Plate-type heat exchanger core body applied to nuclear power system

A plate heat exchanger and core technology, applied in heat exchanger types, heat exchanger shells, indirect heat exchangers, etc. Problems such as high salt viscosity, to achieve the effect of small footprint, improved heat exchange efficiency, and sufficient heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

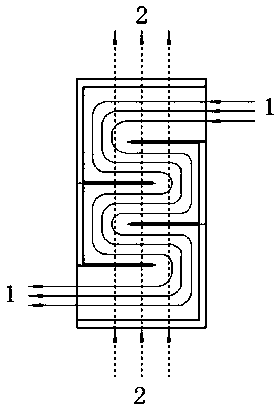

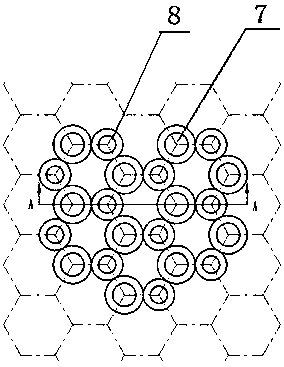

[0025] Such as Figure 1 to Figure 4 The core of a plate heat exchanger for a nuclear power system is shown, which includes a plurality of stacked plate pairs 5, each set of plate pairs 5 includes two opposite plates 6, and the plates 6 are hexagonal honeycomb rows The topological structure of concave-convex corrugated units of cloth, each sheet 6 contains several corrugated units, each corrugated unit includes convex corrugations 7 arranged in regular triangles and concave corrugations 8 arranged in regular triangles, convex corrugations 7 and concave corrugations 8 are arranged alternately The two plates 6 that form a group of plate pairs 5 are fastened together, the outer walls of the conflicting concave corrugations 8 are welded and sealed, and the outer walls of the convex corrugations 7 in the two plates 6 form the cold medium side flow channel 2; The outer walls of the convex corrugations 7 that are in conflict with the adjacent two sets of plate pairs 5 are welded and ...

Embodiment 2

[0028] Such as Figure 5 The core of a plate heat exchanger for a nuclear power system is shown, which includes a number of stacked plate pairs 5, each set of plate pairs 5 includes two opposite plates 6, and the plates 6 are arranged in a regular quadrilateral honeycomb shape The topological structure of concave-convex corrugated units, each sheet 6 contains several corrugated units, each corrugated unit includes convex corrugations 7 and concave corrugations 8 arranged in a matrix, and the convex corrugations 7 and concave corrugations 8 are arranged alternately; forming a group of plates The two plates 6 of the pair 5 are fastened to each other, the outer walls of the conflicting concave corrugations 8 are welded and sealed, and the outer walls of the convex corrugations 7 in the two plates 6 form the cold medium side flow channel 2; The outer wall of the convex corrugation 7 that is in conflict with the plate pair 5 is welded and sealed, and the outer walls of the two sets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com