Method and system for continuous or semi-continuous laser deposition

A laser deposition, semi-continuous technology, applied in the direction of ion implantation plating, metal material coating process, coating, etc., can solve the problems of low control level of ablation process and hindering high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

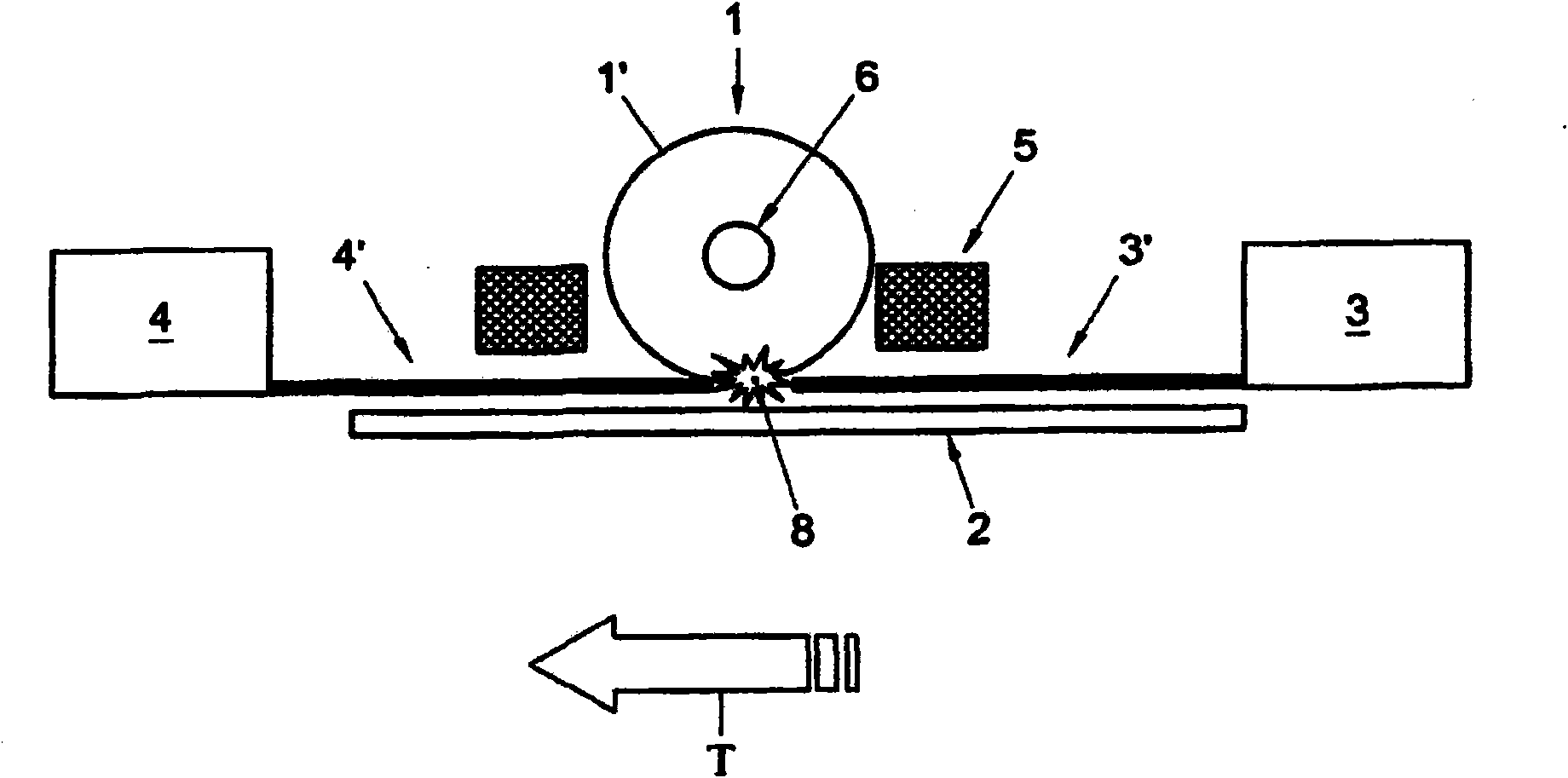

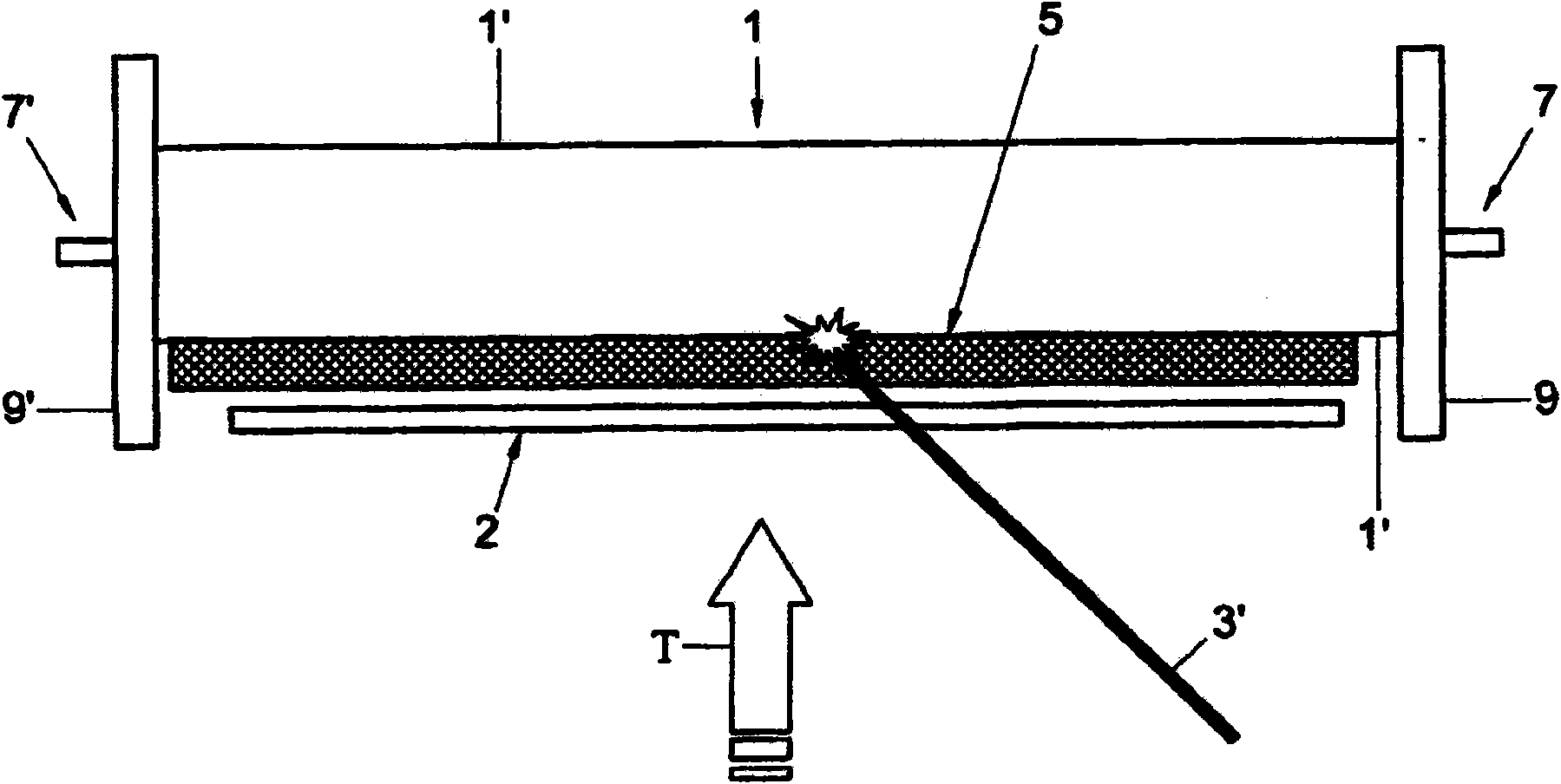

[0018] figure 1 and figure 2 A laser deposition system according to the invention is shown. The figures show the following elements: a cylindrical target 1 with a target surface 1' provided with an internal fluid channel 6 with end connectors 7 and 7'; in the direction of transport T A moving substrate 2; a first continuous or semi-continuous laser 3 emitting a laser beam 3'; a second laser 4 emitting a laser beam 4'; a gas or plasma gas environment 5, a cloud of laser evaporated material 8, and two Shields 9, 9'. The aforementioned target 1, substrate 2 and gas or plasma gas environment 5 are located within a deposition chamber (also not shown) which is evacuated to sub-atmospheric pressure by means of a pump (not shown) . The lasers 3, 4 do not have to be located inside the deposition chamber; they can also be located outside the deposition chamber, whereby the resulting laser beams 3', 4' travel through one or more transparent windows into the deposition chamber. Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com