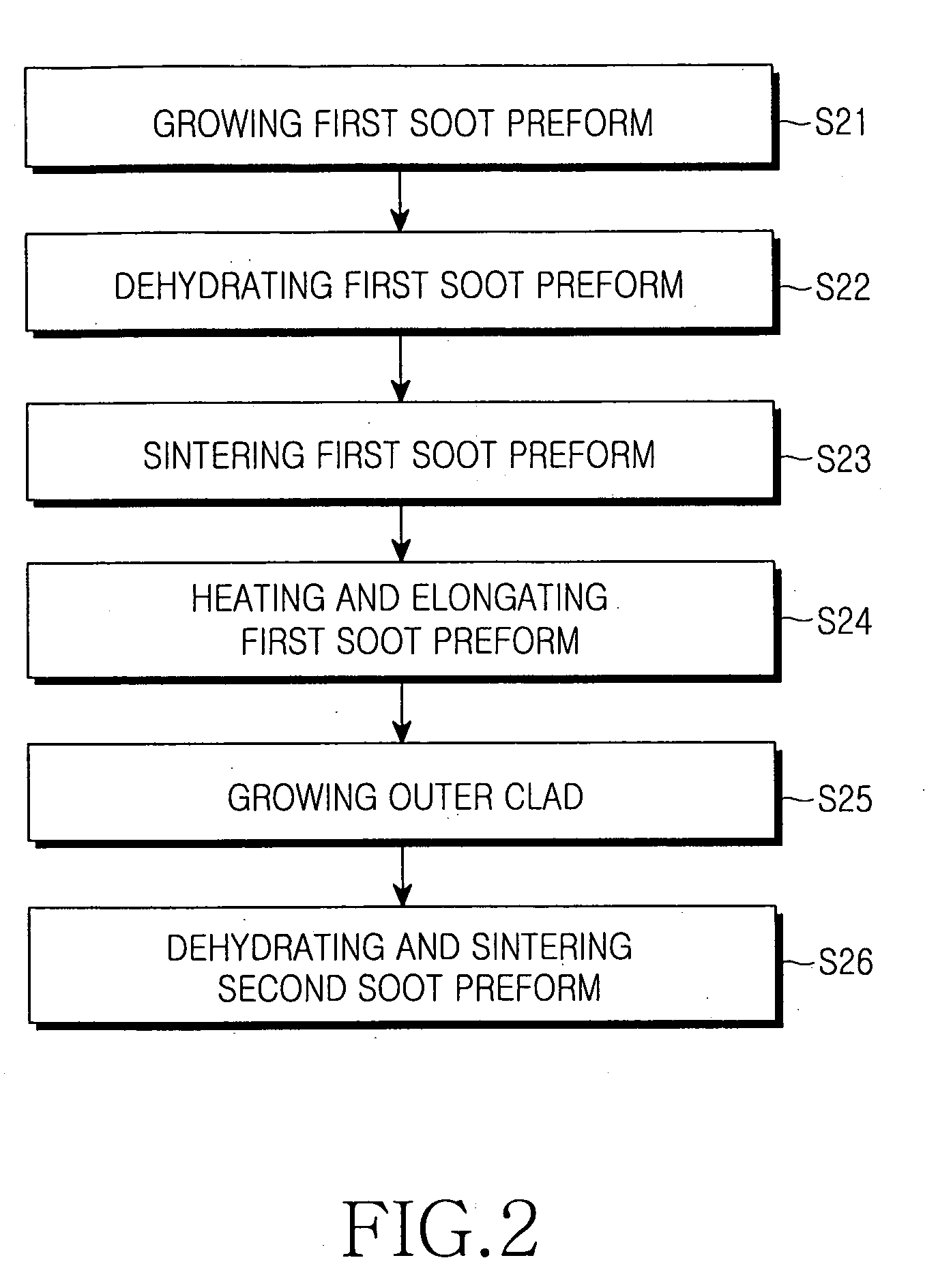

Apparatus for fabricating optical fiber preform and method for fabricating low water peak fiber using the same

Disclosed is a method for fabricating an optical fiber preform. The method includes: (a) growing a first soot preform on a starting member along a lengthwise direction of the starting member by a soot deposition; (b) dehydrating the first soot preform; (c) sintering the dehydrated first soot preform, to obtain a first glassed optical preform; and (d) elongating the first optical fiber preform by heating the first optical fiber with a heat source that excludes hydrogen, wherein the first glassed optical fiber is elongated by means of only a heat source that excludes the use of hydrogen.

Owner:SAMSUNG ELECTRONICS CO LTD

Microstructured optical fibers and methods

Owner:CORNING INC

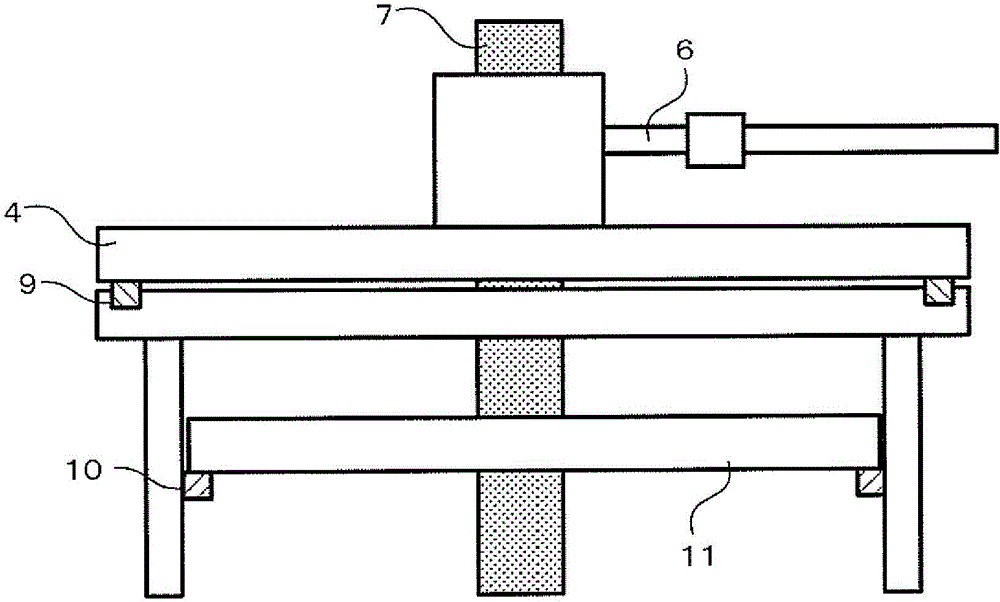

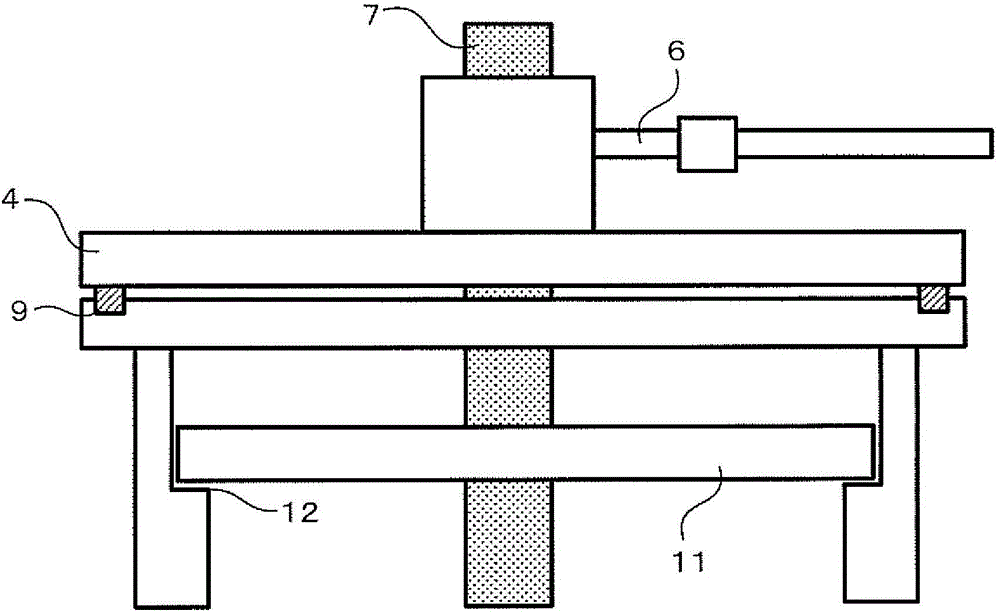

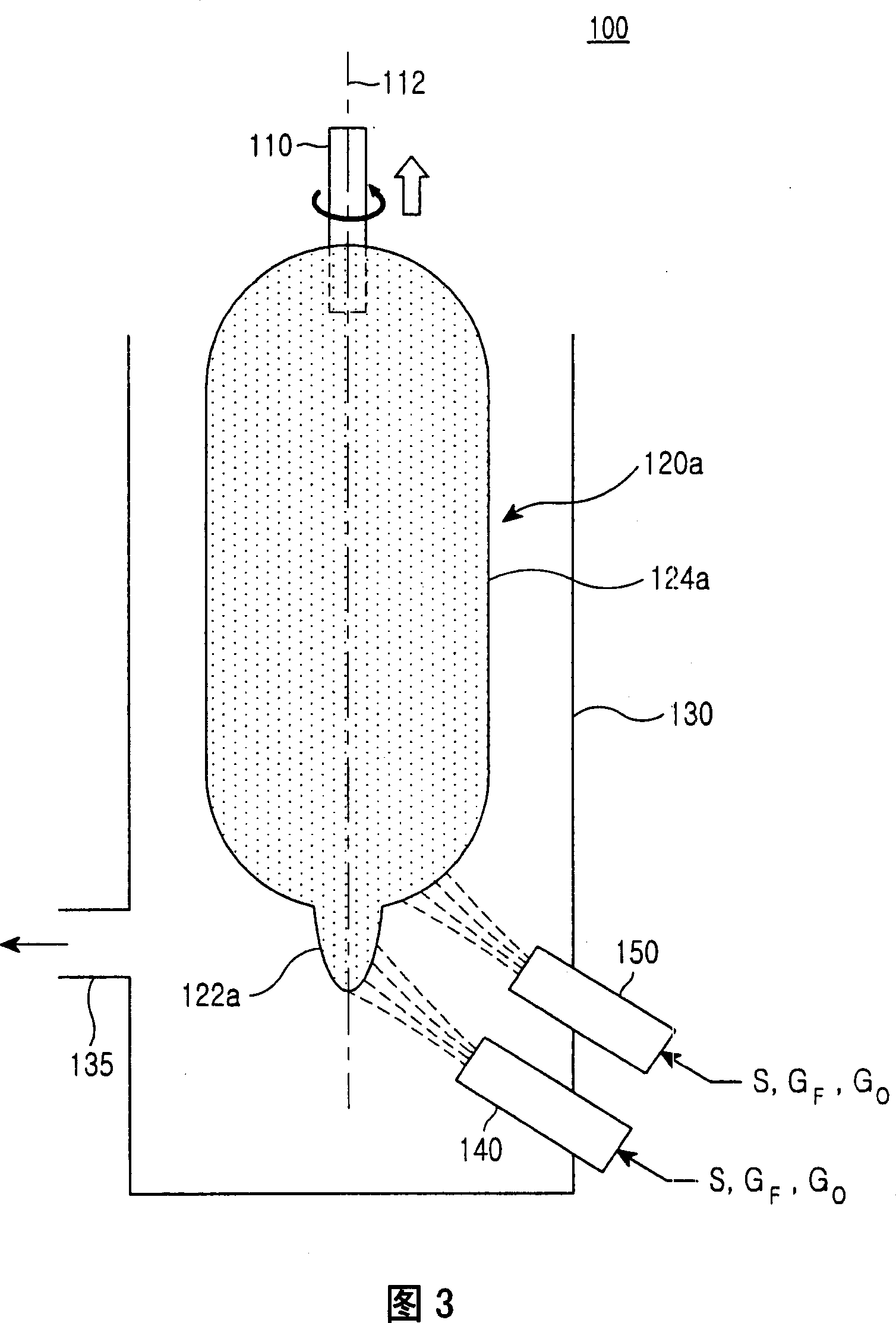

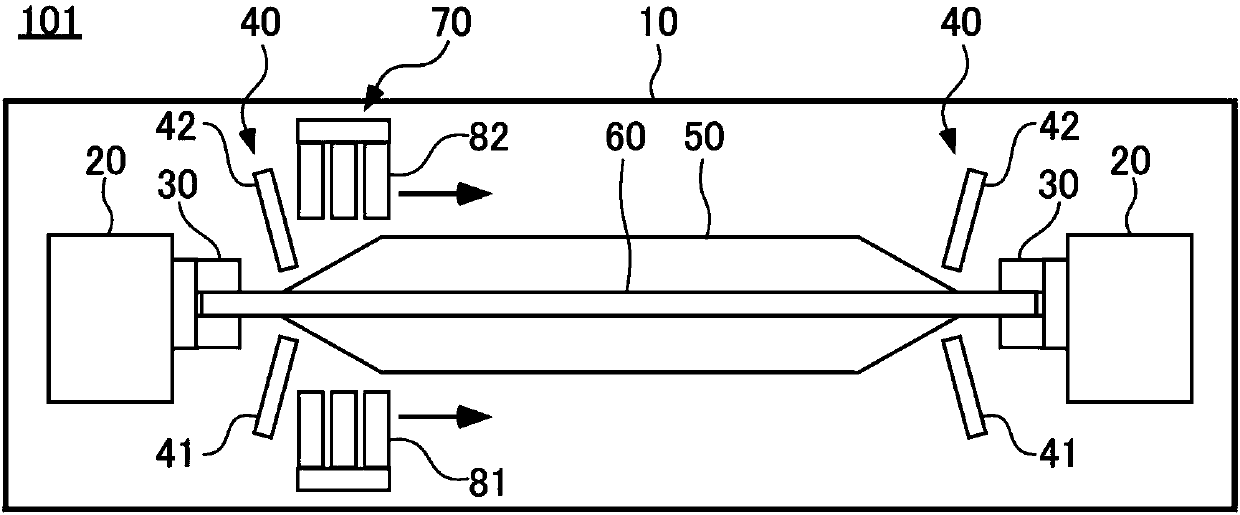

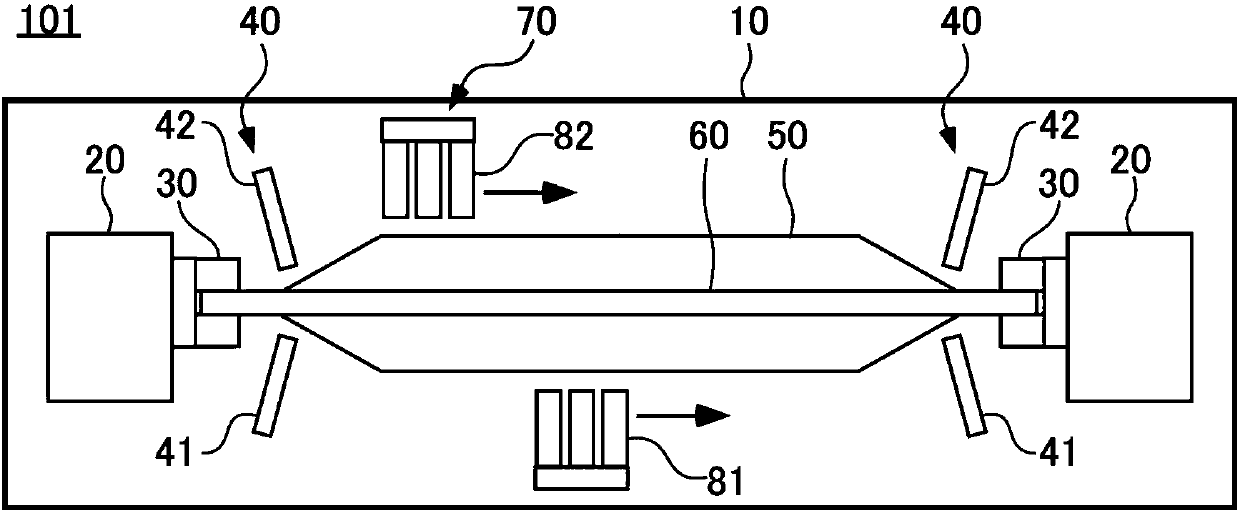

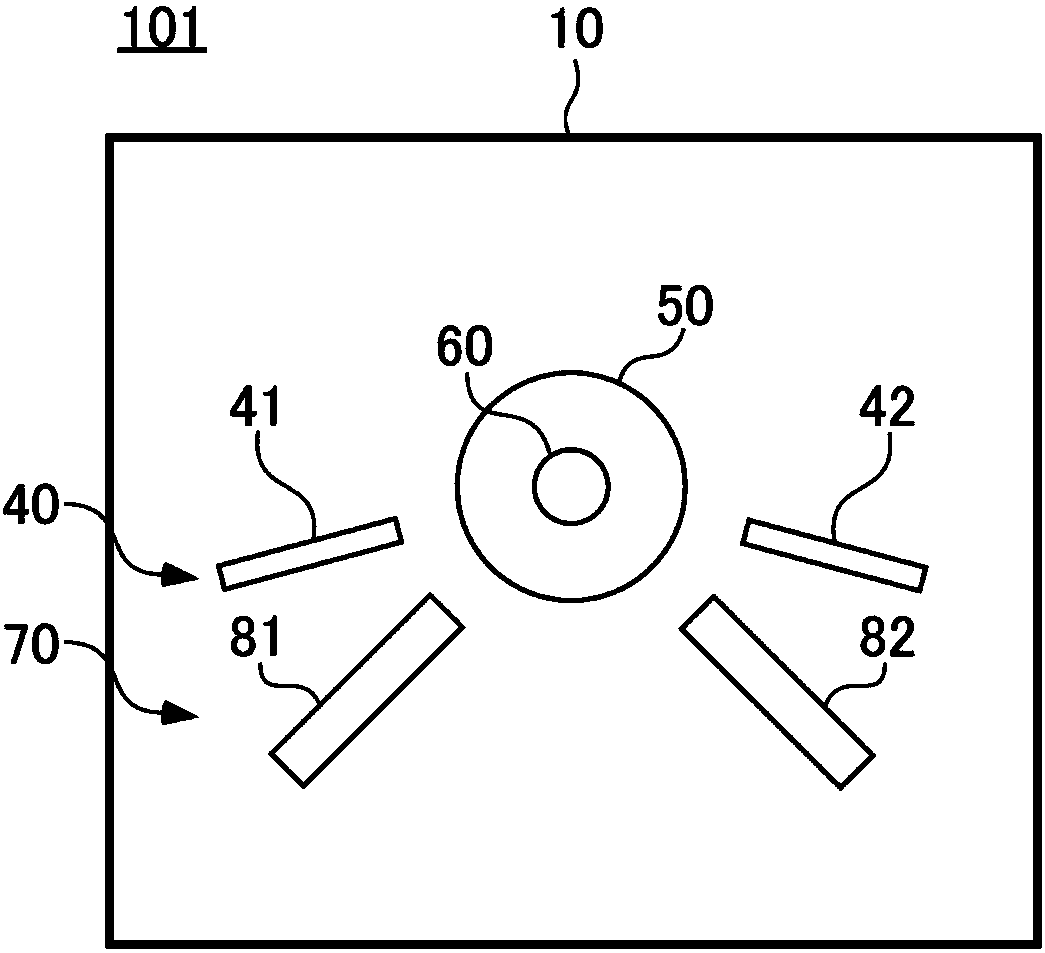

Soot deposition body manufacturing apparatus and manufacturing method

Provided is a manufacturing apparatus for manufacturing a soot deposition body, including a main burner that deposits glass microparticles on a target rod while moving parallel to a longitudinal direction of the target rod; and a side burner that is positioned outside of a movement range of the main burner in a movement direction of the main burner, and fires an end portion of the soot depositionbody formed on the target rod. The side burner includes a plurality of heating burners arranged distanced from each other in a circumferential direction of the target rod. In the manufacturing apparatus described above, the main burner may include a plurality of deposition burners that are arranged distanced from each other in the circumferential direction of the target rod. The manufacturing apparatus improves yield of the soot deposition body.

Owner:SHIN ETSU CHEM IND CO LTD

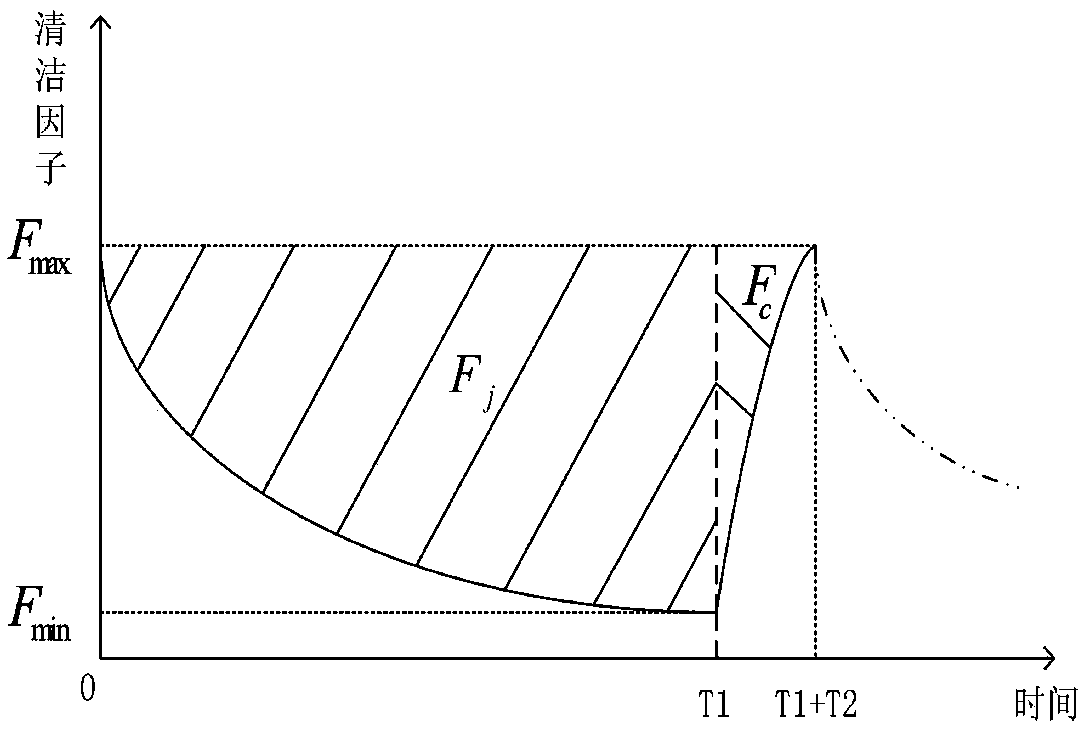

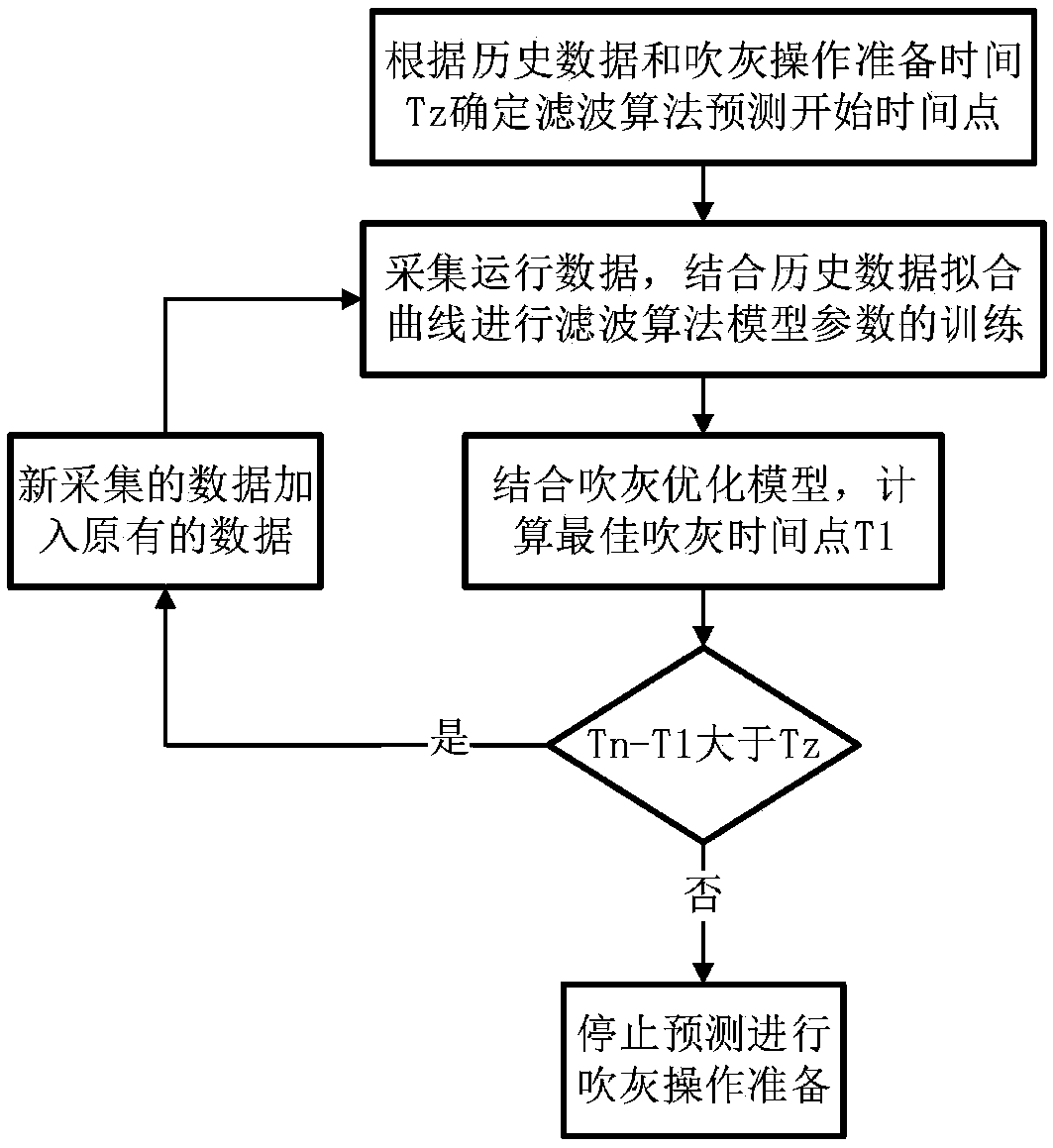

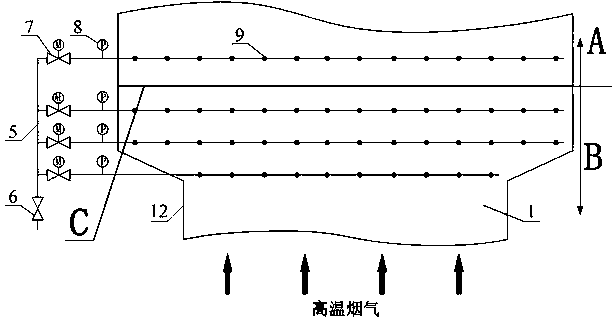

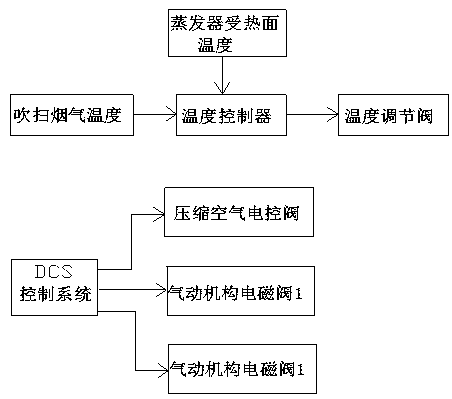

Boiler soot blowing optimization method based on heating surface health state prediction

ActiveCN109654517ATroubleshoot operational inaccuraciesEasy accessSolid removalProgramme total factory controlState predictionFilter algorithm

The invention discloses a boiler soot blowing optimization method based on heating surface health state prediction. The boiler soot blowing optimization method is characterized in that drum-type prediction for characteristic change of cleaning factors of a soot deposition section in a single soot blowing period is achieved through a filtering algorithm, a functional expression is acquired, a unitminimum heat transfer energy consumption soot blowing optimization model in the single soot blowing period is utilized, and a single soot blowing optimization strategy at the optimal soot blowing timepoint in the single soot blowing period is acquired. According to the boiler soot blowing optimization method, the problem that making of the soot blowing optimization strategy based on big data is inaccurate on single soot blowing operation is solved, and with a 300-MW coal-fired power plant boiler adopted as an example, the boiler soot blowing optimization method has relatively good economy andscientificity and has a guiding function for soot blowing strategy making of a coal-fired power plant.

Owner:ZHONGBEI UNIV

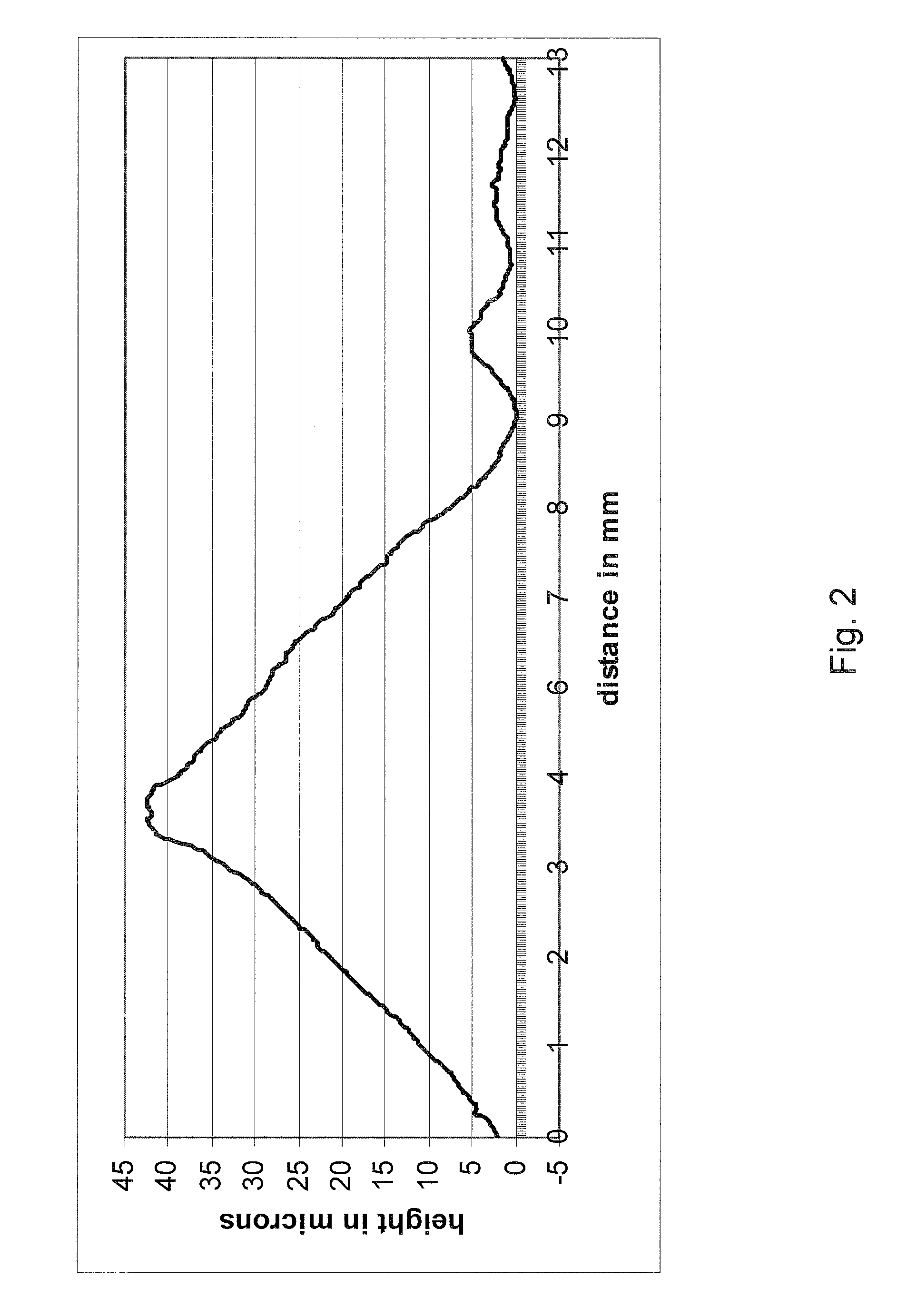

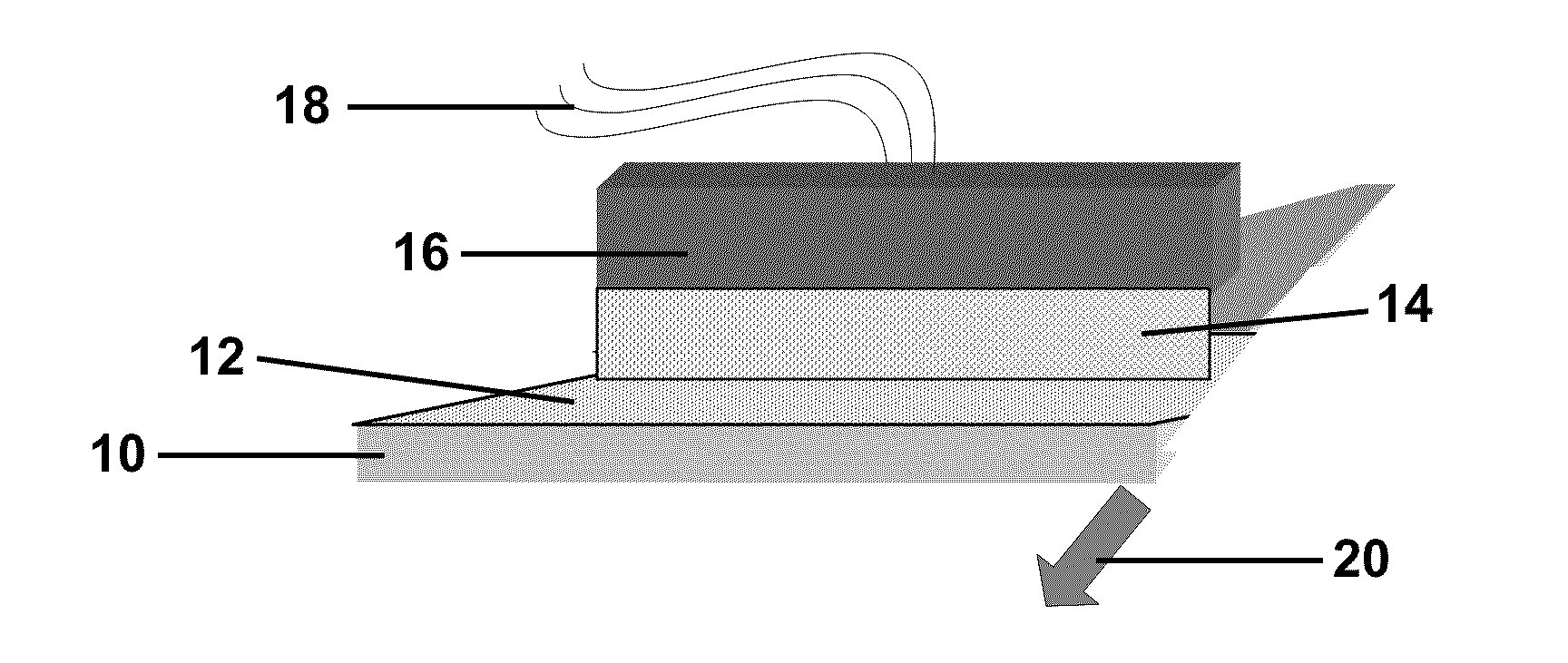

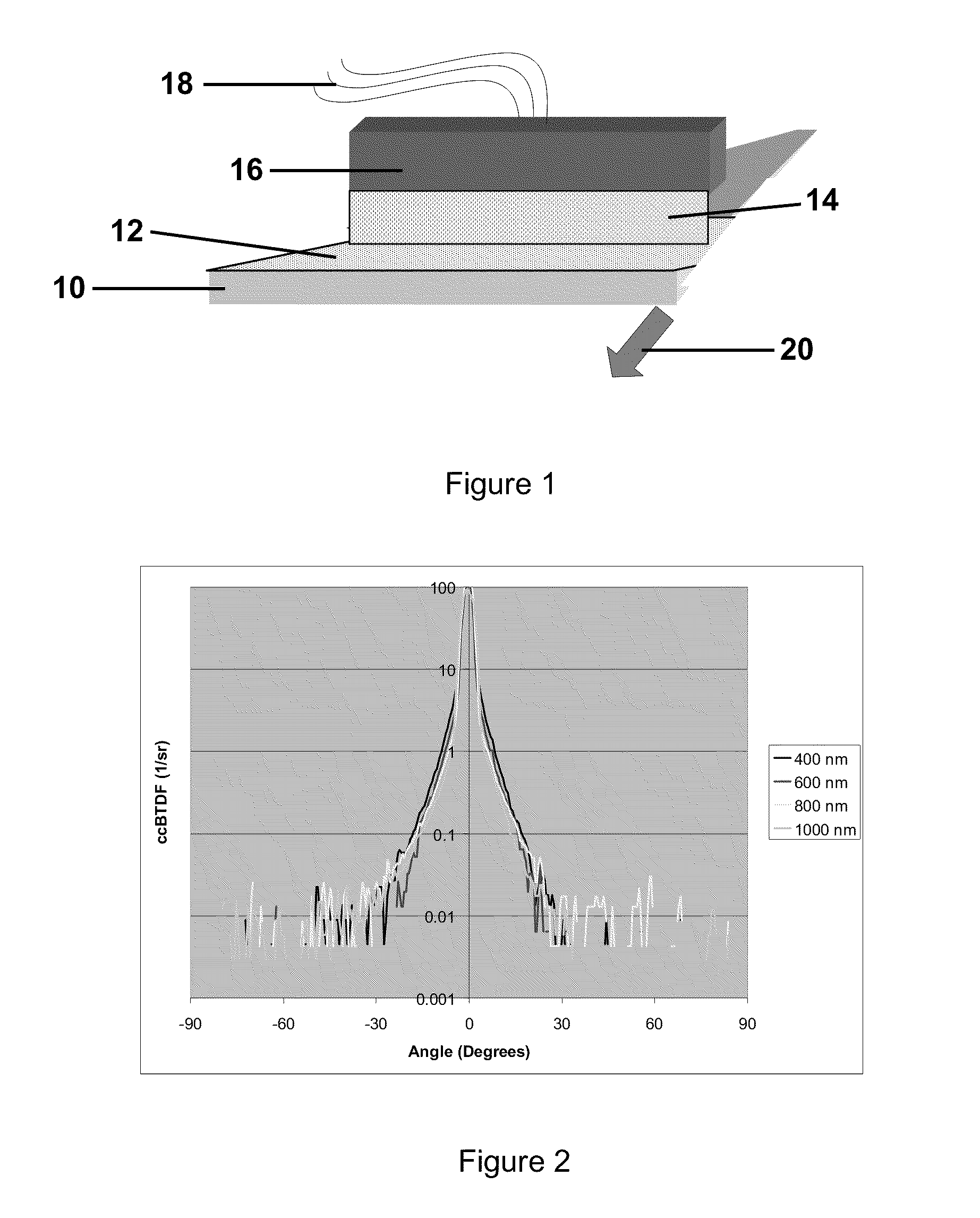

Light scattering inorganic substrates by soot deposition

InactiveUS20110290316A1Stable changeLess to createDiffusing elementsFinal product manufactureSoot particlesSilicon

Light scattering inorganic substrates and articles comprising soot particles and methods for making light scattering inorganic substrates and articles comprising soot particles useful for, for example, photovoltaic cells. The method for making the substrates and articles comprises providing an inorganic substrate comprising at least one surface, applying soot particles pyrogenically to the at least one surface of the inorganic substrate to form a coated substrate, and heating the soot particles to form the light scattering inorganic substrate. The invention creates a scattering glass surface that is suitable for subsequent deposition of a TCO and a thin film silicon photovoltaic device structure. The scattering properties may be controlled by the combination of substrate glass and soot composition, deposition conditions, patterning of the soot, and / or sintering conditions.

Owner:CORSAM TECH

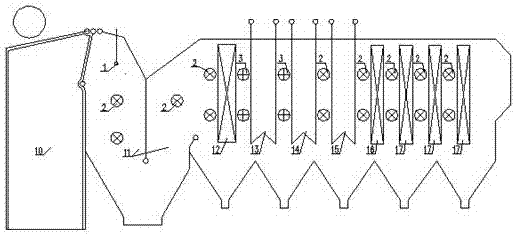

Combined type soot removal arrangement structure and arrangement method for waste incineration boiler

The invention relates to the field of waste incineration, in particular to an arrangement structure and arrangement method for a soot removal device suitable for a waste incineration boiler. Accordingto the arrangement structure and arrangement method, the waste incineration boiler is divided into different areas according to the medium temperature of each heating surface of the waste incineration boiler, the temperature of flue gas flowing through the heating surfaces and the factors of forming coking soot deposition, and soot removal devices with a reasonable types are arranged in the areas; and the areas are characterized in that a boiler wall soot blower and a pulse shock wave soot blower are arranged in a cavity flue formed by a water cooling wall, a pulse shock wave soot blower is additionally arranged at the evaporation heating surface with the flue gas temperature of 600 DEG C or more and is arranged at the front part of a superheater, a steam soot blower is additionally arranged on the heating surface of the superheater with the flue gas temperature of 400 DEG C or more, and a pulse shock wave soot blower is additionally arranged on the convection heating surface with theflue gas temperature of 400 DEG C or less and is arranged at the rear part of the superheater.

Owner:SHANGHAI SUS ENVIRONMENT

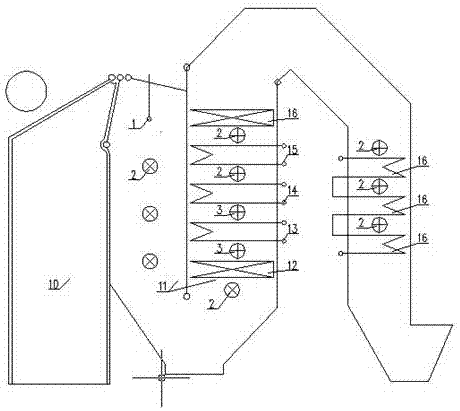

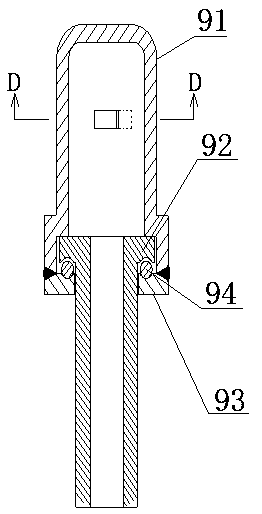

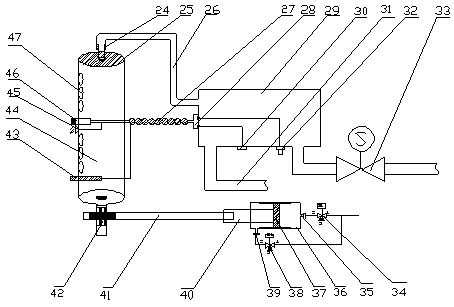

Rotary soot blower device and soot blower method for improving uniformity of denitrification inlet flue flow field

PendingCN109458626AExpand coverageSafe and Stable Economic OperationSolid removalFlue gasEngineering

The invention relates to a rotary soot blower device and a soot blower method for improving the uniformity of a denitrification inlet flue flow field, and belongs to the technical field of coal-firedpower plant flue soot deposition prevention. The rotary soot blower device comprises a compressed air mother pipe, a compressed air branch pipe, a pressure gage and a rotary soot blowing air cap, wherein the compressed air mother pipe communicates with a house-service compressed air pipeline; the compressed air branch pipe communicates with the compressed air mother pipe; the rotary soot blowing air cap communicates to the compressed air branch pipe; the pressure gage is arranged on the compressed air branch pipe; the pressure gage and the rotary soot blowing air cap are sequentially arrangedalong a compressed air flowing direction; the rotary soot blowing air cap is arranged in a flue; a flow guiding plate is arranged in the flue and is connected with a downstream flue; and the flue, theflow guiding plate and the downstream flue are sequentially arranged along a flue gas flowing direction. According to the rotary soot blower device and the soot blower method for improving the uniformity of the denitrification inlet flue flow field provided by the invention, a largen umber of manpower and time spent on clearing soot deposition during machine halt every time due to severe soot deposition are saved, and the flue leakage caused by long-time erosion of a conventional soot blower is avoided.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

Integrated automatic cleaning system for otorhinolaryngology treatment table

PendingCN107343971AEasy to cleanGuaranteed cleanlinessMedical devicesSuction drainage systemsOtorhinolaryngologyAutomation

The invention discloses an ENT treatment table integrated self-cleaning system, comprising a main sniffer system and a self-cleaning system. The ENT treatment table integrated self-cleaning system of the invention can filter the sniffer system of the ENT treatment table. The filter can be automatically cleaned, and the resistance change of the filter can be monitored in real time. When the resistance loss caused by the filter reaches the set value, it means that the amount of dust deposited on the filter has reached the level that needs cleaning. At this time, the self-cleaning system can complete the cleaning process. The washing of the filter not only reduces the resistance loss caused by the dust accumulation of the filter, improves the working efficiency of the sniffer gun, but also ensures the cleaning of the entire cleaning system, and realizes inhalation, filtration, cleaning and disinfection during the use of the ENT examination and treatment table. Integration and automation of steps.

Owner:徐州贝尔斯电子科技有限公司

Apparatus for fabricating optical fiber preform and method for fabricating low water peak fiber using the same

InactiveUS20070157674A1Minimize permeation of hydrogenReduce manufacturing costGlass making apparatusOptical light guidesFiberHydrogen

Disclosed is a method for fabricating an optical fiber preform. The method includes: (a) growing a first soot preform on a starting member along a lengthwise direction of the starting member by a soot deposition; (b) dehydrating the first soot preform; (c) sintering the dehydrated first soot preform, to obtain a first glassed optical preform; and (d) elongating the first optical fiber preform by heating the first optical fiber with a heat source that excludes hydrogen, wherein the first glassed optical fiber is elongated by means of only a heat source that excludes the use of hydrogen.

Owner:SAMSUNG ELECTRONICS CO LTD

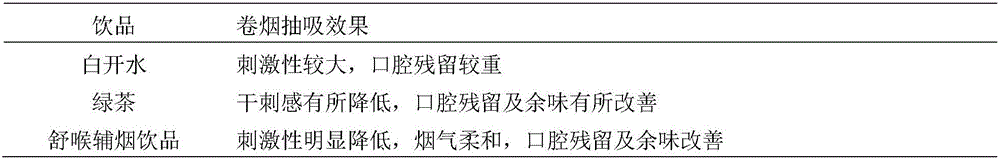

Tobacco supplementing beverage having throat comforting effect and application thereof

The invention discloses a tobacco supplementing beverage having a throat comforting effect and application thereof. The beverage is prepared from, by weight parts, 4-8 parts of hovenia acerba, 2-4 parts of bergamot, 4-6 parts of green tea, 2-6 parts of loquat, 2-6 parts of olive, 1-3 parts of tangerine peel, 1-3 parts of mulberry leaf and 5-10 parts of honey. The tobacco supplementing beverage has light herbal fragrance, is drunk during smoking, can reduce dryness and irritation to the oral cavity and the throat caused by smoke, reduce residue in the oral cavity and improve comfort and sense of pleasure during the cigarette smoking, so that the cigarette smoking quality is improved from another way. Moreover, the tobacco supplementing beverage has a certain retarding effect on tobacco soot deposition on smokers' teeth and is suitable for being drunk during the smoking.

Owner:CHINA TOBACCO YUNNAN IND

Online soot blowing device for waste heat boiler for sintering vertical cold furnace

ActiveCN110657444AProtection securityReduce adverse effectsSolid removalProcess engineeringSteam drum

The invention relates to an online soot blowing device for a waste heat boiler for a sintering vertical cold furnace. The soot blowing device comprises the waste heat boiler, a steam drum, the vertical cold furnace, a draft fan and a blowing assembly; the waste heat boiler is vertically arranged; the steam drum is arranged at the top part of the waste heat boiler; the waste heat boiler is arrangedon a boiler support adjacent to the vertical cold furnace; the blowing assembly includes three blowing devices, i.e., a high-temperature blowing device, a low-temperature blowing device and an economizer blowing device; a high-temperature evaporator, a low-temperature evaporator and an economizer evaporator are arranged in the waste heat boiler; one side of the bottom part of the waste heat boiler is provided with a cooling water tank; an outlet of the cooling water tank is additionally provided with a water pump; and an outlet of the water pump is still additionally provided with three groups of corresponding temperature adjustment assemblies. According to the scheme, the soot blowing device can automatically adjust in blowing direction, and is provided with temperature measuring equipment; and by additionally installing an endoscope, functions of monitoring the soot deposition condition and blowing soot online, and the like, can be realized.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com