High-temperature gas-cooled reactor pressure-maintaining overhauling and sealing control system

A high temperature gas-cooled reactor, maintenance and sealing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

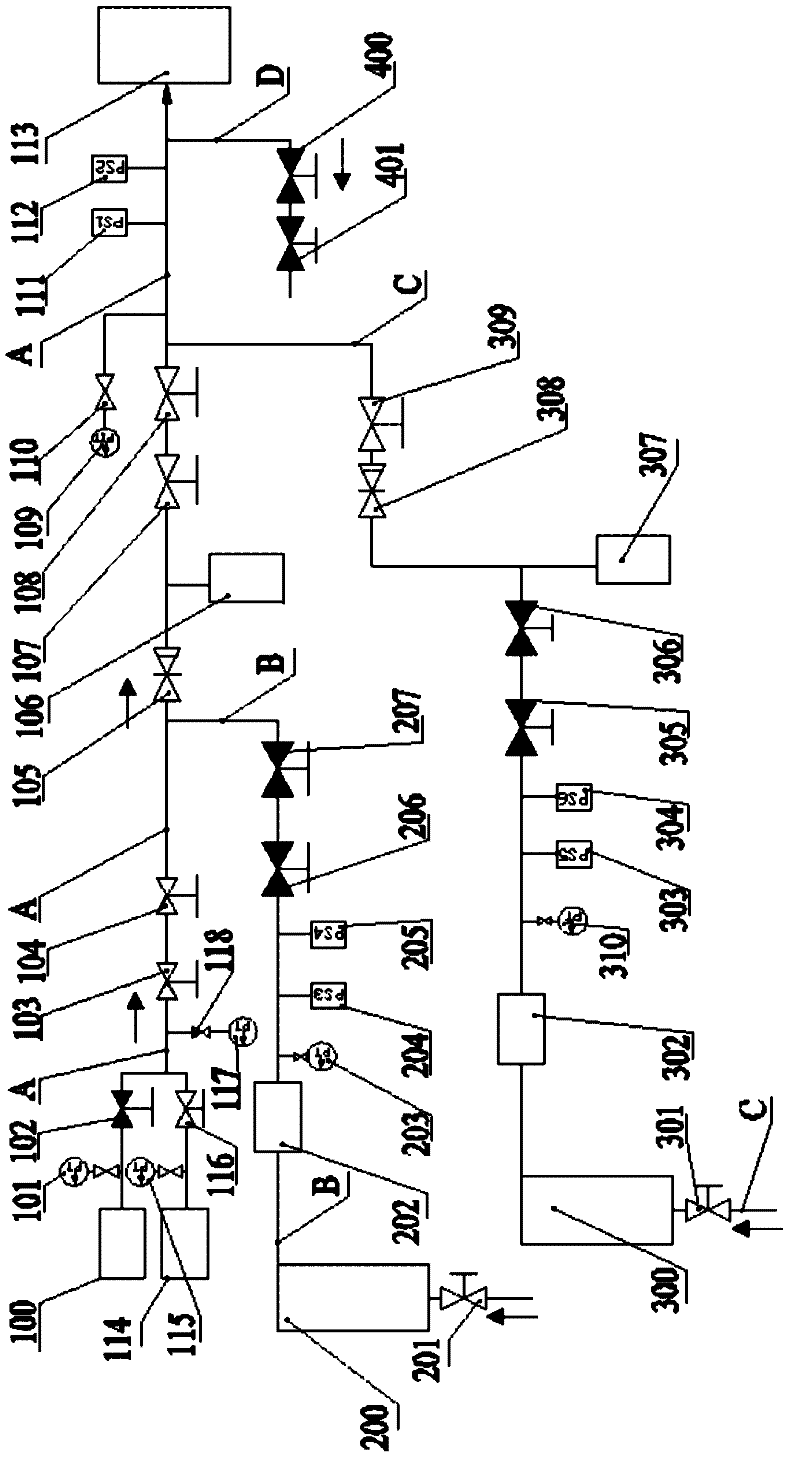

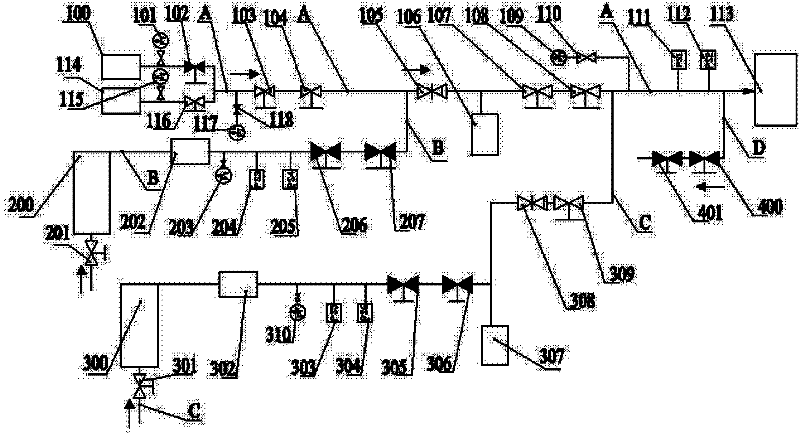

[0020] As shown in the accompanying drawings, the present invention is a high-temperature gas-cooled reactor pressure maintenance and sealing control system, which adopts pressure control and includes:

[0021] The main gas supply pipeline A is connected to the first high-pressure helium cylinder 100 at its inlet, and its outlet is connected to the pressure maintaining maintenance sealing body 113. The first remote pressure gauge 101, the first remote pressure gauge 101, and the first Stop valve 103, second stop valve 104, first one-way valve 105, third stop valve 107, fourth stop valve 108, near ground remote pressure gauge 109, first pressure sensor 111 and second pressure sensor 112, in Between the first one-way valve 105 and the third shut-off valve 107, there is a first pressure-holding gas tank 106 communicated with the main gas supply p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com