Ferritic/martensitic oxide dispersion strengthened steel with enhanced creep resistance and method of manufacturing the same

一种抗蠕变性、弥散强化的技术,应用在涡轮机、机械设备等方向,能够解决长期蠕变性能降低等问题,达到高拉伸强度、优异抗蠕变性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

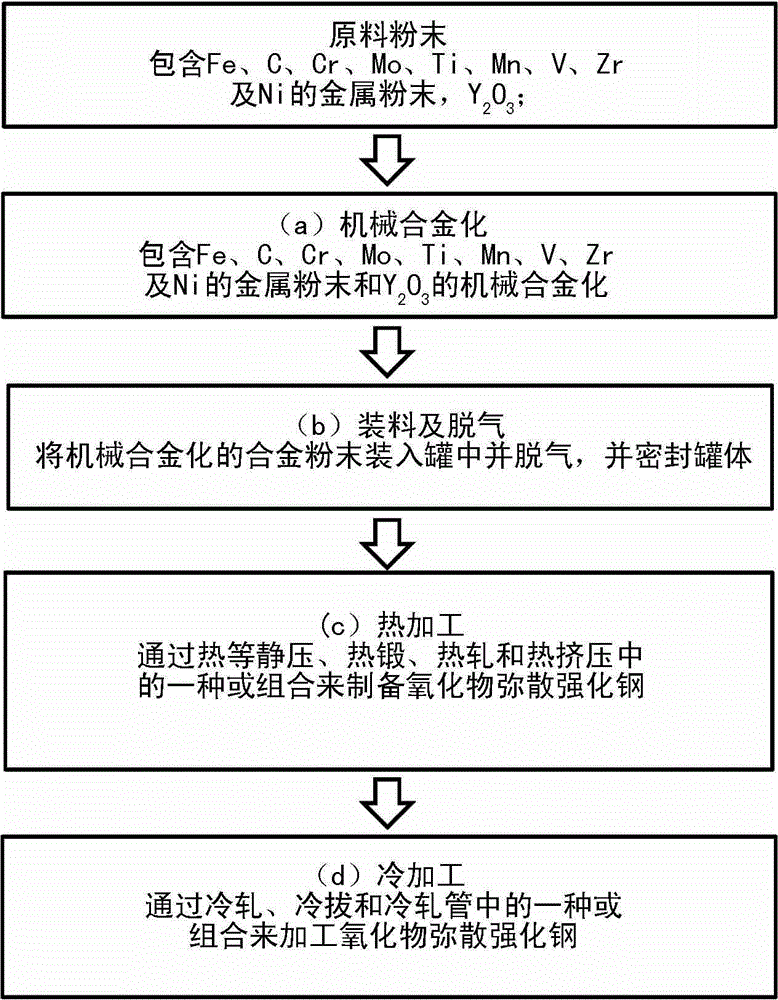

[0043] Example 1 Preparation of Oxide Dispersion Strengthened Steel

[0044] Ferritic / martensitic oxide dispersion strengthened steels having the composition described in Table 1 were prepared.

[0045] [Table 1]

[0046]

[0047] That is, high-purity raw material powders (Fe, C, Cr, W, Mo, Ti, Mn, Zr, Ni, V; particle size 200 mesh or below, purity 99% or above) and Y 2 o 3 The powder (50nm or below, purity 99.9%) was mixed for 48 hours, and the mechanically alloyed powder was prepared by mechanical alloying. -5 A vacuum of torr or below was used for 3 hours for degassing. The can containing the prepared powder was treated by hot isostatic pressing (HIP) at 1150°C and 100 MPa for 3 hours, and the resulting product was reheated at 1150°C for 1 hour at a thickness reduction ratio of 80% or more. The product obtained by rolling treatment to prepare oxide dispersion strengthened steel .

Embodiment 2

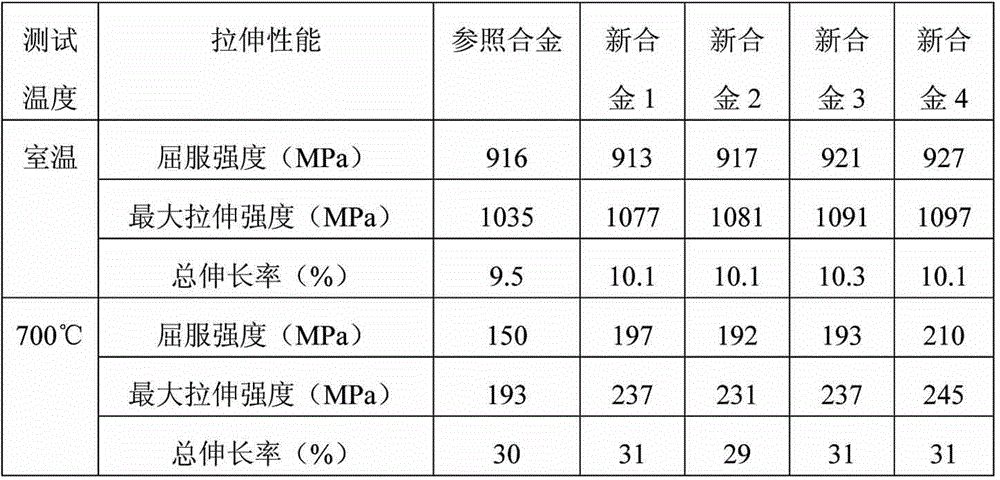

[0048] Example 2 Determination of Tensile Properties of Oxide Dispersion Strengthened Steel

[0049] The yield strength, maximum tensile strength and total elongation of the five ferrite / martensitic oxide dispersion strengthened steels prepared in Example 1 were measured at room temperature and 700°C. result in figure 2 shown in . Tensile specimens were taken, placed on a calibrated length section parallel to the hot rolling direction of oxide dispersion strengthened steels and prepared according to ASTM E8. Tensile tests were performed at room temperature and 700°C with a strain rate of 1ⅹ10 -4 the s -1 . Perform more than three tensile tests on each sample at this temperature, and calculate the average value and reflect it on the result.

[0050] Such as figure 2 As shown in , the room temperature yield strength of the conventional oxide dispersion strengthened steel as a control alloy is 916 MPa, and the yield strengths of the new alloys 1, 2, 3 and 4 are 913, 917...

Embodiment 3

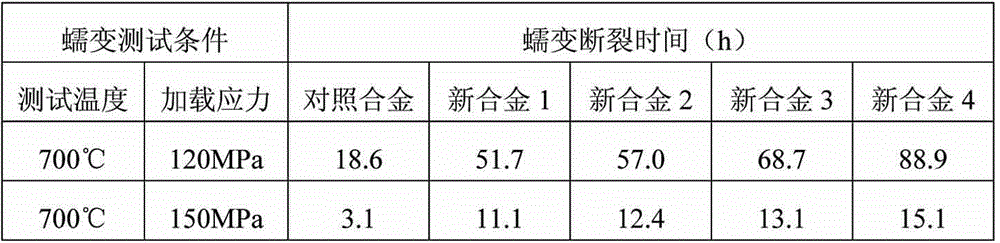

[0052] Example 3 Confirmation of Creep Resistance of Oxide Dispersion Strengthened Steel

[0053] The five types of oxide dispersion strengthened steels prepared in Example 1 were subjected to creep tests at 700°C, and the results were in image 3 shown in .

[0054] Such as image 3 As shown, it can be confirmed that the new alloys 1, 2, 3 and 4 of the present invention, compared with the control alloys, show a significant increase in creep rupture time at stresses of 150 and 120 MPa.

[0055] It can be seen from the results that the ferrite / martensitic oxide dispersion strengthened steel of the present invention has excellent high temperature creep resistance and excellent long-term stability compared with the conventional oxide dispersion strengthened steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com