Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45 results about "Secondary Energy Resource" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary energy resources are those which do not occur naturally but which are obtained from one or more of the primary energy resources. Example: Petrol or gasoline, electrical energy from coal burning, hydrogen obtained by electrolysis of water etc. Non-commercial source of energy: Firewood, cow dung, and vegetable wastes.

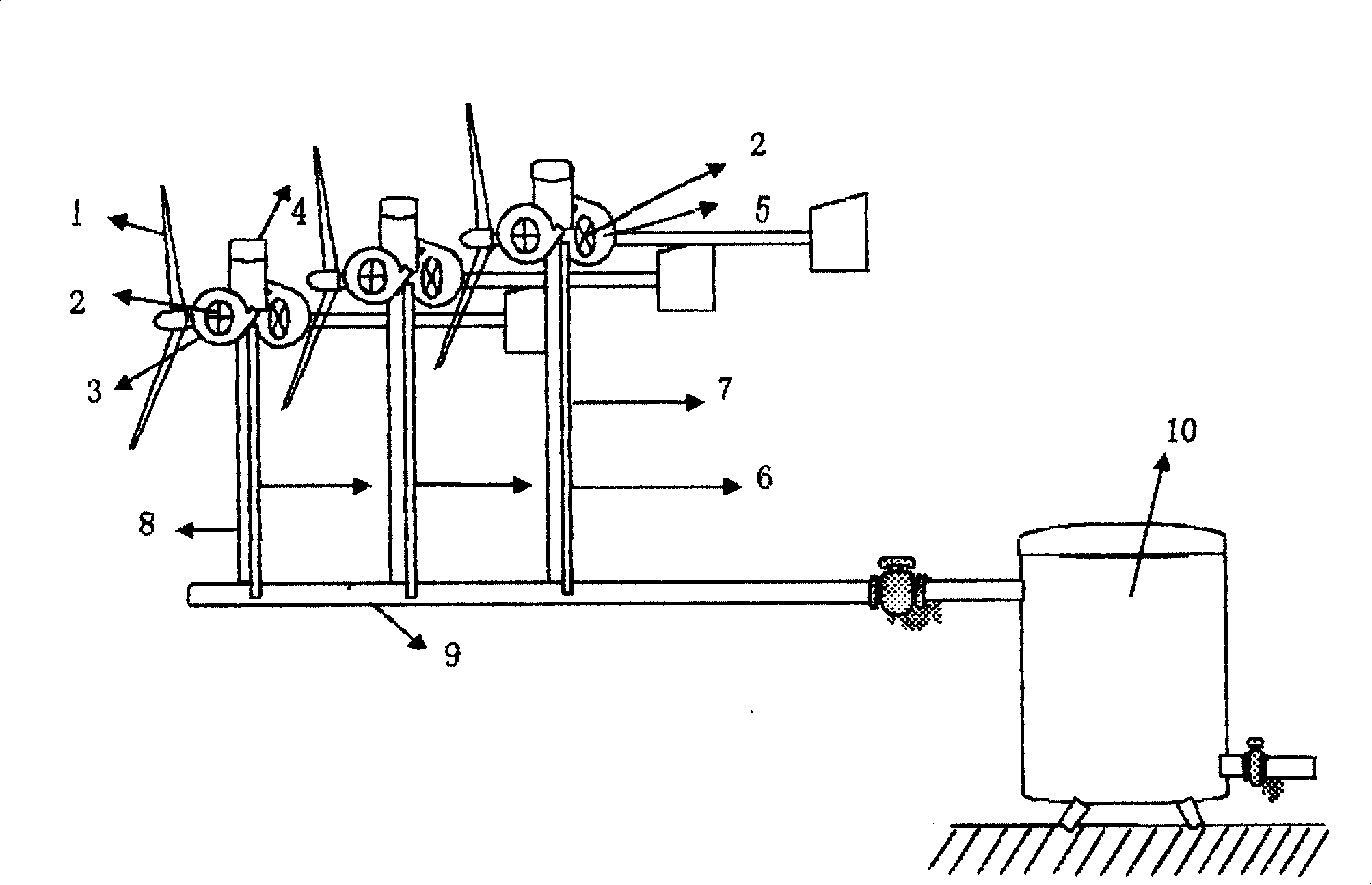

Method for preparing compressed air by pneumatic air compressor

InactiveCN101162073AIncrease productionImprove powerContainer filling under pressureElectricityAir compression

The invention relates to a preparation process for compressed air, in particular to a preparation process for compressed air, in which, a wind turbine sends the produced power to an air compression fan for air compression, then the compressed air is conveyed into a gas storage tank or directly conveyed to a pneumatic air compression fan of the user. The prior preparation process for compressed air mainly adopts that a motor is electrically driven in second energy conversion mode to produce the compressed air, which causes the vast waste of the energy during the conversion; wind is the never-ending renewable energy, and the compressed air produced by wind has no pollution to the environment and can be repeatedly used for a long time.

Owner:邸慧民

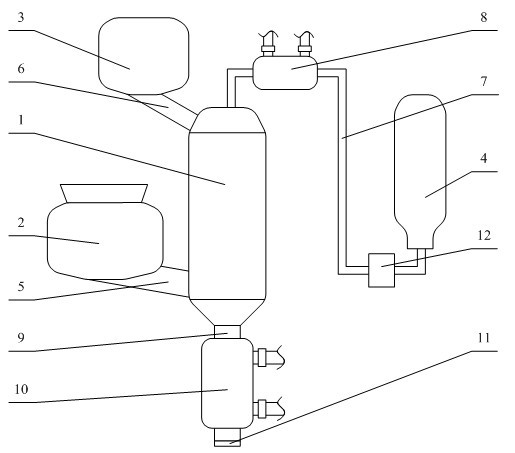

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

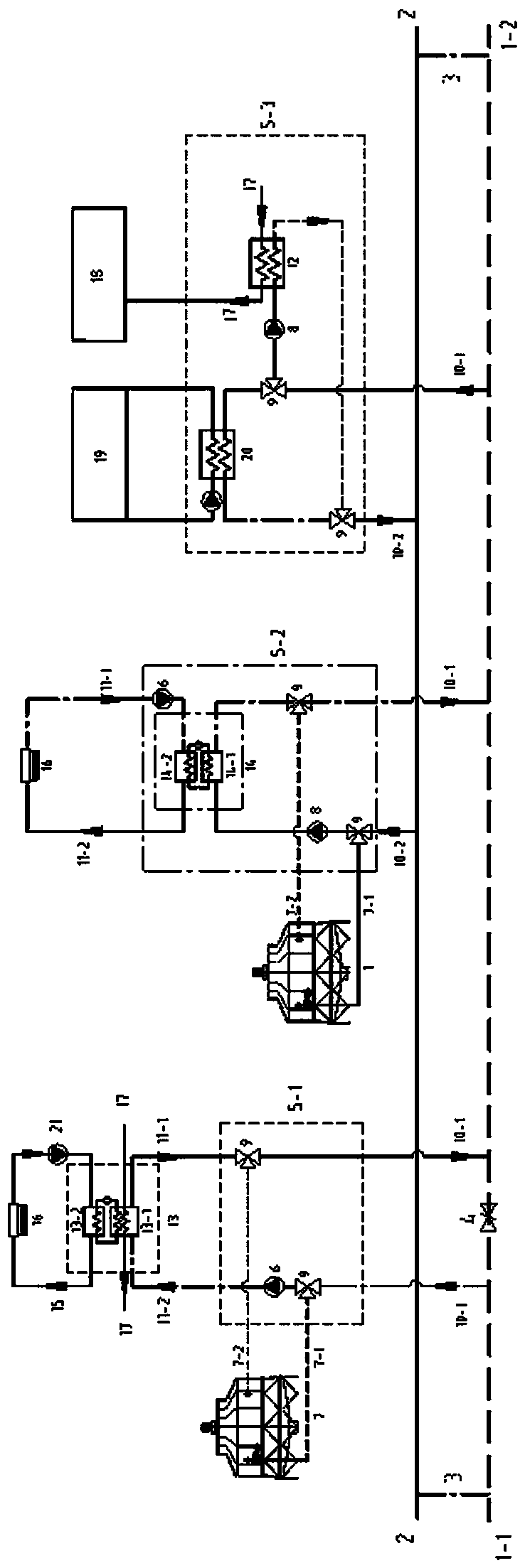

Coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and coupled power generation method thereof

InactiveCN105275515ARealize high-value utilizationReduce wasteIncreasing energy efficiencySteam engine plantsDevice formMain channel

The invention relates to a coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and a coupled power generation method thereof. The system comprises a dry-quenching waste-heat recycling device and the dry-quenching waste-heat recycling device comprises a dry-quenching furnace and a dry-quenching waste-heat boiler which are communicated with each other. A dry-quenching secondary superheater, a dry-quenching primary superheater, a first evaporator, a second evaporator, a coke oven flue-gas waste-heat superheater and a dry-quenching economizer are sequentially arranged in the dry-quenching waste-heat boiler. A coke oven flue-gas waste-heat recycling device comprises a coke oven. A coke oven flue-gas main channel is connected to the coke oven and sequentially connected with a coke oven flue-gas waste-heat economizer, a coke oven flue-gas waste-heat evaporator, a coke oven flue-gas draught fan and a coke oven flue-gas chimney. A steam turbine generator unit, the dry-quenching waste-heat recycling device and the coke oven flue-gas waste-heat recycling device form a loop through a condensing unit. According to the coke oven flue-gas waste-heat and dry-quenching waste-heat coupled power generation system and the coupled power generation method, coupled power generation is achieved in the manner that coking flue exhaust fume waste heat enters dry-quenching waste-heat power generation circulation in a coupled manner, and the purposes of efficient utilization of secondary energy and energy saving and emission reduction are achieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Chinese medicine residue-fermented feed and preparation method thereof

InactiveCN103385358ASolve pollutionReduce pollutionFood processingAnimal feeding stuffBiotechnologyTrichoderma koningii

The invention discloses a Chinese medicine residue-fermented feed and a preparation method thereof, relating to a solid waste fermentation composting treatment technology and belonging to the field of secondary energy. The preparation method of the Chinese medicine residue-fermented feed is characterized by comprising the steps: grinding Chinese medicine residues to be particle size of 5-10mm by adopting a grinder, mixing maize straws, vinegar yeast and the ground Chinese medicine residue chippings according to the mass ratio of 2:1:3 to form mixed materials; and adding trichoderma koningii for fermenting to obtain the Chinese medicine residue-fermented feed. The Chinese medicine residue-fermented feed has the beneficial effects that the most proper survival environment of the dominant bacterial community can be beneficially maintained by adopting anaerobic fermentation of the Chinese medicine residues, and the advantages of being short in fermentation period, improving the treatment efficiency and system running stability and the like can be achieved; the problem of environmental pollution caused by Chinese medicine residues is solved and clean energy resources can be recovered by inoculating the trichoderma koningii; the generated waste liquid quantity is less; the Chinese medicine residue-fermented feed can be used as humidity control and fermentation inoculants of feedstock; the post-treatment of waste liquid is not required; the Chinese medicine residue-fermented feed is small in environment pollution, complete in nutrition and suitable for household livestock.

Owner:ZHUANGLANG LUOYI PHARMA

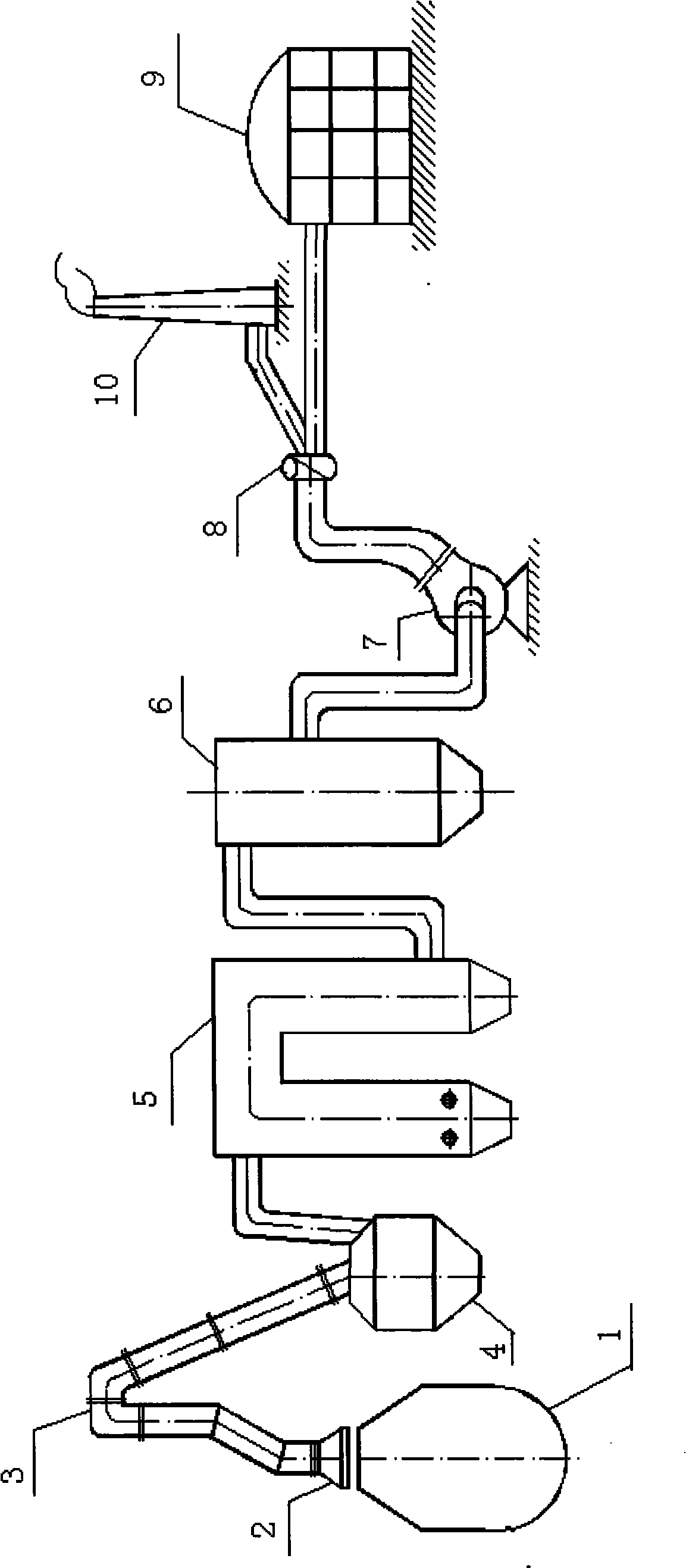

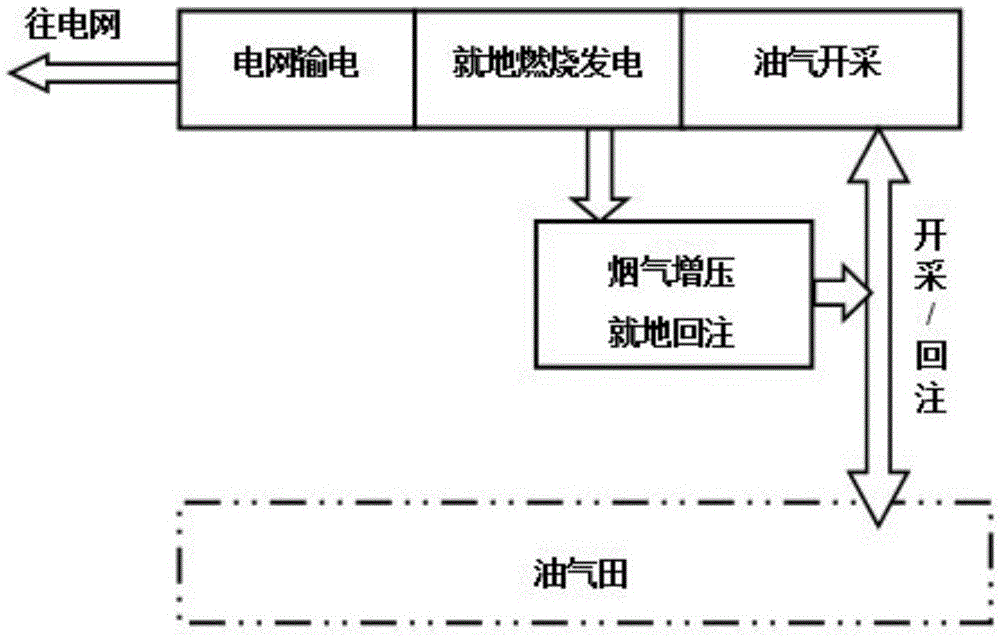

Carbon-emission-free combined oil gas power-generating method and device

InactiveCN105484705AEfficient use ofEliminate emissionsOther gas emission reduction technologiesFluid removalThermodynamicsProcess engineering

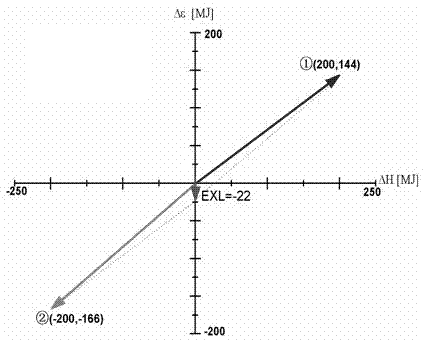

The invention relates to a carbon-emission-free oil gas power-generating method and device and provides a carbon-emission-free oil gas resource utilization mode for in-place oil gas exploitation, in-place combustion for power generation and in-place reinjection for sealed carbon dioxide storage and far-end electric energy utilization, namely a complete-flow large-scale CCS technology. The carbon-emission-free oil gas power-generating method and the device enable an oil gas exploitation source, a carbon emission source and a sealed storage source to have zero distance, accordingly eliminate carbon trapping, transportation and sealed storage links and overall additional carbon emission and enable primary energy to be free of carbon emission and to be converted into clean secondary energy. The carbon-emission-free oil gas power-generating method and the device have the advantages that large-scale emission reduction and safe sealed fossil fuel storage are achieved, produced carbon dioxide is utilized, meanwhile the actual exploitation quantity of oil gas resources is increased, a feasible way for carbon-emission-free clean fossil fuel utilization is opened compared with theoretical reserves, and a breakthrough clean energy solution is added for achieving the global climate purpose of 2 DEG C or even 1.5 DEG C.

Owner:彭斯干

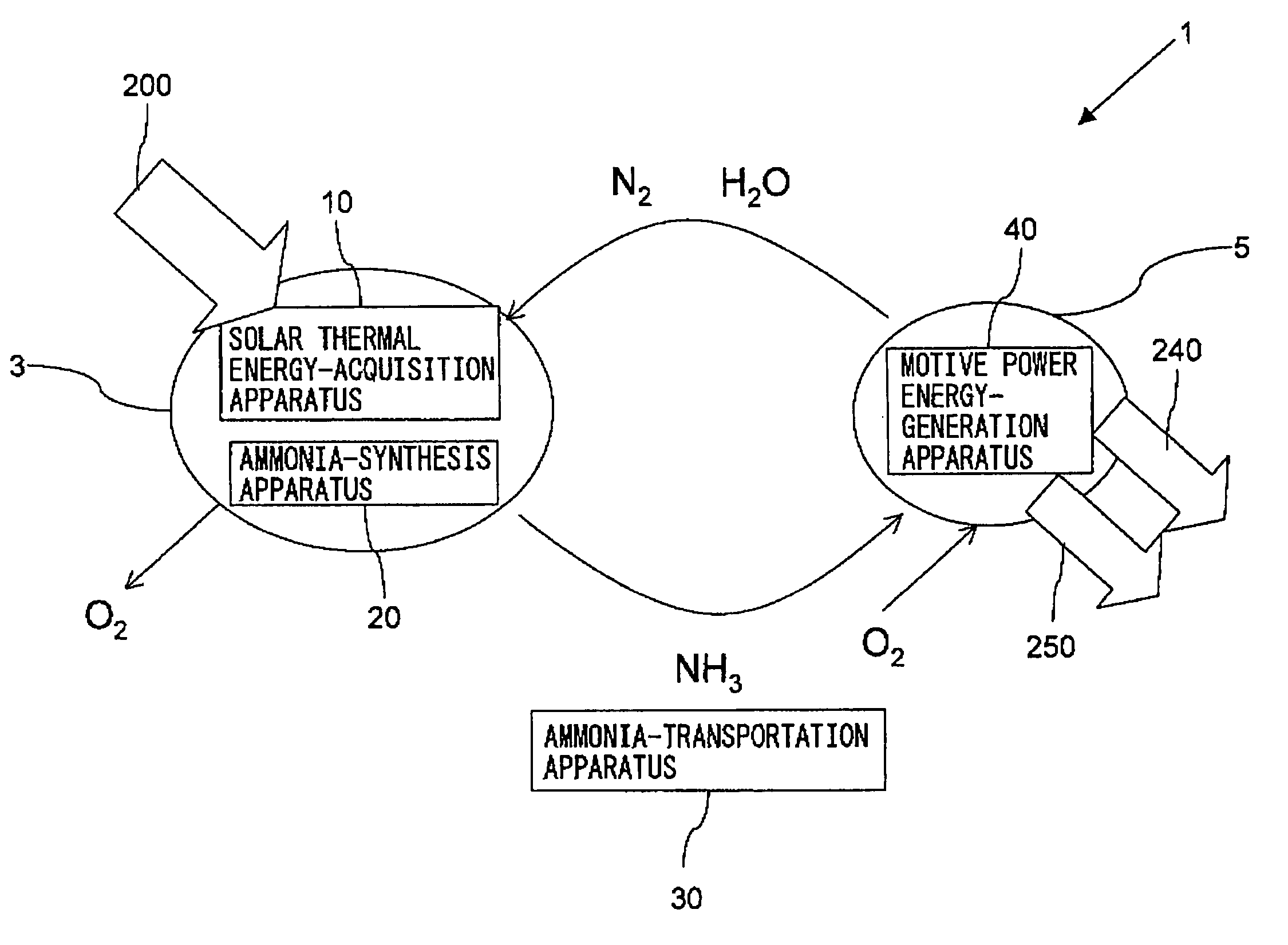

Method for converting solar thermal energy

[Subject]The subject is to provide a method of converting solar energy into the transportable and stockable secondary energy[Means for Solving the Problem]There is provided a method of converting solar thermal energy obtained in a first region into motive power energy used in a second region, the second region having a solar-radiation amount smaller than that of the first region, comprising: synthesizing ammonia from air and water by using, as an energy source; only the solar thermal energy acquired in the first region, transferring the ammonia from the first region to the second region; and, burning the ammonia in the second region such that nitrogen and water are produced, thereby obtaining motive power energy.

Owner:TOYOTA JIDOSHA KK

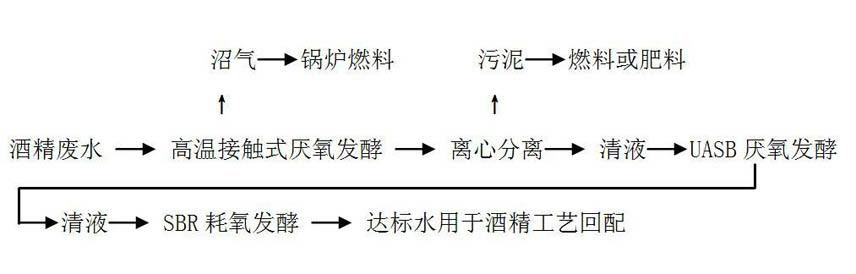

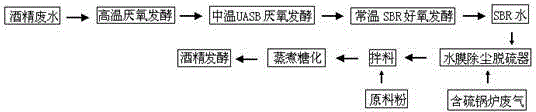

Method for treating waste water generated in production process of alcohol by fermenting

InactiveCN102320707AEmission reductionAvoid emissionsBio-organic fraction processingClimate change adaptationSequencing batch reactorAlcohol production

The invention discloses a method for treating waste water generated in the production process of alcohol by fermenting. The method comprises the following steps of: (1) performing high-temperature contact type anaerobic fermentation on the generated alcohol waste water; (2) performing centrifugal separation; (3) performing medium-temperature combined upflow anaerobic sludge blanket (UASB) anaerobic fermentation on the clear solution obtained through separation; (4) separating methane, sludge and clear solution from the waste water subjected to anaerobic fermentation under the action of a triphase separator on the upper part of an anaerobic fermentor; (5) performing sequencing batch reactor (SBR) normal-temperature oxygen-consuming fermentation on the clear solution obtained through separation in the step (4), settling again after fermentation, and separating out the clear solution; and (6) applying the clear solution obtained through separation in the step (5) to alcohol process recycle. In a 'waste water and waste treatment-resource comprehensive utilization' circular economy standardization system established by the invention, natural resources and secondary energy sources are utilized reasonably by comprehensively utilizing resources, saving energy, reducing consumption and saving water, so that the natural resources and the energy sources can be utilized most reasonably and discharge of wastes and pollutants can be reduced.

Owner:太仓意发石化矿材检测有限公司

Heat recycling system adopting centralized heat supply pipe network to transfer refrigeration waste heat in summer

InactiveCN109373551AMeet scattered and discontinuous heat demandImprove the level of comprehensive utilizationEnergy recovery in ventilation and heatingHeat recovery systemsCold airEngineering

The invention provides a heat recycling system adopting a centralized heat supply pipe network to transfer refrigeration waste heat in summer. The system comprises an urban centralized heat supply underground primary network water supply main pipeline and water return main pipeline, and a refrigeration unit of cold air users; the innovation made is that a central refrigeration waste heat recycle bin and / or a household refrigeration waste heat recycle bin, a consumption hot water heat exchange station, and a primary network branch pipeline connected with the waste heat recycle bin are arrangedalong a heat supply primary network. The system has the positive effects that the centralized heat supply primary network which is in the dormant state in the summer is recovered, and is used for conveying the collected heat extraction caused by refrigerating and converting the collected heat extraction into the required hot water in the area, so that all-weather energy storage and long-distance heat conveying can be achieved, and the requirement of the hot water users dispersing along the primary network is met. The utilization efficiency of the secondary energy is improved, and the single central refrigeration and the household refrigeration are changed into the large-scale regional cold-hot combined supply comprehensive utilization. The comprehensive utilization level on the refrigeration waste heat of the household along the primary network is improved, and the energy consumption for producing the hot water is reduced, and the system relieves the urban heat island effect caused byrefrigeration.

Owner:吉林天亮人工环境科技有限公司

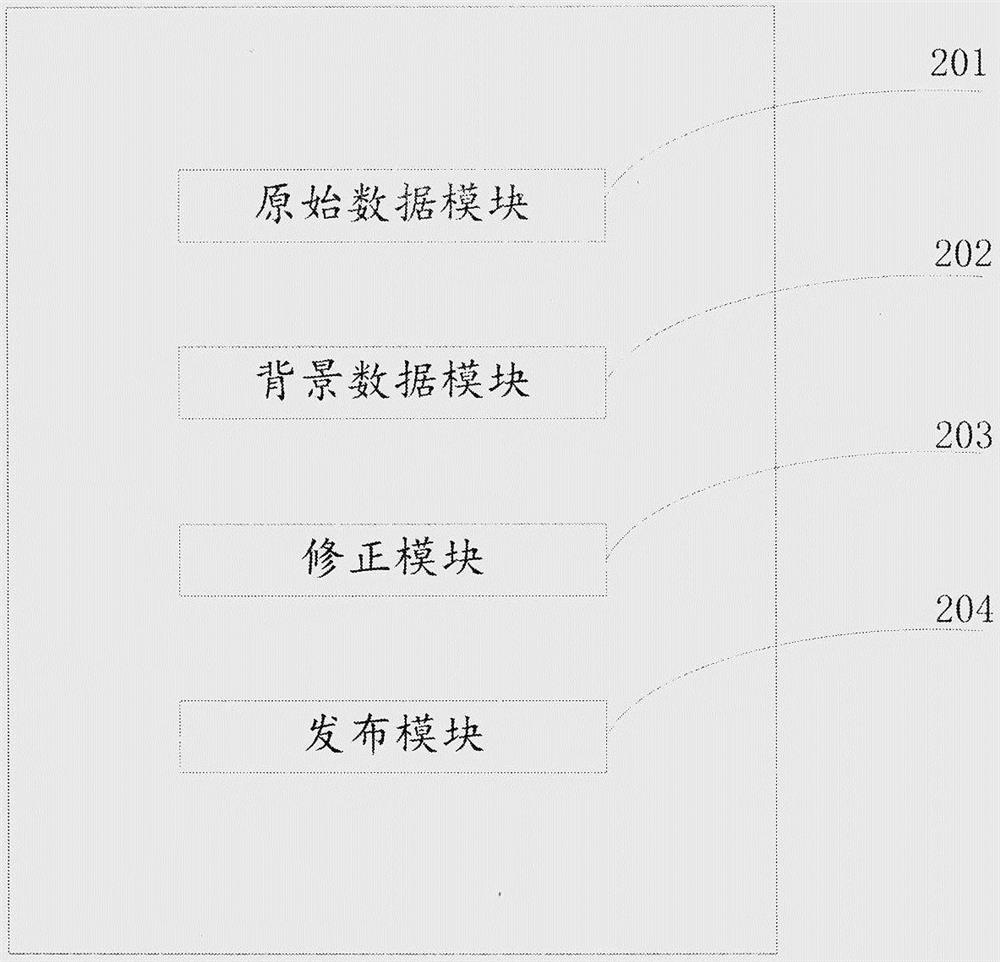

Environmental footprint assessment method and system for agricultural products

PendingCN113537425AThe solution is not easy to obtainSolve the problem of data deviationData processing applicationsCo-operative working arrangementsEnvironmental resource managementAgricultural engineering

An environmental footprint assessment method and system for agricultural products, and the method comprises the following steps: obtaining agricultural original activity data of a target area through an Internet of Things technology, the agricultural original activity data including direct natural resource consumption data, direct emission data, secondary energy consumption data and resource material consumption data; acquiring background environment data of the target area; and setting an initial LCIA model, and improving the LCIA model by using the background environment data to obtain an LCIA evaluation model. According to the application, the Internet of Things platform technology is utilized to solve the problem that agricultural production LCI list data is missing, especially the first-hand primary activity data is not easy to obtain, and particularly, various types of sensors are installed on the first site of agricultural production activities to collect first-hand LCI primary activity data; so that the problem of data deviation caused by the fact that the LCI data is based on the secondary data type at present is solved.

Owner:思藤(深圳)科技咨询有限公司

Method and device for recovering sensible heat of blast furnace slag

InactiveCN102050959AAvoid wastingSolve resource problemsChemical industryPlastic recyclingSlagProcess engineering

The invention provides a method for recovering sensible heat of blast furnace slag and a device for realizing the method. In the method for recovering sensible heat of blast furnace slag, sensible heat of blast furnace slag is recovered as chemical energy for pyrolytic reaction of a printed circuit board substrate, thereby avoiding wasting water resources; and thus, the invention has the advantage of high recovery rate of sensible heat of blast furnace slag, solves the problems of high consumption of water and low recovery rate of sensible heat in the existing water quenching treatment process for blast furnace slag, avoids the problem of secondary energy consumption in the pyrolytic treatment of the printed circuit board substrate, can be used for industrial treatment of printed circuit board substrate materials in electronic waste, and is beneficial to realizing energy saving and emission reduction. In addition, the obtained gas products and solid residues can be further utilized, and thus, the product utilization ratio is high. The device for recovering sensible heat of blast furnace slag comprises a pyrolyzing furnace, a dry-type granulating device, a powder container and a gas collection container. The device for recovering sensible heat of blast furnace slag has the advantage of simple structure, is easy to operate and is suitable for industrial application.

Owner:重庆飞耀电炉有限公司

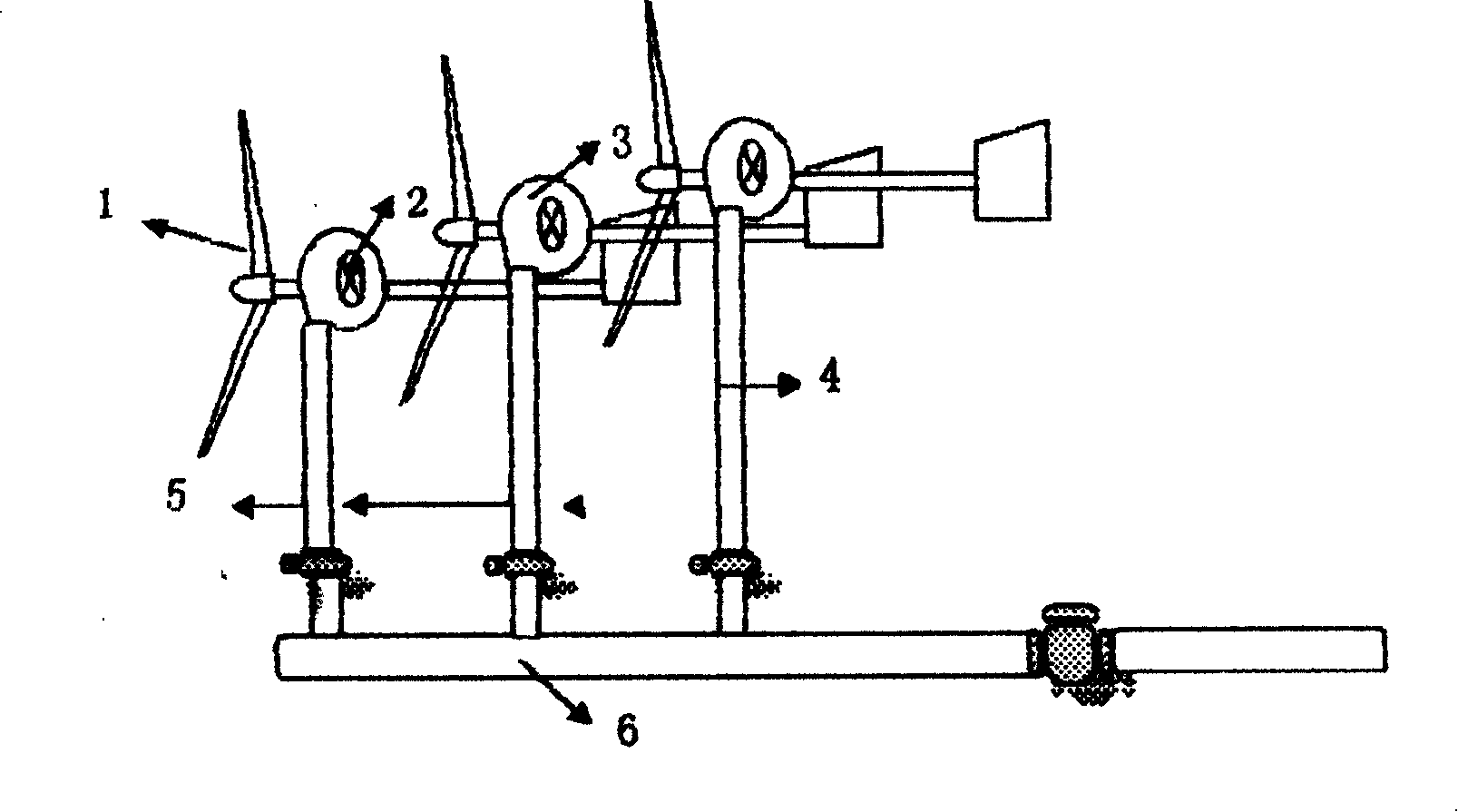

Wind power compressed air energy sources application net system method

InactiveCN101349248ALow costReduced stabilityWind energy with garvitational potential energyEnergy storageElectricityNew energy

The invention relates to a method of an application net system of wind compressed air energy, which is composed of a production and storage system of wind compressed air energy, an air duct network of wind compressed air energy and a subscriber tube network system of wind compressed air energy. Compressed air as a superior energy has the features of flexibility and softness which are not found in other energies. The aim of utilizing primary wind energy in production of compressed air energy is to get rid of dependence on secondary energies such as electricity and the like, and the compressed air energy is enabled to be a clean low-price independent energy. Wind power is of much randomness, which can vary constantly along with different times, seasons, spaces and areas, so the utilization of wind power relies on weather usually. The invention utilizes the systematic method to resolve the problem that the wind power varies easily in space-time randomness so as to result in unstable power production and supply. The method of the invention is placed to develop a safe, stable and low-price novel energy on a large scale.

Owner:邸慧民

Automobile tire recovery processing method

An automobile tire recovery processing method mainly comprises the steps of: crushing a decontaminated automobile tire into strips with end surface area of less than 50mm<2>, carrying out thermal pyrolysis on the strip-shaped rubber in a special thermal pyrolyzer at the temperature of 450-500 DEG C under the state of negative pressure of 0.05-0.07MPa for 10-15 minutes, carrying out gas and oil recovery and separation through a condenser, wherein the primary fuel adopted for pyrolysis is coal, after combustible gas generated in continuous running of the pyrolyzer can entirely return back to the bottom of the pyrolyzer as a secondary energy resource for pyrolysis and heating so as to replace a part of primary energy resource; and removing metal parts by adopting an electromagnet to obtain carbon black of 700-900 meshes. The automobile tire recovery processing method has the advantages that the process flow is high, the effluent oil quality and oil extraction rate are high, the calorific value of the recovered industrial fuel oil is far higher than that of natural gas, liquefied gas and other fuels, so that the recovered industrial fuel oil is extremely good high-performance liquid fuel, and the automobile tire recovery processing method is the most environment-friendly processing mode with highest economic benefits.

Owner:STATE GRID CORP OF CHINA +1

Method for utilizing boiler waste gas in fermentation alcohol production

InactiveCN104998529AEmission reductionAchieve recyclingUsing liquid separation agentMultistage water/sewage treatmentWater savingAlcohol production

The invention provides a method for utilizing boiler waste gas in fermentation alcohol production. The method comprises the following steps that alcohol waste water is treated, the boiler waste gas with sulphur is enriched, and SBR water is acidized; the SBR water is blended, and the blended water is used for an alcohol fermentation process. A circular economy standardization system of waste gas and waste water treatment resource comprehensive utilization is built, natural resources and secondary energy are utilized reasonably through comprehensive utilization of resources, energy saving, consumption reducing and water saving, most rationalization of utilization of natural resources and energy is achieved, and emissions of waste and pollutant are reduced.

Owner:太仓意发石化矿材检测有限公司

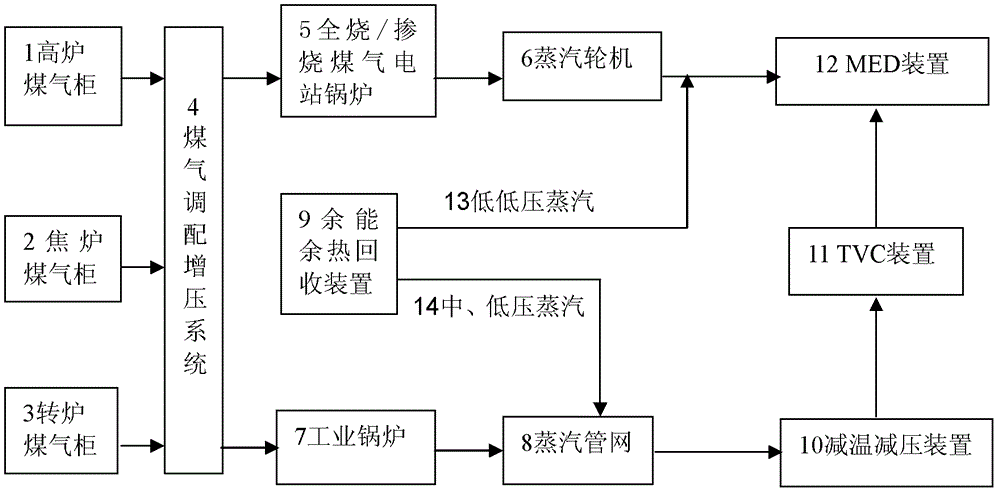

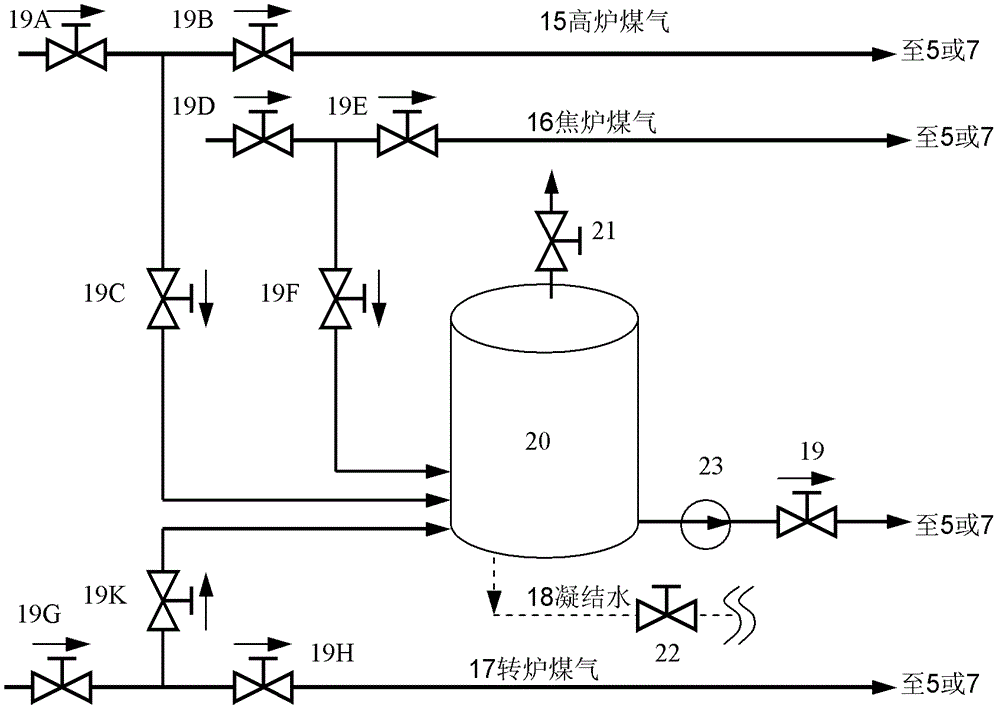

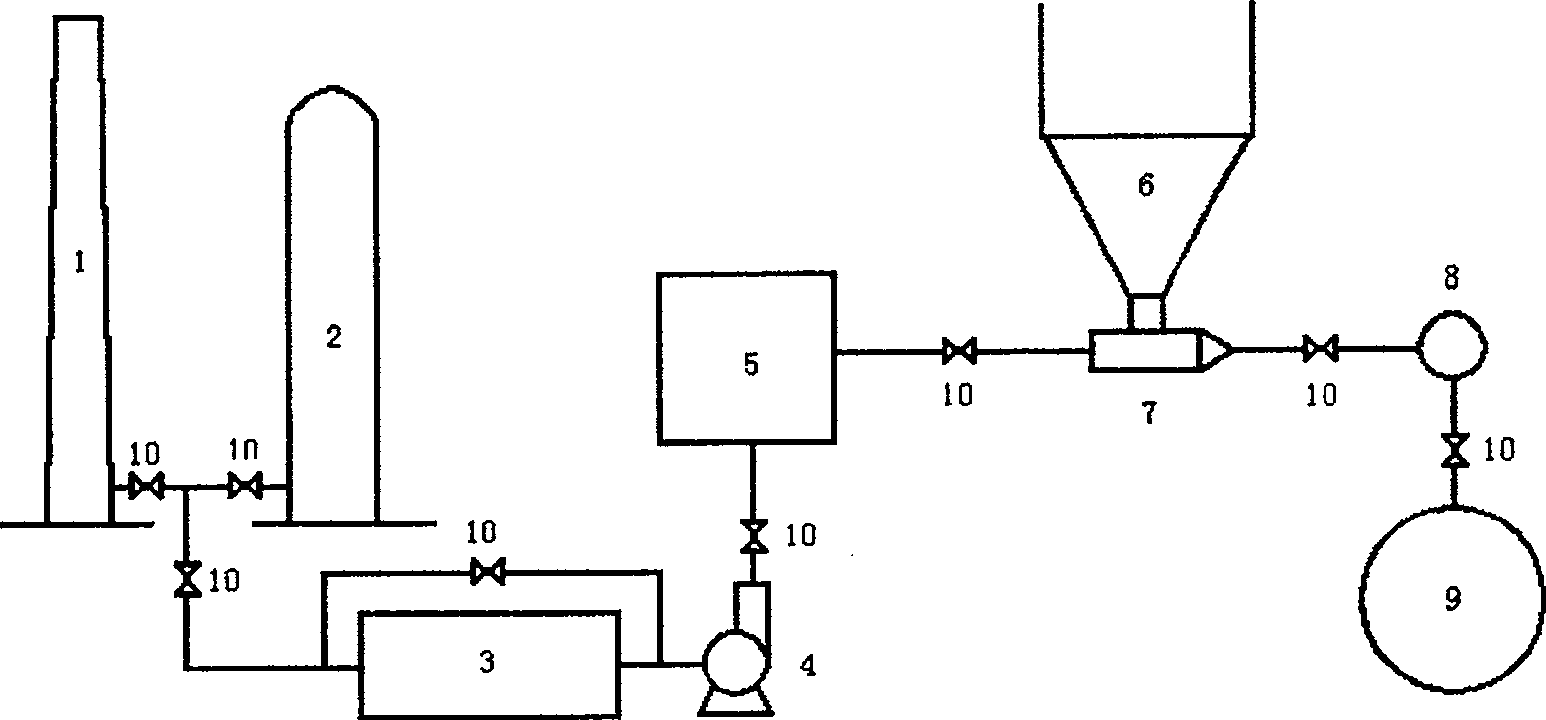

System and process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination

ActiveCN102502903BImprove utilization efficiencyGuaranteed zero emissionsGeneral water supply conservationSeawater treatmentEnergy conservationSecondary Energy Resource

The invention discloses a system and a process for realizing zero discharge of gas and steam in iron and steel plants by adopting seawater desalination, which belongs to the technical field of secondary energy comprehensive utilization in iron and steel plants, and particularly relates to converting gas and steam into water resource through low-temperature and multiple-effect seawater desalination. The system comprises a blast furnace gas holder, a coke oven gas holder, a converter gas holder, a gas distributing and pressurizing system, a pure combustion / blending combustion gas station boiler, a steam turbine, an industrial boiler, a steam pipe network, a complementary-energy waste-heat recovery device, a temperature and pressure reduction device, a TVC (thermal vapor compressor) device and an MED (multi-effect distillation) device. Residual gas which can not be consumed in production process of the iron and steel plants is used for a pure combustion / blending combustion gas boiler and / or the industrial boiler, and steam is produced through combustion, which is used in preparing desalinated water through the MED device with steam recovered in the iron and steel plants on the premise of reasonable classification. Compared with the prior art, the system and the process can ultimately recover gas and steam in the iron and steel plants, have good economic effects, and are applicable to the energy conservation and emission reduction of coastal iron and steel plants.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD +1

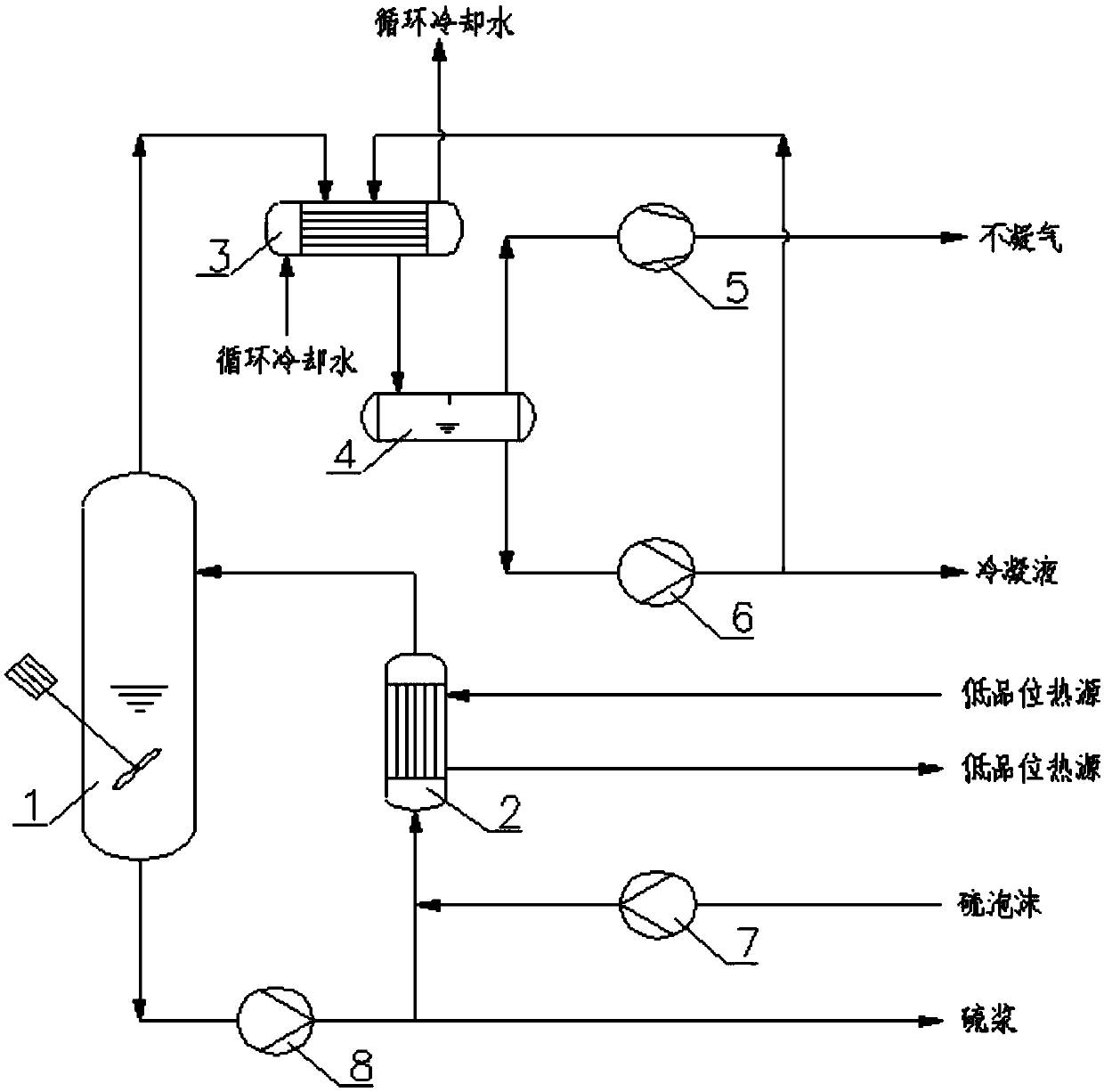

Technology and device for preparing sulfur pulp by performing vacuum evaporation treatment on coked sulfur foams

PendingCN109534299ASimple processSave construction investmentSulfur compoundsEnergy inputProcess engineeringVacuum evaporation

The invention relates to a technology and a device for preparing sulfur pulp by performing vacuum evaporation treatment on coked sulfur foams. A vacuum evaporation technology and a low-grade heat source for heating treatment are adopted for treating the coked sulfur foams, so as to prepare sulfur pulp. Compared with the prior art, the invention has the beneficial effects: 1) process flow is simple, construction investment is less and operation cost is low; 2) development and utilization of low-grade residual heat source as secondary energy are realized, energy utilization rate is increased, environmental pollution caused by heat discharge is reduced and energy-saving and emission-reducing effects are excellent; 3) temperature of low-grade heat source is lower than a melting point of sulfur, so that suspending sulfur in sulfur foams is prevented from melting and consequently attaching to heat exchange tubes and reducing heat exchange efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

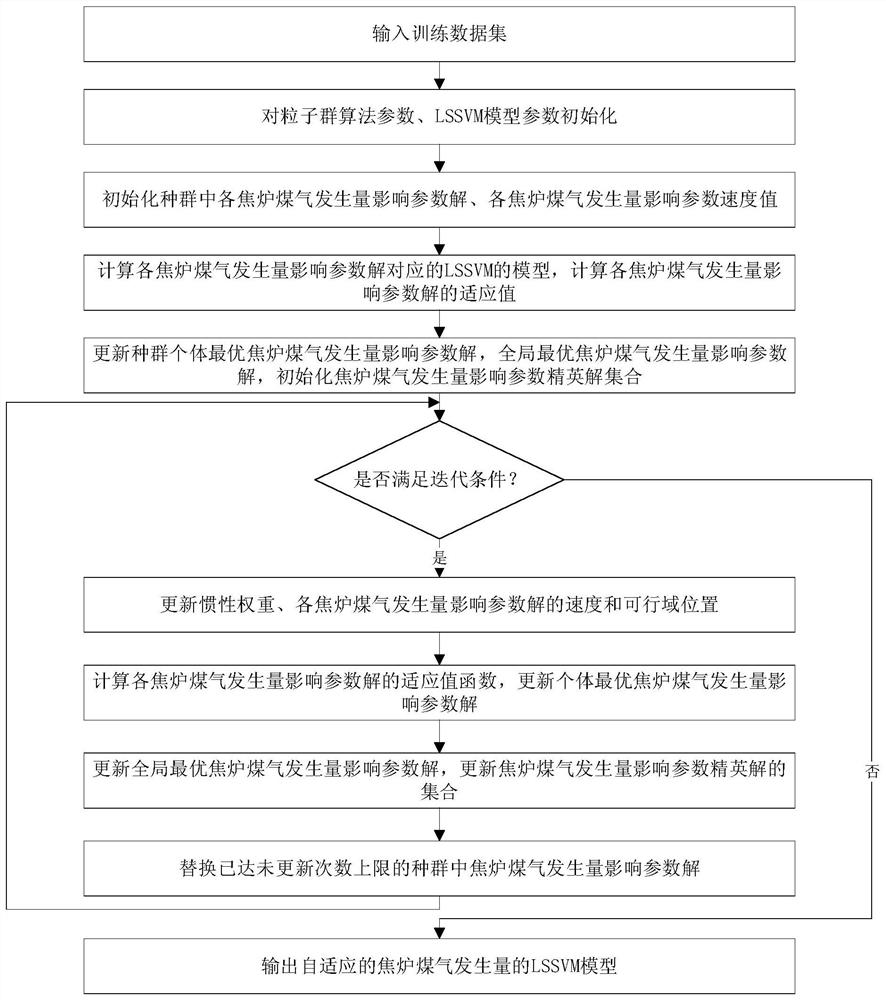

Self-adaptive multi-working-condition steel secondary energy generation amount dynamic prediction method

PendingCN112541625AReduce energy costsReduce computing timeKernel methodsForecastingData setAdaptive learning

The invention provides a self-adaptive multi-working-condition steel secondary energy generation amount dynamic prediction method, and relates to the technical field of steel energy prediction. The method comprises the following steps: acquiring coke oven gas generation amount historical data under multiple working conditions, setting a coke oven gas generation amount data preprocessing time interval, reading system clock data, preprocessing the acquired coke oven gas generation amount data, and dividing a multi-working-condition data set; setting particle swarm optimization method parametersand least square support vector machine parameters, initializing the parameters, fitting coke oven gas generation amount prediction model parameters in time series data by utilizing an intelligent method, and identifying working conditions to finish coke oven gas generation amount prediction. Stable, reliable and accurate coke oven gas dynamic multi-working-condition prediction application is realized, prediction model parameters can be learned adaptively, and scientific data support is provided for energy management personnel to make a gas scheduling plan, so that energy diffusion is reduced,refined utilization is improved, production supply is stabilized, and energy cost is reduced.

Owner:NORTHEASTERN UNIV

Distributed energy management system management method and device

PendingCN112383083AIncrease the proportionOptimize resource distributionData processing applicationsLighting and heating apparatusIndustrial engineeringSupply energy

The invention relates to the technical field of distributed energy, in particular to a distributed energy management system management method and equipment, and the equipment comprises a primary energy supply end, distribution equipment and a secondary energy supply end. By collecting the ratio of the total energy consumption and the energy consumption type of the second energy supply end of the user end, the energy composition from the first energy end is changed, so non-renewable energy sources such as fossil fuel are reduced as much as possible, the proportion of clean renewable energy sources is larger, the resource distribution of the distributed energy system is optimized, and the resource utilization efficiency is improved.

Owner:中机碳中和研究院无锡有限公司

Reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method

InactiveCN111623641AAchieve recyclabilityIncrease waste heatIncreasing energy efficiencySteam generation using hot heat carriersFlue gasProcess engineering

The invention discloses a reducing roasting flue gas and roasting finished product waste heat comprehensive recovery device and method. The device comprises a reducing roasting rotary kiln, a heat exchange rotary cylinder, a flue gas waste heat boiler and a flue gas post-processing system, wherein the heat exchange rotary cylinder is arranged obliquely, the front end of a cylinder body is higher than the rear end of the cylinder body, the front end of the cylinder body communicates with a discharge port of a kiln head of the reducing roasting rotary kiln, the rear end of the cylinder body communicates with a kiln tail flue gas outlet of the reducing roasting rotary kiln, the communication is used for reducing roasting low-temperature flue gas and a high-temperature roasting product for heat exchanging in the cylinder, the flue gas waste heat boiler communicates with the front end of the heat exchange rotary cylinder body and is used for producing steam by using the waste heat of flue gas, and the flue gas post-processing system communicates with the flue gas waste heat boiler and is used for removing dust and cooling. The device and the method comprehensively recover the reductionroasting low-temperature flue gas waste heat and the roasted finished product waste heat to produce the steam, the steam can be used for subsequent power generation, heating in the production processor domestic heating, and the purposes of effective recovery of secondary energy, energy saving and emission reduction are achieved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

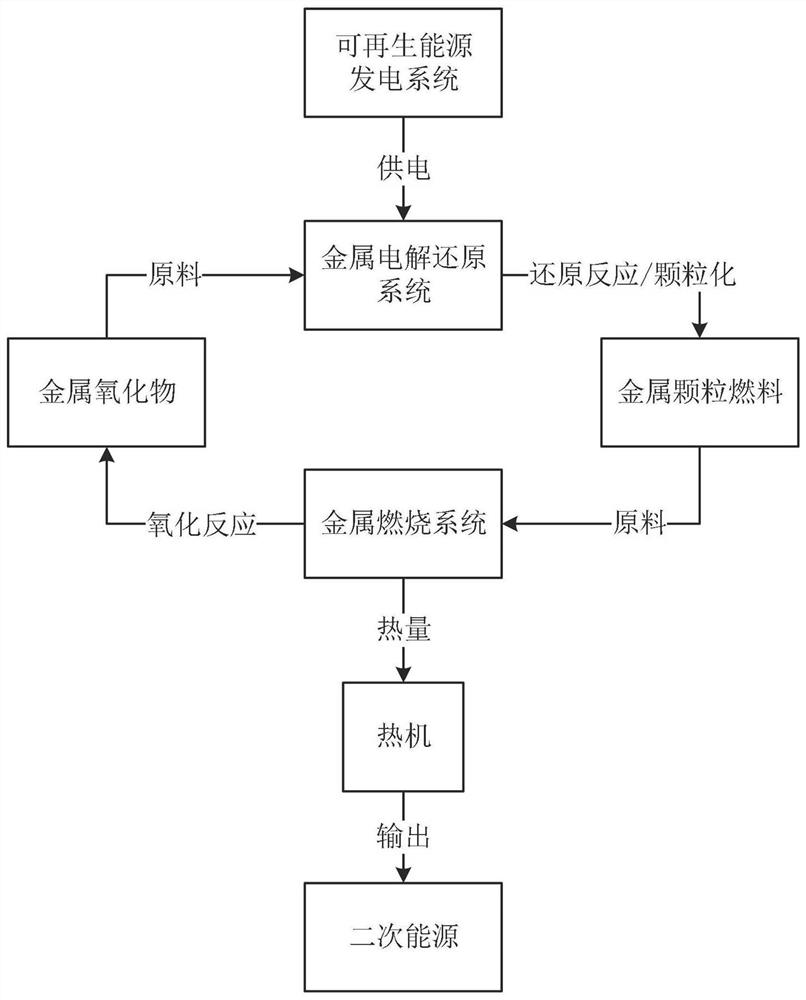

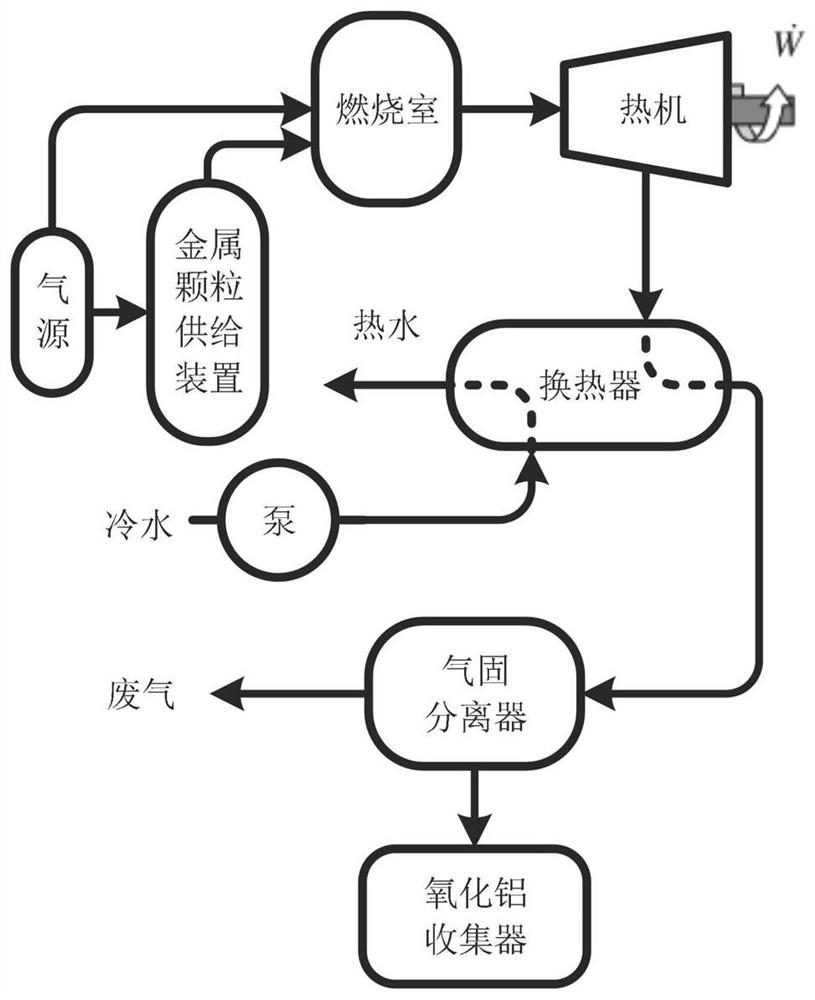

Metal fuel-based zero-carbon emission energy conversion system

PendingCN111853762AAchieve recyclabilityAchieve emissionsFluidized bed combustionIndirect carbon-dioxide mitigationElectrolysisEngineering

The invention discloses a metal fuel-based zero-carbon emission energy conversion system. The metal fuel-based zero-carbon emission energy conversion system comprises a metal particle supply device, agas source, a metal combustion system, a metal electrolytic reduction system and a heat engine, and is characterized in that the metal particle supply device is used for conveying metal fuel particles to the metal combustion system to be combusted with an oxidant conveyed by the gas source to generate oxidation reaction, heat generated by the oxidation reaction is converted into secondary energythrough the heat engine, solid metal oxide generated in the oxidation reaction is conveyed to the metal electrolytic reduction system to be subjected to the reduction reaction, and metal generated after the reduction reaction is treated into metal fuel particles and then conveyed to the metal combustion system again through the metal particle supply device, so that recycling of the metal fuel is realized. Compared with traditional thermal power generation, the metal fuel does not generate any toxic substance or greenhouse gas during combustion, and according to experimental measurement, the carbon emission level is 7 g / kW.h and is only 0.67% of that of coal-fired power generation. The purposes of zero carbon emission and stable combustion power supply are achieved.

Owner:NAT UNIV OF DEFENSE TECH

Method for activating land and recycling garbage in landfill

InactiveCN111215425AHigh resource recycling valueGood benefitWaste processingSolid waste disposalMicroorganismDecomposition

The invention relates to a method for activating land and recycling garbage in a landfill. According to the method, the landfill is deodorized by microbial bacteria first and then excavated, the excavated garbage is directly crushed, and the crushed garbage is preliminarily screened into combustible materials and incombustible materials, specifically, the screened combustible materials are furtherscreened by a wet construction method, the screened combustible materials are subjected to compression and coating operation, the combustible materials can be subjected to cracking processing througha cracking device and a subcritical water decomposition device to respectively prepare secondary plastics and secondary energy sources, and thus higher resource recycling value is achieved; the incombustible materials are backfilled in the landfill or are recycled; therefore, the original land of the landfill is regenerated and activated, the garbage is recycled, and then good economic benefits and green energy environmental protection effects are produced.

Owner:厦门德星绿色环境科技有限公司

Primary combustion auxiliary heating electric arc furnace steelmaking equipment and method

PendingCN113699308AReduce burning lossRaise the furnace temperatureExhaust gas handlingElectric furnaceSteelmakingElectric arc furnace

The invention discloses primary combustion auxiliary heating electric arc furnace steelmaking equipment and method, and belongs to the technical field of metallurgy. Primary energy combustion added in an electric arc furnace is selected to supplement heat energy, the primary energy is adopted to replace secondary energy so as to obtain a larger carbon reduction benefit, and through equipment improvement, scrap steel discharging and flue gas entering a shaft furnace to pass in different channels. Smoke does not flow through the scrap steel discharging channel, and the smoke enters the shaft furnace independently through the flue. In order to uniformly distribute gas, the shaft furnace enters the furnace by adopting a plurality of branch pipes of an annular flue. The technical problems that due to the fact that a smoke inlet channel and a waste steel discharging channel are shared in traditional waste steel heating, the bearing temperature of a first-layer mechanical arm is high, materials are difficult to select, potential safety hazards are caused by water cooling, and mechanical arm bonding is likely to be caused by waste steel melting are solved. The effects of emission reduction and cost reduction are comprehensively achieved, the burning loss of steel and iron materials is reduced, and meanwhile it is guaranteed that all flue gas emission reaches the standard.

Owner:SHENYANG DONGDASHANHUI ENVIRONMENTAL TECH CO LTD

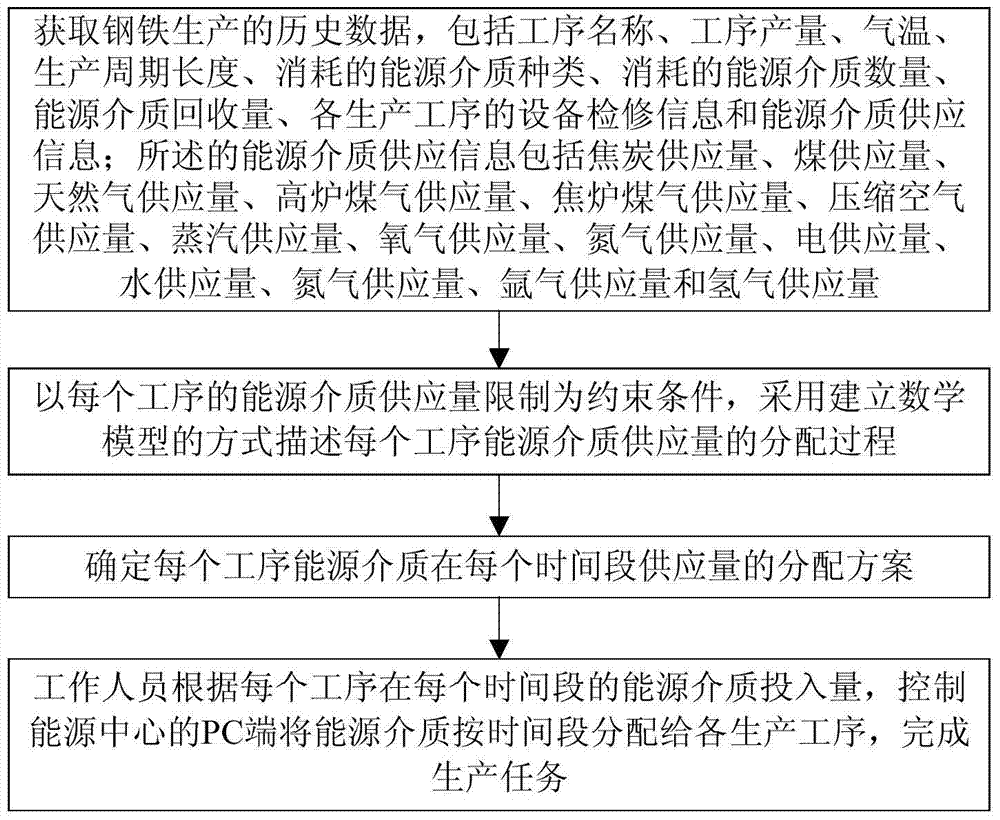

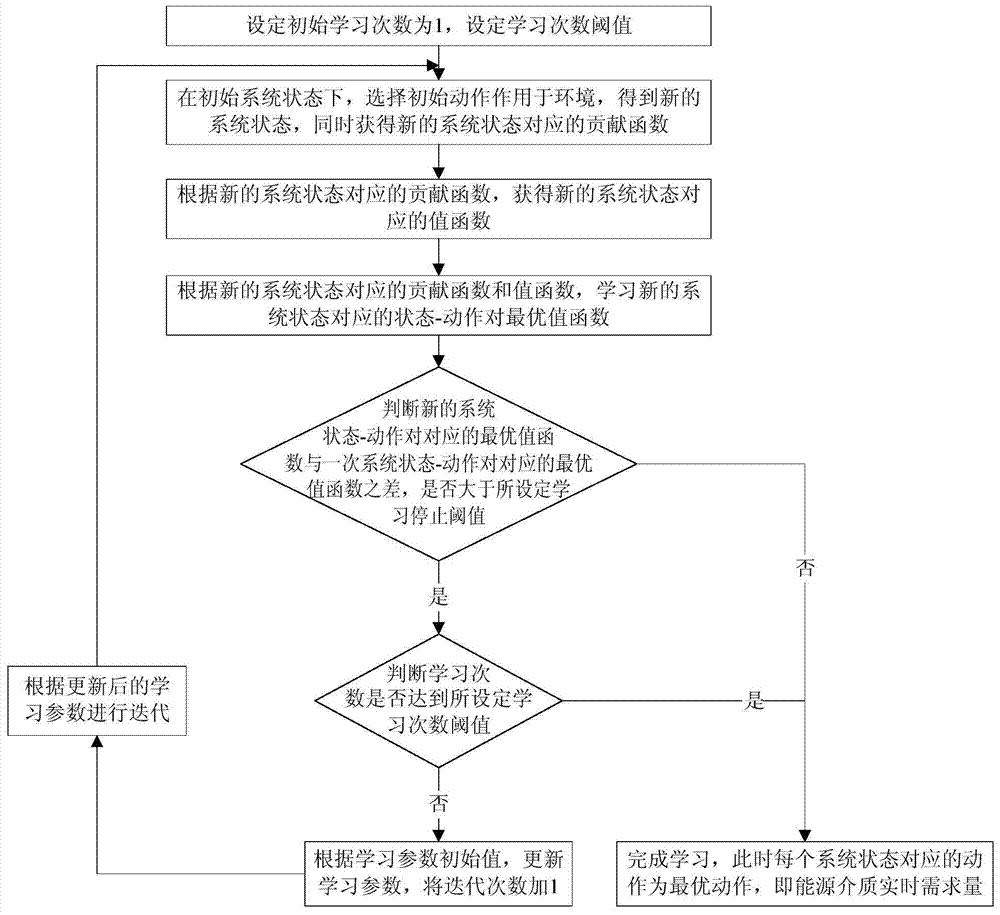

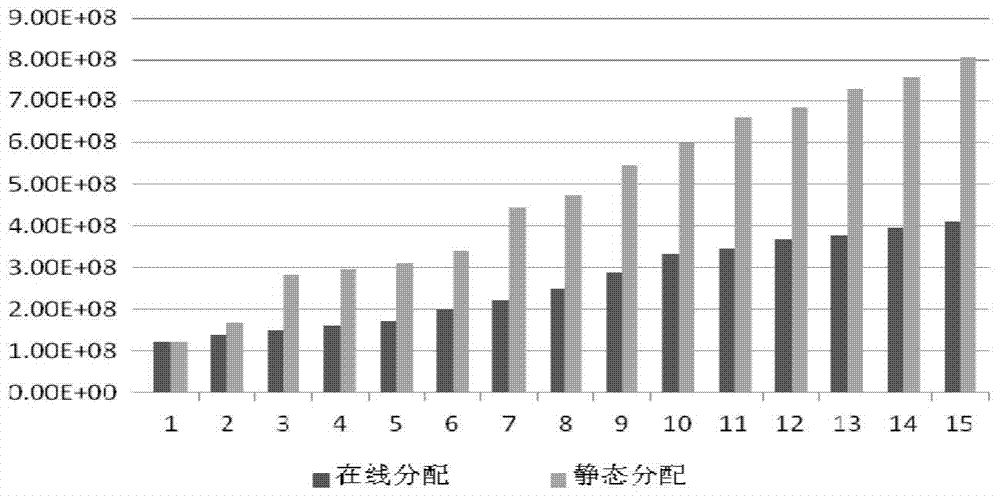

An Online Energy Distribution Control Method for Improving Iron and Steel Energy Utilization

ActiveCN104977911BIncrease profitReduce consumptionEnergy industryTotal factory controlEnergy controlMathematical model

The present invention is an online energy distribution control method for improving steel energy utilization, which belongs to the field of information technology. The present invention first obtains historical data of steel production, and uses the method of establishing a mathematical model to describe the distribution process of energy medium input in each process. Secondly, Determine the distribution plan for the input amount of energy media in each process in each time period. Finally, the staff controls the PC end of the energy center to allocate the energy media to each production process according to time periods to complete the production tasks; the present invention takes into account the impact of emergency orders. Add in the real-time changes in production status caused by factors such as the operating status of equipment and differences in workers' operating levels, as well as the consumption of primary energy and the generation of secondary energy in production, closely track real-time changes in the production environment, and achieve efficient use of energy. It improves energy utilization, reduces energy consumption, reduces emissions, reduces energy outsourcing costs and inventory costs, and ultimately reduces overall production costs.

Owner:NORTHEASTERN UNIV LIAONING

Method and device for recovering sensible heat of blast furnace slag

InactiveCN102050959BAvoid wastingAvoid secondary energy consumption problemsChemical industryPlastic recyclingSlagProcess engineering

The invention provides a method for recovering sensible heat of blast furnace slag and a device for realizing the method. In the method for recovering sensible heat of blast furnace slag, sensible heat of blast furnace slag is recovered as chemical energy for pyrolytic reaction of a printed circuit board substrate, thereby avoiding wasting water resources; and thus, the invention has the advantage of high recovery rate of sensible heat of blast furnace slag, solves the problems of high consumption of water and low recovery rate of sensible heat in the existing water quenching treatment process for blast furnace slag, avoids the problem of secondary energy consumption in the pyrolytic treatment of the printed circuit board substrate, can be used for industrial treatment of printed circuit board substrate materials in electronic waste, and is beneficial to realizing energy saving and emission reduction. In addition, the obtained gas products and solid residues can be further utilized, and thus, the product utilization ratio is high. The device for recovering sensible heat of blast furnace slag comprises a pyrolyzing furnace, a dry-type granulating device, a powder container and a gas collection container. The device for recovering sensible heat of blast furnace slag has the advantage of simple structure, is easy to operate and is suitable for industrial application.

Owner:重庆飞耀电炉有限公司

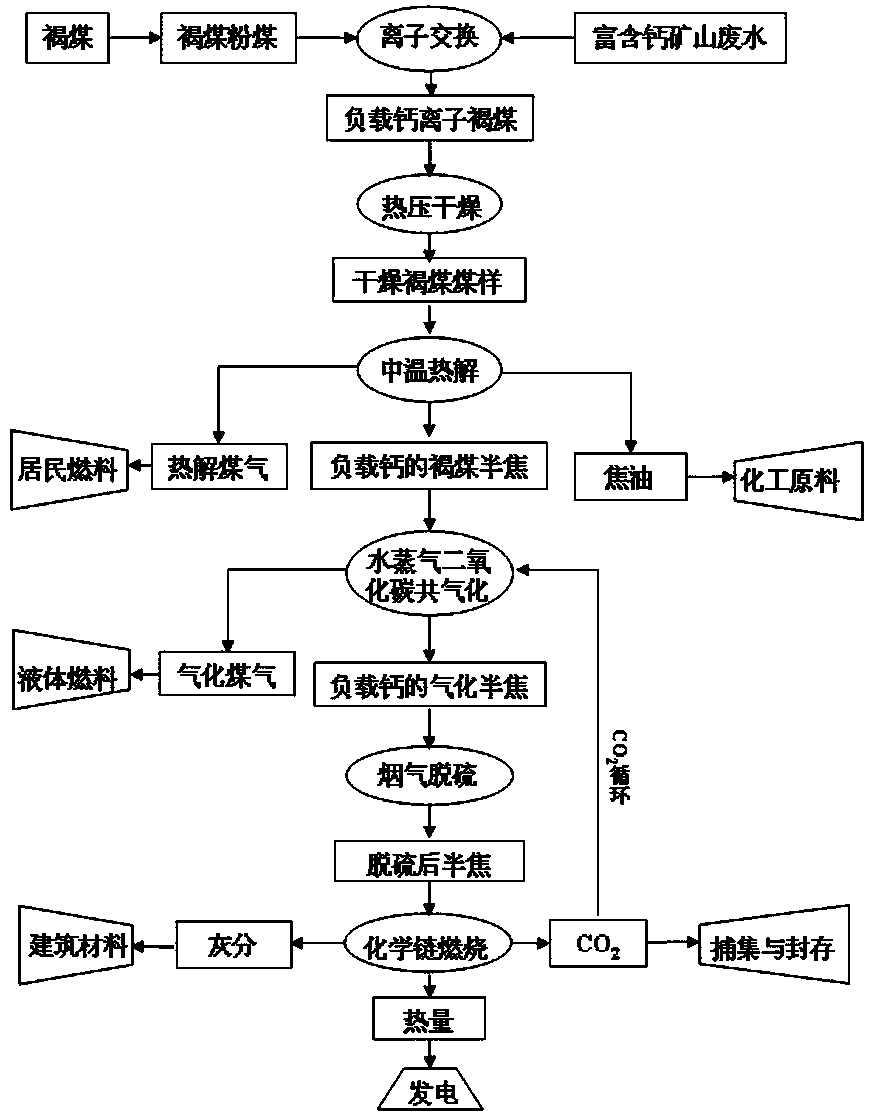

Method for efficient resource utilization of lignite

ActiveCN108285799AEfficient use ofPromote conversionLiquid hydrocarbon mixture productionSpecial form destructive distillationIon exchangeChemical products

The invention relates to a method for efficient resource utilization of lignite. The method includes the steps that ion exchange of lignite with mine wastewater containing calcium ions is performed, medium-temperature pyrolysis is performed on the lignite loaded with the calcium ions to obtain pyrolysis semi-coke, water vapor and CO2 are used for co-gasification activation of the pyrolysis semi-coke, the semi-coke loaded with calcium after gasification is obtained and used for flue gas desulfurization, the vulcanized semi-coke is obtained for chemical chain combustion to obtain heat in the semi-coke, and generated CO2 is partially returned to the co-gasification activation step for recycling. According to the method, various coal chemical technologies such as pyrolysis, gasification, fluegas desulfurization and chemical chain combustion are integrated, secondary energy and various chemical products are obtained, efficient grading and resource utilization of the lignite are achieved, the carbon discharge amount in the utilization process of the lignite are decreased, and effective utilization of the calcium ions in the mine wastewater is achieved.

Owner:TAIYUAN UNIV OF TECH

Blast-furnace coal powder injection method using waste gas of hot-blast stove flue as carrier

InactiveCN100489393CAvoid large emissionsReduce pollutionLump/pulverulent fuel feeder/distributionEngineeringAir compressor

The invention provides a blast furnace coal spraying method using flue gas of hot-air furnace, concretely using induced draft fan to draw the flue gas of hot-air furnace through special pipeline and control valve out of the flue, cooling by heat exchanger to enter air compressor, after compression, using coal feeder to blow the pulverized coal inputted by blowing tank to distributor, and thus spraying the pulverized coal into the blast furnace from each tuyere. And it implements waste gas utilization, saving primary energy sources; and helps indirect reduction reaction in furnace, so that secondary energy sources can be utilized; besides, largely avoids waste gas CO2 exhaust, reducing atmospheric pollution; can preheat pulverized coal, increasing combustion speed; and has the same system safety as N2 carrier, especially suitable for large scale blast furnace applications and having extremely remarkable energy saving and environmental protection effects.

Owner:ANGANG STEEL CO LTD

Cascade recovery and utilization method of flue gas waste heat of domestic waste incineration boiler

ActiveCN114165794BSave conversionsEmission reductionCombustion technology mitigationIncinerator apparatusCooling towerPower station

The invention discloses a method for cascaded recovery and utilization of flue gas waste heat of domestic waste incineration boilers, which solves the problem of how to deeply recycle the waste heat of flue gas in existing domestic waste incineration power plants. The flue gas-water heat exchanger and the gas-water direct contact heat exchanger are used to reduce the temperature of the high-temperature and high-humidity flue gas discharged from the flue gas purification system of the domestic waste incineration boiler through two steps of heat exchange, so that the temperature of the flue gas is reduced from 140°C-150°C is reduced to 20°C-30°C; the external circulation water heat exchange closed-loop system is composed of heat users, heat pump or cooling tower system, water-water heat exchanger and flue gas-water heat exchanger, which consists of water-water The heat exchanger and the deep wet-cooling heat exchanger form an internal circulating water heat exchange closed-loop system. After the internal circulating water in the internal circulating water heat exchange closed-loop system absorbs the heat of the flue gas in the air-water direct contact heat exchanger, it is combined with the heat from the heat pump. The cooling water is heat exchanged, and the cooling water is initially heated to make it meet the requirements, which improves the heat utilization of the secondary energy.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Boiler-gas mixed-combustion gas supply pipe and gas supply method

InactiveCN102588994BMixed combustion achievedMeet the needs of stable operationFuel feedersCombustion systemThermodynamics

The invention relates to a boiler-gas mixed-combustion gas supply pipe which comprises a gas supply pipe body of a main coal gas supply pipeline (1) and a blending coal gas supply pipeline (2), wherein the mixing coal gas supply pipeline (2) is connected with the middle part of the main coal gas supply pipeline (1) in a mode of gas seal. A water-sealed valve (3) and a mixed coal gas flow regulating valve (5) are arranged on the main coal gas supply pipeline, and a blending coal gas flow regulating valve (4) is arranged on the mixing coal gas supply pipeline. The inner part of the main coal gas supply pipeline is also provided with a plurality of guide plates (6). The invention also discloses a gas supply method based on the boiler-gas mixed-combustion gas supply pipe. According to the gas supply pipe and the gas supply method, under the premise that the original combustion system and combustion equipment of a gas fired-boiler are not changed, the gas fired-boiler is changed from single combustion of blast-furnace gas into mixed combustion of various coal gases in a mode of direct pipeline mixing. Parts meet the requirement of stable operation of the boiler, other by-product coal gases are fully utilized, and secondary energy sources are fully utilized.

Owner:上海盈德宝气气体有限公司

Novel environment-friendly waste gas emission device

PendingCN112742164AContinuous adsorption and purification capacityReduce consumptionGas treatmentDispersed particle separationHeat transmissionExhaust gas emissions

The invention relates to the technical field of paint spraying workshop waste gas treatment equipment, in particular to a novel environment-friendly waste gas emission device which comprises a waste gas storage block, a first conveying pipeline is welded to one end of the waste gas storage block, and a manual control valve is fixed to one end of the first conveying pipeline through a screw. A carbon filtration catalysis heat energy generation structure is fixed to one end of the manual control valve through a screw, one end of the carbon filtration catalysis heat energy generation structure is connected with an air extracting pump through an air conveying pipe, and a heat transmission pipeline is inserted into the top end of the air extracting pump. Secondary energy is utilized in the device, and through cooperation of renewable energy sources, energy consumption and waste are greatly reduced in the waste gas treatment process of the device; and through cooperation of a multilayer filtering device and a high-degree sterilization device, the device highly purifies and sterilizes waste gas generated by the paint spraying workshop, the waste gas treatment capacity of the device is greatly improved, and the purification degree of exhausted air is enhanced.

Owner:倪加福

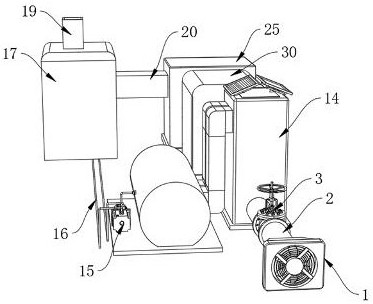

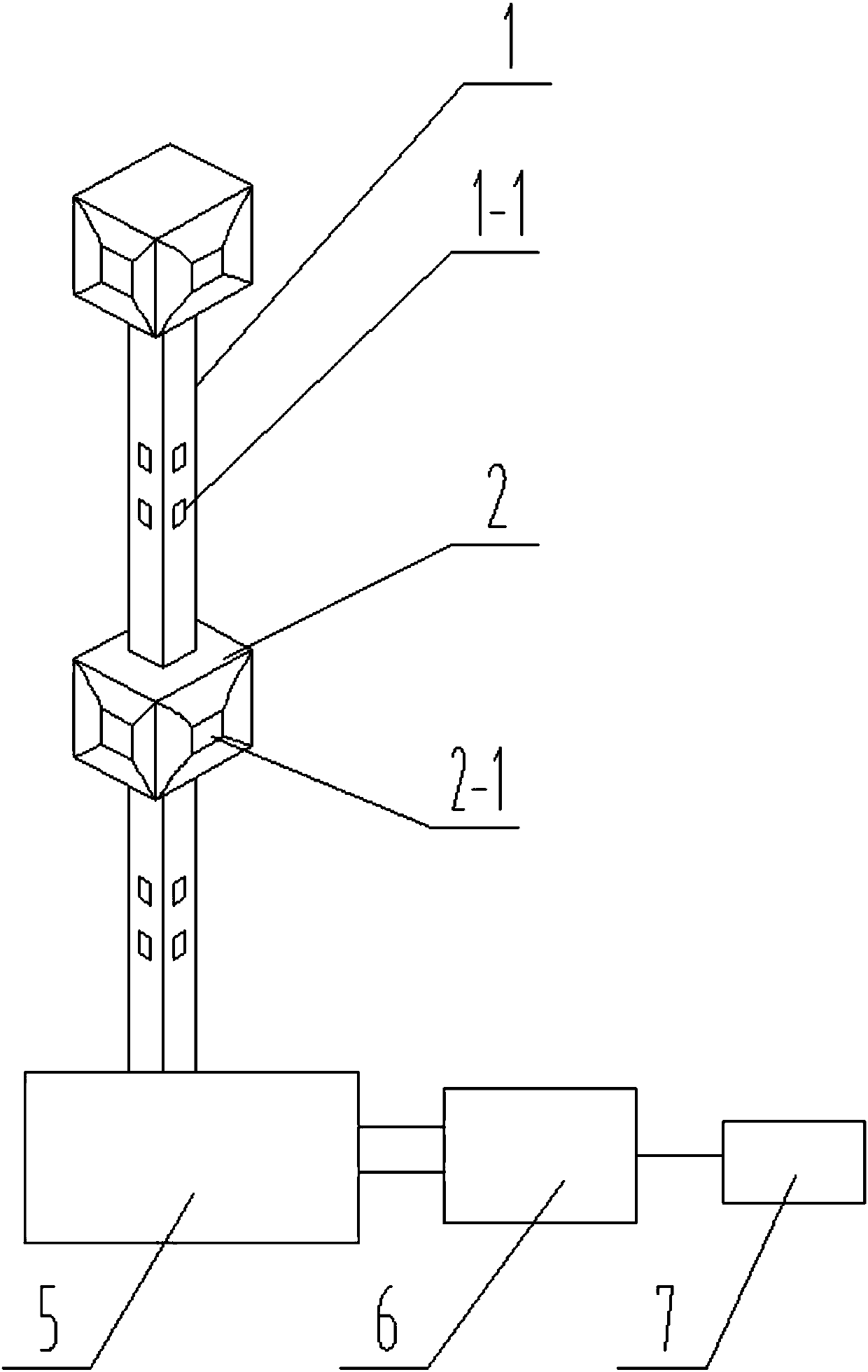

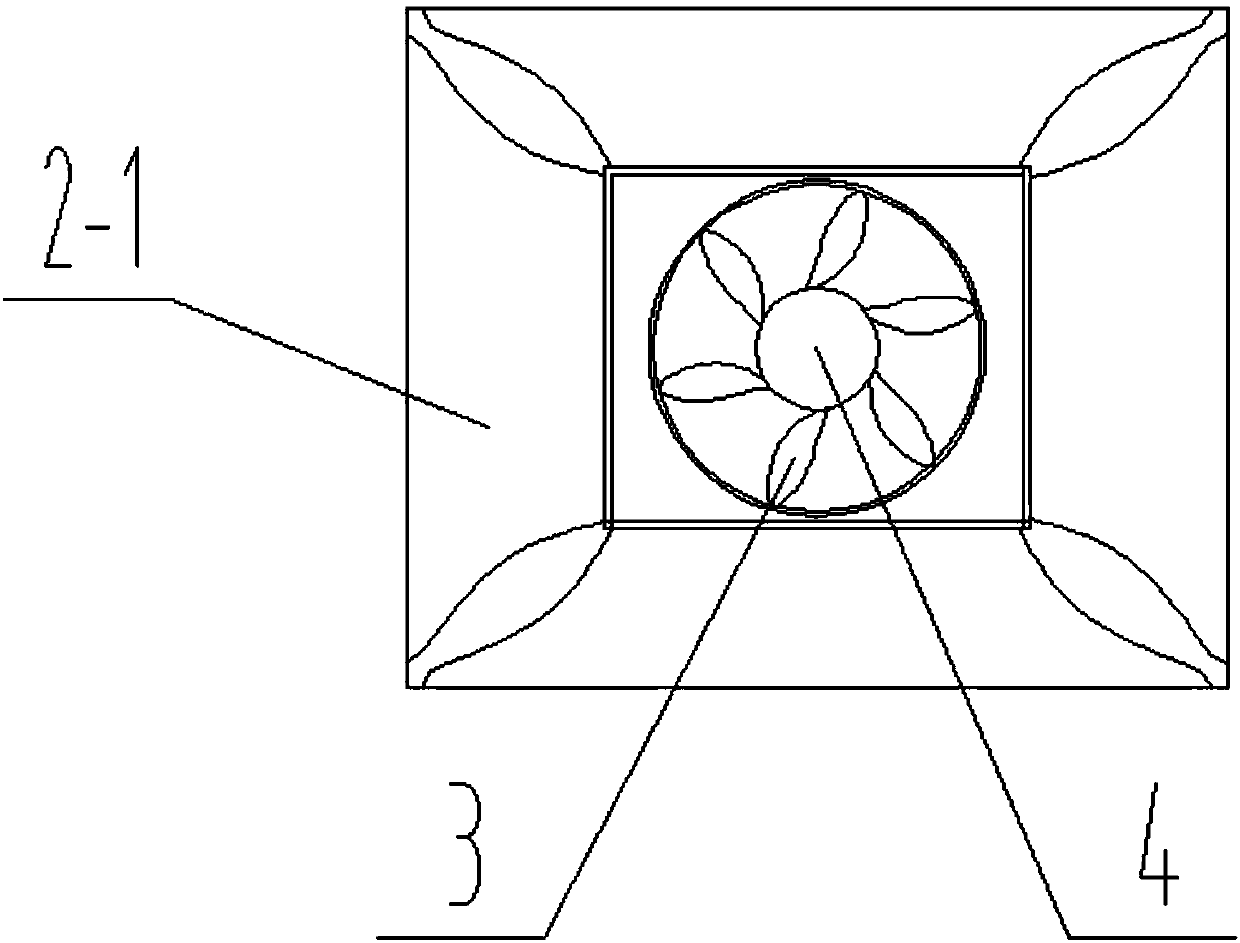

Small-sized gas energy conversion device

InactiveCN109899234ASimple structureEasy to disassembleWind energy with electric storageFinal product manufactureEconomic benefitsProcess engineering

The invention discloses a small-sized gas energy conversion device which is unique and simple in shape and rich in art impression. The small-sized gas energy conversion device comprises a fixing column (1), gas guiding pools (2), a fan body (3), a stirring rod (4), a gearshift box (5), an energy conversion device (6) and a secondary energy source (7). The fixing column (1) is provided with gas inlet holes and gas outlet holes (1-1). The four sides of each gas guiding pool (2) are each provided with a group of air guide openings (2-1). The bottom of each gas guiding pool (2) is provided with anair outlet. Each gas guiding pool (2) is installed at a group of gas inlet holes of the fixing column (1). The air outlets of the gas guiding pools (2) communicate with the gas inlet holes of the fixing column (1). The two ends of the stirring rod (4) are movably arranged in the fixing columns through strut bases. The small-sized gas energy conversion device can collect and efficiently convert multi-directional energy into electric energy, and the small-sized gas energy conversion device is simple in structure, low in cost, easy to detach and maintain and capable of obtaining good economic benefits on the market.

Owner:许小莉

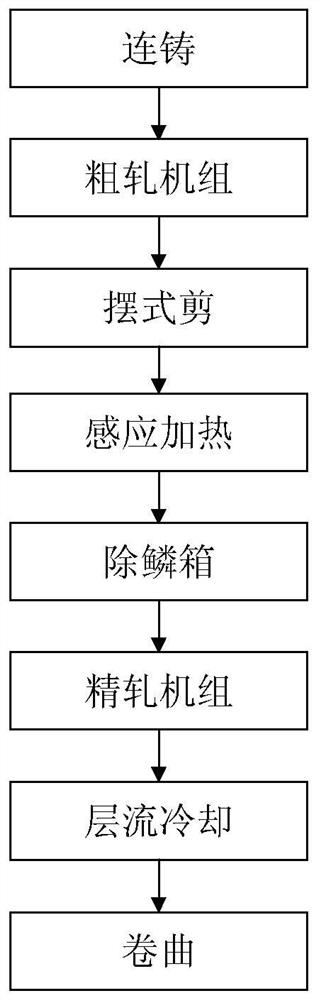

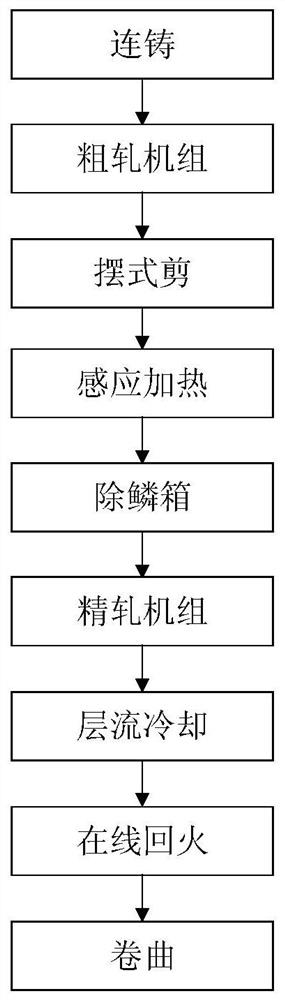

Method of Improving Low Temperature Toughness of Materials Based on tscr Dynamic Variation Rules

ActiveCN109482647BAchieve transformationRealize joint reorganizationTemperature control deviceWork cooling devicesTemperingIndustrial engineering

The invention discloses a method for improving the material low-temperature toughness based on TSCR dynamic variable regulation. In and after the process that '5-1'dynamic variable regulation is conducted through a finishing mill group, online tempering is started, '5-1' dynamic variable regulation of the finishing mill group is combined with online tempering, the microstructure of a material is significantly affected in a short time, waste energy resources such as waste heat and waste pressure of a rolled strip can be effectively utilized and combined with online tempering in the low-temperature waste heat stage, structural phase transition is freely controlled, the production process is simplified, energy consumption is reduced, best strength and toughness match is achieved, comprehensive utilization of secondary energy such as the low-temperature waste heat is promoted, and the purposes of energy saving, consumption reducing and environmental protection are achieved; and meanwhile,a strategic cooperation mechanism between steel enterprises and users can be established, transformation of the steel enterprises from producers to service providers is promoted, regional manufacturing enterprise industrial upgrading accelerating is improved, joint reorganization of a rolling process and a heat treatment technology is realized, and great prospects in industrial application are achieved.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com