Continuous rapid laser coating method of superconducting layer in second-generation high-temperature superconducting strip

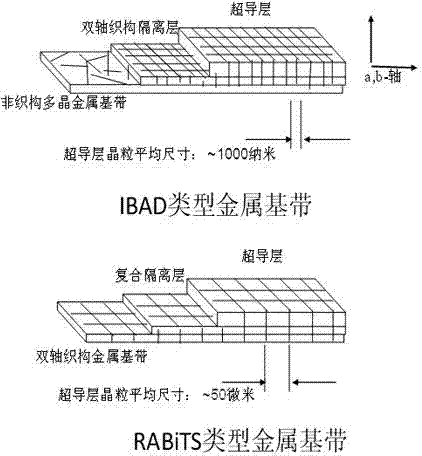

A high-temperature superconducting strip and laser coating technology, which is applied in metal material coating process, coating, sputtering plating, etc., can solve the difficulty and complexity of increasing the epitaxial growth isolation layer, cost-effective barriers, and loss of superconductivity To achieve the effect of improving laser utilization rate and strip preparation speed, reducing strip manufacturing cost and increasing the width of coating area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] based on the following Figure 4 ~ Figure 8 , specifically explain the preferred embodiment of the present invention.

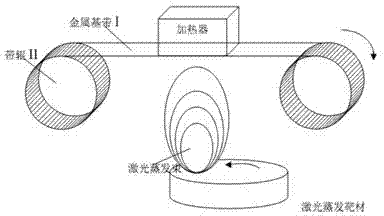

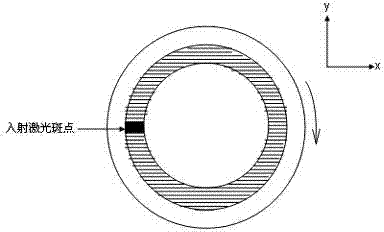

[0057] Such as Figure 4 As shown, a multi-channel laser coating method is used to prepare the rare earth oxide superconducting layer in the second-generation high-temperature superconducting strip. The continuous rapid laser coating method includes the following steps:

[0058] Step 1. Put the metal base tape that has been coated with the composite isolation layer and is about to prepare the superconducting layer into the coating chamber, and wind it multiple times on the belt roller II of the metal strip transmission device of the multi-channel laser coating equipment;

[0059] The metal baseband is nickel-tungsten alloy, Hastelloy or stainless steel metal baseband;

[0060] Step 2, start the heater, and raise the temperature of the heater to the set coating temperature;

[0061] press 10-30 o C / min heating rate;

[0062] Coating temperature is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com