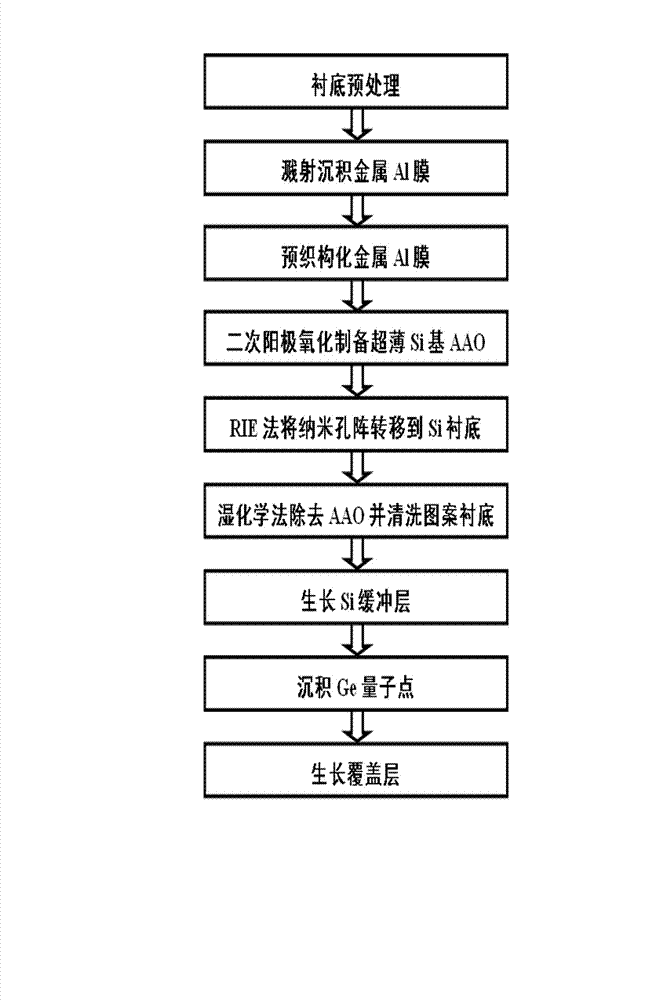

Novel self-assembly method of ordered Ge/Si quantum dot array by nano-pore replication and sputtering deposition

A technology of nanoholes and quantum dots, which is applied in the growth field of self-organized Ge/Si quantum dots, and can solve the problems of not being able to use low cost, not being able to reach the substrate surface, and removing by wet chemical methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

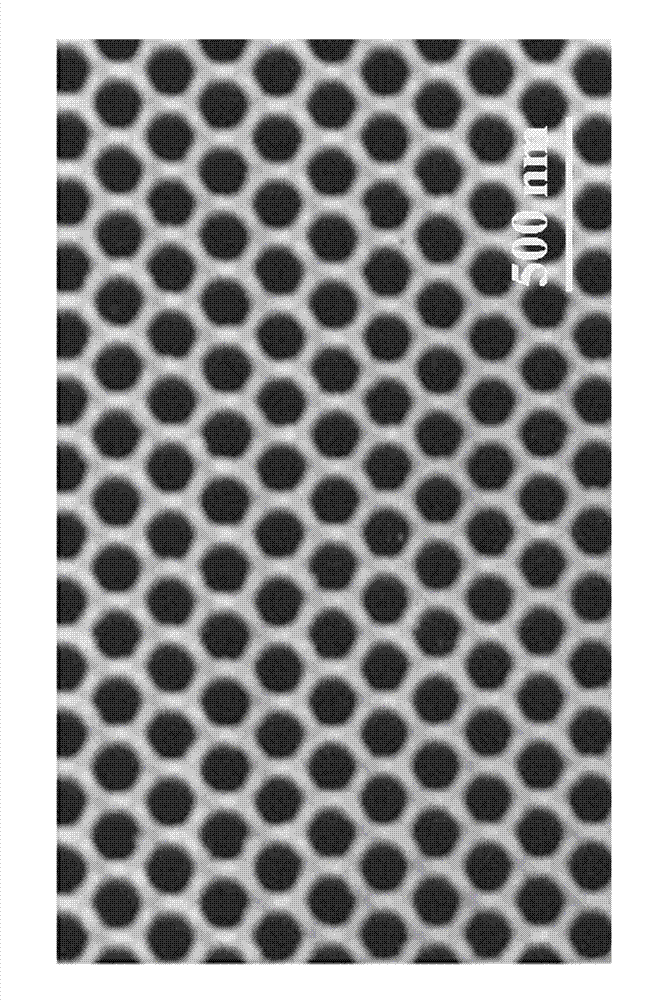

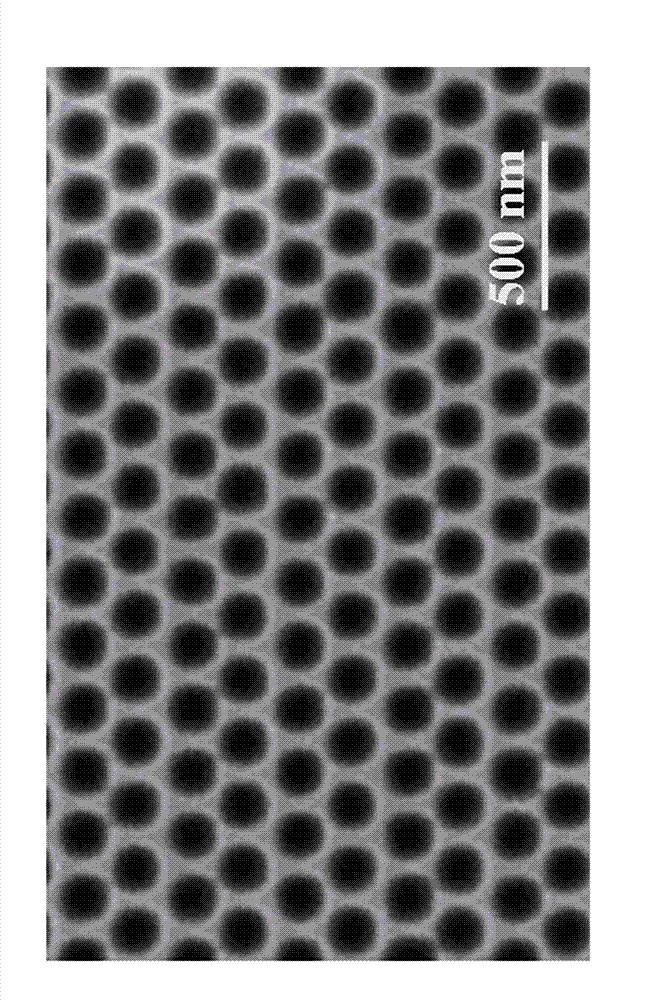

[0034] To prepare a diameter of 100 nanometers and a Ge / Si quantum dot array with a distribution period of 200 nanometers as an example to illustrate the content of the present invention:

[0035] First, the ultra-thin Si-based AAO is prepared, and the (100)-oriented n-type single crystal Si is selected as the substrate. After the substrate is cleaned by the standard Shiraki method, it is dried with high-purity nitrogen and transferred to a high-vacuum sputtering deposition chamber. The vacuum degree of the body is better than 3.0×10 -4 Pa, at a substrate temperature of 300 °C, a metal Al film with a thickness of 1.5 microns was deposited on the surface of a Si substrate by sputtering, and the Al film was pre-woven by extruding the Al film with a quartz template with nanopillars periodically distributed on the surface. Texturization, forming indentations with a diameter and period of 100 nanometers and a period of 200 nanometers, and a depth of 20 nanometers on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com