Multichannel pulsed laser deposition method for preparing YSZ buffer layer

A laser coating and multi-channel technology, applied in the direction of coating, sputtering plating, ion implantation plating, etc., can solve the problems of limited space for improvement, short heater life, peeling, etc., to achieve superior surface quality, improve Effect of coating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

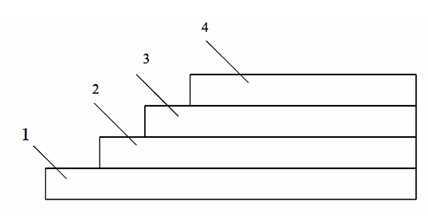

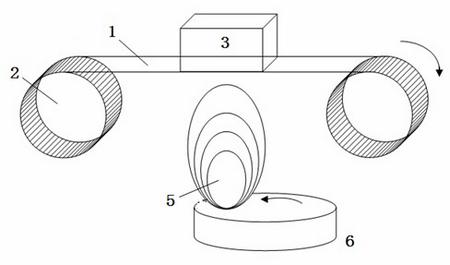

[0041] This embodiment provides a multi-channel laser coating method for preparing a YSZ buffer layer on a nickel-tungsten metal base band or a metal base band such as a Hastelloy band or a stainless steel band, comprising the following steps:

[0042] Step 1. Put the nickel-tungsten metal base belt or Hastelloy belt, stainless steel belt and other metal base belts that need to prepare the YSZ buffer layer into the coating chamber, and wind them on the belt roller of the metal strip transmission device of the multi-channel laser coating equipment for many times ; Before the coating starts, the background vacuum in the coating chamber is 5×10 -7 Torr;

[0043] Step 1.1, winding one end of the nickel-tungsten metal base tape on the first reel;

[0044] Step 1.2, pulling the nickel-tungsten metal base belt and winding it on the two rollers of the multi-channel transmission device multiple times;

[0045] Step 1.3, fixing the other end of the nickel-tungsten metal base tape on t...

Embodiment 2

[0055] This embodiment provides a multi-channel laser coating method for preparing a YSZ buffer layer on a nickel-tungsten metal base band or a metal base band such as a Hastelloy band or a stainless steel band, comprising the following steps:

[0056] Step 1. Put the nickel-tungsten metal base belt or Hastelloy belt, stainless steel belt and other metal base belts that need to prepare the YSZ buffer layer into the coating chamber, and wind them on the belt roller of the metal strip transmission device of the multi-channel laser coating equipment for many times ; Before the coating starts, the background vacuum in the coating chamber is 5×10 -6 Torr;

[0057] Step 2. Start the heater, press 10 o The heating rate of C / min raises the heater temperature to the set coating temperature, i.e., 800 o Between C;

[0058] Step 3. After the temperature of the heater is stable, open the oxygen channel; the flow of oxygen is controlled by the gas mass flow meter, and the oxygen flow ra...

Embodiment 3

[0066] This embodiment provides a multi-channel laser coating method for preparing a YSZ buffer layer on a nickel-tungsten metal base band or a metal base band such as a Hastelloy band or a stainless steel band, comprising the following steps:

[0067] Step 1. Put the nickel-tungsten metal base belt or Hastelloy belt, stainless steel belt and other metal base belts that need to prepare the YSZ buffer layer into the coating chamber, and wind them on the belt roller of the metal strip transmission device of the multi-channel laser coating equipment for many times ;

[0068] Before the coating starts, the background vacuum in the coating chamber is 1×10 -6 Torr;

[0069] Step 2. Start the heater, press 10 o The heating rate of C / min raises the heater temperature to the set coating temperature, i.e., 750 o Between C;

[0070] Step 3. After the temperature of the heater is stabilized, open the oxygen channel; the flow of oxygen is controlled by the gas mass flow meter, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com