NiFeMoS complex and a preparation method thereof

A complex and precursor technology, applied in the direction of chemical instruments and methods, electrodes, electrolysis process, etc., to achieve the effect of good catalytic performance of hydrogen evolution reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Based on the above-mentioned design idea, the preparation method of the NiFeMoS composite body provided by the present invention includes:

[0033] (1) obtain the reactant aqueous solution containing nickel salt, iron salt, molybdenum salt and urea;

[0034] (2) hydrothermally reacting the reactant aqueous solution at 150-170° C. for 8-15 hours, then separating and washing to obtain a complex precursor;

[0035] (3) Calcining and vulcanizing the composite precursor and sulfur powder in an inert gas, the temperature of calcining and vulcanization is 300-600°C, the time of calcining and vulcanization is 0.5-3 hours, and the heating rate is 3-8°C / min .

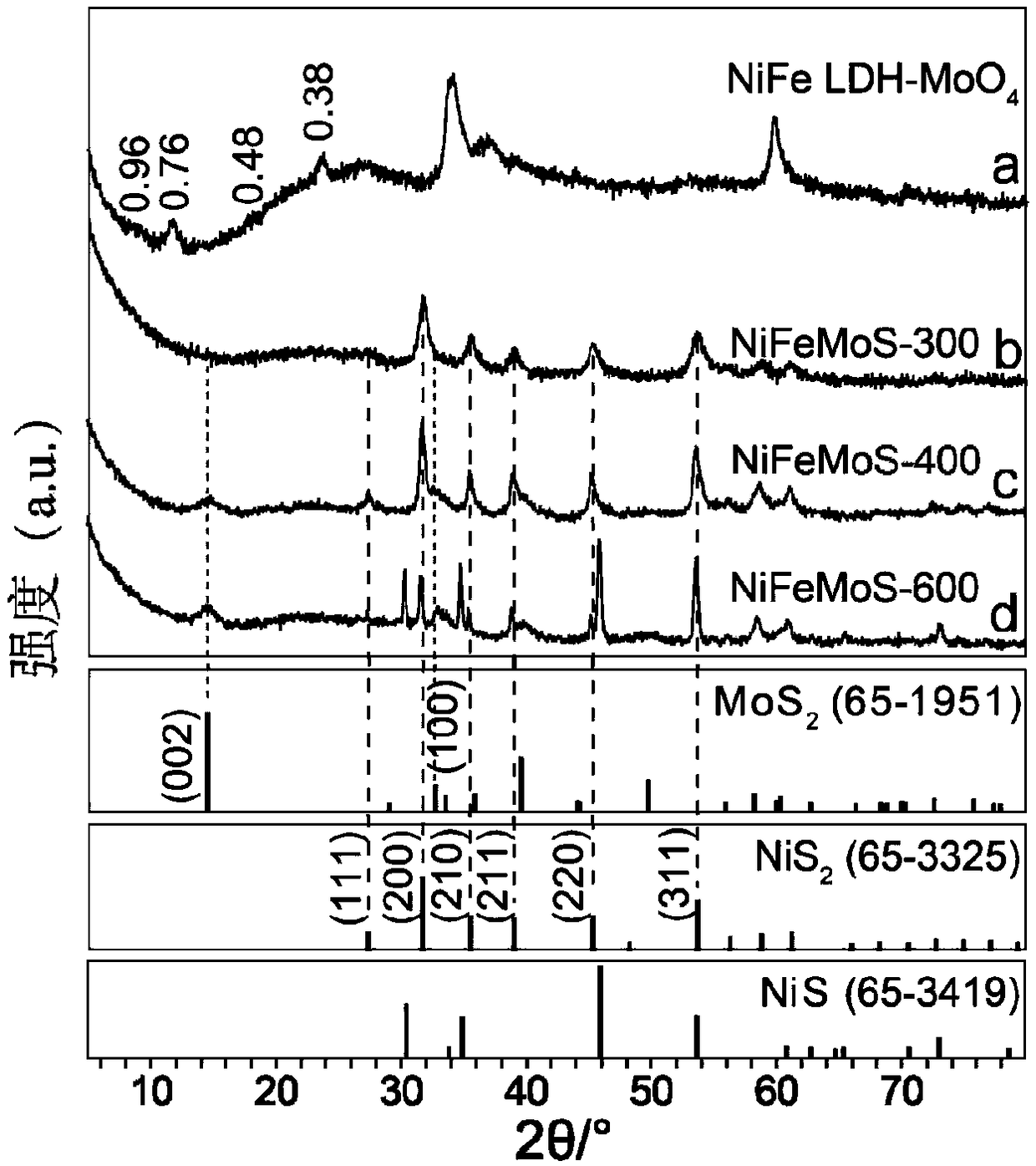

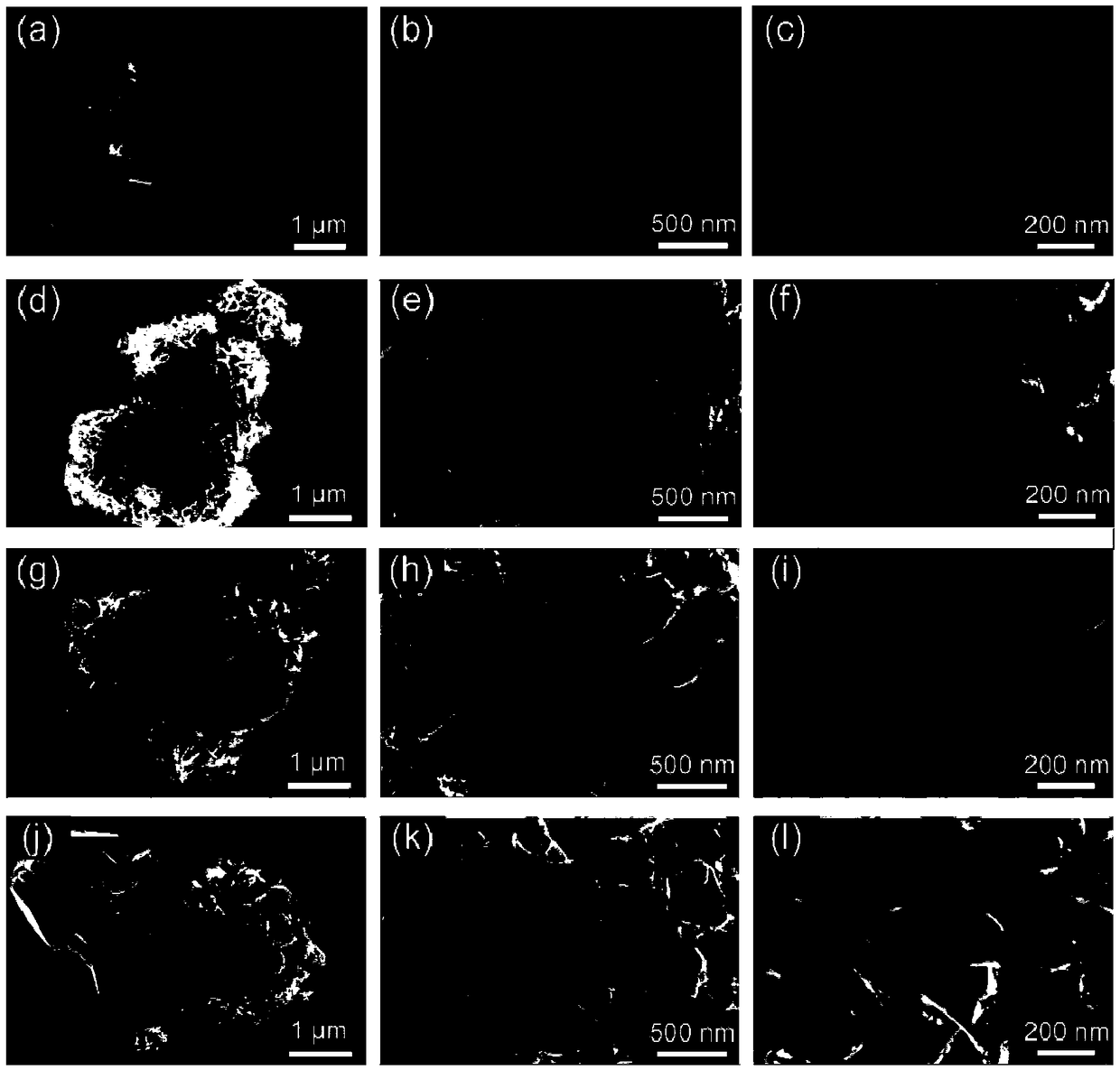

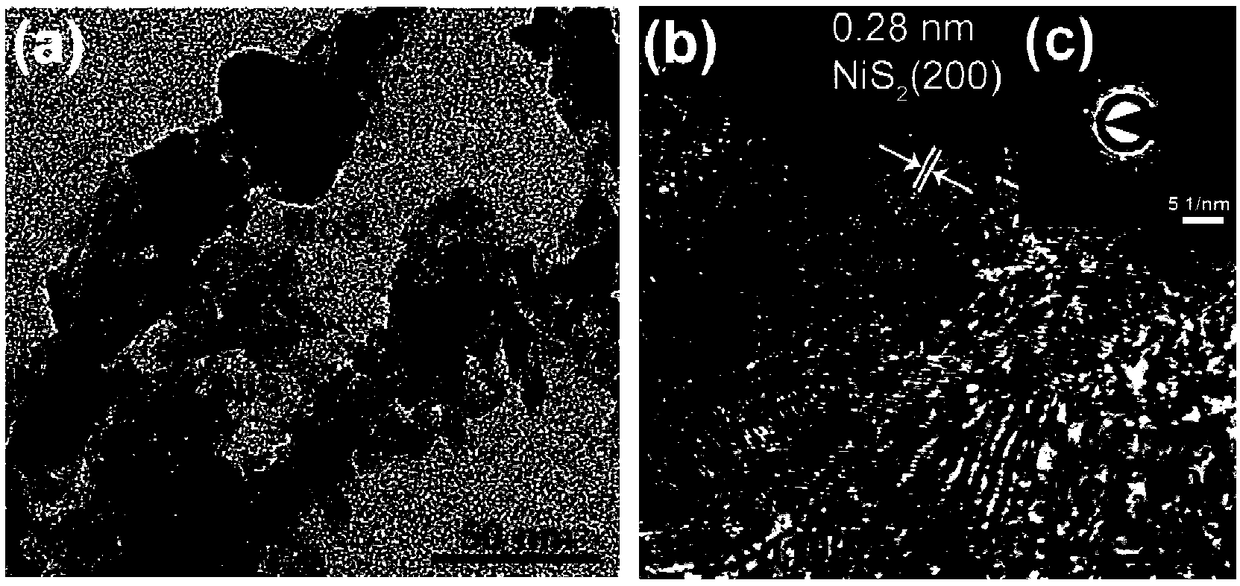

[0036] The present invention adopts one-step reaction to obtain MoO 4 2- Intercalated NiFe LDH, the Ni and Fe elements in the laminate are evenly distributed, and evenly distributed iron sulfide (FeS 2 ) and nickel sulfide (NiS 2 or NiS). And the ultra-small molybdenum disulfide nanosheets are obtained through the co...

Embodiment 1

[0053] Weigh 0.556g (2.2mmol) of nickel acetate, 0.202g of ferric nitrate (0.5mmol), 0.6g of urea (10mmol) and 0.5g of ammonium molybdate (0.4mmol), add 40mL of deionized water, and stir for 20 minutes to obtain the reactant aqueous solution;

[0054] The reactant aqueous solution was transferred to a 50mL reaction kettle, and hydrothermal reaction was carried out at 160°C for 10 hours. After the system was cooled to room temperature, it was filtered under reduced pressure, the filter cake (crude product of the complex precursor) was washed three times with deionized water, and the obtained product was vacuum-dried at 50°C. Obtain the composite precursor, referred to as NiFe LDH-MoO 4 .

[0055] Use tube furnace for vulcanization, weigh 0.1g NiFe LDH-MoO 4 and 1g of S powder were respectively placed on both ends of the porcelain boat, wherein the S powder was placed in the upwind place, and calcined at 400°C for 2 hours, the heating rate was 5°C / min, and argon gas was conti...

Embodiment 2

[0057] The NiFeMoS composite was prepared according to the method of Example 1, the difference from Example 1 was that the temperature of calcination and vulcanization was 300° C., and the obtained product was designated as NiFeMoS-300.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com