Thin film crystalline silicon perovskite heterojunction solar battery and preparation method thereof

A technology of solar cells and perovskite, applied in circuits, electrical components, electric solid devices, etc., can solve the problems of insufficient stability, large usage, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

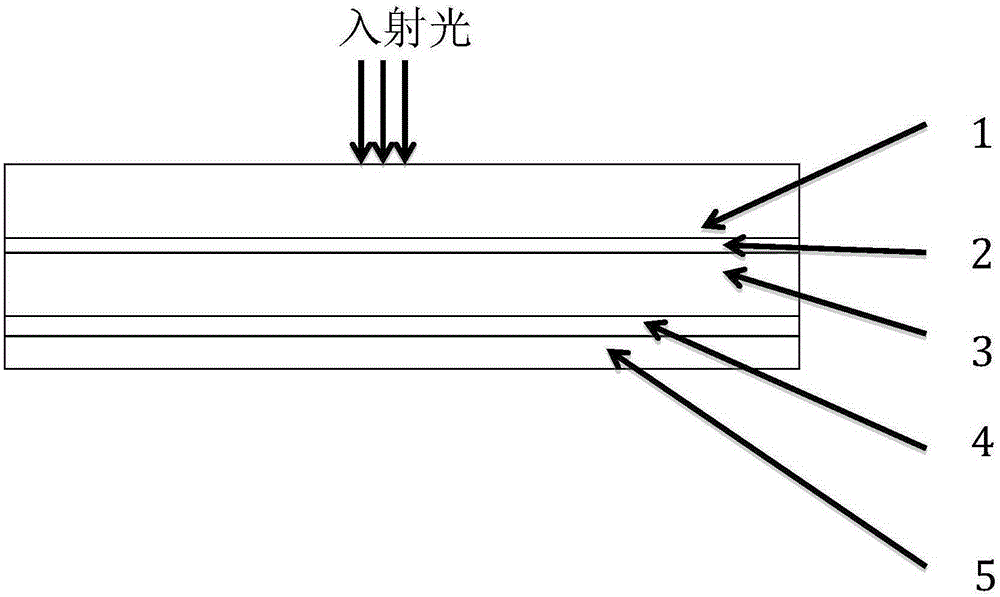

Image

Examples

Embodiment 1

[0060] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0061] Use a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode, and use platinum as the cathode. anodic oxidation with an electric current, corrode the P-type single crystal silicon wafer by electrochemical method, and form a porous silicon structure on the surface of the single crystal silicon wafer, and then form the single crystal silicon wafer with the porous silicon structure in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film crystalline silicon film is epitaxially formed on the layer, and the formed P-type crystalline silicon film is transferre...

Embodiment 2

[0081] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0082] With a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode and platinum as the cathode, in a hydrofluoric acid ethanol solution with a volume ratio of hydrofluoric acid: absolute ethanol = 1:1, the size is 4.5 The current of A is anodized, and the P-type single crystal silicon wafer is corroded by an electrochemical method to form a porous silicon structure on the surface of the single crystal silicon wafer, and then the single crystal silicon wafer with a porous silicon structure is formed in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film crys...

Embodiment 3

[0102] The first step is to prepare a P-type thin film crystalline silicon hole transport layer on a transparent conductive substrate:

[0103] With a P-type single crystal silicon wafer coated with a layer of corrosion-resistant metal on the back as the anode, and platinum as the cathode, in a hydrofluoric acid ethanol solution with a volume ratio of hydrofluoric acid: absolute ethanol = 1:1, a size of 7.5 The current of A is anodized, and the P-type single crystal silicon wafer is corroded by an electrochemical method to form a porous silicon structure on the surface of the single crystal silicon wafer, and then the single crystal silicon wafer with a porous silicon structure is formed in H 2 Annealing at 200°C to 550°C in the atmosphere, during the annealing process, the holes in the small porosity layer on the surface of the single crystal silicon wafer will gradually close to form a quasi-single crystal layer as a template for epitaxial devices. The P-type thin film cryst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com