Combined type soot removal arrangement structure and arrangement method for waste incineration boiler

A technology of waste incineration and layout structure, which is applied in the direction of combustion method, incinerator, combustion type, etc., and can solve the problems of frequent fluctuation and instability of operating conditions and output load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

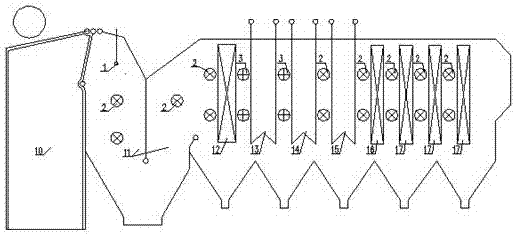

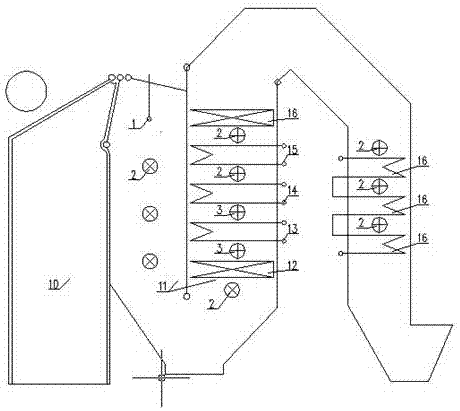

[0017] Compared with the conventional coal-fired power plant boiler, the waste incineration boiler has a simple structure, and the main components (according to the flue gas flow direction) include: a flue 10 of the waste incineration boiler, a water wall flue 11, a primary evaporator 12, and a low-temperature superheater 13. Medium-temperature superheater 14, high-temperature superheater 15, secondary evaporator 16, economizer 17, etc. Among them, the flue 10 of the waste incineration boiler is to prevent the scour and corrosion of high-temperature flue gas, and SiC wear-resistant and corrosion-resistant castables are poured in the furnace.

[0018] For horizontal boilers, the second and third flues (water-cooled wall flue 11) are cavity flues composed of water-cooled membrane walls, and no other heating surface components are placed inside, and no wear-resistant and corrosion-resistant pouring is made on the flue walls. Castable, suitable for installing furnace wall soot blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com