Metal fuel-based zero-carbon emission energy conversion system

An energy conversion system and metal fuel technology, applied in the direction of indirect carbon dioxide emission reduction, fuel burning in molten state, combustion method, etc., can solve random and uneven geographical distribution, renewable energy volatility, and restrict the development of renewable energy And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

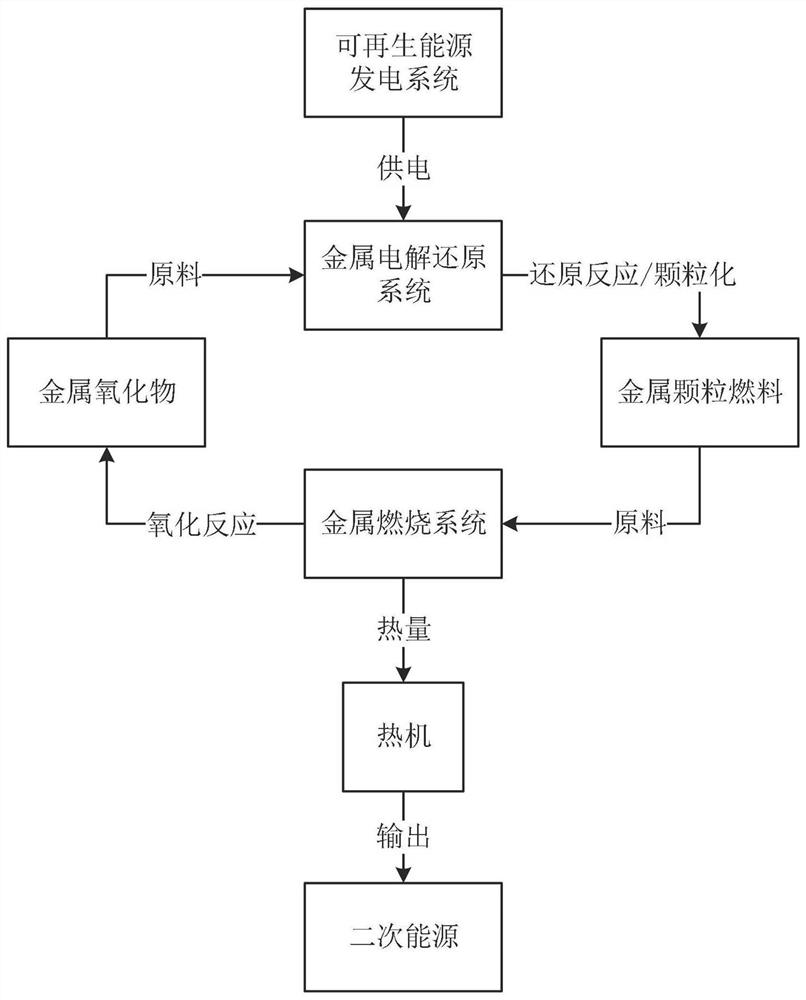

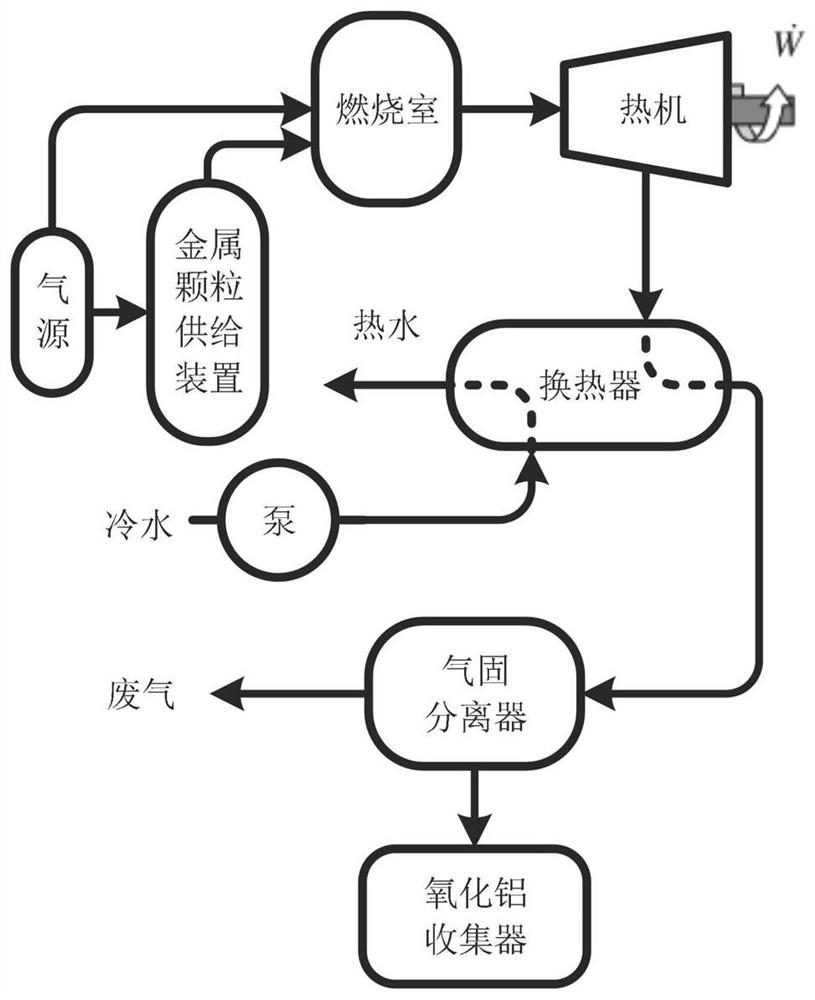

[0023] Figure 1 to Figure 7 It shows a specific embodiment of a metal fuel-based zero-carbon emission energy conversion system of the present invention, including a metal particle supply device, a gas source, a metal combustion system, a metal electrolytic reduction system, and a heat engine. The metal particle supply device The metal fuel particles are transported to the metal combustion system and the oxidant transported by the gas source is burned for oxidation reaction. The heat generated by the oxidation reaction is converted into secondary energy through a heat engine, and the metal solid oxide produced in the oxidation reaction is transported to the metal electrolytic reduction system for reduction. Reaction, the metal produced after the reduction reaction is processed into metal fuel particles and then transported to the metal combustion system through the metal particle supply device. The present invention uses metal as fuel to replace traditional fossil fuels, espec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com