Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141 results about "Nuclear power system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The nuclear island is the heart of the nuclear power plant. On the other hand the conventional (turbine) island houses the key component which extracts thermal energy from pressurized steam and converts it into electrical energy, the turbine generator. Therefore it is also known as the power conversion system.

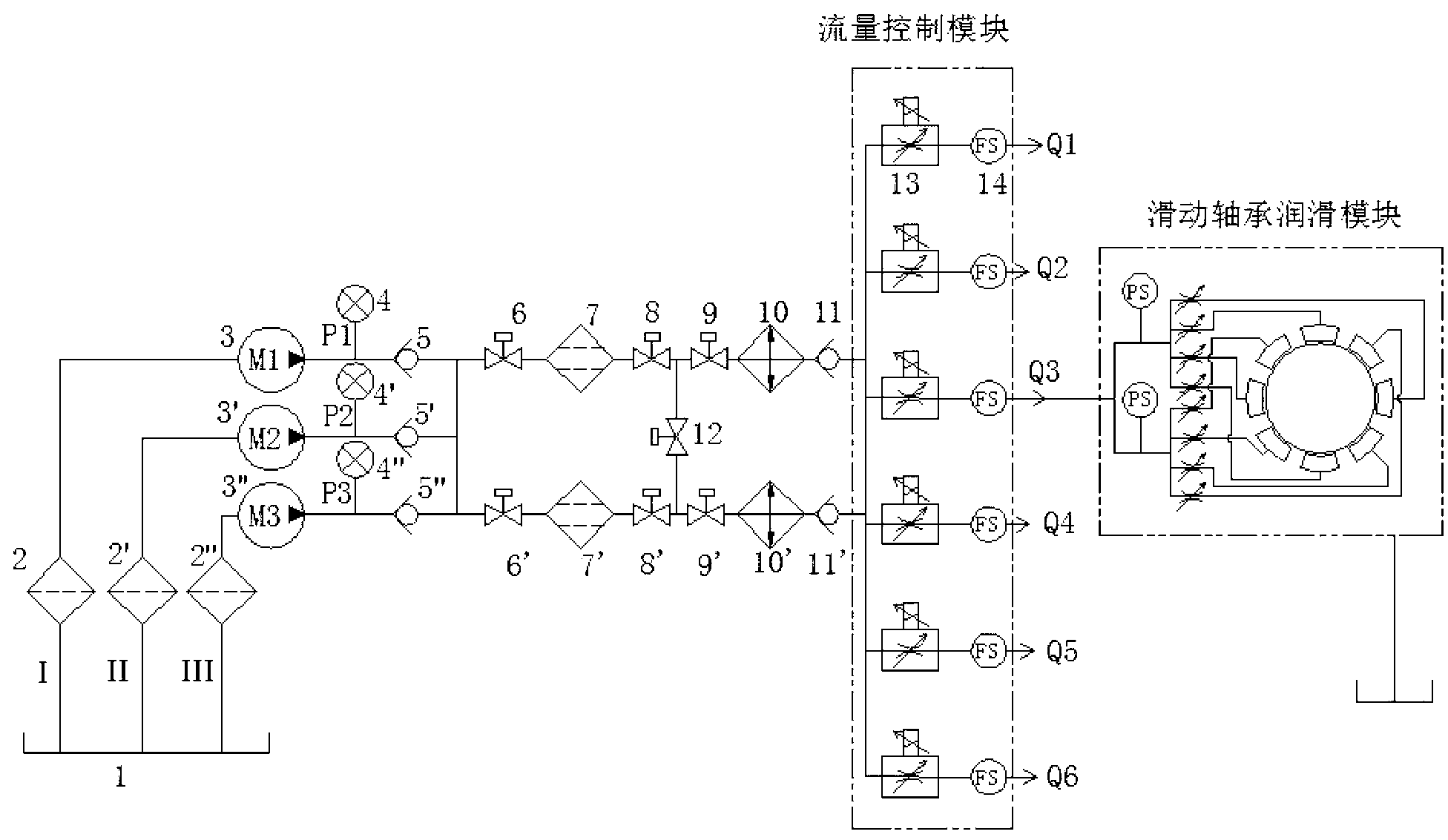

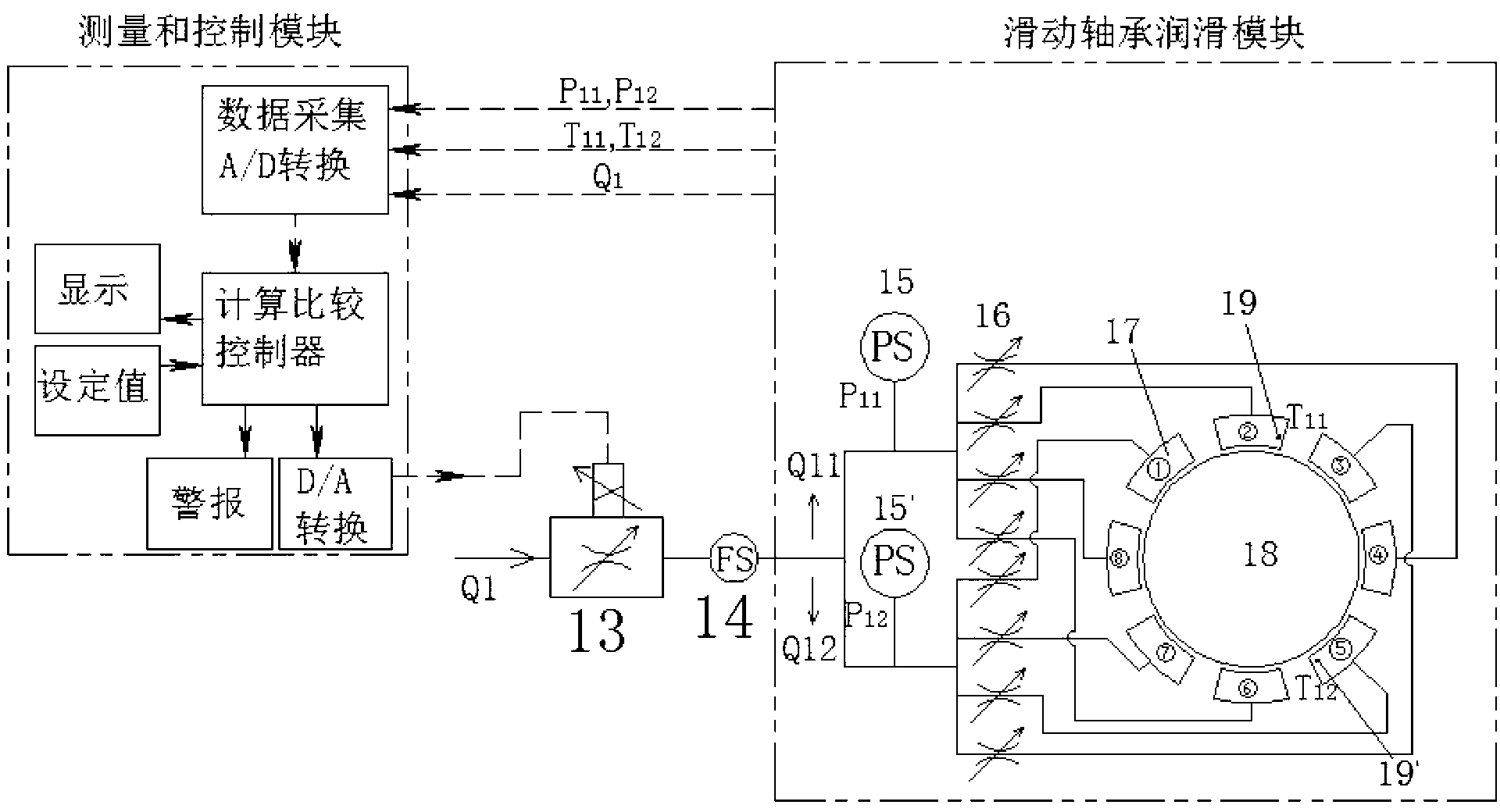

Nuclear power sliding bearing oil feeding system based on comprehensive measurement of flow, pressure and temperature

InactiveCN103062609AImprove securityImprove reliabilityBearing coolingEngine lubricationNuclear engineeringHelium

The invention relates to a nuclear power sliding bearing oil feeding system based on comprehensive measurement of flow, pressure and temperature. The nuclear power sliding bearing oil feeding system based on the comprehensive measurement of the flow, the pressure and the temperature is used for feeding lubricating oil for a sliding bearing of a nuclear power high temperature gas cooled reactor helium compressor and mainly comprises an oil feeding pipeline, a filtering and cooling pipeline and a sliding bearing lubricating pipeline. The nuclear power sliding bearing oil feeding system based on the comprehensive measurement of the flow, the pressure and the temperature utilizes the comprehensive measurement of the flow, the pressure and the temperature of lubricating oil and utilizes a computer to monitor the pressure and the flow to enable the lubricating oil feeding amount and temperature to meet a working requirement to guarantee the common work of every sliding bearing. The nuclear power sliding bearing oil feeding system based on the comprehensive measurement of the flow, the pressure and the temperature has the advantages of obtaining maximal amount of information by utilizing sensors as less as possible, meeting high reliable requirement of nuclear power system through redundancy configuration, being high in control accuracy, reliable in device operation, safe, simple in system and the like.

Owner:TSINGHUA UNIV

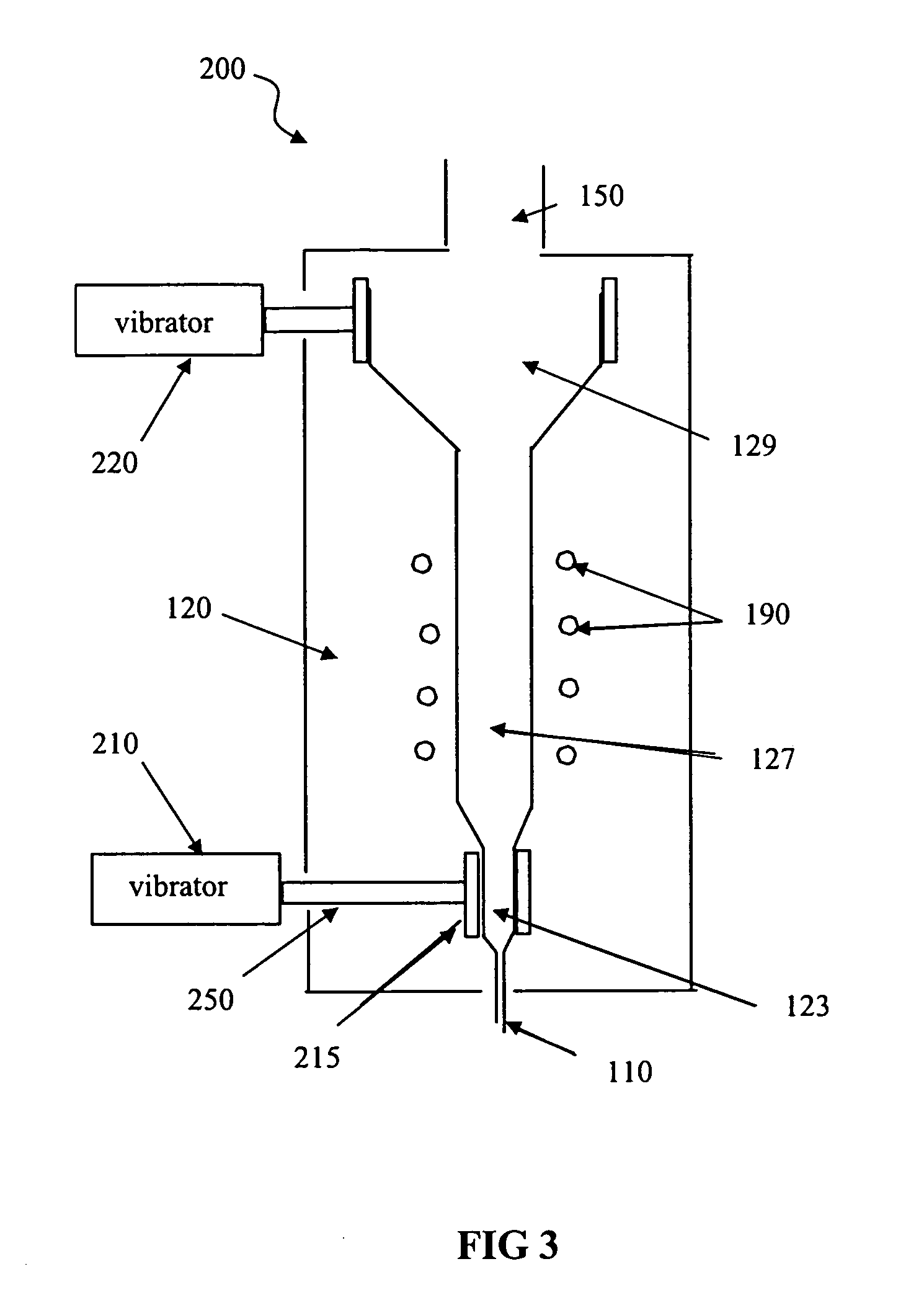

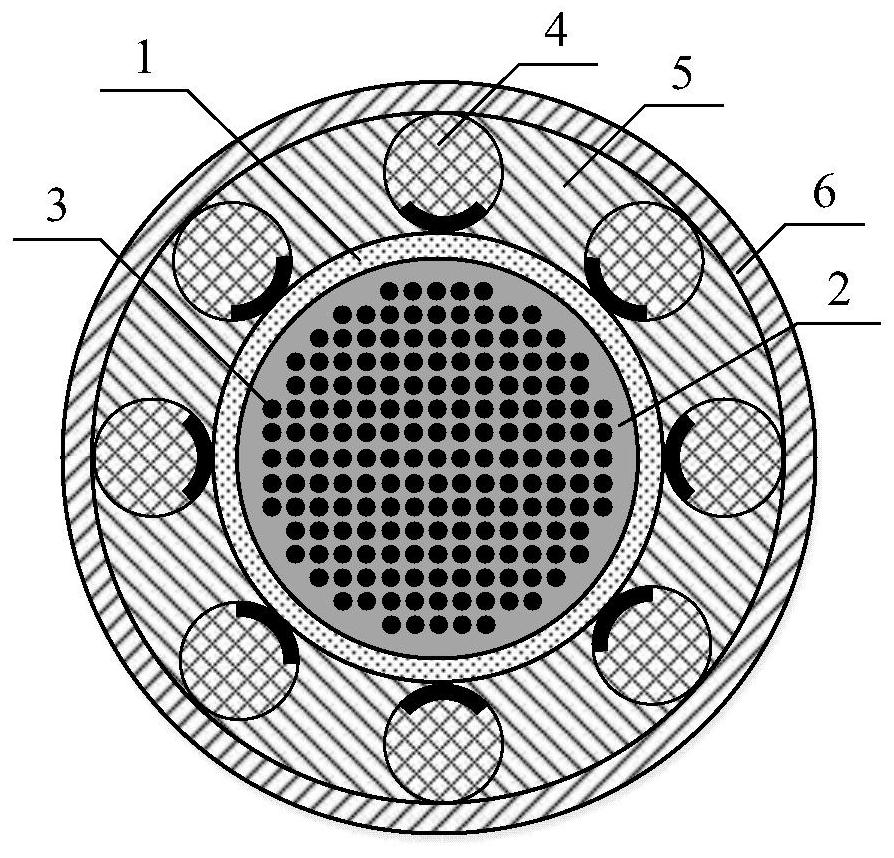

Methods and apparatuses for the development of microstructured nuclear fuels

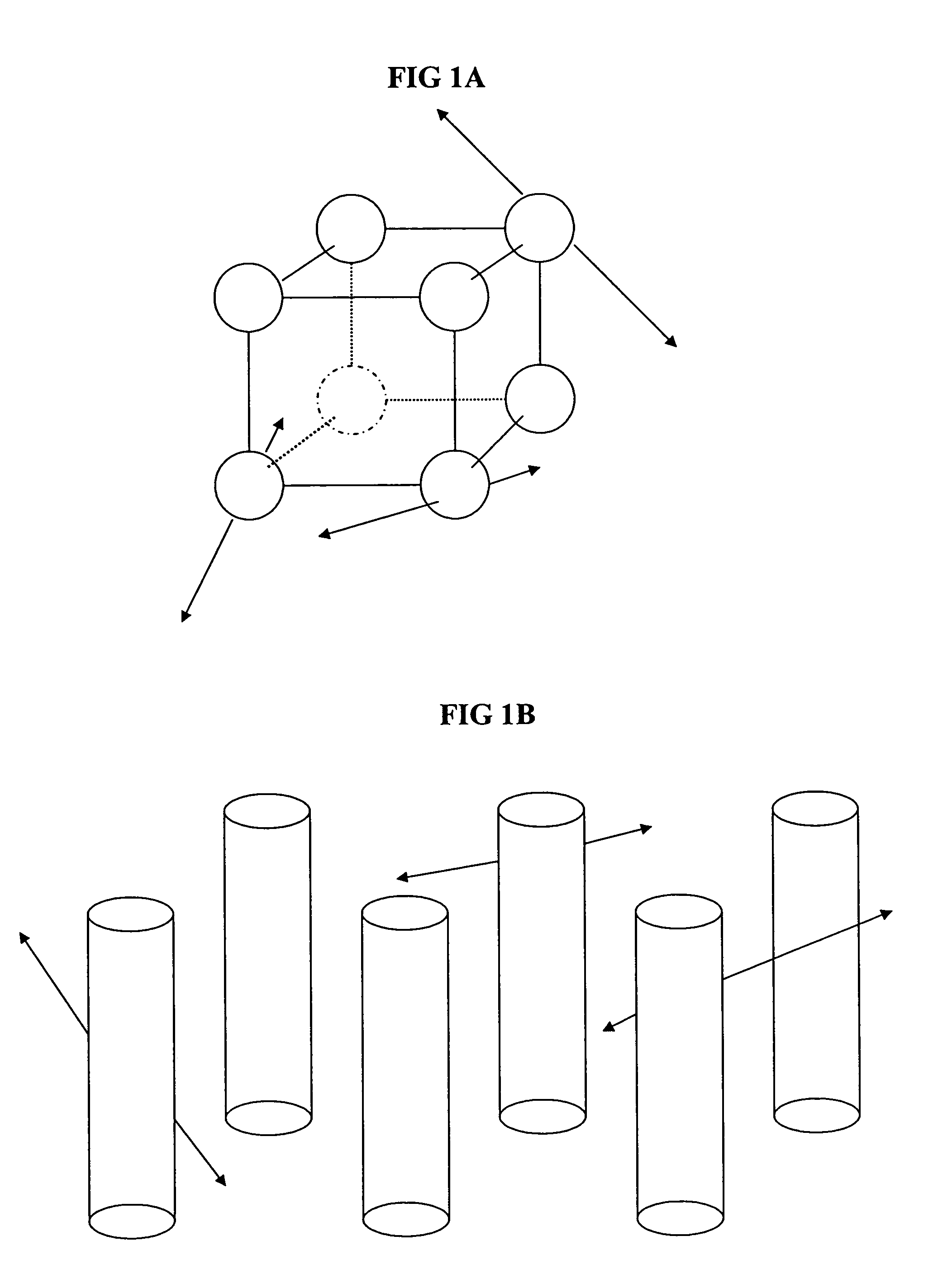

ActiveUS7521007B1Ensure uniform motionLow costFuel elementsNuclear energy generationChemical vapor depositionMaterials science

Microstructured nuclear fuel adapted for nuclear power system use includes fissile material structures of micrometer-scale dimension dispersed in a matrix material. In one method of production, fissile material particles are processed in a chemical vapor deposition (CVD) fluidized-bed reactor including a gas inlet for providing controlled gas flow into a particle coating chamber, a lower bed hot zone region to contain powder, and an upper bed region to enable powder expansion. At least one pneumatic or electric vibrator is operationally coupled to the particle coating chamber for causing vibration of the particle coater to promote uniform powder coating within the particle coater during fuel processing. An exhaust associated with the particle coating chamber and can provide a port for placement and removal of particles and powder. During use of the fuel in a nuclear power reactor, fission products escape from the fissile material structures and come to rest in the matrix material. After a period of use in a nuclear power reactor and subsequent cooling, separation of the fissile material from the matrix containing the embedded fission products will provide an efficient partitioning of the bulk of the fissile material from the fission products. The fissile material can be reused by incorporating it into new microstructured fuel. The fission products and matrix material can be incorporated into a waste form for disposal or processed to separate valuable components from the fission products mixture.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

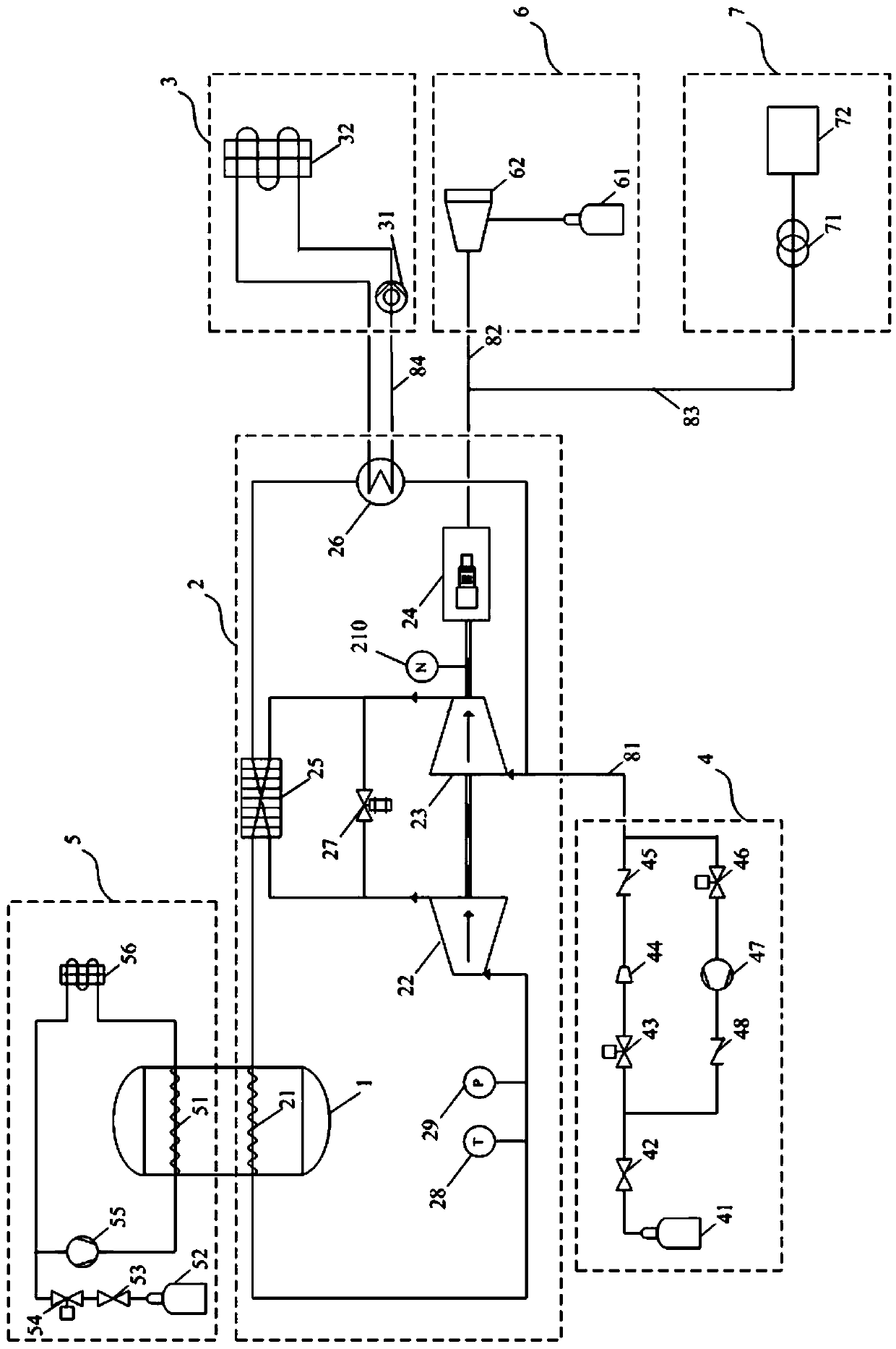

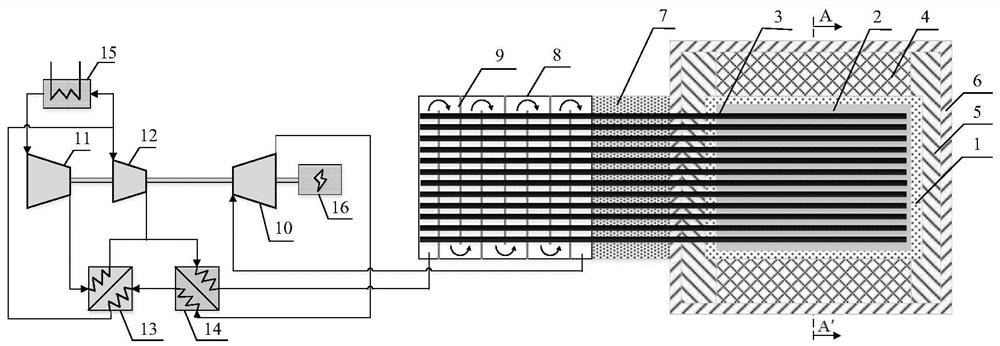

Spatial high-power nuclear power system based on closed Brayton cycle

ActiveCN109677639AEfficient conversionReduce weightCosmonautic vehiclesCosmonautic propulsion system apparatusLow voltageMixed gas

The invention provides a spatial high-power nuclear power system based on a closed Brayton cycle. The spatial high-power nuclear power system comprises a spatial nuclear reactor, a Brayton thermoelectric conversion subsystem, a heat dissipation subsystem, a cycle working medium storage and supply subsystem, an electric propulsion subsystem and an electric loading subsystem. Helium-xenon mixed gasis taken as a cycle working medium so as to realize efficient thermoelectric conversion, and a high-specific-impulse high-thrust electric thruster directly driven by high voltage is utilized for realizing efficient propulsion. According to the spatial high-power nuclear power system, the efficient thermoelectric conversion problem of a nuclear power air vehicle and the large-range electric power adjusting problem are solved, and the problem that the high voltage of a motor end is not matched with the lower voltage of the electric thruster is solved.

Owner:SHANGHAI INST OF SPACE PROPULSION

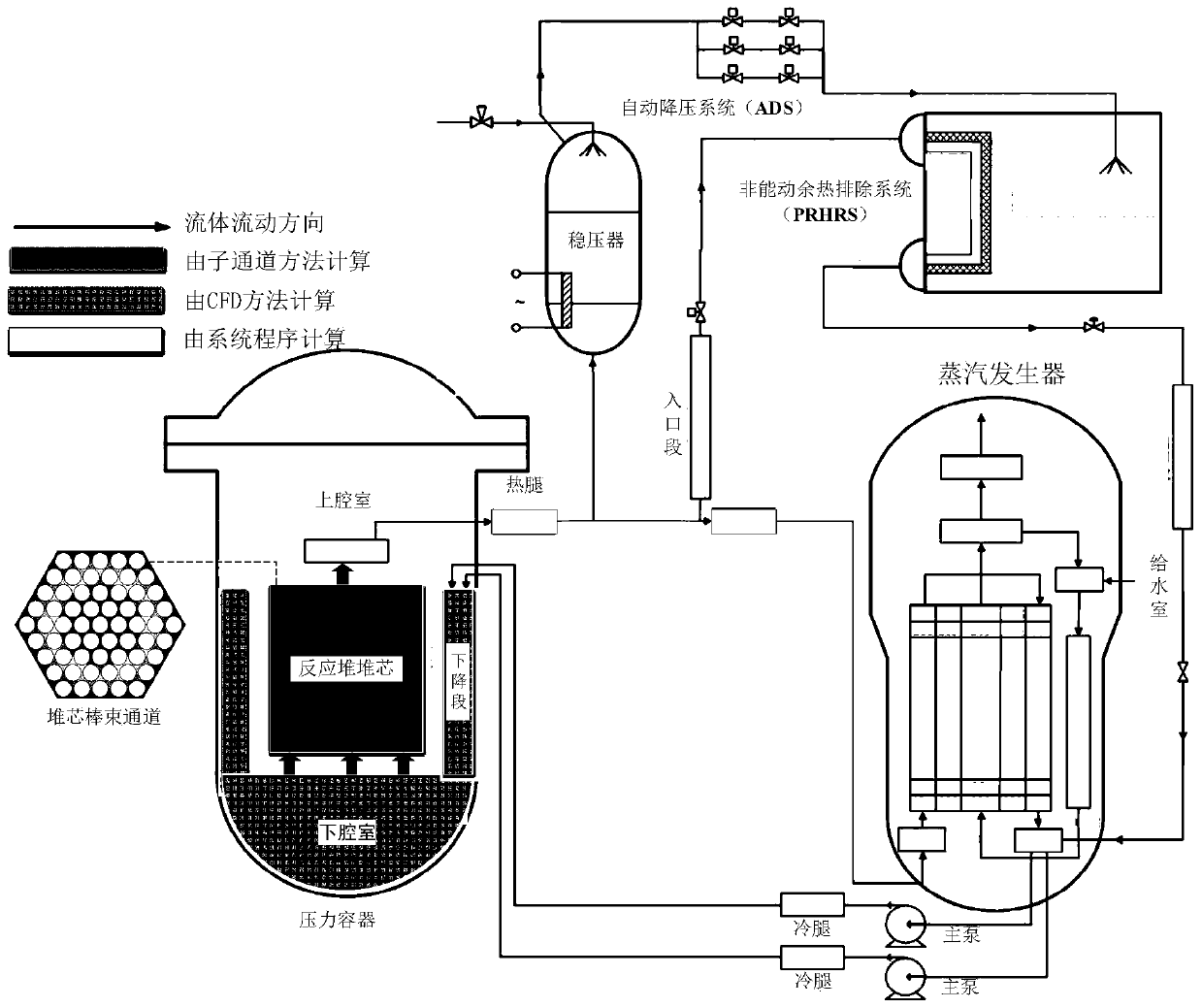

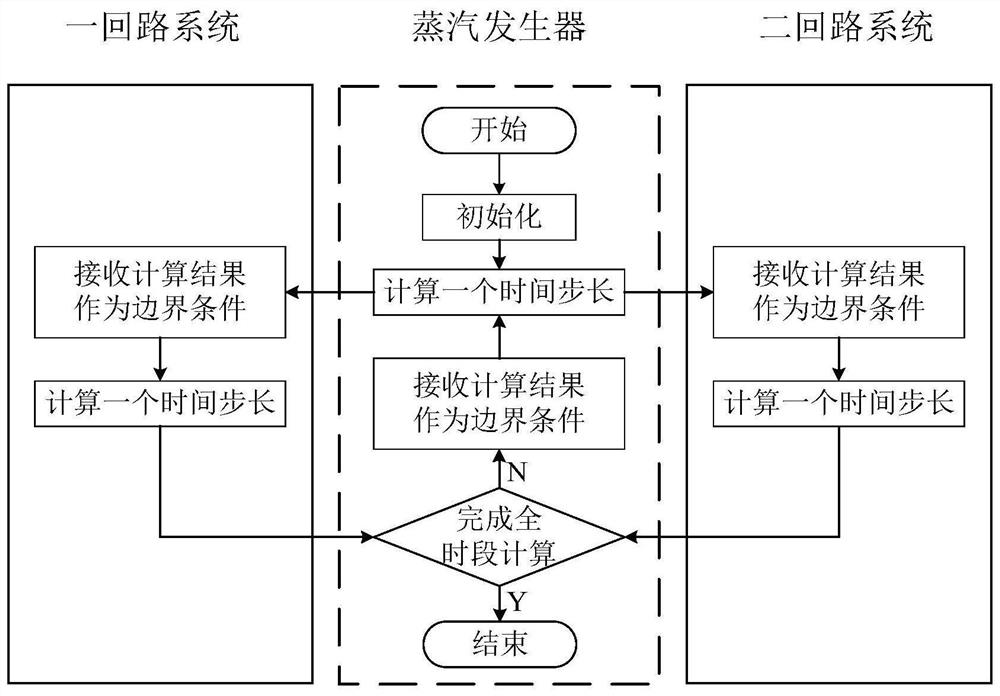

Nuclear power system interdimensional coupling simulation method

ActiveCN109903870ADo not change modeling propertiesEasy to implementNuclear energy generationNuclear power plant controlSystems analysisCoupling

The invention discloses a nuclear power system interdimensional coupling simulation method which includes the steps: firstly, performing modeling on components of a nuclear power system through different reactor thermal hydraulics analysis programs; secondly, preliminarily calculating a reactor thermal hydraulic system analysis program and a reactor thermal hydraulic sub-channel analysis program according to set initial boundary conditions; thirdly, taking calculation results of the reactor thermal hydraulic system analysis program and the reactor thermal hydraulic sub-channel analysis programas boundary conditions of computational fluid dynamics software to perform calculation; fourthly, taking calculation results acquired in the third step as boundary conditions of the reactor thermal hydraulic system analysis program to calculate thermal hydraulic parameters of next time step reactor; fifthly, taking calculation results acquired in the fourth step as boundary conditions of the thermal hydraulic sub-channel analysis program to calculate thermal hydraulic parameters of a reactor core; sixthly, repeating the third step to the fifth step until full time calculation is completed.

Owner:XI AN JIAOTONG UNIV

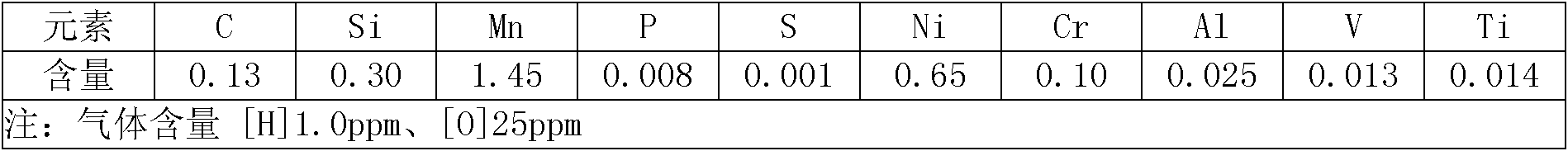

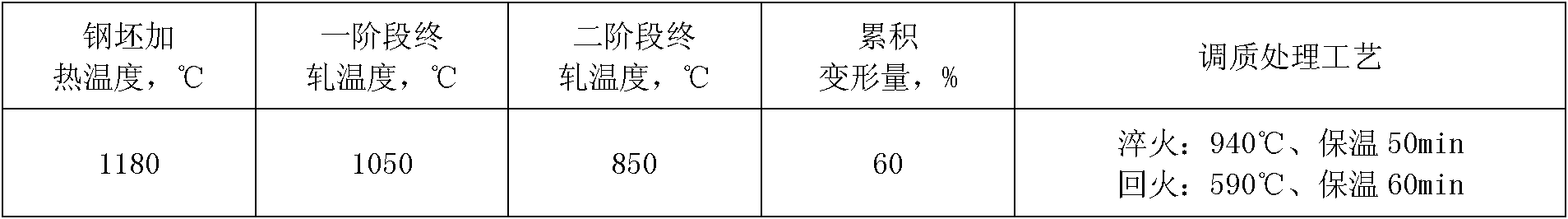

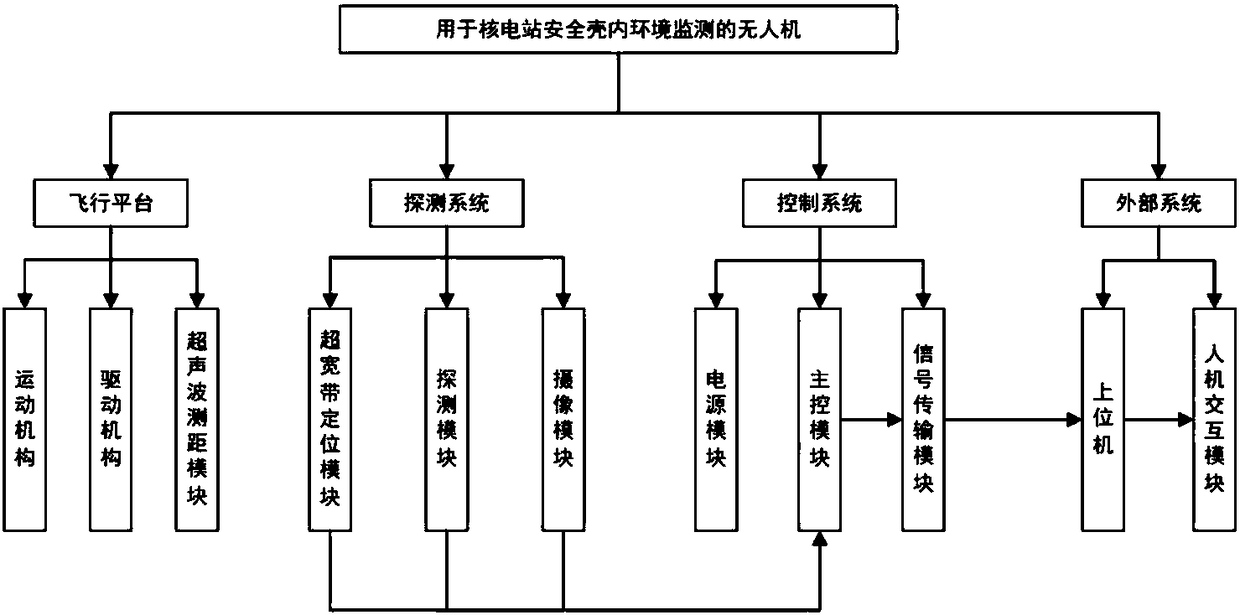

Steel for nuclear power pressure-bearing equipment and manufacturing method thereof

ActiveCN103160732AGood intensity levelLittle decrease in strengthChemical compositionNon-metallic inclusions

The invention discloses steel used for nuclear power pressure-bearing equipment and a manufacturing method thereof. The steel comprises the following chemical components by weight: 0.12%-0.18% of C; 0.15%-0.35% of Si; 1.20%-1.65% of Mn; less than or equal to 0.015% of P; less than or equal to 0.010% of S, 0.50%-0.85% of Ni; less than or equal to 0.15% of Cr; 0.020%-0.050% of Al; less than or equal to 0.02% of V; less than or equal to 0.02% of Ti, and the balance Fe and unavoidable impurities. At the same time, non-metallic inclusions in the steel are controlled, and A, B, C and D impurities are guaranteed less than or equal to grade 1.5. The manufacturing method mainly includes steel smelting, rolling, as well as quenching and tempering treatment. Through further optimization of the chemical components, a heat treatment process, and reduction of gas and non-metallic inclusions in steel, the method enables the mechanical properties of a steel plate to be maintained at a high level under a heat treatment state, a simulated post-weld heat treatment state, and a 200DEG C high temperature state, so that the steel plate completely meets the technical index requirements. Meanwhile, the 0DEG C impact absorption energy is still maintained at a high level, and good matching of steel plate strength and toughness is reflected, so that the steel provided in the invention is completely suitable for nuclear power pressure-bearing equipment.

Owner:ANGANG STEEL CO LTD

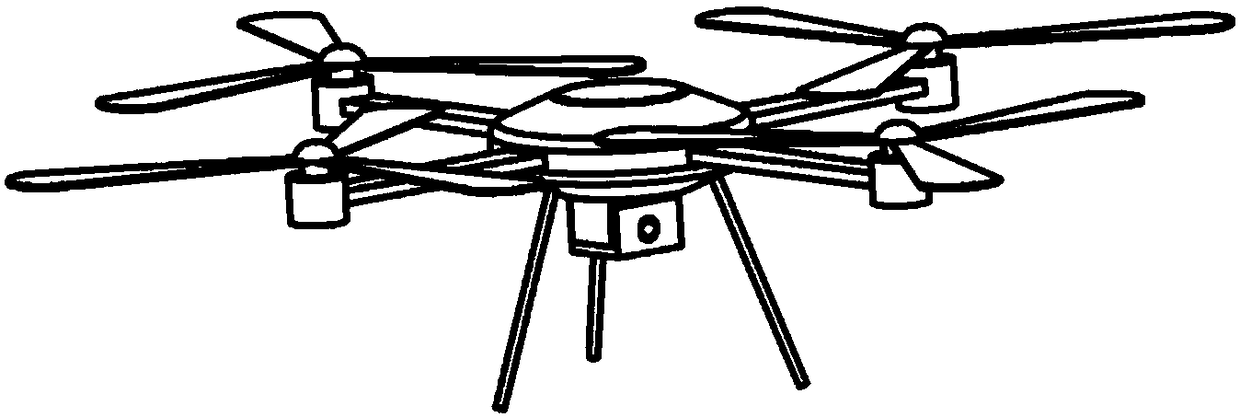

Nuclear power station containment internal environment monitoring drone and control method thereof

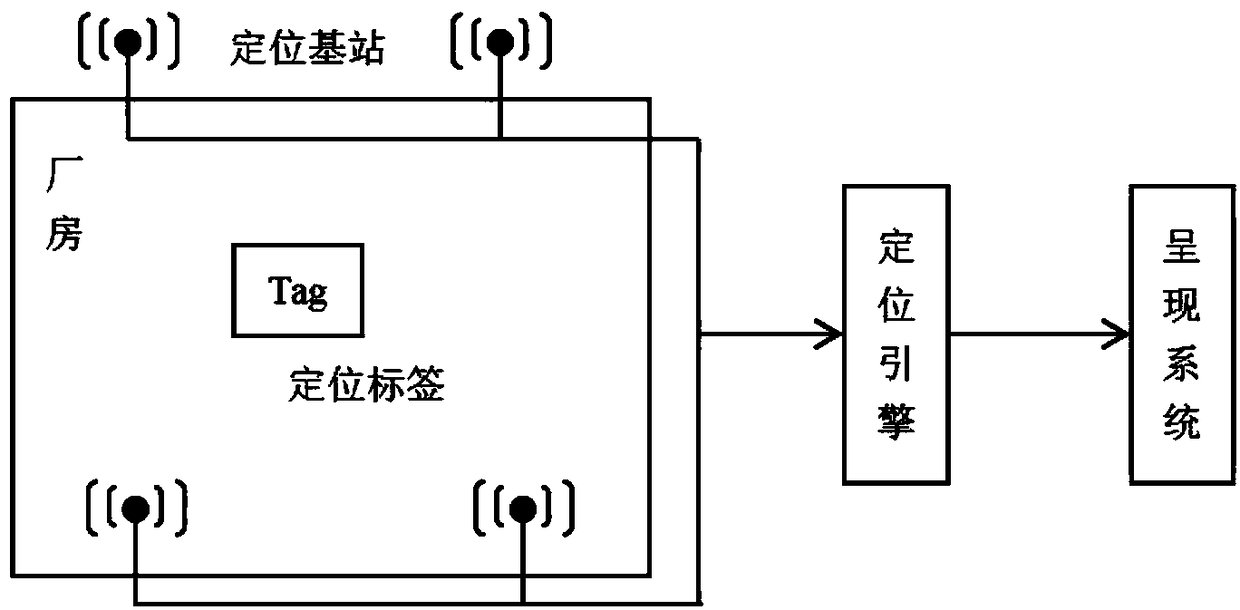

PendingCN108279702AHumidity measurementMeasure temperaturePosition fixationClosed circuit television systemsNuclear engineeringControl system

The invention provides a nuclear power station containment internal environment monitoring drone and a control method thereof. The nuclear power station containment internal environment monitoring drone comprises a flight platform, a detecting system, a control system and an external system, wherein the flight platform specifically comprises a motion mechanism, a driving mechanism and an ultrasonic ranging module; the detecting system specifically comprises an ultra-wide band positioning module, a detecting module and a camera module; the control system specifically comprises a power module, amaster control module and a signal transmission module; the external system specifically comprises an upper computer and a man-machine interaction module. By means of the drone technology, the nuclear power station containment internal environment monitoring drone can enter a nuclear power station containment unreachable for technical personnel for detection to rapidly collect and transmit related information of areas to be monitored into the upper computer, thereby being capable of effectively monitoring and alarming security inside the containment and further improving the operating safetyof a nuclear power system.

Owner:SOUTH CHINA UNIV OF TECH

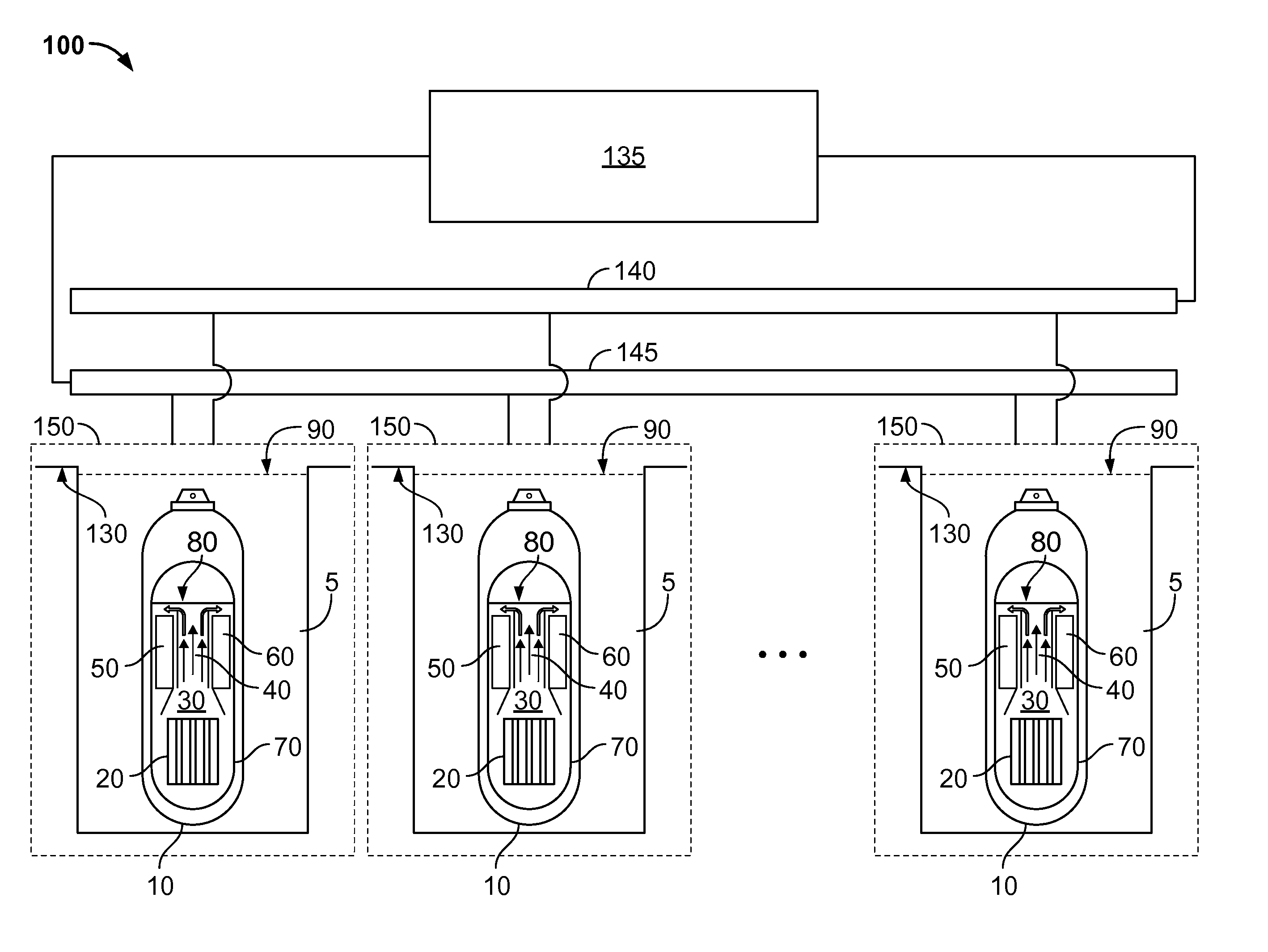

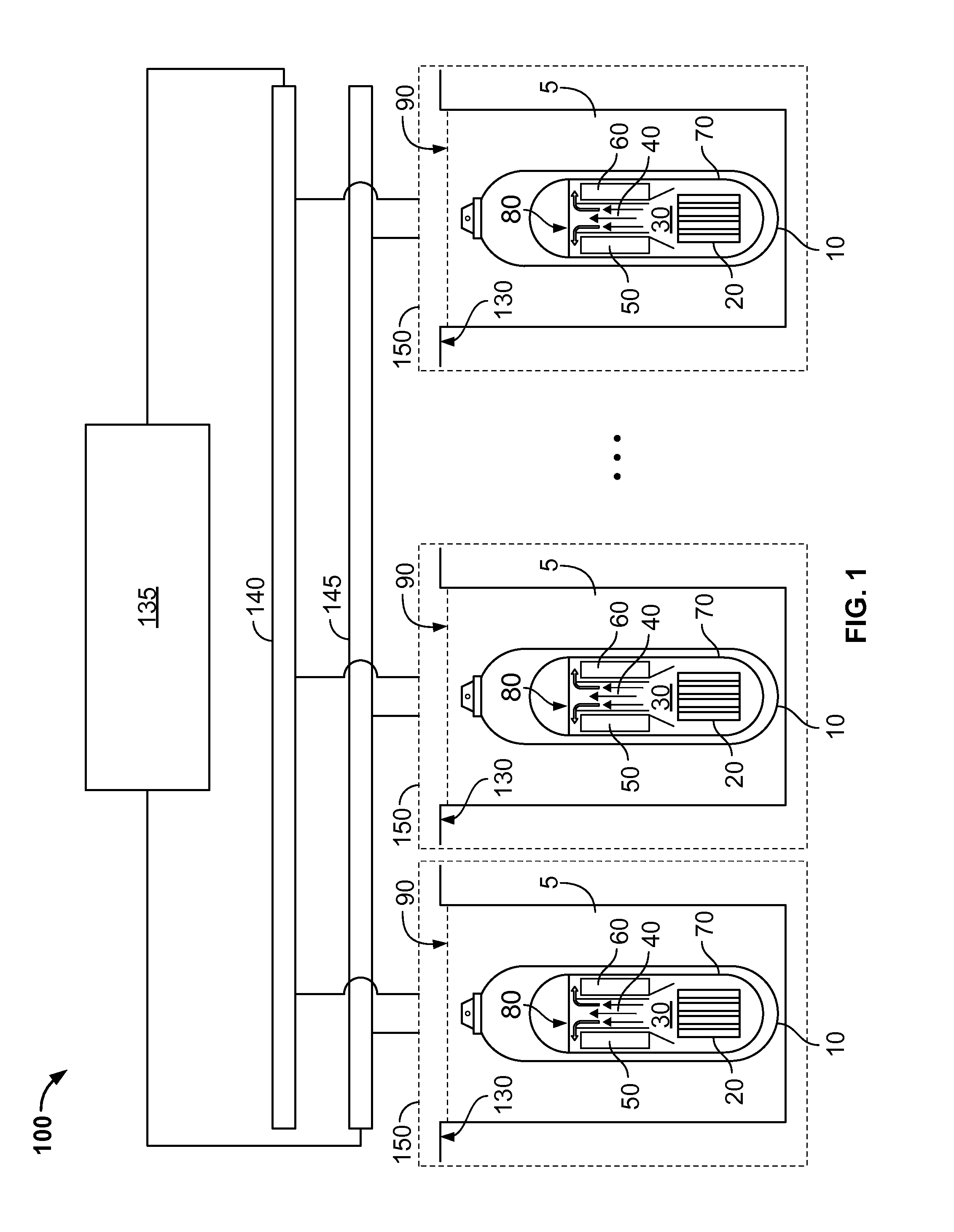

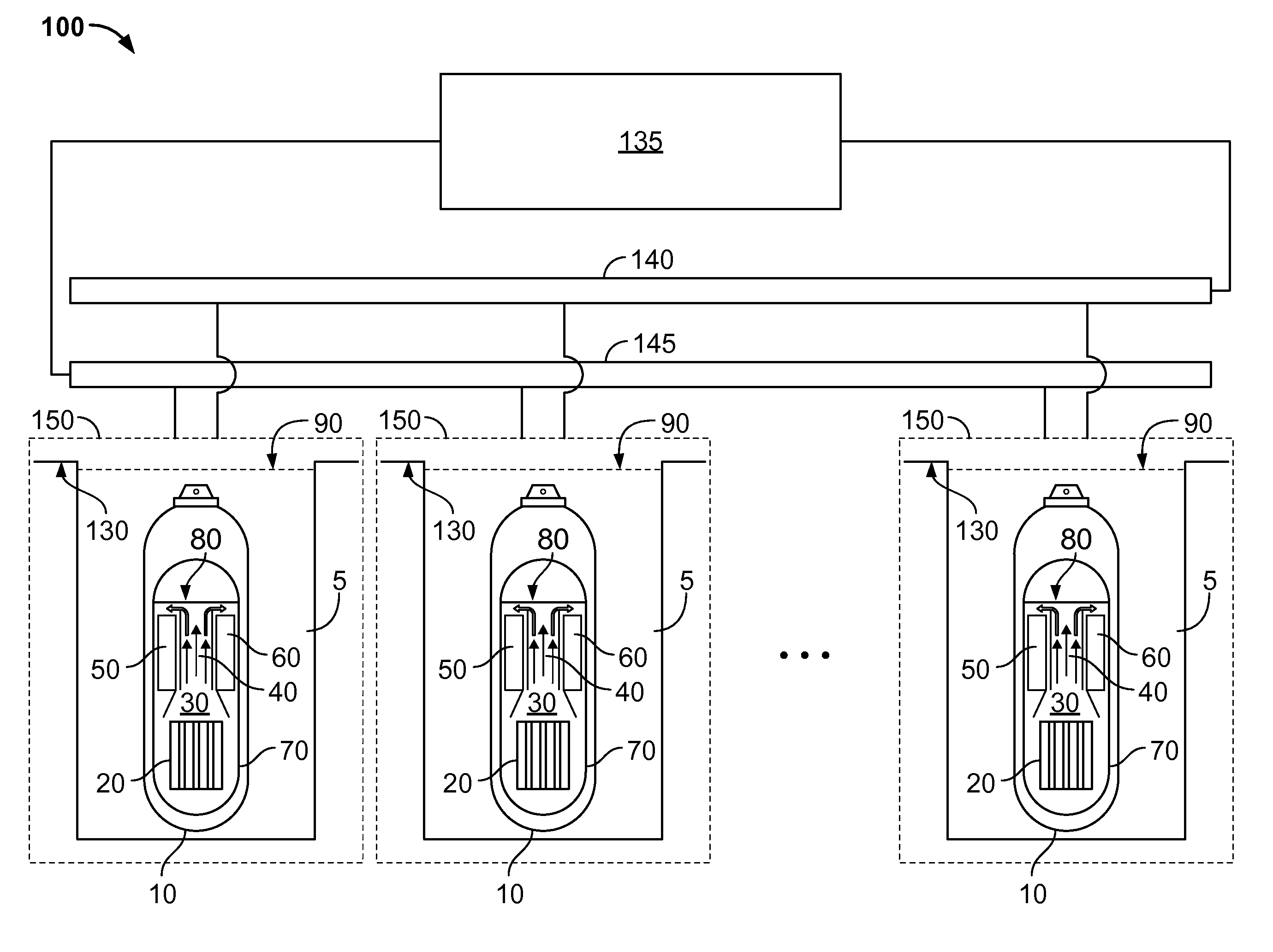

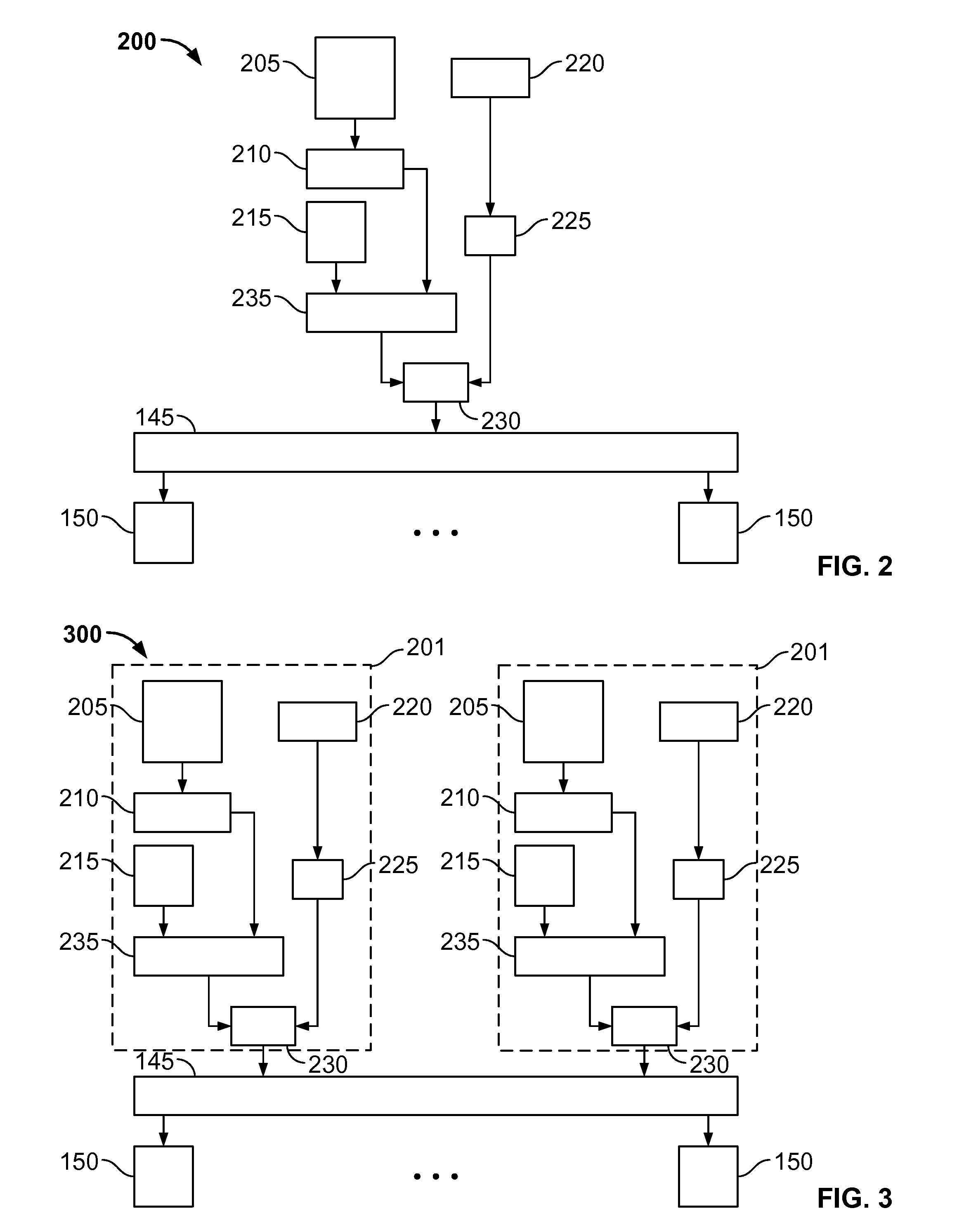

Managing Electrical Power for a Nuclear Reactor System

ActiveUS20140152098A1Maintenance costLow costPower plant safety arrangementNuclear energy generationElectricityNuclear reactor

An electrical power system for a nuclear power facility includes an active alternating current (AC) power bus configured to be electrically coupled to a plurality of engineered safety feature (ESF) loads of a plurality of nuclear power systems, each of the ESF loads configured to fail to a safe position upon loss of primary AC power; a critical battery system electrically coupled to the active AC bus, the critical battery system comprising a plurality of valve regulated lead acid (VRLA) batteries; and a primary AC power source electrically coupled to the active AC bus.

Owner:NUSCALE

Liquid nuclear fuel heat pipe reactor power supply system and method for recompressing Brayton cycle

PendingCN111968764ARealize direct heat exchangeReduce in quantityNuclear energy generationCooling arrangementBrayton cycleHelium gas

The invention discloses a liquid nuclear fuel heat pipe reactor power supply system and a method for recompressing Brayton cycle. Heat generated by liquid nuclear fuel in a reactor core enables liquidpotassium in a heat pipe to be evaporated and then moved to a heat pipe condensation section, and the heat is transferred to a working medium in a recompression Brayton cycle system through a heat pipe cold end heat exchanger in the condensation section; the working medium does work in a turbine; the working medium sequentially passes through a high-temperature heat regenerator and a low-temperature heat regenerator, then one part of the working medium enters a main compressor after being cooled by a cooler, the other part of the working medium enters a recompressor, and the compressed working medium enters the heat pipe cold end heat exchanger to be heated after being preheated by the heat regenerator, so that a closed recompression Brayton cycle is formed. In the energy conversion system, recompression circulation with helium as a working medium is adopted, and the requirements for small size and high efficiency of a nuclear power system can be met.

Owner:XI AN JIAOTONG UNIV

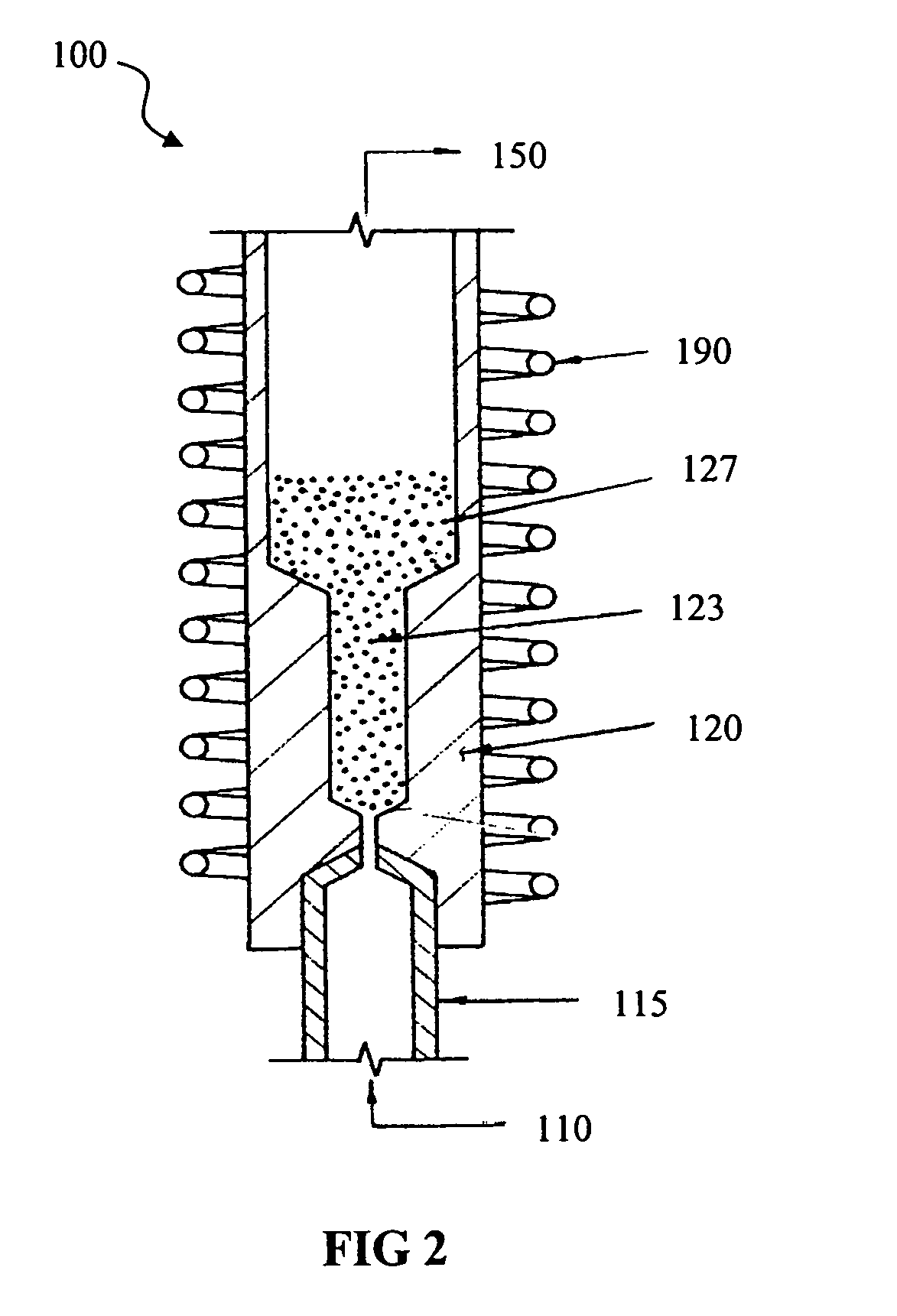

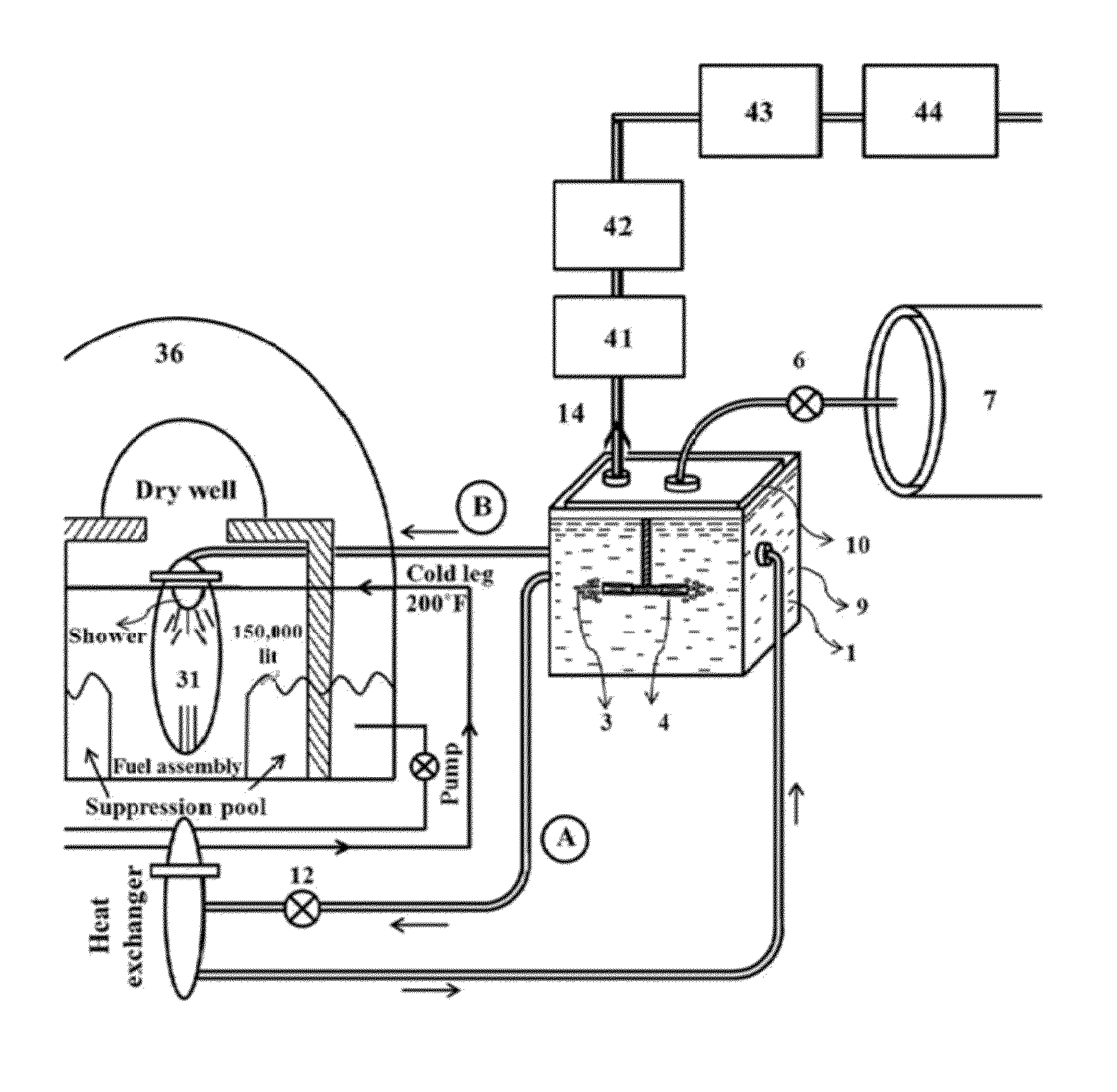

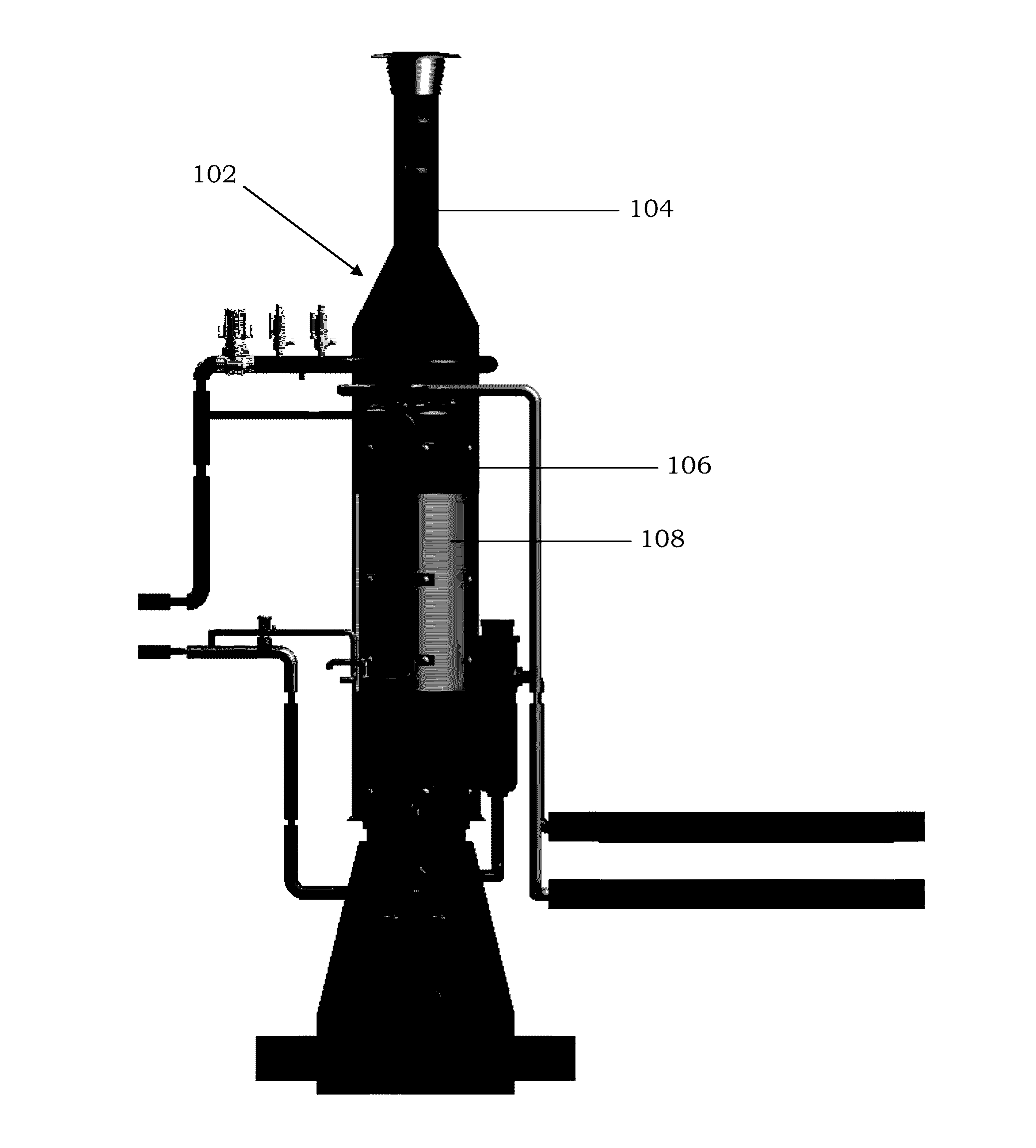

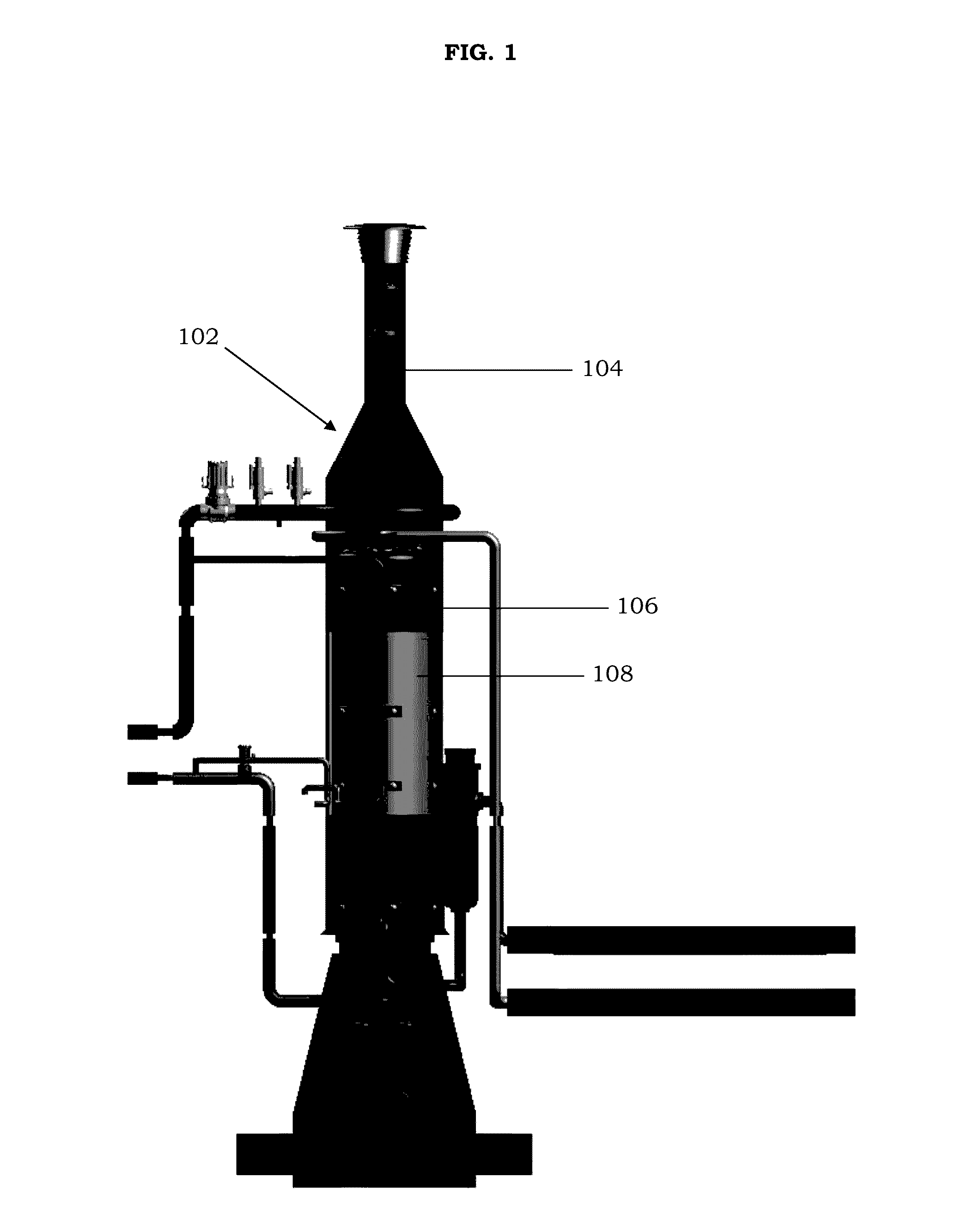

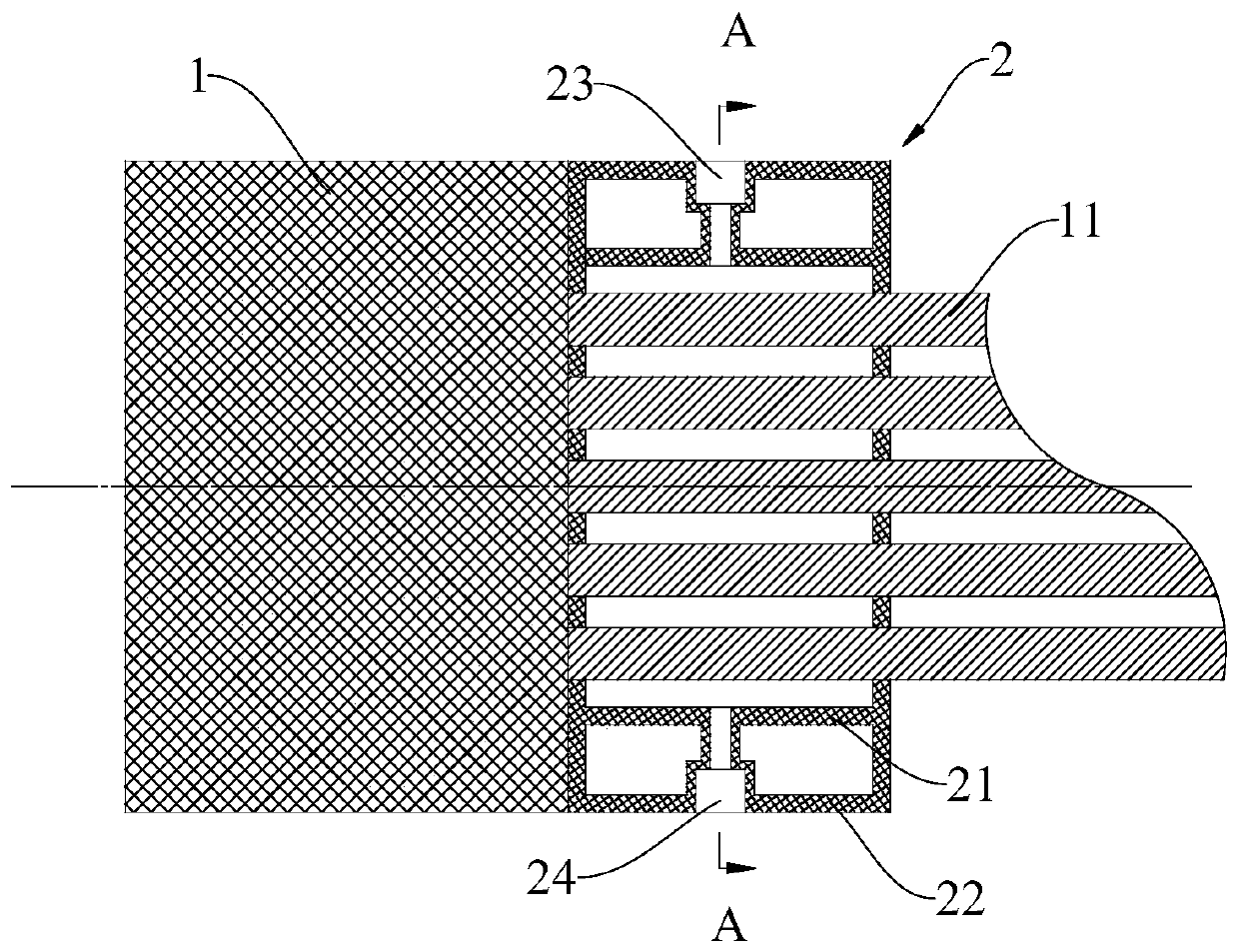

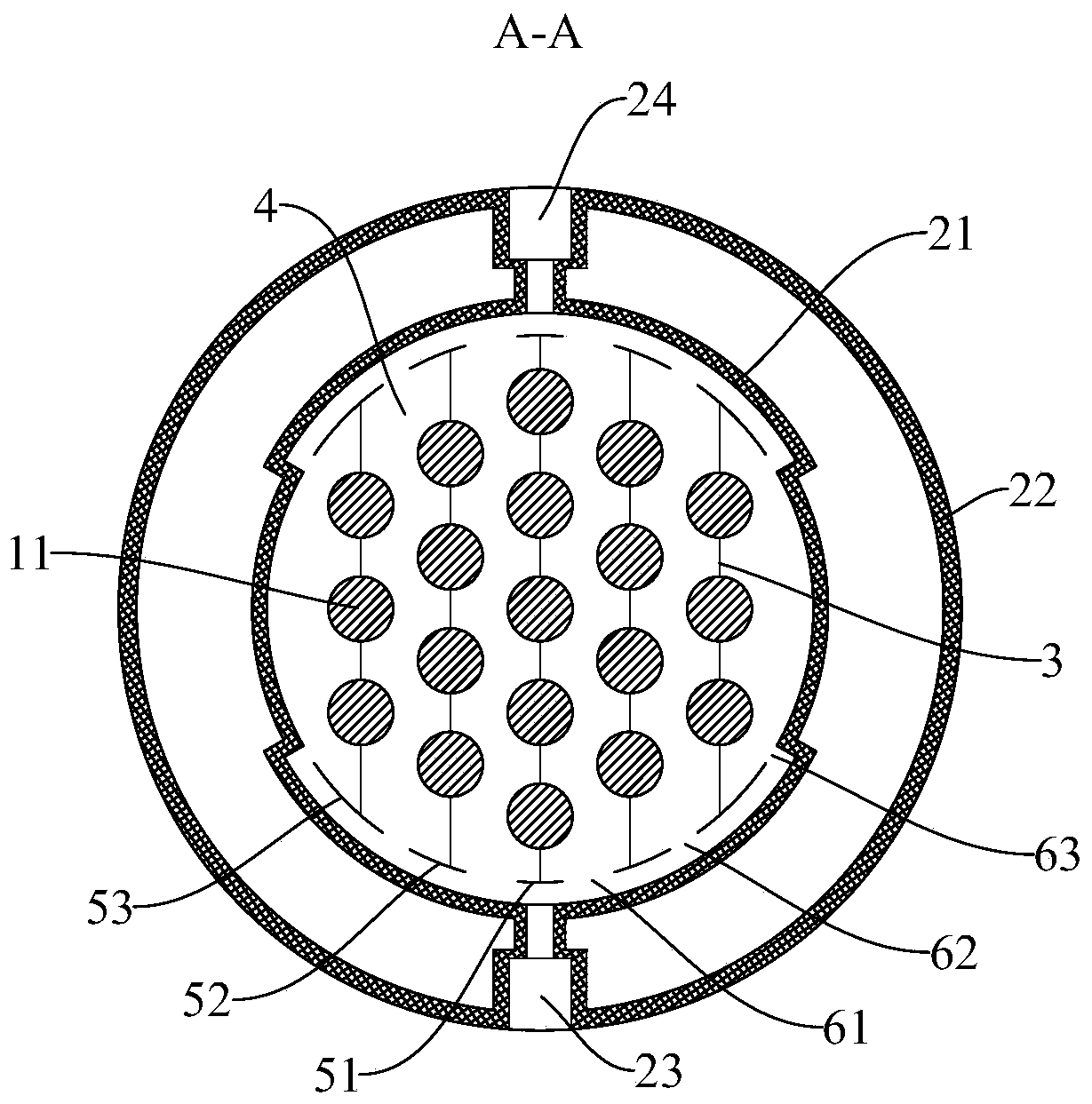

Modified dry ice heat exchanger for heat removal of portable reactors

InactiveUS20130301781A1Increase in sizeEffective temperaturePower plant safety arrangementLighting and heating apparatusReactor pressure vesselSlurry

A novel heat exchanger (FIG. 1) designed and fabricated based on dry ice-ethylene glycol (DIEG) bath 1 as the coolant mixture for the emergency core cooling system (ECCS) of the nuclear power systems to avoid core meltdown during the normal reactor shutdown or reactor scram in the emergency conditions.This method is proposed to upgrade the safety systems including modified ECCS which utilizes fast non-water coolant emergency system by fast cooling of reactor pressure vessel (RPV) 31 based on dry ice+ethylene glycol slurry 1.

Owner:PARVIN PARVIZ +1

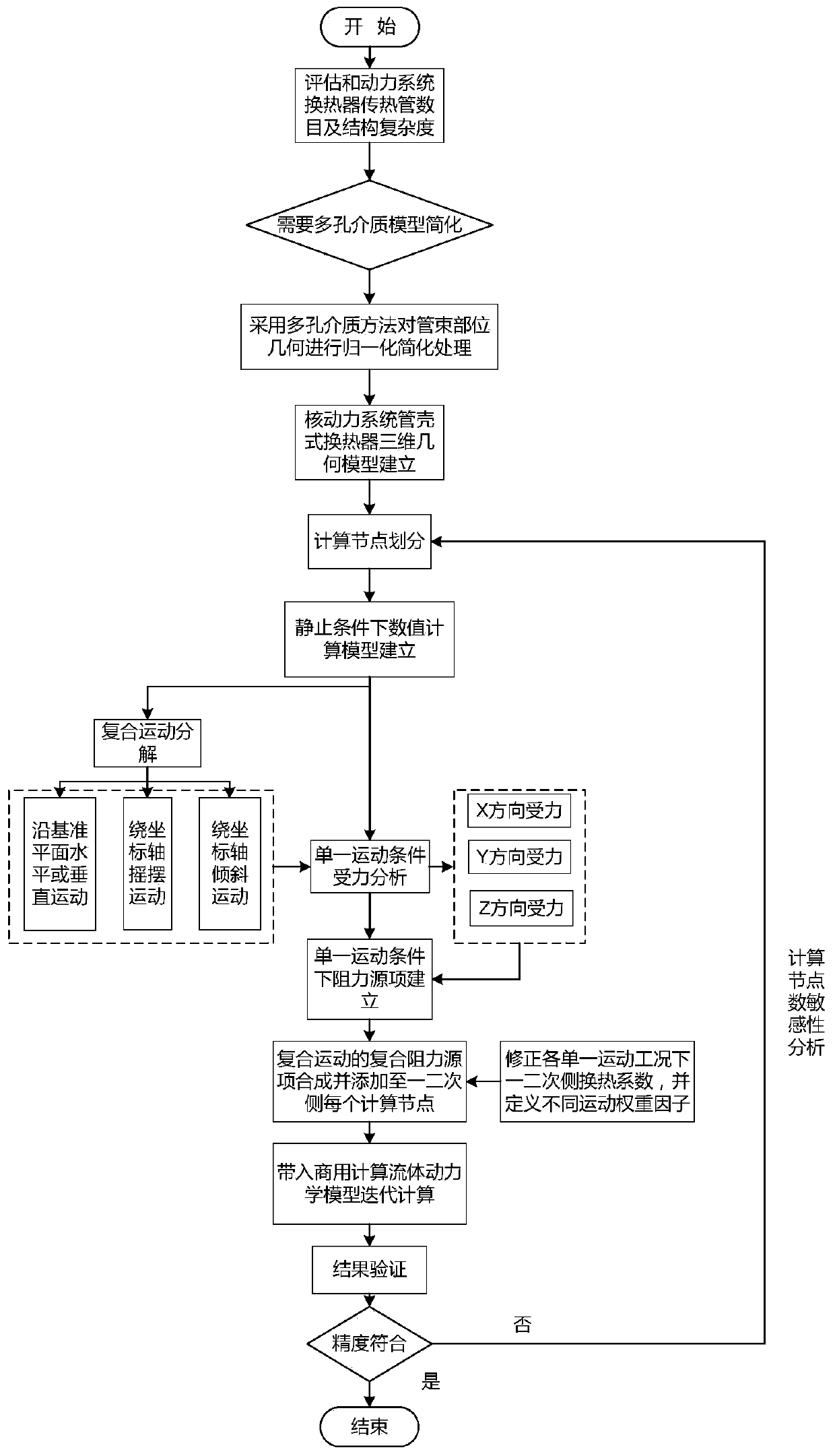

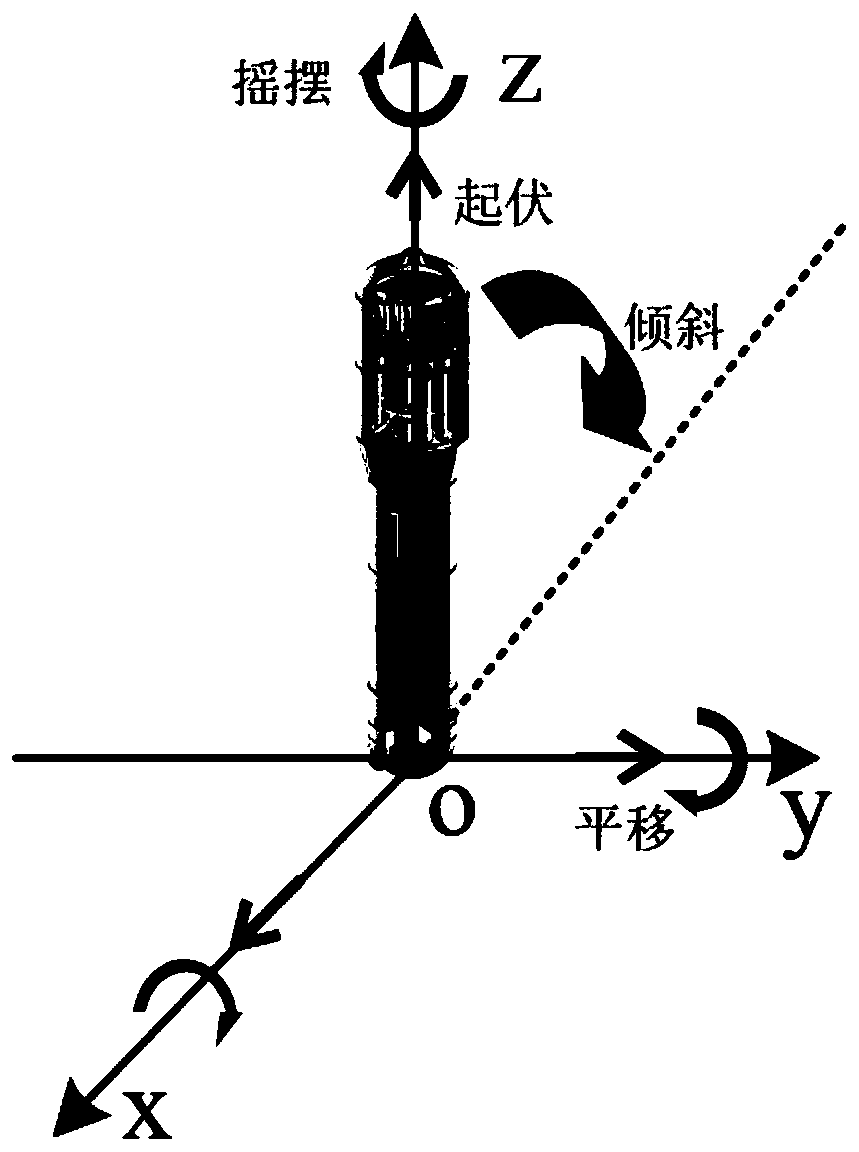

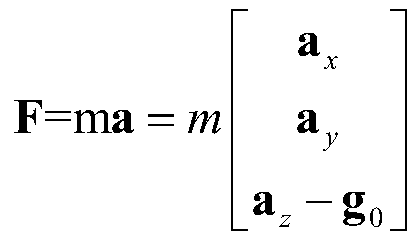

Method for establishing nuclear power system shell-and-tube heat exchanger numerical model under motion condition

ActiveCN111274747AConsider mobilityConsider all featuresDesign optimisation/simulationCAD numerical modellingComputational modelEngineering

The invention discloses a method for establishing a numerical model of a shell-and-tube heat exchanger of a nuclear power system under a motion condition. The method is suitable for establishing a three-dimensional numerical calculation model of large heat exchange equipment of the nuclear power system under the motion condition that different forms are generated under certain external force. Thethree-dimensional numerical calculation model is mainly based on a three-dimensional thermal hydraulic numerical calculation model of the shell-and-tube heat exchanger in static operation. According to the motion forms and the stress characteristics under different motion conditions, the stress is uniform; motion decomposition, stress analysis and decomposition of a single motion, establishment ofan additional force source item acting on a momentum equation under the single motion, and a composite motion additional force source item synthesis process are carried out on a shell-and-tube heat exchanger under a composite motion condition; and finally, establishing a set of numerical calculation model capable of accurately describing the thermal hydraulic characteristics of the shell-and-tubeheat exchanger of the nuclear power system under the composite motion condition.

Owner:XI AN JIAOTONG UNIV

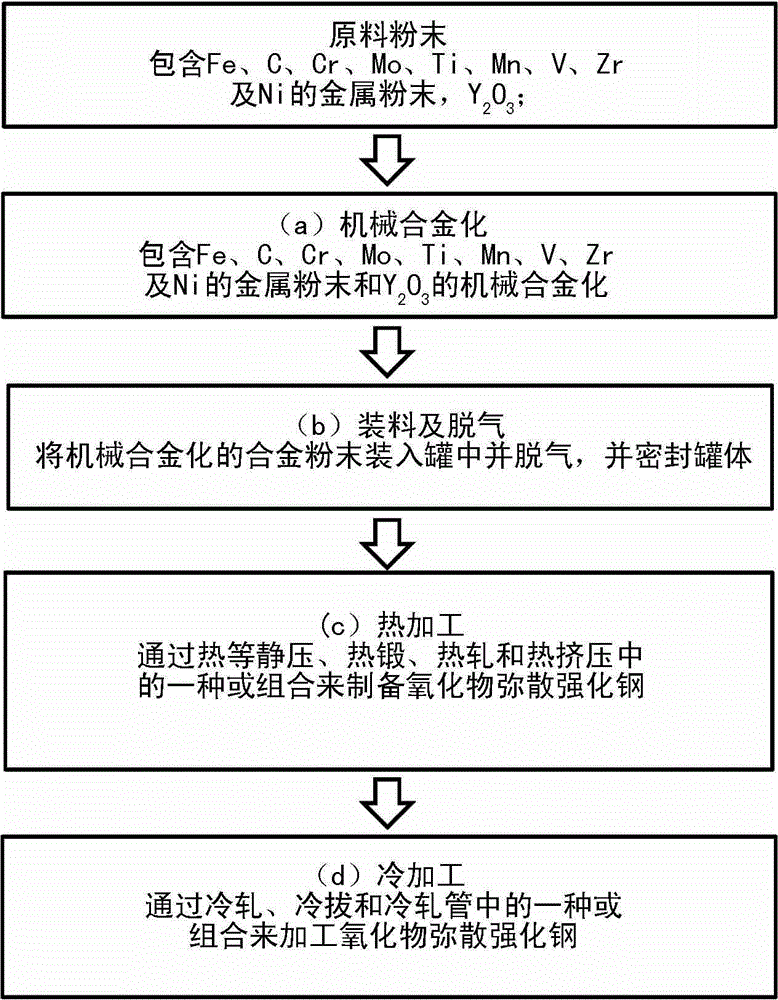

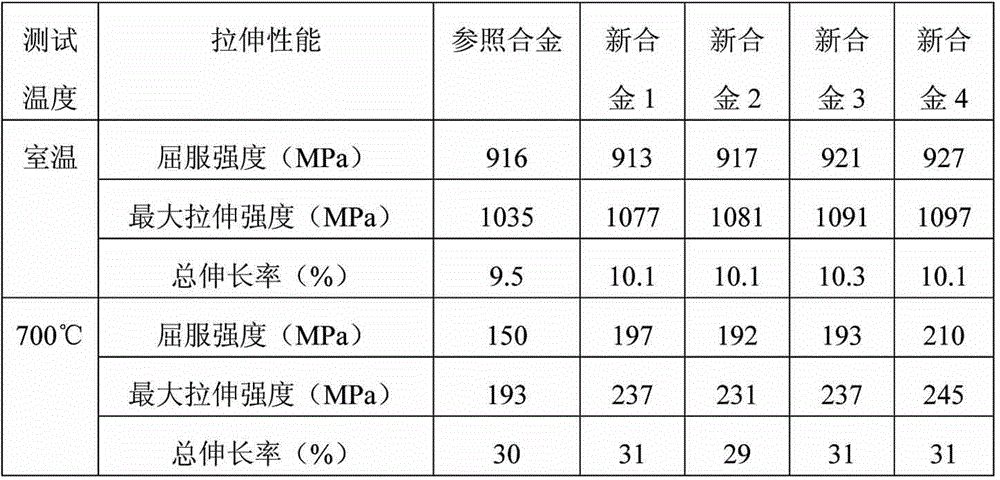

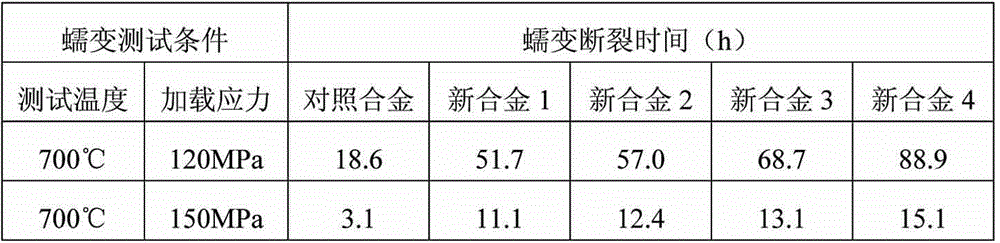

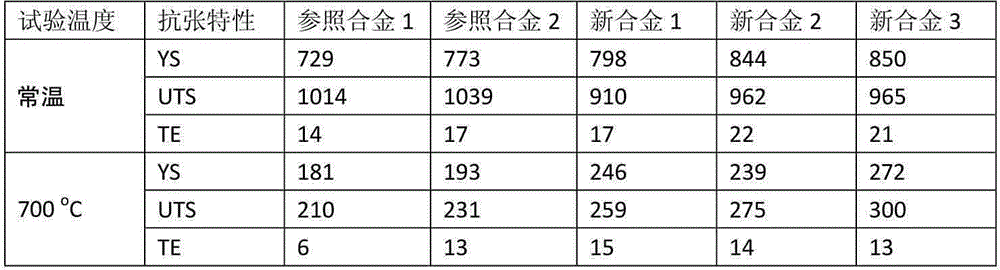

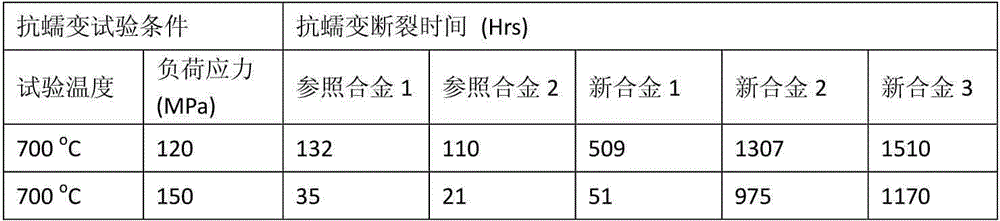

Ferritic/martensitic oxide dispersion strengthened steel with enhanced creep resistance and method of manufacturing the same

Provided are a ferritic / martensitic oxide dispersion strengthened steel with increased high temperature creep resistance, including 0.02 to 0.2 wt % of carbon (C), 8 to 12 wt % of chromium (Cr), 0.1 to 0.5 wt % of yttria (Y2O3), 0.2 to 2 wt % of molybdenum (Mo), 0.01 to 0.5 wt % of titanium (Ti), 0.01 to 1 wt % of manganese (Mn), 0.01 to 0.3 wt % of vanadium (V), 0 to 0.3 wt % of zirconium (Zr), 0 to 0.5 wt % of nickel (Ni), and the remaining content of iron (Fe), and a method of manufacturing the same. The ferritic / martensitic oxide dispersion strengthened steel may be useful as a material for core structural components of a nuclear power system, ultra supercritical pressure steam generator components of a thermal power plant, or engine components of an airplane due to a high tensile strength at 700° C. and excellent creep resistance.

Owner:KOREA ATOMIC ENERGY RES INST

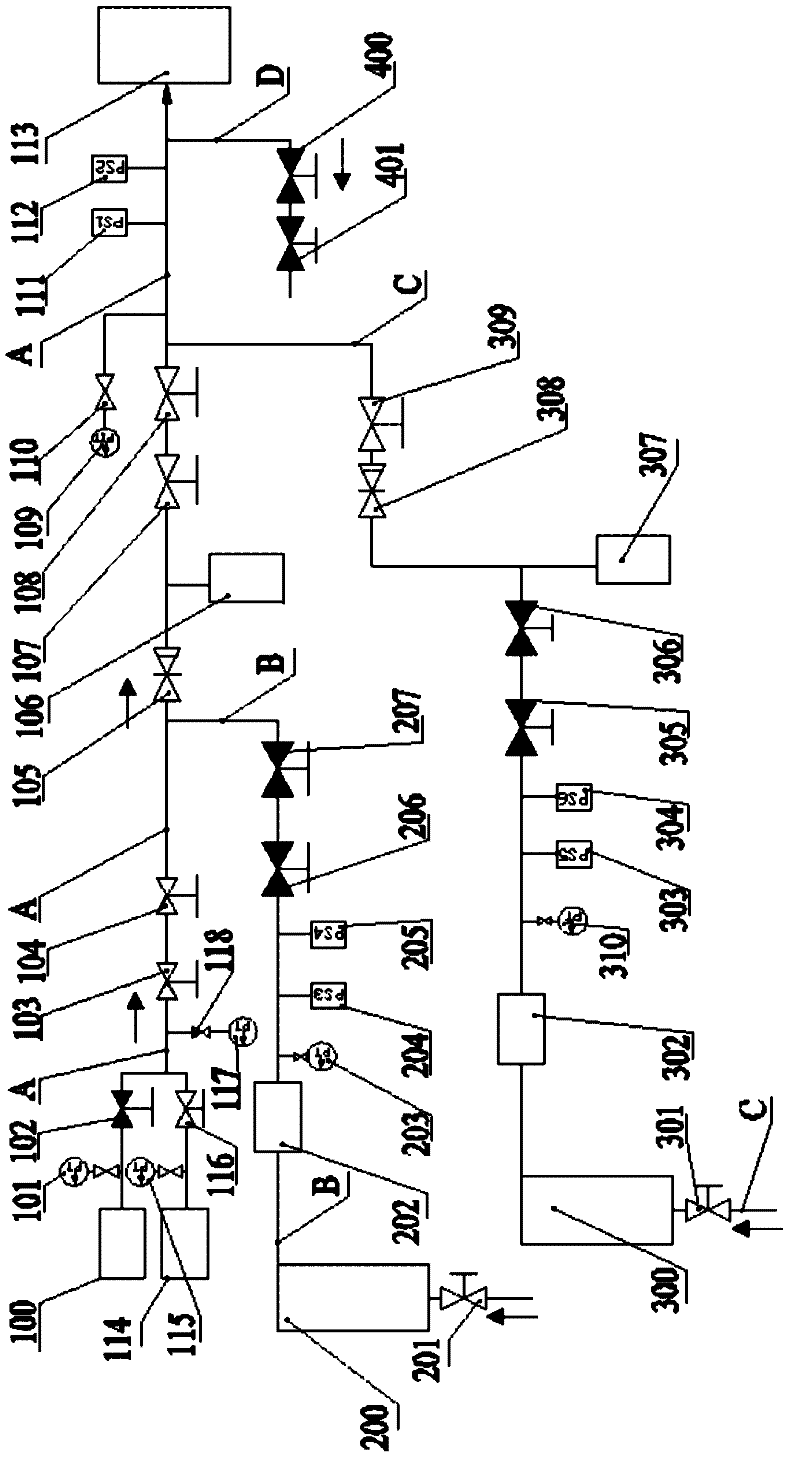

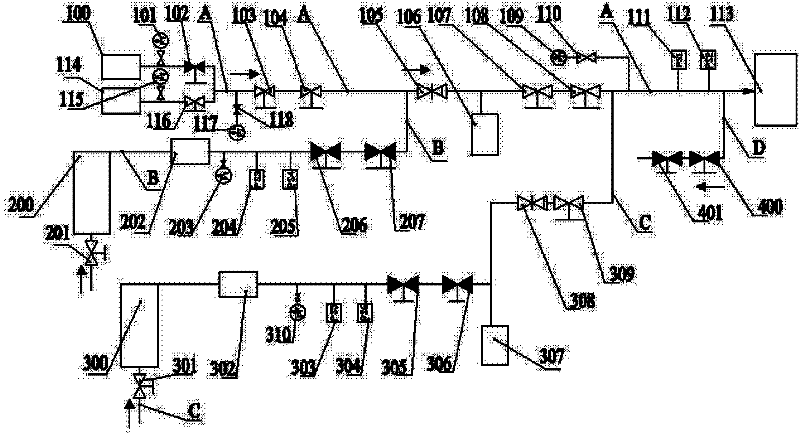

High-temperature gas-cooled reactor pressure-maintaining overhauling and sealing control system

InactiveCN102243898AMeet safety requirementsReach Reliability RequirementsPower plant safety arrangementNuclear energy generationReactor pressure vesselGas cylinder

The invention relates to a high-temperature gas-cooled reactor pressure-maintaining overhauling and sealing control system, which comprises a main gas supply pipeline, a first redundancy gas supply pipeline, a second redundancy gas supply pipeline and a gas exhaust spare pipeline, wherein an inlet of the main gas supply pipeline is connected with a high-pressure helium tank, an outlet of the maingas supply pipeline is connected with a pressure-maintaining overhauling and sealing body; a plurality of pressure gauges, a stop valve and a pressure-maintaining gas tank are arranged on the main gas supply pipeline in sequence from the inlet to the outlet; an inlet of a basic redundancy gas supply pipeline is connected with the high-pressure helium tank, an outlet of the basic redundancy gas supply pipeline is connected with the main gas supply pipeline, and a plurality of pressure gauges and a stop valve are arranged on the basic redundancy gas supply pipeline in sequence from the inlet tothe outlet; total two redundancy gas supply pipelines are arranged and respectively are the first redundancy gas supply pipeline and the second redundancy gas supply pipeline; an inlet of the first redundancy gas supply pipeline is connected with a pressurizer, an inlet of the second redundancy gas supply pipeline is connected with the pressurizer, and the detection of the system adopts the design mode of two-in-three and different working principles. The pressure control strategy is applied to the high-temperature gas-cooled reactor pressure-maintaining overhauling and sealing control system, and the requirement of high reliability of a nuclear power system is met by redundancy configuration. The high-temperature gas-cooled reactor pressure-maintaining overhauling and sealing control system has the characteristics of high control accuracy and reliability equipment operation.

Owner:TSINGHUA UNIV

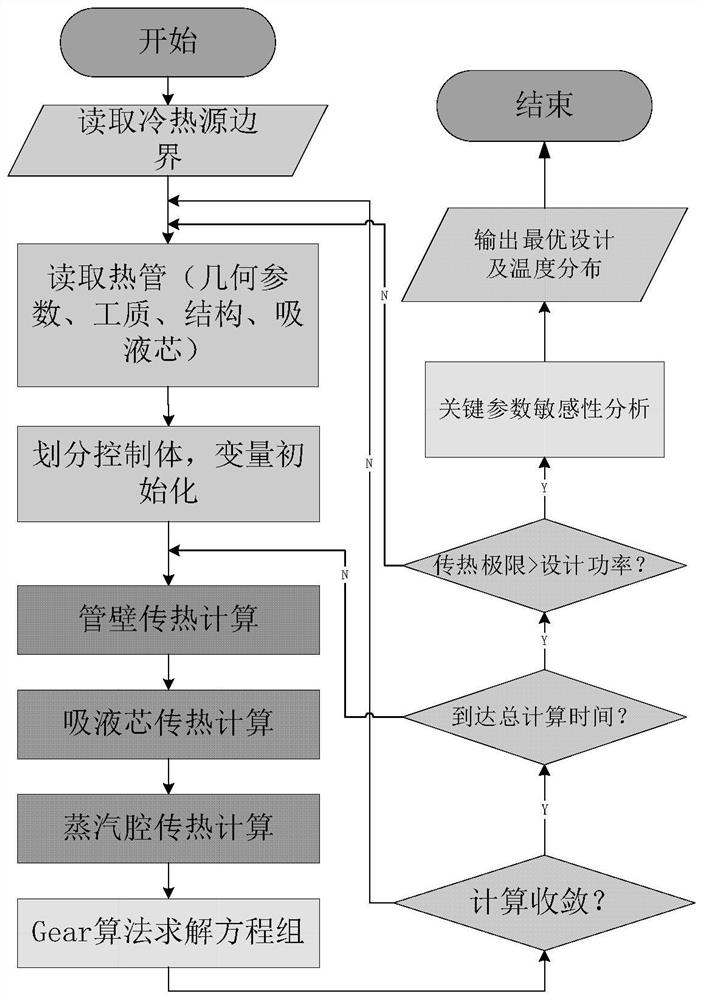

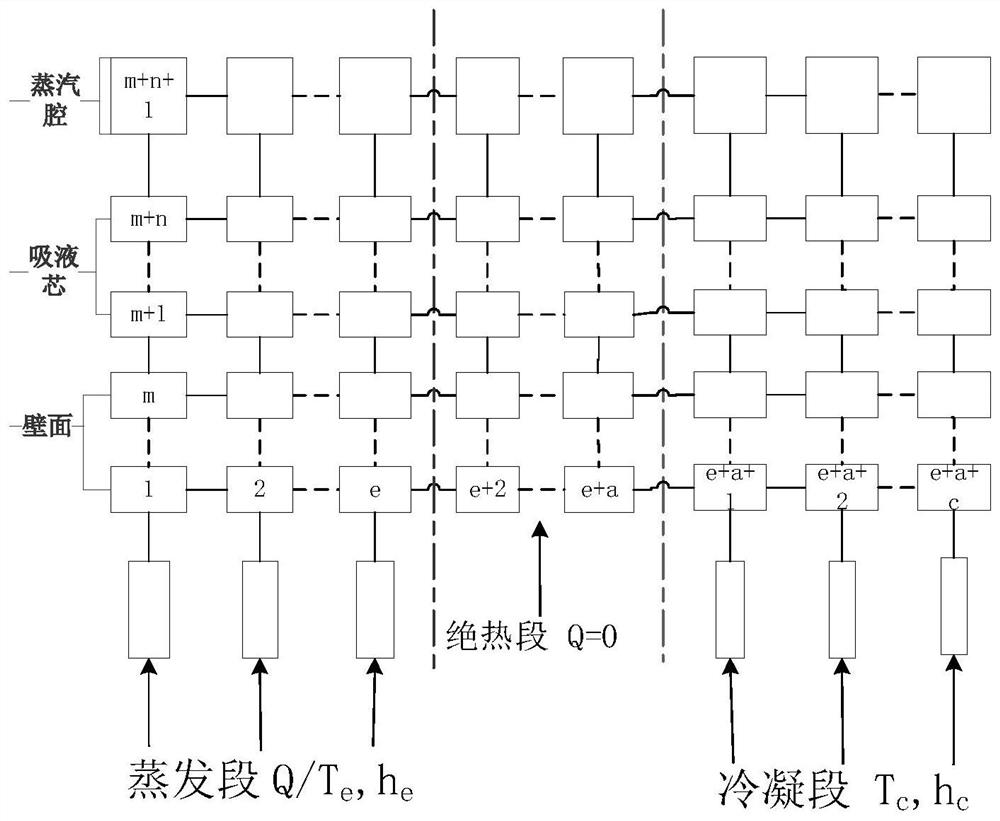

Heat transfer characteristic analysis method for heat pipe in nuclear power system

ActiveCN113434988AExcellent heat pipe parametersSolve the single point of failure problemGeometric CADNuclear energy generationEngineeringMechanical engineering

A heat transfer characteristic analysis method for a heat pipe in a nuclear power system mainly comprises the following steps that 1, inputting a heat source of the heat pipe, the working condition of a heat trap, a working medium, a structure and geometric parameters, and setting calculation time; 2, dividing the heat pipe into control bodies and carrying out initialized calculation; 3, calculating the change rate of the temperature of the pipe wall control body along with time, and considering the axial heat transfer and boundary conditions of the heat pipe; 4, calculating the change rate of the temperature of the control body in the wick along with time, ignoring convective heat transfer caused by liquid flow, and regarding the change rate as pure heat conduction; 5, calculating the change rate of the temperature of the control body in the steam cavity along with time, and simplifying continuous steam flowing into thermal resistance heat conduction; 6, solving the equation set by using a Gear algorithm, and completing calculation of all time points; 7, checking the heat transfer limit of the heat pipe and calculating equivalent thermal resistance; 8, comparing and analyzing the influence of the heat pipe key parameters on the heat transfer performance. Transient calculation and heat transfer characteristic analysis are carried out on different heat pipes, and suggestions and guidance are provided for design of a high-performance heat pipe heat exchanger in a nuclear power system.

Owner:XI AN JIAOTONG UNIV

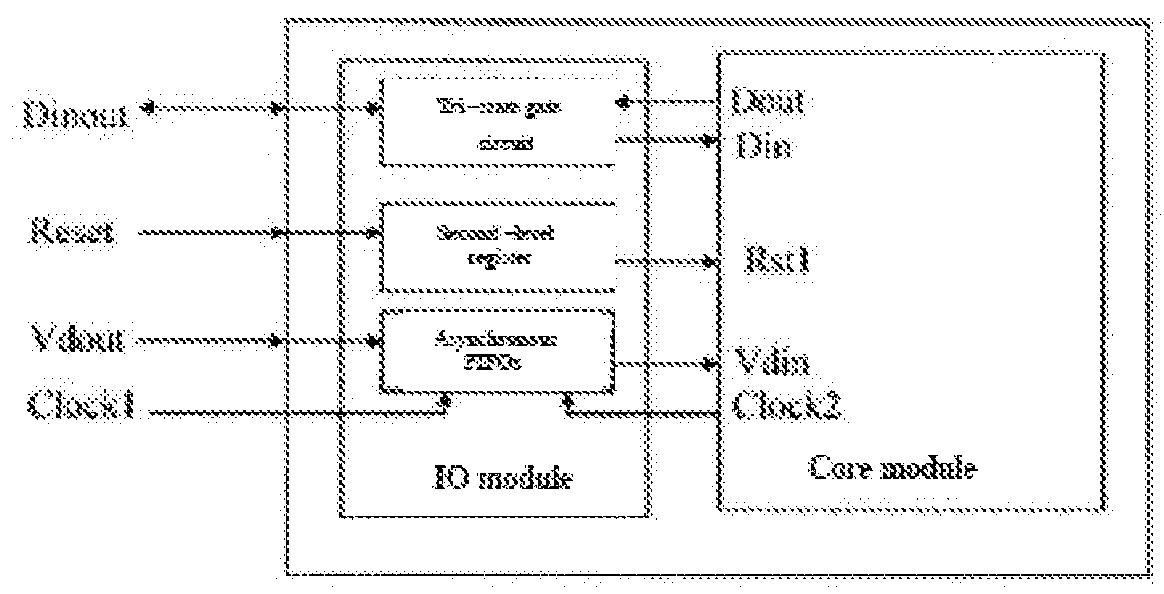

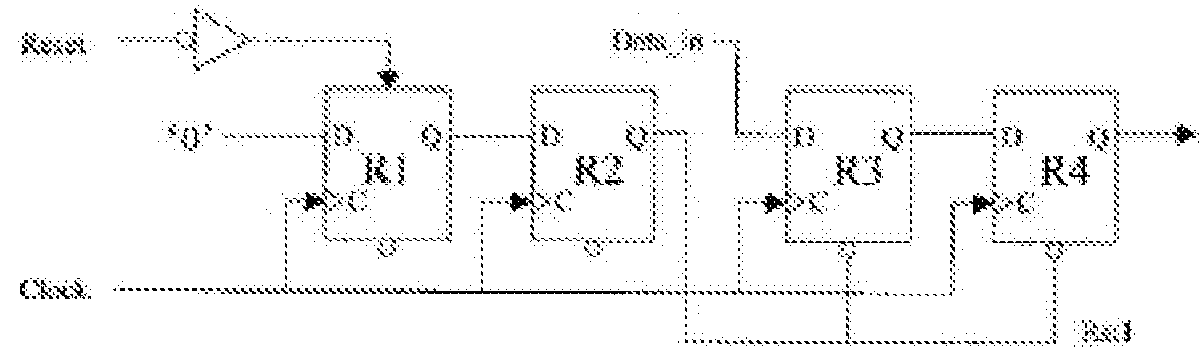

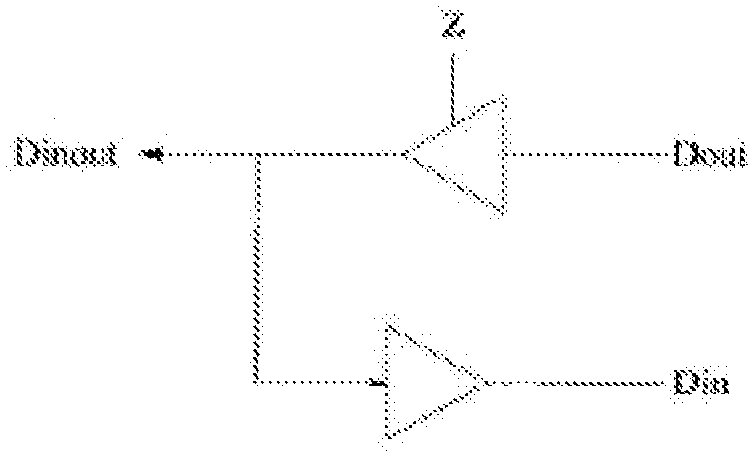

FPGA-based Interface Signal Remapping Method

ActiveUS20180107622A1Improve reliabilityImprove readabilityData resettingGenerating/distributing signalsMultiplexingFpga chip

An FPGA-based interface signal remapping method, relates to the technical field of nuclear power system, and solves the technical problems of poor reliability, readability and debuggability in the prior art. The method comprises dividing an internal programmable logic of an FPGA chip into two independent modules, with one module being an I / O module and the other module being a Core module, using the I / O module to process signal excursion occurring when an external signal is input to or output from the FPGA chip, signal collision caused by line multiplexing, metastable state in a data transmission process, and a data transmission error between asynchronous clock domains, using the Core module to implement logical processing and computing; and introducing a master clock signal outside the FPGA chip into the FPGA chip through a global clock pin of the FPGA chip. The method provided in the invention is suitable for a nuclear power protection system platform.

Owner:STATE NUCLEAR POWER AUTOMATION SYST ENGCO

Managing electrical power for a nuclear reactor system

ActiveUS9305671B2Maintenance costLow costPower plant safety arrangementElectric signal transmission systemsNuclear reactor coreElectricity

An electrical power system for a nuclear power facility includes an active alternating current (AC) power bus configured to be electrically coupled to a plurality of engineered safety feature (ESF) loads of a plurality of nuclear power systems, each of the ESF loads configured to fail to a safe position upon loss of primary AC power; a critical battery system electrically coupled to the active AC bus, the critical battery system comprising a plurality of valve regulated lead acid (VRLA) batteries; and a primary AC power source electrically coupled to the active AC bus.

Owner:NUSCALE

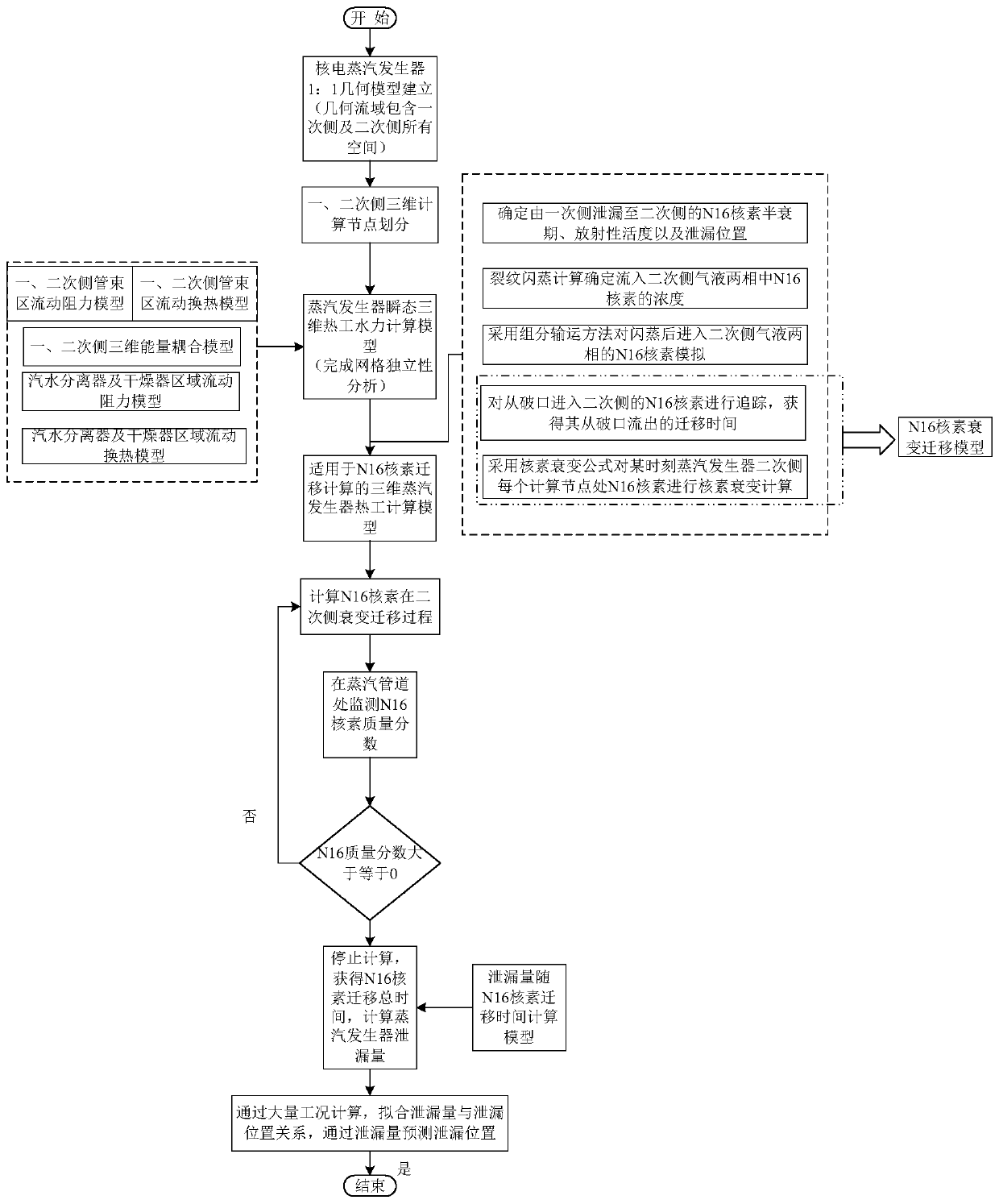

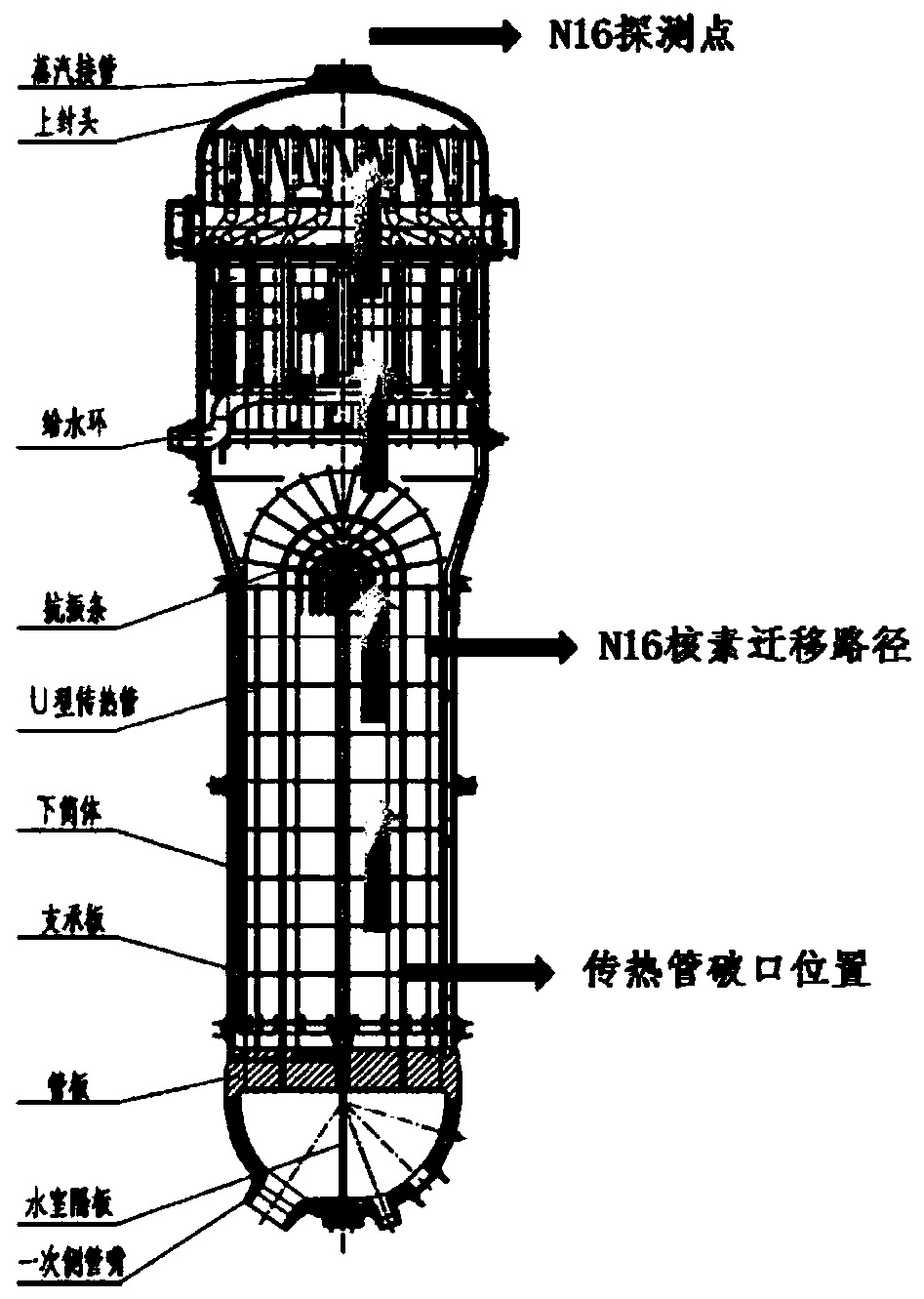

Method for establishing three-dimensional solving model of migration time of N16 nuclide on secondary side of steam generator

ActiveCN111507018AFully consider the migration pathTake migration time into accountDesign optimisation/simulationSpecial data processing applicationsNuclear engineeringNuclide

The invention discloses a method for establishing a three-dimensional solving model of migration time of N16 nuclide on a secondary side of a steam generator. The method is suitable for three-dimensional calculation of radionuclide migration time and primary side coolant leakage amount in the process that coolant with N16 nuclide on the primary side leaks and migrates to a secondary side nuclide monitoring point under the working condition that a heat transfer pipe of a nuclear power system steam generator is damaged. The establishment of the numerical calculation model mainly comprises the following steps of: 1, performing geometric simplification of the steam generator and establishment of a three-dimensional geometric model; 2, dividing calculation nodes on two sides of the steam generator; 3, establishing a transient three-dimensional thermal hydraulic calculation model of the steam generator; 4, determining N16 nuclide concentration at leakage positions of a heat transfer tube anda leakage part; 5, carrying out N16 nuclide migration time tracking and N16 nuclide decay migration model development; and 6, iteratively calculating the migration time of the N16 nuclide from the leakage point to a nuclide monitoring position, deriving to obtain the leakage amount of a coolant according to the nuclide migration time and the specific activity, and predicting a rupture position through the crevasse leakage amount.

Owner:XI AN JIAOTONG UNIV

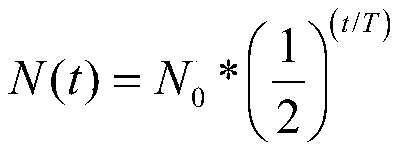

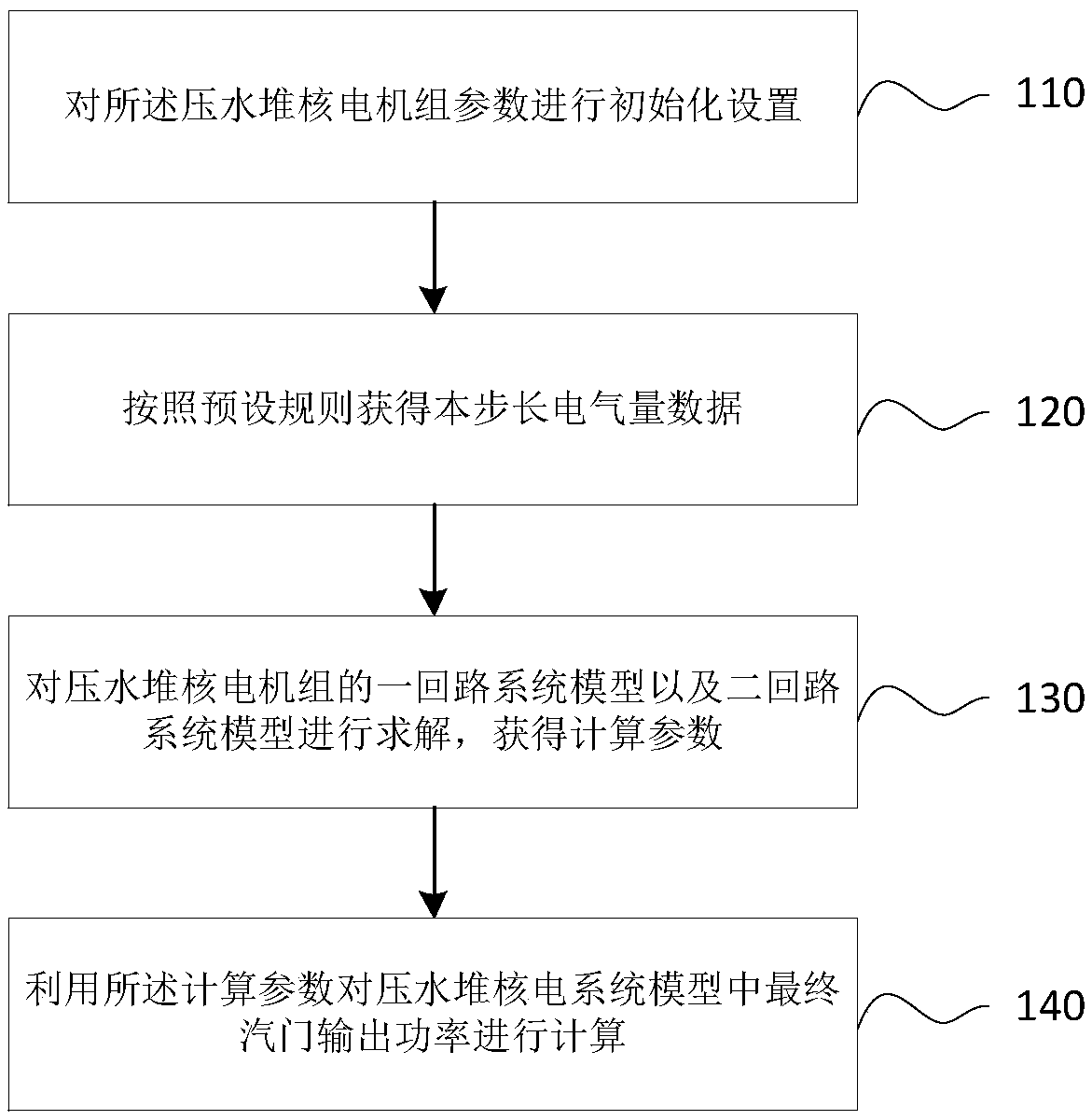

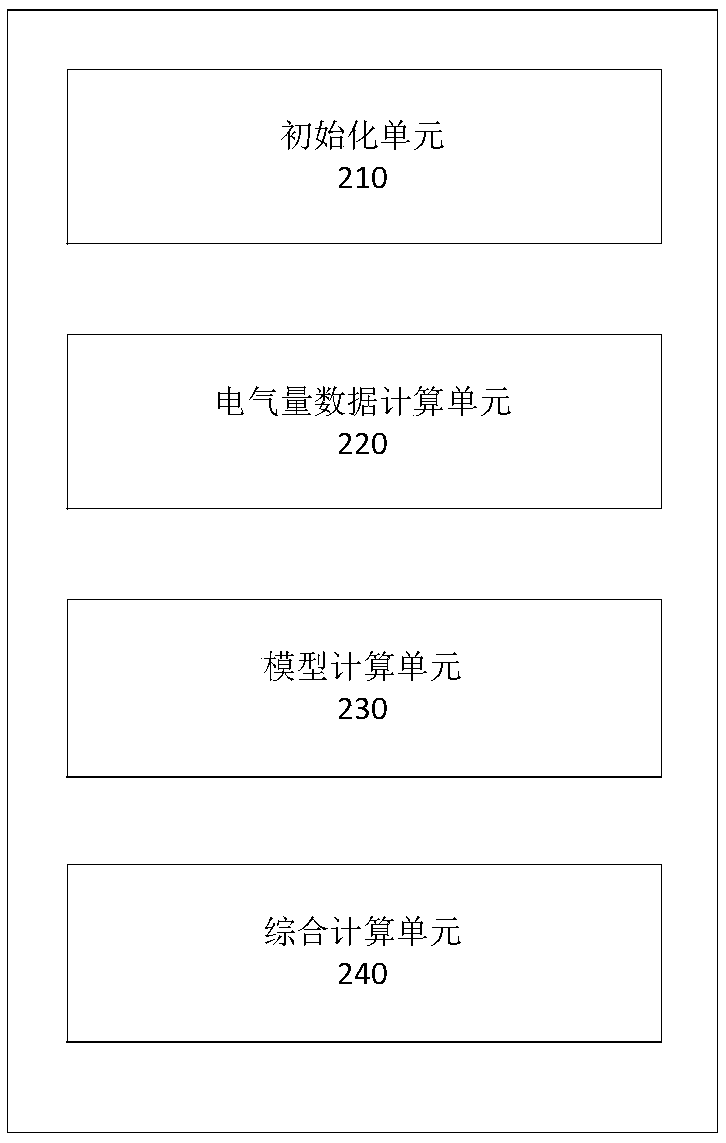

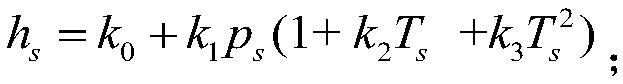

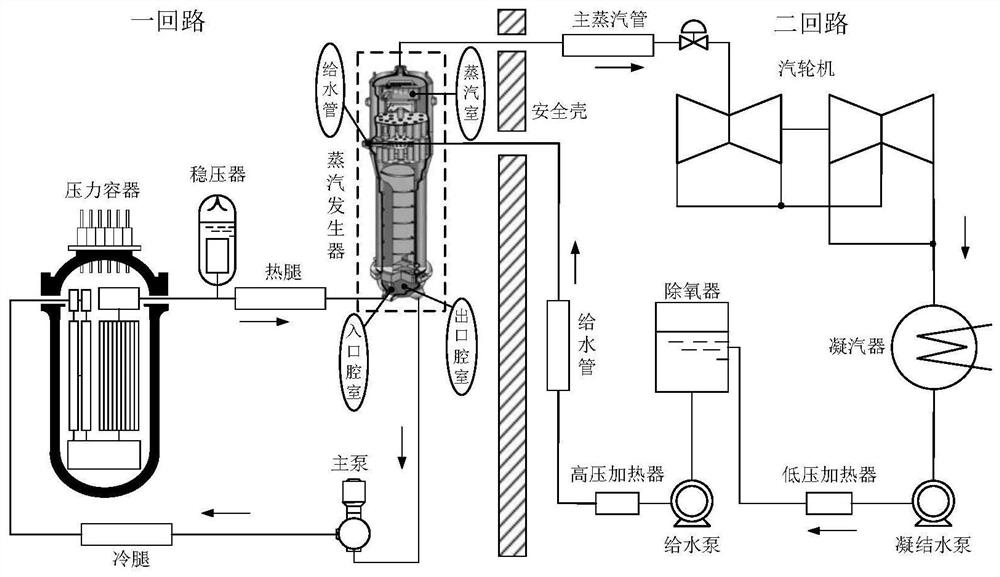

Pressurized water reactor nuclear power unit primary and secondary loop system transmission power simulation method and system

PendingCN109002741AOvercoming the Difficulty of Excessive Dynamic ErrorSolve the problem that the transmission power is difficult to calculate accuratelyAnalogue computers for electric apparatusAnalogue computers for nuclear physicsPressurized water reactorElectric power system

The invention discloses a pressurized water reactor nuclear power unit primary and secondary loop system transmission power simulation method and system. The method comprises the following steps of: initializing the parameters of the pressurized water reactor nuclear power unit; obtaining the electric quantity data of the step size according to the preset rules; solving the primary loop system model and the secondary loop system model of PWR nuclear power unit and obtaining the calculation parameters. The final steam valve output power in the PWR nuclear power system model is calculated by using the calculation parameters, and the output power of the final steam valve is the transmission power of the primary and secondary loop systems of the PWR nuclear power unit. By fitting the specificenthalpy of the main steam and the feed water and taking into account the bypass discharge and the thermal efficiency of the unit, the method and the system solve the problem that the transfer power of the primary and secondary loop systems of the existing nuclear power unit model cannot be accurately calculated by adopting the method of calculating the enthalpy drop per unit time, and improve thesimulation accuracy of the nuclear power unit model.

Owner:CHINA ELECTRIC POWER RES INST +2

Ferritic oxide dispersion strengthened alloy with enhanced room temperature and high temperature strength and manufacturing method thereof

The invention relates to a ferritic oxide dispersion strengthened alloy with enhanced room temperature and high temperature strength containing Cr in a range of from 12 to 20wt%, Y2O3 in a range of from 0.1 to 0.5wt%, W 0.1 to4wt%, Mo 0.5 to 2 wt%, Ti 0.1 to 0.3 wt%, and Zr 0.02 to 0.3 wt%, and Fe, and a manufacturing method thereof. The ferritic oxide dispersion strengthened alloy is advantageous in that under the 700-degree temperature condition, the anti-tensioning performance is good, the alloy can be used for the supercritical steam generator part (rotor wings, and shafts) used for the thermal power, airplane engine part (circular discs, and effusers), and sodium-cooled fast reactor and other nuclear power system reactor core structural parts such as nuclear coating tube, conduits, conductors, and end plugs).

Owner:KOREA ATOMIC ENERGY RES INST +1

Passive safety system for removing decay heat and method of passively increasing a coolant flow using the same

ActiveUS20170025194A1Increase coolant flowThermoelectric device with peltier/seeback effectNuclear energy generationElectricityElectrical connection

A passive safety system for removing decay heat from a nuclear power system may comprise a shroud structure and a heat generator that is within the shroud structure. A thermoelectric device may be disposed in thermal contact with the heat generator. The thermoelectric device is configured to generate a voltage based on a temperature difference between opposite parts of the thermoelectric device. A fan arrangement is disposed above the heat generator and in electrical connection with the thermoelectric device. The fan arrangement is configured to increase a coolant flow through the coolant passage to the outlet opening based on the voltage from the thermoelectric device.

Owner:GE HITACHI NUCLEAR ENERGY AMERICAS

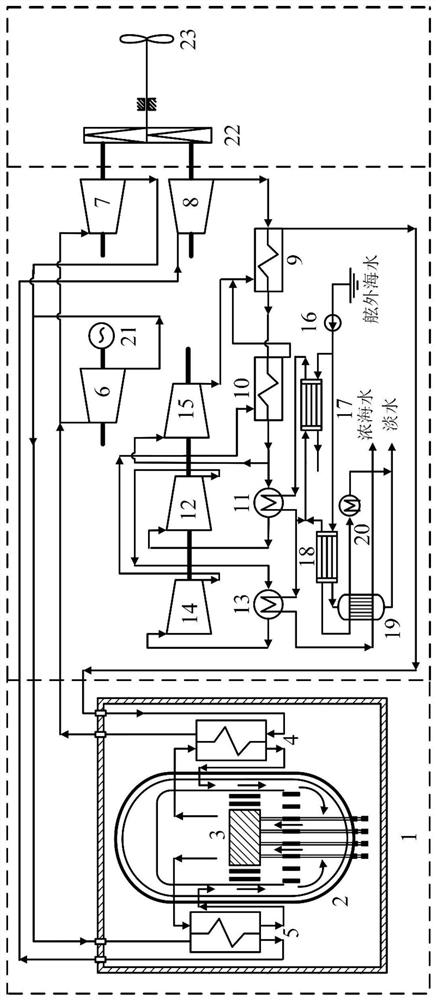

Supercritical carbon dioxide circulation and seawater desalination coupled vessel nuclear power system

InactiveCN112249293AImprove performanceGive full play to the advantages of high efficiencyPower plants using nuclear energyPropulsion based emission reductionIntercoolerSeawater

The invention discloses a supercritical carbon dioxide circulation and sea water desalination coupled vessel nuclear power system which comprises a reactor cabin, a ship cabin and a propelling device,the reactor cabin comprises a high-temperature gas cooled reactor system, and the ship cabin comprises a supercritical carbon dioxide power circulation system and a sea water desalination subsystem.A first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger are arranged on the two sides of a high-temperature gas cooled reactor in the high-temperature gas cooled reactor system correspondingly. The supercritical carbon dioxide power circulation system is coupled with the high-temperature gas cooled reactor system through a first-stage intermediate heat exchanger and a second-stage intermediate heat exchanger. The seawater desalination subsystem is coupled with the supercritical carbon dioxide power circulation system through a precooler and an intercooler. Thepropelling device is connected with the supercritical carbon dioxide power circulation system. Vessel propulsion power and electric power are provided through the supercritical carbon dioxide circulation system, fresh water needed by the whole vessel is provided in cooperation with the sea water desalination system, the vessel is driven to sail in a direct propulsion mode, and the energy conversion rate and the device compactness are improved.

Owner:SOUTHEAST UNIV

Method for preparing oxide dispersion strengthen (ODS) high-temperature alloy pipe

InactiveCN102758181ASmall sizeEvenly distributedOptical rangefindersNuclear energy generationElectron beam physical vapor depositionGas phase

The invention relates to a method for preparing an oxide dispersion strengthen (ODS) high-temperature alloy pipe. The problems that in prior methods for preparing nuclear fuel cladding ODS alloy pipes, the process is complex, the efficiency is low and pipes with various diameters and various wall thicknesses are difficult to obtain are solved. The method comprises steps of cleaning the outer surface of a base pipe; conducting preparation work before electron beam physical vapor deposition; and depositing the ODS high-temperature alloy pipe. By the aid of the method, ODS high-temperature alloy pipes with various diameters and various wall thicknesses are prepared. The method can be applied to preparation of nuclear fuel cladding materials of supercritical water reactor in a nuclear power system and preparation of other components which are used under high-temperature environments.

Owner:HARBIN INST OF TECH

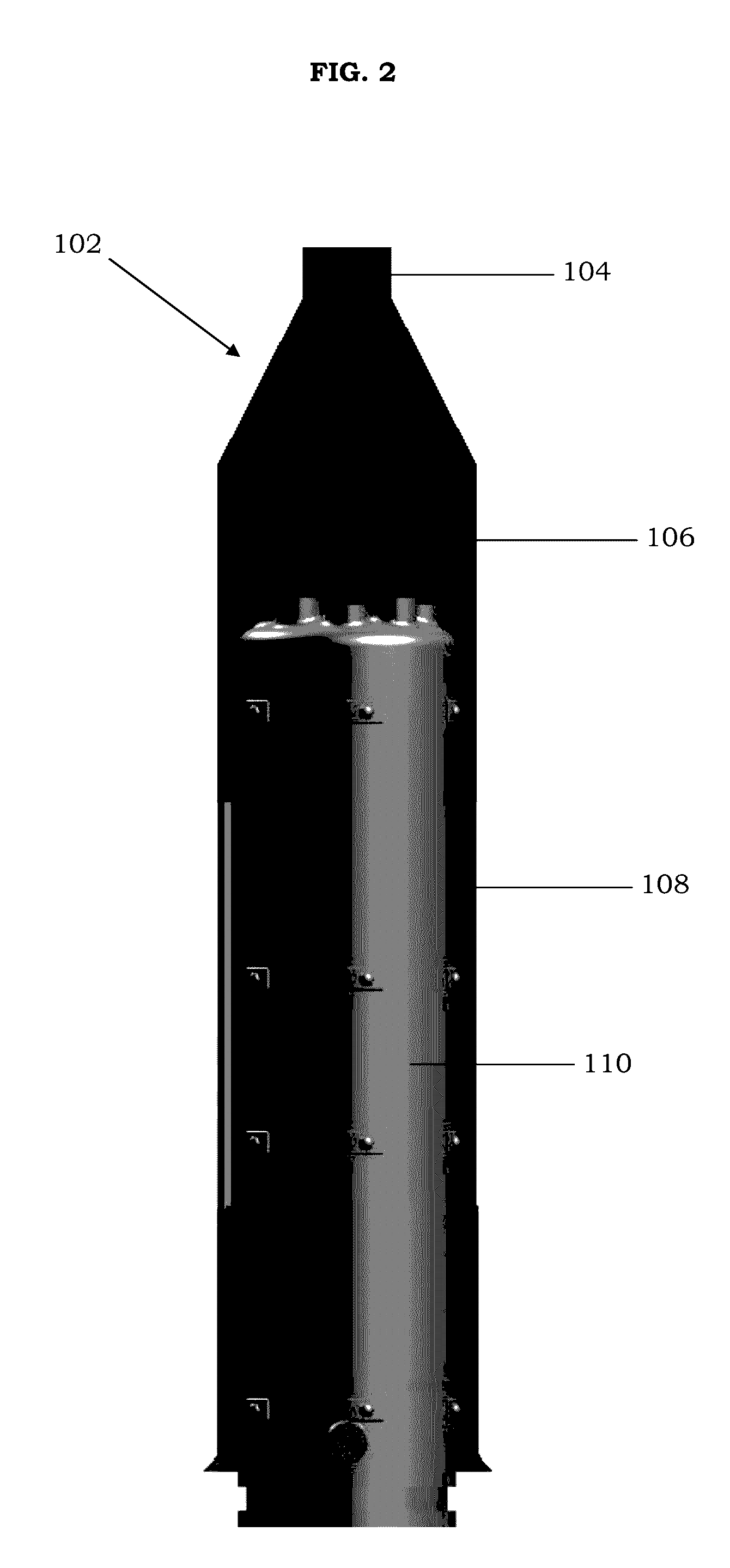

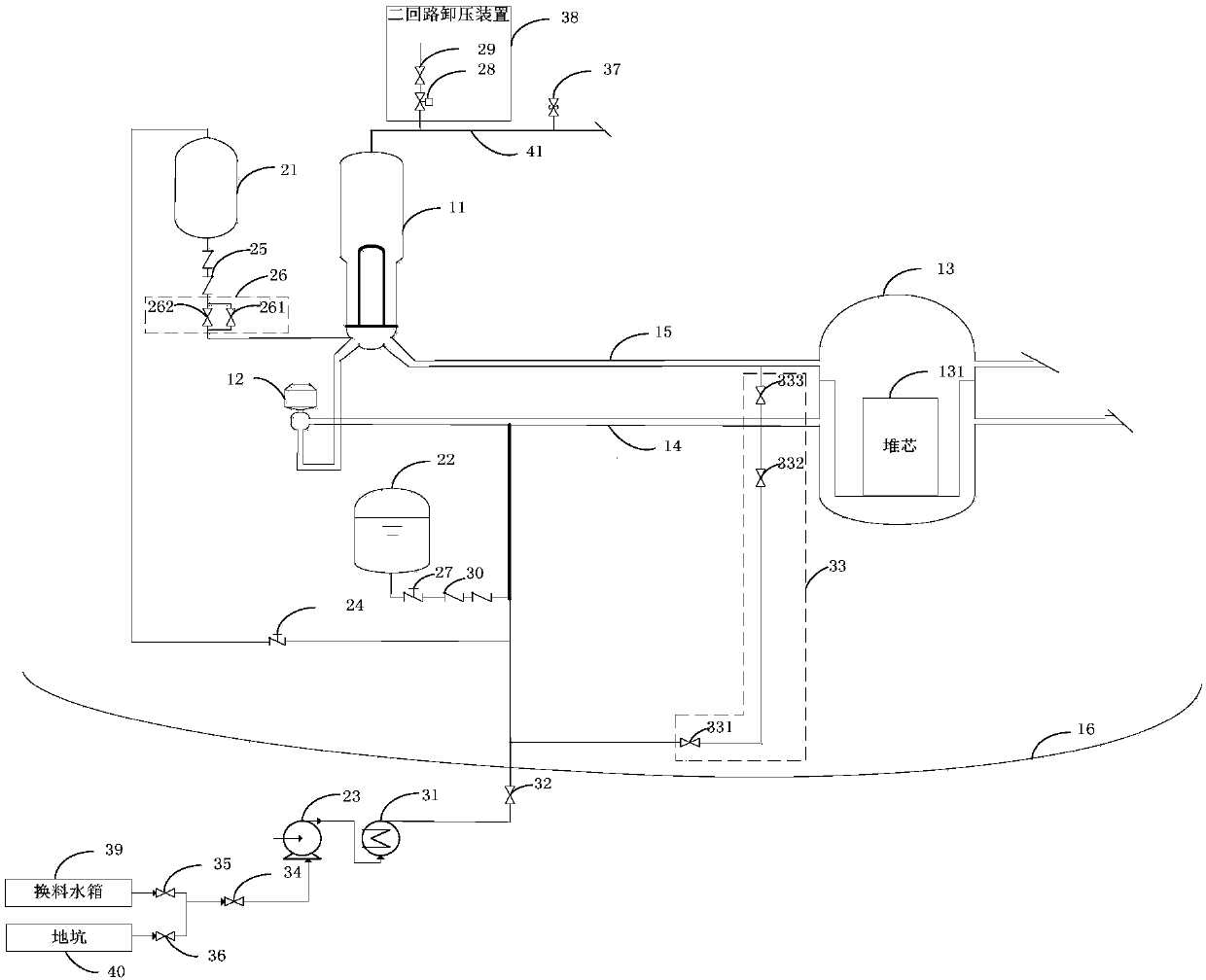

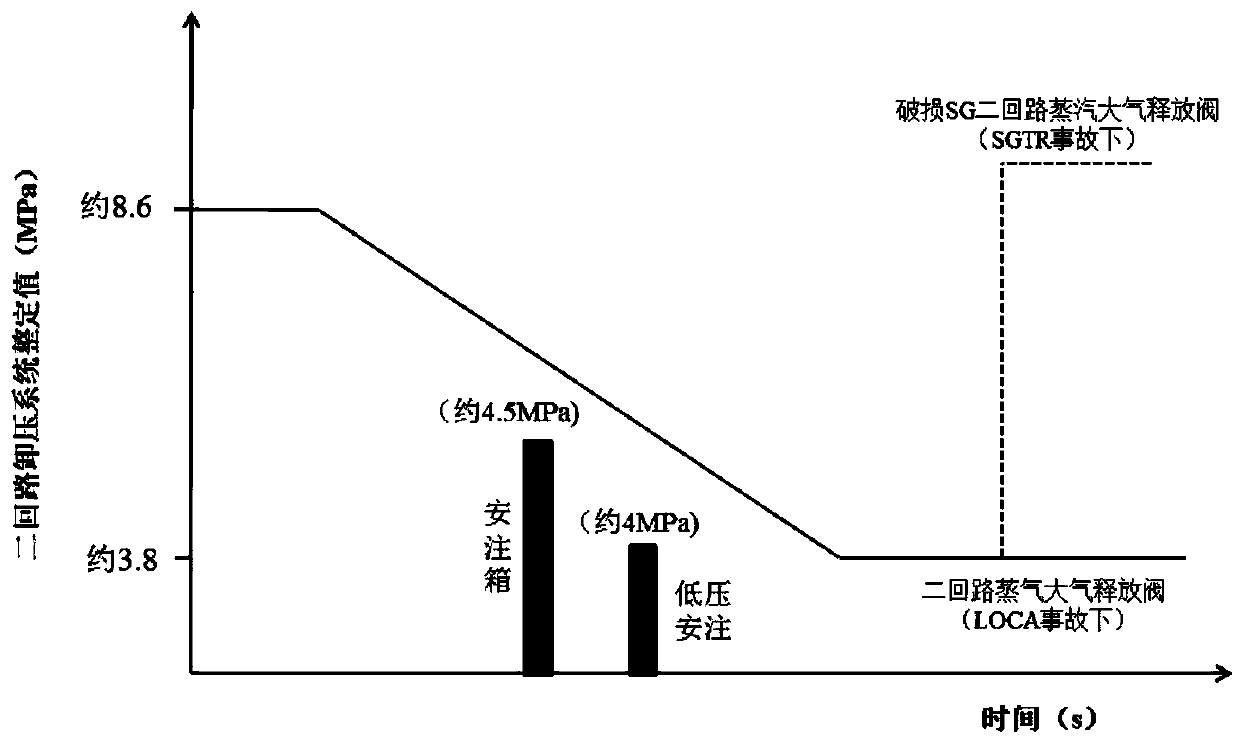

Safety injection system and nuclear power system

PendingCN109903863AImprove cooling effectEfficient dischargeNuclear energy generationCooling arrangementRadioactive agentNuclear engineering

The embodiment of the invention provides a safety injection system and a nuclear power system. The safety injection system includes: a core makeup tank, an accumulator, a safety injection pump and a secondary circuit pressure relief device. A first interface of the core makeup tank, a first interface of the safety injection pump and a first interface of the accumulator are respectively communicated with a cold leg, and a second interface of the core makeup tank is communicated with a third interface of a steam generator; the secondary circuit pressure relief device is communicated with a fourth interface of the steam generator; when a safety signal is triggered, the core makeup tank injects a first coolant into a pressure container through the cold leg; when the pressure of a primary circuit is lower than that of the accumulator top, the accumulator injects a second coolant into the pressure container through the cold leg; and / or when the pressure of the primary circuit is lower than apreset value, the safety injection pump injects a third coolant into the pressure container. The safety injection system and nuclear power system provided by the invention reduce the release of radioactive substances, and are beneficial to the recovery of power plants after rupture accidents.

Owner:HUALONG PRESSURIZED WATER REACTOR TECH CORP LTD

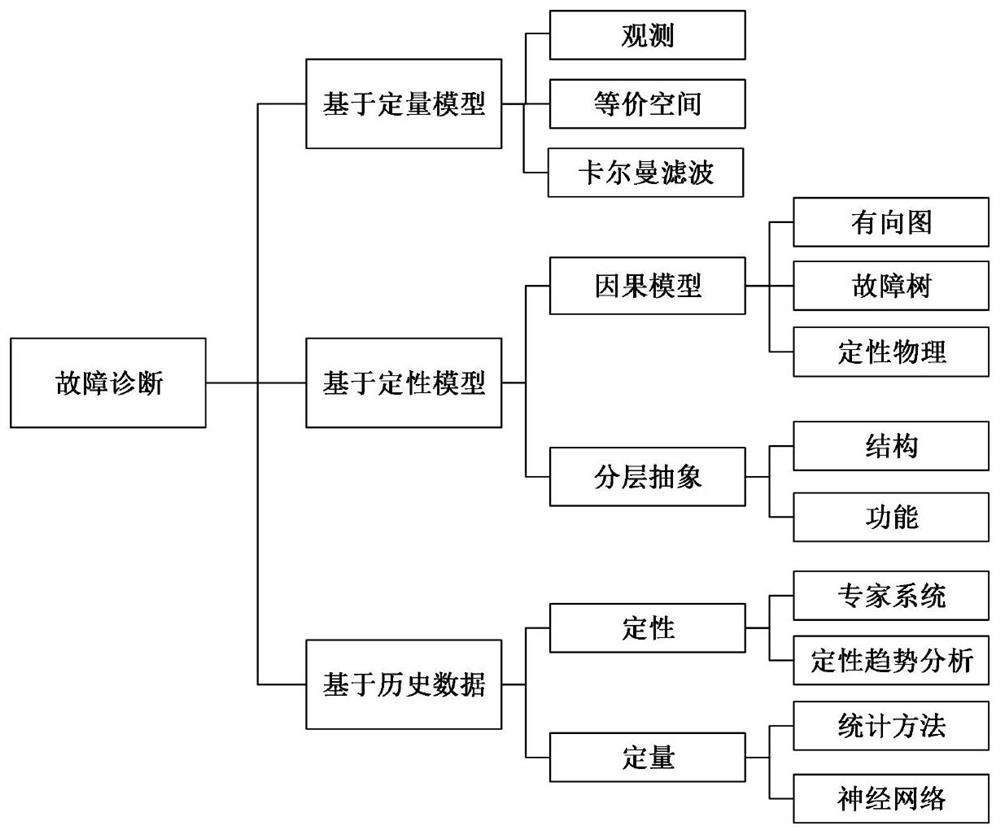

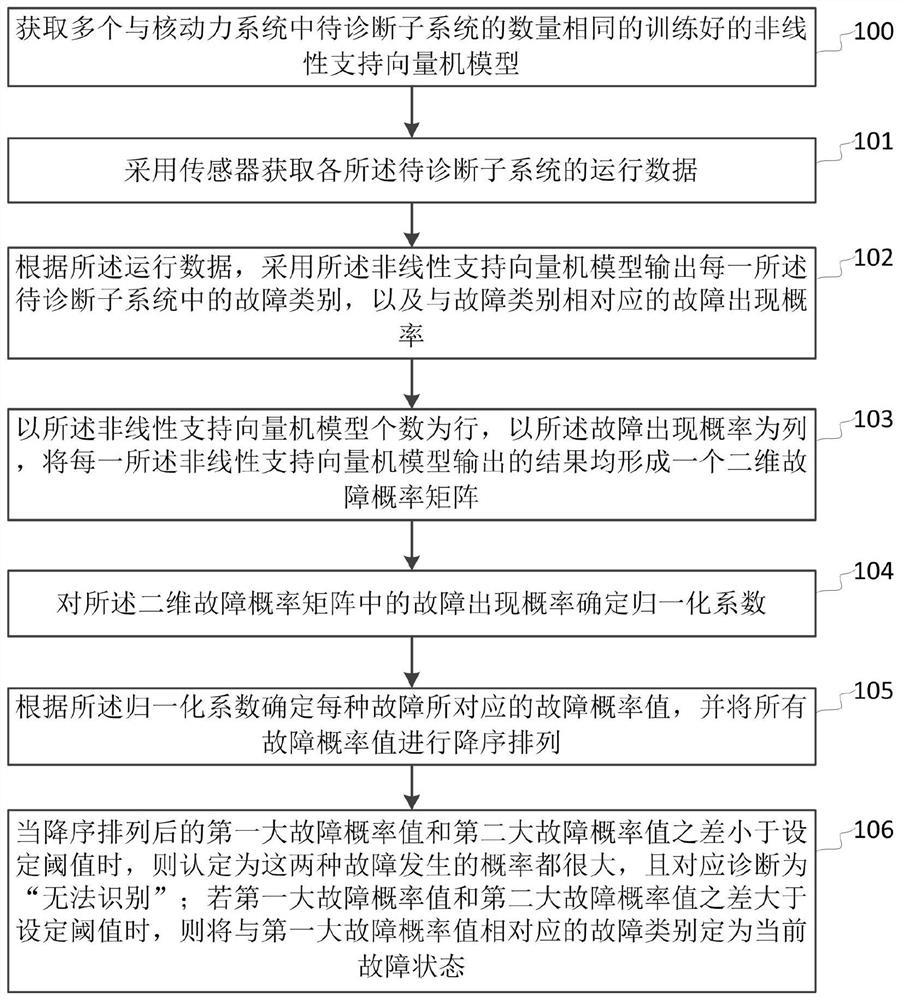

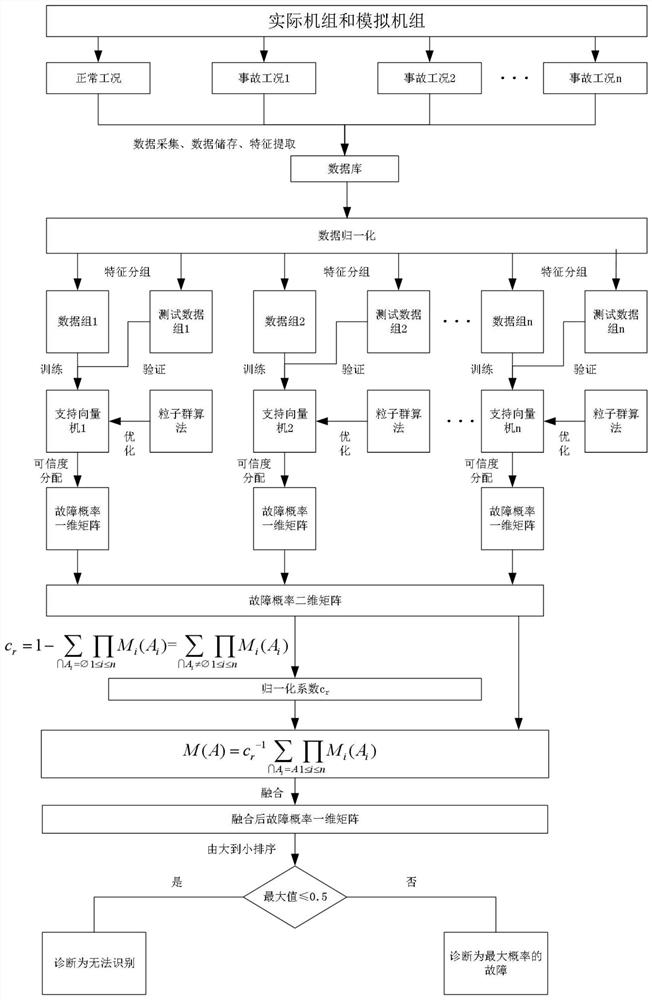

Nuclear power system fault diagnosis method and system

ActiveCN111767657AImprove diagnostic accuracyImprove adaptabilityKernel methodsDesign optimisation/simulationFault occurrenceFault class

The invention relates to a nuclear power system fault diagnosis method and system. According to the nuclear power system fault diagnosis method and system, through a trained nonlinear support vector machine model, the fault category of each subsystem in a nuclear power system and the fault occurrence probability corresponding to the fault category can be accurately obtained; after a normalizationcoefficient is determined according to the fault occurrence probability in a constructed two-dimensional fault probability matrix, a fault probability value corresponding to each fault is determined according to the normalization coefficient; and the difference value between a first large fault probability value and a second large fault probability value in the probability values after descendingsort is compared with a set threshold value to obtain the fault diagnosis result of the nuclear power system, so that the adaptability of the whole nuclear power system fault diagnosis method and system is improved while the diagnosis accuracy is improved.

Owner:HARBIN ENG UNIV

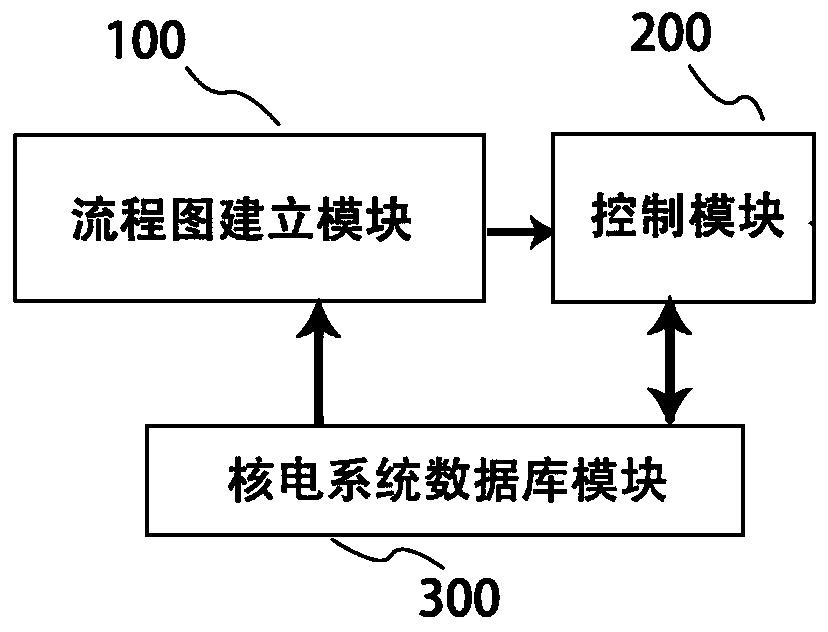

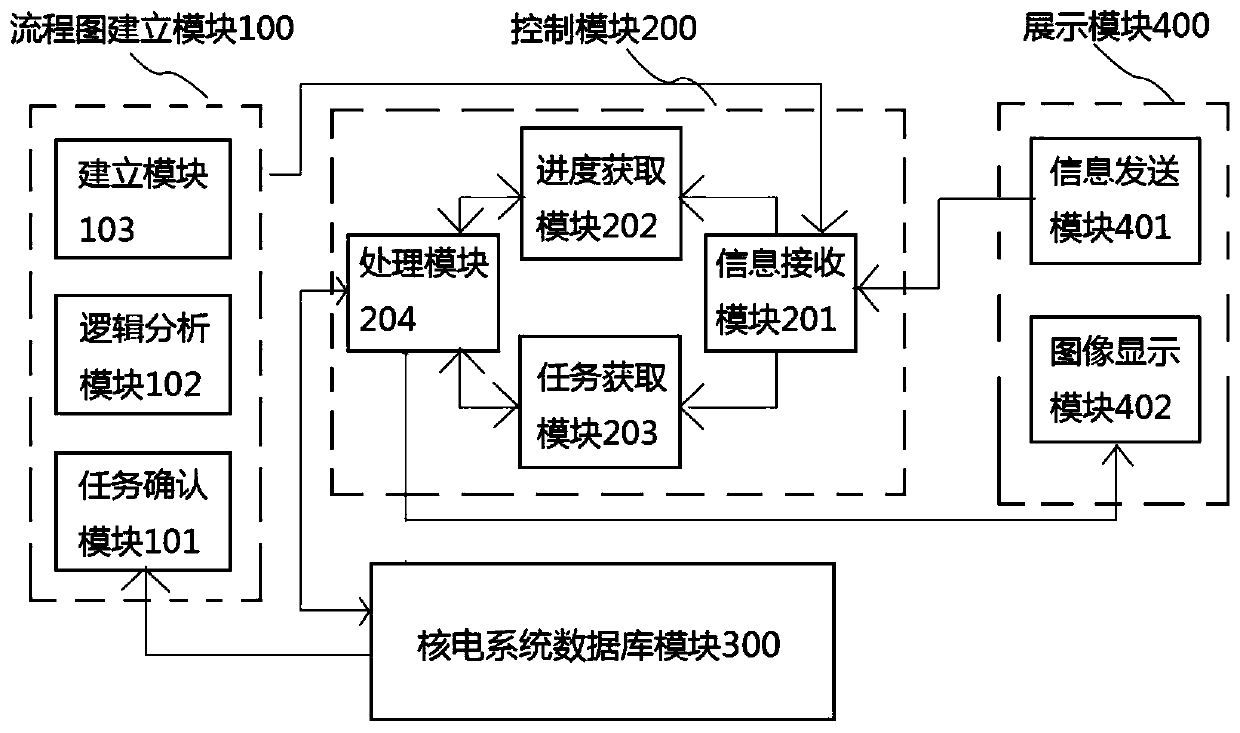

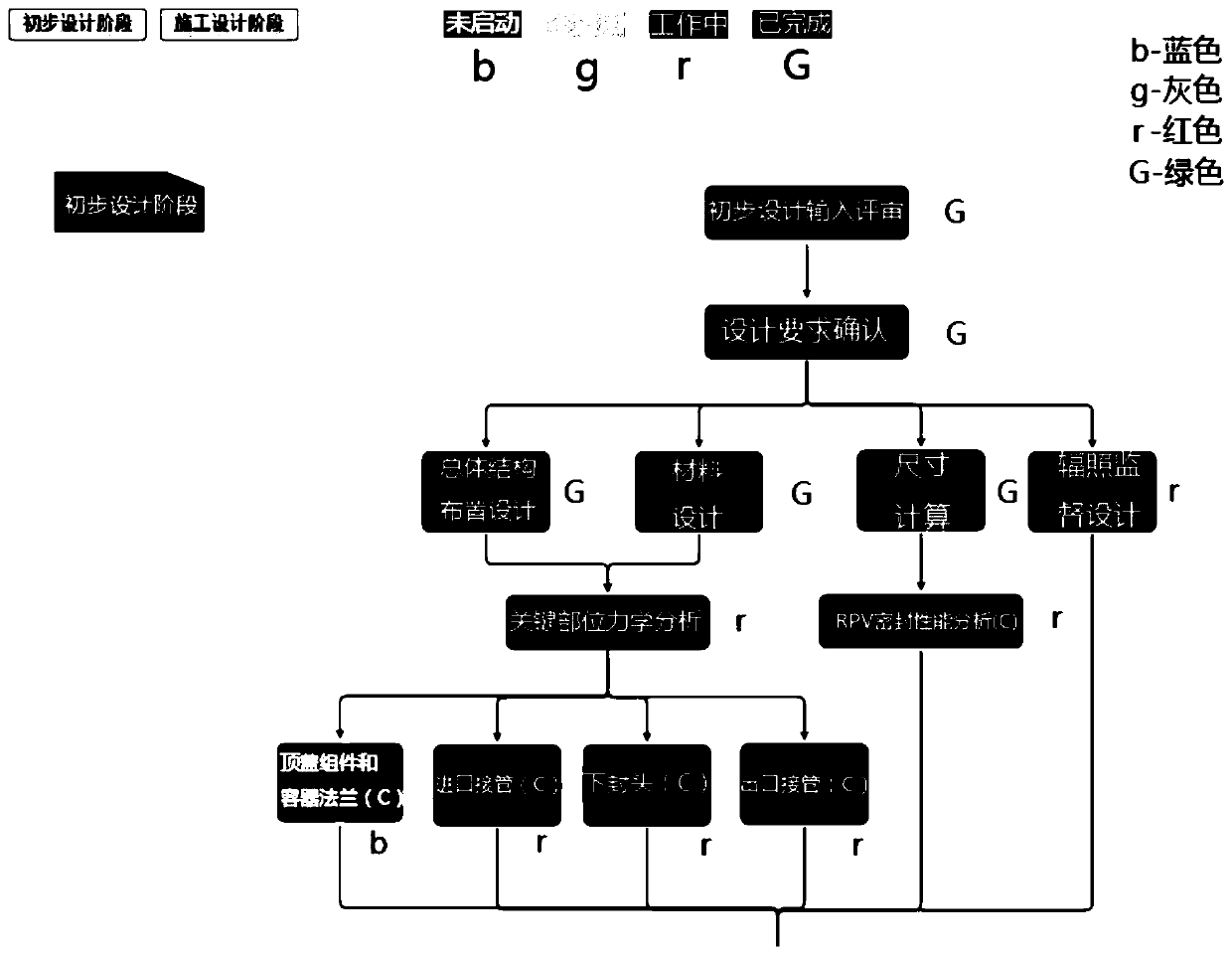

Nuclear power design task management system and method and storage medium

ActiveCN110705036AClear and defined processClear and definite progressDatabase management systemsDesign optimisation/simulationContent analyticsLogisim

The invention discloses a nuclear power design task management system. Method and storage medium, relating to the field of computer software, the system includes: a processor; the method is used for determining design task link contents. Analyzing the logic relationship among the links; node division is carried out on the design task; associating the specific task of each link with the corresponding node; the flow chart establishing module is used for establishing all node design logic flow charts; and the control module is used for acquiring request information, acquiring related design taskinformation from the nuclear power system database module according to the process and the node name, and controlling the completion condition of all design tasks associated with the node or the detailed list of the design tasks to be displayed according to the request information. According to the method, the defects that task logic cannot be embodied, design progress display is not visual enoughand management experience is difficult to accumulate and reuse in current nuclear power design task table management are overcome, so that the design process and progress are clearer and more definite, Meanwhile, reference is provided for the design process of other nuclear power projects.

Owner:中广核工程有限公司 +3

Heat pipe pile waste heat removal system

PendingCN111554416AReduce lossesSimple structureNuclear energy generationIndirect heat exchangersInterior spaceEngineering

The embodiment of the invention relates to the technical field of deep sea nuclear power systems, and provides a heat pipe pile waste heat removal system. The heat pipe pile waste heat removal systemcomprises a heat pipe pile and a heat exchanger; the heat pipes of the heat pipe stack are in a horizontal lying state; the heat exchanger comprises a shell; the heat pipes are inserted into the shellin a penetrating mode; the shell comprises an inner layer shell body and an outer layer shell body; a water outlet and a water inlet are formed in the upper portion and lower portion of the shell which are corresponding to each other; the interior of the inner layer shell body is communicated with the exterior of the outer layer shell body through the water outlet and the water inlet. According to the heat pipe pile waste heat removal system provided by the embodiments of the invention, a special cooler is omitted, so that the system is simplified in structure and is reduced in size and can assist in saving precious cabin space compared with a traditional reactor waste heat removal system. The heat pipe pile waste heat removal system can be suitable for underwater vehicles with extremelynarrow internal space.

Owner:WUHAN SECOND SHIP DESIGN & RES INST

Primary-secondary loop coupling calculation method for nuclear power system

ActiveCN112231990AAccurate analysisGuaranteed computing efficiencyGeometric CADDesign optimisation/simulationReduced modelEngineering

The invention discloses a primary and secondary circuit coupling calculation method for a nuclear power system, which comprises the following steps: 1, establishing a three-dimensional geometric modelof a reactor steam generator, dividing grids, and establishing a nuclear reactor primary and secondary circuit one-dimensional simplified model; 2, setting an initial boundary condition and a computational domain initial state of the geometric model of the steam generator by using computational fluid dynamics software; 3, calculating the steam generator model by calculation fluid dynamics software to obtain a calculation result, and transmitting the calculation result to a system analysis program to serve as a boundary condition of the time step length of the system analysis program; 4, enabling the system analysis program to calculating the primary and secondary loop model to obtain a calculation result, and transmitting the calculation result to the computational fluid dynamics softwareto serve as a boundary condition for next time step length calculation of the computational fluid dynamics software; 5, repeating step 3 and step 4 until the reactor system model completes all-time calculation. Multi-dimensional and full-system high-fidelity coupling analysis of the reactor system is completed.

Owner:XI AN JIAOTONG UNIV

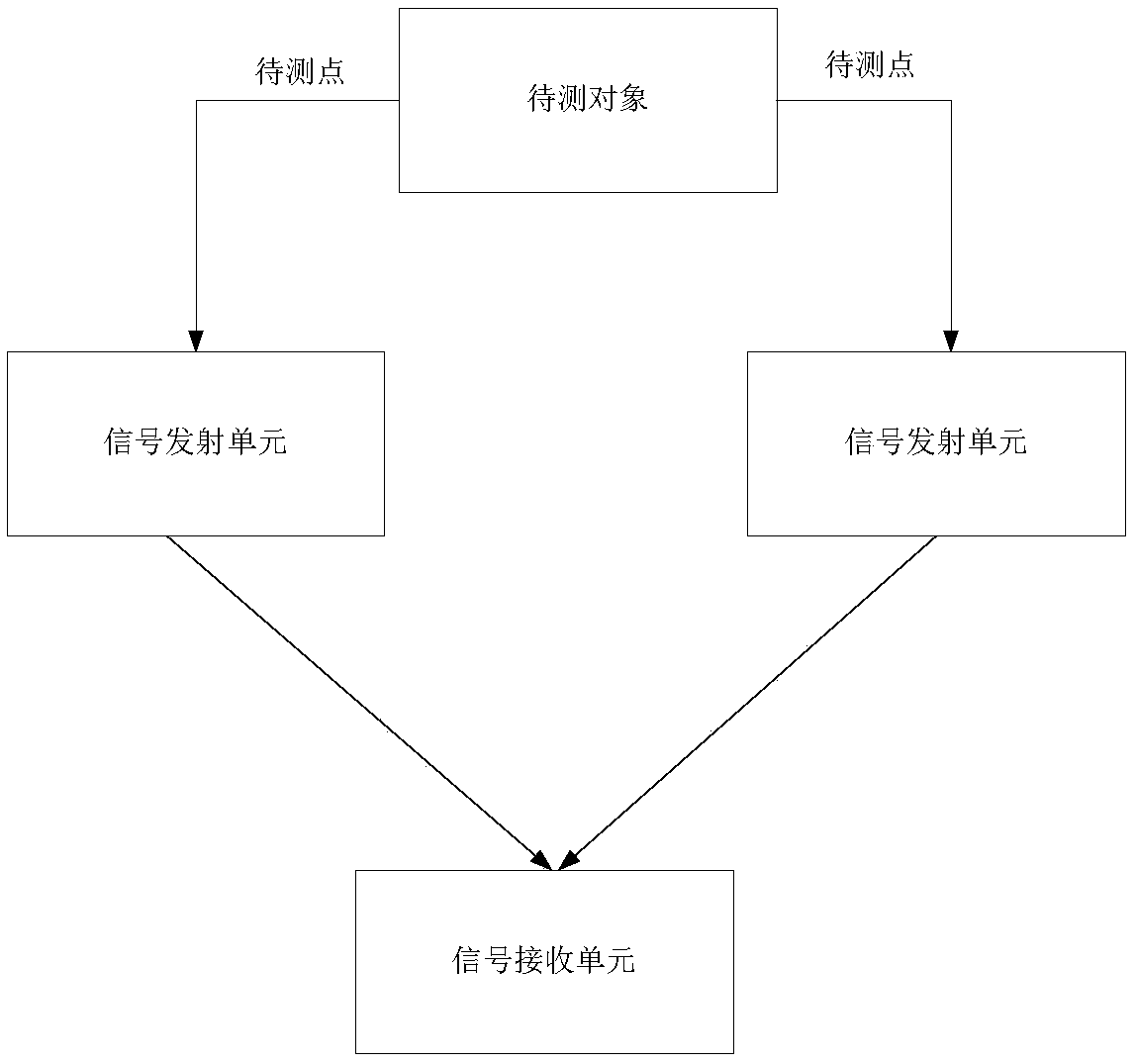

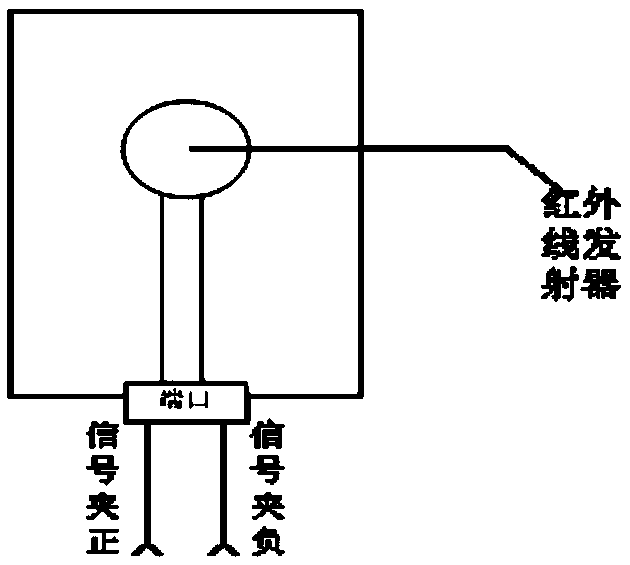

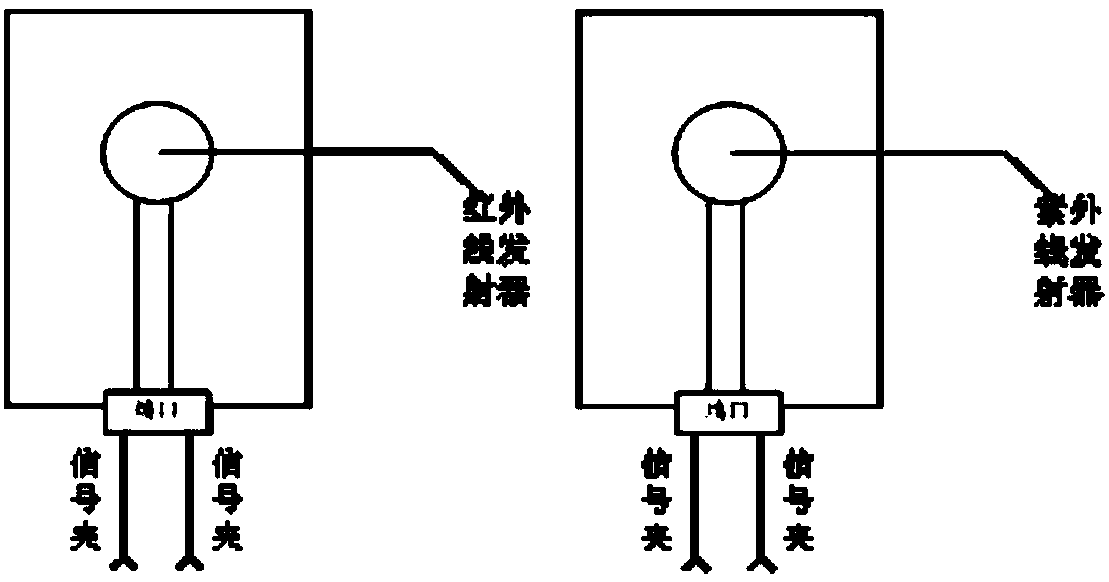

Response time testing system and method for digital instrument control system of nuclear power plant

ActiveCN109239428AAdaptableLower requirementDigital variable/waveform displayEngineeringInstrument control

The invention relates to a response time testing system and method for a digital instrument control system of a nuclear power plant and belongs to the technical field of test of nuclear power systems,which solves the problem of a too large artificial operation error, an oversized testing device and a limited distance between measuring points brought by using an oscilloscope in the existing testing method. The response time testing system comprises a signal emission unit and a signal receiving unit; the signal emission unit is connected with a to-be-tested point; when detecting that a test signal passes through the to-be-tested point, a light source signal is externally emitted; the test signal is a high-frequency pulse signal; the signal receiving unit is used for receiving the light source signal emitted by the signal emission unit, meanwhile, recording the receiving time and calculating a difference value of the receiving time as response time. According to the system and the method, during test, the device is portable and compact; the suitability to the test environment is strong; meanwhile, the test process is simple in operations, thereby reducing the impact of human factorson the test result; moreover, the test cost is greatly reduced, and the economy is strong.

Owner:CHINA TECHENERGY +1

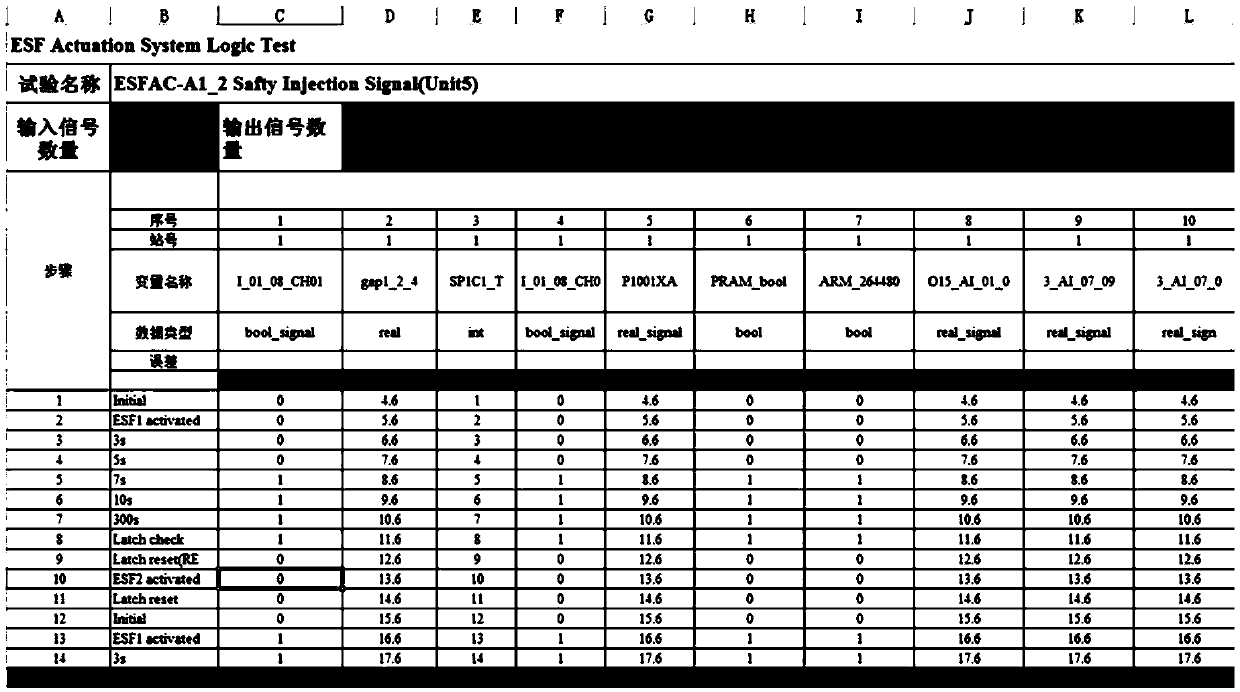

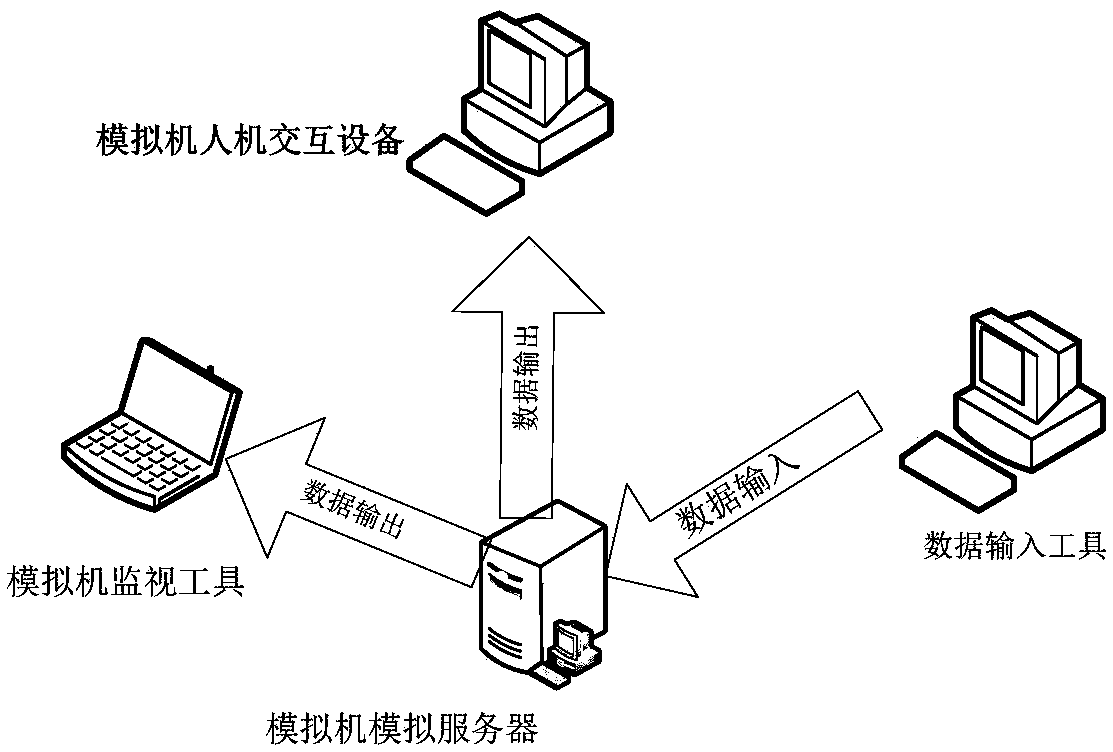

Test method and system for verifying logical operation function of DCS simulator

InactiveCN109557900AConsistent outputImprove test efficiencyElectric testing/monitoringComputer hardwareTest efficiency

The invention relates to a test method and system for verifying a logical operation function of a DCS simulator, and belongs to the field of nuclear power system testing. The method comprises the following steps of: presetting an input setting and an expected result according to the logic required to be verified, forcibly inputting a DCS simulator to perform a logical operation simulation according to the input setting; comparing an output operation result of the DCS simulator according to the logical operation simulation with the expected result to generate a test result judgment table; and obtaining a test result of the logical operation function of the DCS simulator according to the test result judgment table. The method overcomes the problem that existing test methods are low in verification efficiency and easy to introduce human errors, thereby effectively improving the test efficiency and accuracy.

Owner:CHINA TECHENERGY +1

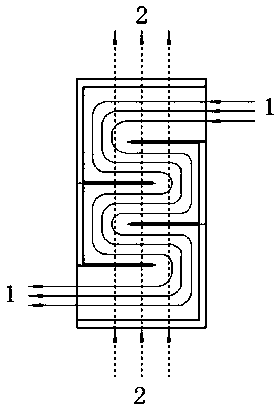

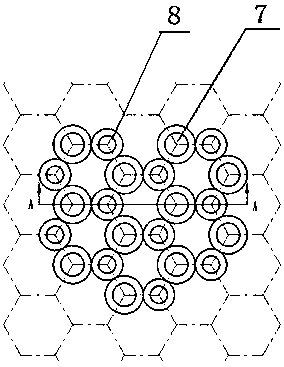

Plate-type heat exchanger core body applied to nuclear power system

PendingCN110514041ASmooth circulationUniform coolingHeat exchanger casingsLaminated elementsArray data structureMolten salt

The invention discloses a plate-type heat exchange core body applied to a nuclear power system. The core body comprises a plurality of plate pairs constituted of plate sheets, wherein each of the plate sheets is of a concave-convex rippled unit topological structure with a hexagonal or right quadrilateral cellular arrangement, and each of the rippled units on each of the plate sheets comprises convex ripples and concave ripples which are arranged in a staggered manner; the two plate sheets which constitute one group of the plate pairs are mutually buckled together, outer walls of the concave ripples which are mutually touched are welded and sealed, and a cold medium side flow way is formed by outer walls of the convex ripples in the two plate sheets; outer walls of the convex ripples, which are mutually contacted, of the two overlaid and adjacent groups of plate pairs are welded and sealed, and a fused salt side flow way is formed by outer walls of the concave ripples in the two groupsof plate pairs; the fused salt side flow way and the cold medium side flow way are mutually perpendicular and have no intersection point; and lateral edges of the plate pairs are welded and sealed with connecting plates. By the cellular structure, high-temperature fused salt on the whole plate sheet is uniformly cooled, so heat exchange of the plate sheet can be completed under a durable temperature, and smooth circulation of the fused salt is ensured.

Owner:LANZHOU LS HEAT EXCHANGE EQUIP

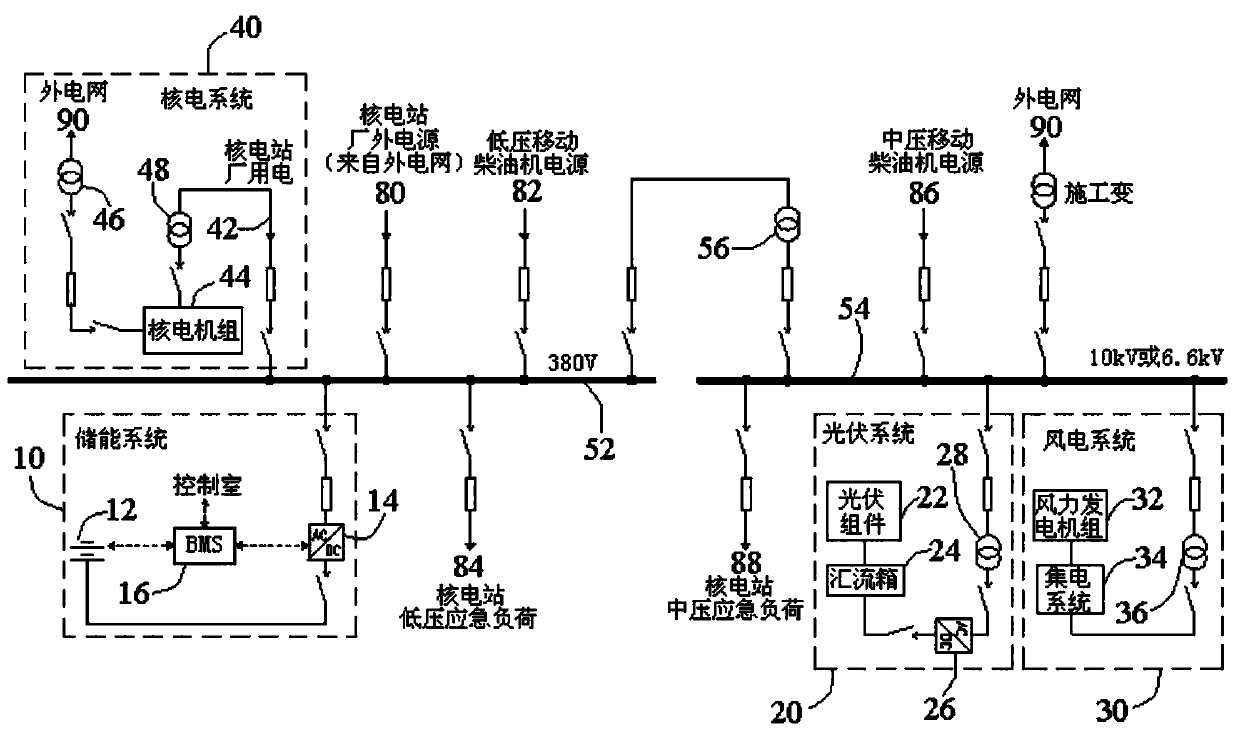

Combined clean energy power generation system and operation method thereof

PendingCN110474321AExtend emergency response timeReduce construction costsBatteries circuit arrangementsSingle network parallel feeding arrangementsElectricityPower grid

The invention discloses a combined clean energy power generation system and an operation method thereof. The combined clean energy power generation system comprises an energy storage system, a photovoltaic system, a wind power system, a nuclear power system and a power transmission bus; the nuclear power stations of the photovoltaic system, the wind power system and the nuclear power system are connected with the power transmission bus so as to transmit photovoltaic electric energy, wind power electric energy and nuclear power energy to the power transmission bus, and the energy storage systemis connected with the power transmission bus so as to transmit the stored electric energy to the power transmission bus or acquire electric energy from the power transmission bus to charge itself. The power transmission bus is connected with an external power grid to sell electricity to the external power grid. The system is a novel clean energy power generation system integrated with nuclear power, photovoltaic power, wind power and energy storage, the four clean energy power generation systems of nuclear power, photovoltaic power, wind power and energy storage are organically combined, beneficial effects are generated for the four systems on the basis that independent operation of the systems is not affected, and therefore, the defects of the single systems are overcome.

Owner:中广核工程有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com