Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Laser evaporation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

A composite layer of a sorbent, chemoselective, non-electrically-conducting polymer and nano-particles of an electrically conducting material dispersed throughout the polymer is formed on a substrate by pulsed laser deposition, matrix assisted pulsed laser evaporation or matrix assisted pulsed laser evaporation direct writing.

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

Fabrication of conductive/non-conductive nanocomposites by laser evaporation

Owner:THE GOVERNMENT OF THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF THE NAVY NAVAL RES LAB WASHINGTON

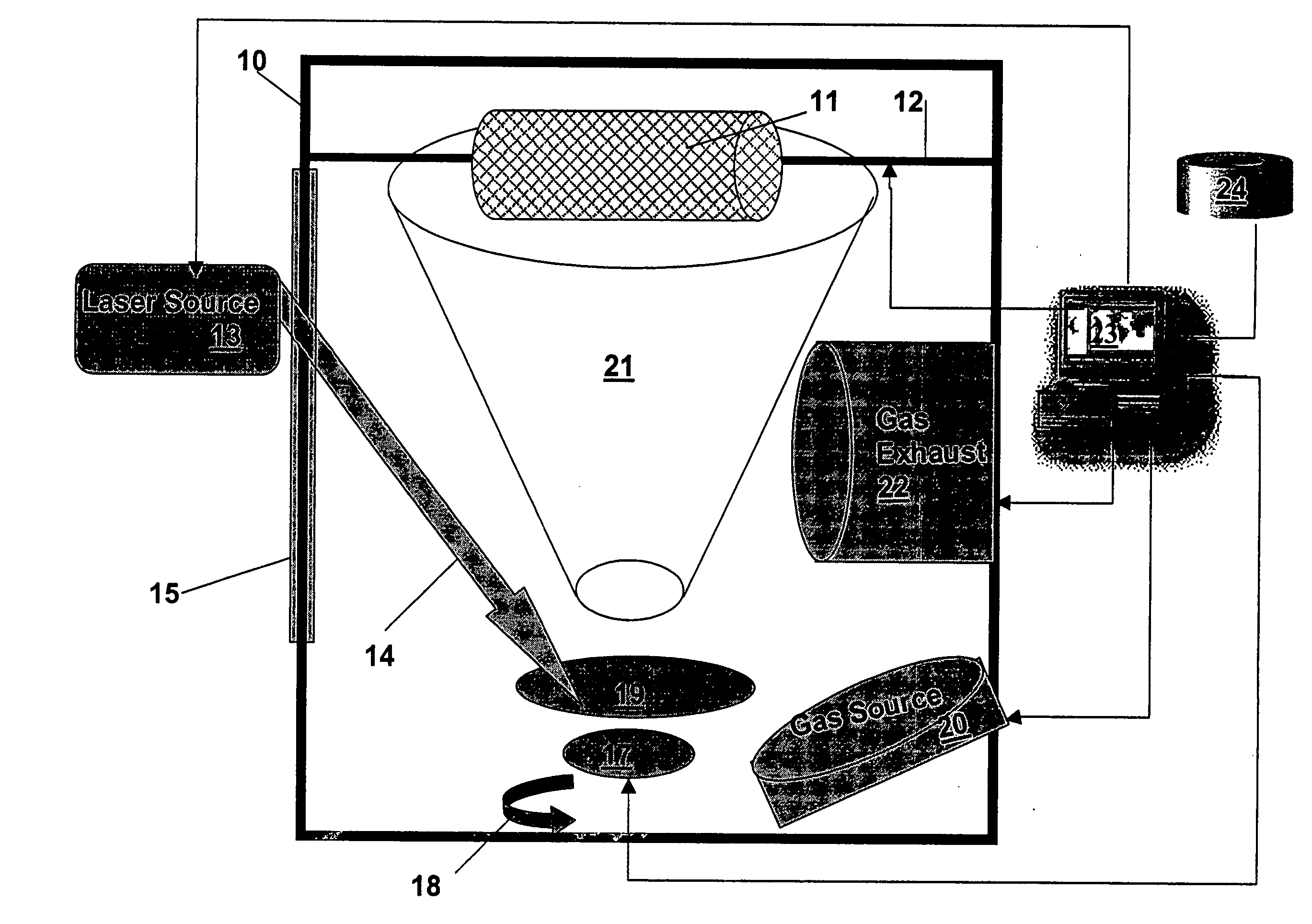

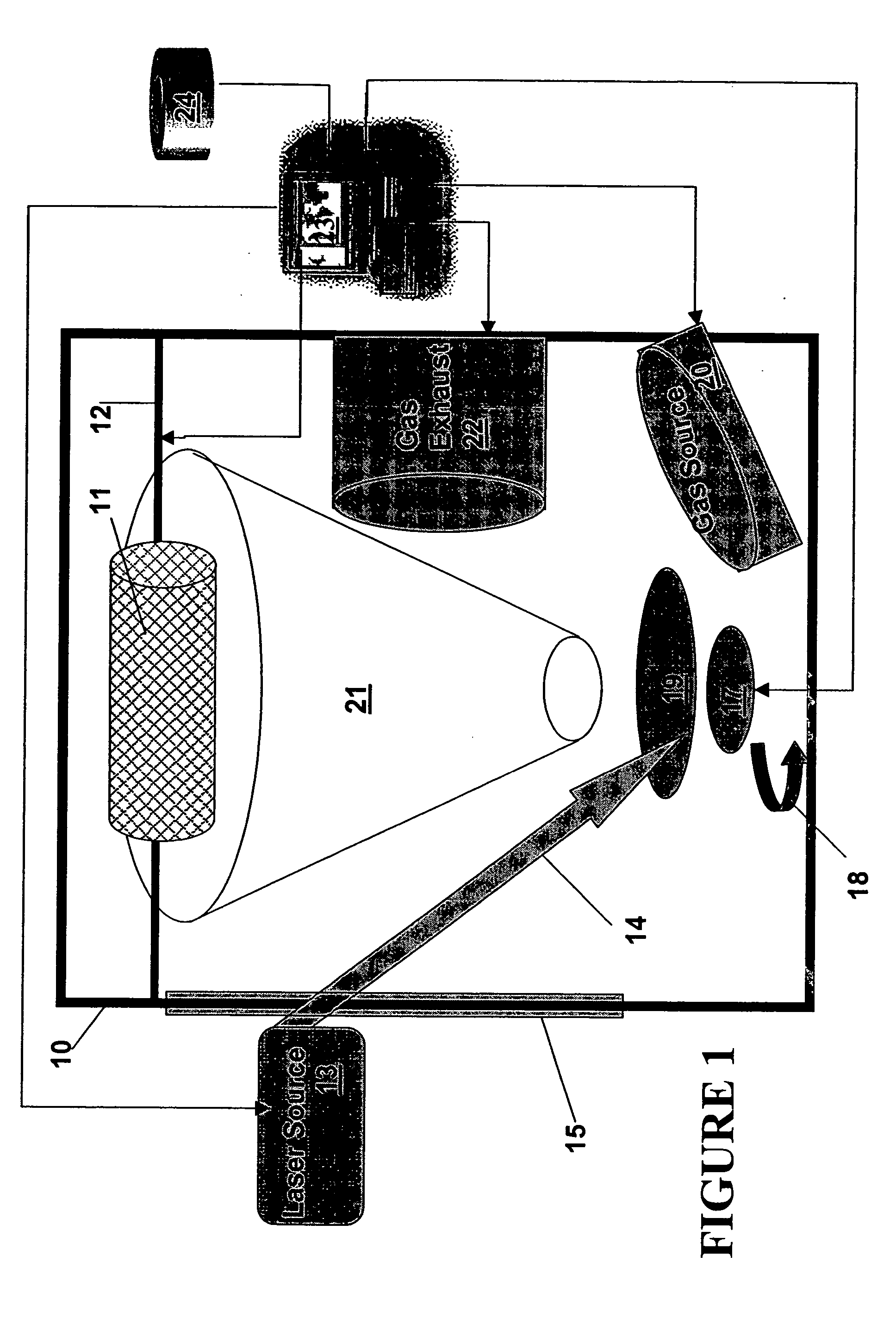

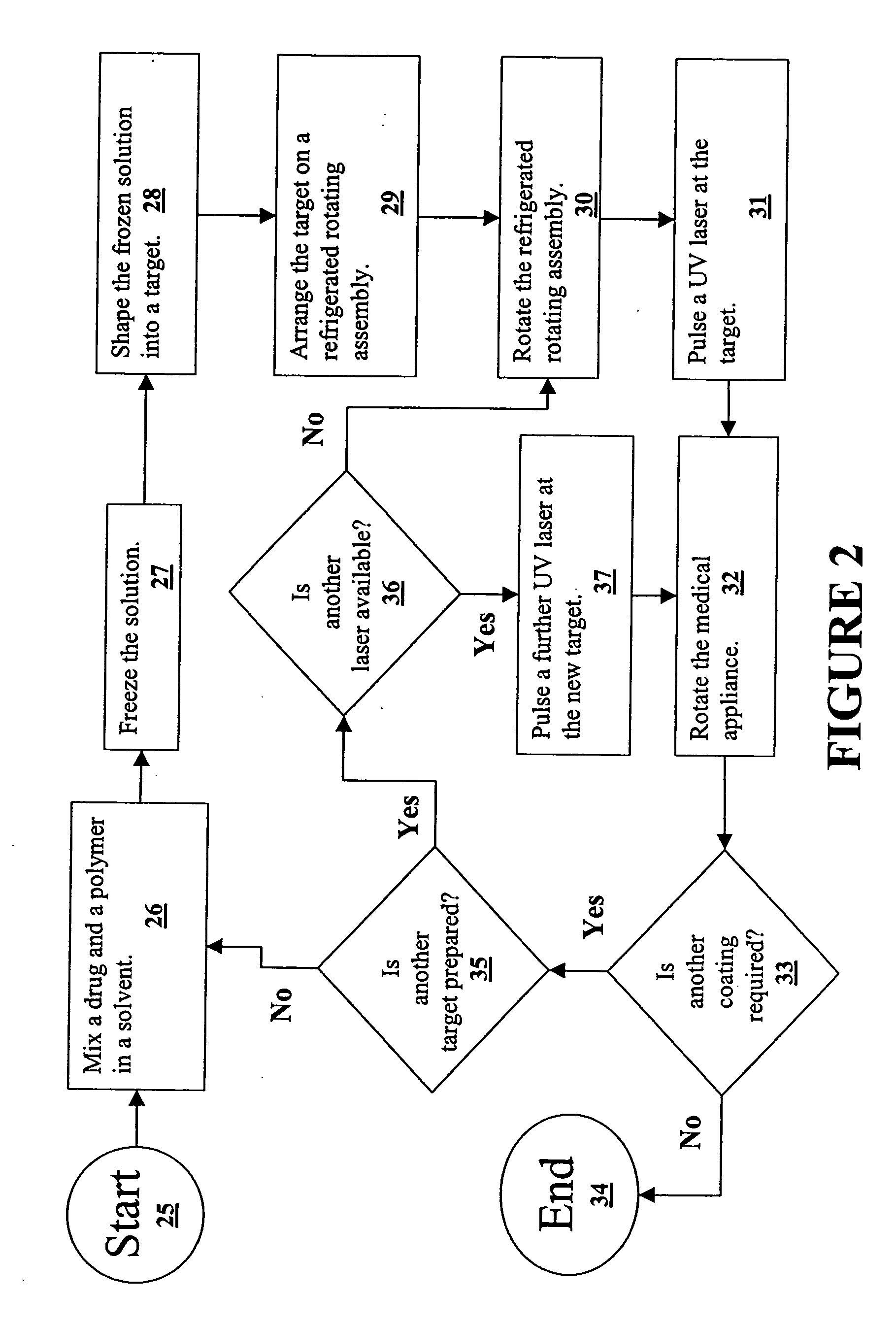

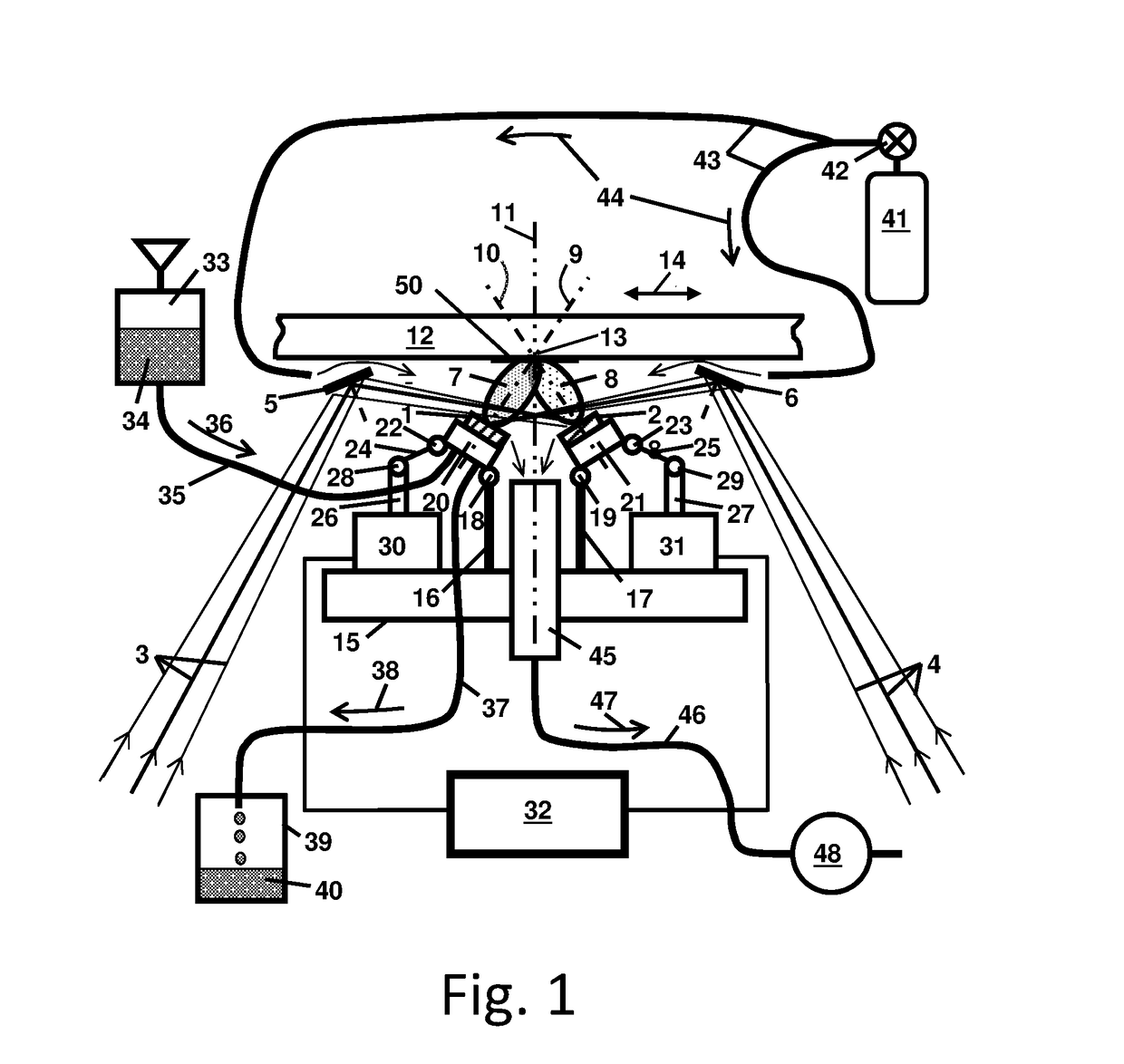

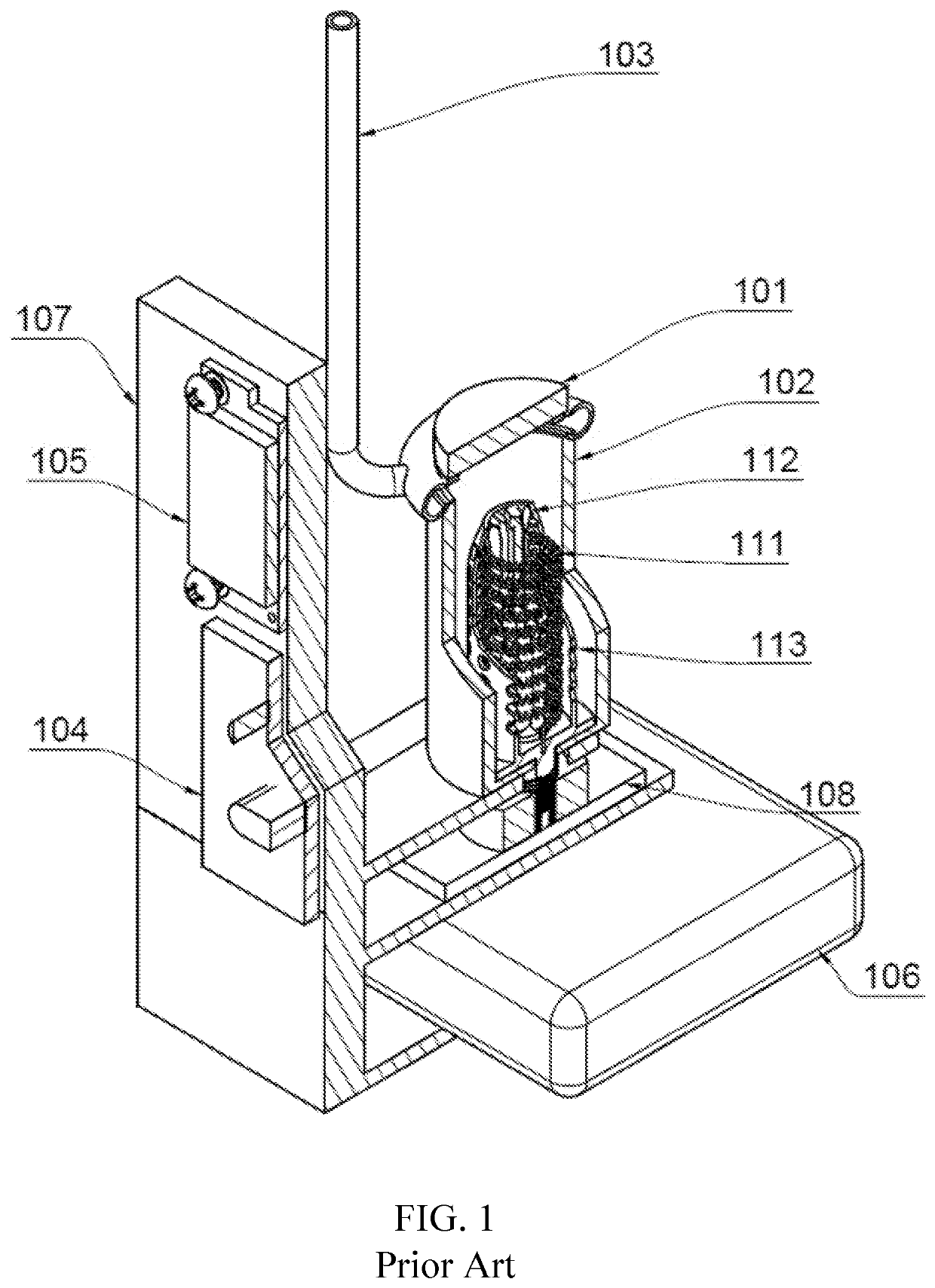

Matrix assisted pulsed-laser evaporation technique for coating a medical device and associated system and medical device

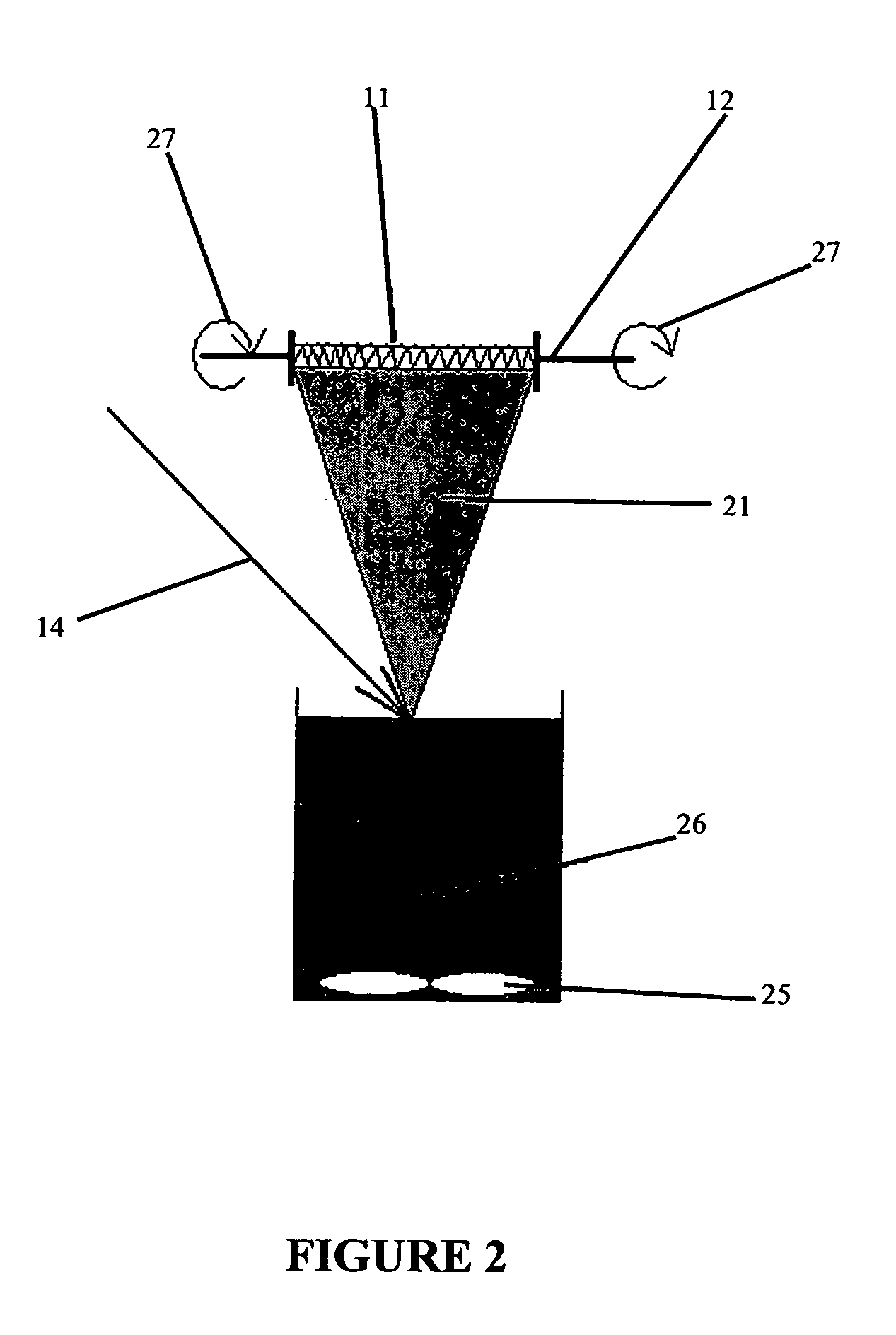

A method is provided for coating at least a portion of at least one medical device. The method includes arranging the at least one medical device in a vapor cone and directing a laser at a frozen target. The target includes an agent and the laser vaporizes the agent into the vapor cone. A device is provided for coating at least one medical device. The device includes a target assembly, a laser directed at the target assembly, and an arrangement adapted to hold the at least one medical device in a vapor cone. The vapor cone originates at a target point that a laser beam or a laser pulse contacts a frozen target in the target assembly. A medical device is provided having a coating applied by a method. The method includes arranging the medical device in a vapor cone and directing a laser at a frozen target. The frozen target includes an agent and the laser vaporizes the agent into the vapor cone.

Owner:BOSTON SCI SCIMED INC

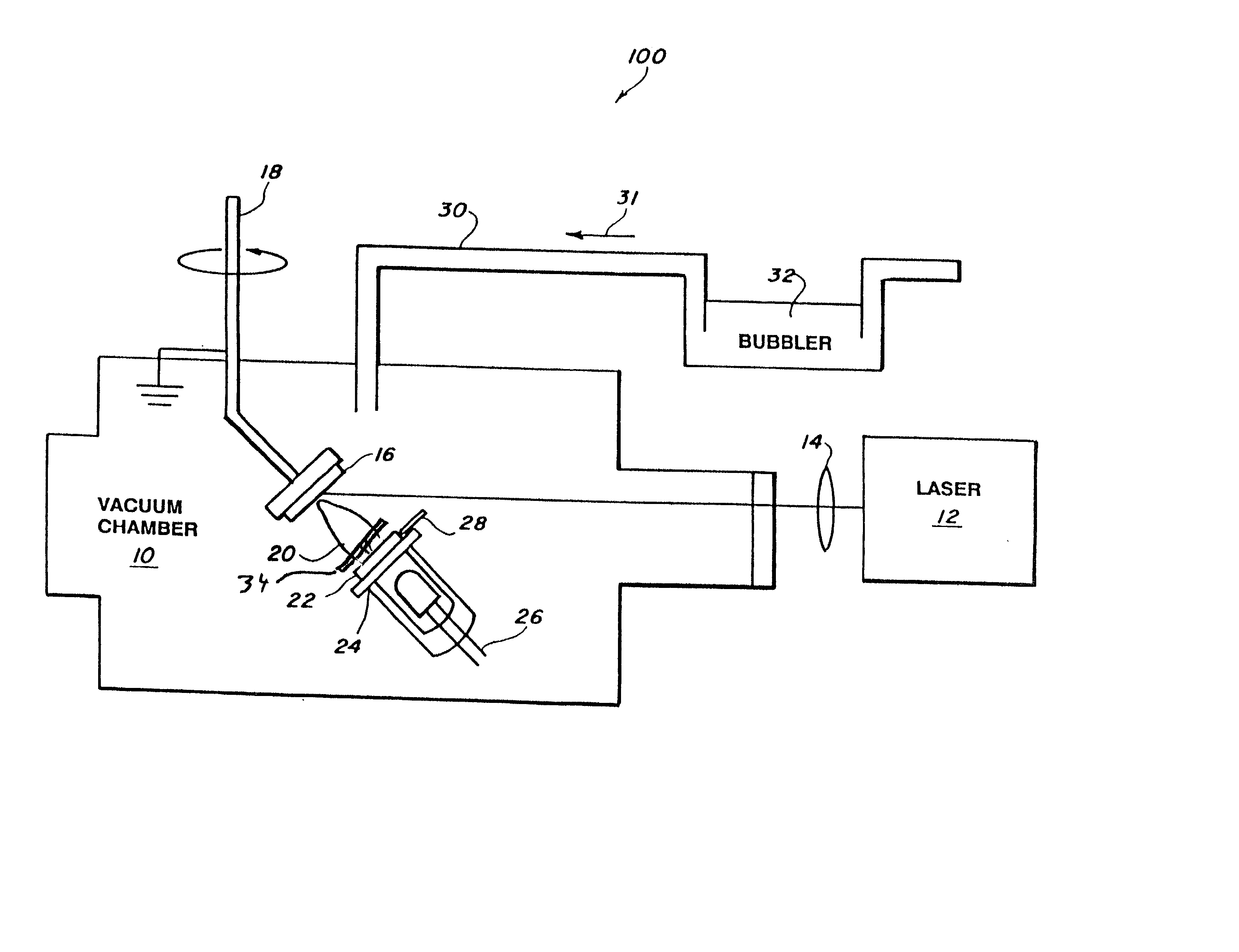

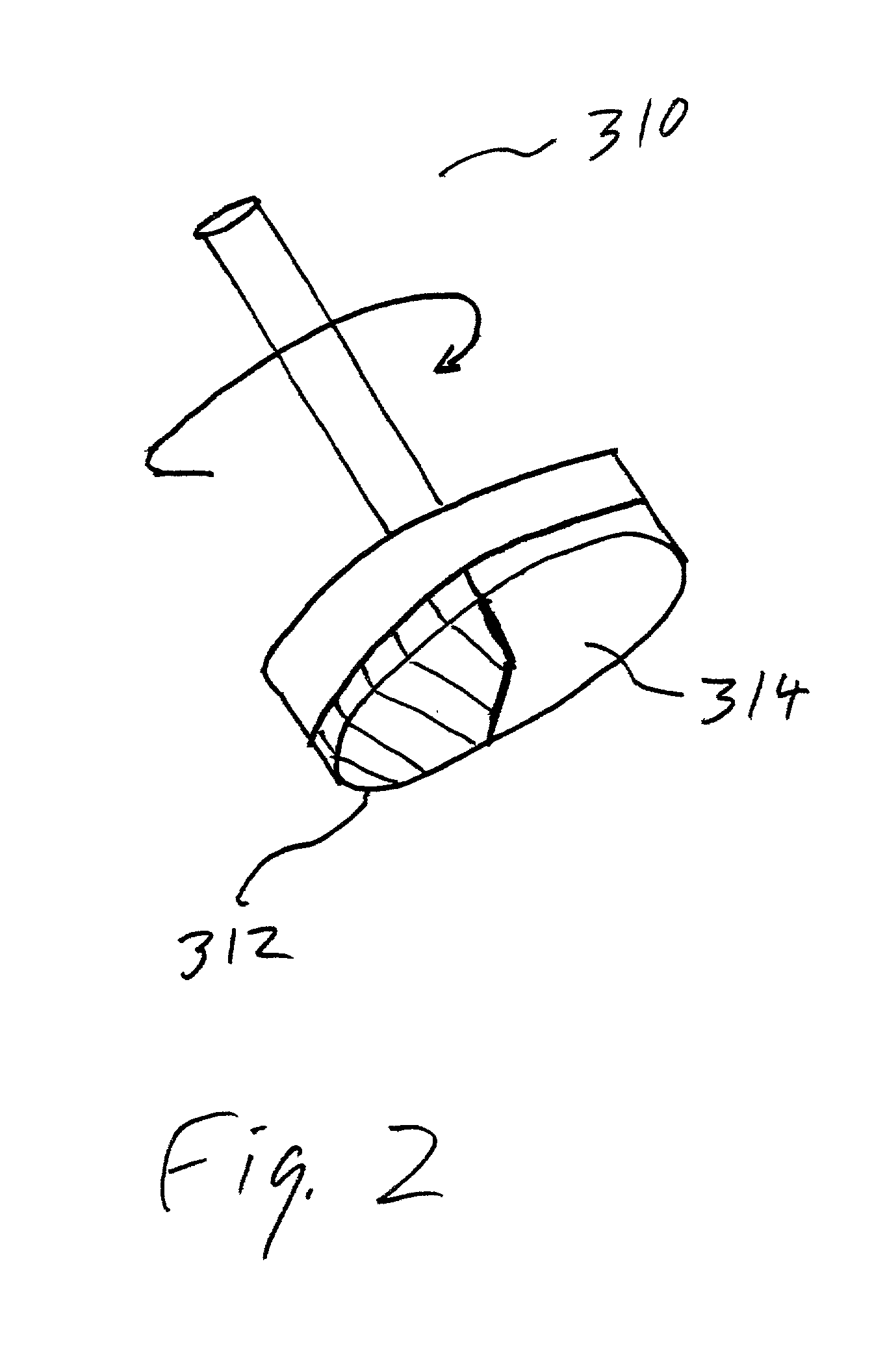

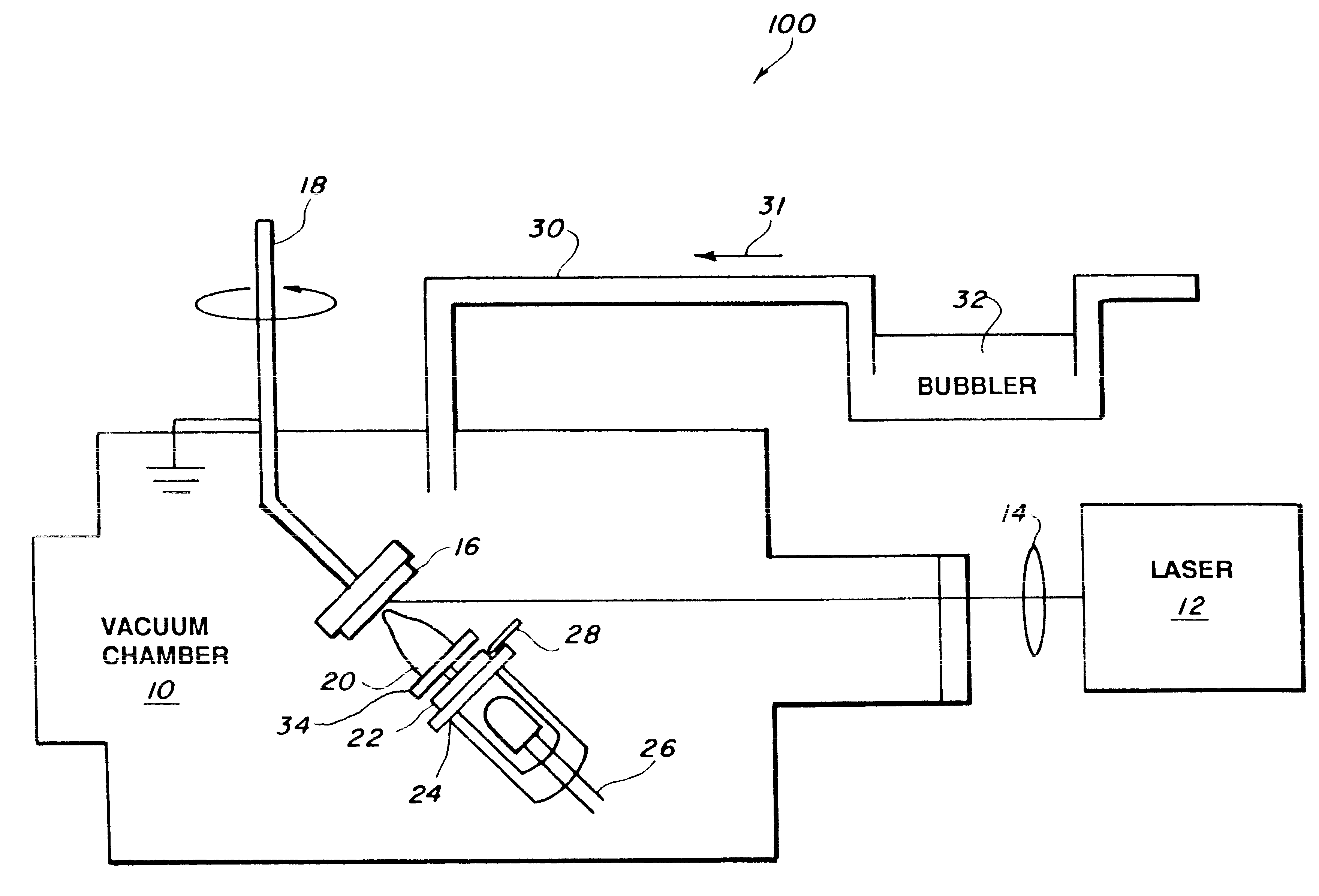

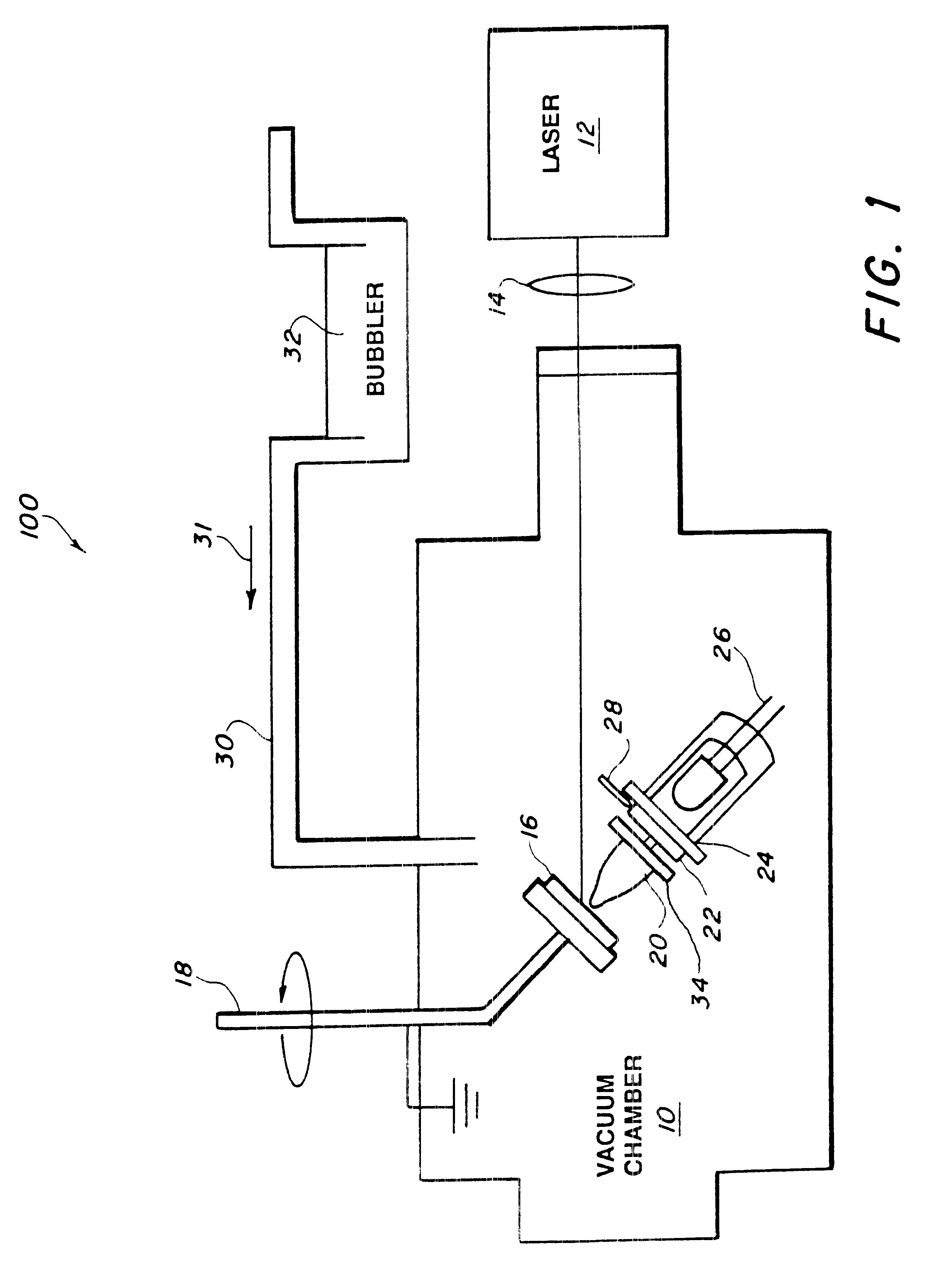

Method for coating a medical device using a matrix assisted pulsed-laser evaporation technique and associated system and medical device

InactiveUS20050181116A1Reduce ratePharmaceutical containersVacuum evaporation coatingEngineeringMedical device

A method is provided for coating at least a portion of at least one medical device. The method includes arranging the at least one medical device in a vapor cone and directing an energy beam at a frozen target. The frozen target includes an agent and the energy beam vaporizes the agent into the vapor cone. A device is provided for coating at least one medical device. The device includes a target assembly, an energy beam directed at the target assembly, and an arrangement adapted to hold the at least one medical device in a vapor cone. The vapor cone originates at a target point that an energy beam beam contacts a frozen target in the target assembly. A medical device is provided having a coating applied by a method. The method includes arranging the medical device in a vapor cone and directing an energy beam at a frozen target. The frozen target includes an agent and the energy beam vaporizes the agent into the vapor cone.

Owner:BOSTON SCI SCIMED INC

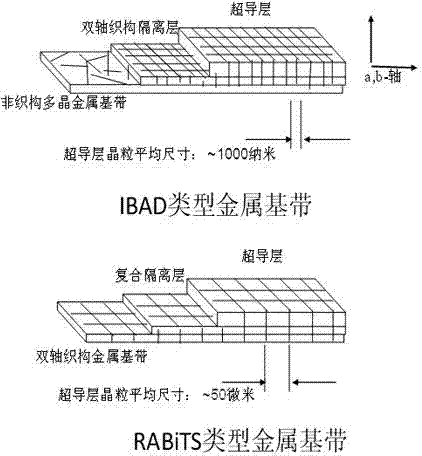

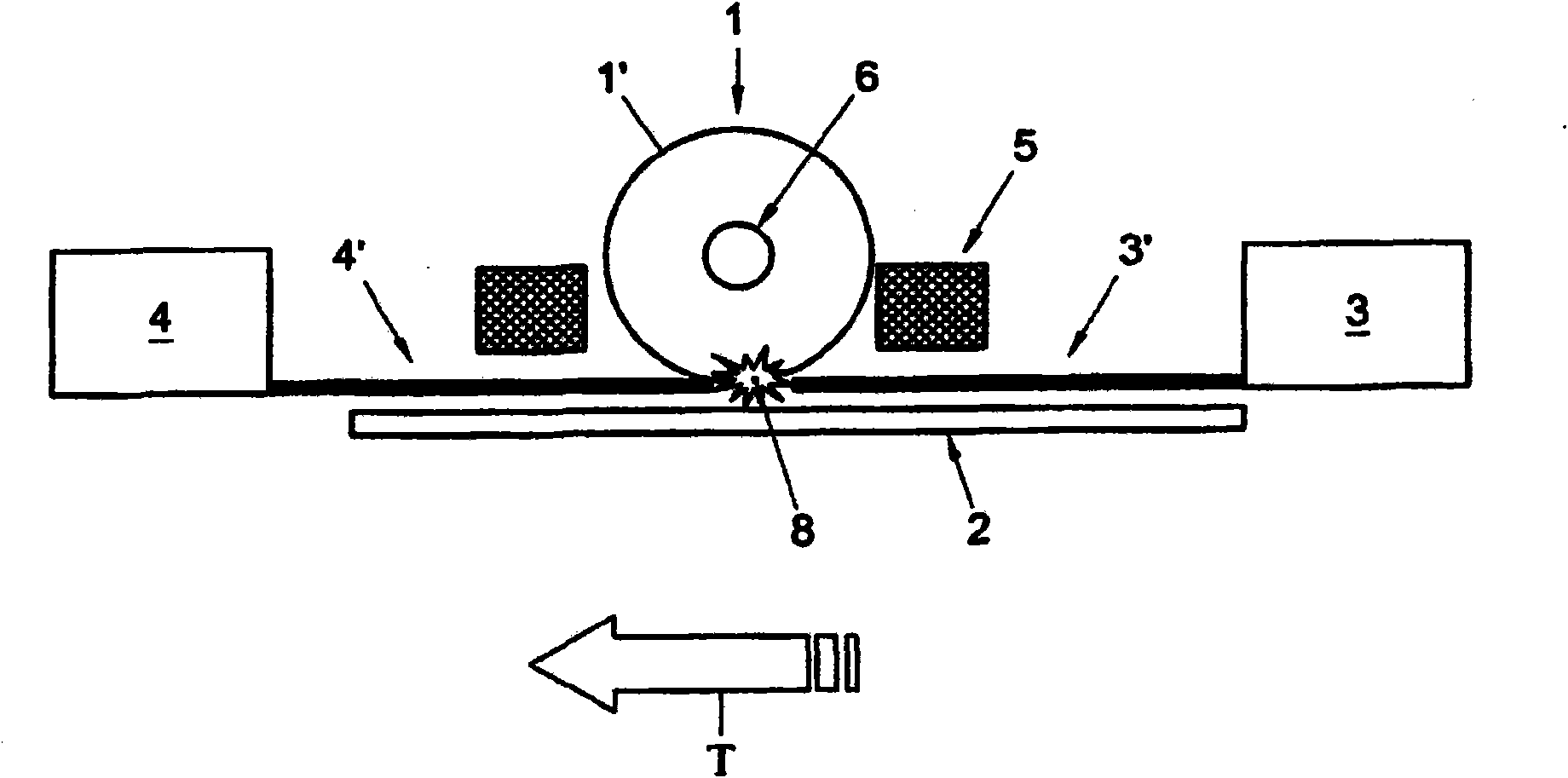

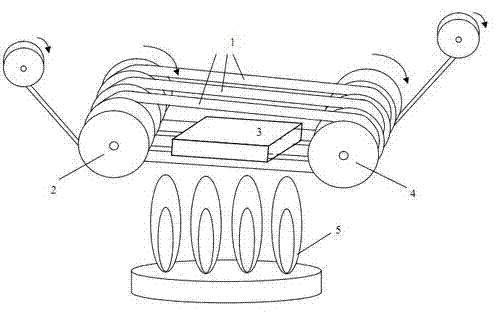

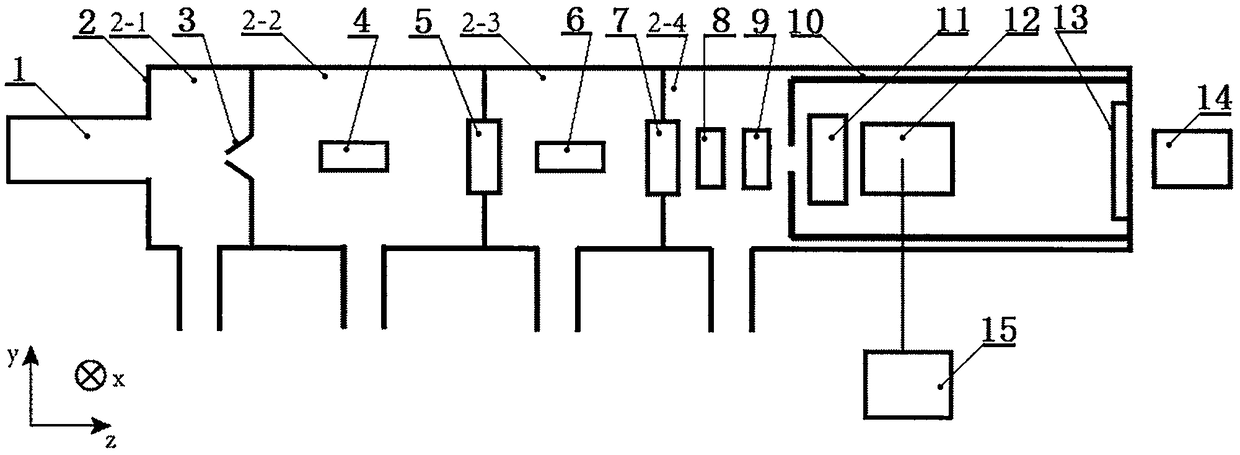

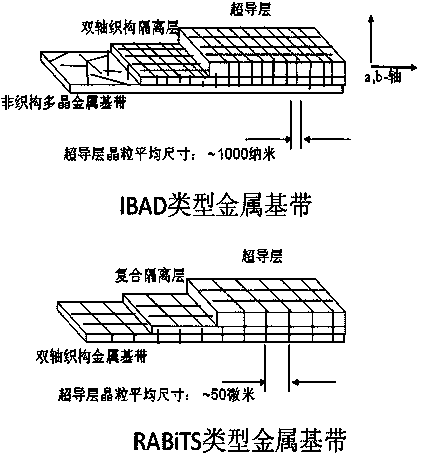

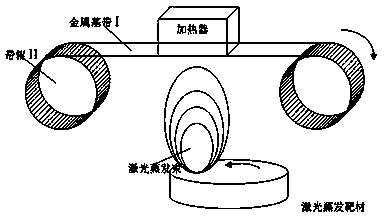

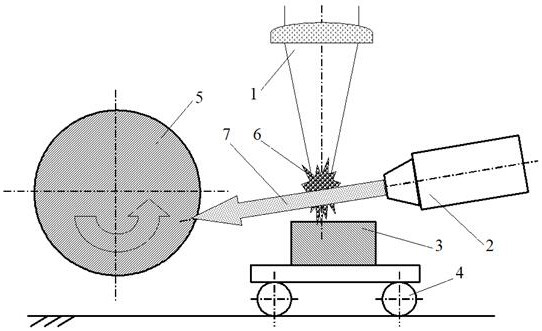

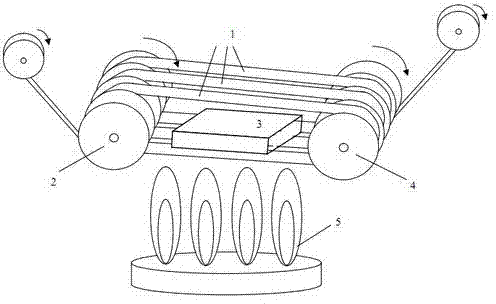

Continuous rapid laser coating method of superconducting layer in second-generation high-temperature superconducting strip

ActiveCN102409298AFast manufacturingAchieve serializationVacuum evaporation coatingSputtering coatingLaser coatingHigh temperature superconducting

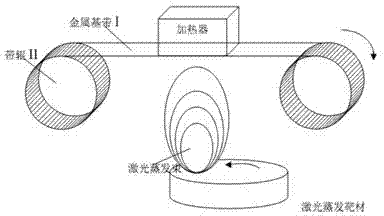

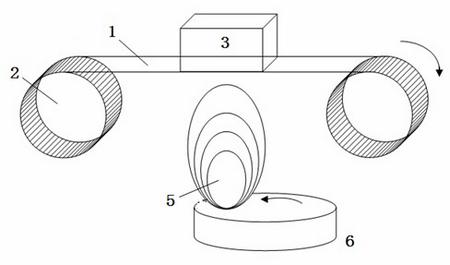

The invention provides a continuous rapid laser coating method of a superconducting layer in a second-generation high-temperature superconducting strip. According to the invention, through a method of bi-dimensionally scanning a superconducting target along an x-y axle, the whole surface of the target can be utilized and a laser evaporation coating process can be stably and sustainably carried out; coating intervals are increased through a method of scanning along the motion direction of the strip by use of laser spots; and the width of the coating interval vertical to the motion direction of the strip is increased through a method of twining the strip on a belt roller above a heater multiple times. By using the method provided by the invention, evaporated substances are fully collected on a metal base band to the greatest extend, thereby effectively improving the preparation speed of the strip, increasing the utilization rates of the target and the evaporated substances, greatly improving the production efficiency and reducing the production cost of the strip. According to the method provided by the invention, the rapid coating of the second-generation high-temperature superconducting strip suitable for large-scale industrial production can be realized.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

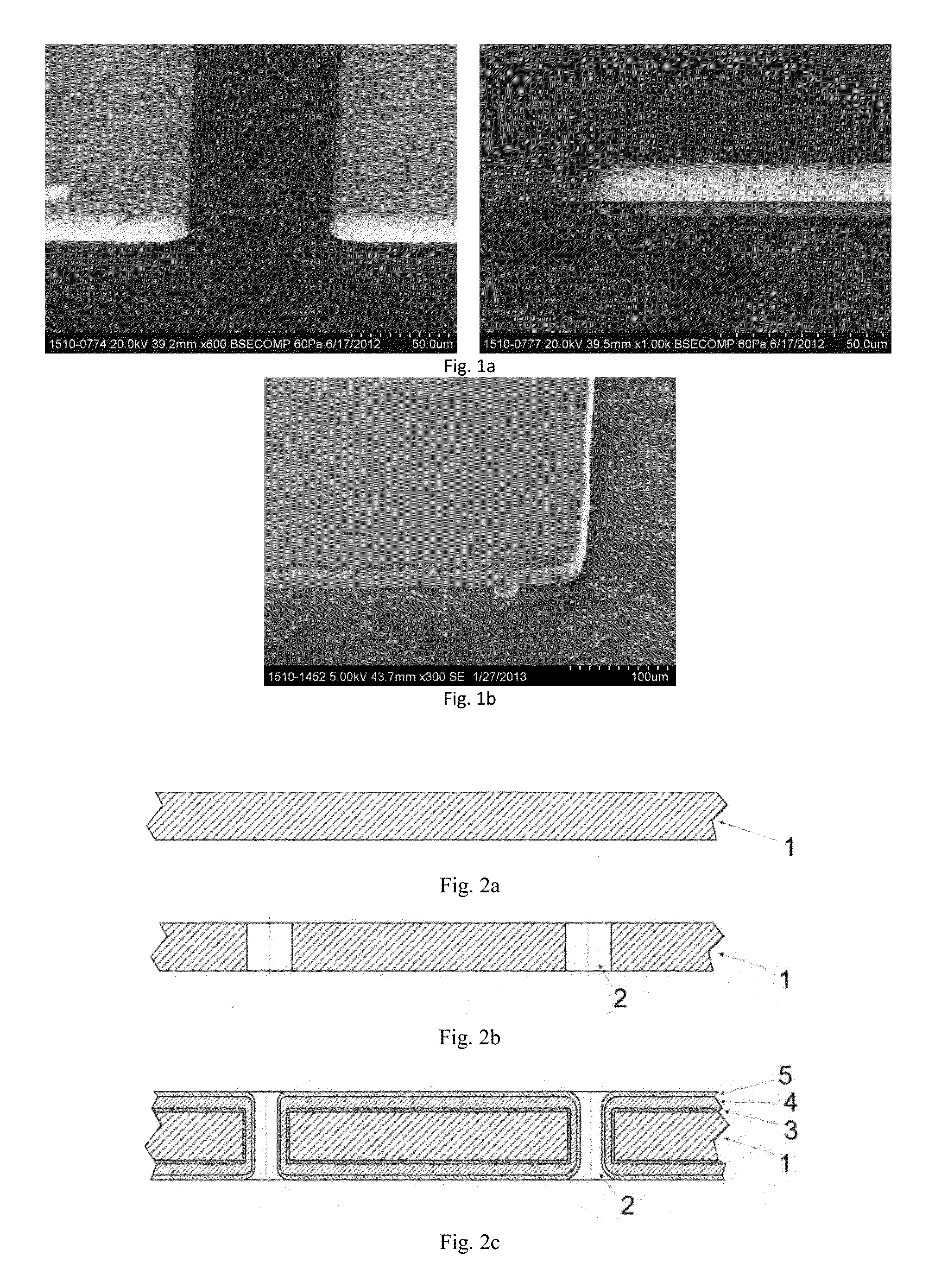

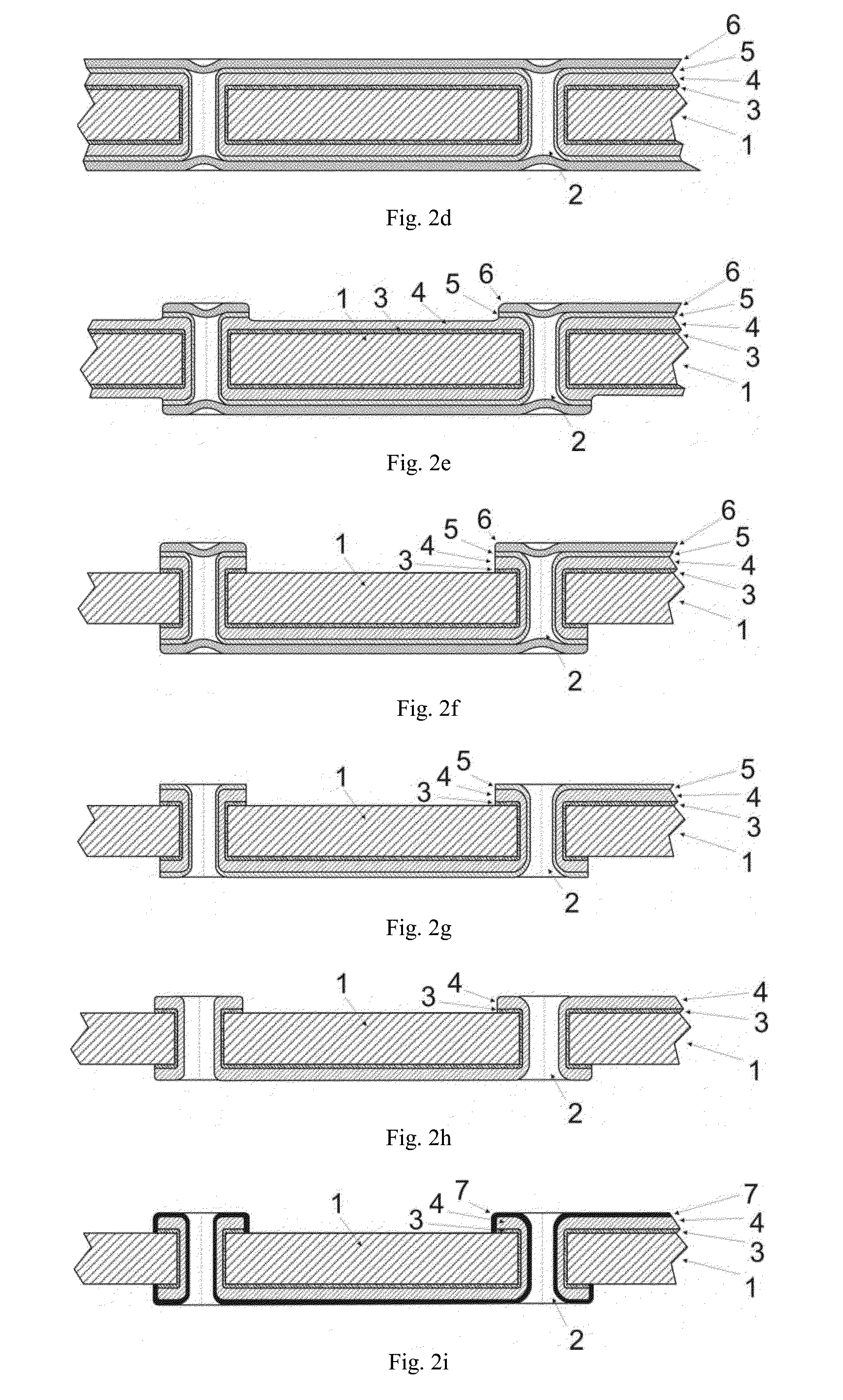

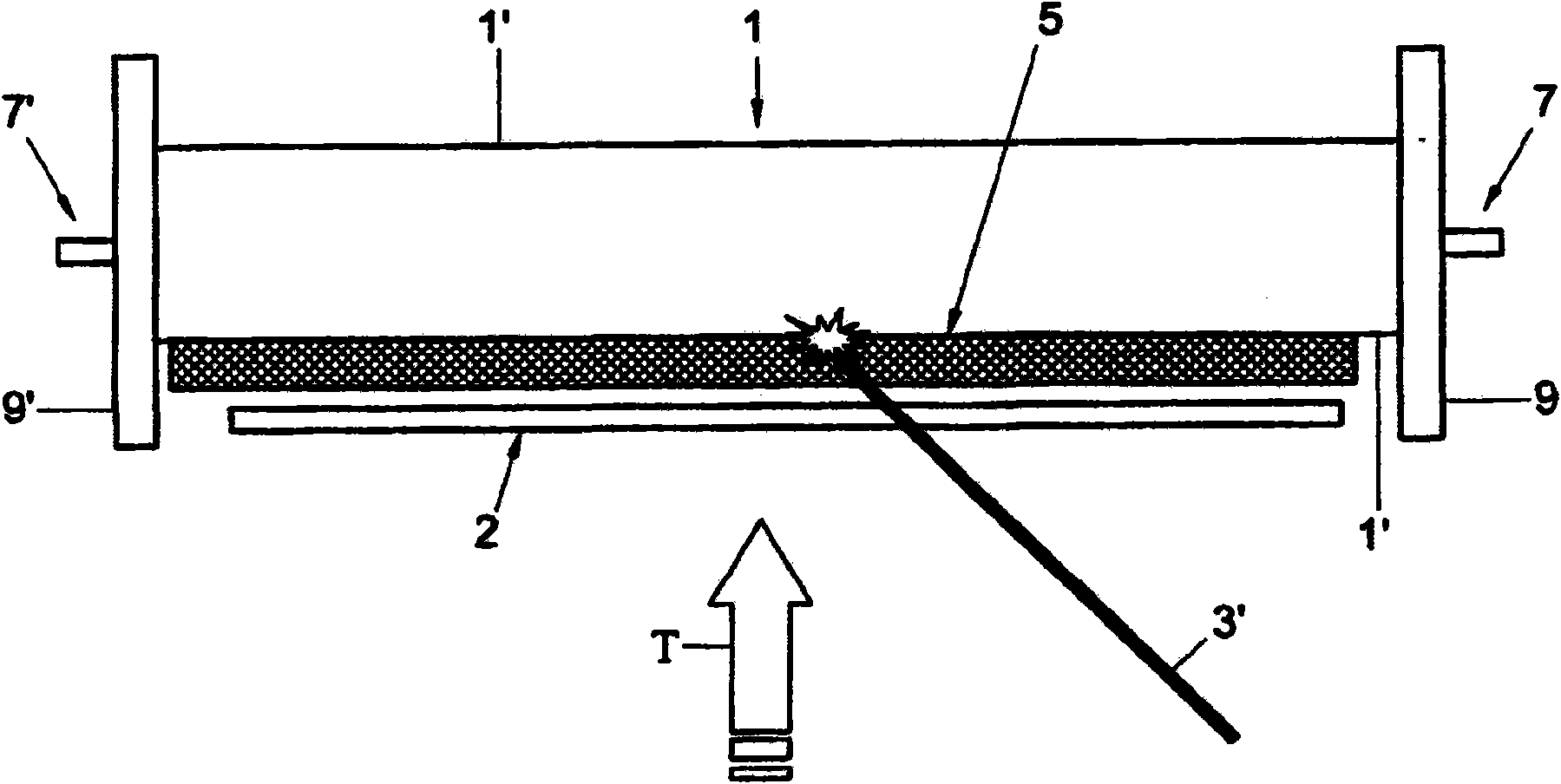

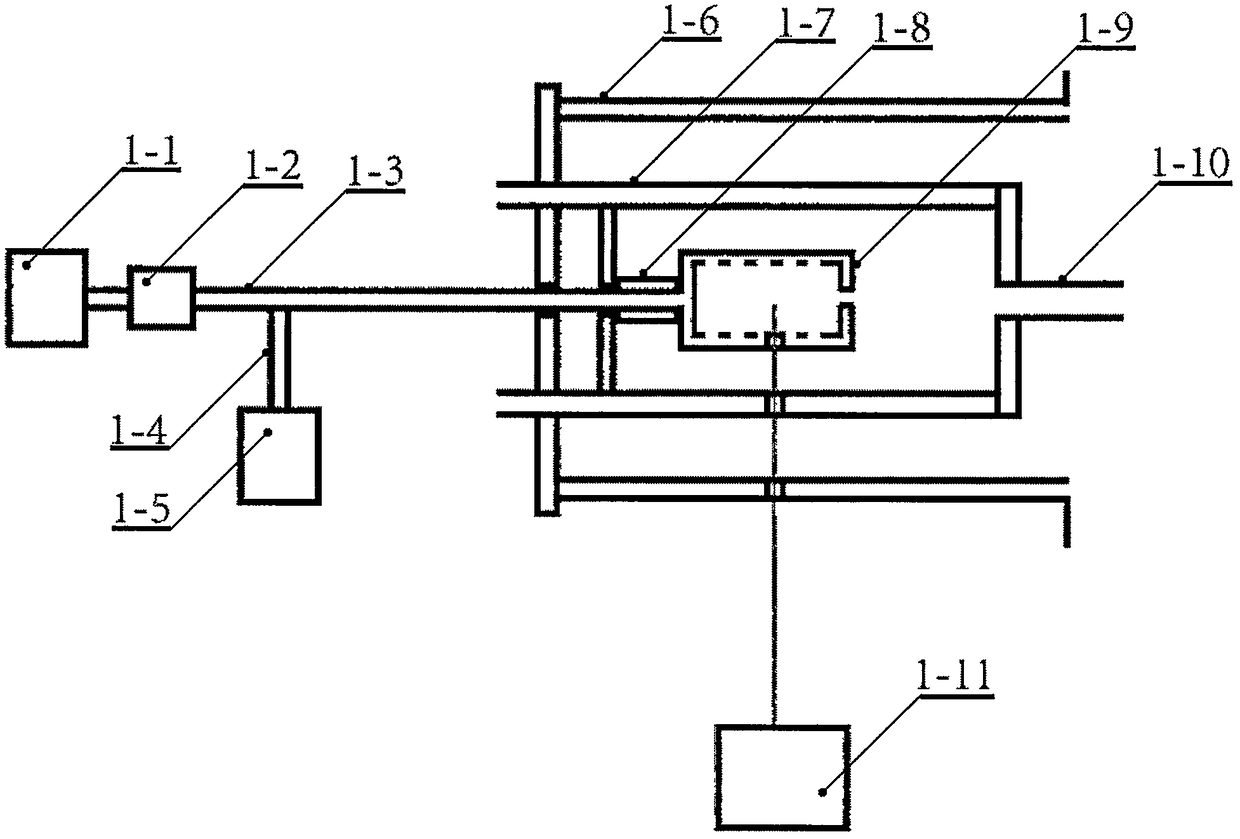

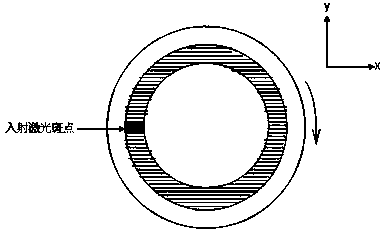

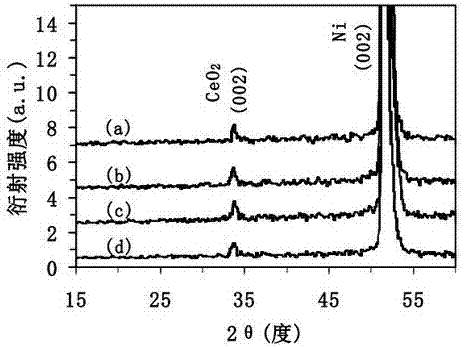

Multichannel pulsed laser deposition method for preparing YSZ buffer layer

ActiveCN102251219AOvercome the disadvantage of small coating areaPurely unidirectionalVacuum evaporation coatingSputtering coatingDeposition temperatureLaser coating

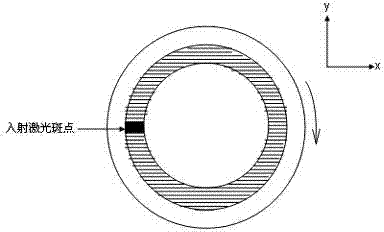

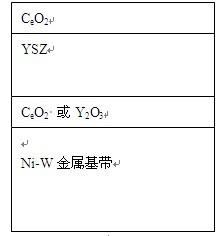

The invention discloses a multichannel pulsed laser deposition method for preparing a YSZ buffer layer, which comprises the following steps of: arranging a nickel-tungsten metal base band, a Hastelloy band, a stainless steel band or other metal base bands in a deposition cavity, winding on a band roller of a metal band transmission device of multichannel pulsed laser deposition equipment for multiple times, and raising the temperature of a heater to deposition temperature; opening an oxygen channel; starting a YSZ target manipulator and beginning the x-direction and y-direction scanning and rotation of a YSZ laser evaporation target platform; opening an optical path window of a laser, and beginning pre-evaporating the YSZ target platform; beginning depositing; and making the metal base band pass through the heater for multiple times due to multiple winding of a roll shaft of the transmission device, and finally stopping corresponding equipment. The YSZ buffer layer is prepared by the multichannel pulsed laser deposition method, so that a defect of a small deposition area of a unichannel pulsed laser deposition method is overcome, the deposition speed is greatly improved, various advantages of the pulsed laser deposition method are exerted fully, and the prepared YSZ buffer layer has single orientation, high surface quality and high crystallinity.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

High-temperature superconductive element based on nano material and its prepn.

InactiveCN1389703AFast heat conductionThermal superconductivityVacuum evaporation coatingSputtering coatingCoated surfaceMetal powder

This invention relates to a thermal super-conductive element based on nano material and preparing method thereof. Firstly high thermal conductivity nano composite metal powder, diamond powder or metal oxide, the grain size of which is 10-100 nm, are prepared, then are made to form a coating by plasma spraying technology, and then one of the metals is made to evaporate by laser evaporation technology to form an nano or sub-micro structure on the coating surface. The heat exchange element with thermal super-conductive characteristic made thereby has the advantages of high thermal conducting rate, low thermal resistance, long service life, high efficiency and compact structure.

Owner:SOUTH CHINA UNIV OF TECH

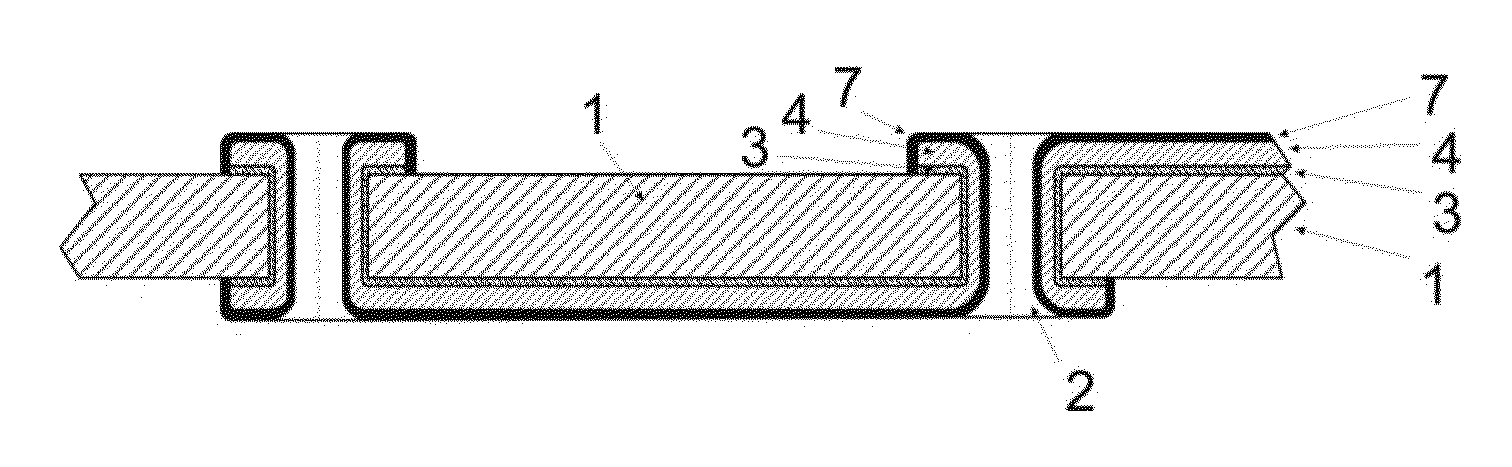

Method for manufacturing a double-sided printed circuit board

InactiveUS20160262271A1Improve metallization qualityImprove efficiencyInsulating substrate metal adhesion improvementConductive material chemical/electrolytical removalSingle processSolderability

The method for manufacturing printed circuit boards includes providing through hole vias in a non-conductive substrate at given coordinates in a printed circuit board topology, then an adhesive undercoat, a conductive layer and a metal mask layer are applied, in a single process, to the surface of the substrate and to the walls of the vias. A soluble protective layer is applied to the mask layer and to the walls of the vias, then a circuit board pattern is formed by laser evaporation, then the conductive layer and the adhesive undercoat in the regions exposed by laser evaporation are removed by selective chemical etching. The protective layer is removed from the regions that are not exposed by laser evaporation and the vias, then the metal mask layer is removed. Finally, a protective barrier layer and a layer that provides solderability and / or weldability of the surface are applied.

Owner:OBSHCHESTVO S OGRANICHENNOJ OTVETSTVENNOSTJU KOMPANIJA RMT

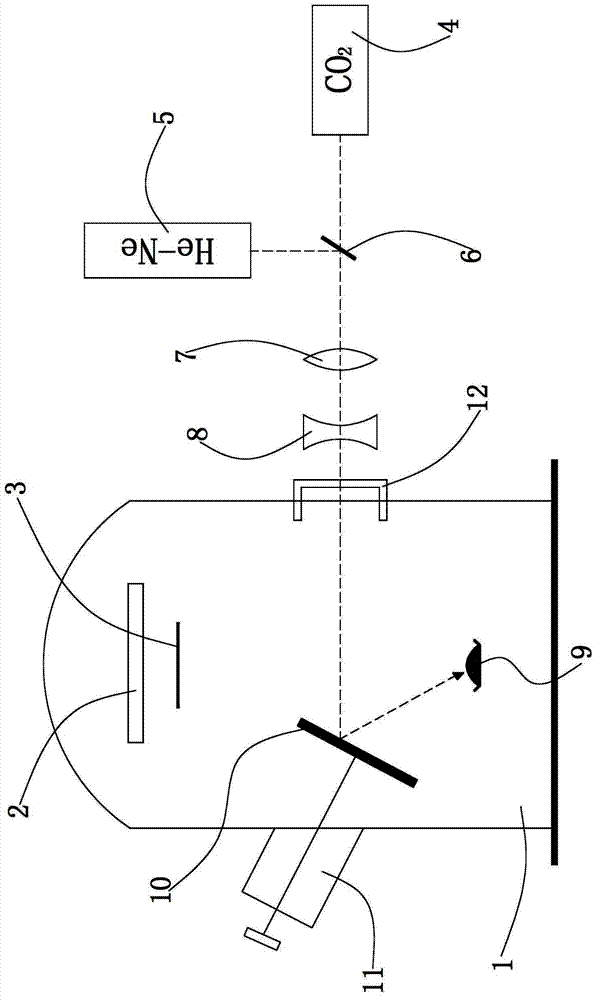

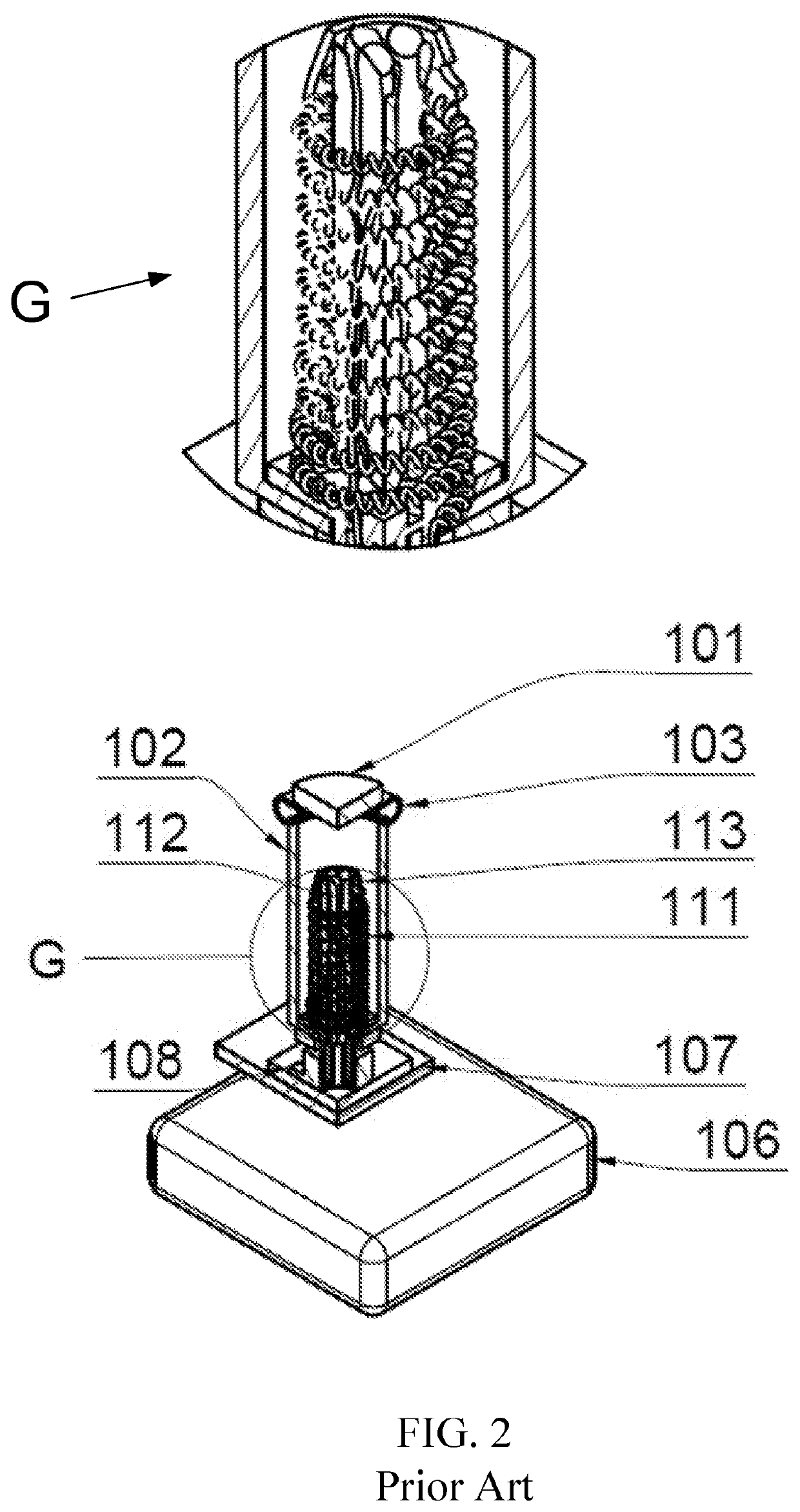

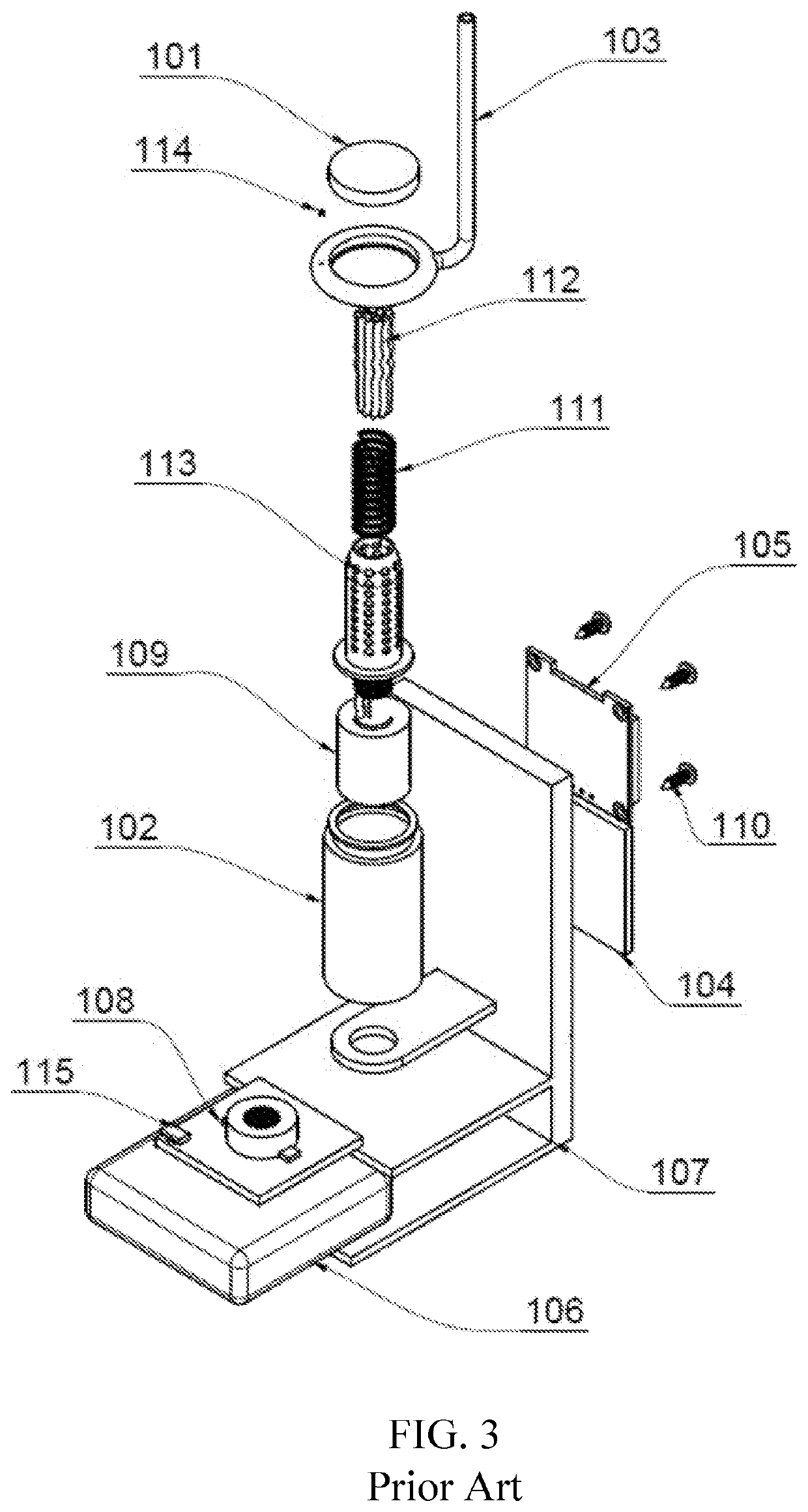

Laser evaporation coating device

InactiveCN102953033ASimple structureWill not polluteVacuum evaporation coatingSputtering coatingBeam splitterGas phase

The invention relates to a laser evaporation coating device, which is characterized by comprising a vacuum reaction chamber, a substrate frame, a CO2 laser device, a He-Ne laser device, a beam splitter, a focusing convex lens, a defocusing concave lens, a crucible and a reflecting mirror, wherein the beam splitter is positioned outside the vacuum reaction chamber and is arranged in the intersected position of laser beams sent out by the CO2 laser device and the He-Ne laser device in an angle of 45 degrees; the crucible is used for containing materials to be evaporated; the reflecting mirror is positioned above the crucible and is used for reflecting the laser sent out by the laser device into the crucible after the laser sequentially passes through the beam splitter, the focusing convex lens, the defocusing concave lens and a window from outside to inside, and the materials to be evaporated in the crucible are heated and evaporated by the laser, so that a film layer containing the materials to be evaporated is deposited on the surface of a base material or substrate on the substrate frame through vapor deposition. The laser evaporation coating device disclosed by the invention has a simple structure, and can be used for heating high-melting metal materials in a non-contact mode to evaporate the materials so as to realize laser evaporation coating, and the body of the vacuum reaction chamber can not be polluted.

Owner:ZHONGSHAN CHUANGKE RES TECH SERVICE

Process for performing steel-strip film coating by using pulse laser evaporation ablation in vacuum

InactiveCN101565816ANo emissionsProduction process is environmentally friendlyVacuum evaporation coatingSputtering coatingLaser beamsFilm coating

The invention discloses a process for performing steel-strip film coating by using pulse laser evaporation ablation in vacuum. The surface quality of a coil strip substrate material is at least at the 05 level; the coil strip enters a vacuum lock after being uncoiled, and the operation velocity of the steel strip is between 0.1 mm / min and 10 m / min; and the coil strip enters a pulse laser film coating unit, reactant gas or inert gas is led into the film coating unit so as to cause a laser beam to irradiate targets in a certain mode to produce target steam, and the film coating is performed when a steel plate passes through the area. The invention has environment-friendly process to realize a plurality of film coating products, rapid system response system and high control precision of a coating layer.

Owner:BAOSHAN IRON & STEEL CO LTD

Method and system for continuous or semi-continuous laser deposition

The invention relates to a method for deposition of material by laser evaporation wherein the employed laser is a continuous or semi-continuous laser. Using such a laser, it is possible to evaporate the target material in a controlled manner from a local pool of liquid or fluidized target material at the target surface. The invention also provides a system for executing said method.

Owner:OTB SOLAR

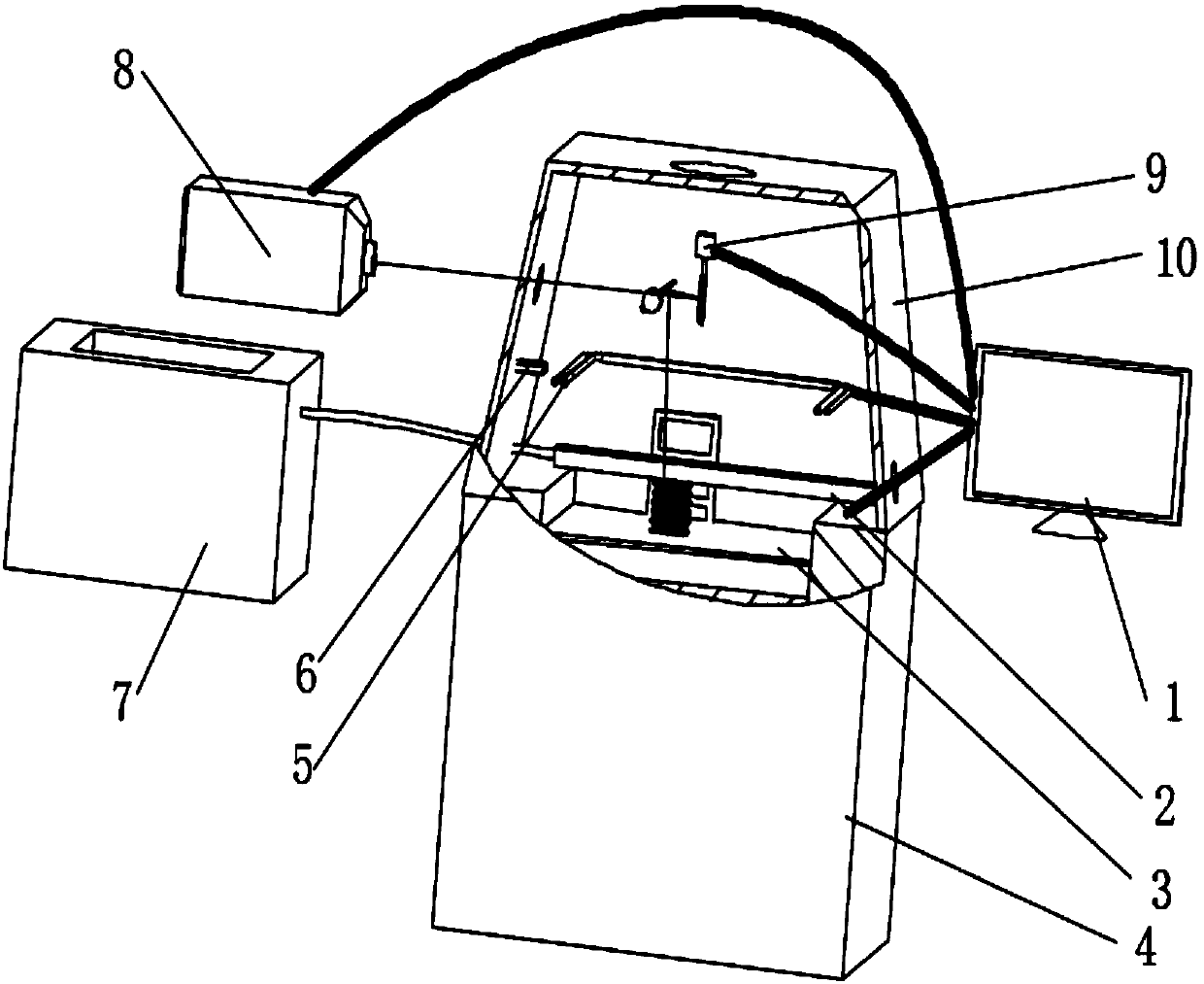

Dual ion source slow electron velocity imaging device

ActiveCN111739785ABroaden the channels of productionEasy to operateTime-of-flight spectrometersMaterial analysis by electric/magnetic meansIon clustersMass Spectrometry-Mass Spectrometry

The invention discloses a dual ion source slow electron velocity imaging device. The device comprises a laser evaporation ion source, an electrospray ion source, an analysis chamber, a time-of-flightmass spectrometry system and a slow electron velocity imaging system, wherein the laser evaporation ion source and the electrospray ion source are respectively arranged on two sides of the analysis chamber, the time-of-flight mass spectrometry system and the slow electron velocity imaging system are both arranged in the analysis chamber, and a matched camera is arranged outside the analysis chamber. The design of the double ion sources widens the research system of a single device and the generation channel of the target anion cluster; the device has the capability of detecting single-charge and multi-charge anion clusters generated by solid-phase and liquid-phase samples, and compared with two instruments with single ion sources, the integration of the double ion sources has the advantages that accessories such as a vacuum cavity, a molecular pump and a detector are saved, the expenditure is saved, and meanwhile, the operation steps of the instrument are simplified.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

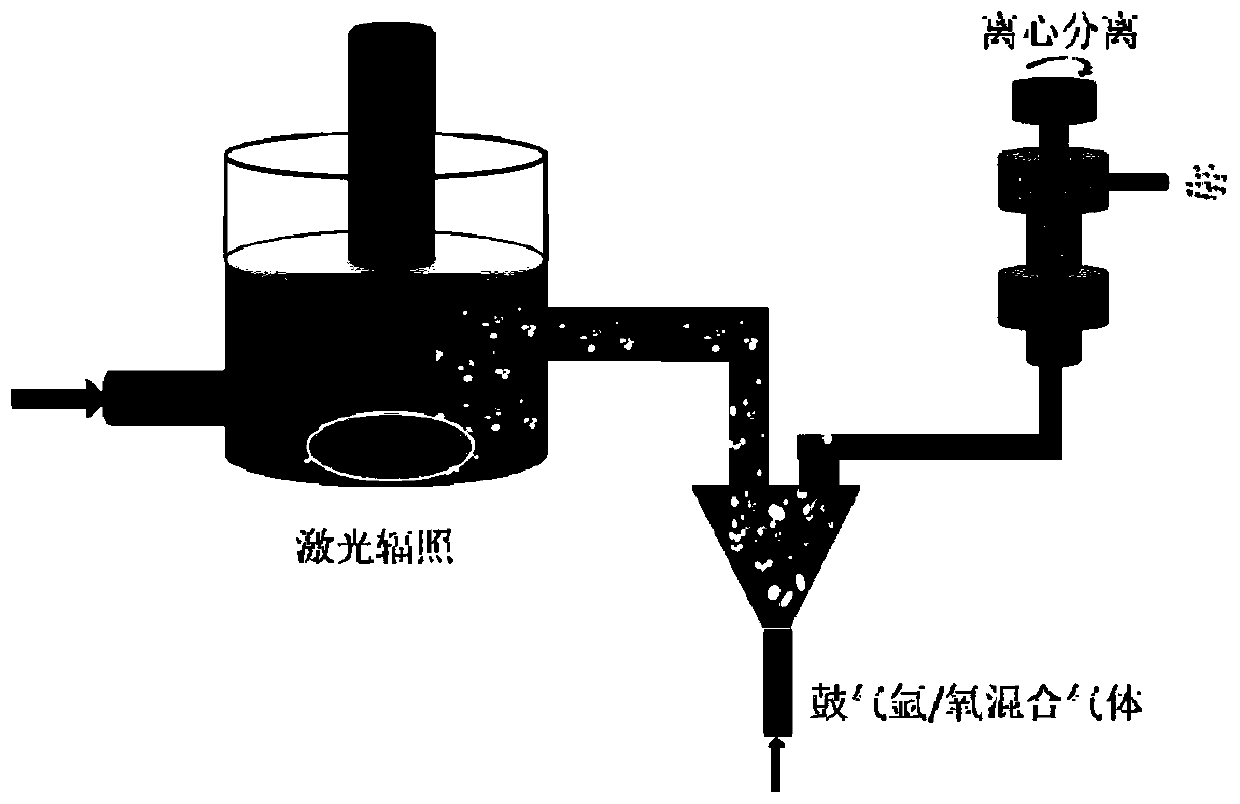

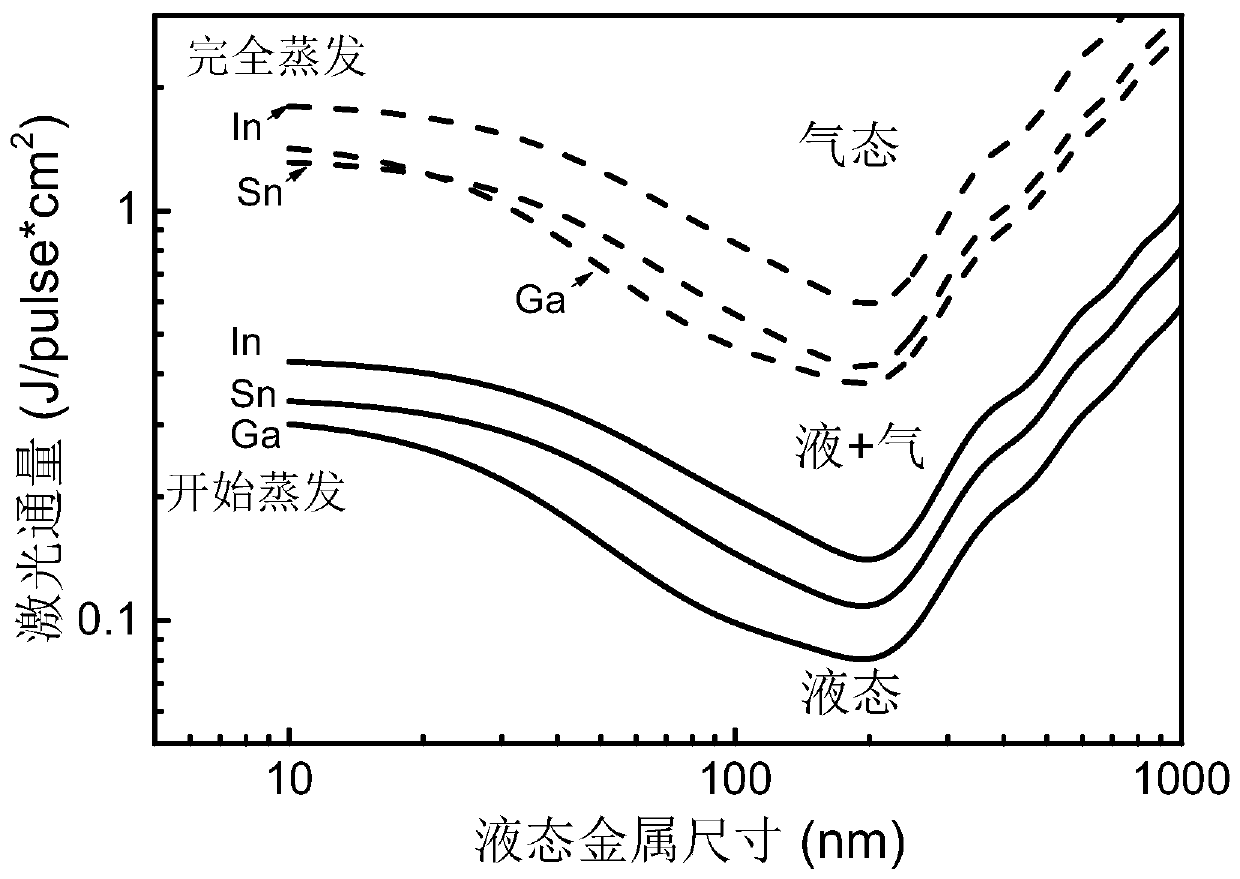

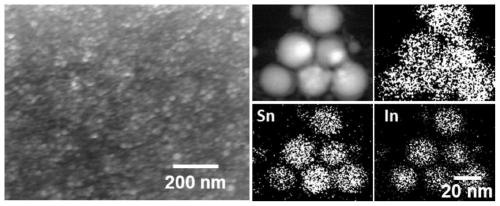

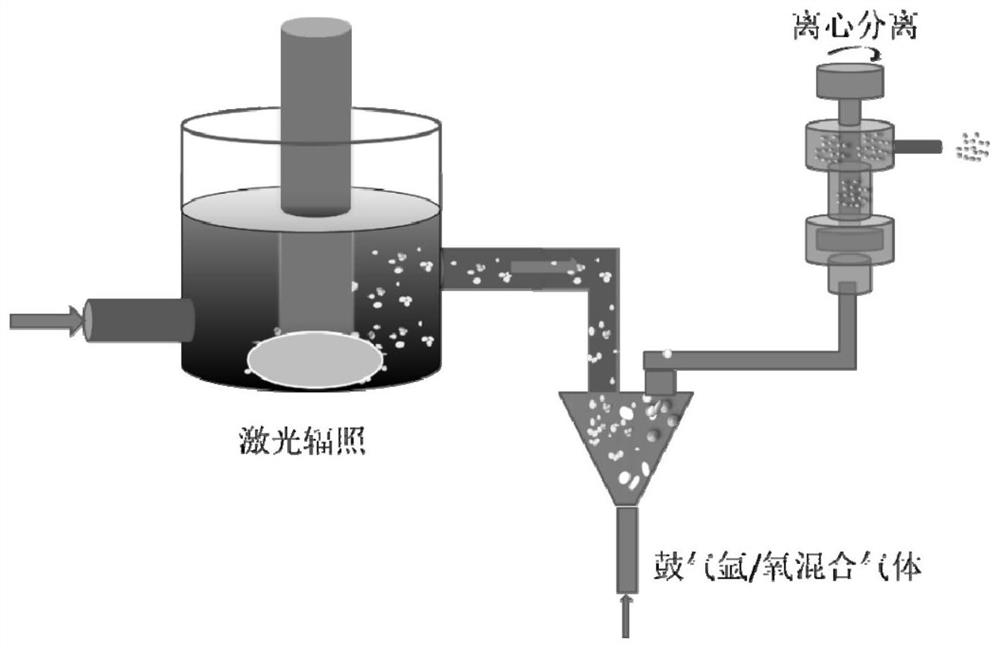

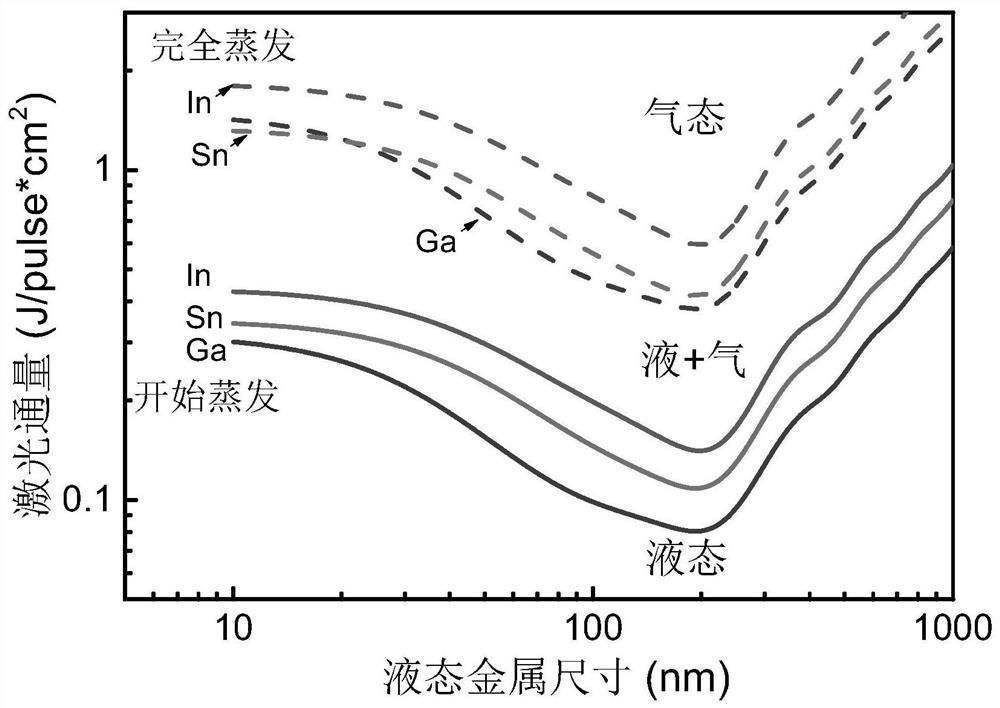

Method for preparing nano alloy liquid drops through laser irradiation

InactiveCN111570811AAchieving controllable equipmentAvoid self-fusionTransportation and packagingChemical/physical/physico-chemical microreactorsOrganic solventLiquid metal

The invention discloses a method for preparing nano alloy liquid drops through laser irradiation, and belongs to the technical field of liquid metal. The method comprises the following steps that S1,the liquid metal is pre-dispersed, the pre-dispersed liquid metal is placed in an organic solvent, and a liquid metal / organic solvent precursor solution is prepared; S2, non-focused laser is introduced into the liquid metal / organic solvent precursor solution prepared in the step S1, and laser irradiation evaporation is carried out under the stirring condition; S3, under the stirring condition, mixed gas containing oxygen is introduced into a system obtained after laser evaporation in the step S2, and generation of a passivation layer is promoted; and S4, after the passivation layer is generated, concentration or separation is carried out, and the nano alloy liquid drops are prepared. The nano liquid drops prepared through the preparation method are uniform in component, controllable in size structure, free of ligand on the surface and high in modifiability, and the method for preparing a base material is provided for application in the fields of flexible electronics, photocatalysis, nano medicine and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Scintillation screen structure for X-ray radiation detector

ActiveCN103344984AImprove waterproof performanceGood light transmissionX/gamma/cosmic radiation measurmentTransmittanceCesium iodide

The invention relates to a scintillation screen structure for an X-ray radiation detector. The scintillation screen structure comprises a silicon substrate. A cesium iodide hybrid film is deposited on the silicon substrate through the laser evaporation process. The cesium iodide hybrid film is a cesium iodide thick film doped with thallium and boron. A transparent water blocking film is deposited on the cesium iodide thick film. The visible light transmittance of the transparent water blocking film is larger than or equal to 90%. The water vapor transmittance of the transparent water blocking film is smaller than or equal to 0.01g / m<-2>.day<-1>. The scintillation screen structure for the X-ray radiation detector is compact, even in component and good in cohesiveness with the substrate, and has good water blocking and waterproof performance.

Owner:SHENZHEN BASDA MEDICAL APP

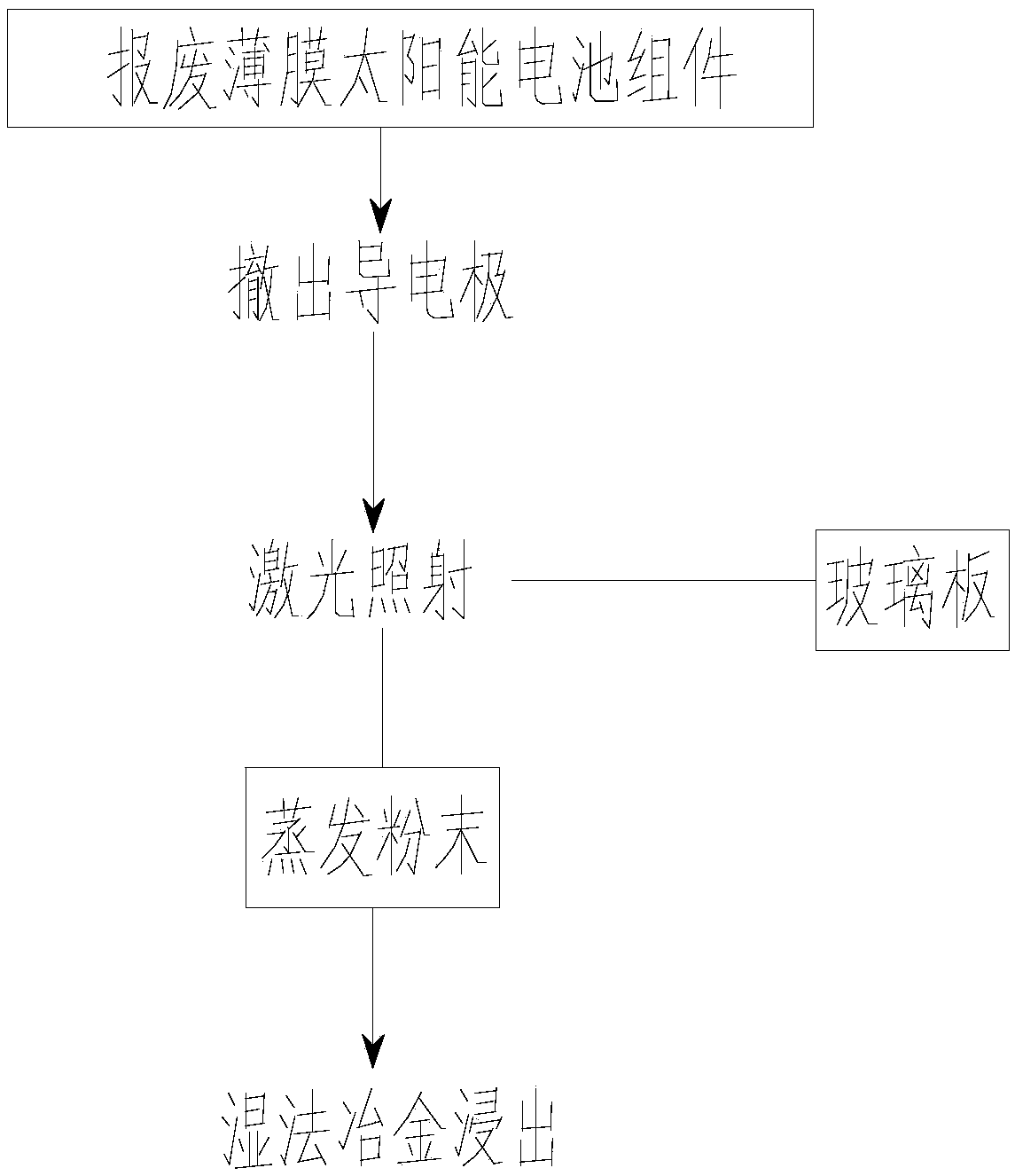

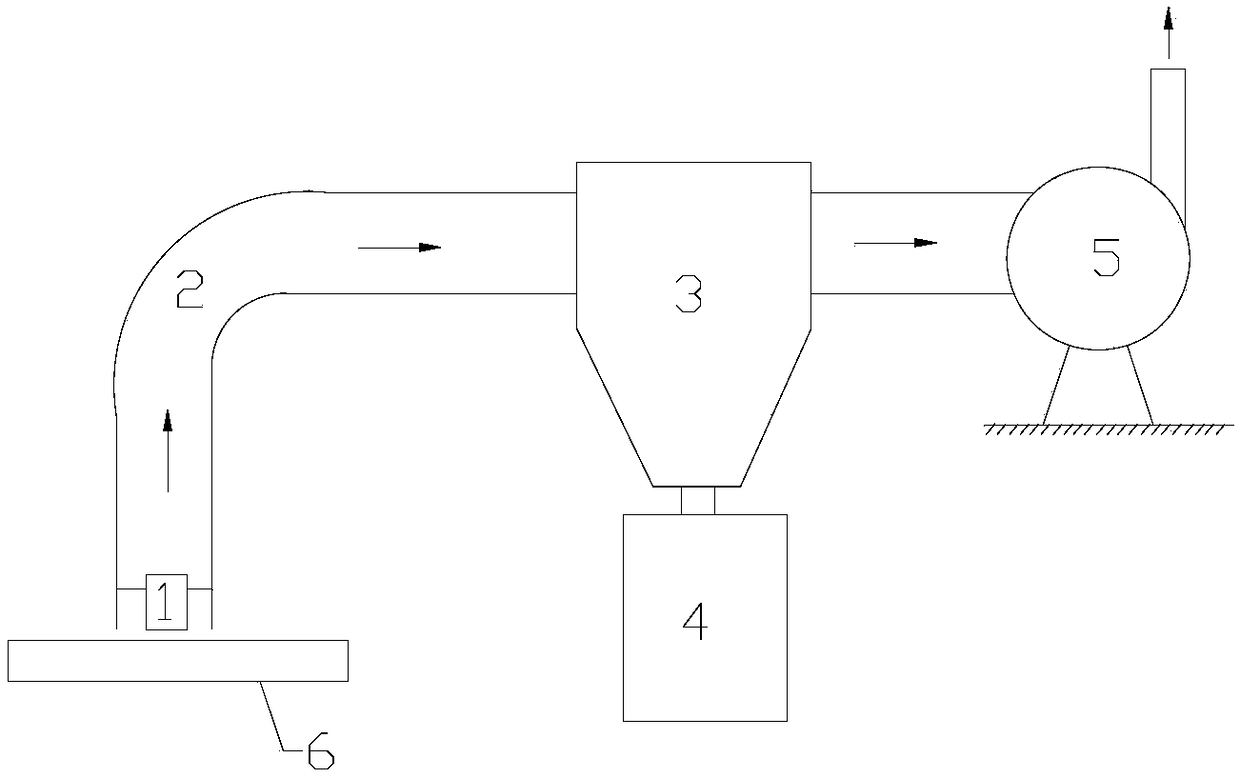

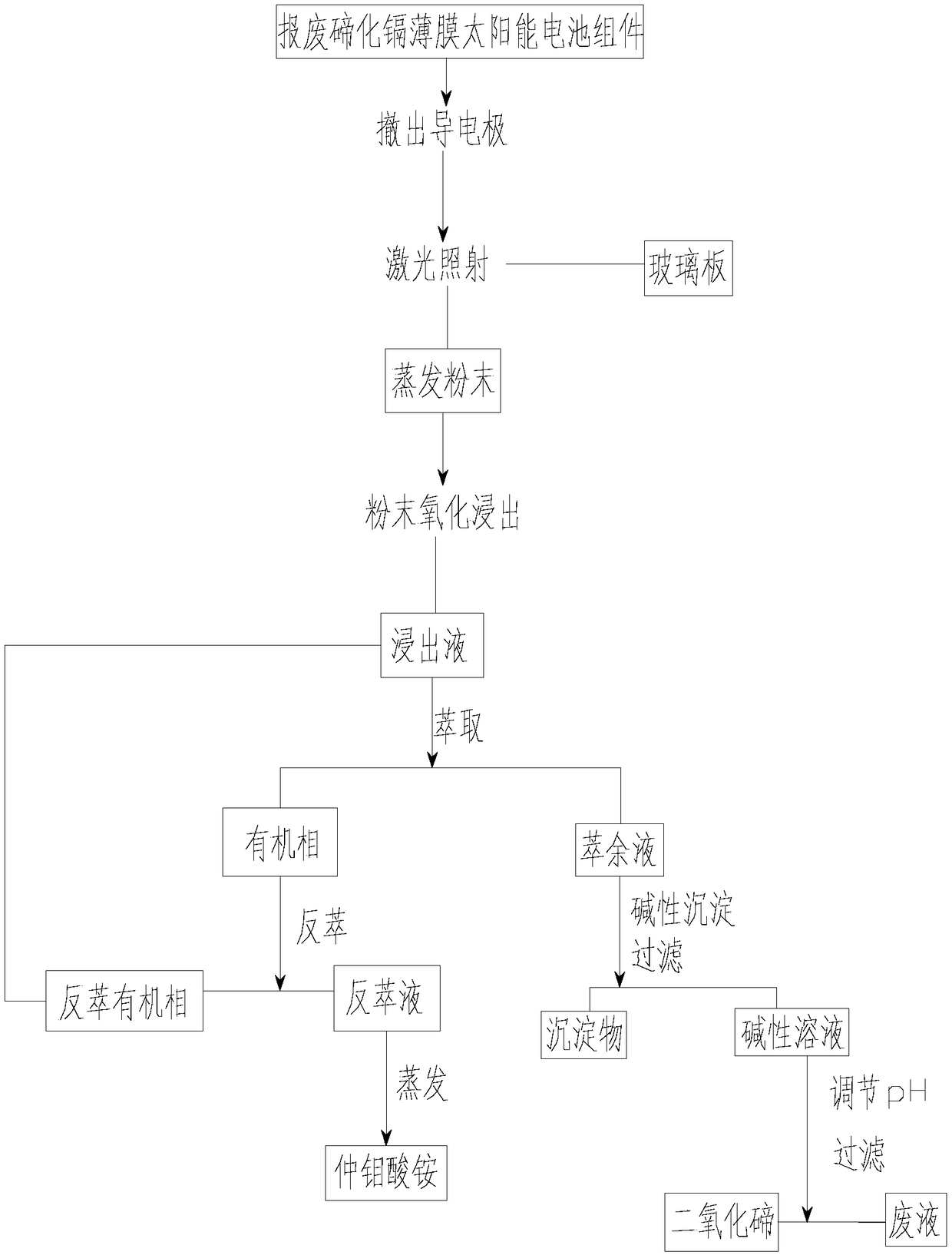

Laser evaporation recovery processing method for film solar cell module

InactiveCN108913902AHigh recovery rateImprove working environmentFinal product manufactureProcess efficiency improvementShortest distanceResource utilization

The invention discloses a laser evaporation recovery processing method for a film solar cell module. The method comprises the following steps: after removing backplate glass and an electric conductingelectrode of the waste film solar cell module, obtaining a glass substrate with a photovoltaic film layer, using a laser to irradiate the photovoltaic film layer on the glass substrate at short distance until the photovoltaic film layer is totally evaporated to obtain the whole glass substrate, enabling an evaporant of the photovoltaic film layer to enter a solid powder collecting chamber, finally extracting by a hydrometallurgy technology, and realizing comprehensive recovery of a valuable metal in the photovoltaic film layer. The method is very short in a flow of stripping the photovoltaicfilm layer and collecting valuable metal solids in the photovoltaic film layer, and rapid in speed; the recovery rate of the valuable metal is high, the work environment is good, the damage to the glass substrate is small and the recyclability rate is high; and th emethod is capable of completely using an automatic mechanical technology and good working environment, the whole environment friendliness of a product chain is ensured, the material recovery rate and recovering effect of the film solar cell module are improved, and a source utilization ratio is improved.

Owner:CNBM CHENGDU OPTOELECTRONICS MATERIAL

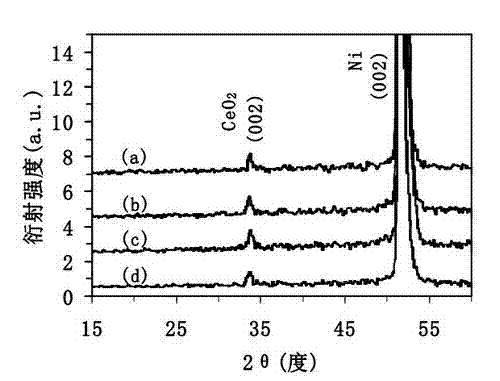

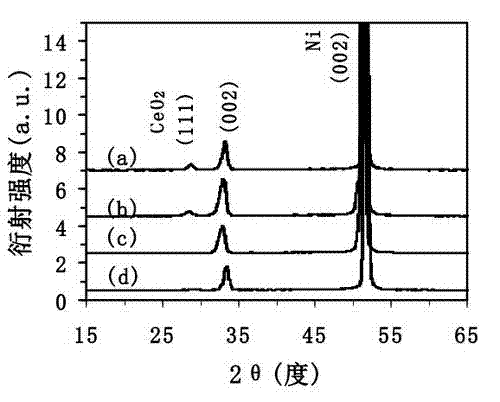

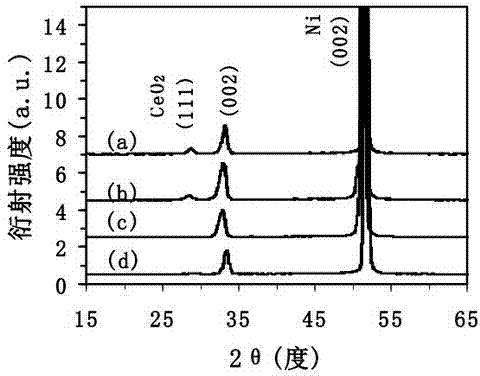

Multi-channel laser coating method for preparing ceo2 seed layer

ActiveCN102268643AChemically activeChemically stableVacuum evaporation coatingSputtering coatingLaser coatingCoating system

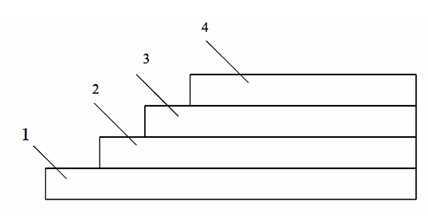

The invention discloses a multi-channel laser coating method for preparing a cerium dioxide seed layer. According to the invention, a multi-channel transmission device is adopted; the cerium dioxide seed layer is prepared on an annealed nickel-tungsten metal base band through a multi-channel laser evaporation coating method; in the coating process, the coating speed of the cerium dioxide seed layer on the base band is greatly accelerated through winding repeatedly the nickel-tungsten metal base band on a roll shaft and passing through a coating region, can reach over one hundred meters per hour and is suitable for kilometer-level long band preparation; the atmosphere adopted when the method is used for coating is a mixed gas of argon and hydrogen, the argon is am inert gas and mainly plays a buffer function, and the hydrogen has the main function of consuming residual oxygen in the coating cavity in the coating process, so that baseband surface oxidation which can be generated under the condition of high-temperature coating and affects the orientation of the cerium dioxide seed layer is avoided; in addition, the coating atmosphere is the mixed gas of argon and hydrogen so that therequirement on base vacuum degree of a coating system can be greatly reduced, the equipment investment is saved, and the band material cost is reduced.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

Particle imaging method

PendingCN109115660AShort cooldownEffective aggregationMaterial analysisLiquid storage tankCombined method

Owner:JINHUA VOCATIONAL TECH COLLEGE

Selective laser evaporation deposition method and device

InactiveCN107839218AImprove liquidityImprove molding qualityAdditive manufacturing apparatus3D object support structuresGalvanometerEngineering

The invention discloses a selective laser evaporation deposition method and device. A saturated solution is taken as a forming material, a printing model is generated through a computer, and a signalis output through control software, so that motion of a scanning galvanometer is controlled, laser forms a point light source in a forming cylinder, a solution is evaporated, and solute is formed by deposition and sintering. The device comprises a light path system and a forming system which are connected with a computer, wherein the computer is connected with a laser unit and a scanning galvanometer; the forming system comprises a pre-heating device (a heater and a temperature sensor), a forming cylinder, a liftable forming tray, a fluid supplementing scraping plate, a fluid supplementing slot and an inert gas protective bin. The selective laser evaporation deposition method provides a novel personalized forming mode for a soluble high polymer material; and compared with an existing selective sintering technology using a powdered material, the selective laser evaporation deposition method adopts a liquid material, is good in mobility, is ideal in forming effect, does not need to prepare powder, is low in cost, is good in forming quality, is wide in processing material range, and the like.

Owner:陕西百普生医疗科技发展有限公司

Painting and calligraphy carved on silver-imitated magnesium alloy metal plate

The invention relates to work of art carved on a silver-imitated metal plate, which is prepared by the following steps: taking a magnesium alloy plate as a raw material; forming various planar carving and hollows by various carving methods, such as mechanical carving, laser evaporation carving and electrochemical and chemical carving; post-processing the formed planar carving and hollows to obtain the work of art of painting and calligraphy. The steps are applicable for carved work of arts in various breadths with high silver-imitation degree in terms of the color and the texture.

Owner:山西银光华盛镁业股份有限公司

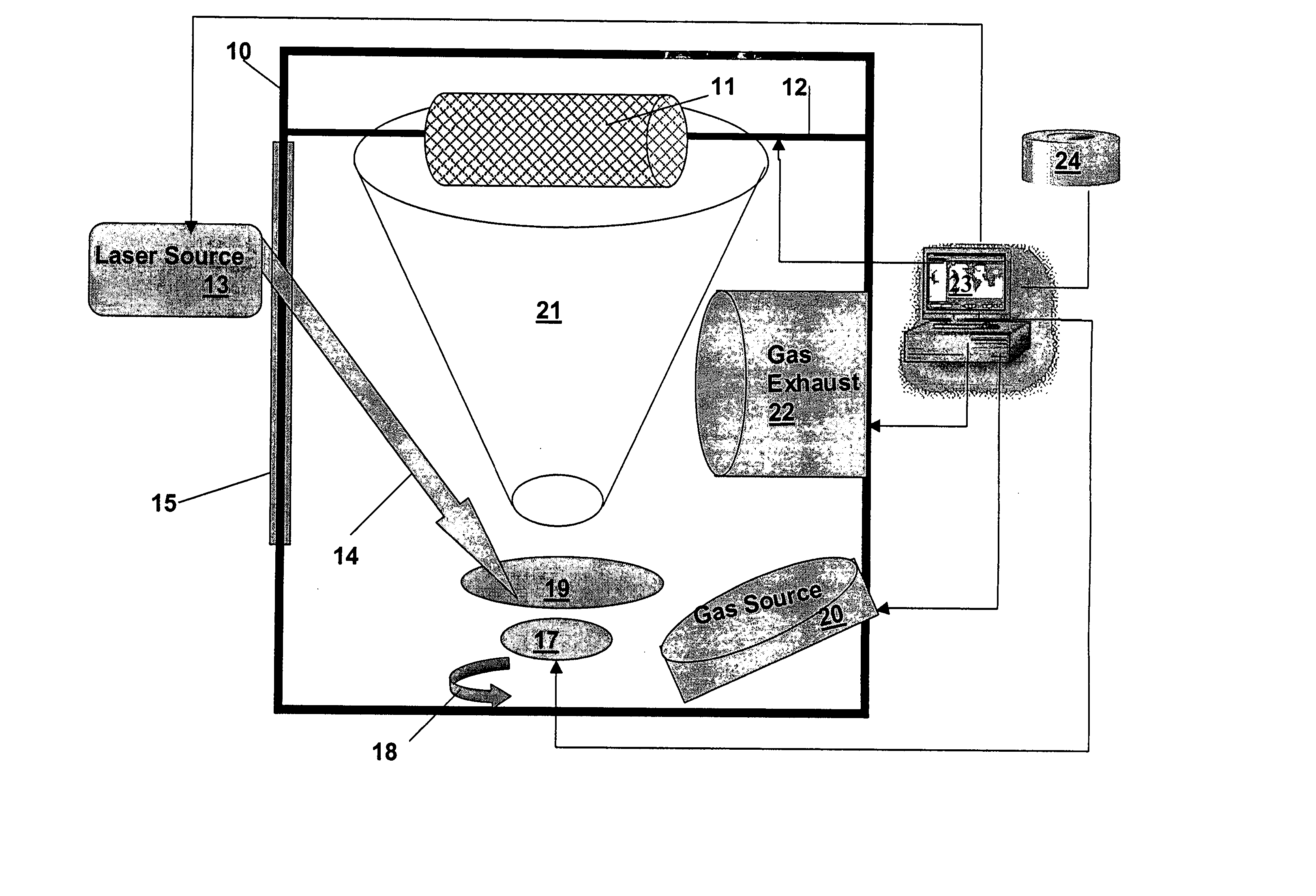

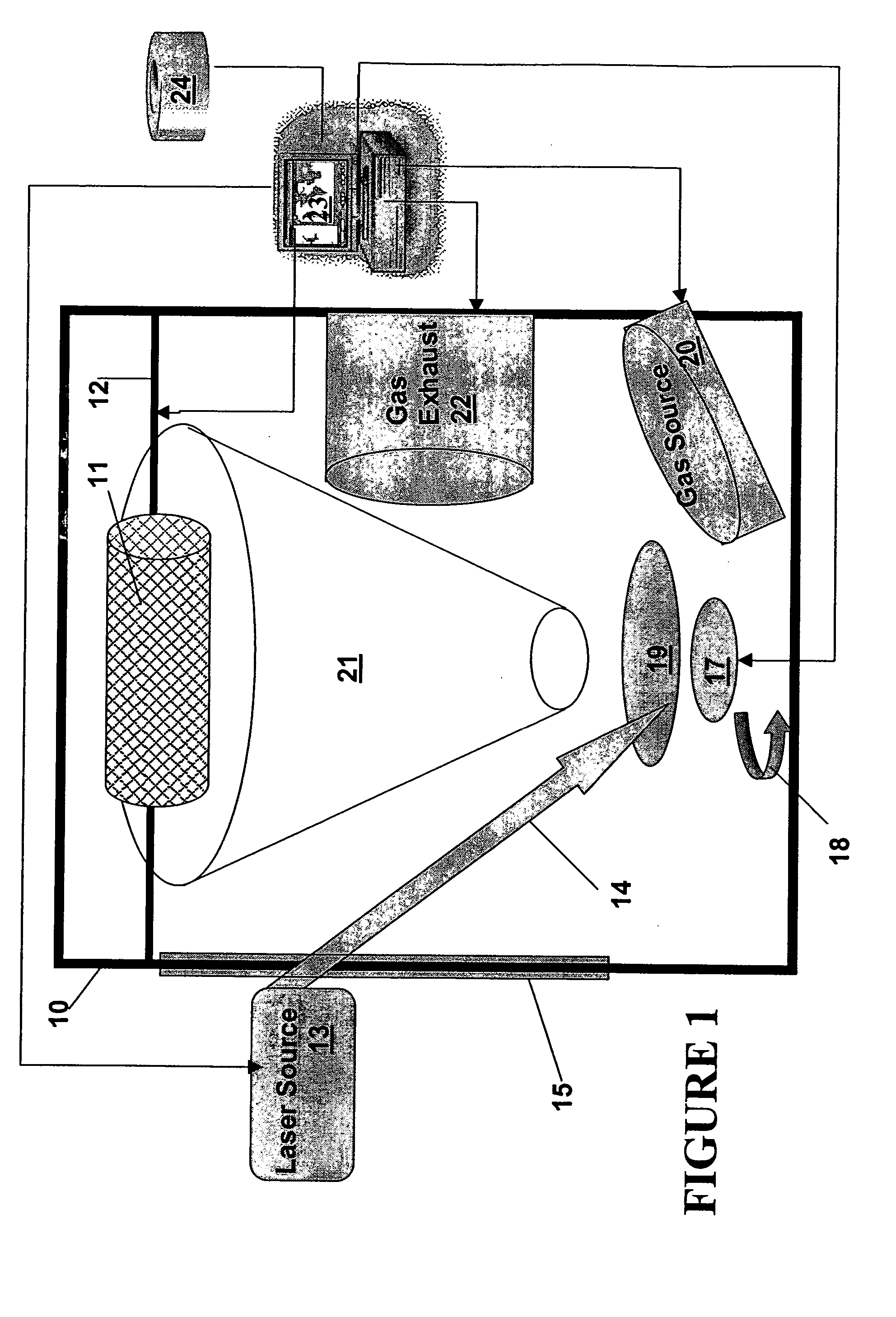

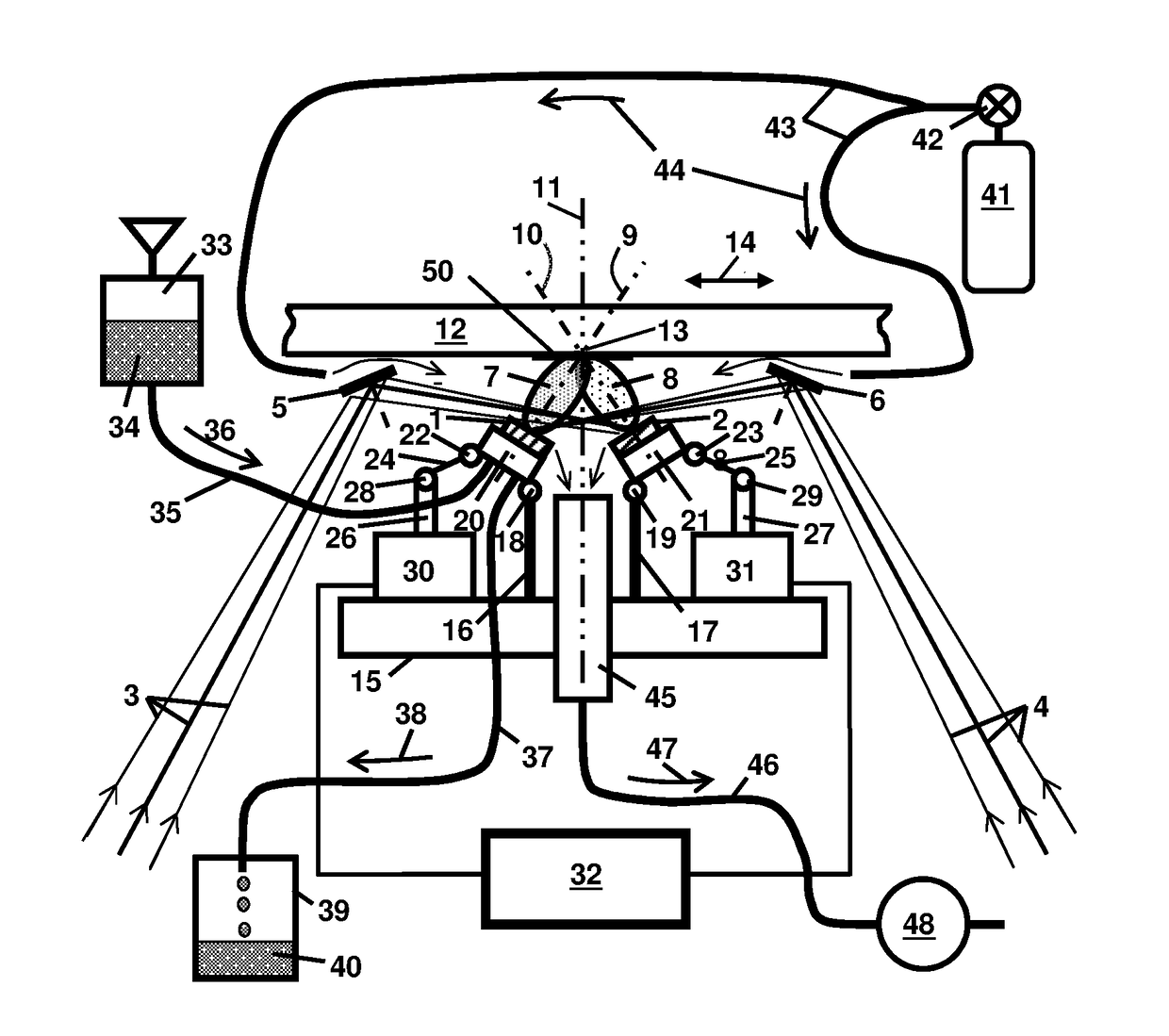

Method and Apparatus for Open-Air Pulsed Laser Deposition

A method and apparatus for open-air pulsed laser deposition with a low pressure zone maintained between the targets and the substrate by pumping the ambient gas out with a vacuum pump. The zone between the targets and the substrate may be shielded from ambient oxygen with an inert gas flowing from outside. The films can be deposited on a large substrate, which may be freely translated with respect to the targets. The apparatus may accommodate multiple pulsed laser beams and multiple targets. The targets may be remotely tilted in order to provide optimal plume overlapping on the substrate. At least one target may be deposited using the matrix assisted pulsed laser evaporation process. The target may be made of a polymer solution frozen with circulating liquid nitrogen.

Owner:DILLARD UNIVERSITY

Continuous rapid laser coating method of superconducting layer in second-generation high-temperature superconducting strip

ActiveCN102409298BFast manufacturingReduce manufacturing costVacuum evaporation coatingSputtering coatingLaser coatingHigh temperature superconducting

The invention provides a continuous rapid laser coating method of a superconducting layer in a second-generation high-temperature superconducting strip. According to the invention, through a method of bi-dimensionally scanning a superconducting target along an x-y axle, the whole surface of the target can be utilized and a laser evaporation coating process can be stably and sustainably carried out; coating intervals are increased through a method of scanning along the motion direction of the strip by use of laser spots; and the width of the coating interval vertical to the motion direction of the strip is increased through a method of twining the strip on a belt roller above a heater multiple times. By using the method provided by the invention, evaporated substances are fully collected on a metal base band to the greatest extend, thereby effectively improving the preparation speed of the strip, increasing the utilization rates of the target and the evaporated substances, greatly improving the production efficiency and reducing the production cost of the strip. According to the method provided by the invention, the rapid coating of the second-generation high-temperature superconducting strip suitable for large-scale industrial production can be realized.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

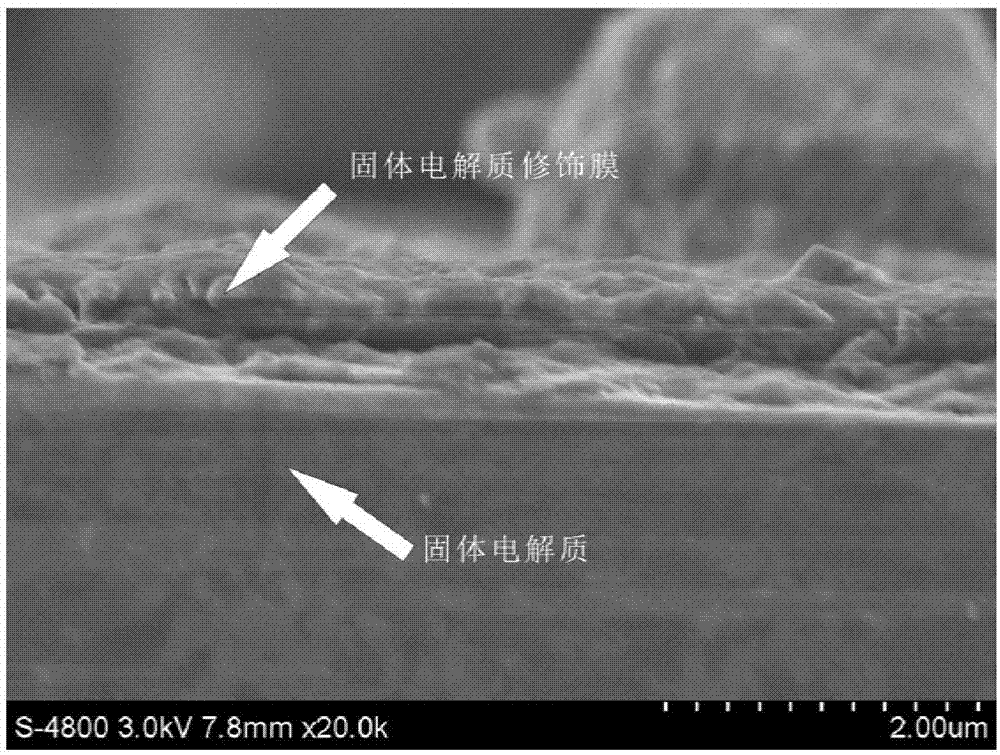

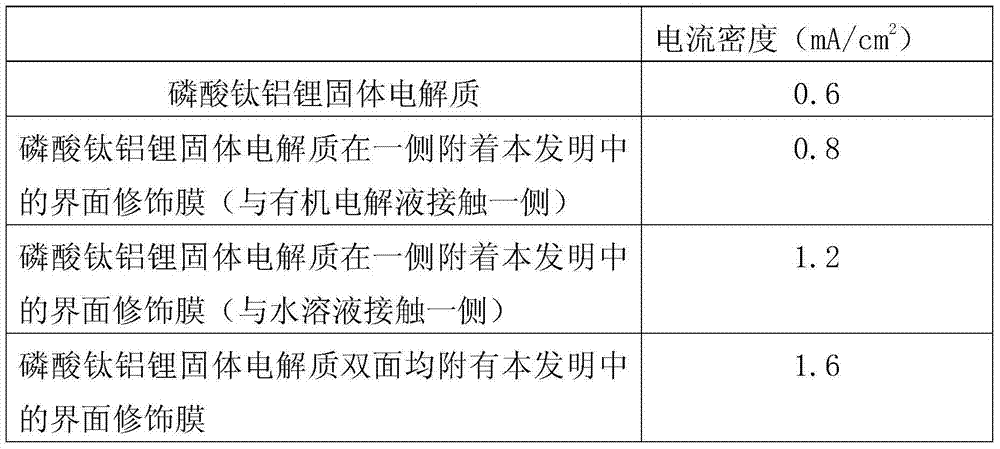

Solid electrolyte interface modification film for lithium battery and preparation method thereof

ActiveCN102646801BReduce interface impedanceImproves ion transmissionHybrid cell detailsCell component detailsElectrical conductorInterfacial impedance

The invention relates to an interfacial modification membrane for a solid electrolyte for a lithium battery and a preparation method thereof. The interfacial modification membrane for the solid electrolyte for the lithium battery is characterized in that a layer of interfacial modification membrane is attached to one face or both faces of a solid electrolyte. The preparation method of the interfacial modification membrane comprises the following steps of: (1) selecting a fast-ionic conductor or a uniform mixture of a lithium-ion active material and water; (2) forming a target material by compressing the fast-ionic conductor or the uniform mixture, sintering the target material for 3-24 hours at the temperature of 500-1200 DEG C, and then, carrying out natural cooling with a furnace; and (3) attaching the target material to the face or the both faces of the solid electrolyte through magnetron sputtering, laser evaporation or electron beam evaporation, thereby obtaining the interfacial modification membrane for the solid electrolyte. According to the interfacial modification membrane for the solid electrolyte for the lithium battery and the preparation method thereof, as the layer of interfacial modification membrane is attached to the face / faces of the solid electrolyte playing a diaphragm role, the interfacial impedance between the solid electrolyte and an electrolytic solution and other types of electrolytes is reduced, the ion transmission capacity of an interface layer of the solid electrolyte is improved, and the discharge performance of the battery is effectively improved; and the preparation method is simple, and the large-scale production is facilitated.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Coating method for plasma deposition after laser evaporation

The invention belongs to the technical field of material surface treatment, and particularly relates to a coating method for plasma deposition after laser evaporation. Comprising the following steps that S1, a plasma accelerator pointing to the surface of a to-be-sprayed part is used, and the plasma accelerator generates plasma flow and provides laser radiation perpendicular to the plasma flow; s2, focusing the evaporation target material through laser radiation to generate steam; and S3, the steam generated in the step S2 is deposited on the surface of the sprayed part through indirect plasma jet, and finally the thin film coating is formed. The method has the advantages that the coating can be coated through laser evaporation, then target material vapor particles are atomized through plasma and deposited, and the possibility is provided for coating the uniform thin film coating (from 10 nm to 100 microns).

Owner:浙江巴顿焊接技术研究院 +3

Multi-channel laser coating method for preparing cerium dioxide seed layer

ActiveCN102268643BChemically activeChemically stableVacuum evaporation coatingSputtering coatingLaser coatingCoating system

The invention discloses a multi-channel laser coating method for preparing a cerium dioxide seed layer. According to the invention, a multi-channel transmission device is adopted; the cerium dioxide seed layer is prepared on an annealed nickel-tungsten metal base band through a multi-channel laser evaporation coating method; in the coating process, the coating speed of the cerium dioxide seed layer on the base band is greatly accelerated through winding repeatedly the nickel-tungsten metal base band on a roll shaft and passing through a coating region, can reach over one hundred meters per hour and is suitable for kilometer-level long band preparation; the atmosphere adopted when the method is used for coating is a mixed gas of argon and hydrogen, the argon is am inert gas and mainly plays a buffer function, and the hydrogen has the main function of consuming residual oxygen in the coating cavity in the coating process, so that baseband surface oxidation which can be generated under the condition of high-temperature coating and affects the orientation of the cerium dioxide seed layer is avoided; in addition, the coating atmosphere is the mixed gas of argon and hydrogen so that therequirement on base vacuum degree of a coating system can be greatly reduced, the equipment investment is saved, and the band material cost is reduced.

Owner:SHANGHAI SUPERCONDUCTOR TECH CO LTD

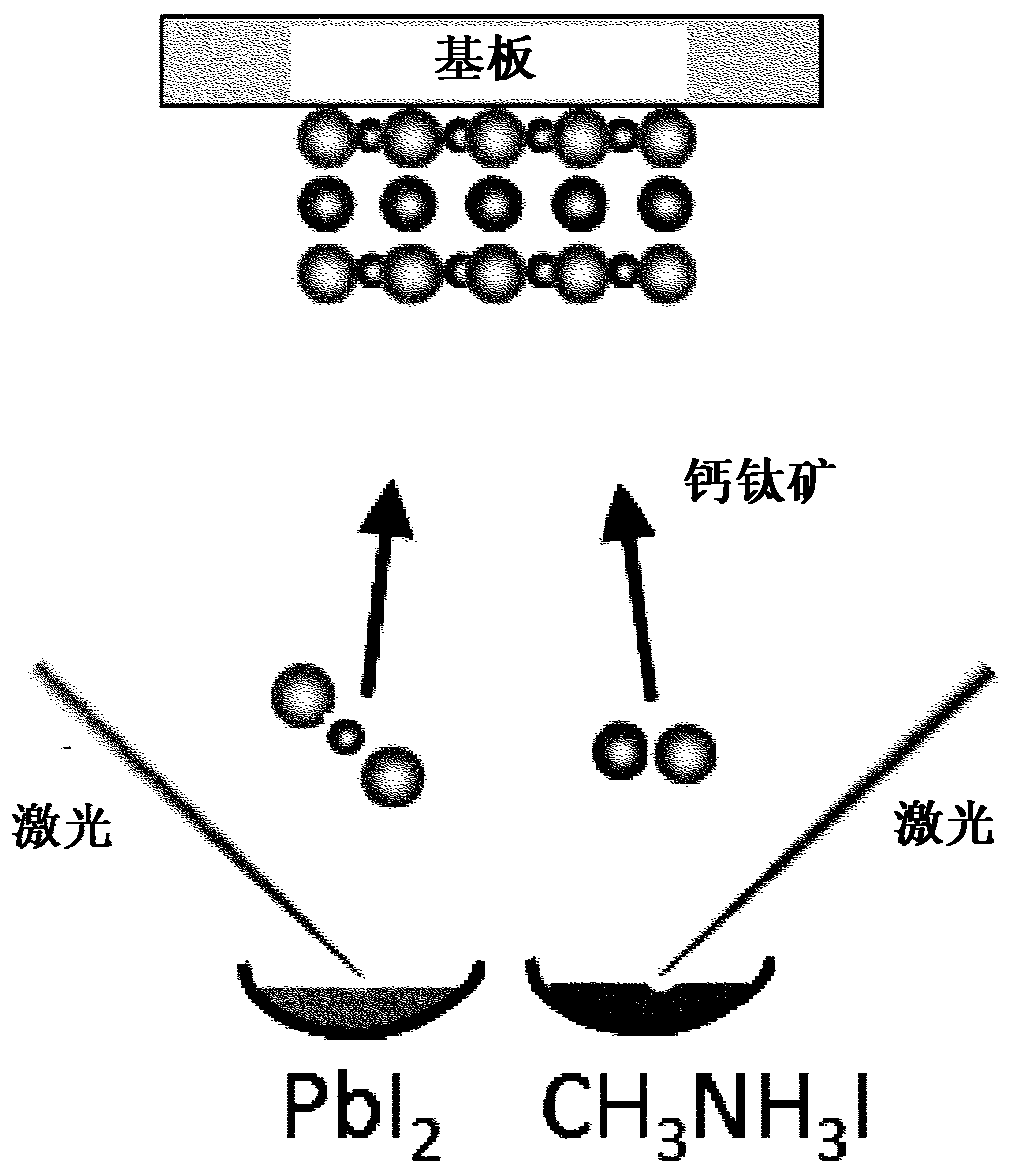

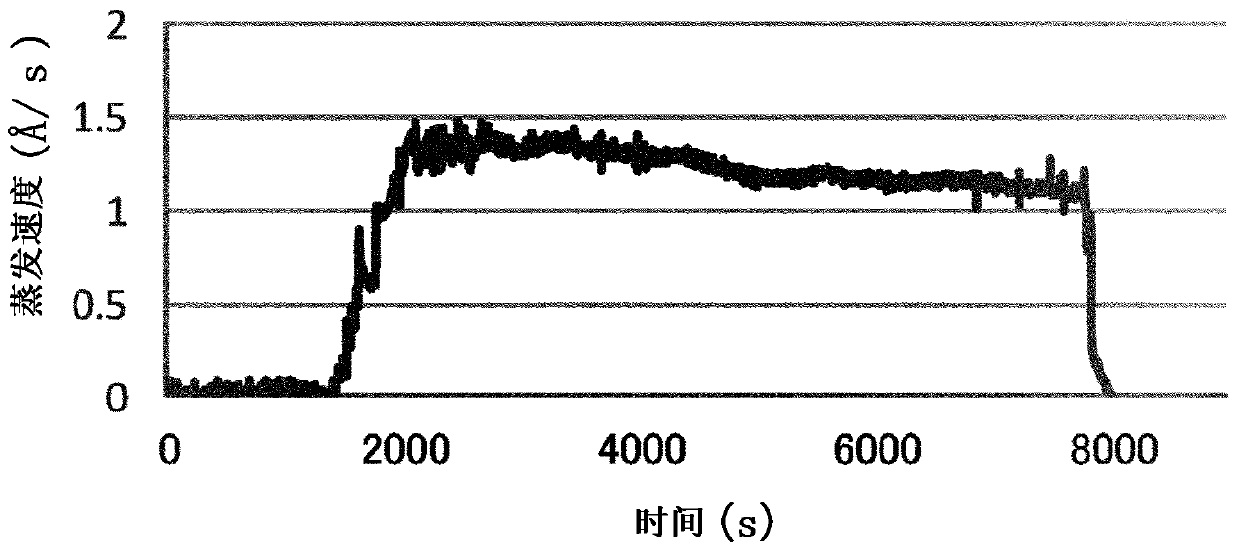

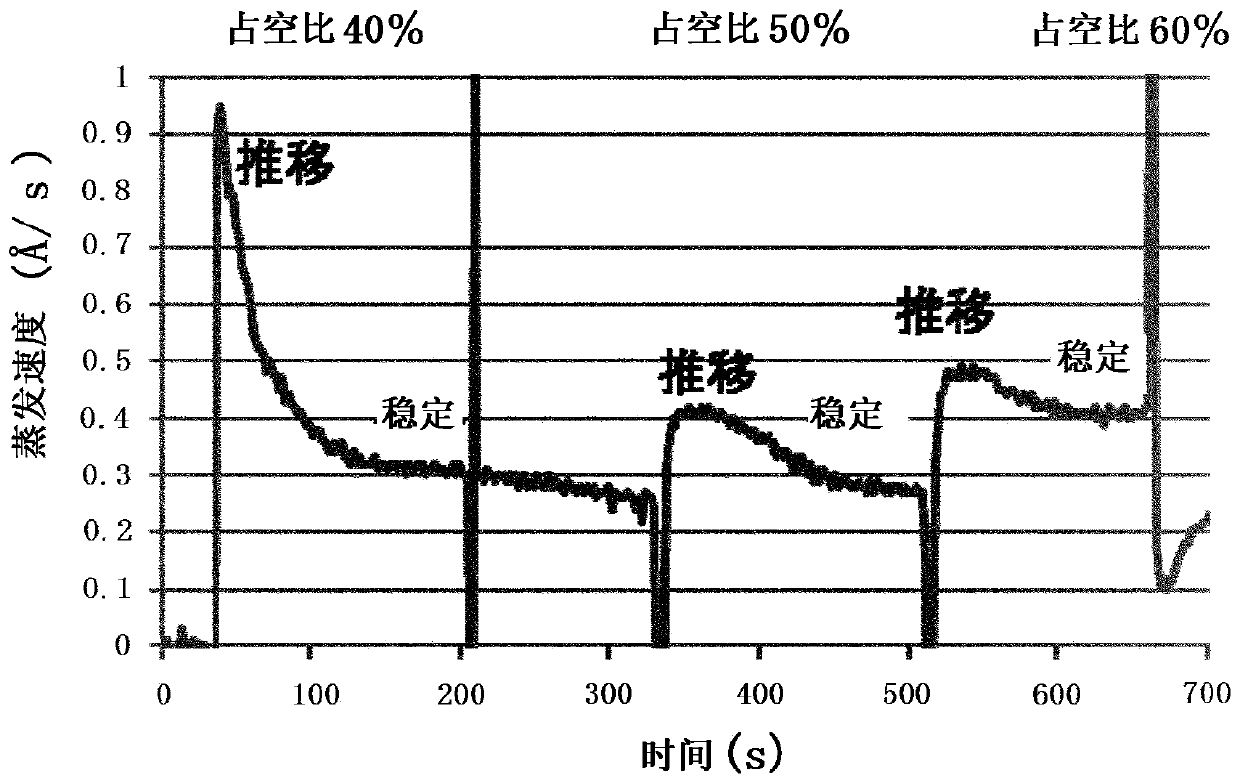

Laser evaporation method and laser evaporation device for organic material film or organic-inorganic composite material film

InactiveCN107109628BReduce gasificationAvoid pollutionElectrolytic capacitorsVacuum evaporation coatingEvaporation (deposition)Laser light

The object of the present invention is to solve the problems in the prior art such as contamination of other raw materials for evaporation due to gasification of organic materials, or loss of control due to uncontrollable film formation speed, and to provide a method that can stably adjust and control the deposition rate. A laser vapor deposition method and a laser vapor deposition device for an organic material with a film speed and an evaporation rate, in the method of carrying out laser vapor deposition of at least one organic material, it is characterized in that the duty ratio of the laser light that vaporizes the organic material is Make adjustments. In addition, it is characterized in that the above-mentioned duty ratio is adjusted based on the evaporation rate of the above-mentioned organic substance and the vapor pressure in the vacuum chamber for vapor deposition.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Scintillation screen structure for X-ray radiation detector

ActiveCN103344984BImprove waterproof performanceGood light transmissionX/gamma/cosmic radiation measurmentTransmittanceCesium iodide

Owner:SHENZHEN BASDA MEDICAL APP

Laser evaporation multi-cavity metal/carbon nanometer powder continuous production method

InactiveCN109759601ARealize simultaneous preparationAvoid mutual contaminationCarbon nanotubesProduction effectPollution

The invention relates to the technical field of nanometer powder production, in particular to a laser evaporation multi-cavity metal / carbon nanometer powder continuous production method. By utilizinga laser evaporation multi-cavity nanometer powder preparation device, the laser power is increased to the target melting power; the evaporation efficiency of an anode is changed by controlling the laser power; and temperature gradients in cavities are controlled, so that nanometer powder with different particle sizes is formed, and continuous production can be realized. According to the productionmethod, simultaneous preparation of multiple kinds of powder with different components can be realized, the mutual pollution in the preparation process of the powder is avoided, the purity of the powder is improved, the production efficiency is greatly improved, and the cost is reduced; and the production effects that the different cavities are continuously switched, and the nanometer powder canbe continuously evaporated can be achieved in industry, and the continuous production can be realized on the premise that a vacuum system meets the continuous work.

Owner:DALIAN UNIV OF TECH

High-temperature superconductive element based on nano material and its prepn.

InactiveCN100455975CFast heat conductionThermal superconductivityVacuum evaporation coatingSputtering coatingCoated surfaceMetal powder

Owner:SOUTH CHINA UNIV OF TECH

Laser vaporizer

PendingUS20220088322A1Avoid introducingMedical devicesMedical atomisersPharmaceutical drugErbium lasers

A laser vaporizer includes a laser, a heating vial, and an exit port. The laser heats a target substance to a vaporization temperature in a vaporization chamber. The vaporization chamber is made of glass or other inert material. The laser vaporizer is configured to safely deliver vaporized medicines, plant material and extracts without introducing further contaminants to the vapor so as to prevent the leaching of elements into the vapor. The vaporized target substance is passed through the exit port for inhalation.

Owner:OLADAPO IFEDAYO OLUSEYI ADEDAYO

A method for preparing nano-alloy droplets by laser irradiation

InactiveCN111570811BAchieving controllable equipmentAvoid self-fusionTransportation and packagingChemical/physical/physico-chemical microreactorsOrganic solventLiquid metal

The invention discloses a method for preparing nano-alloy droplets by laser irradiation, which belongs to the technical field of liquid metal, and comprises the following steps: S1, pre-dispersing the liquid metal, placing the pre-dispersed liquid metal in an organic solvent to obtain Liquid metal / organic solvent precursor; S2, introduce non-focused laser into the liquid metal / organic solvent precursor prepared in S1, and conduct laser radiation evaporation under agitation; S3, system after laser evaporation to S2 under agitation Into a mixed gas containing oxygen to promote the generation of the passivation layer; S4, after the passivation layer is generated, concentrate or separate to make nano-alloy droplets; the nano-droplets prepared by the preparation method provided by the invention are uniform in composition, The size structure is controllable, and the surface is highly modifiable without ligands, which provides a method for preparing basic materials for applications in the fields of flexible electronics, photocatalysis, and nanomedicine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com