Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Sodium orthophosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

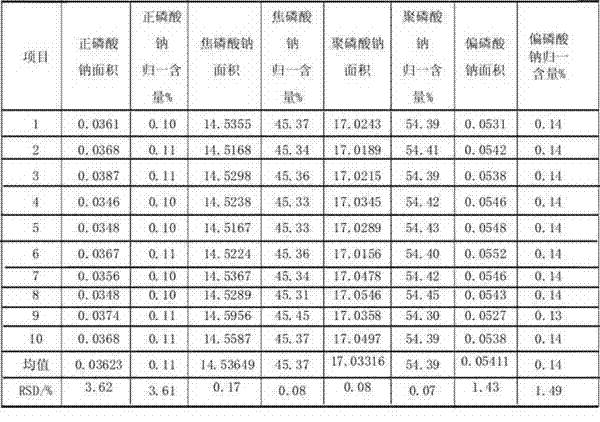

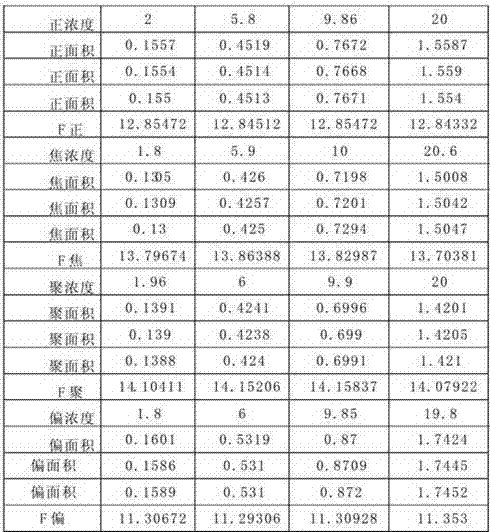

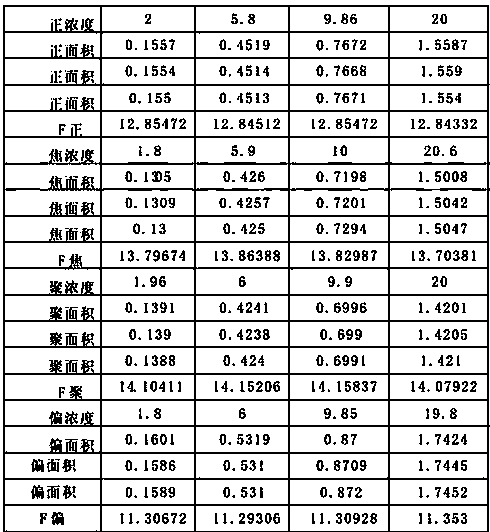

Method for detecting content of phosphate of different type in complex sodium phosphate product

ActiveCN103048402AGood repeatabilityImprove stabilityComponent separationSodium phosphatesPhosphate product

The invention provides a method for detecting the content of phosphates of different types in a complex sodium phosphate product, comprising: diluting the complex phosphate product with pure water, eluting the solution in gradient by an ion chromatograph, separating the phosphates of different types in a sample, and determining a response value; preparing four groups of standard solutions of sodium orthophosphate, sodium pyrophosphate, sodium polyphosphate and sodium trimetaphosphate in a concentration range of 2-20mg / L, determining the corresponding area response values of the standard solutions by the ion chromatograph under same conditions, and calculating by the formula FI=cI / SI; selecting a average value of FI of the four groups of solutions of each component, to determine a correction factor of each component, and finally, calculating the content of each component in the complex sodium phosphate products. The product provides a method for simultaneously detecting the content of phosphates of different types in a complex sodium phosphate product by a simple method and a precision apparatus. The detection result is good in repeatability and stability. The method is suitable as a common quantitative analysis method.

Owner:HUBEI XINGFA CHEM GRP CO LTD

High efficiency water purification agent

InactiveCN101085686ADense flocSettling fastWater/sewage treatment by flocculation/precipitationPersulfateAutoclave

The invention relates to a method for preparing high- performance water purification agent. The activated sodium silicate is polymerized with ferric sulfate, and modifies with chloride ion during process of producing polymeric ferric sulfate. It comprises following steps: adding 5- 6 units sodium silicate ((M=3.3,SiO2%=26) into autoclave, adding 20- 13 units water, stirring evenly, adding 2 units industrial concentrated sulfuric acid quickly, reacting at 40- 50 Deg. C for 0.5 hour, then adding 42- 45uints 90% ferric persulfate, 1- 2 units sodium chloride, 3- 5 units aluminum sulphate acetate, 4- 5 units industrial concentrated sulfuric acid, dropping 13- 14 units 27.5% hydrogen dioxide solution slowly, controlling temperature to be lower than 60 Deg. C, reacting for 2 hours, dissolving 1- 2 units sodium orthophosphate in 10- 7 units water and adding them into autoclave, reacting for another 0.5 hour, curing 24 hours and getting final product. The product is characterized by apparent functions of removing color, odor, oil, disinfection and removing COD and BOD.

Owner:GUANGZHOU GELONG ENVIRONMENTAL PROTECTION TECH DEV

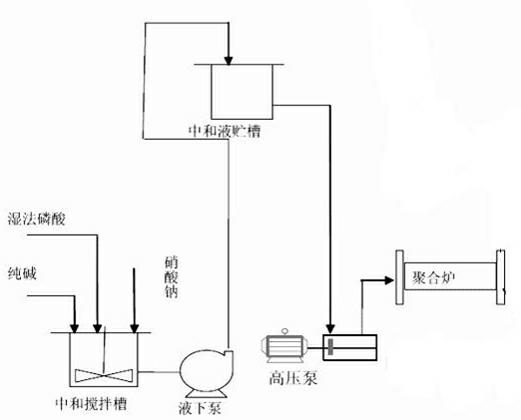

Method for producing sodium tripolyphosphate by replacing ammonium nitrate with sodium nitrate taken as catalyst

InactiveCN102583294AReduce transportationLow costPhosphorus compoundsLiquid storage tankPhosphoric acid

The invention discloses a method for producing sodium tripolyphosphate by replacing ammonium nitrate with sodium nitrate taken as catalyst. The method comprises the steps as follows: adding soda and wet process phosphoric acid are in a neutralization agitation tank for neutralization reaction, adding sodium nitrate in the product according to the proportion that 4 to 5 kg of sodium nitrate added in one ton of sodium tripolyphosphate after the neutralization reaction is largely over, boiling for 15 to 20 min to produce sodium orthophosphate neutralization liquid, pumping the sodium orthophosphate neutralization liquid into a neutralization liquid storage tank, and finally pumping the neutralization liquid into a polymerization furnace by a high pressure pump to synthesize sodium tripolyphosphate. The pH value of the neutralization reaction is controlled to be 6.5 to 7.0, the Baume density of neutralization slurry is controlled to be 54 to 56 Degree Baum'e, and the relative density is 1.50 to 1.60. After the method provided by the invention is adopted, the cost for transportation and safety management of nitramine (hazardous chemical substance) can be reduced; and when nitramine is replaced by sodium nitrate, Na<+> ion in Na NO3 can be fully utilized, and the consumption of soda can be reduced, so that the manufacturing cost can be lowered.

Owner:WENGFU (GRP) CO LTD

Preparation method for phosphoric acid sodium salts

ActiveCN104843662AReduce manufacturing costSolve the worries of environmental protectionPhosphorus compoundsO-Phosphoric AcidSodium phosphates

The invention discloses a preparation method for phosphoric acid sodium salts, wherein the preparation method comprises the steps: using sodium pyrophosphate as a raw material, carrying out a mixed hydrolysis reaction with wet-process phosphoric acid to obtain sodium orthophosphate, then adding purified wet-process phosphoric acid, adjusting the pH value to obtain disodium phosphate and / or trisodium phosphate, and next carrying out a polymerization reaction to obtain sodium tripolyphosphate. The novel preparation method for the phosphoric acid sodium salts is a new method adopting crude by-products sodium pyrophosphate and sodium hydroxide generated in Caoanning production as the main raw materials and adopting high-temperature and high-pressure hydrolysis process to produce the phosphoric acid sodium salt products. The preparation method is characterized in that the production process is easy to control, the product quality is stable, and the production cost is 35-45% lower than that of a traditional process.

Owner:MIANYANG SHENLONG FEEDSTUFF CO LTD

Novel corrosion-resistant vehicle antifreeze fluid

InactiveCN103160249AImprove stabilityReduce manufacturing costHeat-exchange elementsMethylanilineSodium phosphates

The invention discloses a novel corrosion-resistant vehicle antifreeze fluid. The antifreeze fluid consists of the following components in parts by weight: 10-20 parts of ethylene glycol, 10-20 parts of glycerin, 0.1-0.5 part of sodium orthophosphate, 10-15 parts of sodium benzoate, 0.1-0.5 part of methylaniline, 0.1-0.5 part of phthalic anhydride, 5-18 parts of phenolic resin, 5-10 parts of magnesium sulfate and 1-4 parts of borax. The antifreeze fluid has the advantages of good stability, environment friendliness, excellent antifreeze effect and low production cost.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Weld cleaning fluid

ActiveUS20150027903A1Avoid confusionImprove abilitiesMachining working mediaElectrolysis componentsSodium orthophosphateNeutral ph

The invention relates to a weld cleaning fluid, and method of cleaning weld or discolouration especially on stainless steel. Stainless steel welds, such as those done by TIG welding, require cleaning to remove the resulting surface discolouration and also to passivate the steel. This is often done using an electro-cleaning apparatus with the assistance of electrolyte cleaning fluids. A new cleaning fluid has been developed that has a generally neutral pH, instead of the highly acidic nature of previously used fluids, which avoids environmental and safety issues. The cleaning fluid composition preferably has potassium or sodium orthophosphate salts as the main active ingredient, or similar such salts, and has a pH of around 7. It may also include a sequestering or chelating agent such as a sodium and / or potassium salt of EDTA, and colouring and fragrance.

Owner:ENSITECH IP

Scale-proofing method of boiler

A boiler scale-inhibiting method is carried out by inspecting, feeding medicine and monitoring. Scale inhibitor consists of 1-amino-pyrrolidine, monometallic sodium orthophosphate, sodium sulfite and ethylenimine. It is fast and efficient.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

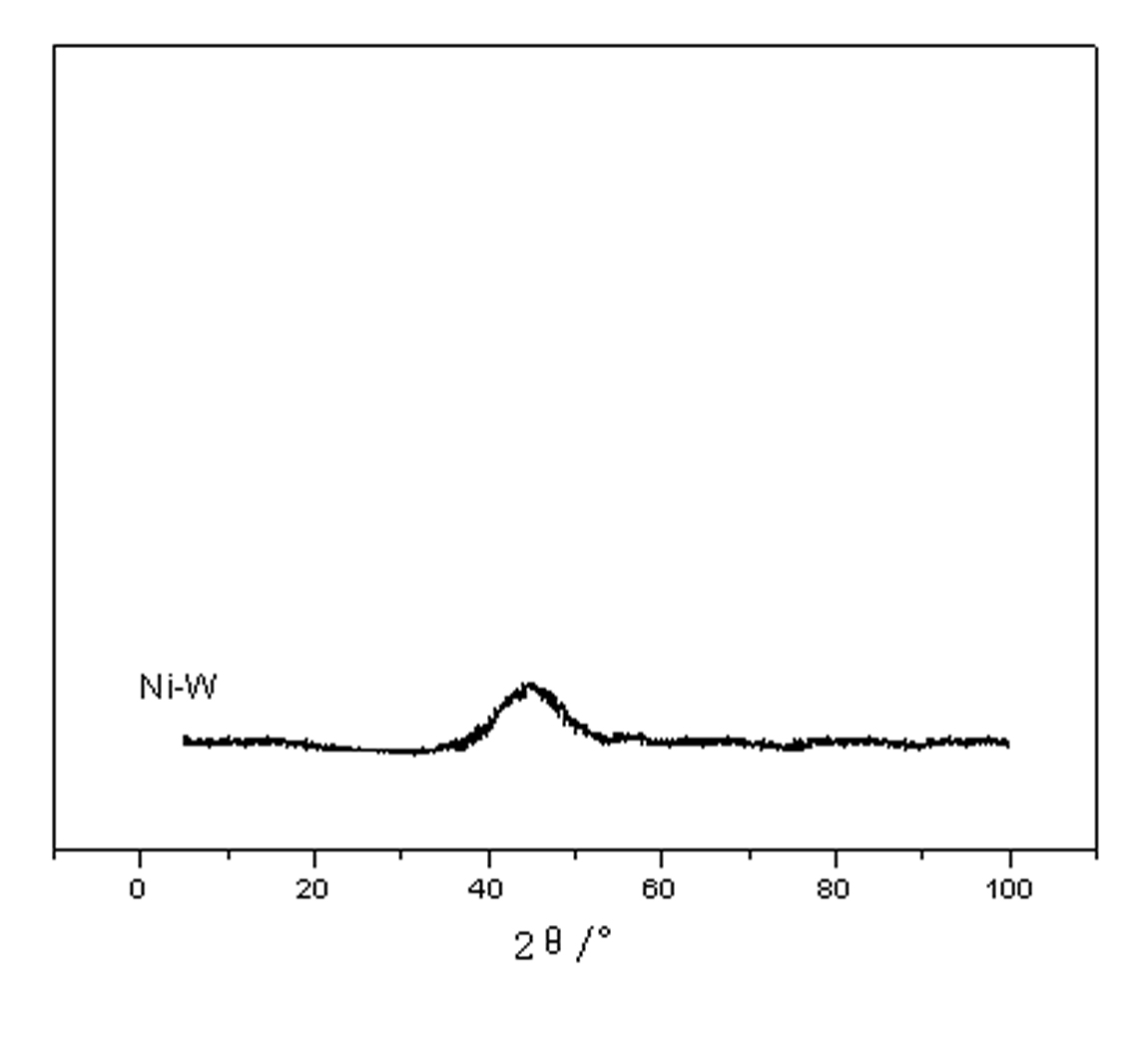

Method for preparing nickel-base amorphous coating on carbon steel surface

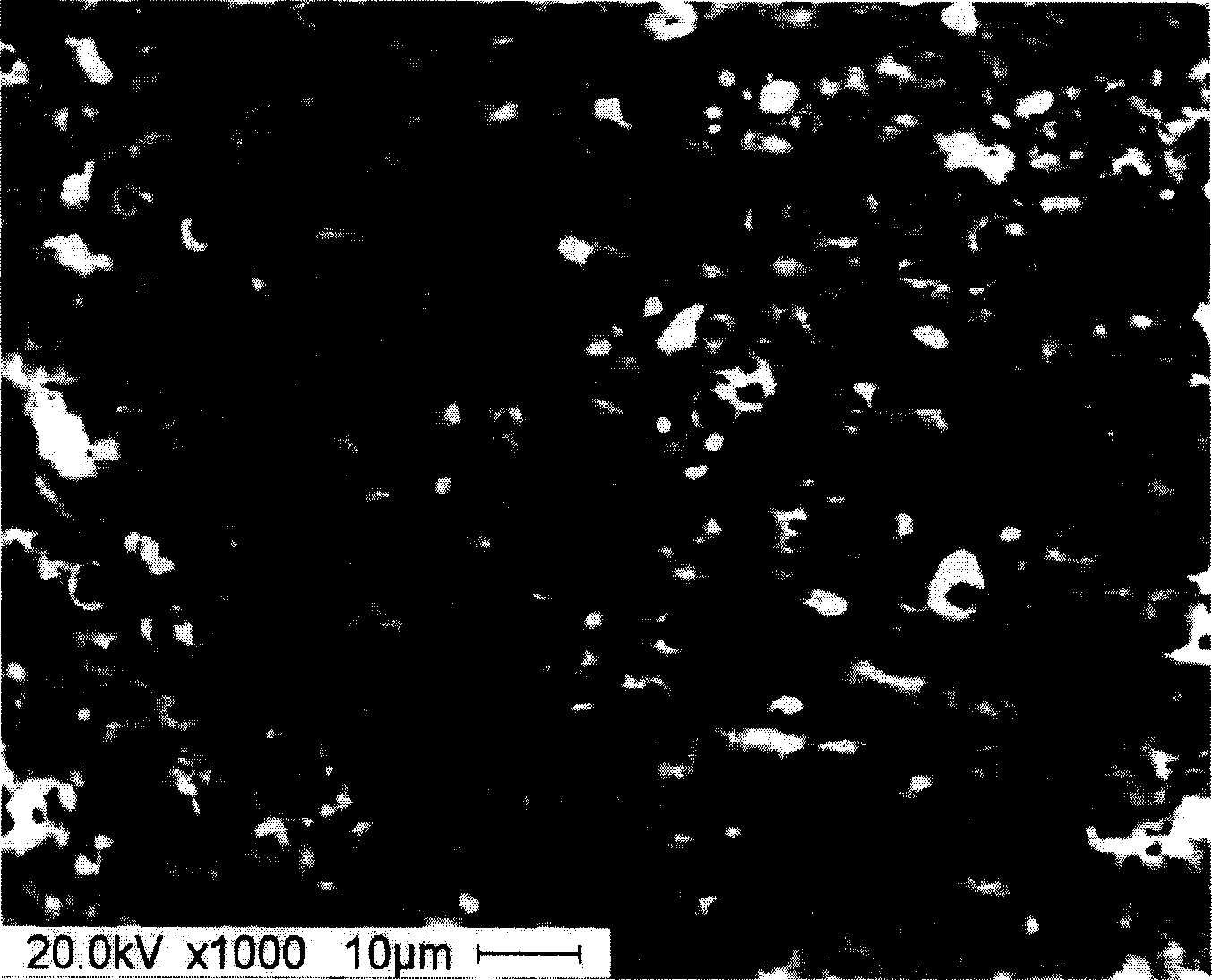

InactiveCN102061497AReduce pollutionHigh hardnessSuperimposed coating processSodium orthophosphatePyrophosphate

The invention provides a method for preparing a nickel-base amorphous coating on a carbon steel surface, and belongs to the technical field of materials. The method comprises the following steps: (1) placing a carbon steel matrix in water for electrodialysis to obtain a conducting carbon steel matrix; (2) soaking the conducting carbon steel matrix in de-stressing solution, washing and drying; (3) placing the dried matrix in degreasing solution, adding sodium pyrophosphate, performing heat preservation and then washing; (4) soaking the matrix in neutralizing solution and then washing; (5) placing the matrix in crystallization solution and then washing, and placing in sodium orthophosphate solution and then washing; (6) placing the matrix in adjusting solution and then washing; (7) placing the matrix in activation solution and then washing; and (8) treating the matrix in amorphous treating fluid and then washing to finally obtain the carbon steel matrix with the nickel-base amorphous coating. The method is simple and convenient in operation; and the obtained nickel-base amorphous coating has the advantages of high hardness, excellent corrosion resistance, excellent wear resistance and beautiful appearance, and can be applied to decorative materials.

Owner:JIUXING HLDG GRP

Abrasion-resistant engineering machinery waterproof paint high in adhesive force

ActiveCN105860808AGood dispersionReduce clumpingInorganic pigment treatmentPolyurea/polyurethane coatingsEpoxySolvent

Owner:东莞真诚化工有限公司

Method for purifying crude sodium pyrophosphate to produce disodium hydrogen phosphate and sodium chloride

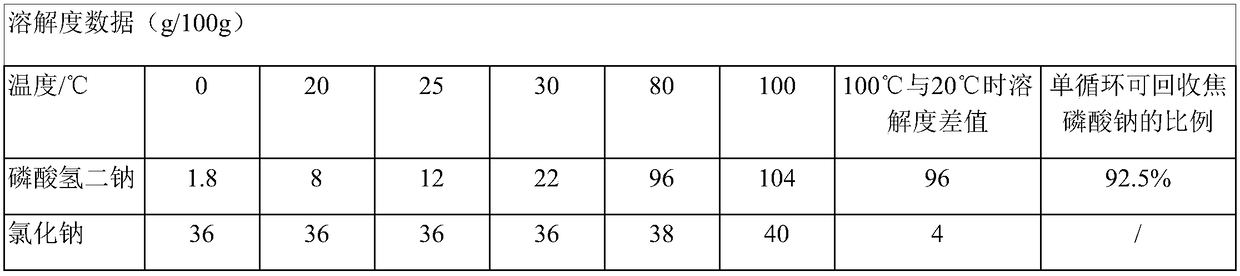

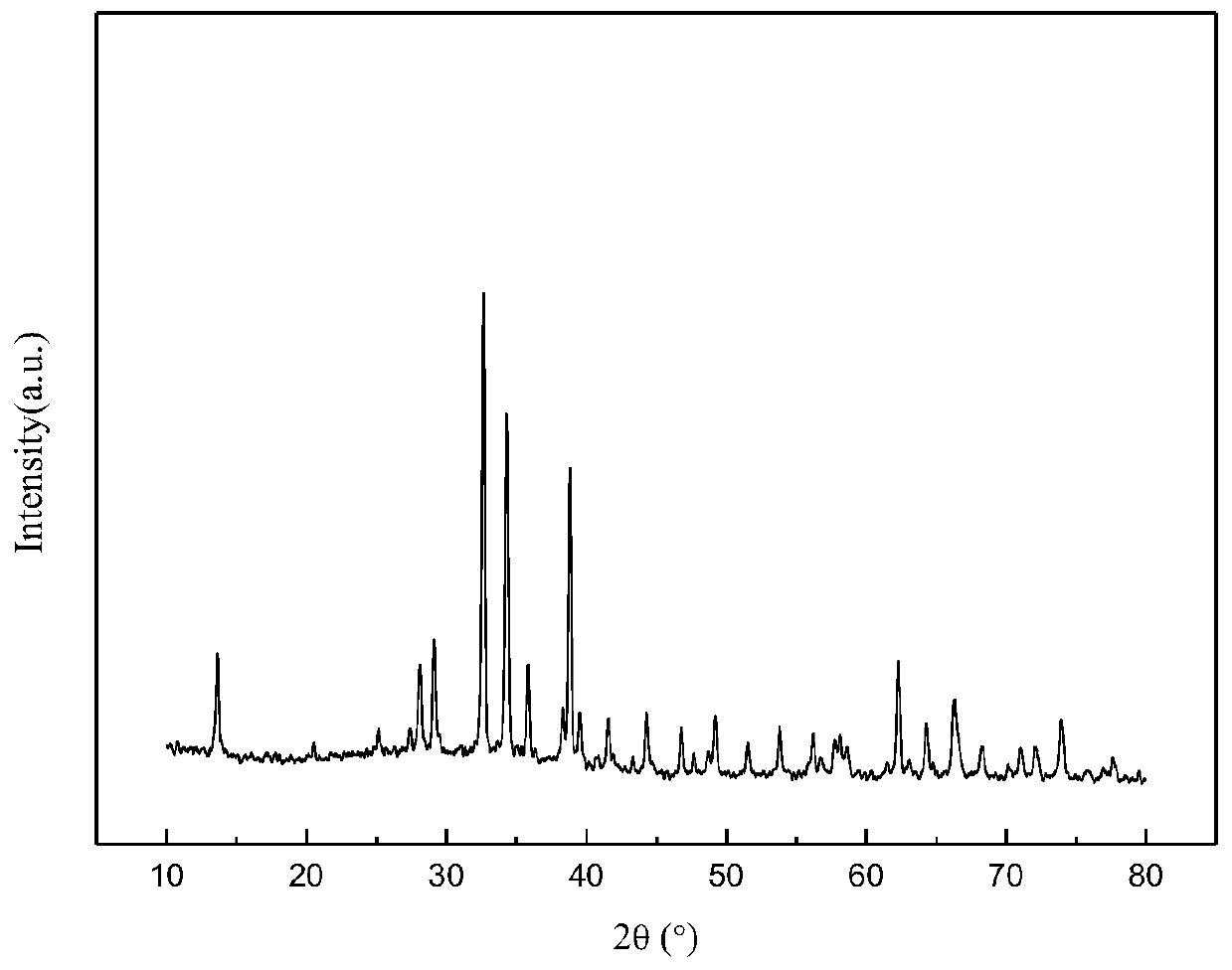

ActiveCN109399593AReduce consumptionReduce productionAlkali metal chloridesPhosphorus compoundsSolubilityHydrolysate

The invention discloses a method for purifying a by-product crude sodium pyrophosphate of wastewater containing phosphorus and salt like a glyphosate mother solution to produce disodium hydrogen phosphate and sodium chloride products. An oxidizing aid is utilized to improve the dispersibility of a crude sodium pyrophosphate mixed solution, and a special use method of process water is adopted to improve the viscosity of slurry and improve the crystallization effect. The sodium orthophosphate and the sodium chloride are extracted by utilizing the difference in solubility of the sodium pyrophosphate, a hydrolysate and the sodium chloride in the crude sodium pyrophosphate under the effect of different temperatures, pH conditions and aids. The production process is high in dissolution speed. The product quality is excellent, the wastewater amount is small, the environmental protection treatment cost is greatly reduced, and the advantages of reaction, environmental protection, quality and cost are achieved.

Owner:HUBEI TAISHENG CHEM

Methylcellulose multicolor coating

ActiveCN104073067AVariety of coating colorsLight and softPolyurea/polyurethane coatingsMulticolor effect coatingsCyclohexanoneLoss rate

The invention discloses a methylcellulose multicolor coating. The methylcellulose multicolor coating is prepared from the following raw materials in parts by weight: 100 parts of methylcellulose, 5-15 parts of zinc oxide, 10-20 parts of sodium pentachlorophenate, 30-40 parts of dimethylbenzene, 15-25 parts of montmorillonite, 25-35 parts of talcum powder, 70-90 parts of deionized water, 10-30 parts of cyclohexanone, 10-20 parts of pigment, 15-35 parts of trimethylolpropane, 20-30 parts of sodium orthophosphate, 5-25 parts of toluene diisocynate, 4-10 parts of plasticizer, 35-45 parts of aluminium stearate, 20-40 parts of polyving akohol and 25-45 parts of epoxidized soybean oil; the coating is multicolor and soft in gloss; the base of the coating is not exposed after the coating is scrubbed for 11,000-13,000 times; the content of solid accounts for 25-35%; when the coating is soaked in water at the temperature of 20 DEG C for 60-80 days, no bubble is formed and no powder is dropped; the surface is dried for 15-25 minutes and the solid is dried for 6-8 hours; and the loss rate of the coating in a coating reciprocating tester reaches 0.004-0.006g / cm<2> after running for 1000 times, so that the coating can be widely produced and used for continuously replacing the existing material.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

Modified wear-resistance paint for casts

InactiveCN104861856AImprove wear resistanceImprove corrosion resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSodium orthophosphateEpoxy

The invention discloses modified wear-resistance paint for casts. The paint is prepared from the following components in parts by weight: 20-27 parts of dual-component polyurethane, 15-22 parts of modified graphene, 6-8 parts of mica powder, 2-3 parts of a silane coupling agent KH-570, 5-7 parts of sodium orthophosphate, 8-19 parts of an alkyd resin, 5-9 parts of aluminum silicate, 25-35 parts of acrylic modified polyurethane, and 15-26 parts of a glycerine epoxy resin. The invention provides the modified wear-resistance paint for the casts, and the outside paint films of the casts, using the paint, not only have high abrasion resistance, but also have high corrosion resistance.

Owner:王俐帧

Marine waterproof paint with high adhesive force and wear resistance

The invention discloses a marine waterproof paint with high adhesive force and wear resistance. The marine waterproof paint comprises, by weight, 54 to 57 parts of an acrylic polymer emulsion, 22 to 26 parts of epoxy resin, 21 to 24 parts of styrene-acrylic emulsion, 0.5 to 0.8 part of an anti-aging agent, 1.8 to 2.1 parts of an anti-sagging agent, 2.2 to 2.5 parts of a film forming aid, 1.2 to 1.5 parts of a leveling agent, 1.5 to 1.8 parts of an antifreezing agent, 27 to 30 parts of modified grapheme, 11 to 16 parts of nano silicon dioxide, 5 to 8 parts of mica powder, 1.2 to 1.6 parts of silane coupling agent KH-570, 4 to 7 parts of sodium orthophosphate, 6 to 10 parts of sodium tripolyphosphate, and 55 to 58 parts of a solvent. The marine waterproof paint possesses high adhesive force and excellent wear resistance.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

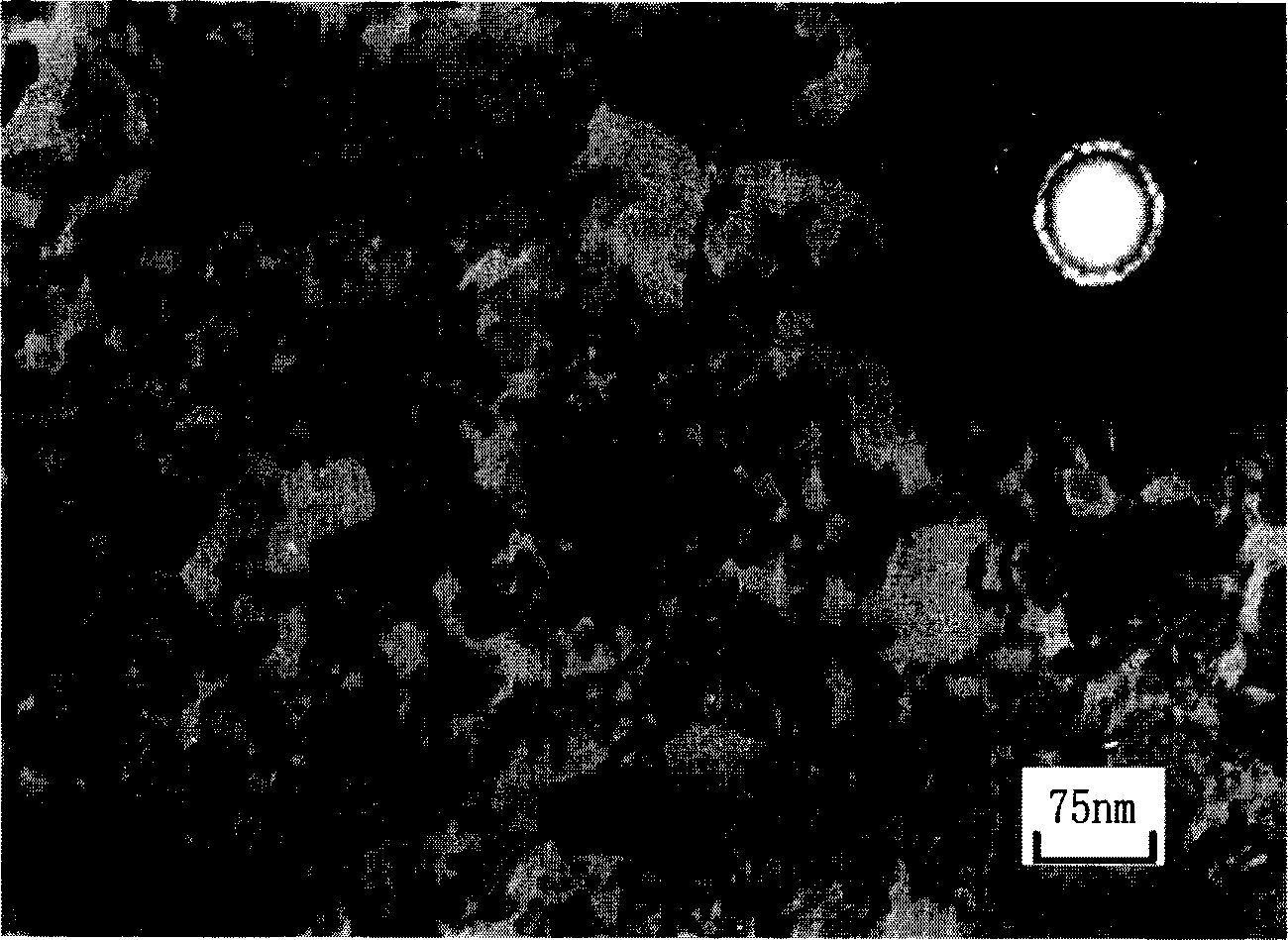

Preparation method of Bi2O2SiO3/Bi2O3/BiOBr heterogeneous composite optical material

ActiveCN110252341AImprove photocatalytic performanceShort preparation cycleWater/sewage treatment by irradiationWater treatment compoundsSodium orthophosphateProcess equipment

The invention discloses a preparation method of a Bi2O2SiO3 / Bi2O3 / BiOBr heterogeneous composite material. According to the method, bismuth nitrate is used as a bismuth source, tetraethoxysilane is used as a silicon source, sodium orthophosphate, lauryl sodium sulfate, polyethylene glycol and the like are added to promote formation of a required crystal phase, and a precursor is prepared to prepare the Bi2O2SiO3 / Bi2O3 / BiOBr heterogeneous composite material. The method is simple in process equipment, short in period and low in cost, and the obtained composite material powder has high photocatalytic performance.

Owner:SHAANXI UNIV OF SCI & TECH

Multifunctional water-treating antisludging agent of boiler

InactiveCN1854091APrevent oxygen-containing chemical reactionsQuick responseScale removal and water softeningSodium orthophosphateSulfite salt

A multifunctional boiler water treatment scale inhibitor consists of 1-amino-pyrrolidine, monometallic sodium orthophosphate, sodium sulfite and ethylenimine and deionized water. It has wide pH range and better dispersion ability, it can control scale effectively under the conditions of high-hardness, high-iron content, high-base content, high-pH and high-temperature.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

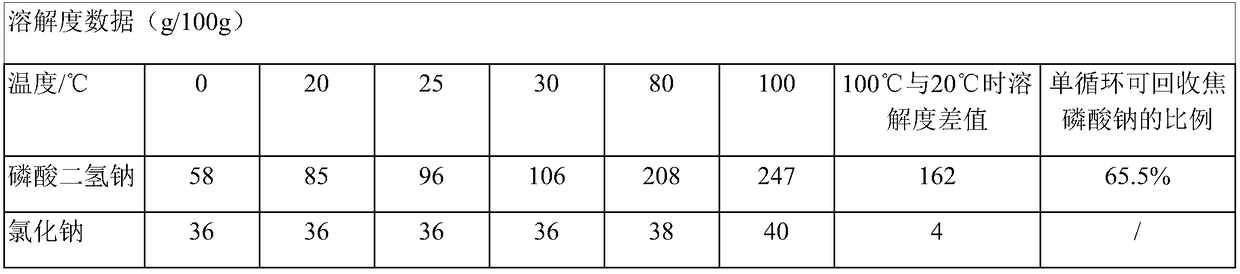

Method for producing sodium dihydrogen phosphate and sodium chloride by purifying crude product sodium pyrophosphate

ActiveCN109455685AReduce consumptionReduce productionAlkali metal chloridesPhosphorus compoundsSolubilityDispersity

The invention discloses a method for producing sodium dihydrogen phosphate and sodium chloride products by purifying by-product crude product sodium pyrophosphate of phosphorus-containing salt-containing wastewater such as glyphosate mother liquor. The method is characterized in that an oxidative assistant is utilized to improve dispersity of a crude product sodium pyrophosphate mixed solution, and a special use method of process water is utilized, so that viscosity of slurry is improved, and crystallization effect is improved. Solubility difference of sodium pyrophosphate and a hydrolysate thereof and sodium chloride in the crude product sodium pyrophosphate under different temperatures, different pH value conditions and the action of different auxiliaries is utilized to extract sodium orthophosphate and sodium chloride. In the production process, dissolving speed is high; product quality is excellent; wastewater amount is small; environment-friendly treatment cost is greatly reduced;and reaction advantages, environment-friendly advantages, quality advantages and cost advantages are achieved.

Owner:HUBEI TAISHENG CHEM

Wear-resistant material for casting

InactiveCN110240838AGuaranteed service lifeImprove performanceStarch coatingsPolyurea/polyurethane coatingsEpoxyWear resistant

The invention relates to a wear-resistant material for casting, prepared from the following in parts by weight: 10-16 parts of dextrin powder, 12-18 parts of polyvinyl alcohol, 12-18 parts of iron oxide powder, 6-10 parts of n-butyl alcohol, 1-6 parts of sodium orthophosphate, 3-9 parts of starch paste, 3-9 parts of lignosulfonic acid, 2-8 parts of sodium carboxymethyl cellulose, 2-10 parts of silica sol, 10-20 parts of modified graphene, 0.3-0.9 parts of iron oxide red powder, 6-12 parts of hollow glass microspheres, 10-18 parts of triphenyl phosphite, 10-30 parts of acrylic modified polyurethane, 10-18 parts of nano ceramics powder, 2-8 parts of sodium benzoate, 3-9 parts of aluminum phosphate, and 3-7 parts of epoxy resin. A wear-resistant layer can be established on the surface of a casting through scientific and reasonable material matching, thereby greatly improving the wear resistance of the casting, fully satisfying the wear-resisting characteristics of the casting under various environments, and effectively prolonging the service life of the casting.

Owner:XUZHOU TIANTAI MACHINERY MFG

Surface treatment material for abrasion-resistant alloy casting

InactiveCN109014024AImprove wear resistanceAccelerated corrosionFoundry mouldsFoundry coresSodium orthophosphateAlcohol

The invention discloses a surface treatment material for an abrasion-resistant alloy casting. The surface treatment material comprises, by weight, 2-5 parts of aluminum silicate, 2-5 parts of calciumbentonite, 5-11 parts of kieselguhr, 2-5 parts of quartz powder, 3-7 parts of olivine powder, 1-3 parts of alundum powder, 11-14 parts of dextrin powder, 2-5 parts of aluminum sulfate powder, 11-13 parts of polyvinyl alcohol, 14-16 parts of ferric oxide powder, 7-9 parts of n-caprylic alcohol, 6-8 parts of nano attapulgite, 5-11 parts of grass ash and 2-5 parts of sodium orthophosphate. By adoption of the surface treatment material, the abrasion resistance and corrosion resistance of the surface of the casting are effectively improved. In addition, the alloy strengthening process of the surface of the casting can be completed at a time at the same time of casting, so that the technique is simplified, the abrasion resistance of a strengthened layer is about 2-3 times that of a base material, and the acid corrosion resistance of the strengthened layer is about 5 times that of the base material.

Owner:马鞍山市九华耐磨材料有限公司

External wall multicolor paint

The invention discloses an external wall multicolor paint which is prepared from distilled water, a pigment, methylisobutyl ethanol, sodium sulfate, n-octanol, sodium pentachlorophenate, montmorillonite, sodium orthophosphate, methyl cellulose and ethylene glycol monobutyl ether. The grains with various colors of the product have clear margins, and can not adhere to each other when being stirred. The solid content is 30-50%, and the coating weight is 0.15-0.35. The drying time is 5-15 hours, the storage time is 11-15 months, and the paint can be widely produced and continuously substituted for the existing materials.

Owner:SUZHOU COMFORT TEXTILE NEW MATERIALS TECH CO LTD

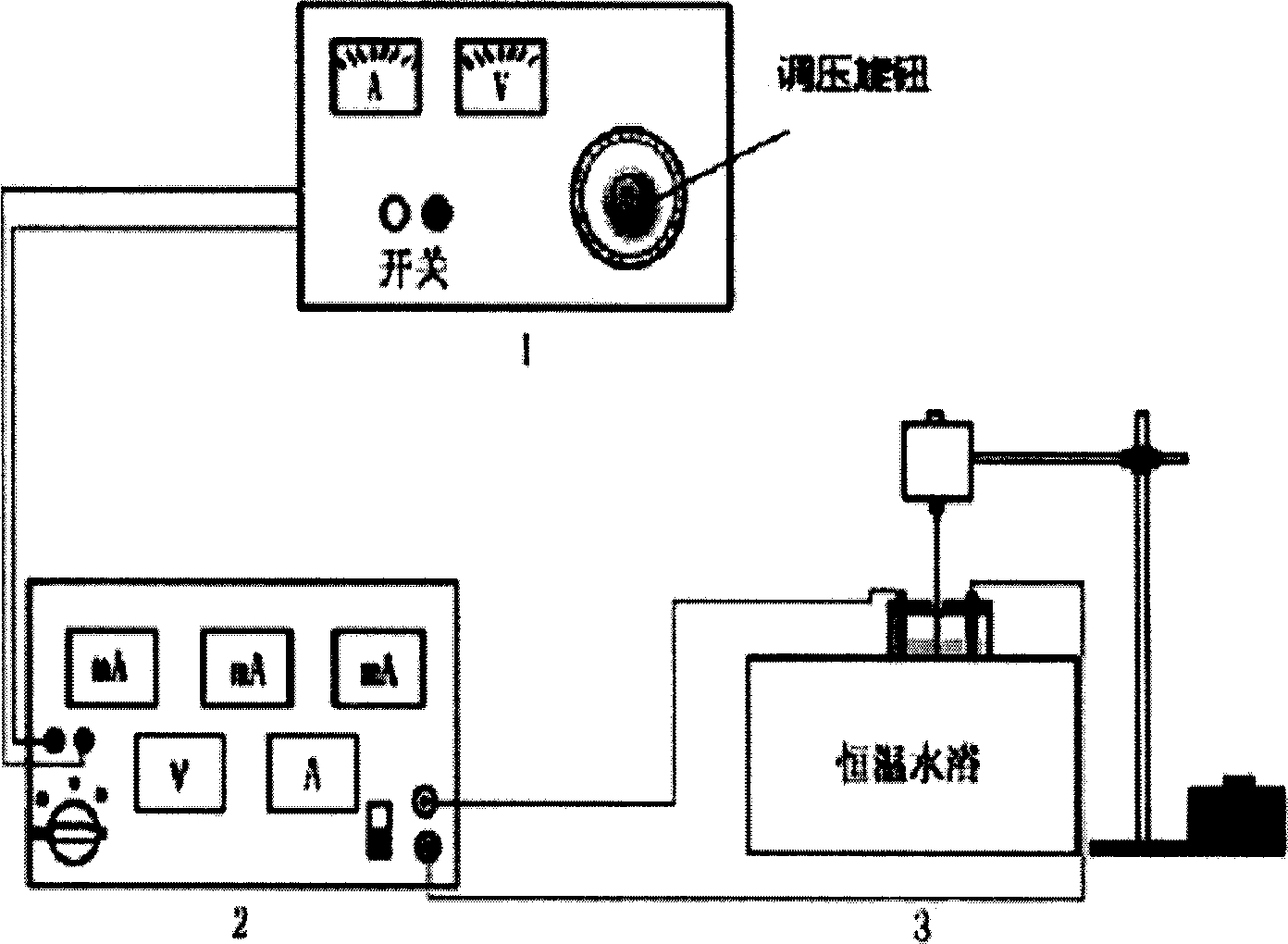

Material for oxygen sensor, preparation method thereof and engine oxygen sensor

InactiveCN1769882AReduce productionIncreased sensitivityMaterial electrochemical variablesElectrochemical anodizationEngineering

The invention relates to a material for oxygen sensor, method for making the same and a motor oxygen sensor manufactured with the material. The material comprises titanium chip base and IiO2 thin film formed on the base surface with anodic oxidation process on home position. The processing method comprises following steps of: 1. processing the titanium chip base with 2-6% (weight percentage) acid solution to remove oxidate on the surface of titanium chip; 2. taking the processed titanium chip as anode, graphite as cathode, and taking 10-30% (weight percentage) sodium orthophosphate solution as base electrolytic solution to electrochemical oxidation on anode and form TiO2 thin film on the titanium chip surface. The motor oxygen sensor is characterized in that its materials comprises titanium chip base and IiO2 thin film formed on the base surface with anodic oxidation process on home position.

Owner:BYD CO LTD

Preparation technology of quick-drying dark red ink

InactiveCN105524519ABright colorStrong coloring powerInksEthyleneglycol monobutyl etherSodium phosphates

The invention discloses a preparation technology of quick-drying dark red ink. The preparation technology comprises the following steps: 1, adding pure water, permanent red F4R, everbright fast red BBN and 107 molybdate red to a reaction kettle provided with a stirrer and a thermometer, and stirring above materials; 2, adding sodium pentachlorophenate, 2 a polyamide resin liquid and ethylene glycol monobutyl ether, and heating and stirring above materials; 3, adding n-octyl alcohol, tritolyl phosphate and methyl cellulose, heating above materials, adding montmorillonite, polyethylene microcrystalline wax and sodium orthophosphate, and stirring above materials; and 4, adding stearic acid or polyol, polydimethylsiloxane and gelatin, adding he obtained mixture to a sand mill, grinding and dispersing the mixture, and cooling the ground mixture to obtain the quick-drying dark red ink. The alcohol tolerance of the quick-drying dark red ink is 12-15t, the viscosity is 1.5-1.7cp, and the expressive force reaches up to 92-95%; and the surface drying time is 1-3s, the complete drying time is 3-7min, and the quick-drying dark red ink can be stored for 8-12 months without deterioration.

Owner:SUZHOU YUXI NEW MATERIAL TECH

Special packing for antistatic flame-retardant capacitor film and preparation method of packing

The invention provides special packing for an antistatic flame-retardant capacitor film. The special packing comprises the following raw materials of, by weight, 10-15 parts of isotatic polypropylene, 2-3 parts of graphene nanoplatelets, 15-20 parts of magnesium hydrate, 3-5 parts of sodium molybdate, 2-3 parts of sodium orthophosphate, 2-3 parts of hydrogenated tallow amine, 3-4 parts of polyethylene wax, 2-3 parts of sasol wax, 2-3 parts of perfluoroalkylethyl acrylate, 50-55 parts of municipal sludge, a proper amount of 5-7% muriatic acid, a proper amount of water and 15-20 parts of additives. The hydrogenated tallow amine is added to the packing, and therefore the film has the antistatic effect and is good in anti-puncturing performance; the magnesium hydrate is added, and therefore the film has an excellent flame retardant property; the perfluoroalkylethyl acrylate is added, and therefore the anti-pollution performance of the film is enhanced; the municipal sludge is used, therefore, the cost is reduced, the fineness is high, and the reinforcement performance is good; the additives are used, therefore, the dispersibility and the reinforcement performance of the packing can be improved, and the strength and the impact toughness of the film can be improved.

Owner:ANHUI ZHUANGYUANLANG ELECTRONICS TECH

Novel STPP (sodium tripolyphosphate) production technology

ActiveCN108178138AReduce consumptionReduce manufacturing costPhosphorus compoundsSodium orthophosphatePhosphoric acid

The invention discloses a novel STPP (sodium tripolyphosphate) production technology. The technology comprises steps as follows: sodium pyrophosphate decahydrate is added to phosphoric acid, temperature, PH value and specific gravity of a neutralization solution are regulated, a ratio of disodium dihydrogen pyrophosphate to sodium pyrophosphate in a flask reaches 1:1.7-1:2.0, the neutralization solution is dewatered and dried by a spray dryer, dried mixed pyrophosphate is subjected to water-loss polymerization in a high-temperature environment, and STPP is produced. According to the technology, sodium pyrophosphate decahydrate belongs to a waste residue produced by a pesticide enterprise, no waste residues are produced in the whole technological process, and the problem about waste residuetreatment of the pesticide enterprise is solved effectively; after direct application of sodium pyrophosphate decahydrate, the use amount of phosphoric acid is greatly reduced, a process of hydrolyzing sodium pyrophosphate into sodium orthophosphate is omitted, and production cost of the enterprise is effectively reduced.

Owner:JIANGSU YOUTH CHEM

Method for preparing anti-wrinkle regenerated silk by using defective silkworm cocoons

InactiveCN110257943ASmall color differenceImprove solubilityMonocomponent fibroin artificial filamentAnimal materialHypochloriteHigh pressure

The invention discloses a method for preparing anti-wrinkle regenerated silk by using defective silkworm cocoons. The method includes the steps of 1), taking out silkworm pupae treated with micropowder and a hypochlorite solution prior to putting into the air; 2), performing degradation of cocoon powder by adopting high pressure cooking, enzymatic hydrolysis of mixed enzyme, a sodium hydroxide solution and a wall breaker by means of stirring; 3), adding an emulsifying modifier and a functional agent to a silkworm cocoon dissolving solution, and respectively performing high speed stirring and constant temperature and constant pressure reaction; 4), mixing polyacrylamide and polytene with acrylic hydroxyacetic acid for ammonia treatment, and then adding a silk modified degradation solution, zinc acetate and monometallic sodium orthophosphate by stirring and mixing for reaction; 5), drying and cooling a mixed solution to form colloidal, and preparing regenerated silk through mold spinning holes; 6), treating the newly spun regenerated silk by using a finishing solution to obtain the spinning regenerated silk.

Owner:金寨新丝路纺织有限公司

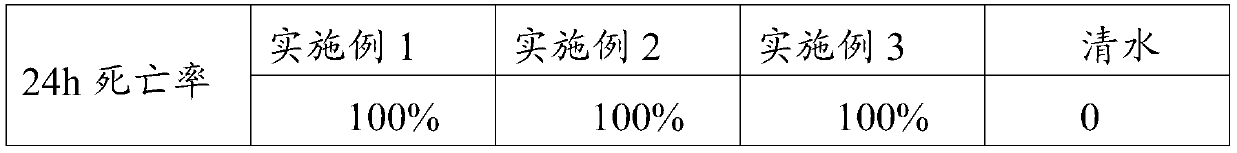

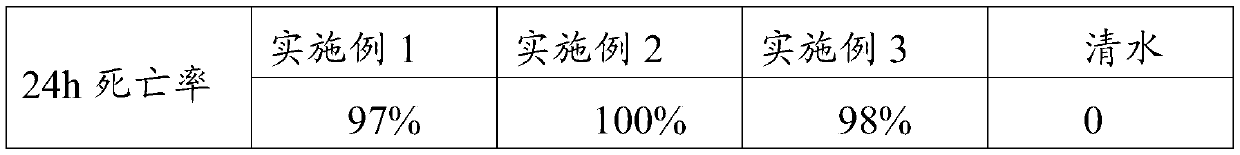

Household anti-mite agent composition and preparation method thereof

ActiveCN111436458AExtensive sources of raw materialsConfiguration method securityBiocideAnimal repellantsBiotechnologySodium orthophosphate

The invention discloses a household anti-mite agent composition and a preparation method thereof, and relates to the technical field of daily chemical products. The household anti-mite agent composition comprises the following components in parts by weight: 2-15 parts of sodium orthophosphate; and 1-15 parts of a peroxide compound. According to the household anti-mite agent composition, the sodiumsalt and the peroxy compound are simultaneously used according to a certain ratio, so that mite bodies can be doubly destroyed, the mite killing rate is high, and the household anti-mite agent composition is safe to people. The preparation method of the household anti-mite agent composition provided by the invention is simple to operate and easy to implement, can remove mites on the surface of furniture or a fabric and mites inside the furniture or the fabric, and is remarkable in mite killing effect, long in effect lasting time and convenient to use.

Owner:广州超威生物科技有限公司

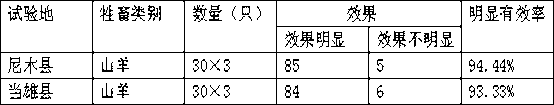

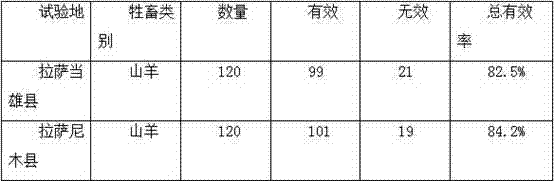

Compound detoxifying agent for treating locoweed poisoning of livestock and preparation method of agent

InactiveCN103006702BIncrease contentMaintain metabolismOrganic active ingredientsInorganic phosphorous active ingredientsBiotechnologyAnimal science

Owner:TIBET ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Compound detoxifying agent for treating locoweed poisoning of livestock and preparation method of agent

InactiveCN103006702AIncrease contentMaintain metabolismOrganic active ingredientsInorganic phosphorous active ingredientsBiotechnologyAnimal science

The invention relates to a compound detoxifying agent for treating locoweed poisoning of livestock and a preparation method of the agent. The compound detoxifying agent is prepared by dissolving an antidote into 1000 parts of sterilization water, and the antidote is prepared from the following components in part by weight: 0.25-0.5 part of yeast mannan, 0.8-1 part of L-rhamnose, 3-5 parts of magnesium sulfate and 8-10 parts of sodium orthophosphate. The compound detoxifying agent for treating locoweed poisoning of the livestock with the formula provided by the invention has definite components, is proven to have no toxic and side effect of teratogenesis, mutagenesis, carcinogenesis and the like by safety toxicology experiments, and is safe and reliable when being applied to production.

Owner:TIBET ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Block for preventing and treating locoweed poisoning of animals

InactiveCN103109979AGood treatment effectPreventive treatment detoxificationAnimal feeding stuffBiotechnologyAnimal science

The invention relates to a block for preventing and treating locoweed poisoning of animals, belonging to the technical field of an animal medicine. The block consists of the following raw materials in parts by weight: 2-3 parts of molasses, 10-15 parts of common salt, 3-4 parts of quick lime, 6-7 parts of bran, 2-3 parts of copper sulfate, 10-20 parts of a trace element mixing agent, 5-10 parts of urea phosphate and 2-4 parts of a yeast mannan-phosphate-Mg2+ induction mixing agent, wherein the yeast mannan-phosphate-Mg2+ induction mixing agent consists of the following components by the following proportioning: yeast mannan, L-rhamnose, pharmaceutical-grade magnesium sulfate and pharmaceutical-grade sodium orthophosphate in weight ratio of (0.25-0.5): (0.8-1): (3-5): (8-10). The nutrition block is remarkable in treating effect, sufficient in various components and raw materials, good in safety, convenient to implement, reasonable in proportion and complete in nutrition.

Owner:TIBET ACAD OF AGRI & ANIMAL HUSBANDRY SCI

Preparation method of moisture retention agent for seafood shellfish products

PendingCN111357803AMaintain water holding capacityFresh and tastyMeat/fish preservation using chemicalsFood ingredient for microbe protectionSodium orthophosphateO-Phosphoric Acid

The invention discloses a preparation method of a moisture retention agent for seafood shellfish products in the technical field of seafood product storage. The method comprises the following steps: S1, preparing a certain mass of sodium carbonate and 85% of hot-process phosphoric acid; S2, firstly adding pre-prepared alkali liquor, and then neutralizing with solid sodium carbonate; S3, after feeding is stopped, performing boiling for 30 min, adding a proper amount of NH3NO3, and preparing a qualified sodium orthophosphate neutralization solution for polymerization; S4, adding the neutralizedmixed sodium orthophosphate solution, then performing calcination polymerization in a rotary polymerization furnace, and carrying out polymerization reaction for a period of time to finally obtain a target product; and S5, after the reaction is finished, keeping the product in the furnace for 30-60 minutes, and then performing cooling to obtain a finished product. According to the invention, a trace amount of the moisture retention agent is added into seafood, so that the water retention of the seafood can be maintained and a fresh and delicious mouth feel of the seafood can be maintained. Thepreparation method is simple and easy to operate, and is suitable for industrial mass production.

Owner:苏州天康生物科技有限公司

Method for detecting content of phosphate of different type in complex sodium phosphate product

ActiveCN103048402BGood repeatabilityImprove stabilityComponent separationSodium orthophosphateSodium phosphates

The invention provides a method for detecting the content of phosphates of different types in a complex sodium phosphate product, comprising: diluting the complex phosphate product with pure water, eluting the solution in gradient by an ion chromatograph, separating the phosphates of different types in a sample, and determining a response value; preparing four groups of standard solutions of sodium orthophosphate, sodium pyrophosphate, sodium polyphosphate and sodium trimetaphosphate in a concentration range of 2-20mg / L, determining the corresponding area response values of the standard solutions by the ion chromatograph under same conditions, and calculating by the formula FI=cI / SI; selecting a average value of FI of the four groups of solutions of each component, to determine a correction factor of each component, and finally, calculating the content of each component in the complex sodium phosphate products. The product provides a method for simultaneously detecting the content of phosphates of different types in a complex sodium phosphate product by a simple method and a precision apparatus. The detection result is good in repeatability and stability. The method is suitable as a common quantitative analysis method.

Owner:HUBEI XINGFA CHEM GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com