Rotary soot blower device and soot blower method for improving uniformity of denitrification inlet flue flow field

A technology of inlet flue and soot blowing device, which is applied in the directions of combustion method, combustion product treatment, removal of solid residue, etc., can solve the problem of soot accumulation in the flue, avoid damage, prevent a large number of deposits, and expand the coverage of soot blowing range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] Example.

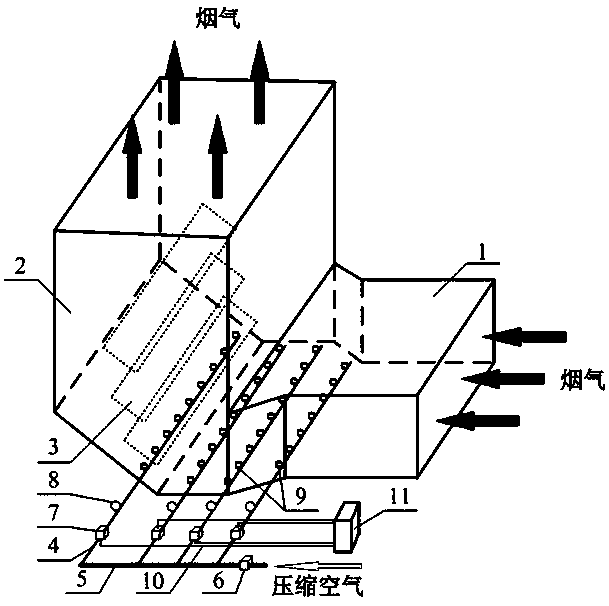

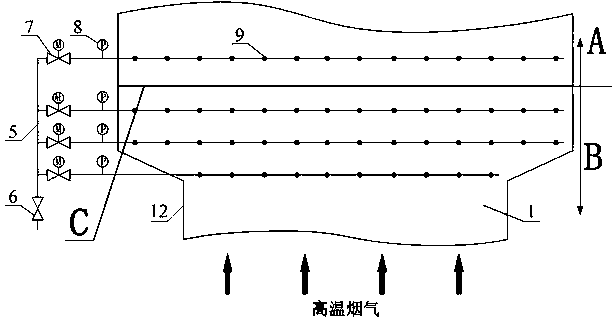

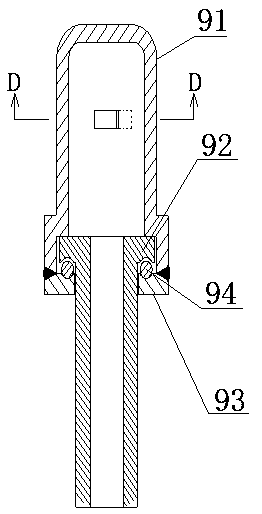

[0022] see Figure 1 to Figure 4 , a rotary soot blowing device for improving the uniformity of the flue flow field at the denitrification inlet, including a compressed air main pipe 5, a compressed air branch pipe 4, a branch pipe pressure monitoring system, a soot blowing device, a compressed air main pipe manual switch valve 6, and a communication cable 10. Branch pipe purge switch and purge time control system.

[0023] As a preference, in this embodiment, the pressure gauge 8 is selected for the branch pipe pressure monitoring system, the rotary soot blowing cap 9 is used for the soot blowing device, the compressed air branch pipe electromagnetic switch valve 7 is used for the branch pipe pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com