Wire harness assembly line

A technology for assembly lines and wire harnesses, applied in the directions of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of low work efficiency, time and labor waste, and achieve the effect of improving work efficiency and saving work time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

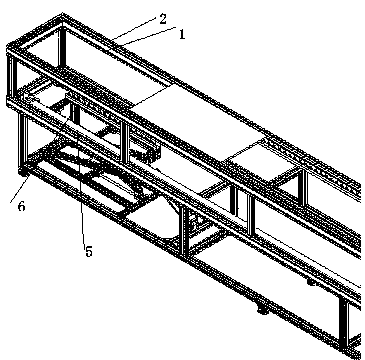

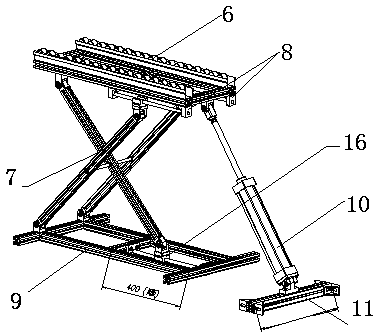

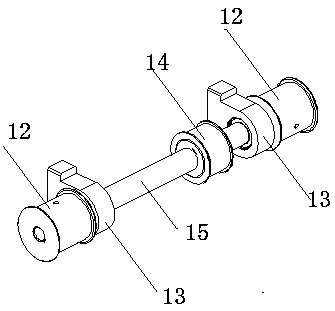

[0017] Such as Figure 1-3 A wiring harness assembly line is shown, including a bracket body 1, a slide rail bracket 2, a slide rail 3, a belt 4, a belt bracket 5, an upper platform 6, a lifting link 7, an upper sliding assembly 8, a lower platform 9, and a cylinder assembly 10 , corner piece 11, driving wheel assembly 12, bearing housing 13, synchronous wheel 14, main shaft 15, lower sliding assembly 16, driving wheel 17, the top of the bracket body 1 is provided with a slide rail bracket 2, and the slide rail bracket 2 and The slide rail 3 is connected, and the slide rail 3 is connected with the driving wheel assembly 12. The middle position and the bottom end of the support body 1 are provided with a belt support 5, the belt support 5 is connected with the belt 4, and the belt support 4 is provided below There is an upper platform 6, the upper platform 6 is provided with an upper sliding assembly 8, the upper sliding assembly 8 is connected to the upper end of the lifting l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com