A method for preparing nano-alloy droplets by laser irradiation

A technology of laser irradiation and nano-alloys, which is applied in the direction of nanotechnology, chemical instruments and methods, metal processing equipment, etc., to achieve the effects of high efficiency, short reaction cycle and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] S1. Preparation of liquid metal / organic solvent precursor

[0038] The liquid metal is pre-dispersed, and the pre-dispersed liquid metal is placed in an organic solvent to obtain a liquid metal / organic solvent precursor. In order to ensure the stability of the precursor, the concentration of the liquid metal / organic solvent precursor is controlled at 0.01~ Between 1mg / ml;

[0039] S2, laser evaporation

[0040] Introduce a non-focused laser into the liquid metal / organic solvent precursor prepared in S1, and conduct laser irradiation evaporation under stirring conditions;

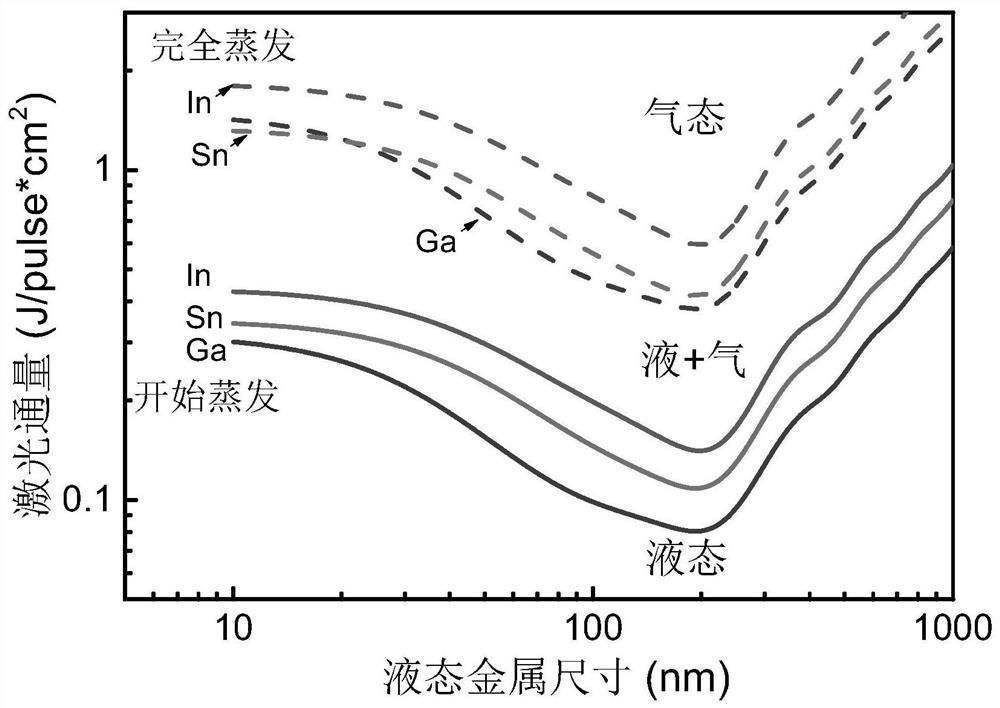

[0041] The introduced non-focused laser meets the following conditions: the wavelength absorption rate of the organic solvent to the non-focused laser is ≤0.1%, and the wavelength absorption rate of the liquid metal to the non-focused laser is ≥50%. This means is to make the liquid metal target absorb enough energy to evaporate , but not too high to break down the liquid metal target to generate pla...

Embodiment 1

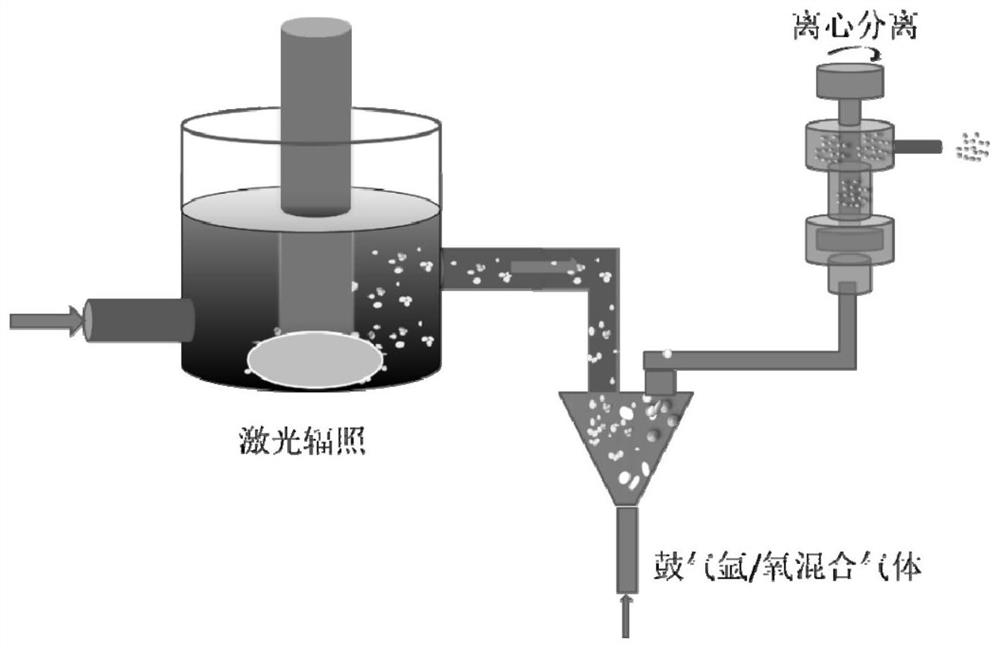

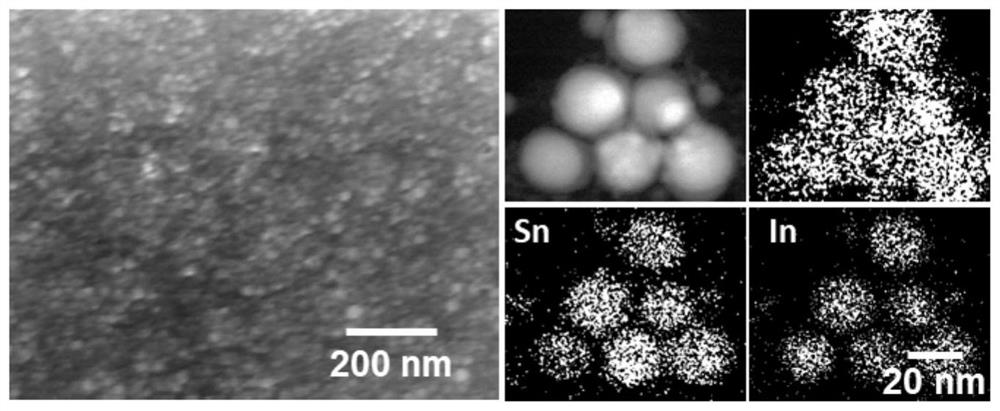

[0048] A preparation method of liquid nano-alloy GaInSn, such as figure 1 shown, including the following steps:

[0049] S1. Preparation steps of liquid metal / organic solvent precursor: Pre-place 0.05mg of liquid metal target GaInSn alloy in 1ml of organic liquid medium ethanol to obtain 0.05mg / ml GaInSn alloy / organic solvent precursor in the form of nano-suspension ;

[0050] S2. Laser evaporation: introduce a non-focused pulsed laser beam with a wavelength of 1064nm and an energy of 200mJ / pulse cm-2 into the precursor solution for 5min irradiation, and during the evaporation process of the laser irradiation, the temperature is controlled at -5~0 ℃, continuously stirring the precursor solution; the reason why ethanol is selected as the organic solvent is that ethanol does not absorb the wavelength of 1064nm, satisfying that it is less than or equal to 0.1%, and the wavelength absorption rate of the liquid metal to the non-focused laser is ≥80%;

[0051] S3. Generation of pa...

Embodiment 2

[0058] A preparation method of liquid nano-alloy GaInSn, comprising the following steps:

[0059] S1. Preparation steps of liquid metal / organic solvent precursor: Pre-place 0.05 mg of liquid metal target GaInSn alloy in 1 ml of organic liquid medium ethyl acetate to obtain a 0.05 mg / ml precursor;

[0060] S2. Laser evaporation: introduce 1064nm into the precursor solution with an energy of 400mJ / pulse cm -2 The unfocused pulsed laser beam was irradiated for 5 minutes. During the evaporation process of the laser irradiation, the temperature was controlled at -5 ~ 0°C, and the precursor solution was continuously stirred; ethyl acetate was selected as the organic solvent in this example, for the same reason as in Example 1. All because ethanol does not absorb the wavelength of 1064nm, satisfying less than or equal to 0.1%, and the wavelength absorption rate of the liquid metal to the non-focused pulsed laser is greater than or equal to 80%.

[0061] S3. Generation of passivation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com