Method for preparing nickel-base amorphous coating on carbon steel surface

A technology of amorphous coating and carbon steel, applied in the field of materials, can solve the problems of complex process, slow growth speed, expensive equipment, etc., and achieve the effect of reducing environmental pollution, easy operation and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

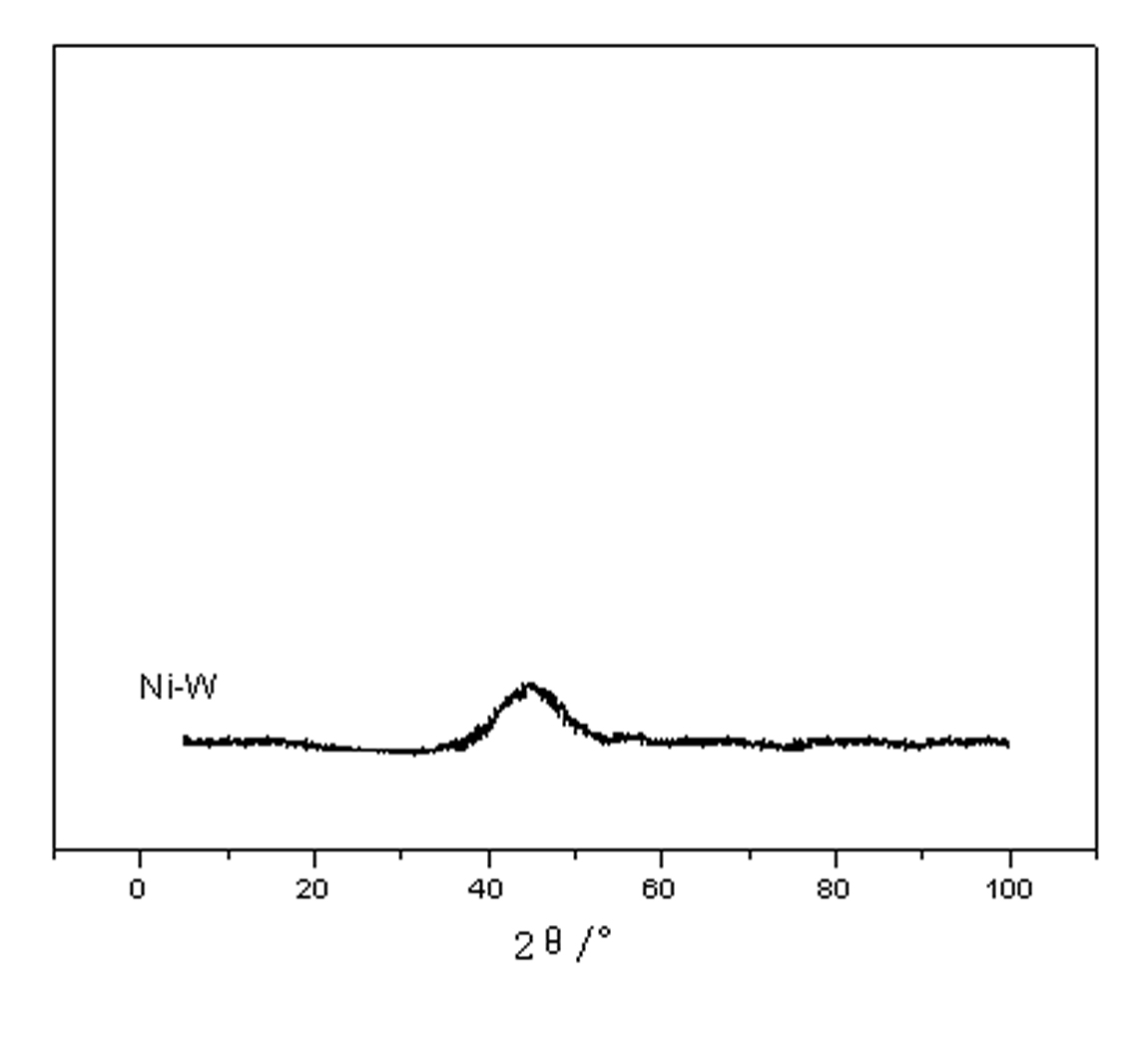

Image

Examples

Embodiment 1

[0034] Put the carbon steel substrate in water, use full-membrane air pressure ion exchanger for electrolysis, control the conductivity of water to 15μS / cm, then add emulsifier OP to the water, control the concentration of OP in water to 2.5mg / L, Electrolysis for 5 hours to obtain a conductive carbon steel matrix with surface activity;

[0035] Place the conductive carbon steel substrate in the stress-relief solution, soak for 8 hours, then take out water to clean the surface, and then dry it at 200°C for 20 hours to obtain the stress-relief carbon steel substrate; the OP concentration in the stress-relief solution is 2g / L , the concentration of sodium metasilicate is 15 g / L;

[0036] Put the stress-relieved carbon steel substrate into the degreasing solution, and add sodium pyrophosphate to the degreasing solution at a temperature of 75°C under stirring conditions until the concentration of sodium pyrophosphate is 0.5 g / L, keep it warm for 35 minutes, and then take it out at ...

Embodiment 2

[0047] Put the carbon steel matrix in water, use full-membrane air pressure ion exchanger for electrolysis, control the conductivity of water to 20μS / cm, then add emulsifier OP to the water, control the concentration of OP in water to 3mg / L, and electrolysis Analyzed for 4 hours to obtain a conductive carbon steel matrix with surface activity;

[0048] Put the conductive carbon steel substrate in the stress relief solution, soak for 10 hours, then take out the water to clean the surface, and then dry it at 190°C for 14 hours to obtain the stress relief carbon steel substrate; the OP concentration in the stress relief is 5g / L, The concentration of sodium metasilicate is 12 g / L;

[0049] Put the stress-relieving carbon steel substrate into the degreasing solution, and add sodium pyrophosphate to the degreasing solution at a temperature of 65°C under stirring conditions until the concentration of sodium pyrophosphate is 2g / L, keep it warm for 25min, and then take it out at a temp...

Embodiment 3

[0060] Put the carbon steel substrate in water, use full-membrane air pressure ion exchanger for electrolysis, control the conductivity of water to 30μS / cm, then add emulsifier OP to the water, control the concentration of OP in water to 3.5mg / L, Electrolysis for 3 hours to obtain a conductive carbon steel matrix with surface activity;

[0061] Put the conductive carbon steel substrate in the stress relief solution, soak for 12 hours, then take out the water to clean the surface, and then dry it at 180°C for 16 hours to obtain the stress relief carbon steel substrate; the OP concentration in the stress relief is 10g / L, The concentration of sodium metasilicate is 20 g / L;

[0062] Put the stress-relieved carbon steel substrate into the degreasing solution, and add sodium pyrophosphate to the degreasing solution under stirring conditions at a temperature of 60°C until the concentration of sodium pyrophosphate is 10 g / L, keep it warm for 15 minutes, and then take it out at a tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com