Method for treating waste water generated in production process of alcohol by fermenting

A technology for waste water production and treatment methods, which is applied in biological organic part treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problems of water eutrophication, environmental pollution, and high consumption of alcohol production water. , to achieve the effect of saving water resources costs and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

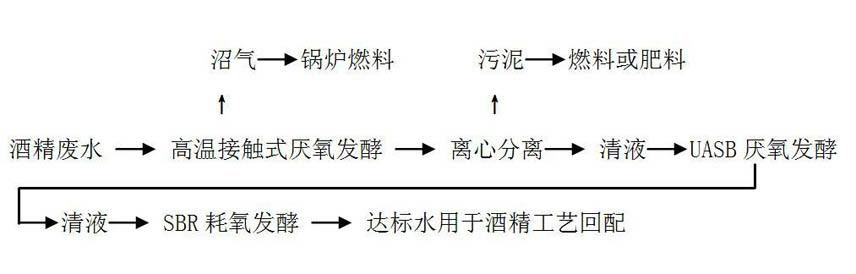

[0035] A method for treating waste water produced by fermented alcohol, the specific steps of the process are as follows:

[0036] (1) First domesticate the sludge, and then perform high-temperature contact anaerobic fermentation on the produced alcohol wastewater; the method of high-temperature contact anaerobic fermentation is: put the anaerobic fermentation produced by 40% of the tank volume into the anaerobic tank. Activated sludge, feed after cooling the wastewater temperature to 40°C, the interval between intermittent feeding is 10 hours, the amount of each feed is less than 10% of the tank volume, and the feeding time is 2 hours; Fermentation in a closed environment at 55°C for 9 days ; Take 9 days as a cycle; in order to increase the contact opportunities between microorganisms and raw materials, accelerate the fermentation speed, and increase the biogas production, 8 cycles of stirring are carried out in each fermentation cycle, and each time is controlled within 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com