Laser evaporation recovery processing method for film solar cell module

A solar cell and laser evaporation technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of high pressure on disposal and stacking and environmental protection, low utilization value of broken glass slag, and poor working environment, so as to improve the material recovery rate and Recycling effect, improving resource utilization, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

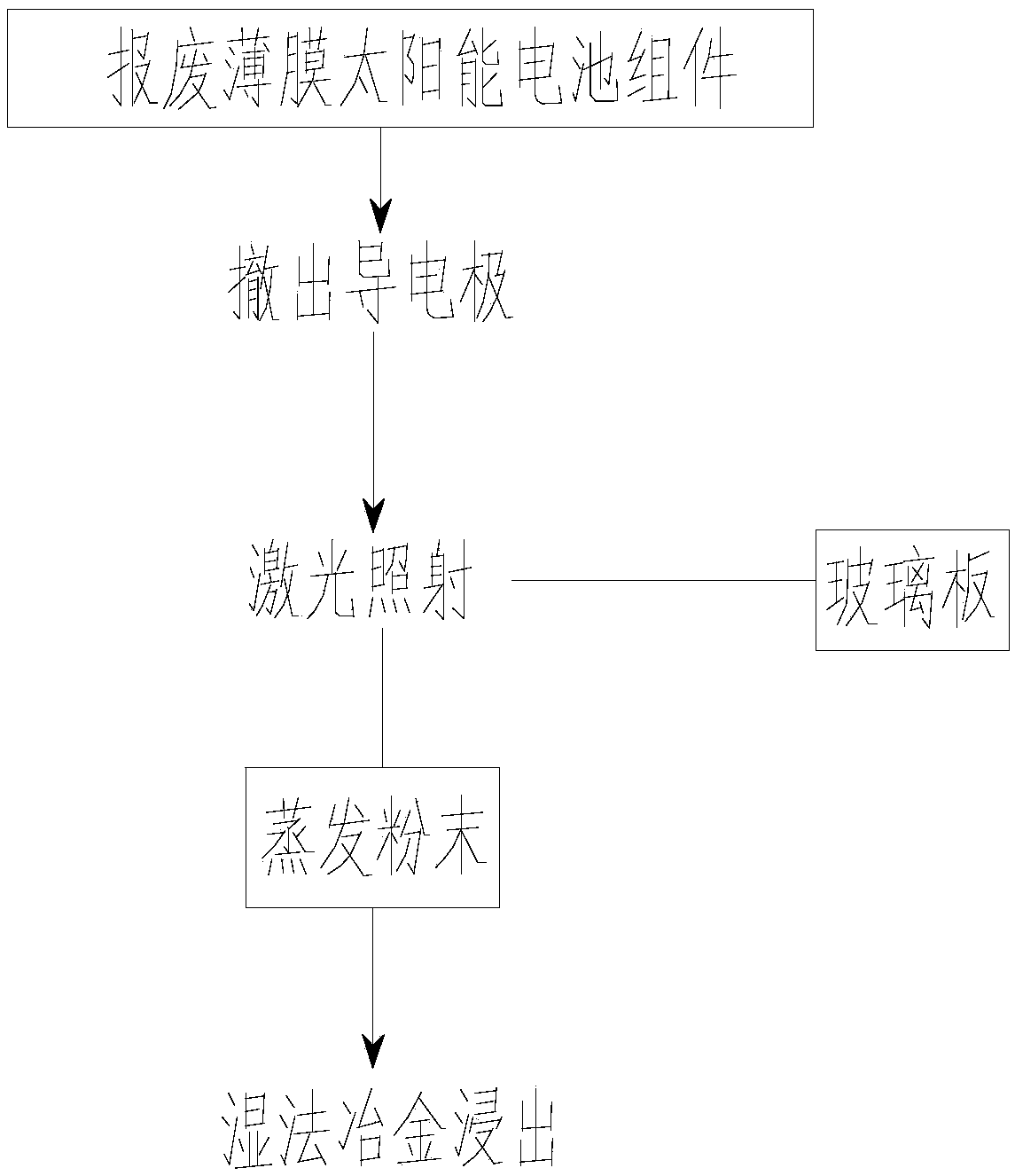

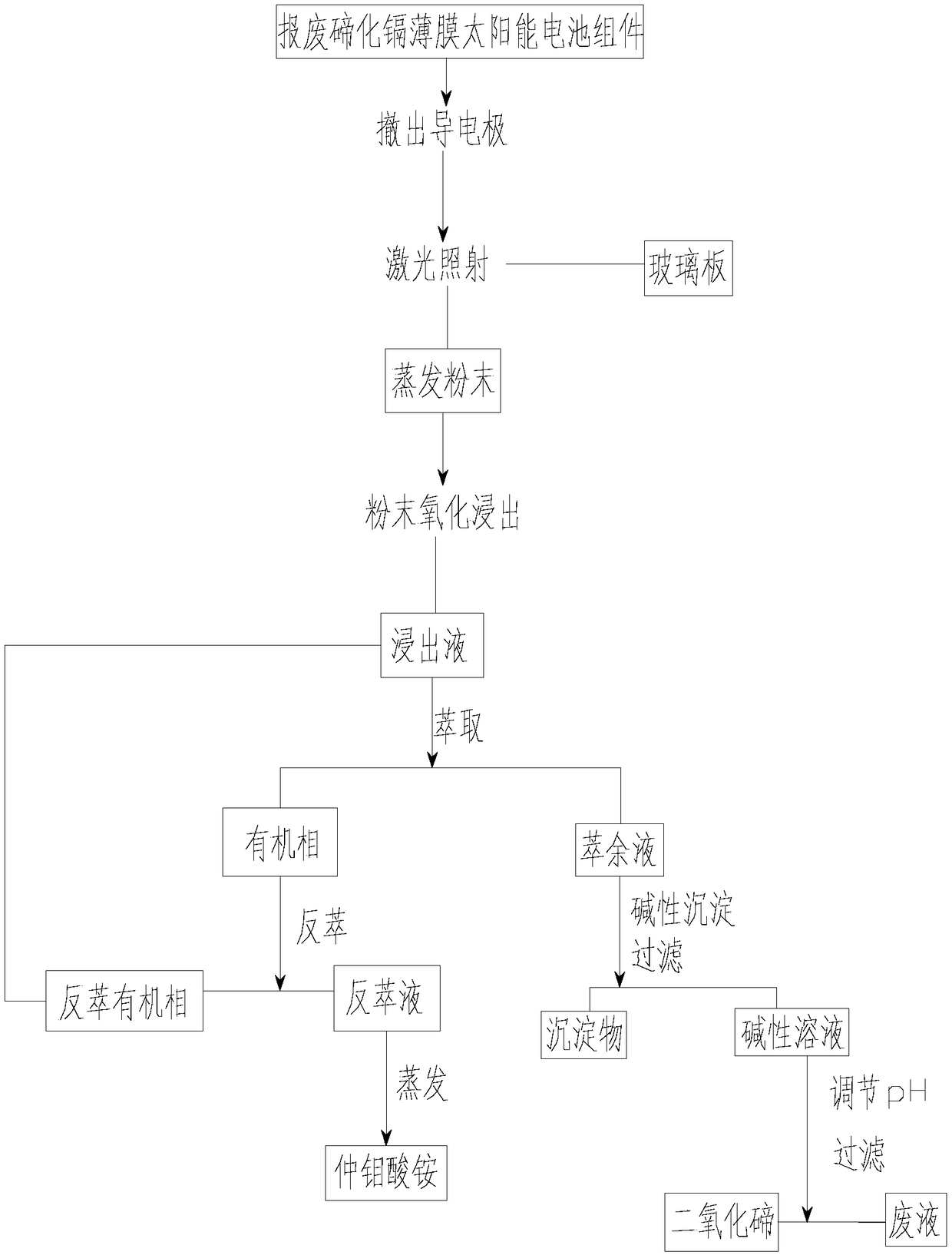

[0031] see figure 1 , a kind of laser evaporation recovery treatment method of thin-film solar cell assembly provided by the present invention, comprises the following steps:

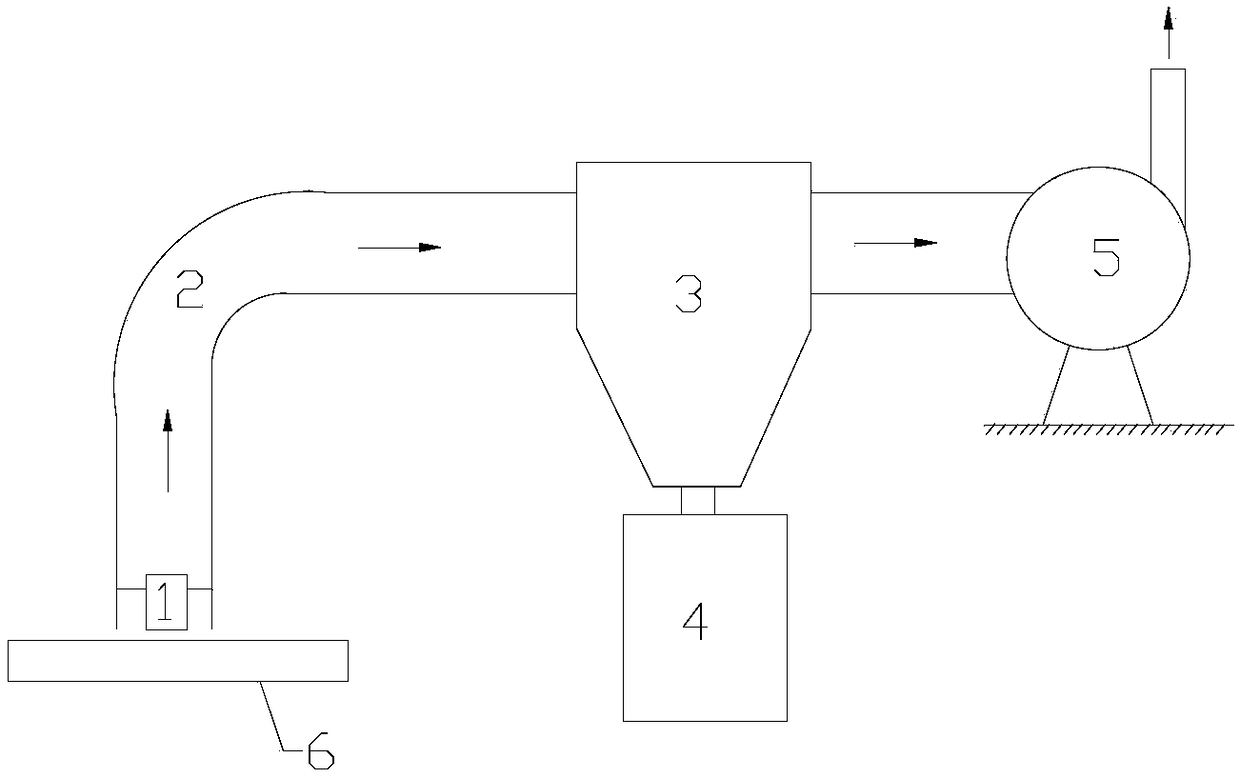

[0032] (1) Photovoltaic film layer evaporated by laser: remove the back glass and conductive electrodes of scrapped thin-film solar cell modules to obtain a glass substrate 6 with a photovoltaic film layer, and use a laser irradiation device to irradiate the photovoltaic film layer on the glass substrate at close range Until the photovoltaic film layer is completely evaporated to obtain a complete glass substrate; see figure 2 , the laser irradiation device includes a laser irradiator 1, a negative pressure air duct 2, a gas-solid separator 3, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com