Nuclear power sliding bearing oil feeding system based on comprehensive measurement of flow, pressure and temperature

A comprehensive measurement and sliding bearing technology, applied in bearing components, bearing cooling, shafts and bearings, etc., can solve problems such as bearing bush burnout, and achieve the effects of convenient control, improved system reliability, system safety and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

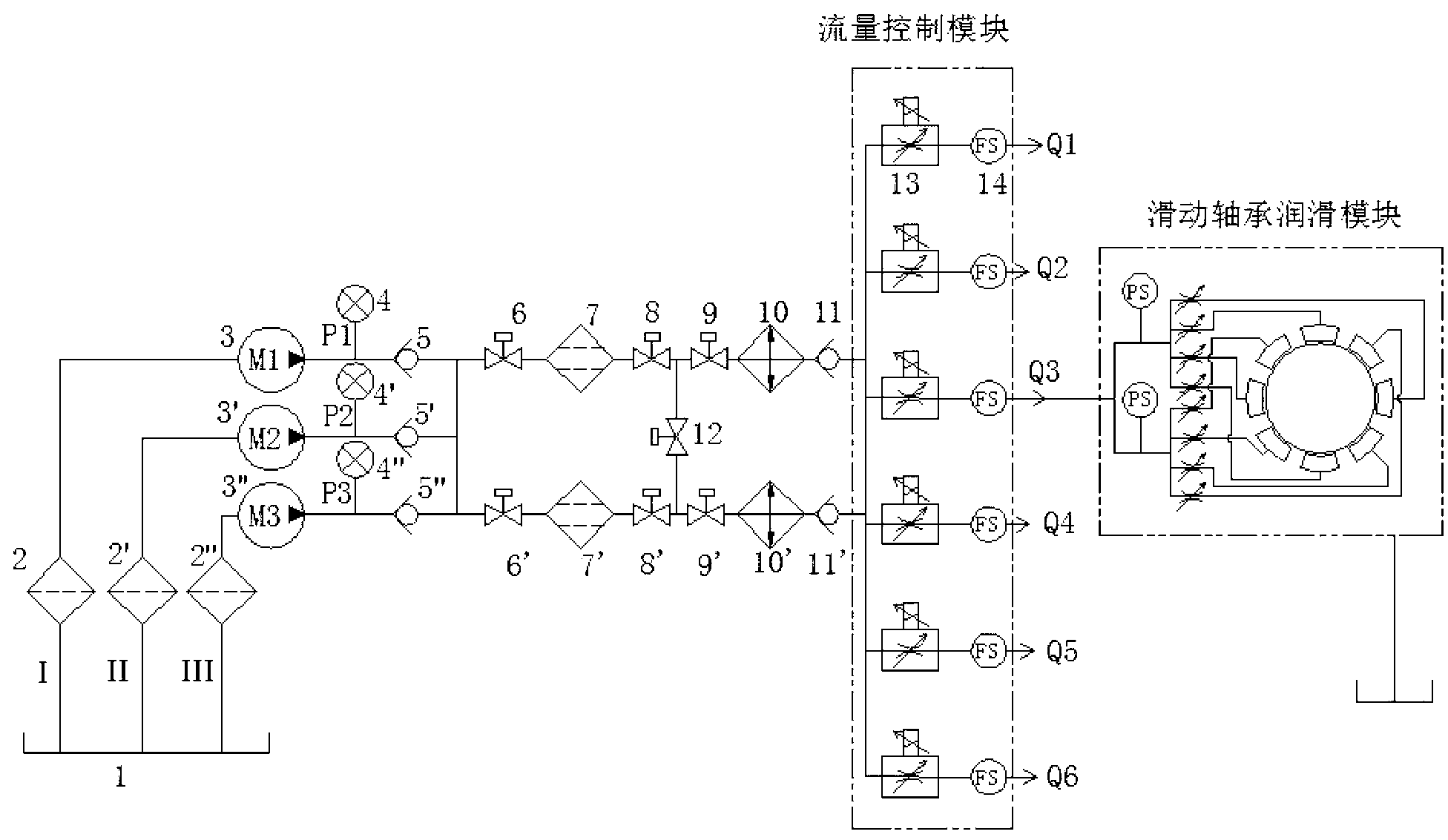

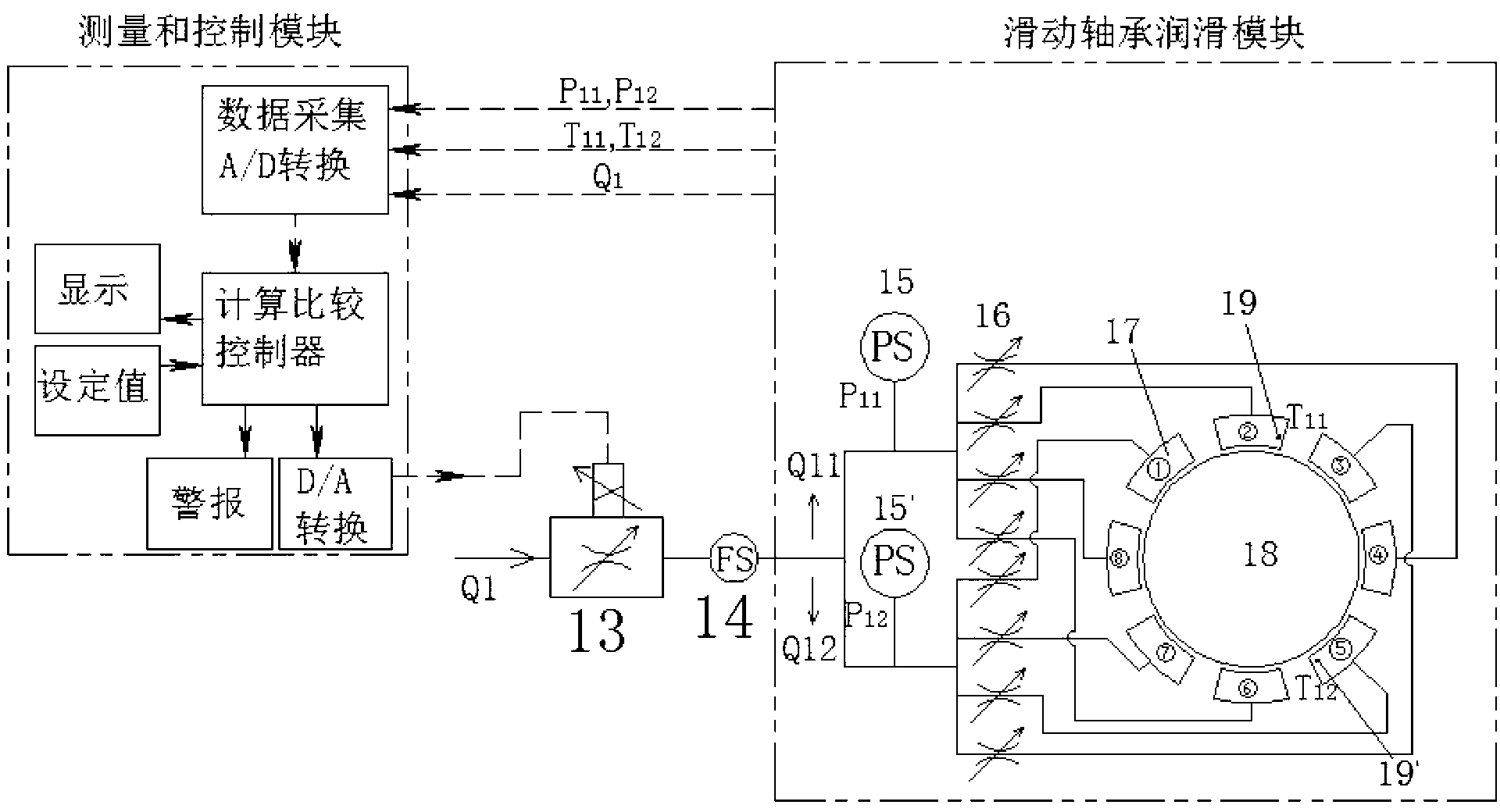

[0028] Such as figure 1 As shown, the present invention is a nuclear power sliding bearing oil supply system based on comprehensive measurement of flow, pressure and temperature, including: an oil supply module composed of a main oil supply line, a first redundant oil supply line and a second redundant oil supply line in parallel ; The filter-cooling module connected to the output of the oil supply module is composed of two fine filter-cooling circuits in parallel; the shunt module connected to the output of the filter-cooling circuit module is composed of six flow control circuits in parallel; A sliding bearing lubrication module composed of eight bearing pads outside the bearing, a temperature sensor located on the bearing pads, a lubricating oil pressure sensor and an adjustable throttle valve arranged on the connection line between the bearing pads and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com