Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

117 results about "Quantum dot array" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

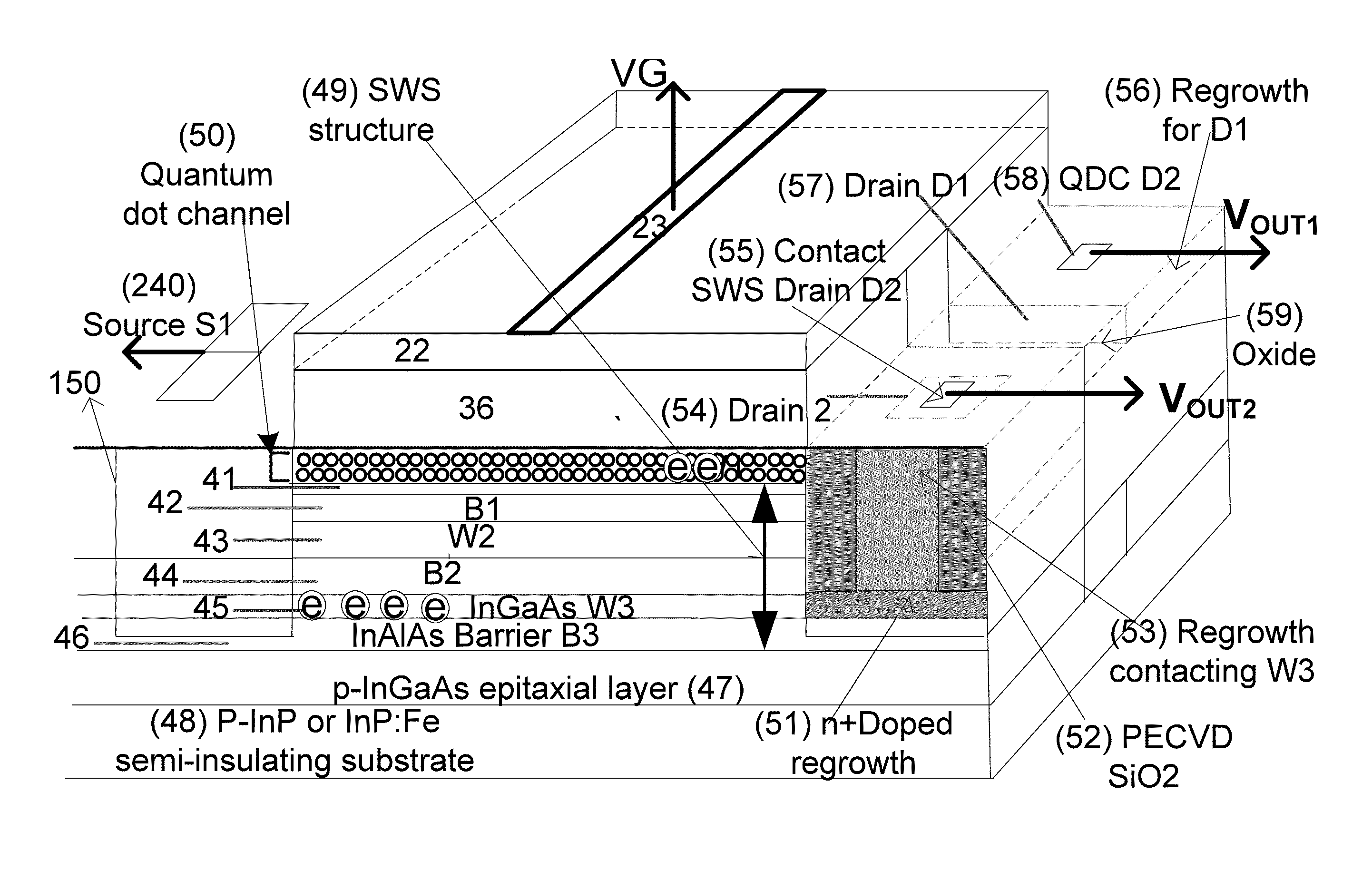

Quantum dot channel (QDC) quantum dot gate transistors, memories and other devices

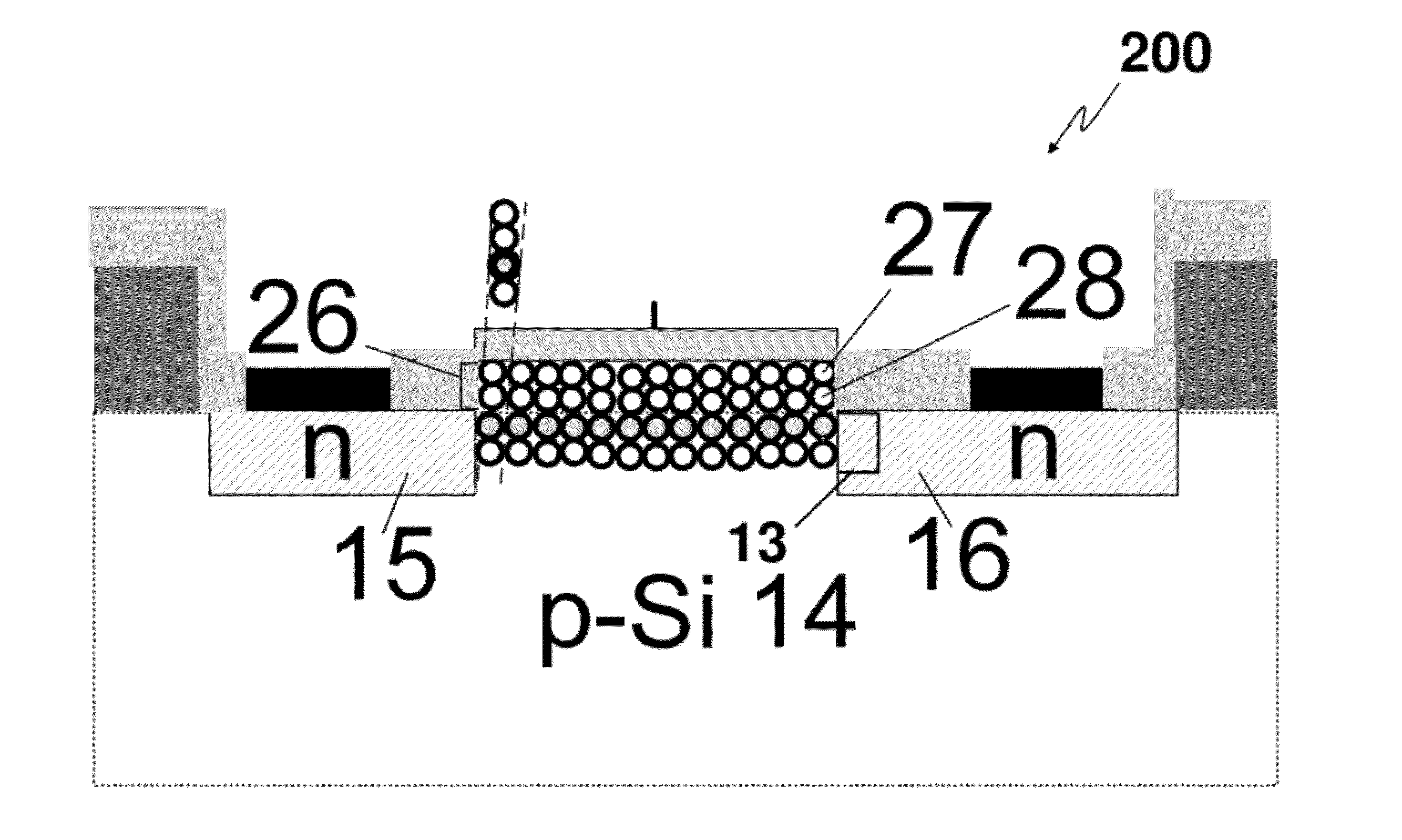

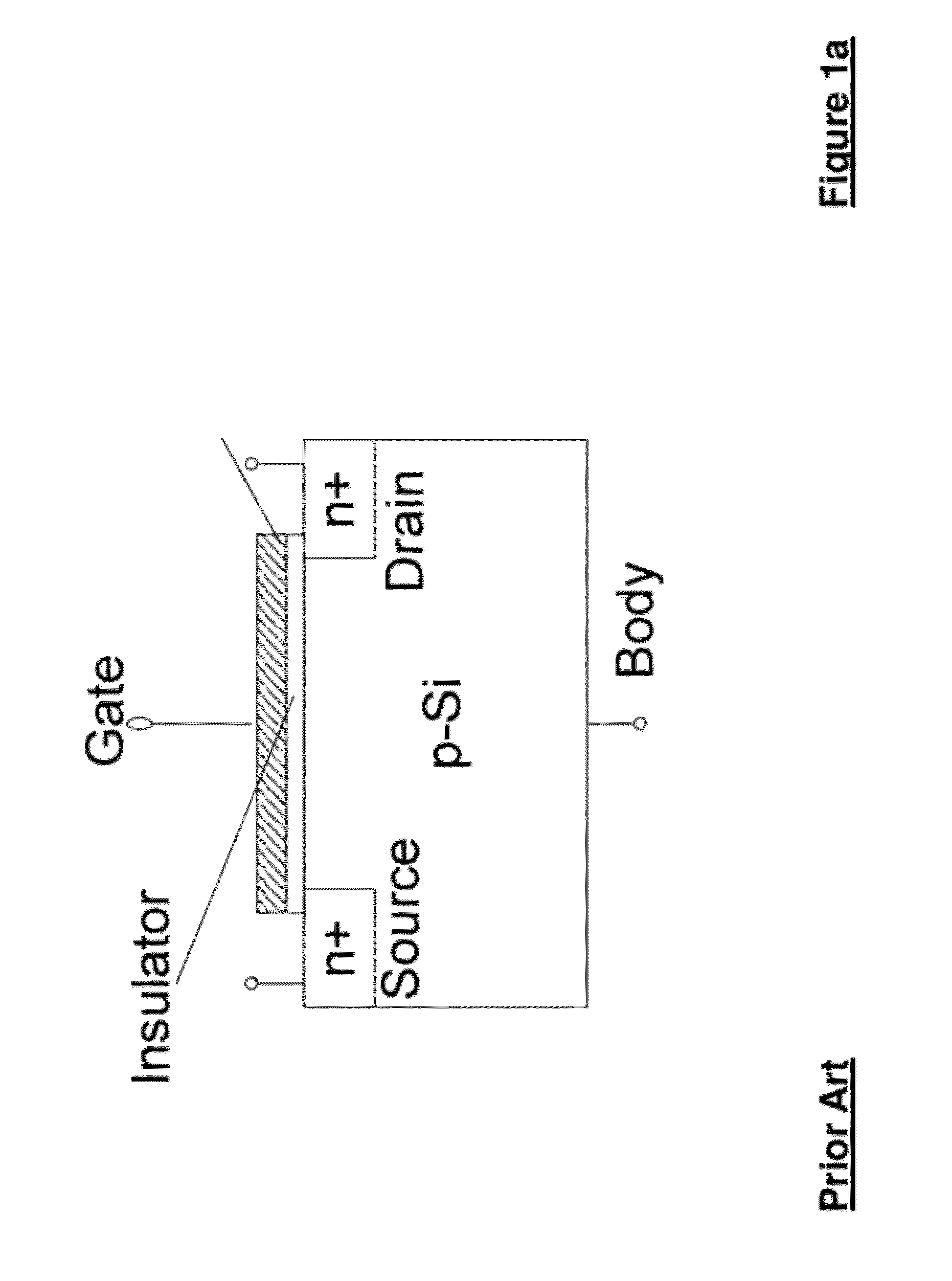

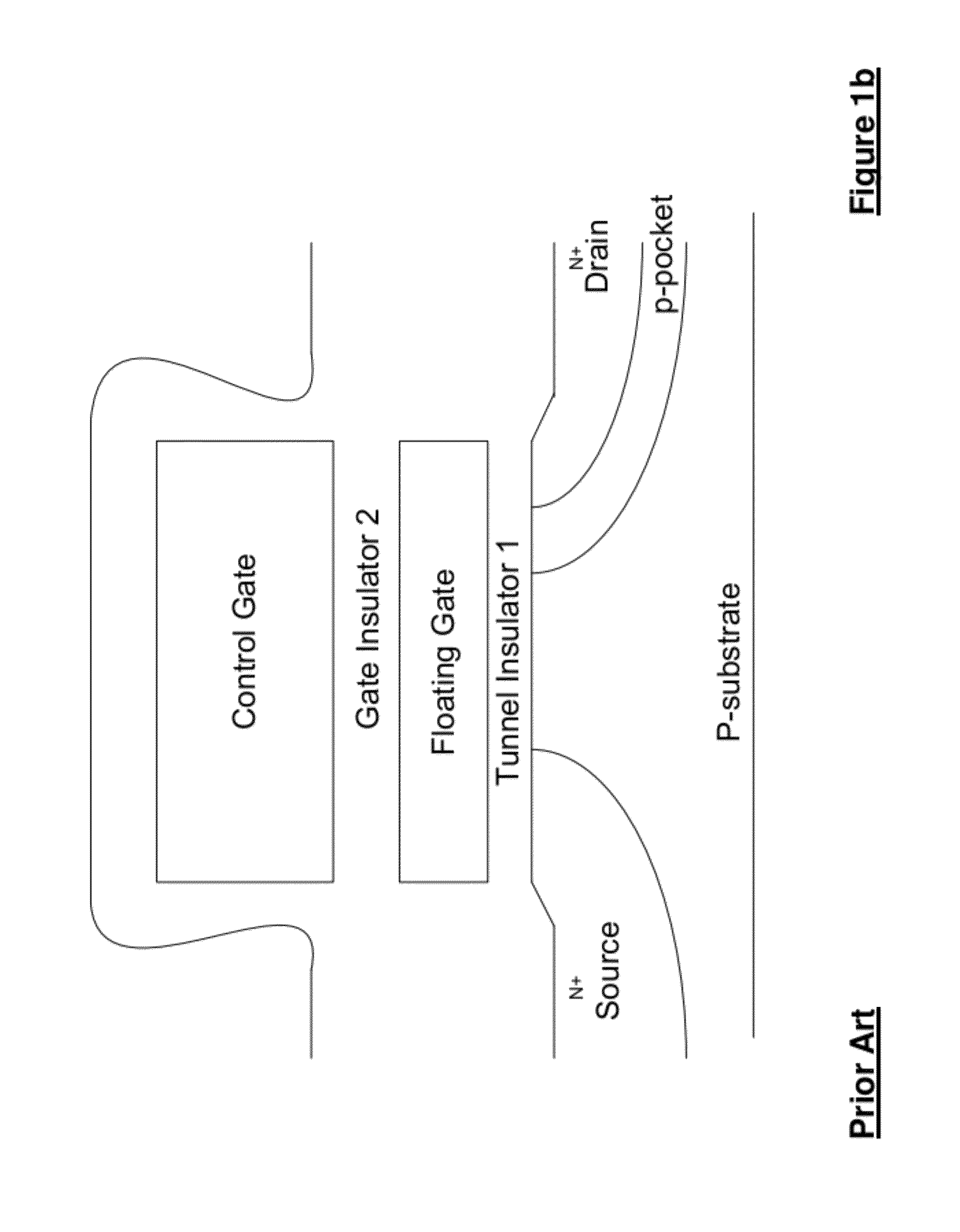

This invention describes a field-effect transistor in which the channel is formed in an array of quantum dots. In one embodiment the quantum dots are cladded with a thin layer serving as an energy barrier. The quantum dot channel (QDC) may consist of one or more layers of cladded dots. These dots are realized on a single or polycrystalline substrate. When QDC FETs are realized on polycrystalline or nanocrystalline thin films they may yield higher mobility than in conventional nano- or microcrystalline thin films. These FETs can be used as thin film transistors (TFTs) in a variety of applications. In another embodiment QDC-FETs are combined with: (a) coupled quantum well SWS channels, (b) quantum dot gate 3-state like FETs, and (c) quantum dot gate nonvolatile memories.

Owner:JAIN FAQUIR CHAND

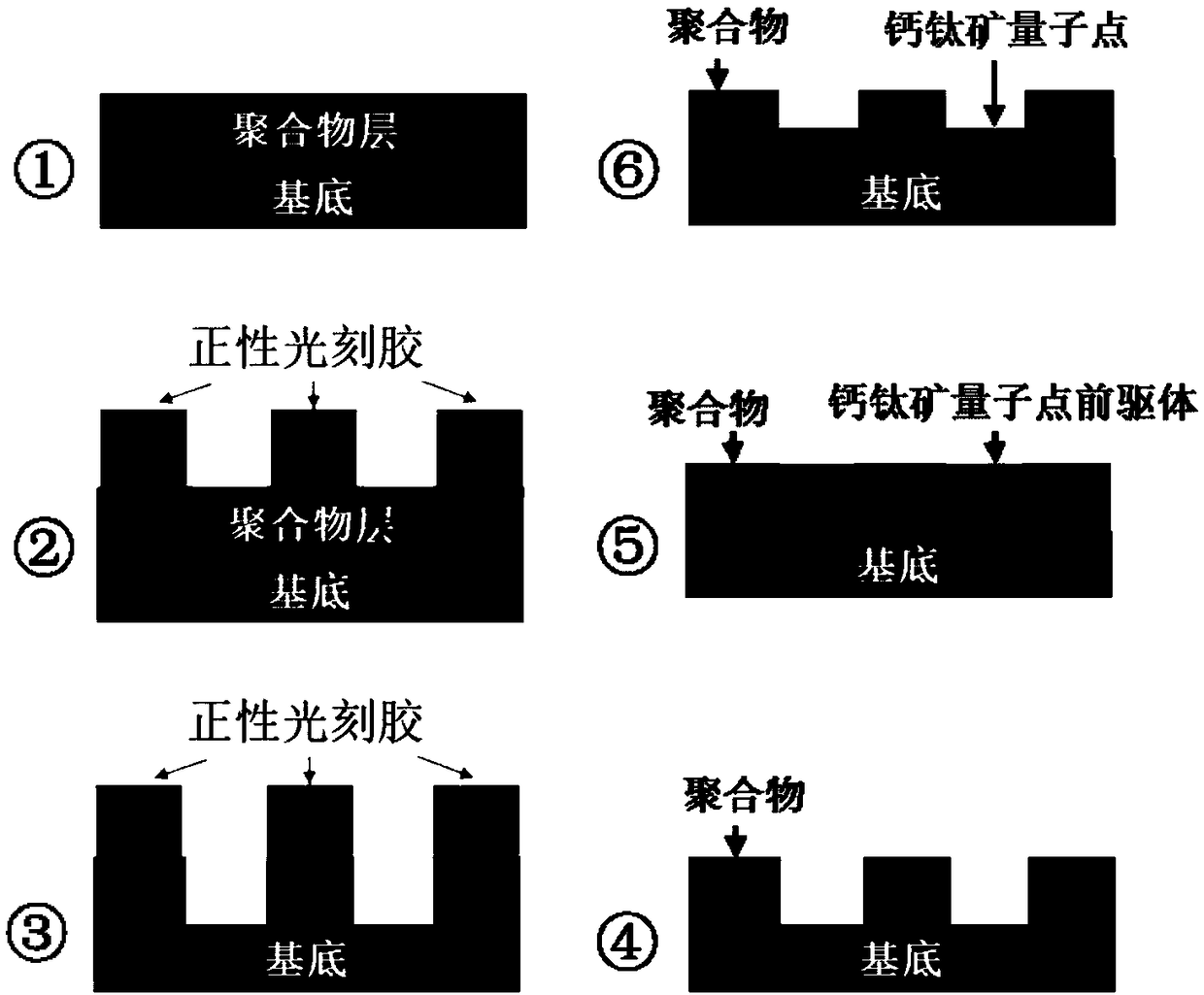

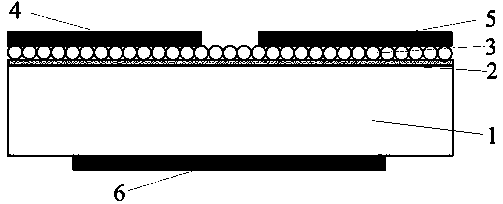

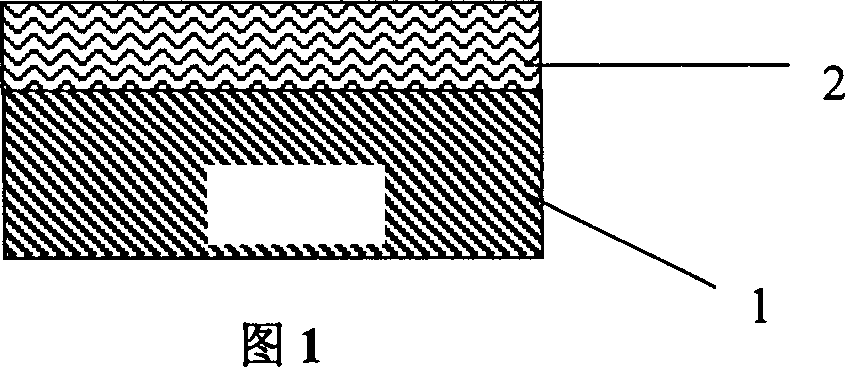

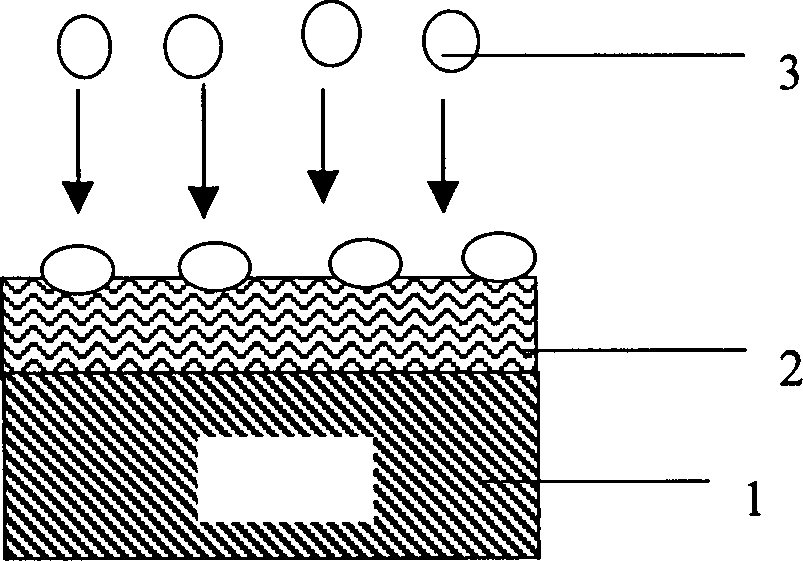

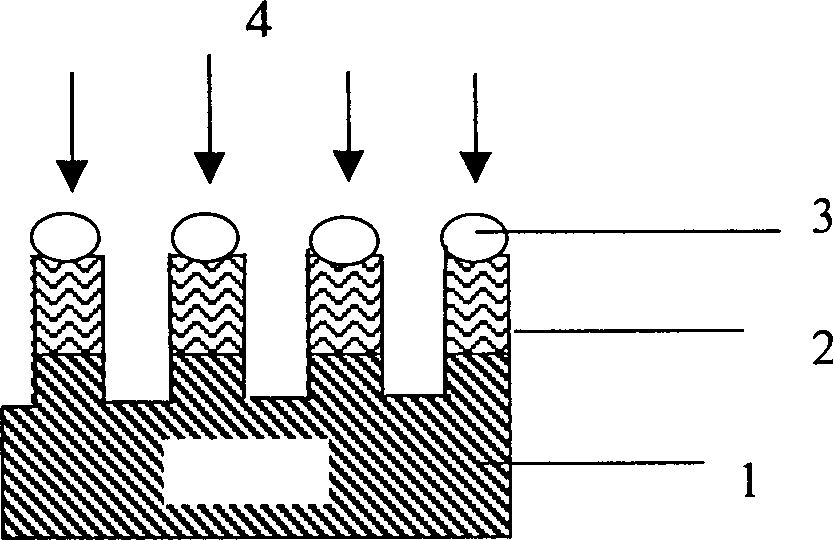

Preparation method of perovskite quantum dot array

InactiveCN108987613APatterned realizationSolid-state devicesSemiconductor/solid-state device manufacturingPhotovoltaic detectorsPhotodetector

The invention discloses a preparation method of a perovskite quantum dot array, which is characterized in that: (1) obtaining a template; (2) filling a precursor solution of the perovskite quantum dotinto the template in the step (1), heating and drying to obtain the perovskite quantum dot array. After filling the lattice with the precursor solution, the perovskite quantum dot material in the prior art cannot be mixed with a photoresist to prepare an array pattern by photolithography by heating the perovskite quantum dot material in situ to generate the perovskite quantum dot. The perovskitequantum dot array generated in situ by the method can be applied to display devices, photodetectors and the like.

Owner:ZHIJING NANOTECH CO LTD

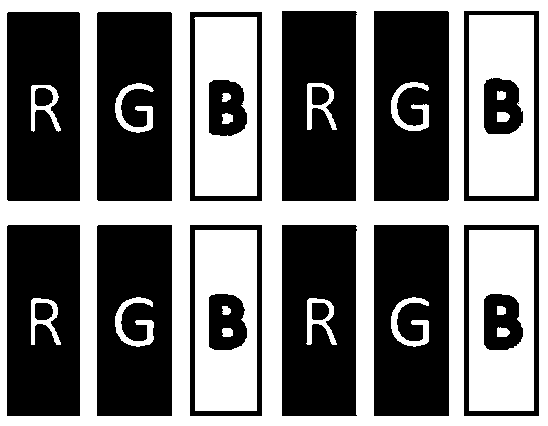

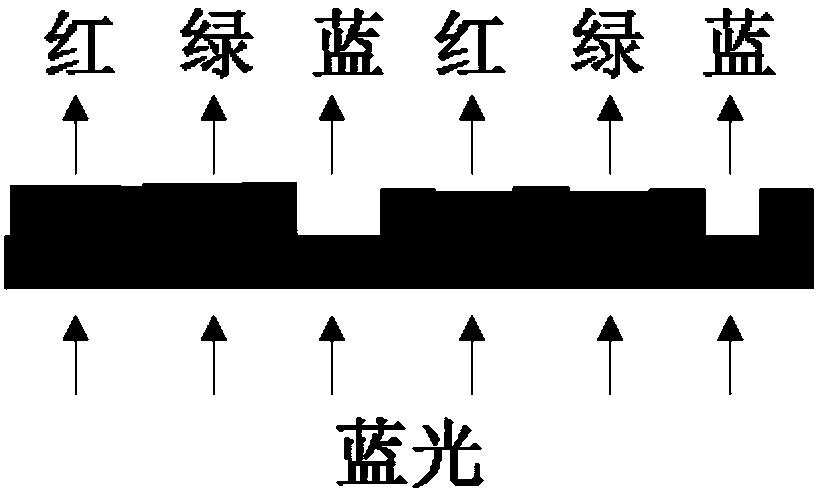

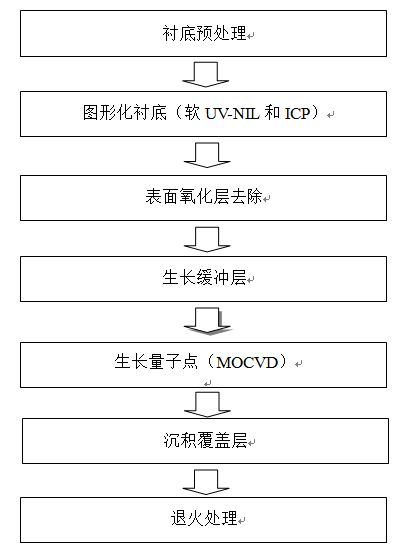

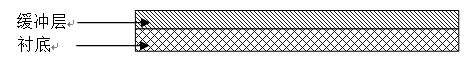

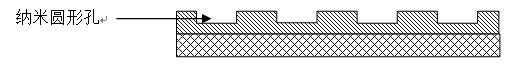

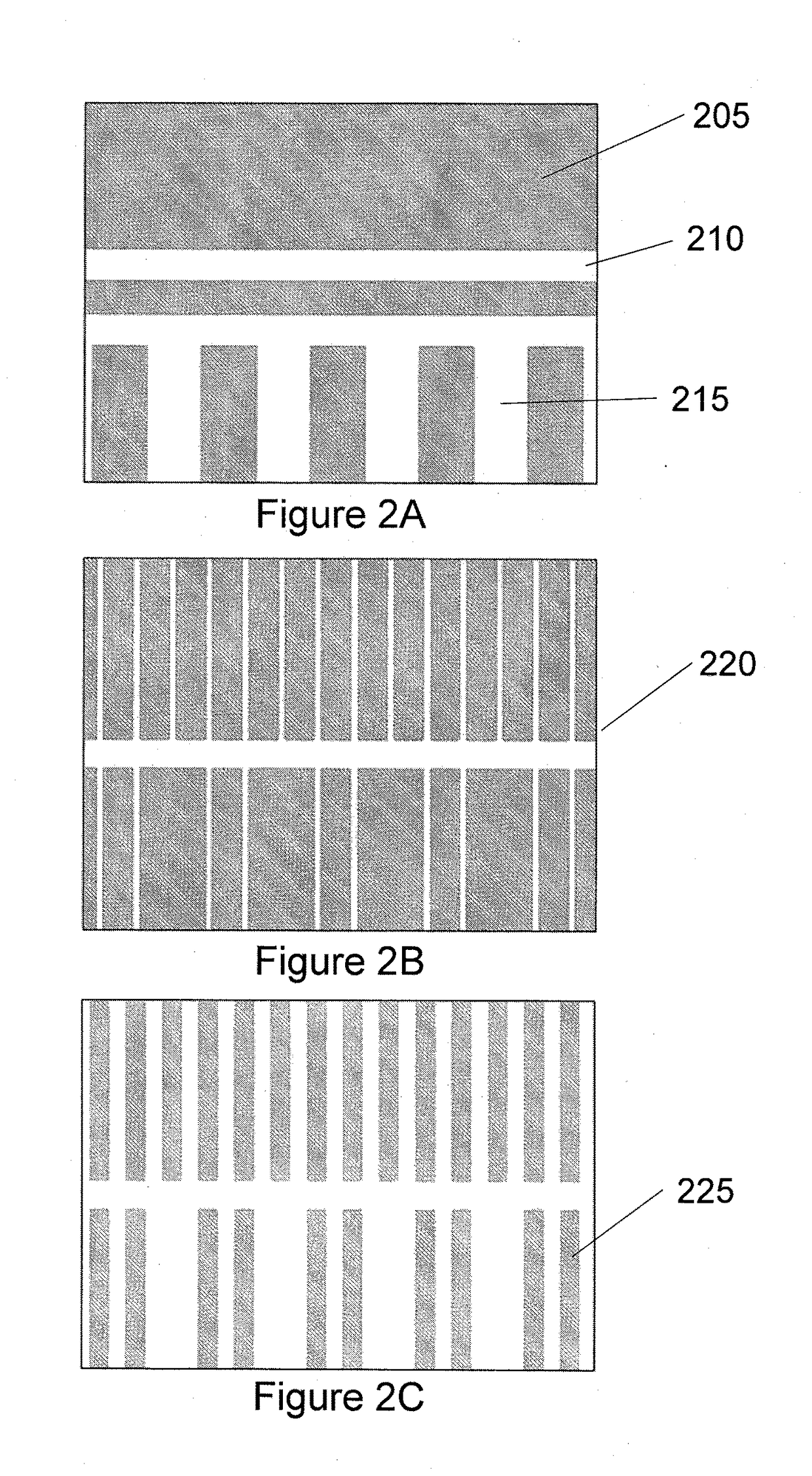

Manufacture method of large-area highly uniform sequential quantum dot array

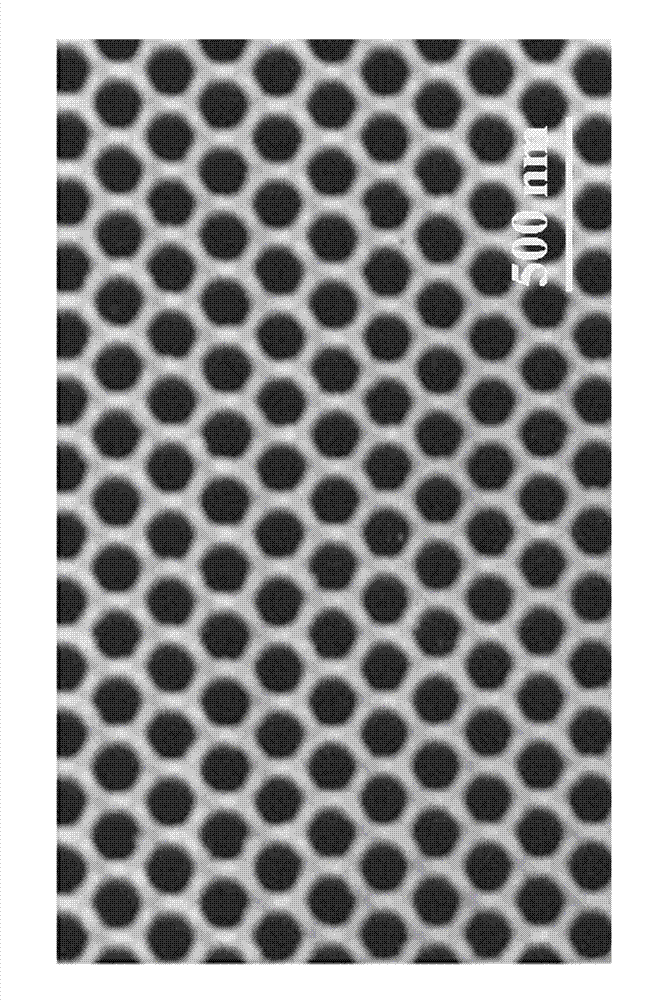

InactiveCN101830430AReduce sizeSmall sizeNanostructure manufactureUltravioletInductively coupled plasma

The invention relates to a manufacture method of a large-area highly uniform sequential quantum dot array. The method comprises the following steps of: preparing a nanopore graphic array on a substrate by adopting soft ultraviolet nano imprint lithography (UV-NIL) and an inductively coupled plasma (ICP) technology; and growing quantum dots in a self-organizing way by using a prepared graphical substrate as a template and using a metal organic chemical vapor deposition (MOCVD) system. The invention realizes the low-cost, consistent and batched preparation of the large-area highly uniform sequential quantum dot array and can be applied to manufacture of devices such as quantum dot lasers, quantum dot memories, quantum dot solar batteries, quantum dot LEDs, single photon emitters, and the like.

Owner:SHANDONG UNIV

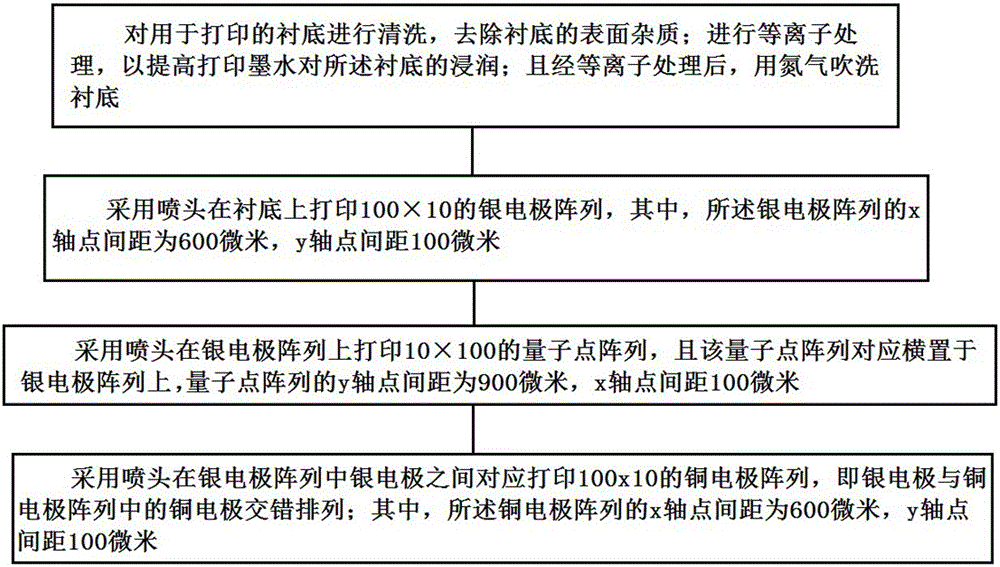

Method for preparing quantum dot photodetection array device based on ink-jet printing technology

InactiveCN104993022AImprove controllabilityScalable productionFinal product manufactureSemiconductor devicesComputer printingInk printer

The invention relates to a method for preparing a quantum dot photodetection array device based on ink-jet printing technology. The method is characterized by carrying out plasma and chloroform processing on a substrate; then, printing a metal electrode array and a quantum dot array on the substrate through an ink-jet printer with metal electrode ink and quantum dot ink respectively; and finally, carrying out current and voltage test in the dark and any monochromatic light source environment. The method for preparing the quantum dot photodetection array device based on the ink-jet printing technology is simple in preparation technology, and can carry out large-scale production; and the photodetection device adopts quantum dots, so that the photodetection device has a better photosensitive characteristic for any excitation light source.

Owner:FUZHOU UNIV

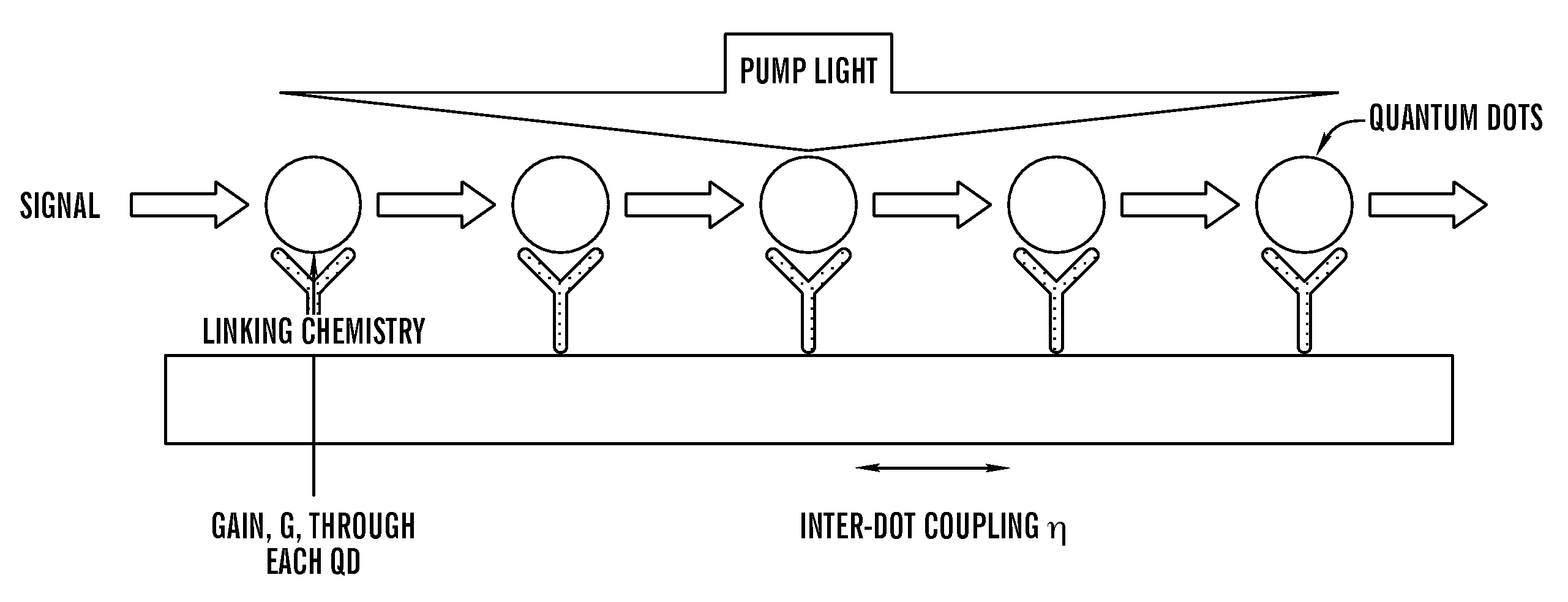

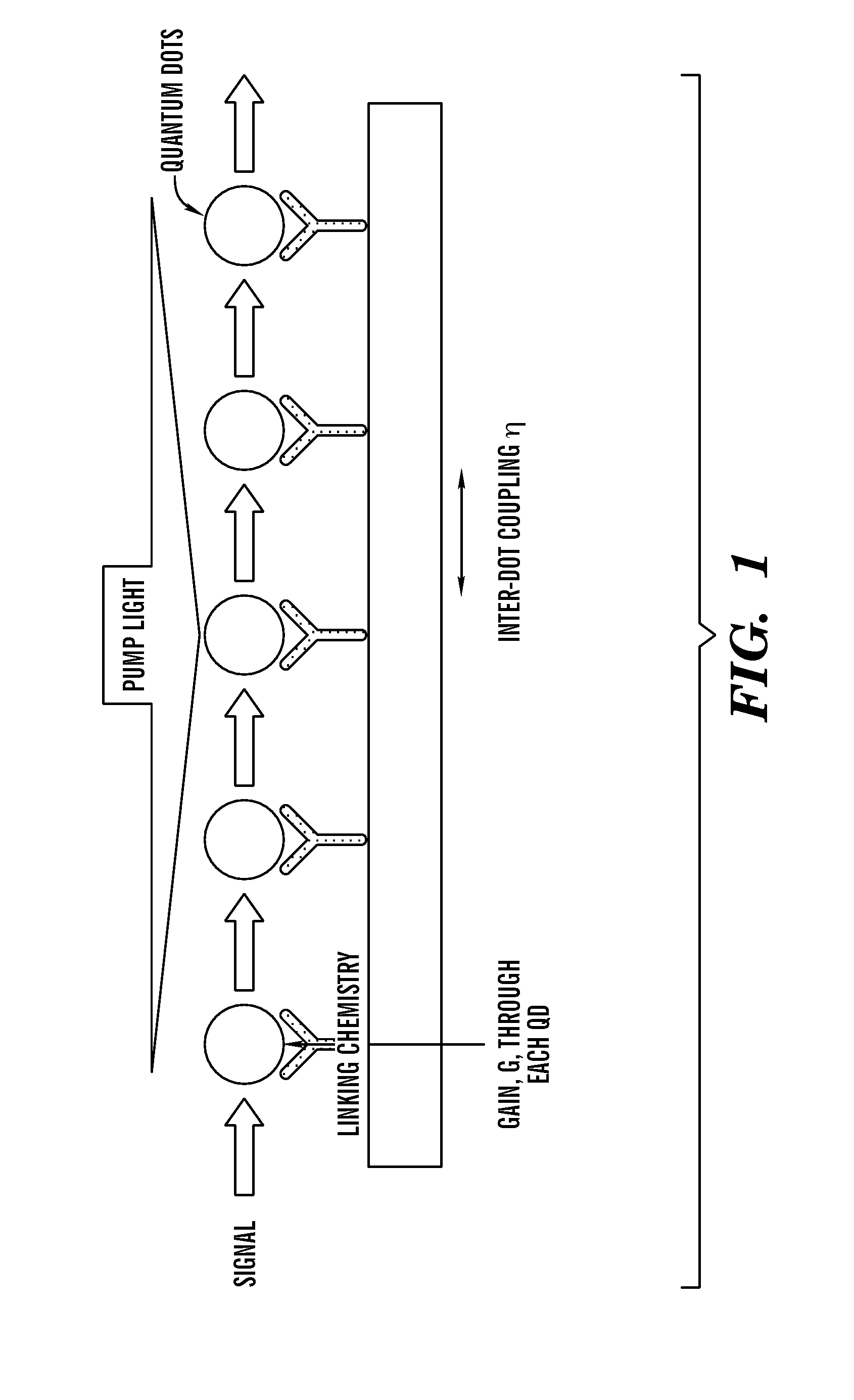

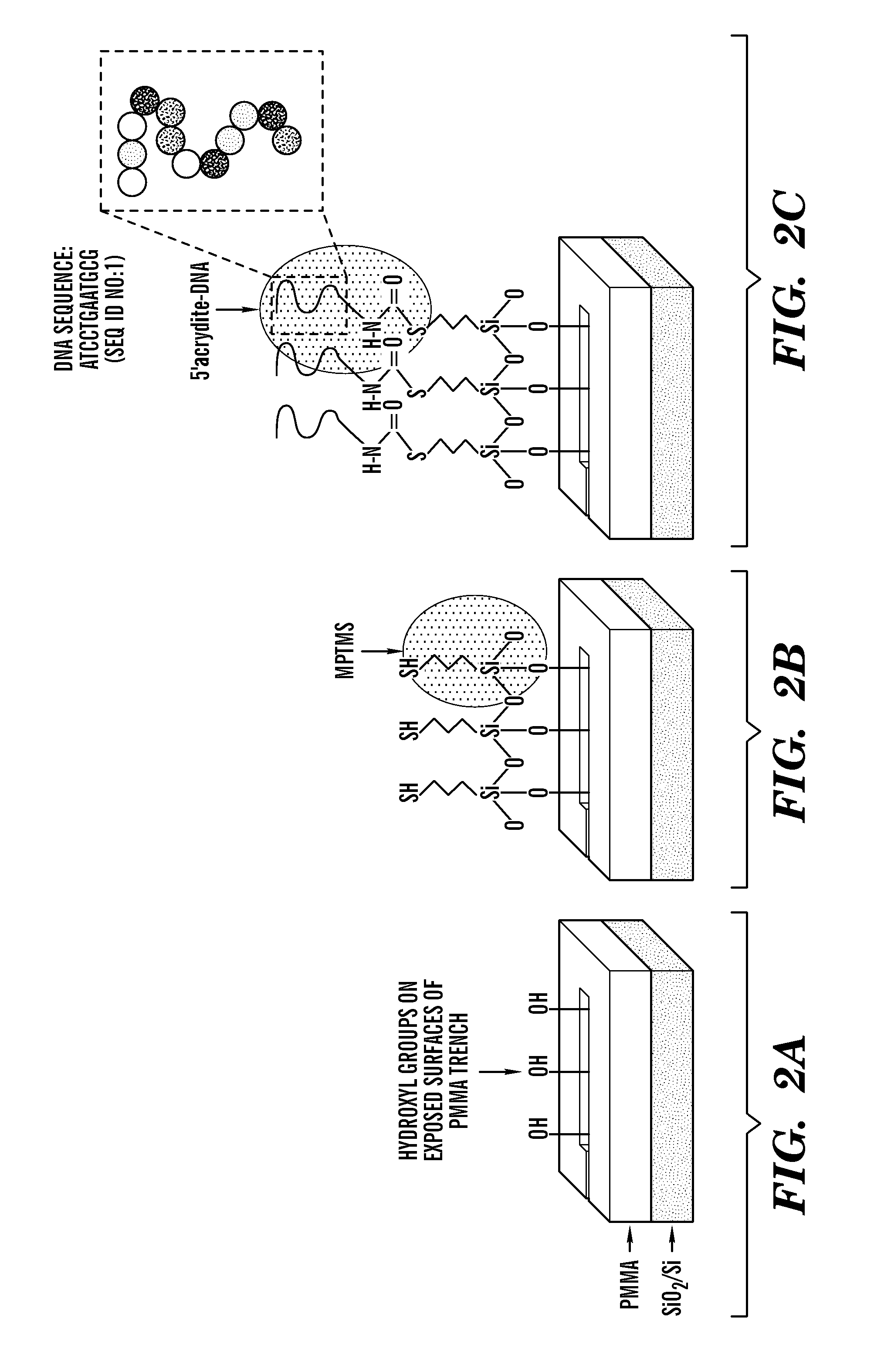

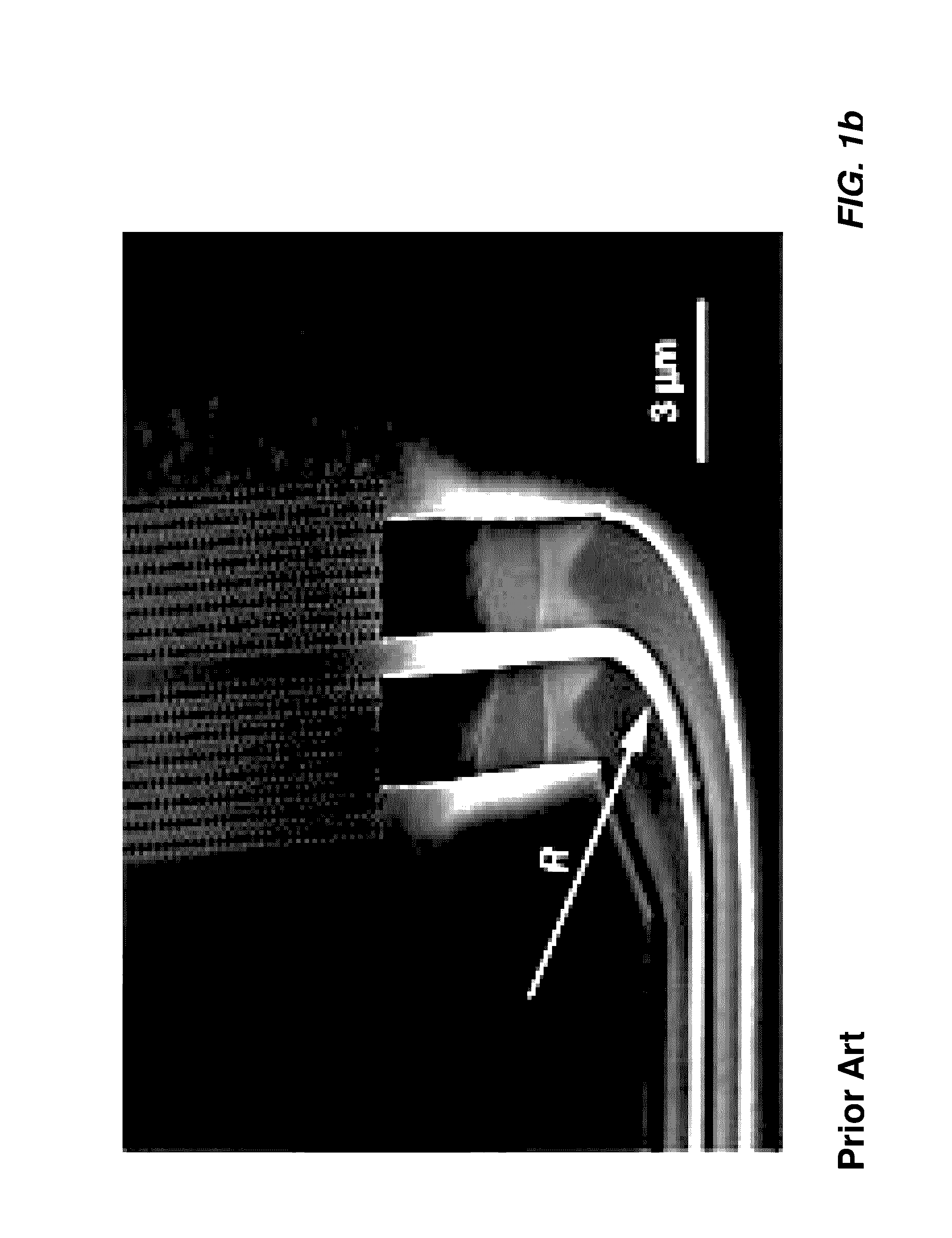

Multiple quantum dot waveguides

InactiveUS20080085088A1Threshold current densityReduced propagation lossLaser detailsNanoopticsSignal lightGain

The present invention relates to an assembly of multiple waveguides which includes a substrate and a plurality of waveguides positioned on said substrate at locations effective to suppress cross-talk between different waveguides. The plurality of waveguides each comprise an elongate array of quantum dots extending between sets of first and second locations on the substrate. The waveguides are positioned to receive: (1) pumped light uniformly applied to the array to produce electron-hole pairs and to enable optical gain and (2) signal light at the first location to trigger an emission from the quantum dot at the first location and transmission of photons along the array to the second location. A light transmission system which includes this assembly as well as methods of making and using the assembly are also disclosed.

Owner:UNIV OF WASHINGTON

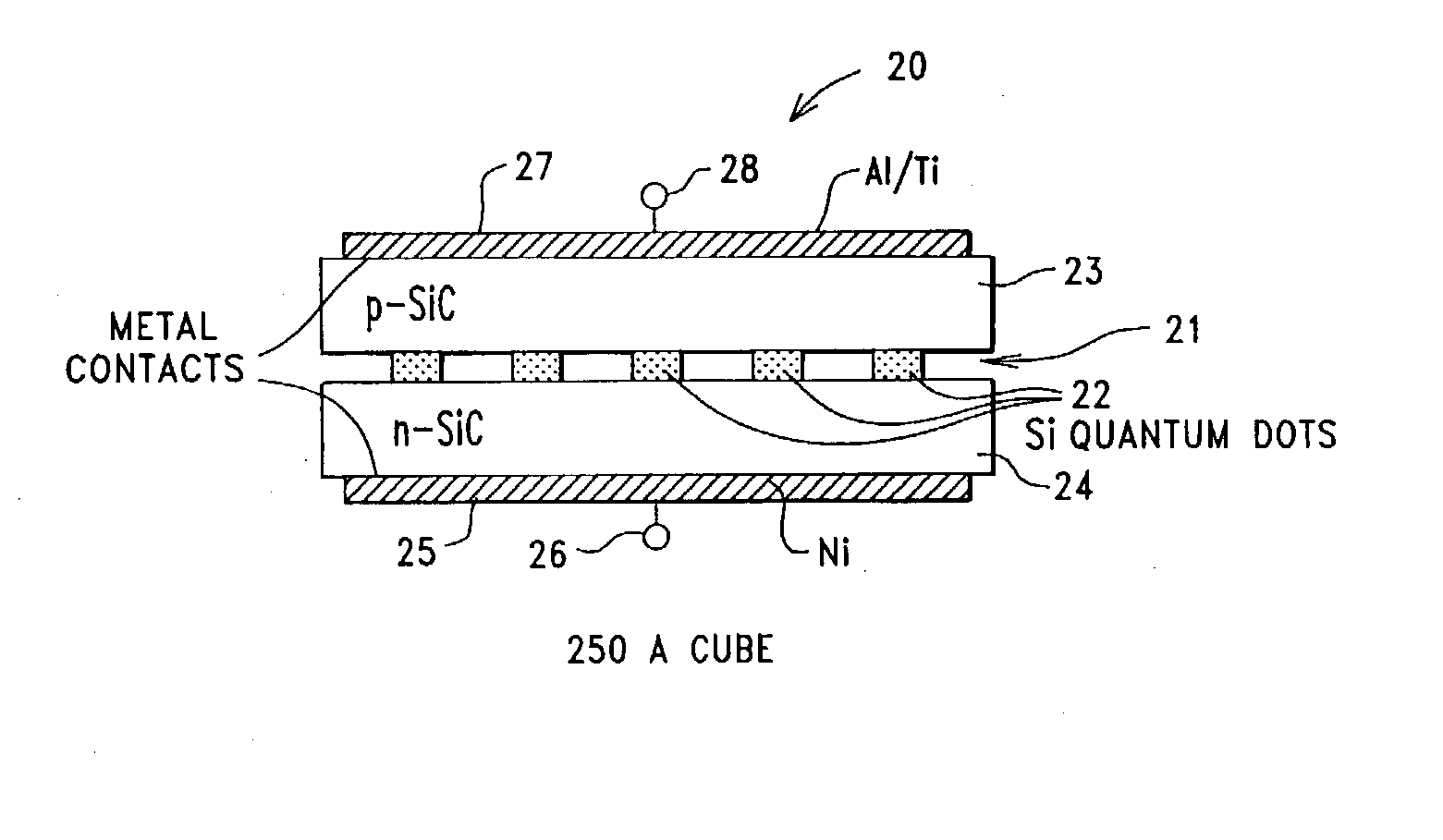

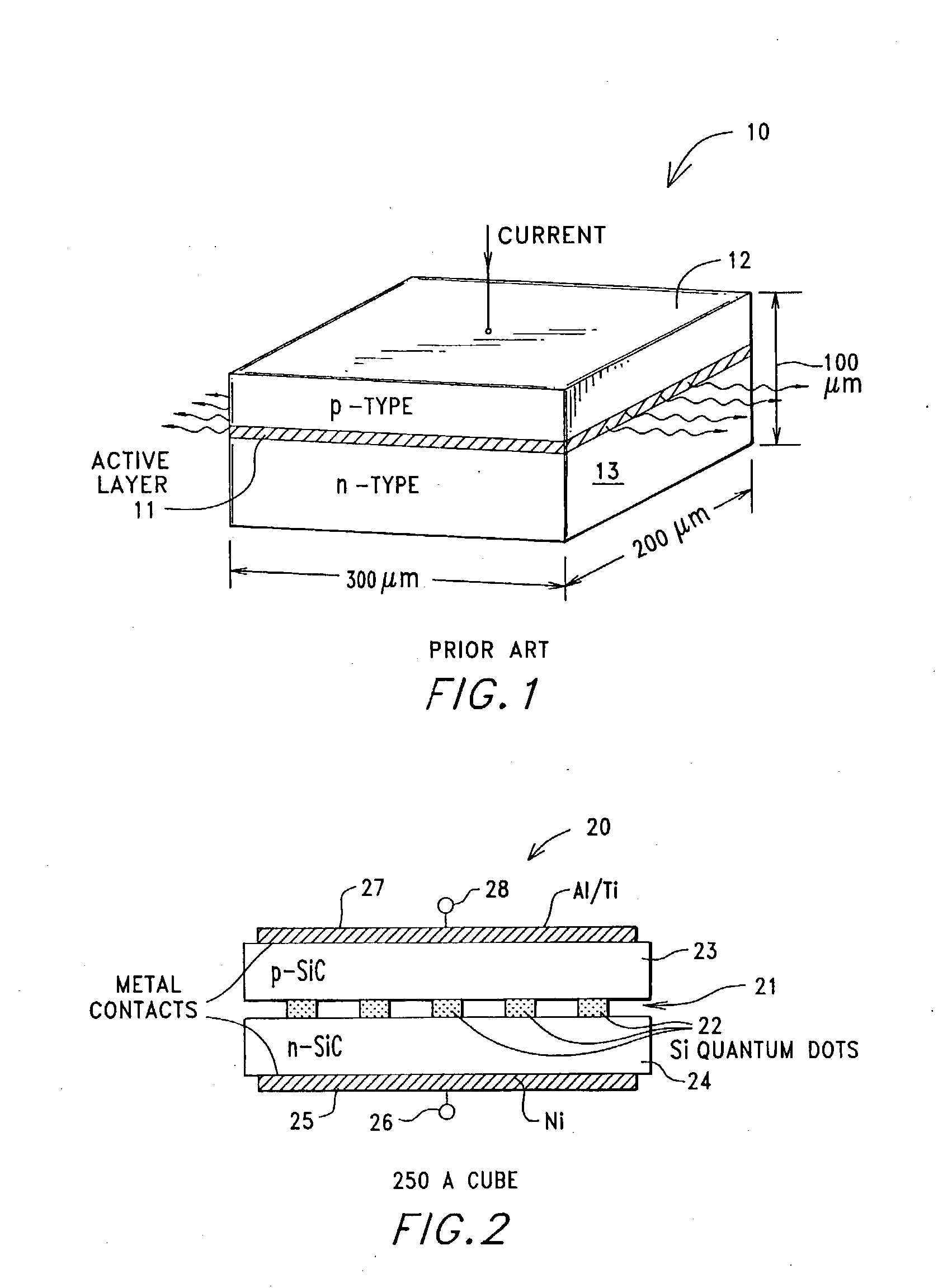

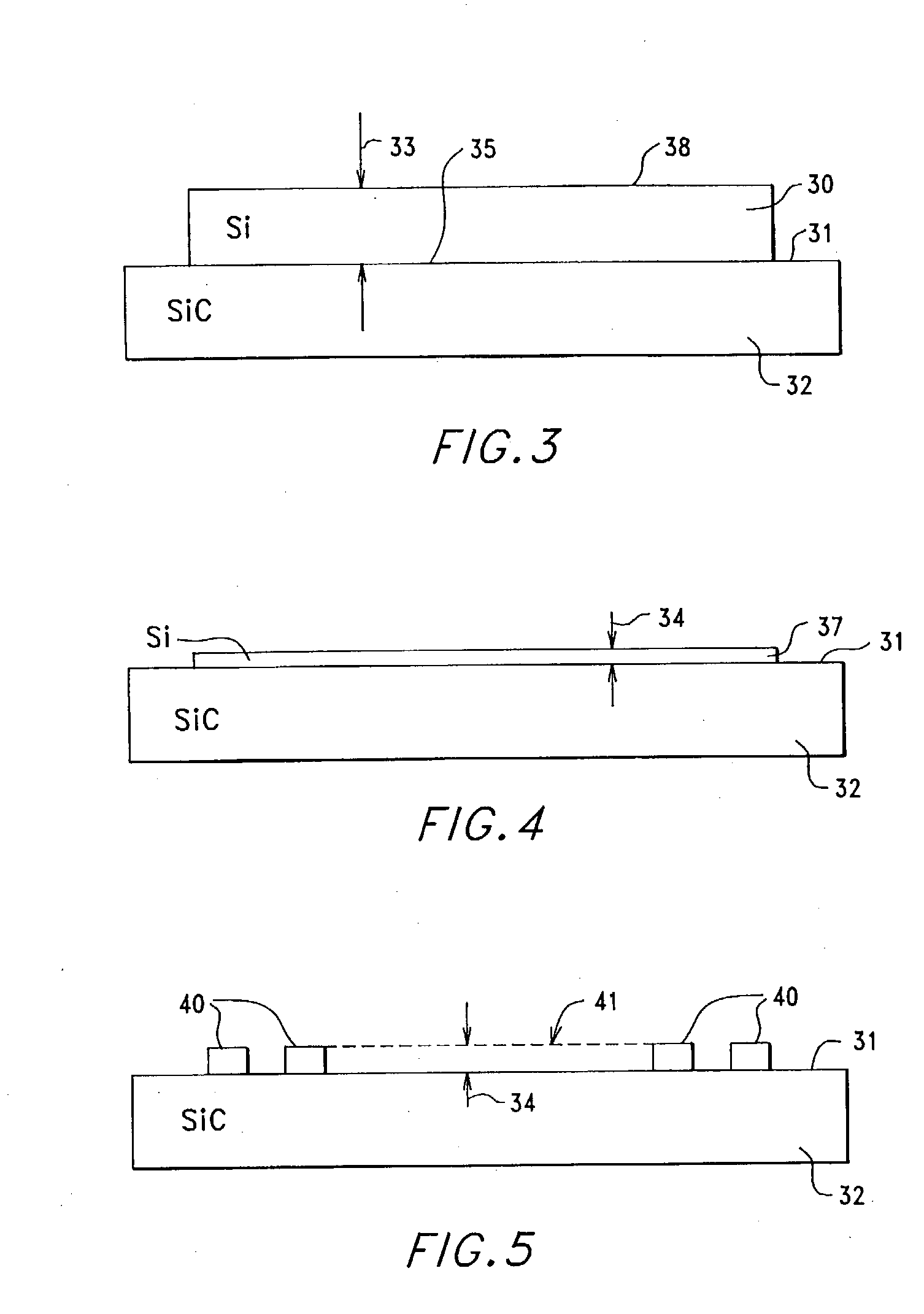

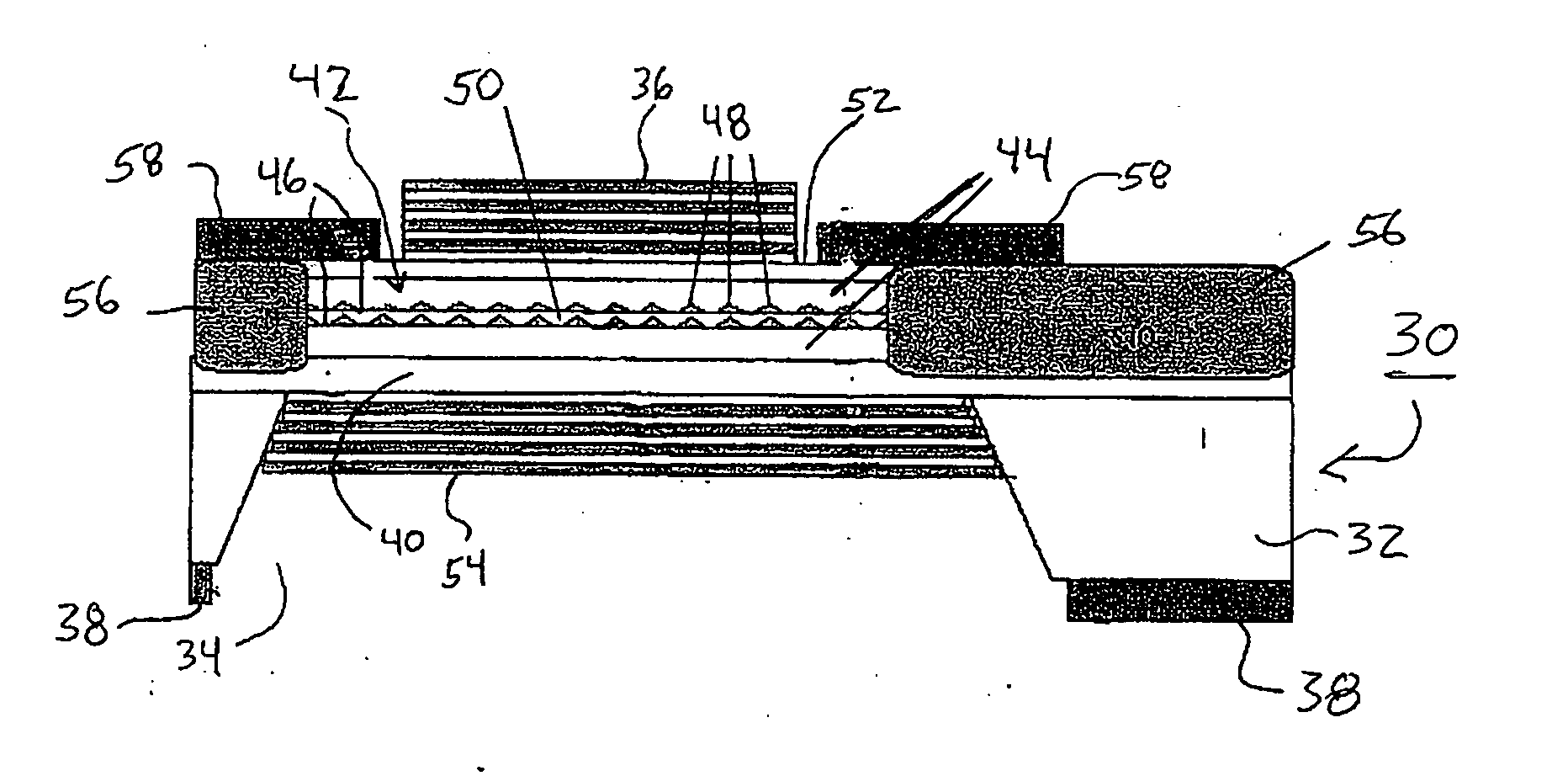

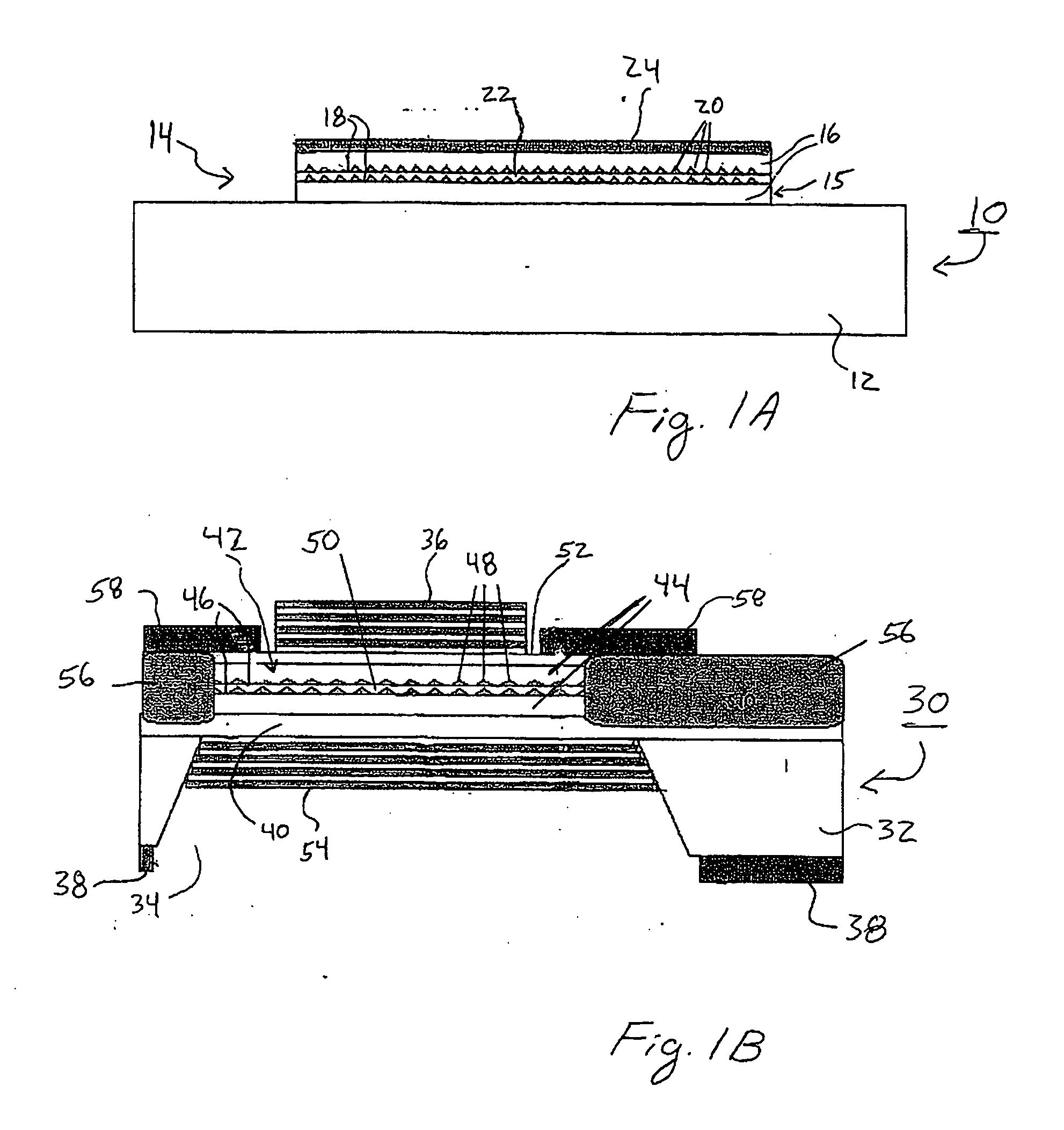

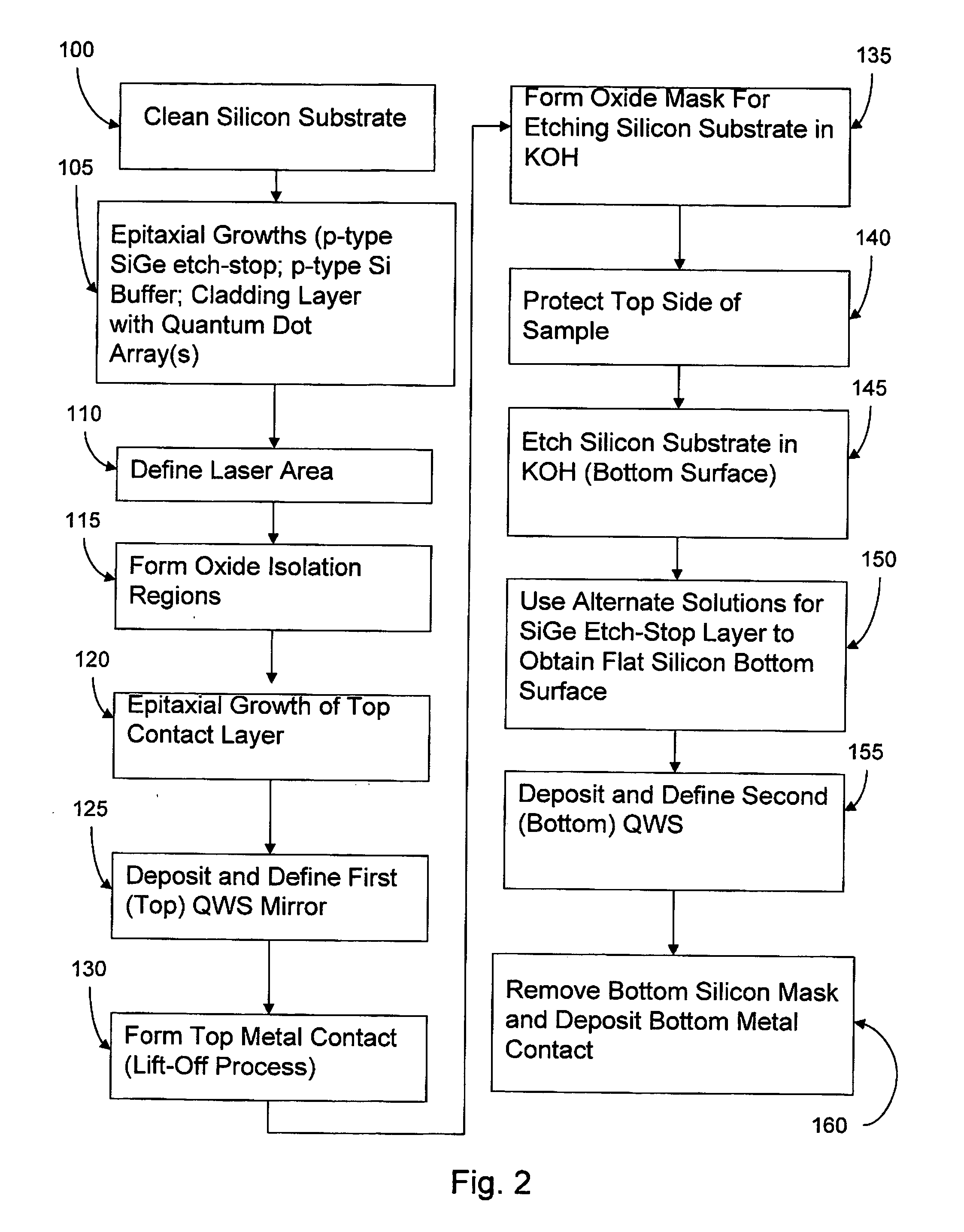

Double heterojunction light emitting diodes and laser diodes having quantum dot silicon light emitters

InactiveUS20050082554A1Laser active region structureSemiconductor laser structural detailsHeterojunctionDevice material

A direct-wafer-bonded, double heterojunction, light emitting semiconductor device includes an ordered array of quantum dots made of one or more indirect band gap materials selected from a group consisting of Si, Ge, SiGe, SiGeC, 3C—SiC, and hexagonal SiC, wherein the quantum dots are sandwiched between an n-type semiconductor cladding layer selected from a group consisting of SiC, 3C—SiC, 4H—SiC, 6H—SiC and diamond, and a p-type semiconductor cladding layer selected from a group consisting of SiC, 3C—SiC, 4H—SiC, 6H—SiC and diamond. A Ni contact is provided for the n-type cladding layer. An Al, a Ti or an Al / Ti alloy contact is provided for the p-type cladding layer. The quantum dots have a thickness that is no greater than about 250 Angstroms, a width that is no greater than about 200 Angstroms, and a center-to-center spacing that is in the range of from about 10 Angstroms to about 1000 Angstroms.

Owner:ASTRALUX

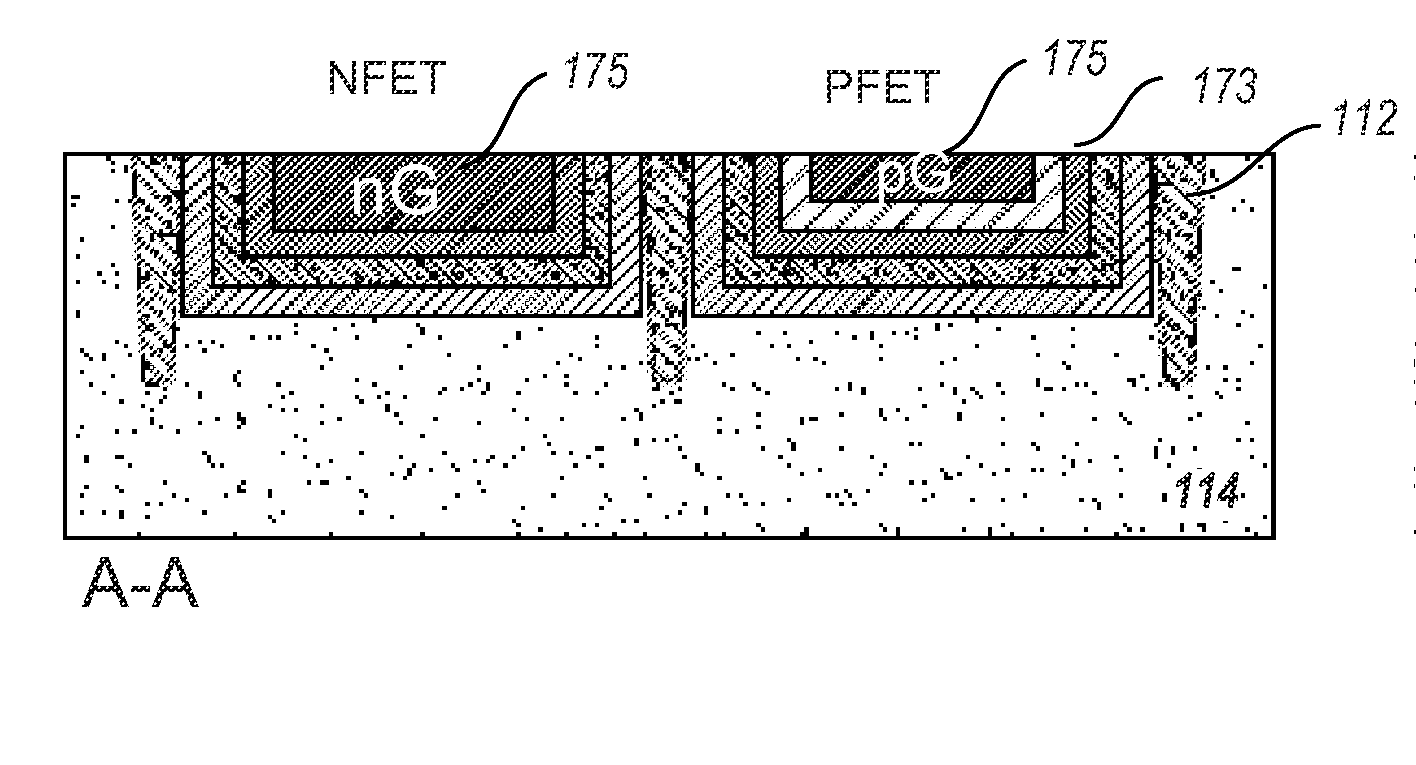

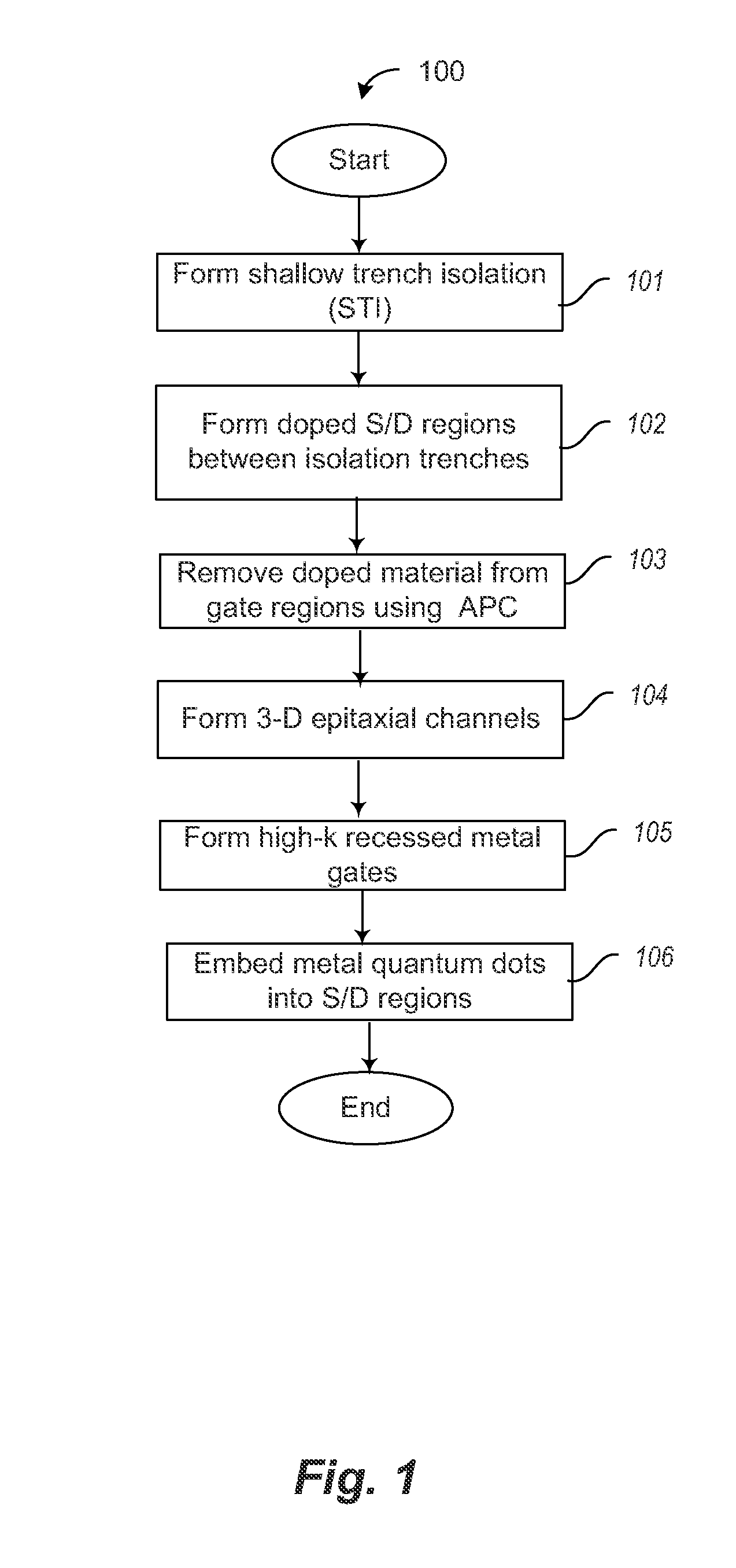

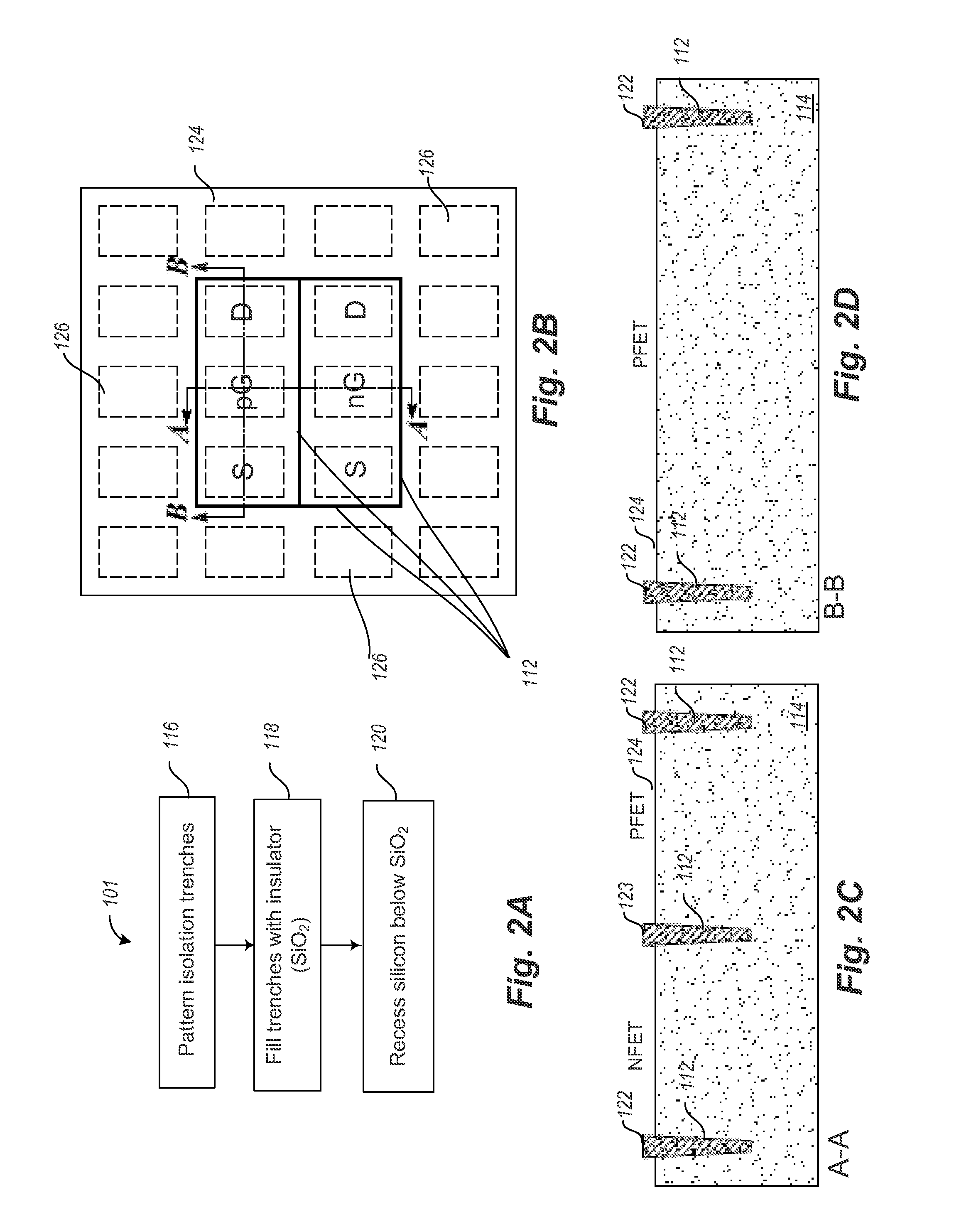

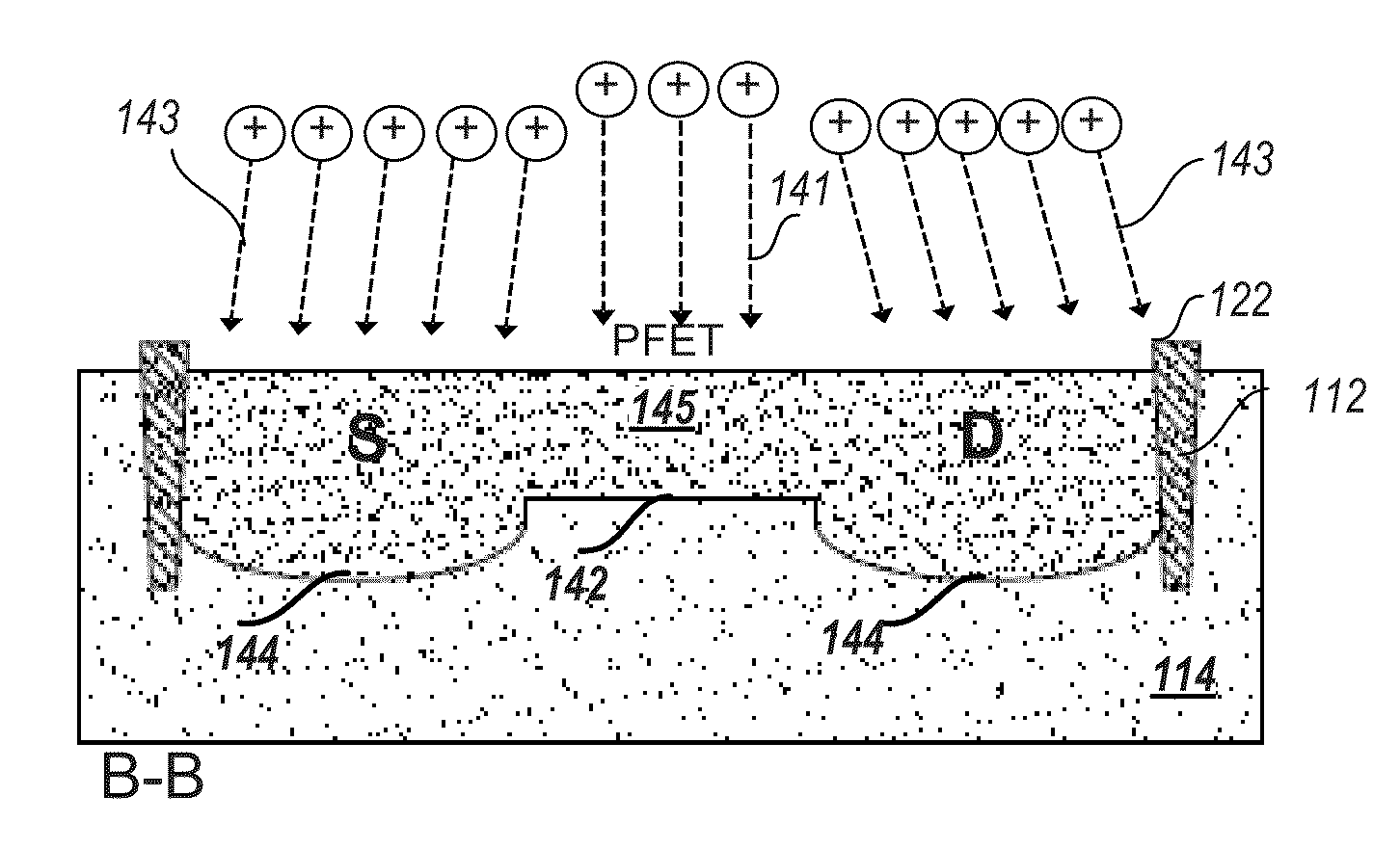

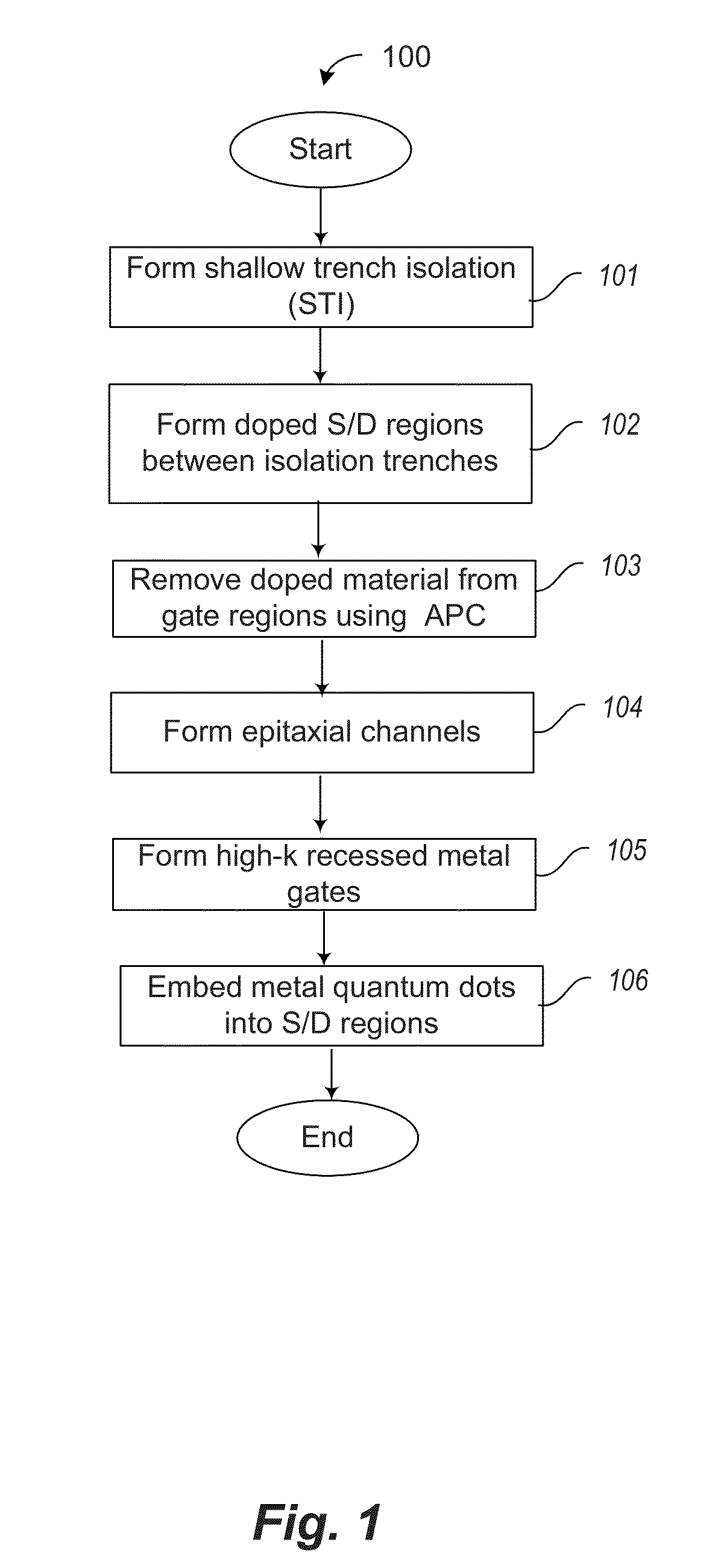

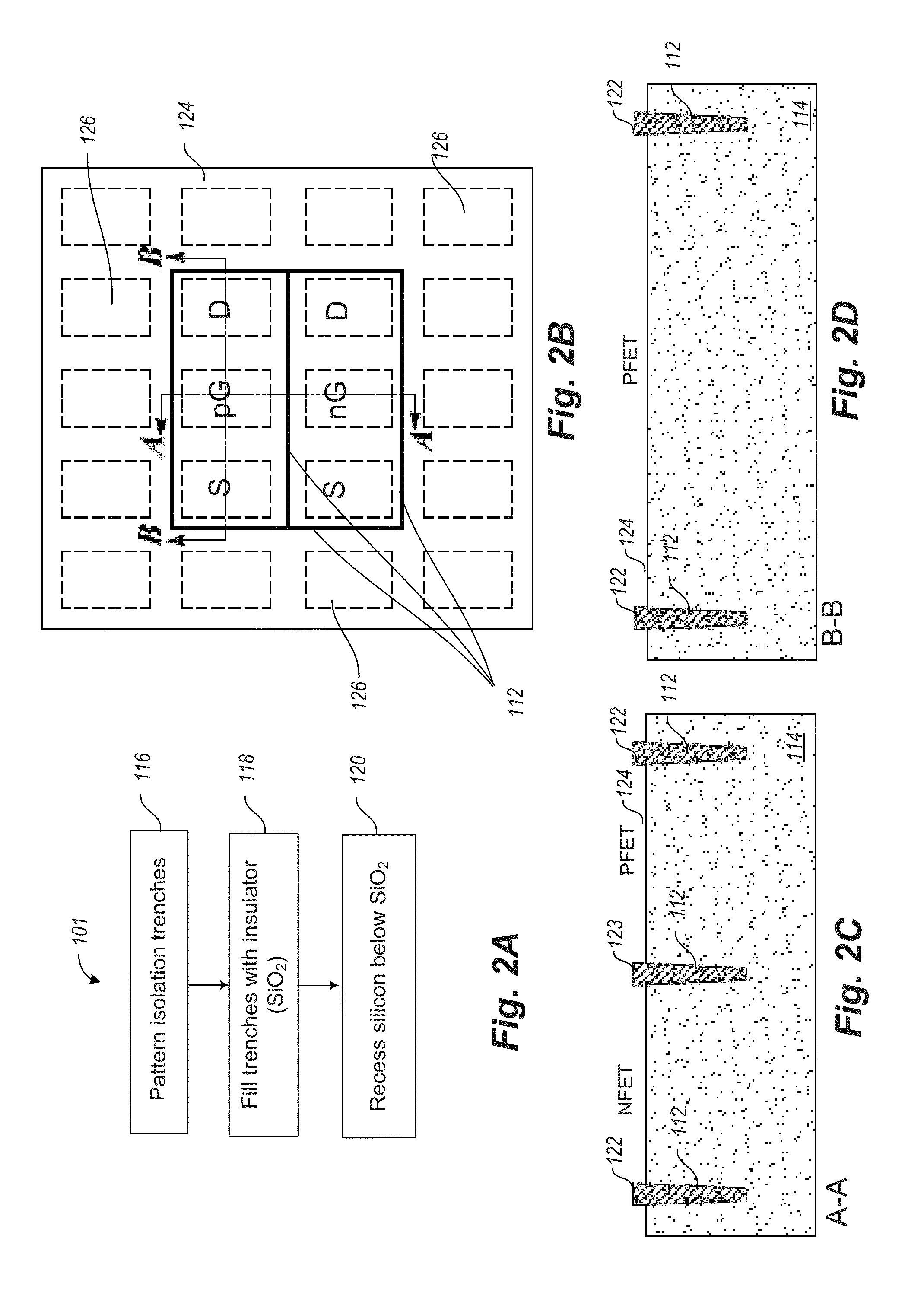

Quantum dot array devices with metal source and drain

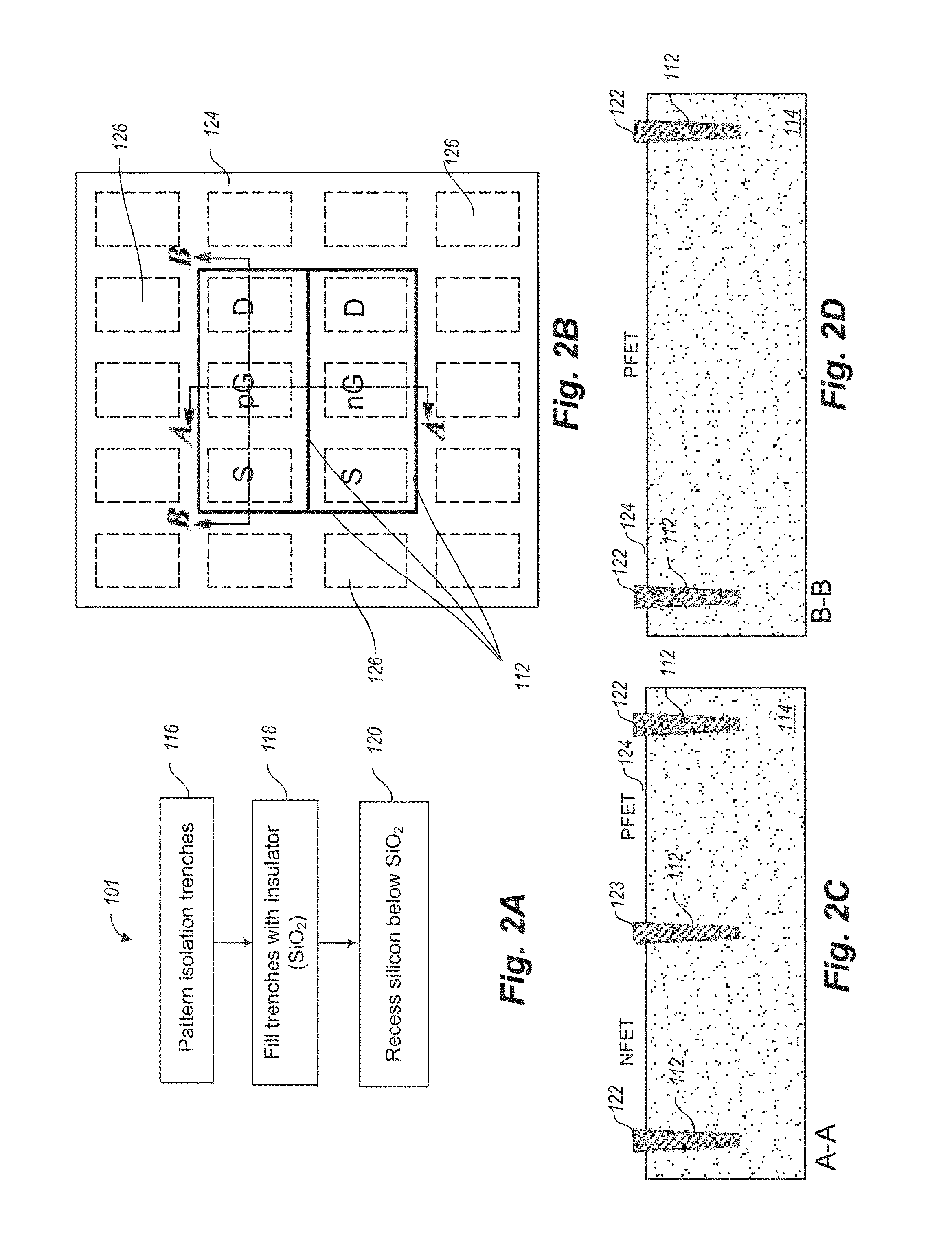

ActiveUS20140084245A1Easy to controlImprove performanceTransistorSemiconductor/solid-state device manufacturingMOSFETSemiconductor

Metal quantum dots are incorporated into doped source and drain regions of a MOSFET array to assist in controlling transistor performance by altering the energy gap of the semiconductor crystal. In a first example, the quantum dots are incorporated into ion-doped source and drain regions. In a second example, the quantum dots are incorporated into epitaxially doped source and drain regions.

Owner:STMICROELECTRONICS INT NV

Semiconductor quantum dot device and method for forming a scalable linear array of quantum dots

An exemplary quantum dot device can be provided, which can include, for example, at least three conductive layers and at least two insulating layers electrically insulating the at least three conductive layers from one another. For example, one of the conductive layers can be composed of a different material than the other two of the conductive layers. The conductive layers can be composed of (i) aluminum, (ii) gold, (iii) copper or (iv) polysilicon, and / or the at least three conductive layers can be composed at least partially of (i) aluminum, (ii) gold, (iii) copper or (iv) polysilicon. The insulating layers can be composed of (i) silicon oxide, (ii) silicon nitride and / or (iii) aluminum oxide.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Threshold adjustment for quantum dot array devices with metal source and drain

ActiveUS20140084247A1Easy to controlImprove performanceSemiconductor/solid-state device testing/measurementSolid-state devicesMOSFETSilver bromide

Incorporation of metallic quantum dots (e.g., silver bromide (AgBr) films) into the source and drain regions of a MOSFET can assist in controlling the transistor performance by tuning the threshold voltage. If the silver bromide film is rich in bromine atoms, anion quantum dots are deposited, and the AgBr energy gap is altered so as to increase Vt. If the silver bromide film is rich in silver atoms, cation quantum dots are deposited, and the AgBr energy gap is altered so as to decrease Vt. Atomic layer deposition (ALD) of neutral quantum dots of different sizes also varies Vt. Use of a mass spectrometer during film deposition can assist in varying the composition of the quantum dot film. The metallic quantum dots can be incorporated into ion-doped source and drain regions. Alternatively, the metallic quantum dots can be incorporated into epitaxially doped source and drain regions.

Owner:STMICROELECTRONICS SRL

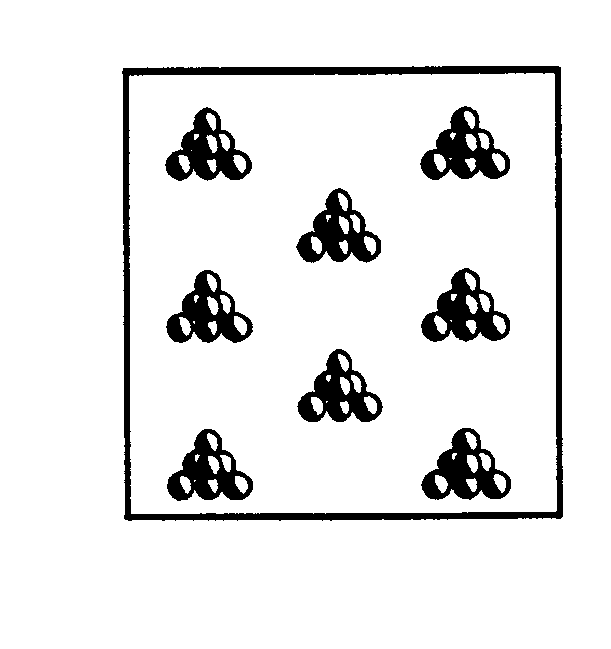

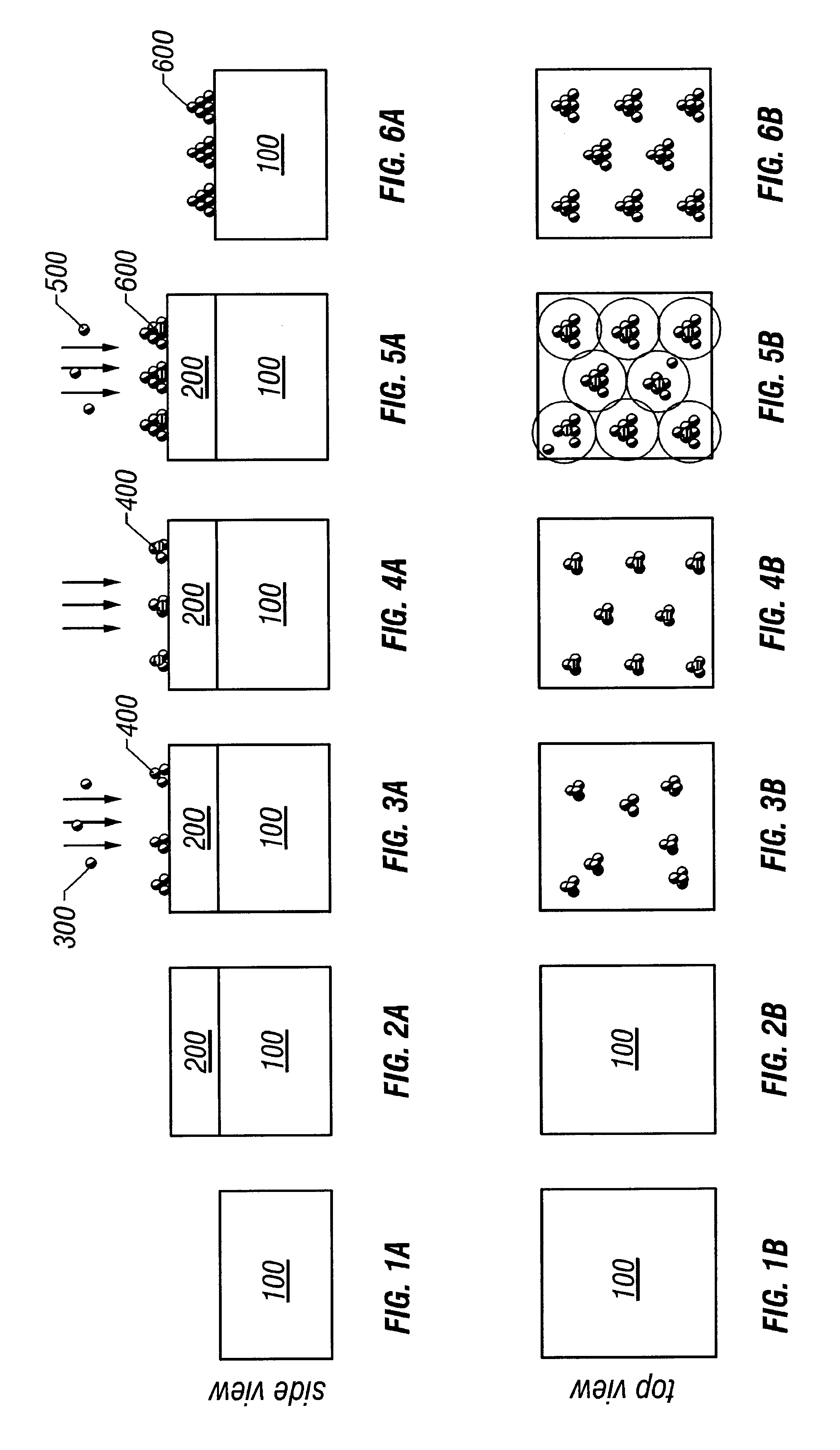

Self-organized formation of quantum dots of a material on a substrate

Systems and methods are described for fabricating arrays of quantum dots. A method for making a quantum dot device, includes: forming clusters of atoms on a substrate; and charging the clusters of atoms such that the clusters of atoms repel one another. The systems and methods provide advantages because the quantum dots can be ordered with regard to spacing and / or size.

Owner:UNIVERSITY OF TENNESSEE +1

Quantum dot channel (QDC) quantum dot gate transistors, memories and other devices

This invention describes a field-effect transistor in which the channel is formed in an array of quantum dots. In one embodiment the quantum dots are cladded with a thin layer serving as an energy barrier. The quantum dot channel (QDC) may consist of one or more layers of cladded dots. These dots are realized on a single or polycrystalline substrate. When QDC FETs are realized on polycrystalline or nanocrystalline thin films they may yield higher mobility than in conventional nano- or microcrystalline thin films. These FETs can be used as thin film transistors (TFTs) in a variety of applications. In another embodiment QDC-FETs are combined with: (a) coupled quantum well SWS channels, (b) quantum dot gate 3-state like FETs, and (c) quantum dot gate nonvolatile memories.

Owner:JAIN FAQUIR CHAND

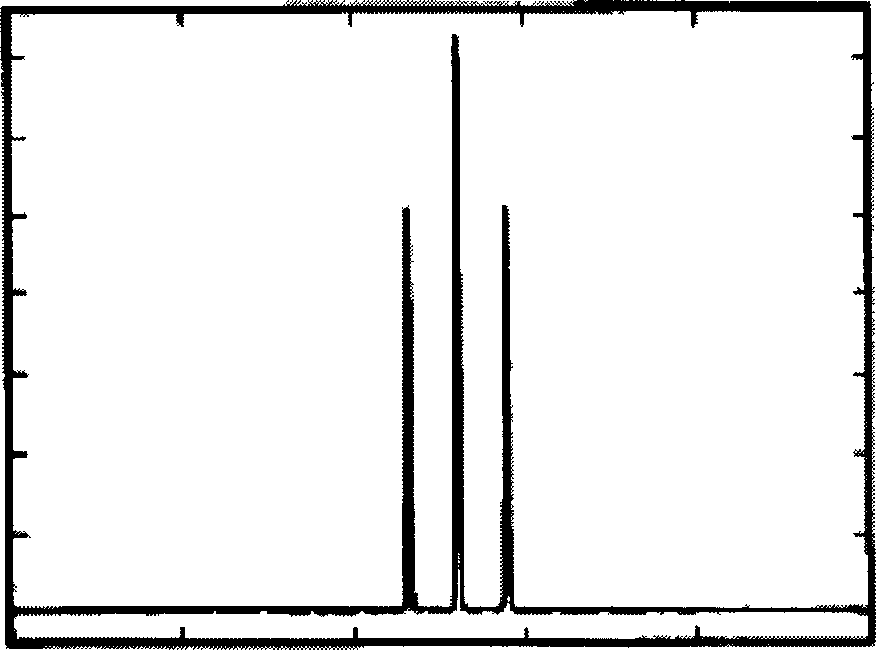

Semiconductor laser with low relative intensity noise of individual longitudinal modes and optical transmission system incorporating the laser

ActiveUS20100142973A1Low intensity-noiseReduce bit error rateLaser detailsLaser optical resonator constructionRelative intensity noiseHomogeneous broadening

A semiconductor laser comprises an electrically isolated active section and at least one noise reducing section and operates on a ground state transition of a quantum dot array having inhomogeneous broadening greater than 10 nm. The laser preferably emits more than 10 optical modes such that a total relative intensity noise of each optical mode is less than 0.2% in the 0.001 GHz to 10 GHz range. The spectral power density is preferably higher than 2 mW / nm. An optical transmission system and a method of operating a quantum dot laser with low relative intensity noise of each optical mode are also disclosed.

Owner:INNOLUME

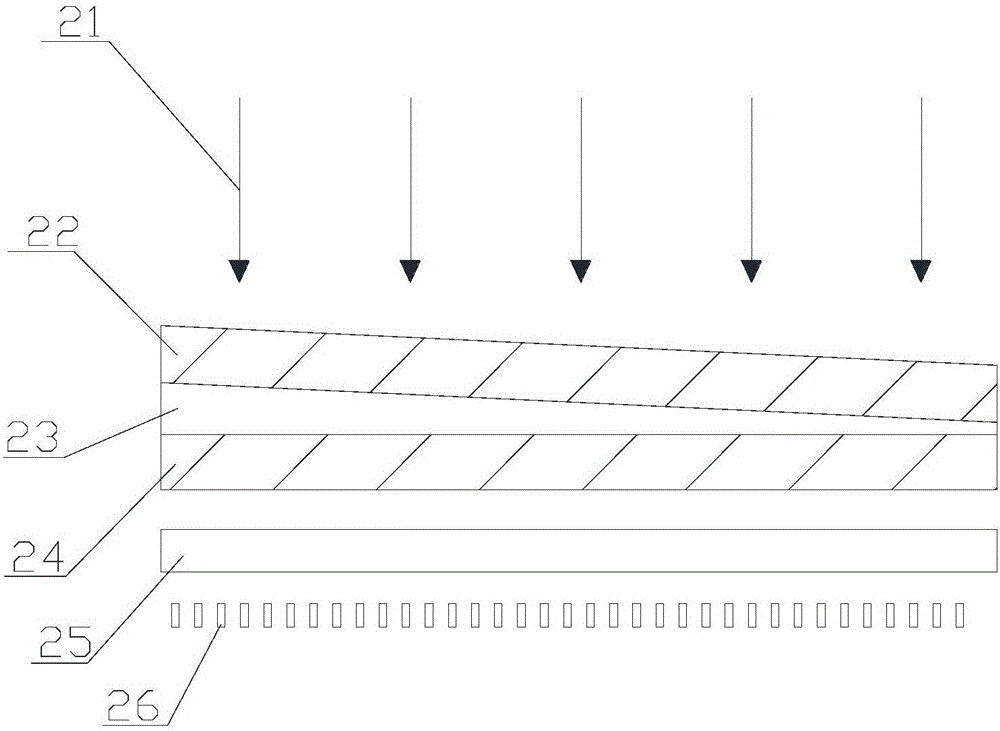

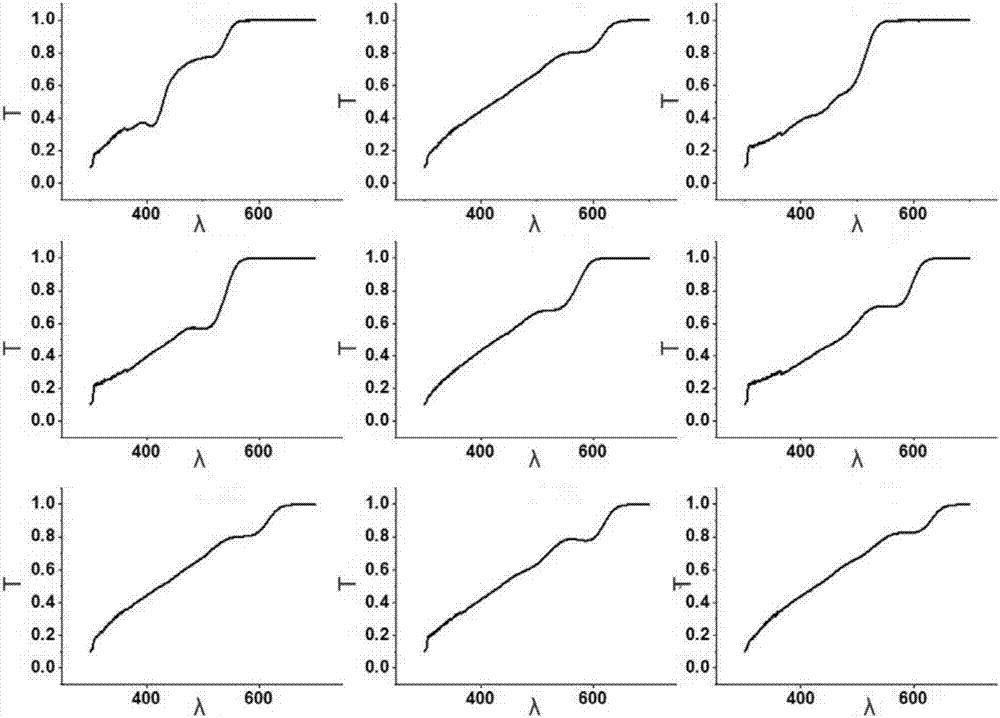

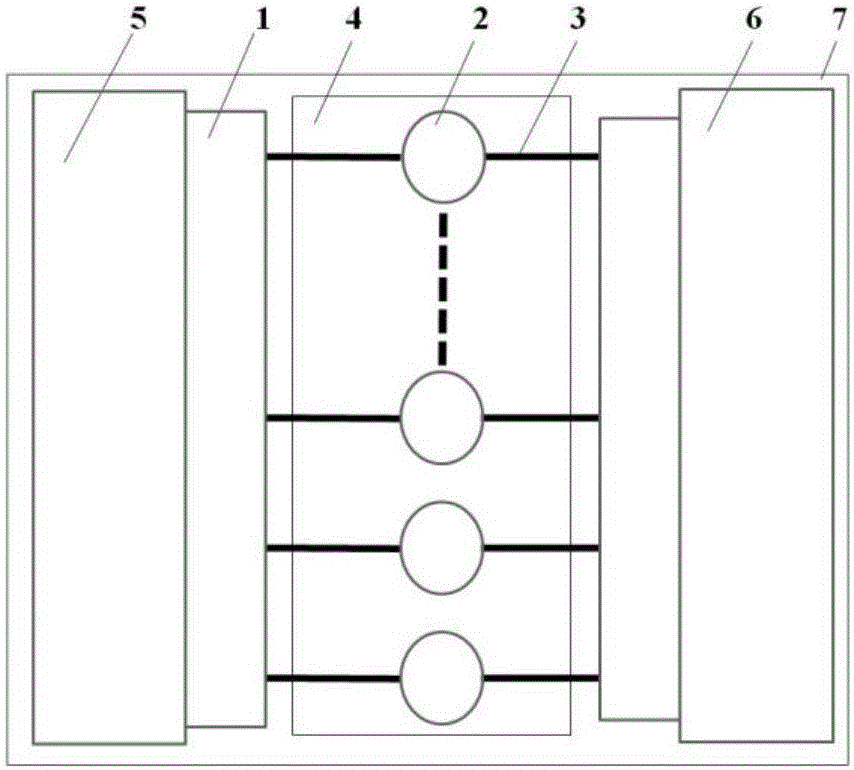

Quantum dot array spectrum sensor

InactiveCN106768331AHigh wavelength resolutionThe number of encoding bits increasesSpectrum investigationPhotovoltaic detectorsLight sensing

The invention discloses a quantum dot array spectrum sensor, comprising: a quantum dot colloidal array film and an array photoelectric detector; the quantum dot colloidal array film is used for bearing a quantum dot colloidal array; the quantum dot colloidal array includes a plurality of quantum dot colloidal units, wherein at least one quantum dot colloidal unit has a different absorbing or transmitting spectrum from other quantum dot colloidal units; the side of the quantum dot colloidal array film bearing the quantum dot colloidal array is opposite to a light-sensing side of the array photoelectric detector; after measured light of measured spectrum irradiates the quantum dot colloidal array film, transmitting light passing through the quantum dot colloidal array is detected by the light-sensing side. With the cooperation of the quantum dot colloidal array and the array photoelectric detector, the quantum dot array spectrum sensor has great bandwidth, high wavelength resolution and good sensitivity to weak light, and properties of existing instruments are improved greatly.

Owner:杭州盗火者科技有限公司

Method for preparing large-area and height ordered nanometer silica quantum dot array

InactiveCN1614740AStrong quantum confinement effectOvercome the shortcomings of not having real quantum effectsSemiconductor/solid-state device manufacturingNano siliconSemiconductor materials

The method includes following steps: firstly alumina molding board is made by using electrochemical method;the molding board with highly ordered pore space structure is transplanted to semiconductor base plat; the natural quantum dot of nano-silicon is grown on the semiconductor base plate through the pore of the molding board by using PECVD; finally the aluminum molding board will be removed by using wet chemical method. The artificial quantum dot obtained by the invention has following features: average diameter is 30-50 nanometers; height is 20-30 nanometers; separation is 100 nanometers; area density is over 1X1010 / cm2;a plenty of silica natural quantum dots whose diameter are from 3-6 nanometers are embedded into each artificial quantum dot.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of silicon and silicon germanium quantum point array

InactiveCN1725438AThe preparation method is simpleLaser detailsNanostructure manufacturePiranha solutionPolystyrene

A preparation method for Si and SiGe quantum spot array includes: carrying out acetone vibration cleaning, alcohol vibration cleaning piranha solution and RCA solution process orderly to a silicon chip or silicon chip deposited with a SiGe film then dropping the styroflex small ball solution with the quality percentage concentration sphere of 0.01-0.9% into the surface cleaned silicon chip or that with SiGe film to be put in air for natural drying then to be heat-insulated under 90-110deg.C for 1-6min and depositing an Ag film of 25-100nm on the substrate wit a vacuum plating instrument, immersing the deposited Ag film sample in the etching solution of hydrofluoric acid and ferric nitrate for process.

Owner:TSINGHUA UNIV

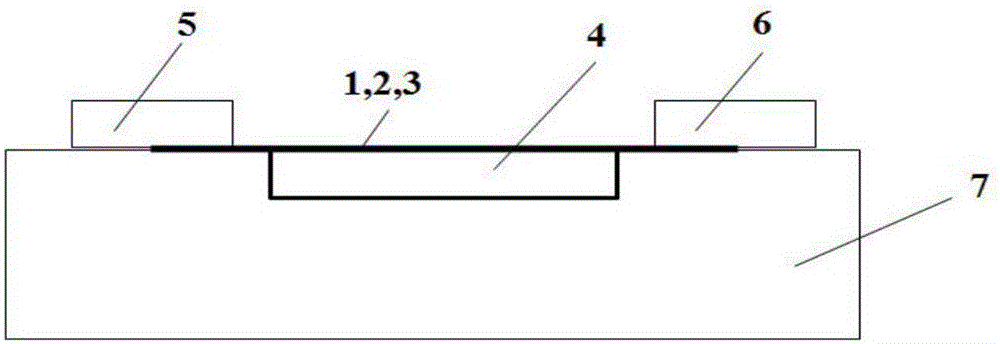

Method for manufacturing field-effect transistor based on quantum dot film conducting channel

ActiveCN104051275ATaking advantage of quantum size effectsFlexible and controllable performanceTransistorSemiconductor/solid-state device manufacturingEvaporationQuantum size effect

The invention discloses a method for manufacturing a field-effect transistor based on a quantum dot film conducting channel. The advanced quantum dot assembly technology is utilized, a single CdSe quantum dot array film is assembled out on a silicon / silicon dioxide substrate to serve as the conducting channel of the field-effect transistor, Cr / Au composite metal electrodes are formed on the single CdSe quantum dot array film and the substrate silicon of the film through a graphical mask covering evaporation process technology respectively, a source electrode, a drain electrode and a grid electrode are correspondingly led out, the quantum dot channel is effectively packaged and protected by spin-coating of organic matter, and consequently the novel field-effect transistor based on the quantum dot film conducting channel is manufactured out. The manufacturing method is novel, low in manufacturing cost, simple in manufacturing process, accurate and controllable, the manufactured field-effect transistor is provided with the special quantum dot array film conducting channel, the quantum size effect of the quantum dot array film can be fully utilized, and therefore the sensitivity of the transistor is effectively improved, and the method has very significant application value in novel photoelectric devices.

Owner:FUZHOU UNIV

Photoetching method for nanoparticle pattern based on self organization

InactiveCN1391264ABest Assembly SolutionImprove versatilitySemiconductor/solid-state device manufacturingNanoparticleGas phase

The ordered array and pattern of nanoparticles formed by gas-phase or liquid-phase deposition is used to replace the mask generated by exposure used in photoetch technology, resulting in structural size less than 10 nm. It features that the copolymer film is used as template to guide the assembling of nanoparticles. Its advantage is high versatility to different substrates.

Owner:SHANGHAI HUA HONG GROUP +1

Article and method for implementing electronic devices on a substrate using quantum dot layers

Novel use of a cladded quantum dot array layer serving as a waveguide channel by sandwiching it between two cladding layers comprised of lower index of refraction materials is described to form Si nanophotonic devices and integrated circuits. The photonic device structure is compatible with Si nanoelectronics using conventional, quantum dot gate (QDG), and quantum dot channel (QDC) FET based logic, memories, and other integrated circuits.

Owner:JAIN FAQUIR CHAND +1

Quantum lattice diffracting rasters

A diffraction grating of quantum dot array is prepared by arranging large amount of quantum dots in quasi-random way on grating base, placing dots on one dimensional space of surface is random distribution and on another dimensional space in sine distribution for obtaining quantum dot array grating. The senior diffraction of the grating is so low as to be ignored.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

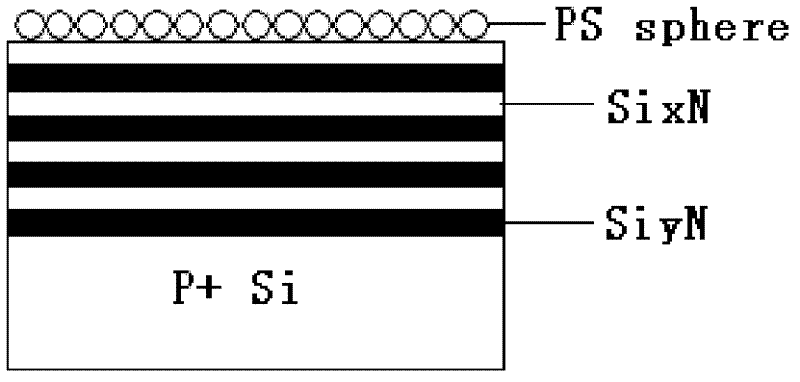

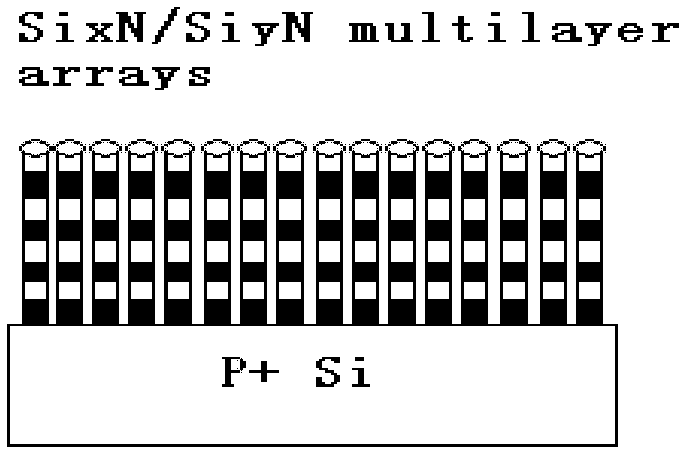

Sequential controllable nanometer silicon quantum dot array resistive random access memory and preparation method thereof

ActiveCN102244196AReduce the cross-sectional areaEasy to reassembleNanostructure manufactureSolid-state devicesNanopillarSilicon oxide

The invention relates to a sequential controllable nanometer silicon quantum dot array resistive random access memory and a preparation method thereof, and belongs to the technical field of non-volatile memories. The resistive random access memory comprises P and a silicon substrate material, and is characterized by also comprising a resistive silicon quantum dot multilayer film nanometer column array attached to the substrate material and an upper electrode and a lower electrode which are attached to the upper surface of the resistive silicon quantum dot multilayer film nanometer column array and the lower surface of the substrate; an insulating medium layer is arranged in the resistive multilayer film nanometer column array; and a silicon quantum dot multilayer film nanometer column is formed by at least two layers of silicon-enriched silicon nitride films which are inlaid with nanometer silicon quantum dots and have different nitrogen components or a silicon-enriched silicon oxide film sublayer which is inlaid with the nanometer silicon quantum dots and has different oxygen components. The sequential controllable nanometer silicon quantum dot array resistive random access memory can be compatible with the current micro-electronic process technology, and can show the advantage of sequential controllable nanometer silicon in resistive random access memory materials to fulfillthe aim of improving the switch ratio and stability of the resistive materials, so that nanometer silicon quantum dots are applied in silica-based nanometer memories in future.

Owner:NANJING UNIV

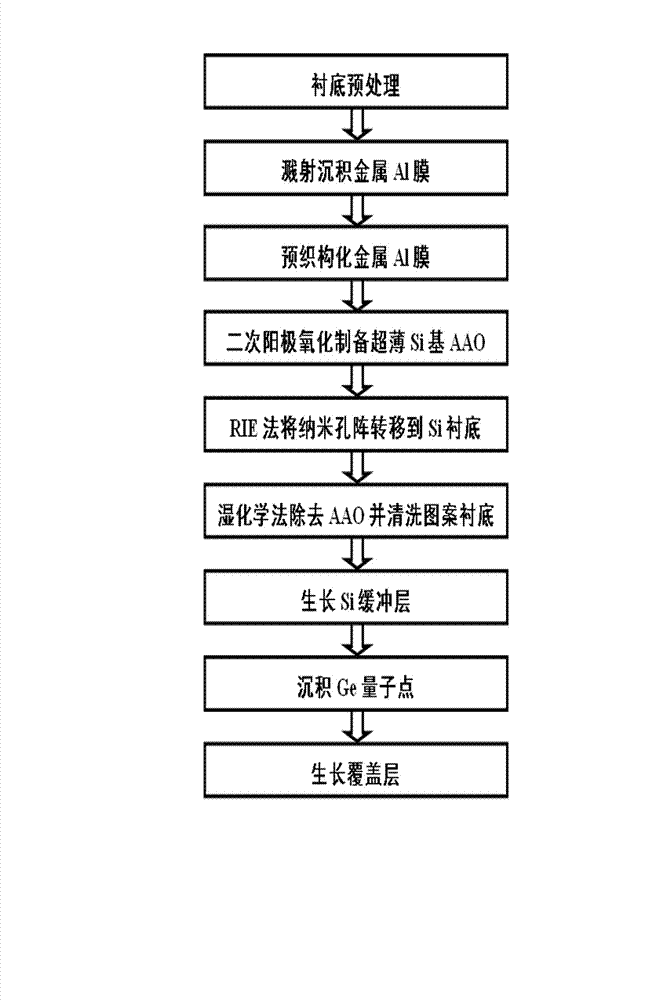

Novel self-assembly method of ordered Ge/Si quantum dot array by nano-pore replication and sputtering deposition

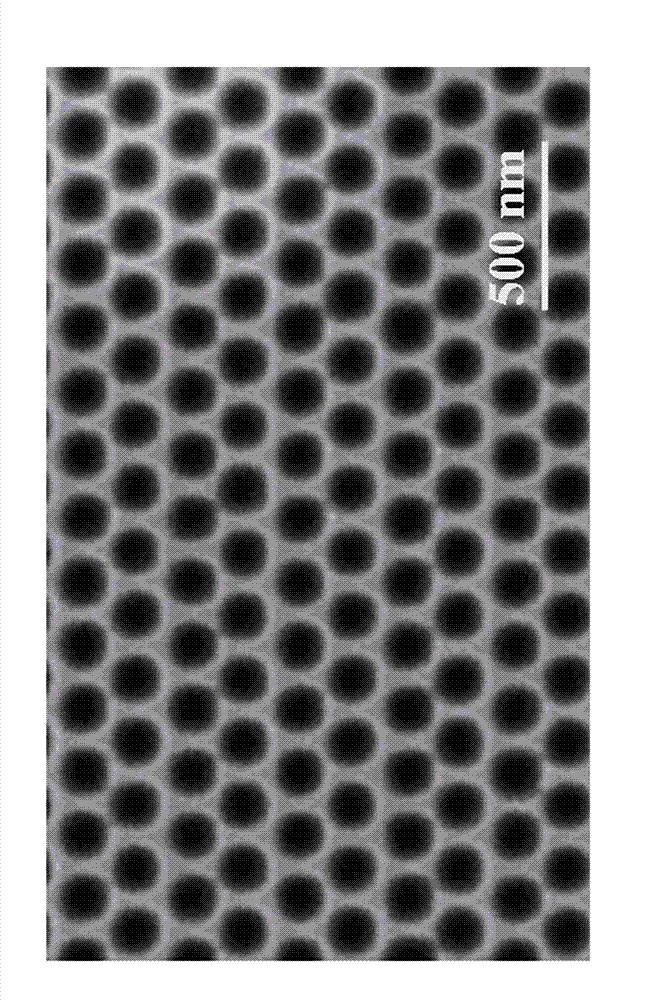

InactiveCN103117210AAvoid damageEasy to removeSemiconductor/solid-state device manufacturingNanoholeSolar cell

The invention provides a method of self-assembly growth of a large-area, even and ordered Ge quantum dot array on a Si substrate by sputtering deposition. The method includes preparation of ultrathin Si-based AAO (anodic aluminum oxide), preparation of a pattern substrate by nano-pore replication, and self-assembly growth of the even, ordered Ge quantum dot array on the surface of the pattern substrate by ion beam sputtering. Quantum dot growth process matching with the pattern substrate is obtained by controlling ion beam sputtering deposition temperature, ion beam flux voltage, and buffer layer thickness, so that Ge quantum dot nano-pores evenly and orderly grow at nucleation center. Even-size Ge quantum dots obtained are in hexagonal symmetrical distribution on the surface of the Si substrate, and the diameter of the quantum dots is adjustable. The method effectively overcomes the defects that distribution of the self-assembled Ge / Si quantum dots is random and disorder in position, the size is uneven, controllability is low, and preparation cost is high. The large-area, even, ordered and small-sized Ge quantum dot array is prepared at low cost. The method is applicable to manufacture of devices such as silicon-base quantum-dot light emitters, quantum-dot photoelectric detectors and efficient quantum-dot solar cells.

Owner:YUNNAN UNIV

Threshold adjustment for quantum dot array devices with metal source and drain

ActiveUS20160111521A1Easy to controlImprove performanceSemiconductor/solid-state device testing/measurementSolid-state devicesMOSFETAtomic layer deposition

Incorporation of metallic quantum dots (e.g., silver bromide (AgBr) films) into the source and drain regions of a MOSFET can assist in controlling the transistor performance by tuning the threshold voltage. If the silver bromide film is rich in bromine atoms, anion quantum dots are deposited, and the AgBr energy gap is altered so as to increase Vt. If the silver bromide film is rich in silver atoms, cation quantum dots are deposited, and the AgBr energy gap is altered so as to decrease Vt. Atomic layer deposition (ALD) of neutral quantum dots of different sizes also varies Vt. Use of a mass spectrometer during film deposition can assist in varying the composition of the quantum dot film. The metallic quantum dots can be incorporated into ion-doped source and drain regions. Alternatively, the metallic quantum dots can be incorporated into epitaxially doped source and drain regions.

Owner:STMICROELECTRONICS SRL

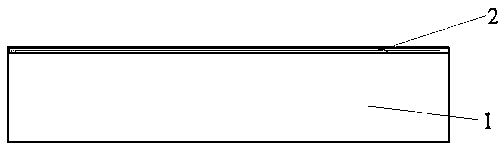

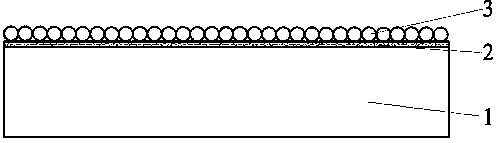

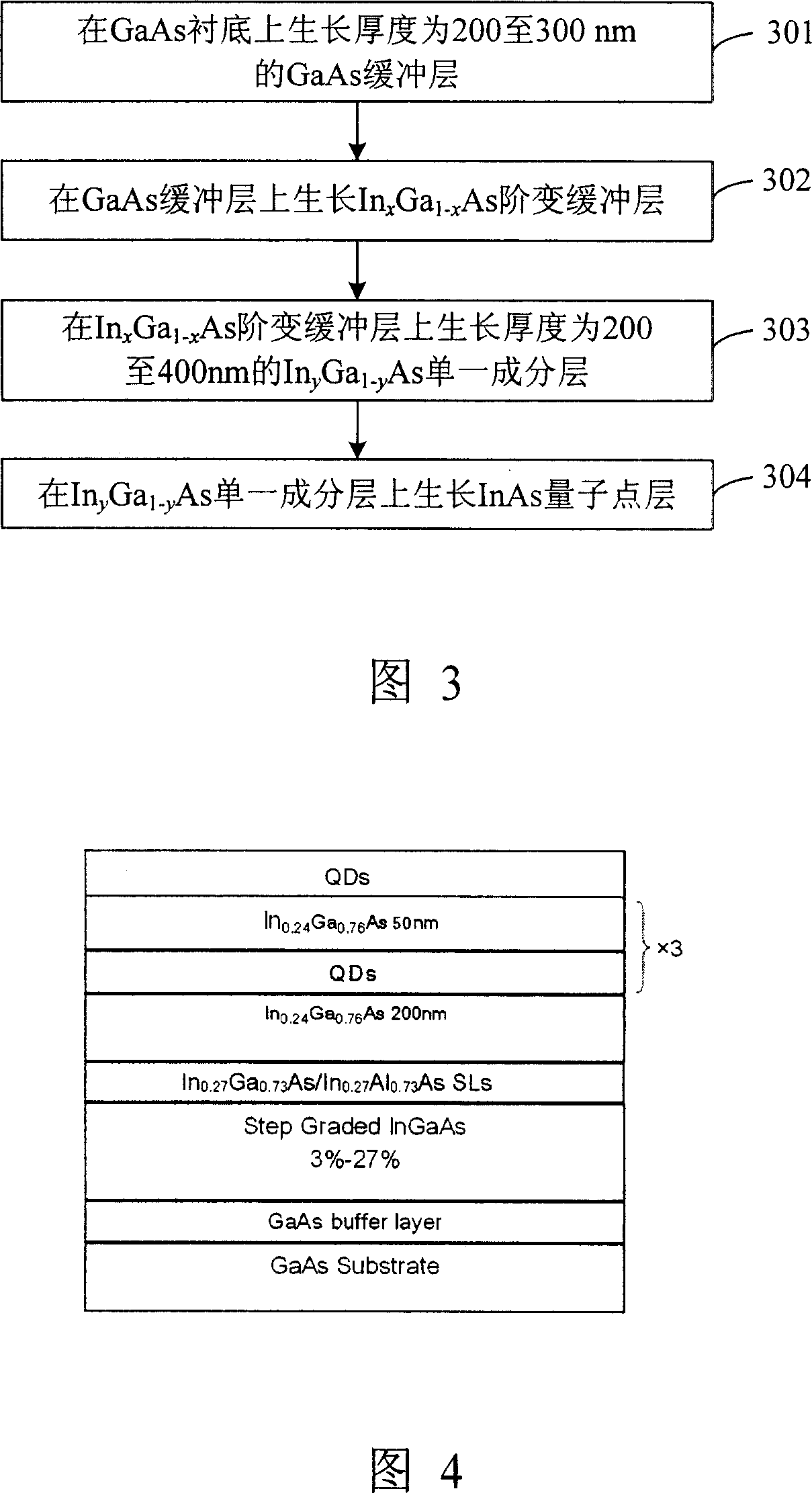

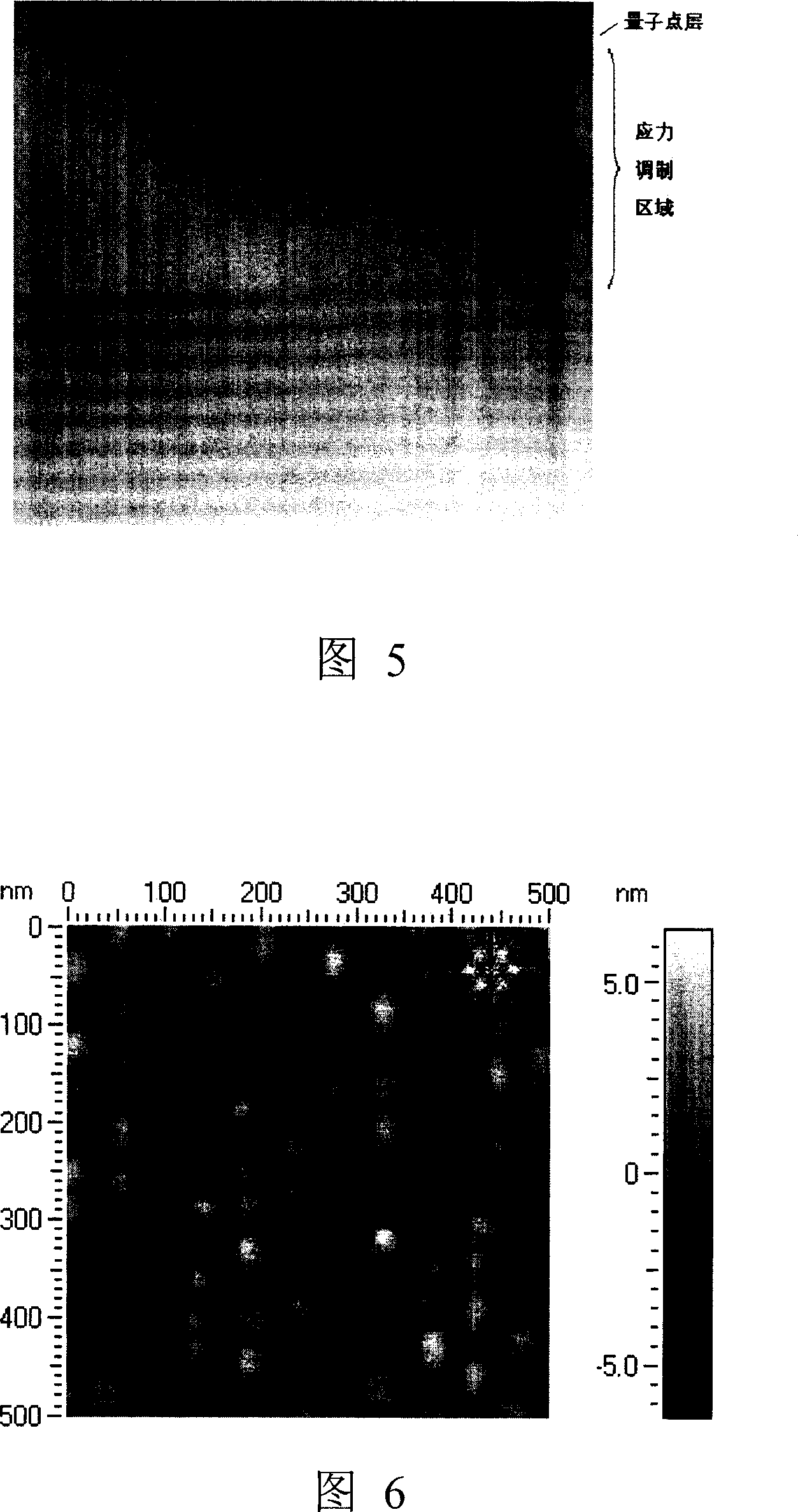

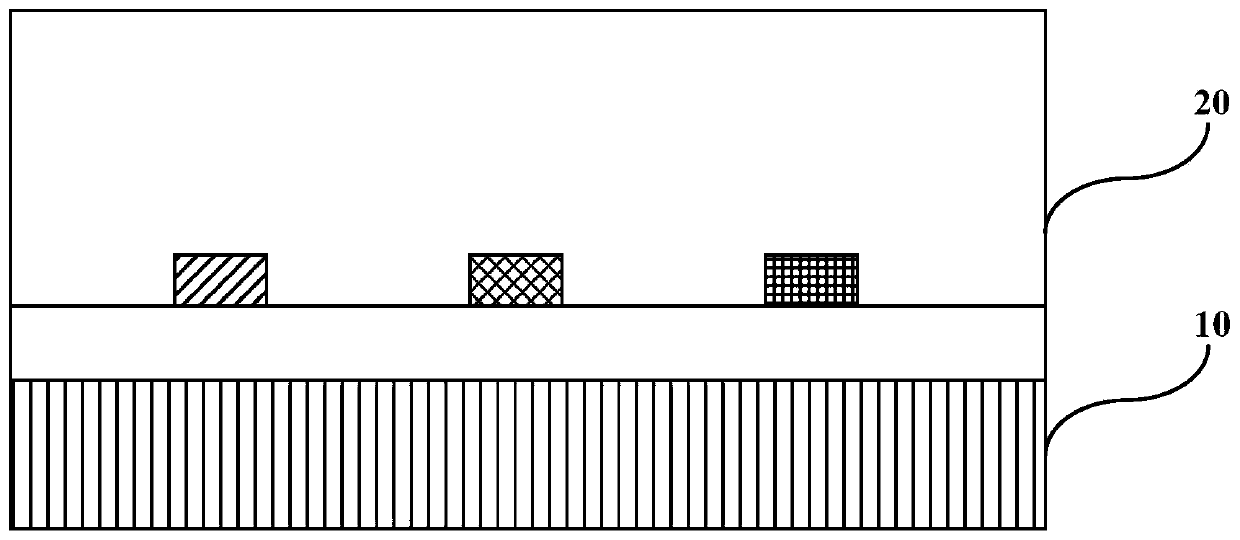

Quantum dot material structure and its growth method

InactiveCN101145590ARestrictiveSimple processLaser detailsFinal product manufactureQuantum devicesGallium arsenide

The invention discloses a quantum point material structure. The structure comprises a gallium arsenide GaAs substrate (10) for supporting the whole quantum point material structure, an epitaxial layer structure growing on the GaAs substrate (10) and comprising buffer layers (11,12,13) and an InAs quantum point layer (14), wherein the buffer layer comprises a GaAs buffer layer (11), an InxGa(1-x)As order variable buffer layer (12) and an InyGa(1-y)As single component layer (13) which grows in order on the substrate; and the InAs quantum point layer (14) grows on the InyGa(1-y)As single component layer (13). The invention further discloses a growth method of the quantum point material structure. With the inventive method, the large-area quantum points with ordered distribution are prepared by using the simple preparation process, the process is simple without special treatment of the substrate before growth and is completely compatible with the molecular beam epitaxy process. Additionally, the method is suitable for the bulk production of self-organization ordered-arrangement quantum point array material, which is significant for the quantum point material to be applied to the future quantum devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

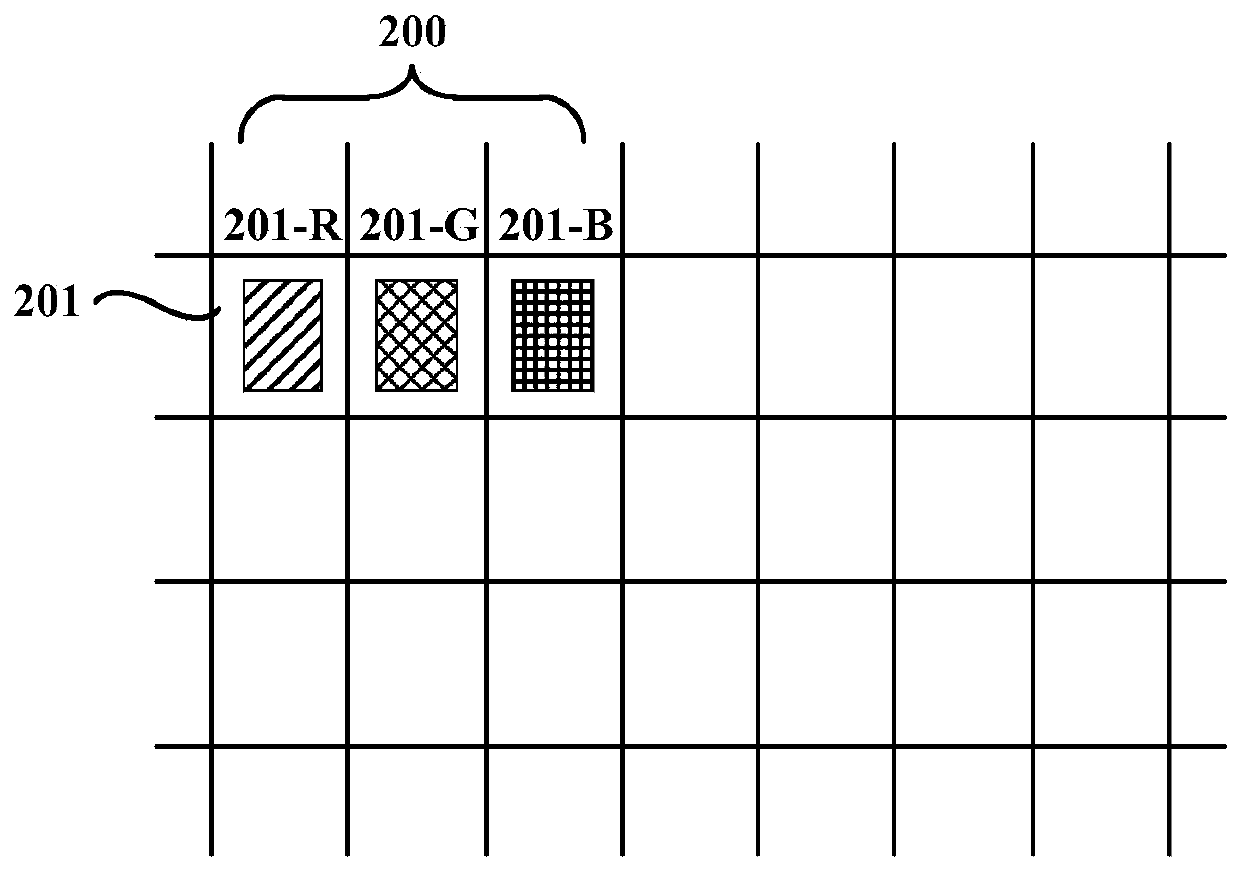

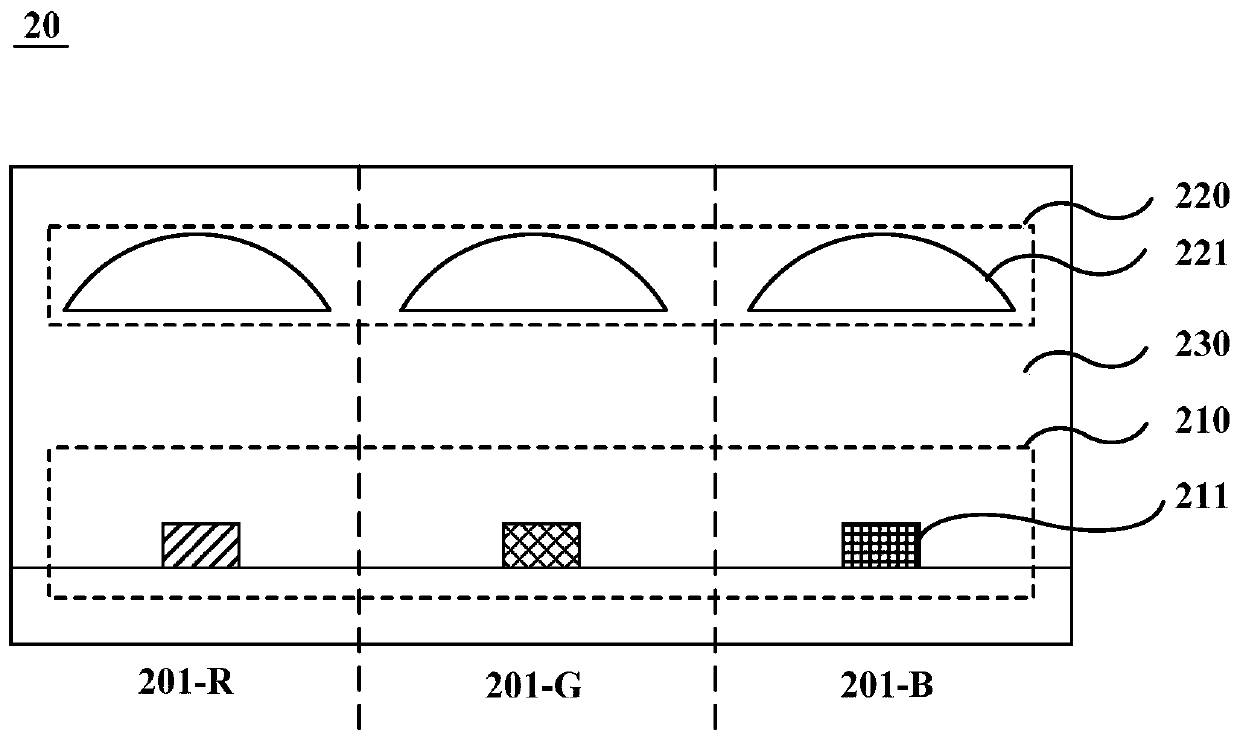

Quantum dot display panel and display device

The invention provides a quantum dot display panel and a display device, relates to the technical field of display, and can solve a problem of low luminous efficiency of a quantum dot display device.The quantum dot display panel is provided with a plurality of sub-pixels. The quantum dot display panel comprises a quantum dot array, a first lens array and a dimming layer. The quantum dot array comprises a plurality of quantum dot luminous layers arranged at intervals, wherein one quantum dot luminous layer is arranged in one sub-pixel. The first lens array is arranged on the light emitting side of the quantum dot array and comprises a plurality of first lenses arranged at intervals. One lens is arranged in one sub-pixel, and the first lens is used for emitting parallel light. The dimming layer is arranged on the light emitting side of the first lens array and is provided with a plurality of dimming regions with adjustable transmittance. One dimming region is arranged in one sub-pixel.The display device comprises the quantum dot display panel provided by the invention.

Owner:BOE TECH GRP CO LTD +1

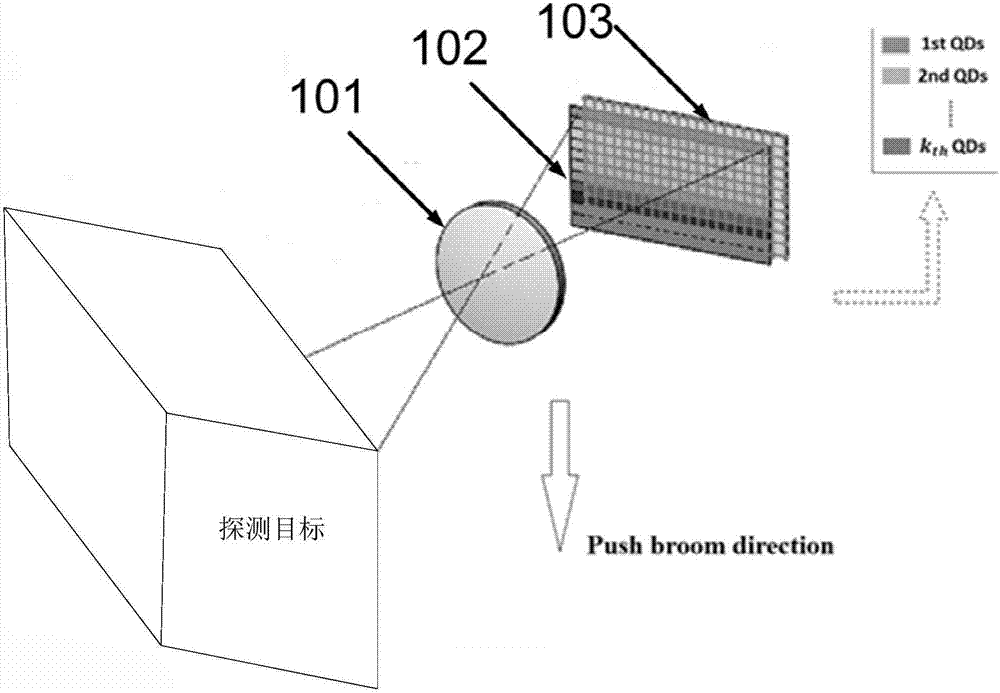

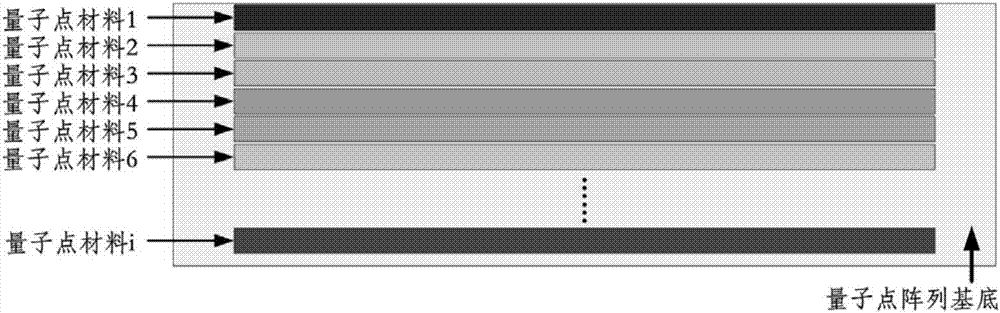

Quantum dot spectral imaging system

InactiveCN106872035AImprove performanceImprove energy utilizationSpectrum investigationSpectral transmissionHigh energy

The invention discloses a quantum dot spectral imaging system which comprises a front telescope, a quantum dot array plate, and an image detector arranged in order. The image detector is at the back focal plane of the front telescope. According to the quantum dot array plate, quantum dot materials with different spectral transmission rate characteristics are parallelly made on a substrate along a spectral dimension direction, each quantum dot material covers one or more rows of detection pixels in the spectral dimension direction, and a quantum dot strip is formed. The scheme is based on the quantum dot spectral imaging system, compared with a traditional spectral imager, the system has the advantages of stable performance, a high energy utilization rate, a simple structure, a small volume, a light weight and low cost, the complexity and development cost of the system are effectively reduced, the system is suitable for airborne or spaceborne equipment, and especially the application requirement of load miniaturization is satisfied. In addition, an incident spectrum can be restored well by using a spectral reconstruction algorithm.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

Micro-bolometer based on graphene quantum points

ActiveCN106197687AHigh temperature coefficient of resistanceImplement detectionPyrometry using electric radation detectorsSemiconductor devicesMicro nanoPhotovoltaic detectors

The invention provides a micro-bolometer based on graphene quantum points. The micro-bolometer comprises a substrate whose middle part is provided with a groove. The graphene quantum points are hanged above the groove and are connected through a graphene strip. Two ends of the graphene strip extend out of a graphene film to cover the substrate at two sides of the groove to form graphene electrodes. The micro-bolometer is characterized in that a hanged island-shaped graphene quantum point array is formed through the micro nano processing technology, the device temperature change in a same incident light power is increased by using the heat insulation effect by groove suspension, the device resistance temperature coefficient is raised by using quantization graphene, and the photoelectric detection is realized based on a micro-bolometer principle. Due to the absorption characteristic of a graphene material in an infrared wave band, the micro-bolometer provided by the invention can be used for the photoelectric detection of middle and far-infrared and terahertz wave bands, and a novel solution is provided for a present infrared photoelectric detector.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

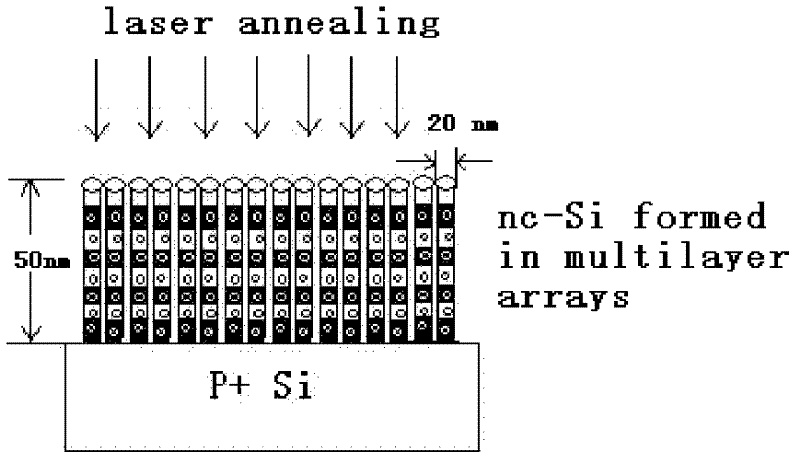

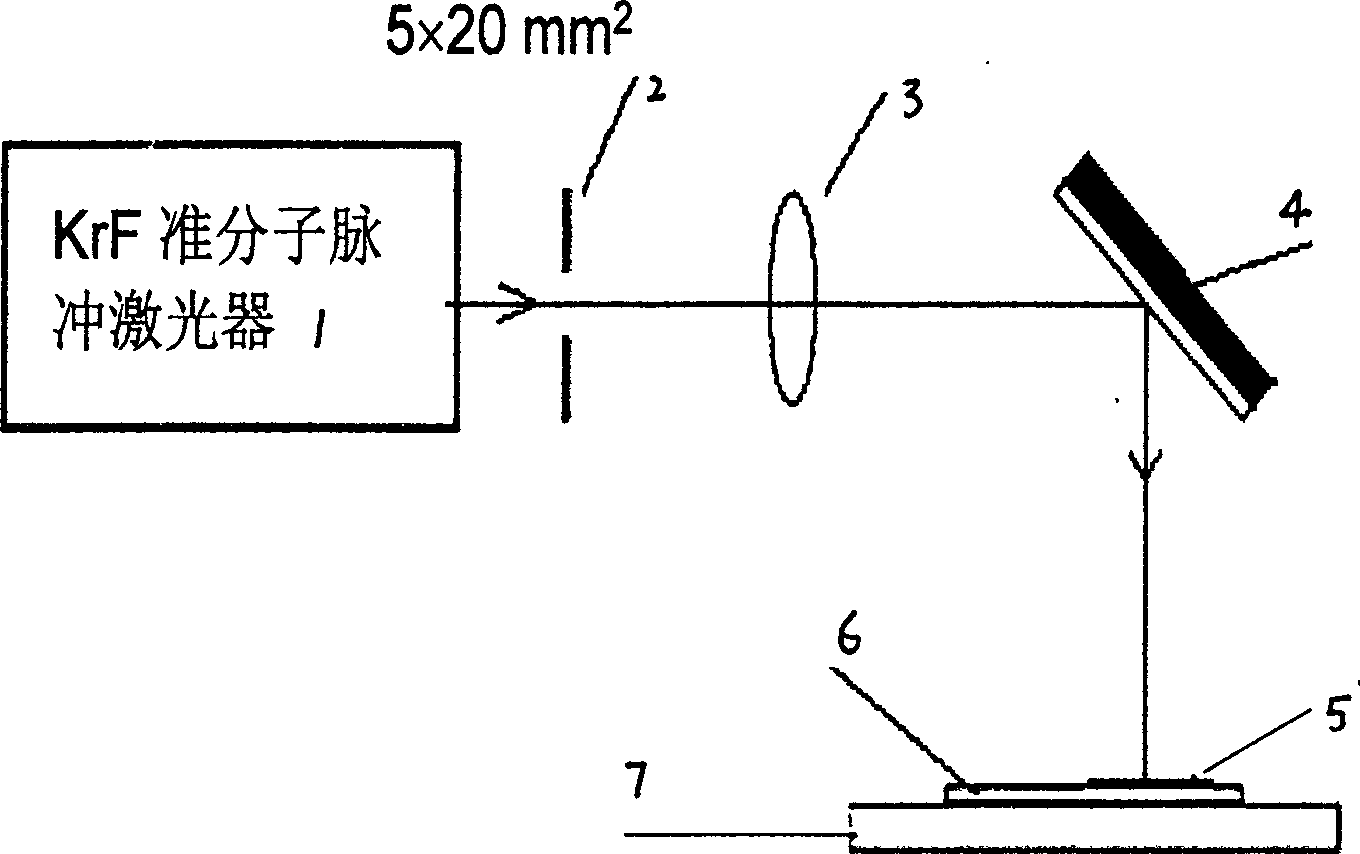

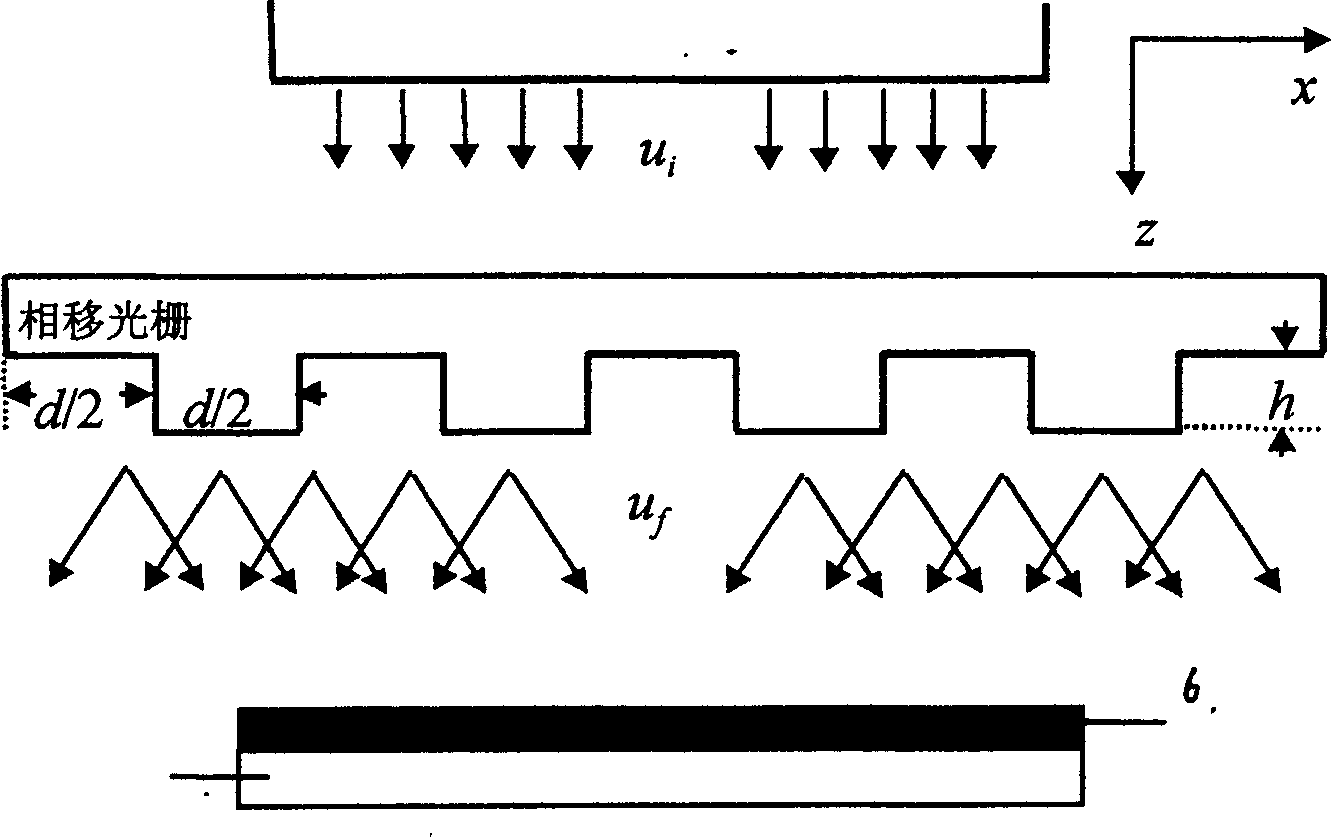

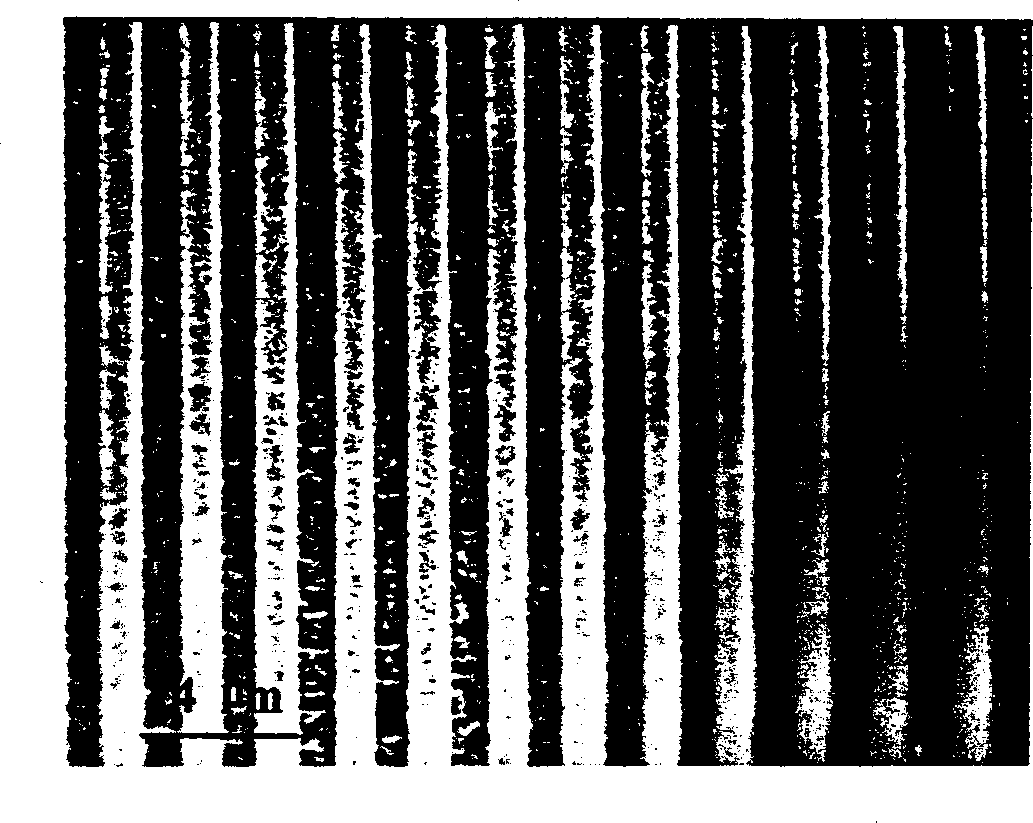

Method for contruction of tow-dimension ordered distributing silicon quantum point figurated nano structure

InactiveCN1484278ARealize graphical distributionControl formationMaterial nanotechnologyNanostructure manufactureGratingNanostructure

A method for building two-dimension orderly distributed Si quantum spot graphic nanameter structure is to process a phase-shift grating form board on the film of a-Si or a-SiNx: H / a-Si: H / a-SiNx: H then to crystallize it by laser interference, the laser beam arrives at surfaces of a-Si film or a-SiNx: H / a-Si: H / a -SiNx: H via the form board to form beam spots of two dimension periodic distribution of the energy density to make a -Si: H film to realize localized crystallization, that is to form nanometer Si quantum spot array of two-dimension space orderly distributed in the film.

Owner:NANJING UNIV

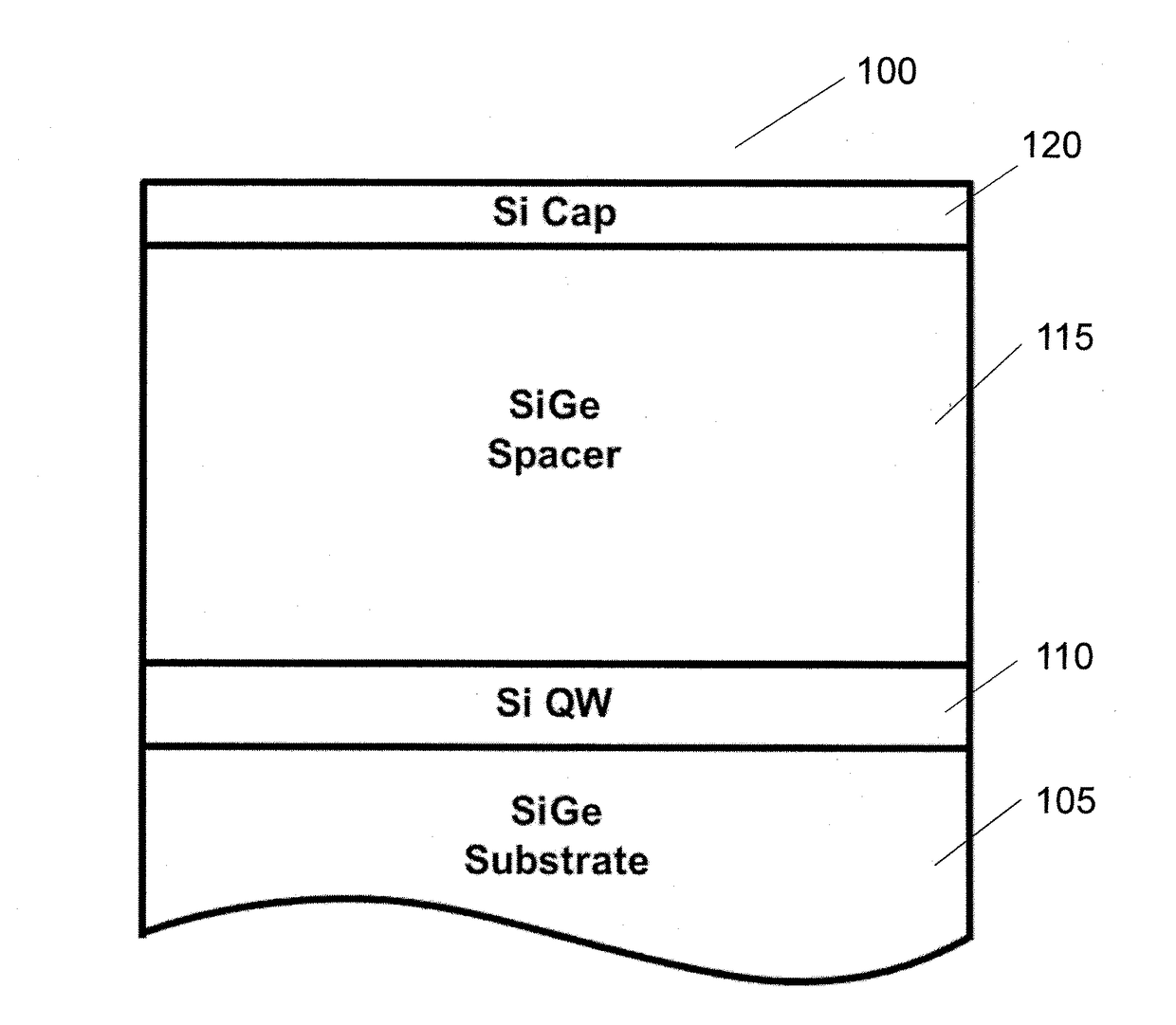

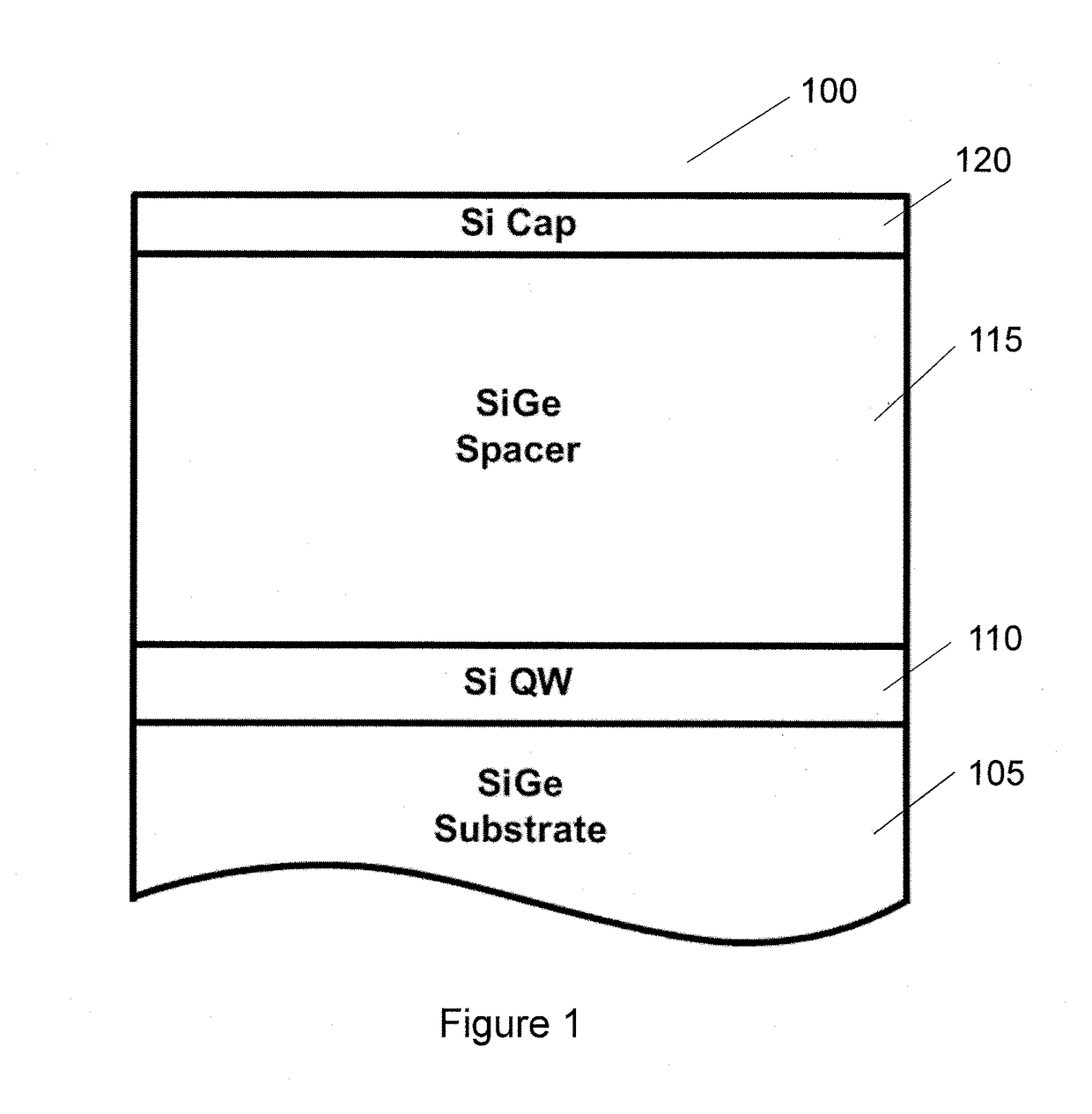

Quantum dot based optoelectronic device and method of making same

ActiveUS20060289855A1Commercial longevityImprove performanceNanoinformaticsSemiconductor/solid-state device manufacturingPhotovoltaic detectorsLattice mismatch

A method of forming an optically active region on a silicon substrate includes the steps of epitaxially growing a silicon buffer layer on the silicon substrate and epitaxially growing a SiGe cladding layer having a plurality of arrays of quantum dots disposed therein, the quantum dots being formed from a compound semiconductor material having a lattice mismatch with the silicon buffer layer. The optically active region may be incorporated into devices such as light emitting diodes, laser diodes, and photodetectors.

Owner:RGT UNIV OF CALIFORNIA

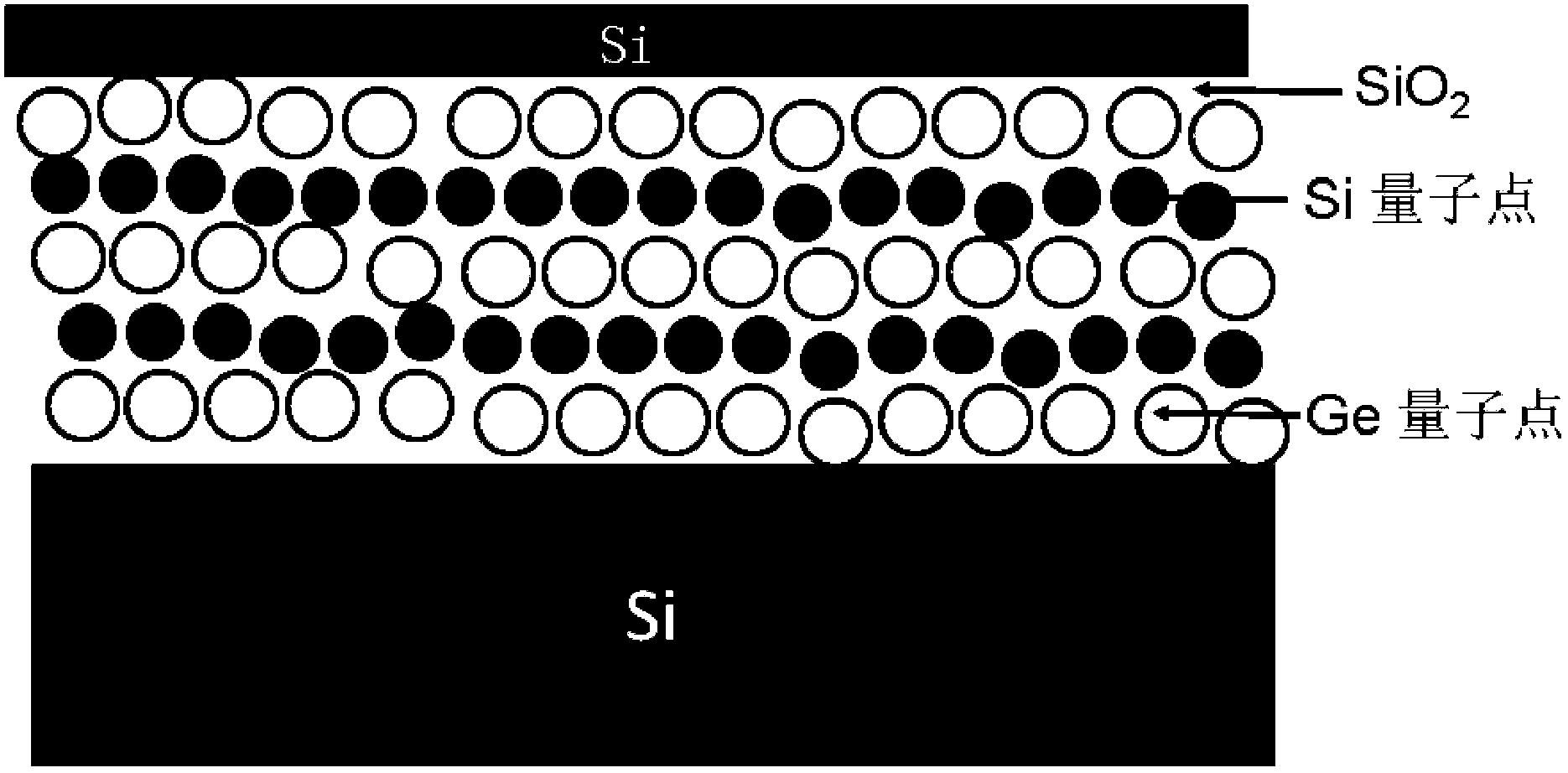

Multi-junction heterogeneous quantum dot array and manufacturing method thereof and multi-junction heterogeneous quantum dot solar cell and manufacturing method thereof

ActiveCN103489939AReduce the temperatureEasy to prepareMaterial nanotechnologyFinal product manufactureElectricityProduction line

The invention discloses a multi-junction heterogeneous quantum dot array and a manufacturing method of the multi-junction heterogeneous quantum dot array. The multi-junction heterogeneous quantum dot array comprises silicon quantum dot layers and germanium quantum dot layers, the silicon quantum dot layers and the germanium quantum dot layers are arranged in a staggered mode. The multi-junction heterogeneous quantum dot array is simple in manufacturing technology, and can achieve industrialized production and reduce production cost effectively. The invention further discloses a multi-junction heterogeneous quantum dot solar cell made of the multi-junction heterogeneous quantum dot arrays and a manufacturing method of the multi-junction heterogeneous quantum dot solar cell. The multi-junction heterogeneous quantum dot solar cell mainly utilizes rich non-toxic and durable silicon as raw materials on the basis of a current silicon solar energy production line. After the method is performed according to the technical scheme, the conversion efficiency of solar chips will be increased in a breakthrough mode and is larger than 31%, the purpose that the production cost is reduced to be 0.5 dollar / watt is also achieved, and the electricity price holds the line with the power grid electricity prize.

Owner:SUZHOU XIEXIN INDAL APPL INST

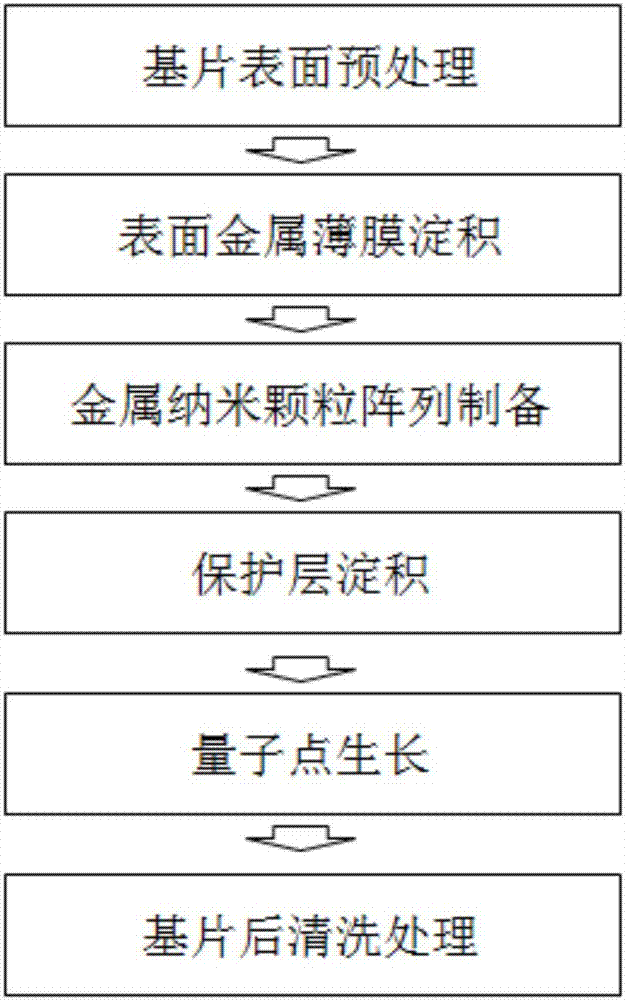

Controllable quantum dot array preparing method based on photo-thermal effect

ActiveCN107993923ASimple processNo damageMaterial nanotechnologySemiconductor/solid-state device manufacturingChemical synthesisThermal effect

The invention discloses a controllable quantum dot array preparing method based on the photo-thermal effect. According to the method, a metal or alloy nanoparticle array serves as a template, the reaction conditions of a quantum dot precursor are controlled through the local surface plasmon thermal effect irritated by a light source, and therefore the preparing site, size and nucleation density ofthe precursor is controlled. The method mainly includes the steps of preprocessing the surface of the substrate, conducting thin-film deposition on surface metal, preparing the metal nanoparticle array, depositing a protecting layer, growing the quantum dot and conducting post-washing on the substrate. The large-area low-cost quantum dot array is prepared through a chemical synthesis method. Themethod can be combined with a semiconductor processing technology, the prepared quantum dot array can be applied for machining and preparing a quantum dot laser device, a single photon light source, asolar cell, a high-efficiency light-emitting diode, a storage and other devices.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com