Selective laser evaporation deposition method and device

An evaporative deposition and selective laser technology, which is applied in the field of additive manufacturing, can solve the problems that the roller or scraper cannot flatten the machined surface, the high cost of preparing powder, and the poor fluidity, etc., and achieves ideal molding effect, low cost, and fluidity. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

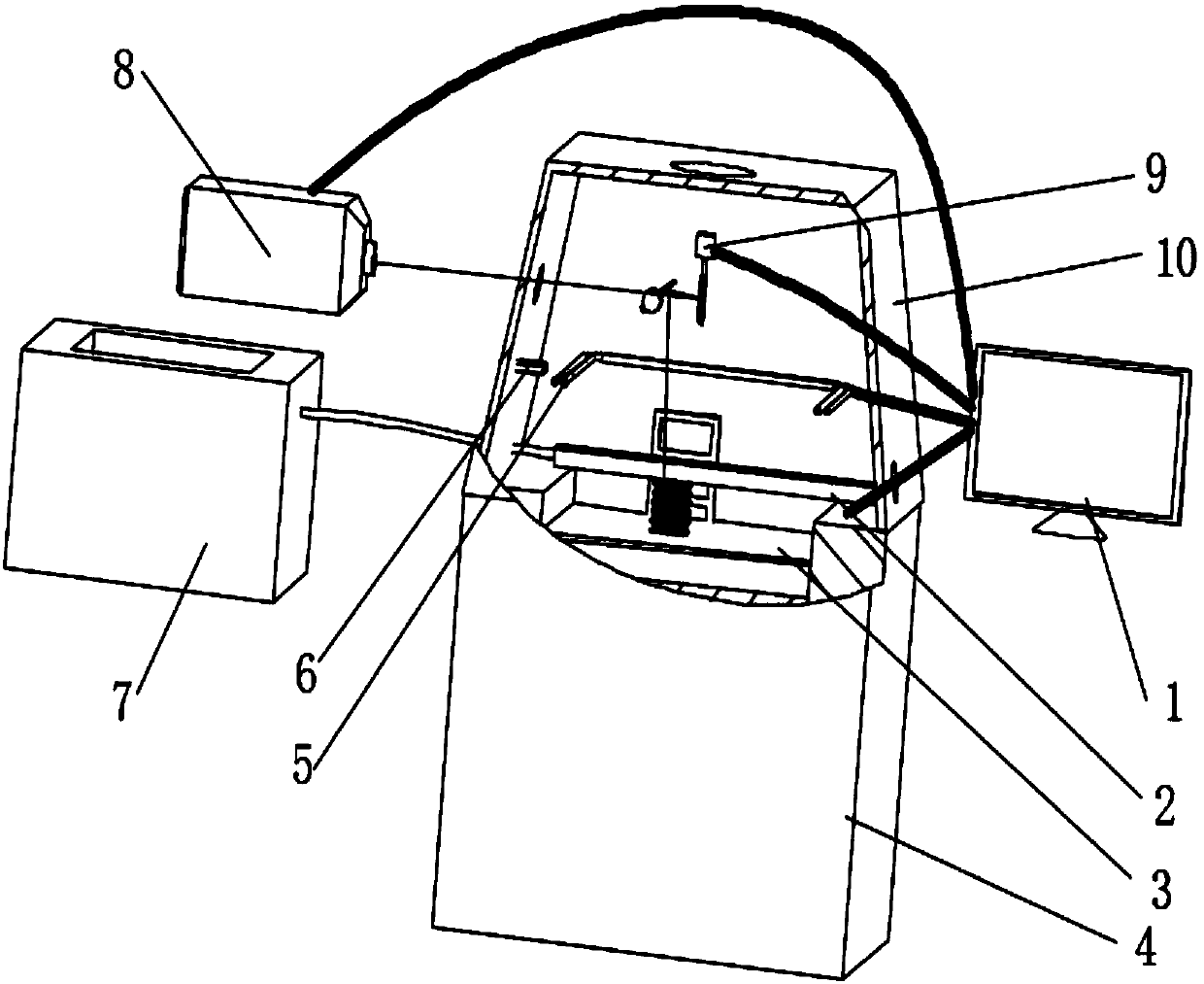

[0028] see figure 1 , a selective laser evaporation deposition device includes: a computer 1, an optical path system, and a molding system, the optical path system includes a laser 8 and a scanning galvanometer 9 controlled by the computer 1; the molding system includes a heater 5, a temperature sensor, and a molding cylinder 4. Liftable forming tray 3, liquid replenishment scraper 2, liquid replenishment tank 7 and inert gas protection chamber 10.

[0029] The computer 1 and its control software are responsible for controlling the opening and closing of the laser 8, are responsible for converting the information of the layered processed model into relevant signals to control the motion track of the scanning galvanometer 9, and are responsible for opening and closing the heater. , responsible for controlling the lifting of the liftable m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com