Manufacture method of large-area highly uniform sequential quantum dot array

A quantum dot, large-area technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of complex manufacturing process, high production cost, low production efficiency, etc., and achieve simple process, low production cost, and improved performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

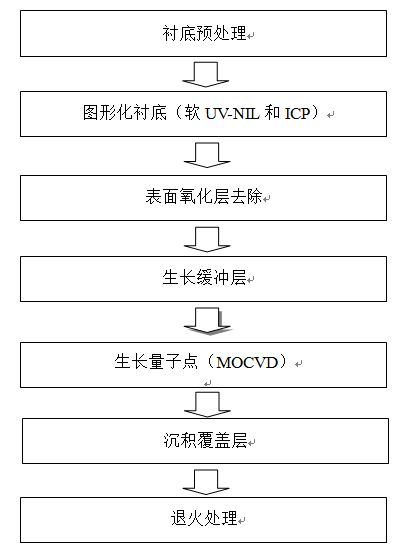

[0054] The technical route of self-organized growth of highly uniform and ordered quantum dot arrays based on soft UV-NIL and MOCVD can be found in figure 1 , including: ①substrate pretreatment; ②patterned substrate; ③remove surface oxide layer; ④grow buffer layer; ⑤grow quantum dots;

[0055] Figure 2a-Figure 2g It is a schematic diagram of making the quantum dot array of the present invention.

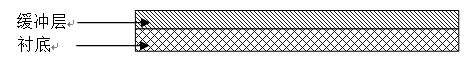

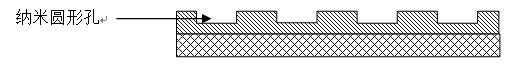

[0056] Its basic technological process is: (a) Figure 2a In, after the substrate is cleaned and decontaminated, a buffer layer with a thickness of 100-200nm is grown on it; (b) Figure 2b Among them, a large-area nanohole pattern array was fabricated on the substrate by soft UV-NIL and inductively coupled plasma etching (ICP); (c) Figure 2c In, use the oxide layer removal process to remove the oxide layer on the graphic surface; (d) Figure 2d In, a buffer layer of 10-30nm was grown; (e) Figure 2e In, MOCVD is used to grow highly uniform and orderly quantum dot arrays with c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com