Soot deposition body manufacturing apparatus and manufacturing method

A technology for manufacturing devices and stacking bodies, which is applied in the direction of manufacturing tools, glass manufacturing equipment, glass deposition furnaces, etc., and can solve problems such as particle peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described through embodiments of the invention. The following embodiments do not limit the invention of the claims. In addition, not all combinations of features described in the embodiments are essential to the solution means of the invention.

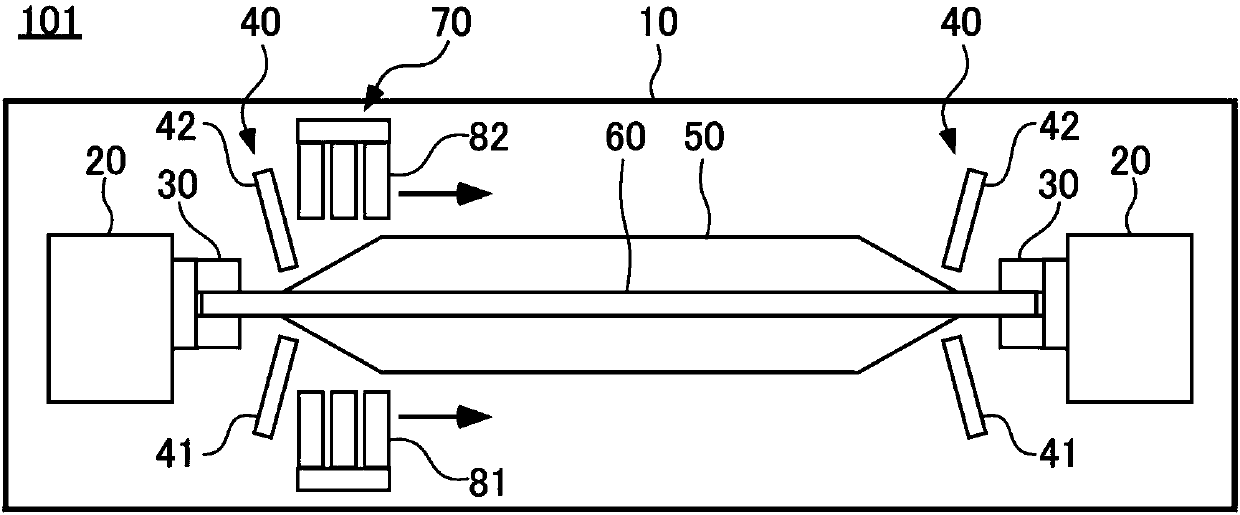

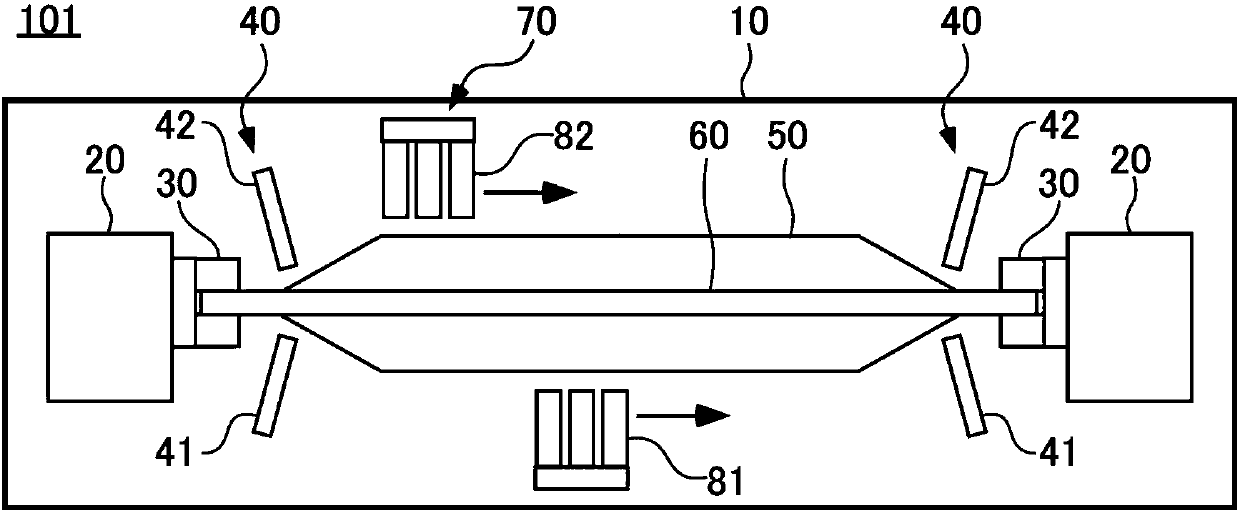

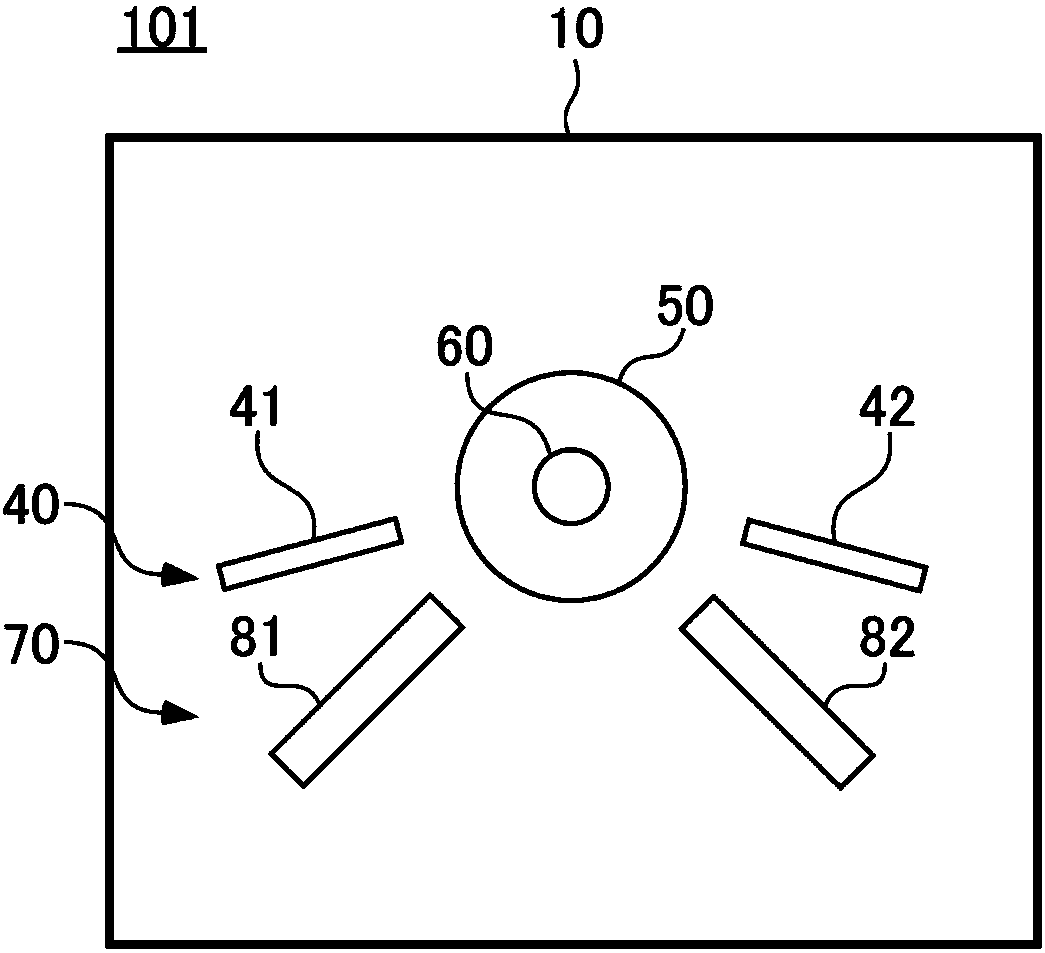

[0020] figure 1 It is a schematic horizontal cross-sectional view showing an example of a manufacturing apparatus 101 for manufacturing a powder accumulation body. The manufacturing apparatus 101 has a chamber 10 , a rotating mechanism 20 , a chuck 30 , a side torch 40 , and a main torch 70 .

[0021] In the vicinity of both ends in the longitudinal direction inside the chamber 10 , a rotating mechanism 20 and chucks 30 are arranged respectively. The pair of chucks 30 are respectively supported rotatably relative to the chamber 10 and hold both ends of the target rod 60 . The rotating mechanism 20 rotates the target rod 60 held by the chuck 30 by rotating the chuck 30 .

[0022] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com