Boiler soot blowing optimization method based on heating surface health state prediction

A health state and boiler soot blowing technology, which is applied in the field of boiler soot blowing optimization based on the prediction of the health state of the heating surface, can solve the problem of inaccurate formulation of soot blowing optimization strategies, achieve great practical application value, reduce operating costs, and simplify calculations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific embodiments described here are only used to explain the present invention, not to limit the invention.

[0059] In order to illustrate the feasibility of the present invention in detail, this embodiment takes the No. 2 300MW unit boiler of a certain coal-fired thermal power station in Guizhou as the research object.

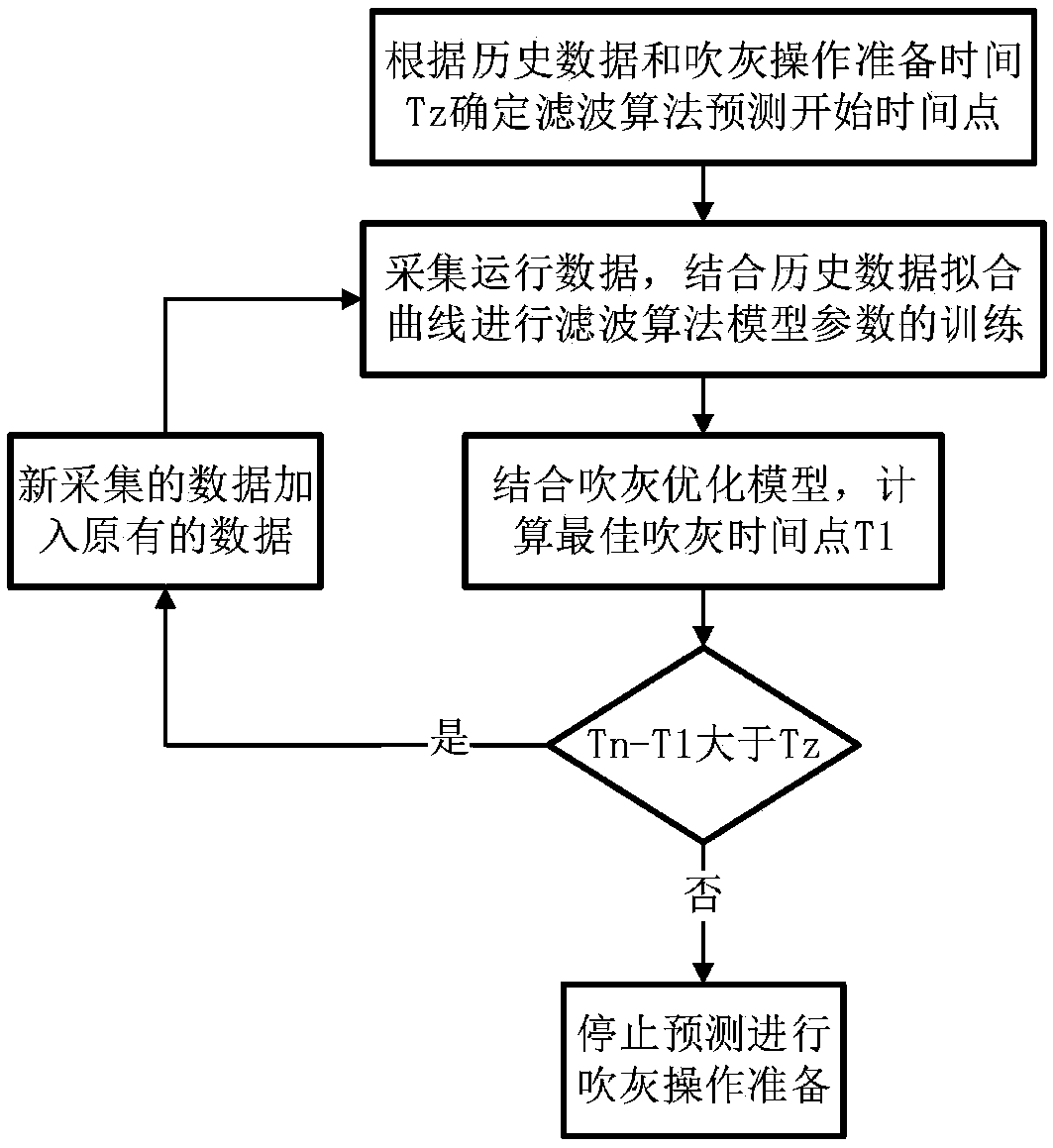

[0060] The first step is to select a fixed sampling time (sampling time is 5 seconds) according to the actual situation of the power station, and obtain the real-time heat transfer coefficient K through the DSC system of the boiler sj , and the theoretical heat transfer coefficient K o Through the following formula:

[0061]

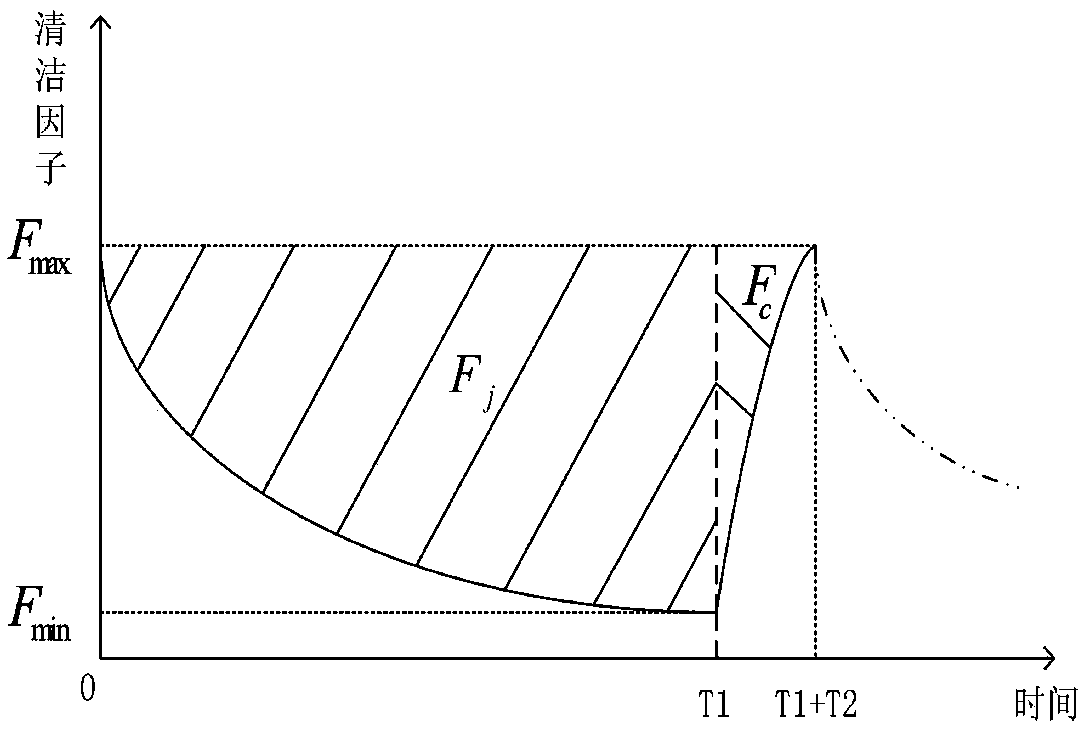

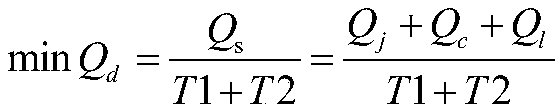

[0062] Calculate the real-time cleaning factor data of the ash accumulation section. At the same time, the bad point p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com