Material for oxygen sensor, preparation method thereof and engine oxygen sensor

An oxygen sensor and engine technology, applied in the direction of analyzing materials, electrochemical variables of materials, and material analysis through electromagnetic means, can solve the problems of low production efficiency, high production cost, complicated process, etc., and achieve low cost, simple structure, The effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

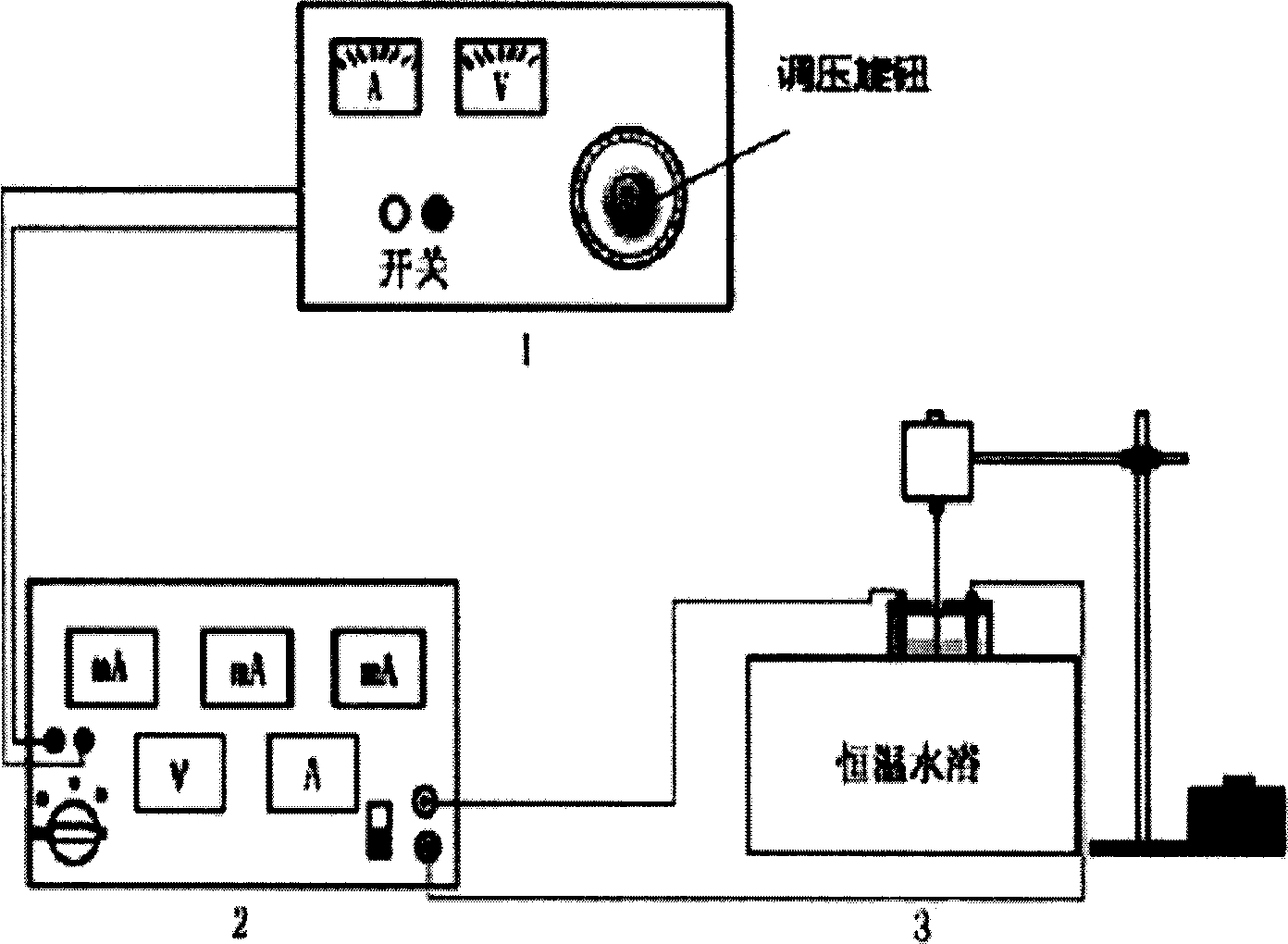

Method used

Image

Examples

Embodiment 1

[0029] Take a 200×30×2 (mm) pure titanium sheet, soak it in a 3% by weight hydrofluoric acid solution for 10 minutes to remove oxides on the surface of the titanium sheet, and then rinse it with distilled water.

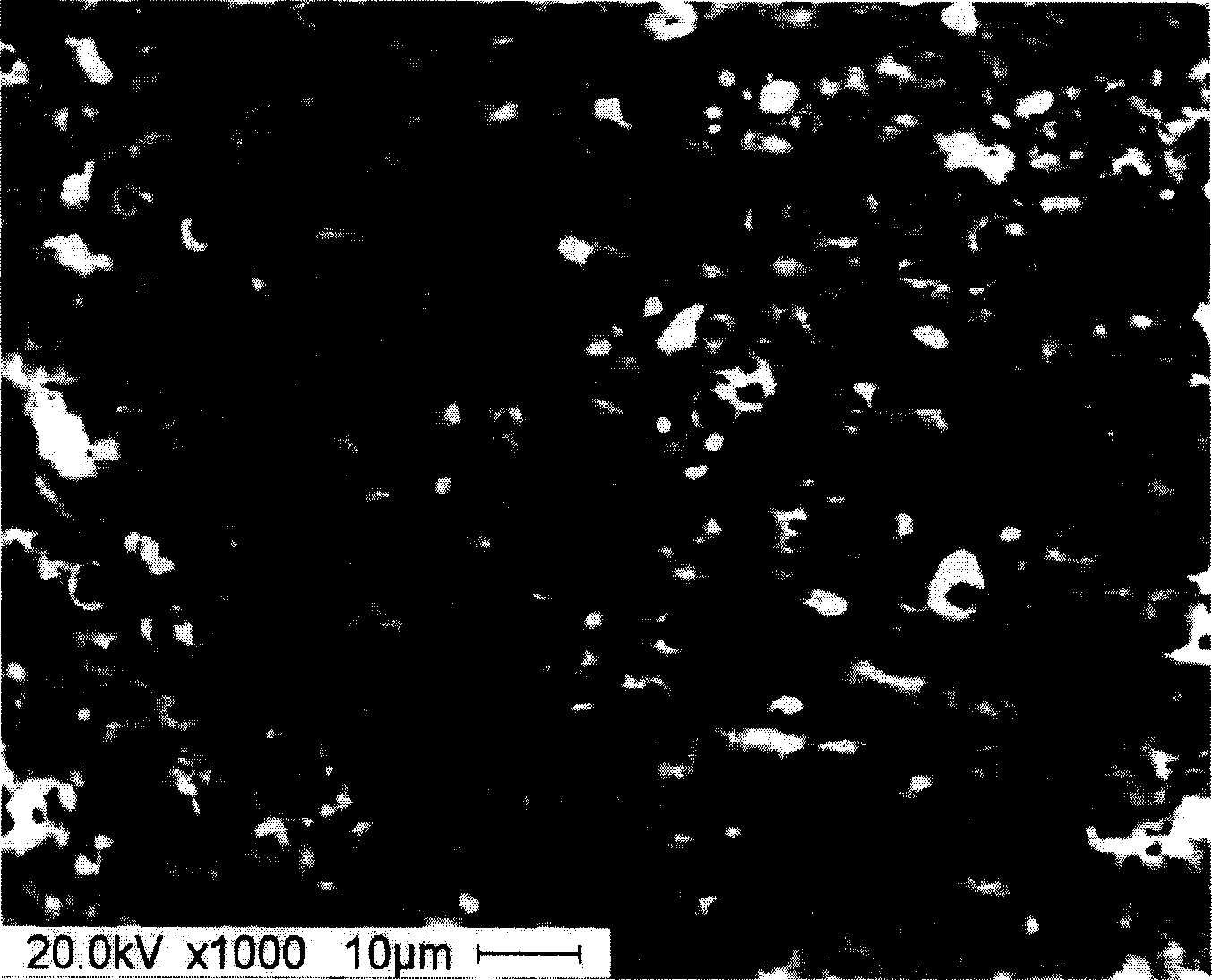

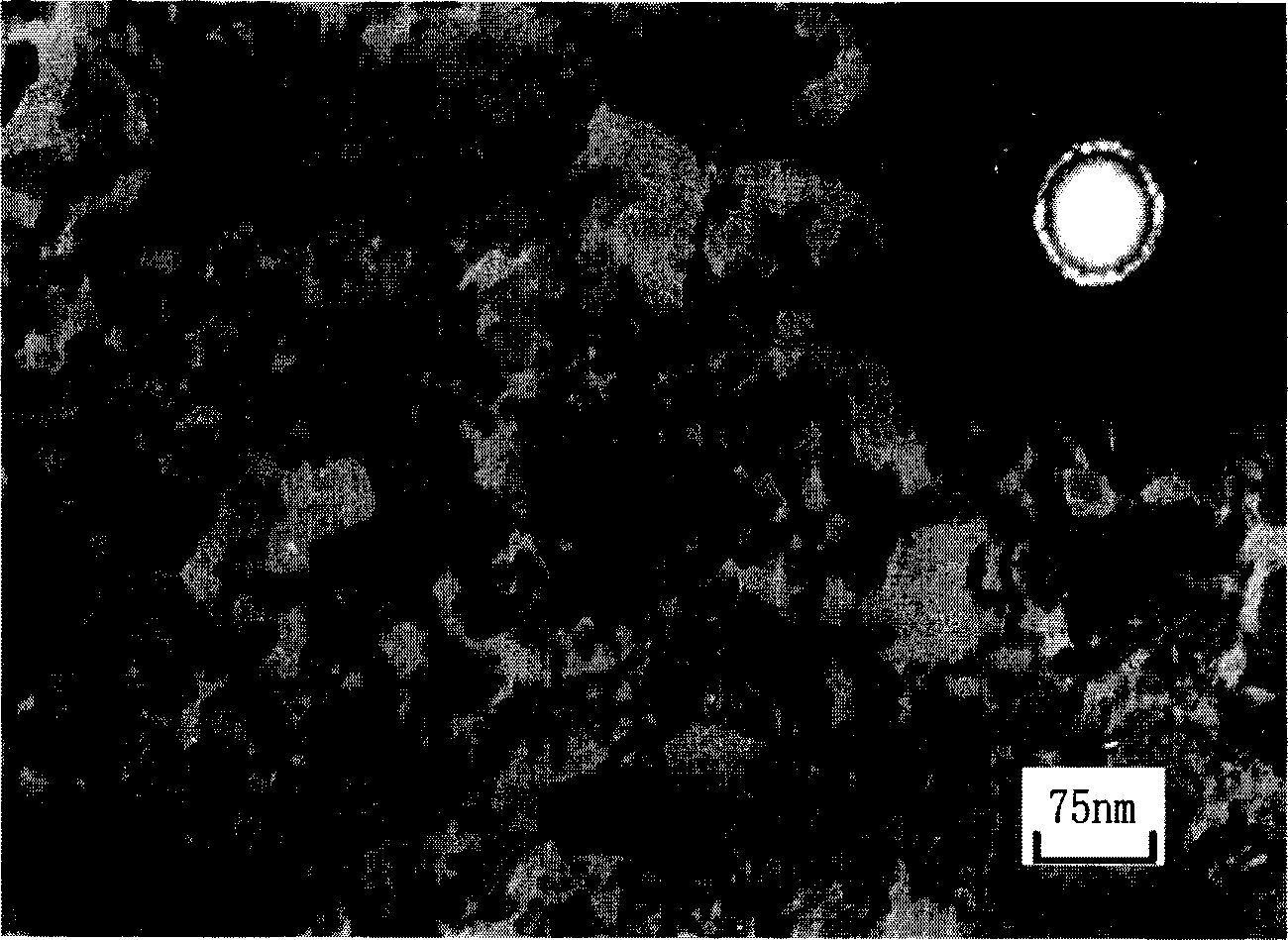

[0030] With the above-mentioned treated titanium sheet as the anode, graphite as the cathode, and an aqueous solution containing 20% by weight of sodium phosphate and 0.5% by weight of platinum phosphate as the electrolyte, the temperature of the electrolyte is 70°C, the oxidation voltage is 80V and stirring Electrochemical anodic oxidation was carried out for 15 minutes under certain conditions to obtain the material for the engine oxygen sensor of the present invention. The scanning electron microscope (SEM) photograph of obtained material is as figure 2 As shown, its transmission electron microscope (TEM) picture is shown in image 3 shown. From the transmission electron microscope photos, it can be seen that about 70% of the TiO on the surface of the film 2...

Embodiment 2

[0033] Take a 200×30×2 (mm) pure titanium sheet, soak it in a 5% by weight hydrofluoric acid solution for 6 minutes to remove oxides on the surface of the titanium sheet, and then rinse it with distilled water.

[0034] With the above-mentioned treated titanium sheet as the anode, graphite as the cathode, and an aqueous solution containing 25% by weight of sodium phosphate and 0.7% by weight of platinum phosphate as the electrolyte, the temperature of the electrolyte is 80°C, the oxidation voltage is 70V and stirring Electrochemical anodic oxidation was carried out for 10 minutes under certain conditions to obtain the material for the engine oxygen sensor of the present invention. From the transmission electron microscope photos, it can be seen that about 60% of the TiO on the surface of the film 2It is a crystalline state, and the average grain size of the film can be calculated as 22.75nm by using Scherrer's formula to calculate the grain size of the film. The content of Pt...

Embodiment 3

[0037] Take a 200×30×2 (mm) pure titanium sheet, soak it in 4% by weight hydrofluoric acid solution for 8 minutes to remove oxides on the surface of the titanium sheet, and then rinse it with distilled water.

[0038] With the above-mentioned treated titanium sheet as the anode, graphite as the cathode, and an aqueous solution containing 15% by weight of sodium phosphate and 0.5% by weight of platinum phosphate as the electrolyte, the temperature of the electrolyte is 80°C, the oxidation voltage is 85V and stirring Electrochemical anodic oxidation was carried out for 18 minutes under certain conditions to obtain the material for the engine oxygen sensor of the present invention. From the transmission electron microscope photos, it can be seen that about 60% of the TiO on the surface of the film 2 It is a crystalline state, and the average grain size of the film can be calculated as 17.67nm by using Scherrer's formula to calculate the grain size of the film. The content of Pt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com