Method for producing sodium tripolyphosphate by replacing ammonium nitrate with sodium nitrate taken as catalyst

A technology of sodium tripolyphosphate and sodium nitrate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as increasing production costs, and achieve reduction in usage, production costs, transportation and safety management costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

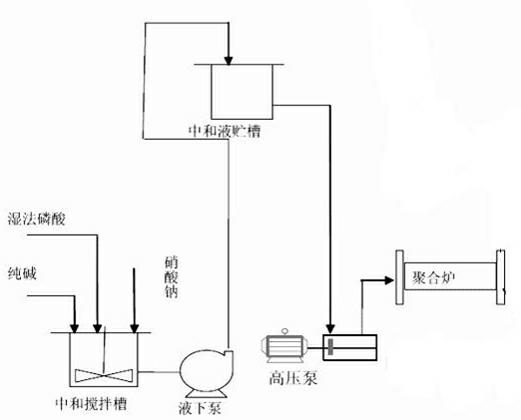

Image

Examples

Embodiment

[0010] In April 2011, a factory only used ammonium nitrate as a catalyst to assist production. The monthly output was 2931.17 tons, and ammonium nitrate was 8.16 tons. Yuan / ton sodium tripolyphosphate;

[0011] In October 2011, the method of the present invention was adopted, and only sodium nitrate was used as a catalyst to assist production. The monthly output was 2748.675 tons, and 11.3 tons of sodium nitrate was used. 2965.81=12.19 yuan / ton of sodium tripolyphosphate, 11.3 tons of sodium nitrate can reduce the consumption of 11.3×106×98%÷(85×98%)=14.09 tons of soda ash, then the use of sodium nitrate in October can reduce the cost by 14.09÷2748.675 ×1725.05=8.84 yuan / ton of sodium tripolyphosphate, the actual cost of adding sodium nitrate should be: 12.19-8.84=3.35 yuan / ton of sodium tripolyphosphate;

[0012] It can be seen from the above that using sodium nitrate instead of ammonium nitrate as a catalyst for industrial pentasodium production can reduce productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com