Multi-channel laser coating method for preparing cerium dioxide seed layer

A laser coating, multi-channel technology, applied in ion implantation, coating, sputtering and other directions, can solve the problem of poor uniformity of superconducting properties, affecting the stability of the superconducting layer coating process, and the existence of the thickness of the seed layer. Errors and other problems to achieve the effect of reducing the substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

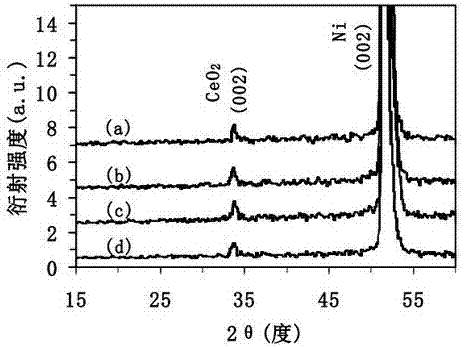

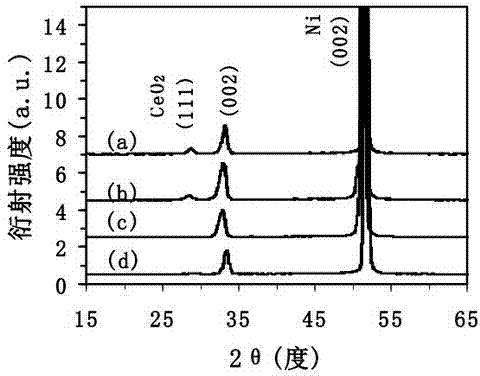

Embodiment 1

[0044] A kind of preparation CeO on the nickel-tungsten metal substrate that this embodiment provides 2 The multi-channel laser coating method of the seed layer comprises the following steps:

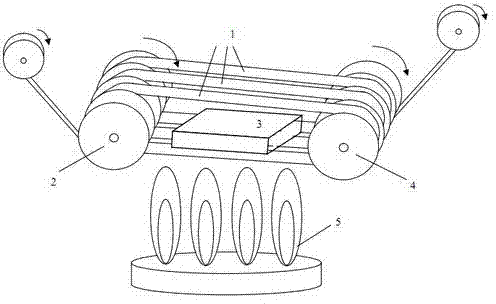

[0045] Step 1. The biaxial textured nickel-tungsten metal base tape is wound multiple times and placed in a multi-channel laser coating system;

[0046] Step 1.1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0047] Step 1.2, pulling the biaxial textured nickel-tungsten metal base belt to be wound on the two rollers of the multi-channel transmission device for multiple times;

[0048] Step 1.3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0049] Step 2, annealing the biaxially textured nickel-tungsten metal substrate;

[0050] Step 2.1, close the vacuum door of the coating system, and evacuate to 1×10 -7 Torr;

[0051] Step 2.2, start the heater, and heat up to the required anne...

Embodiment 2

[0064] A kind of preparation CeO on the nickel-tungsten metal substrate that this embodiment provides 2 The multi-channel laser coating method of the seed layer comprises the following steps:

[0065] Step 1. The biaxial textured nickel-tungsten metal base tape is wound multiple times and placed in a multi-channel laser coating system;

[0066] Step 1.1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0067] Step 1.2, pulling the biaxial textured nickel-tungsten metal base belt to be wound on the two rollers of the multi-channel transmission device for multiple times;

[0068] Step 1.3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0069] Step 2, annealing the biaxially textured nickel-tungsten metal substrate;

[0070] Step 2.1, close the vacuum door of the coating system, and evacuate to 1×10 -6 Torr;

[0071] Step 2.2, start the heater, and heat up to the required anne...

Embodiment 3

[0084] A kind of preparation CeO on the nickel-tungsten metal substrate that this embodiment provides 2 The multi-channel laser coating method of the seed layer comprises the following steps:

[0085] Step 1. The biaxial textured nickel-tungsten metal base tape is wound multiple times and placed in a multi-channel laser coating system;

[0086] Step 1.1, winding one end of the biaxially textured nickel-tungsten metal base tape on the first reel;

[0087] Step 1.2, pulling the biaxial textured nickel-tungsten metal base belt to be wound on the two rollers of the multi-channel transmission device for multiple times;

[0088] Step 1.3, fixing the other end of the biaxially textured nickel-tungsten metal substrate on the second reel;

[0089] Step 2, annealing the biaxially textured nickel-tungsten metal substrate;

[0090] Step 2.1, close the vacuum door of the coating system, and evacuate to 0.5×10 -6 Torr;

[0091] Step 2.2, start the heater, and heat up to the required an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com